Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about "File" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-flute ball endmill for airfoil machining

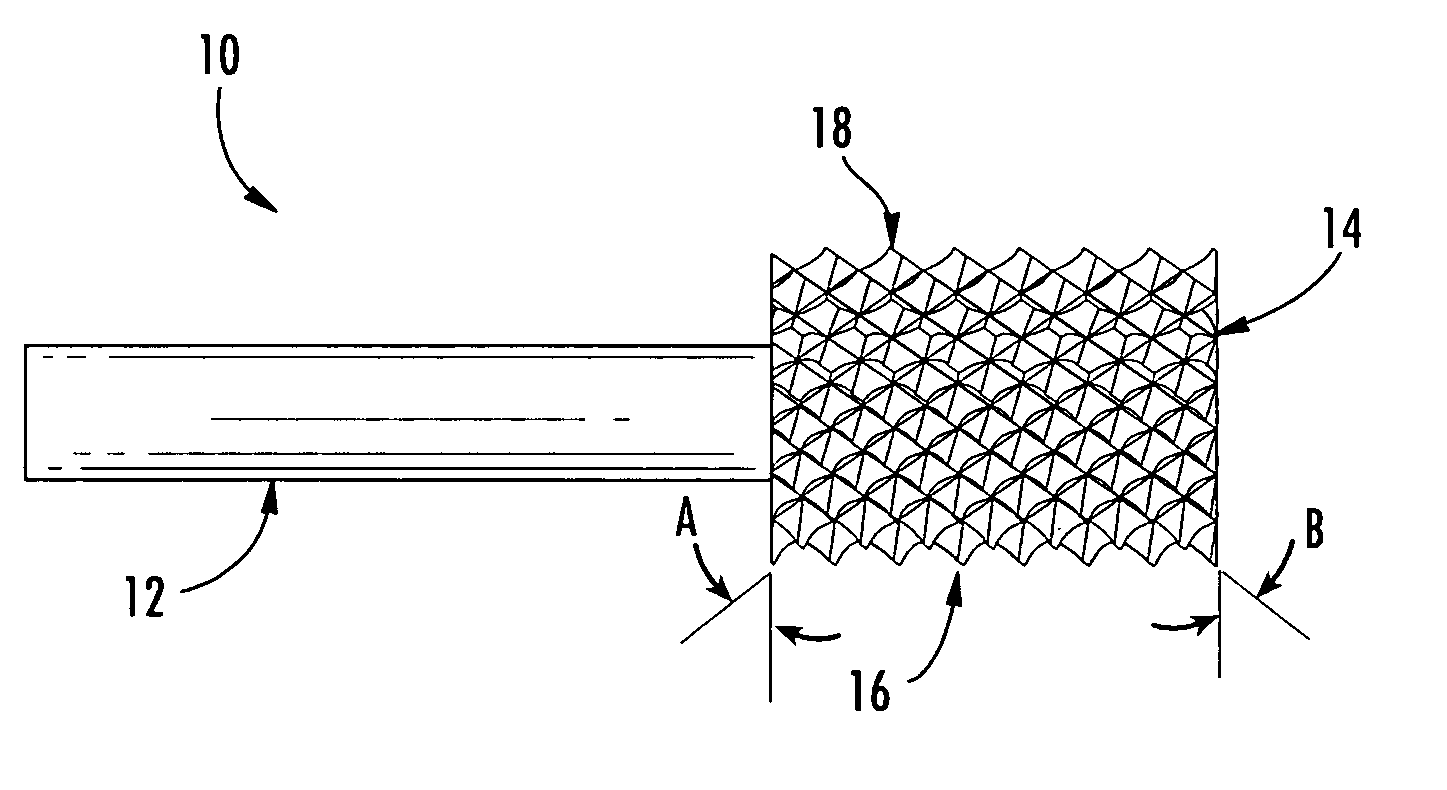

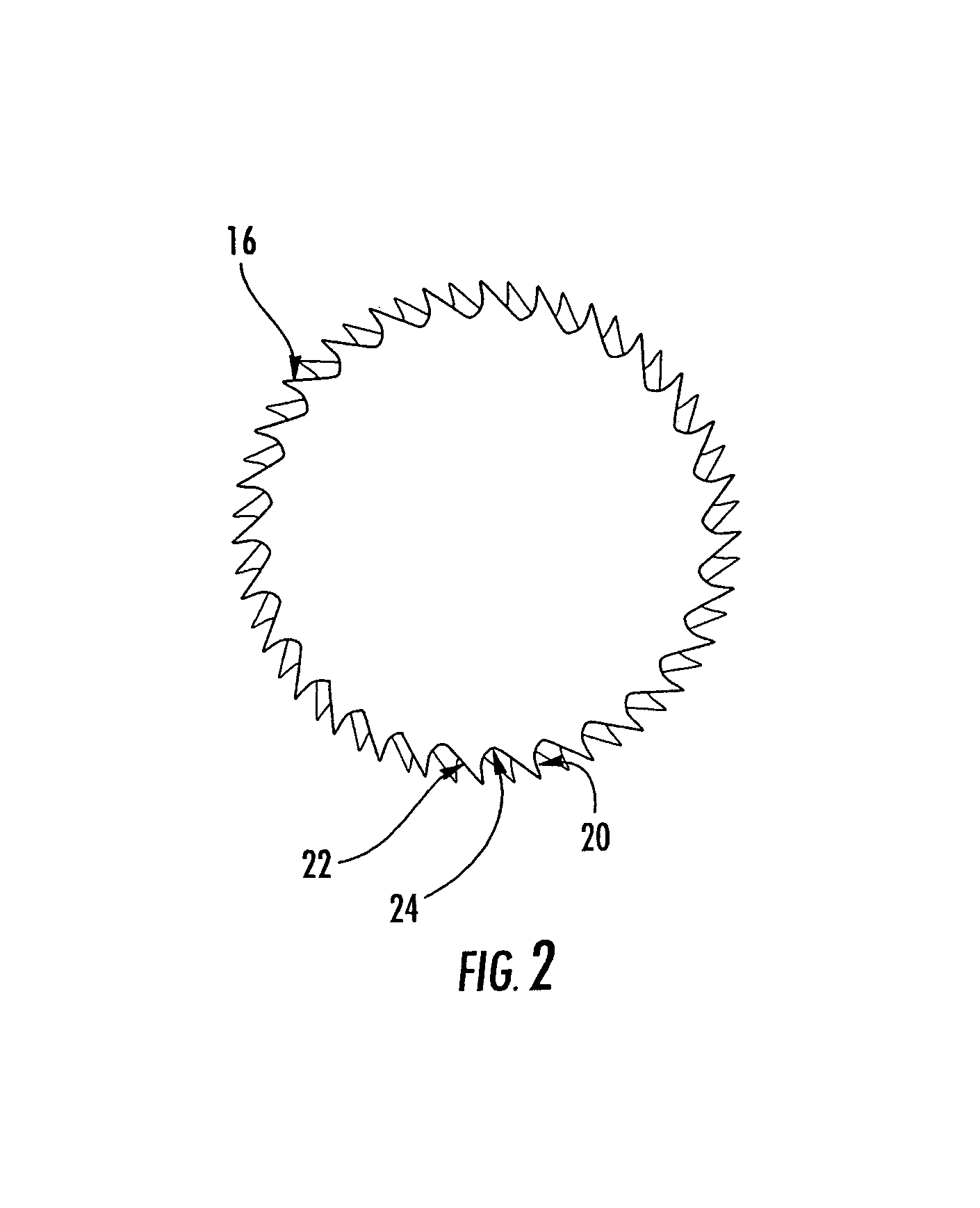

A milling cutter comprises a shank section joined to a cutting section. The cutting section includes a plurality of peripheral teeth separated by a plurality of flutes to form cutting edges extending around the cutting section in a helix direction. The number of respective teeth and flutes is more than 12.

Owner:PRATT & WHITNEY CANADA CORP

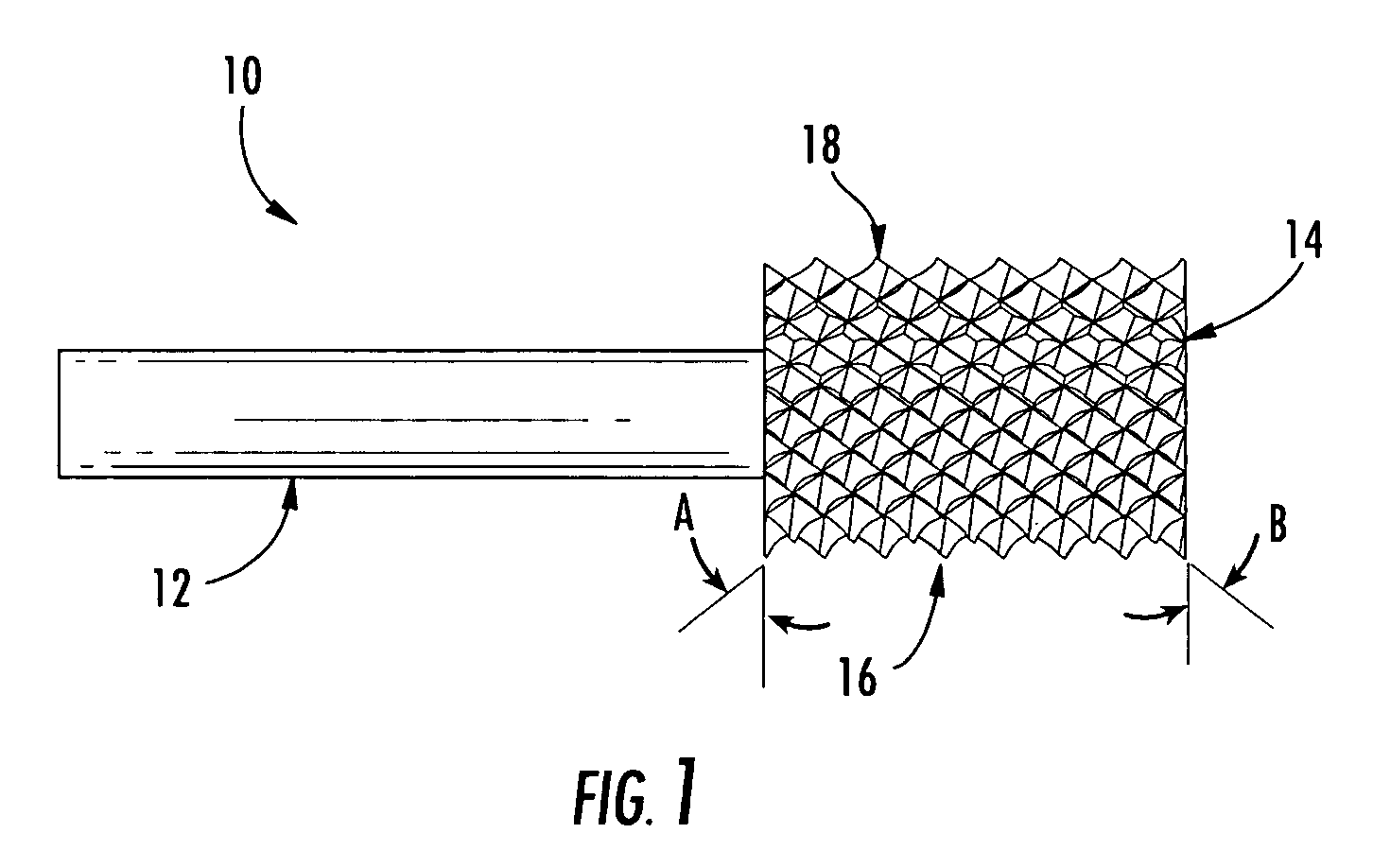

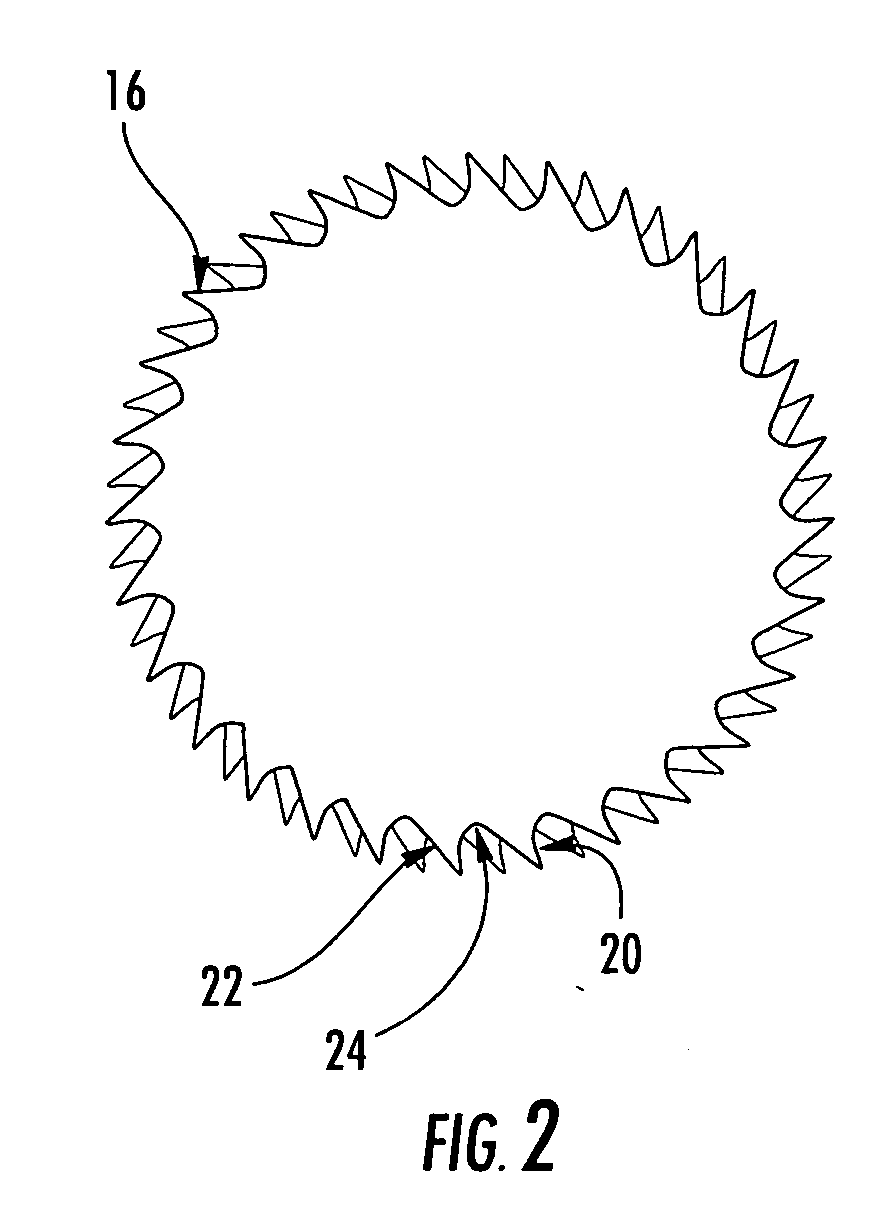

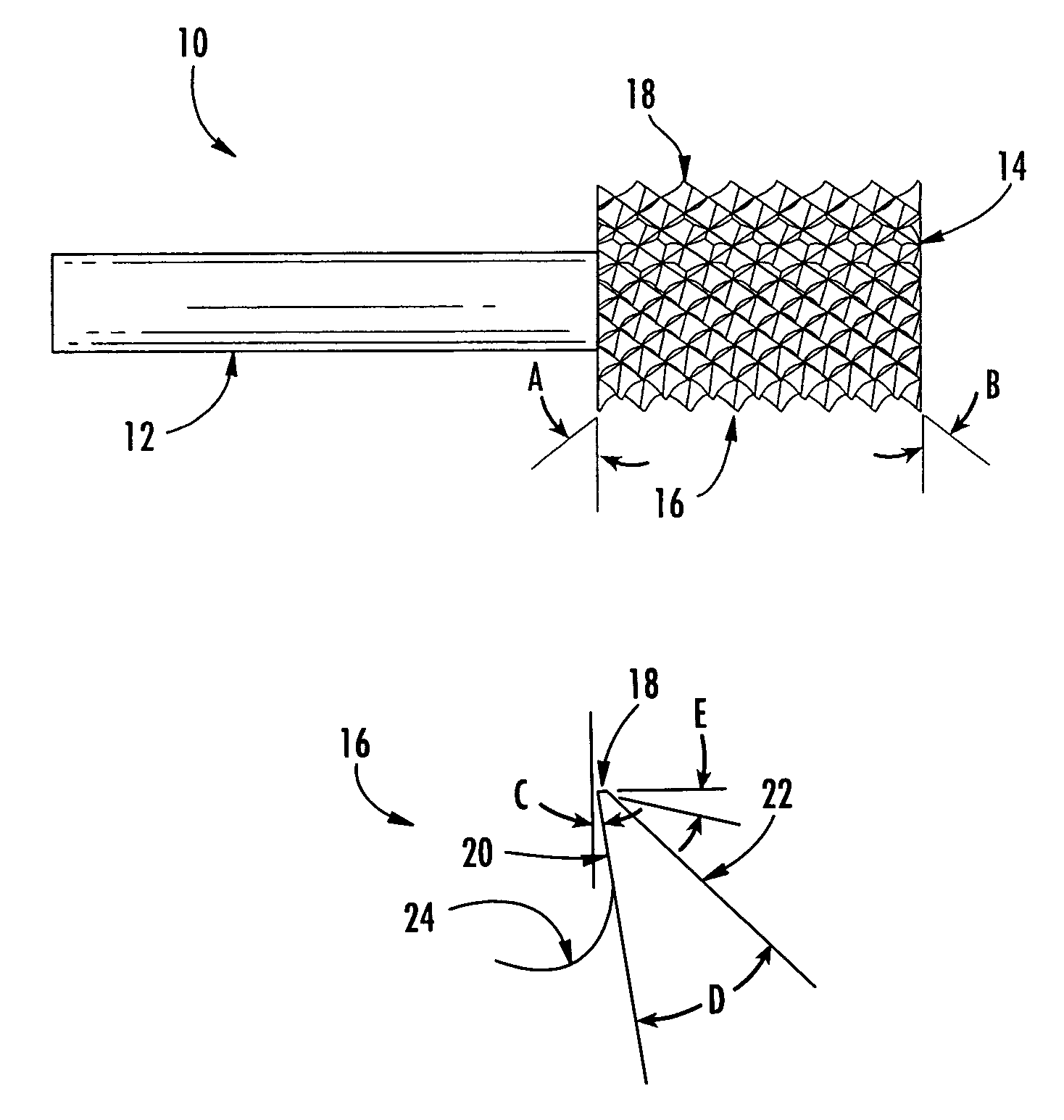

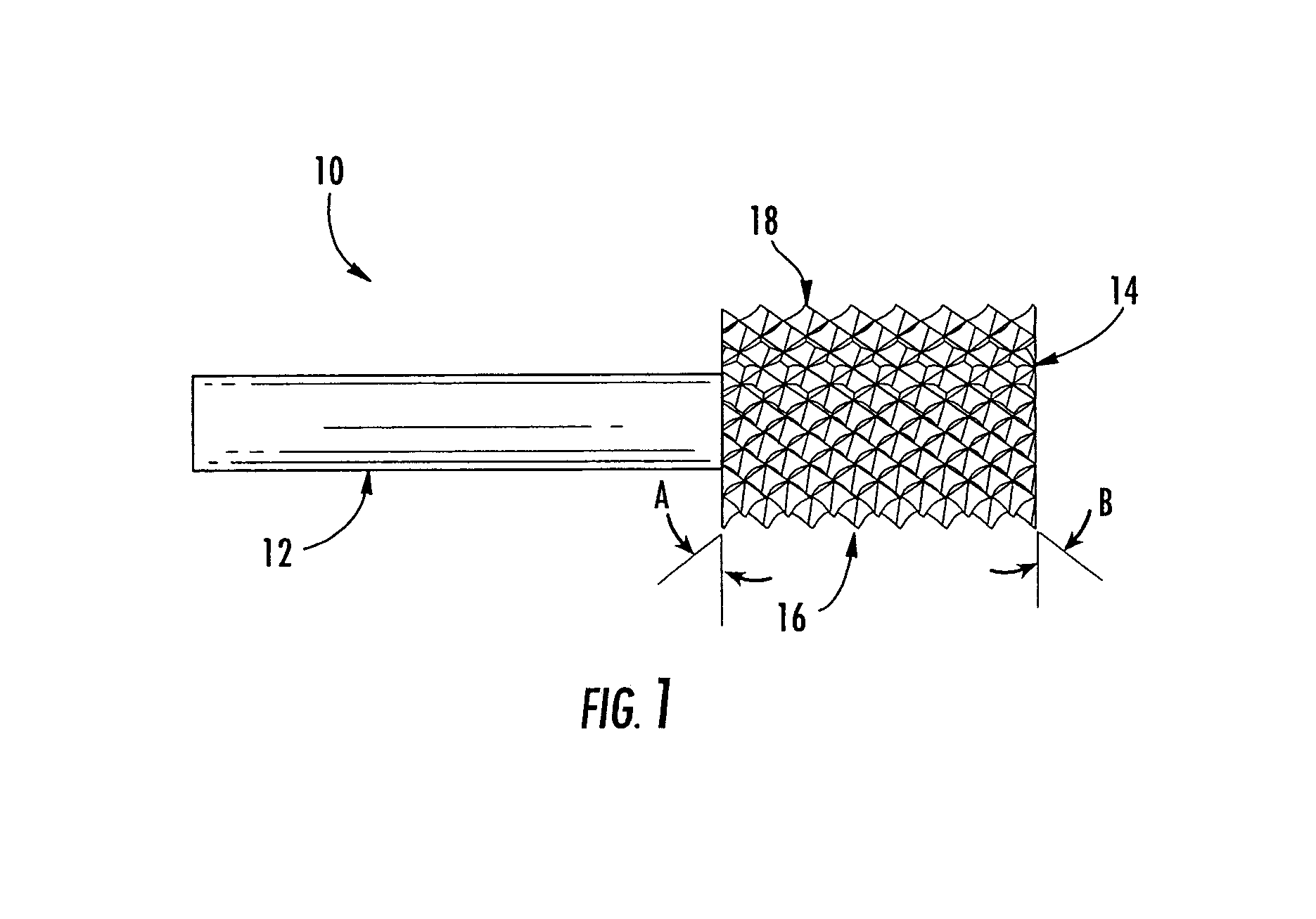

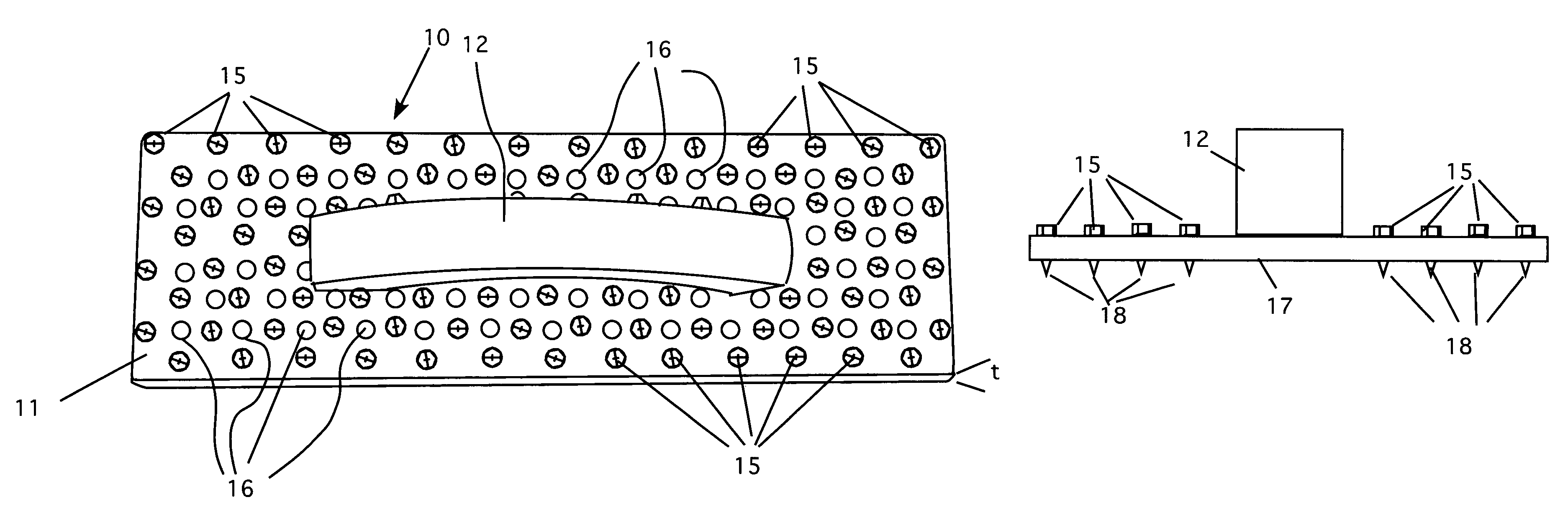

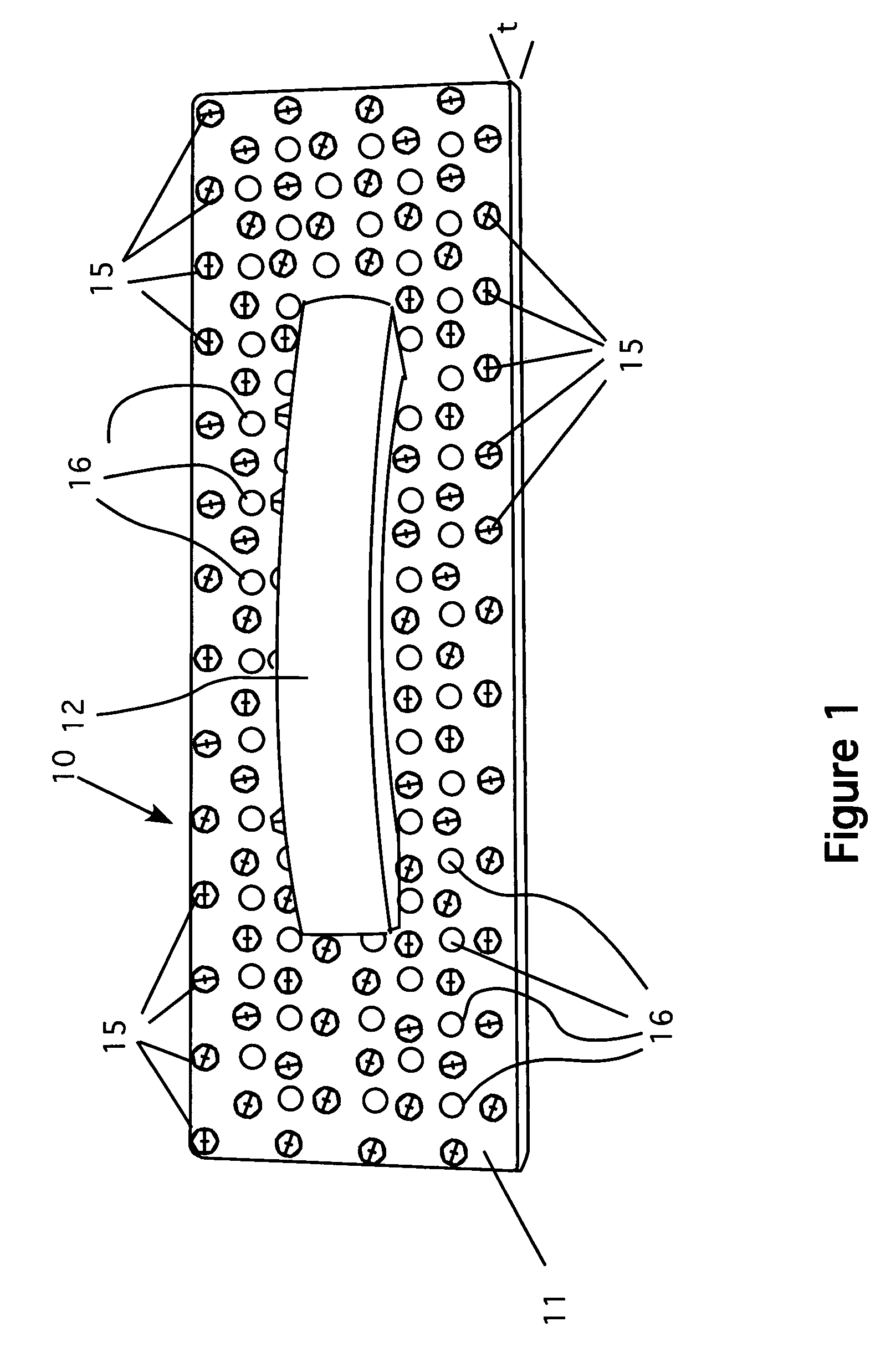

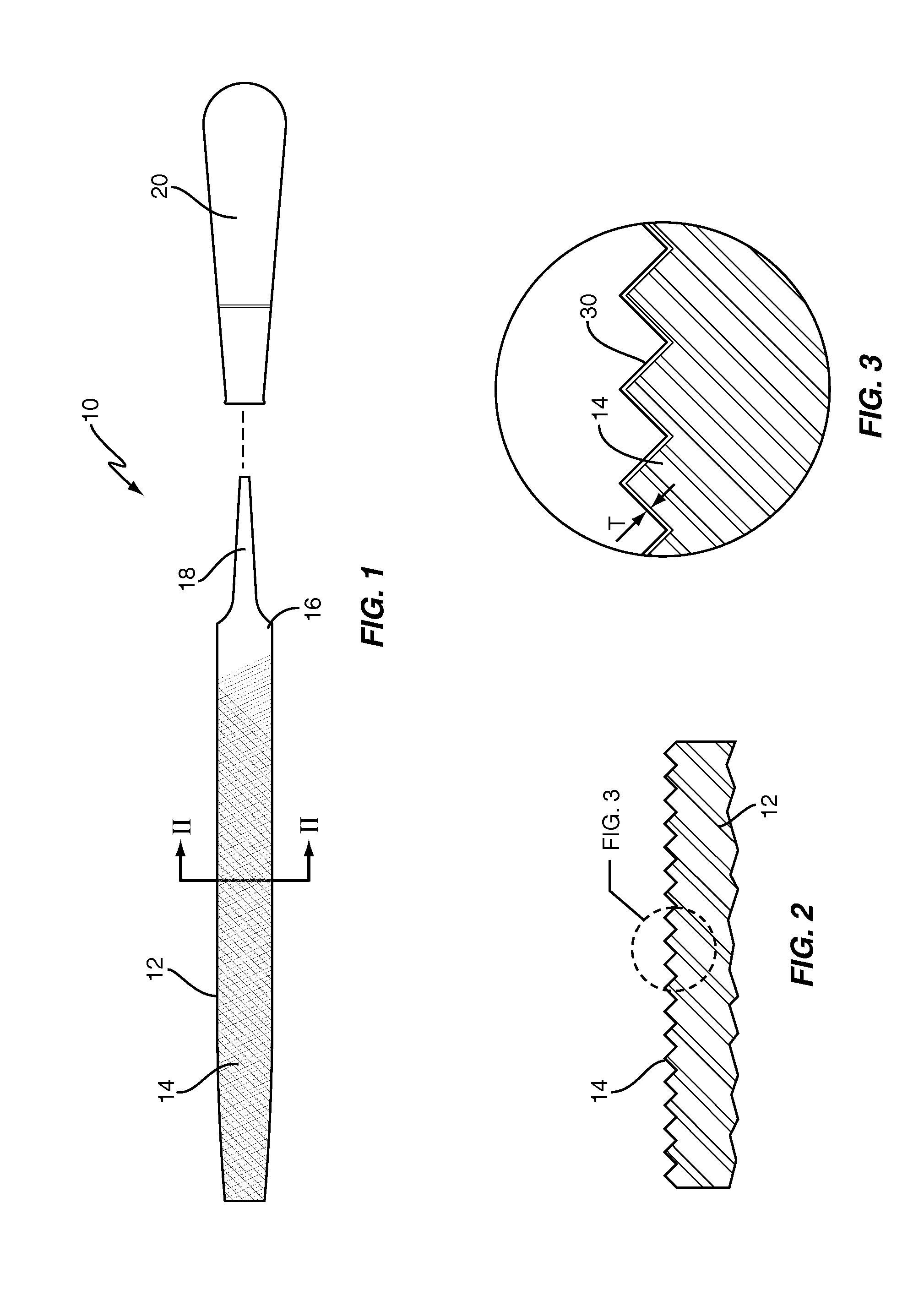

Shaper router and method

ActiveUS20050123363A1Reduce layeringHigh surface finishMilling cuttersFiling/rasping toolsMechanical engineeringHelix

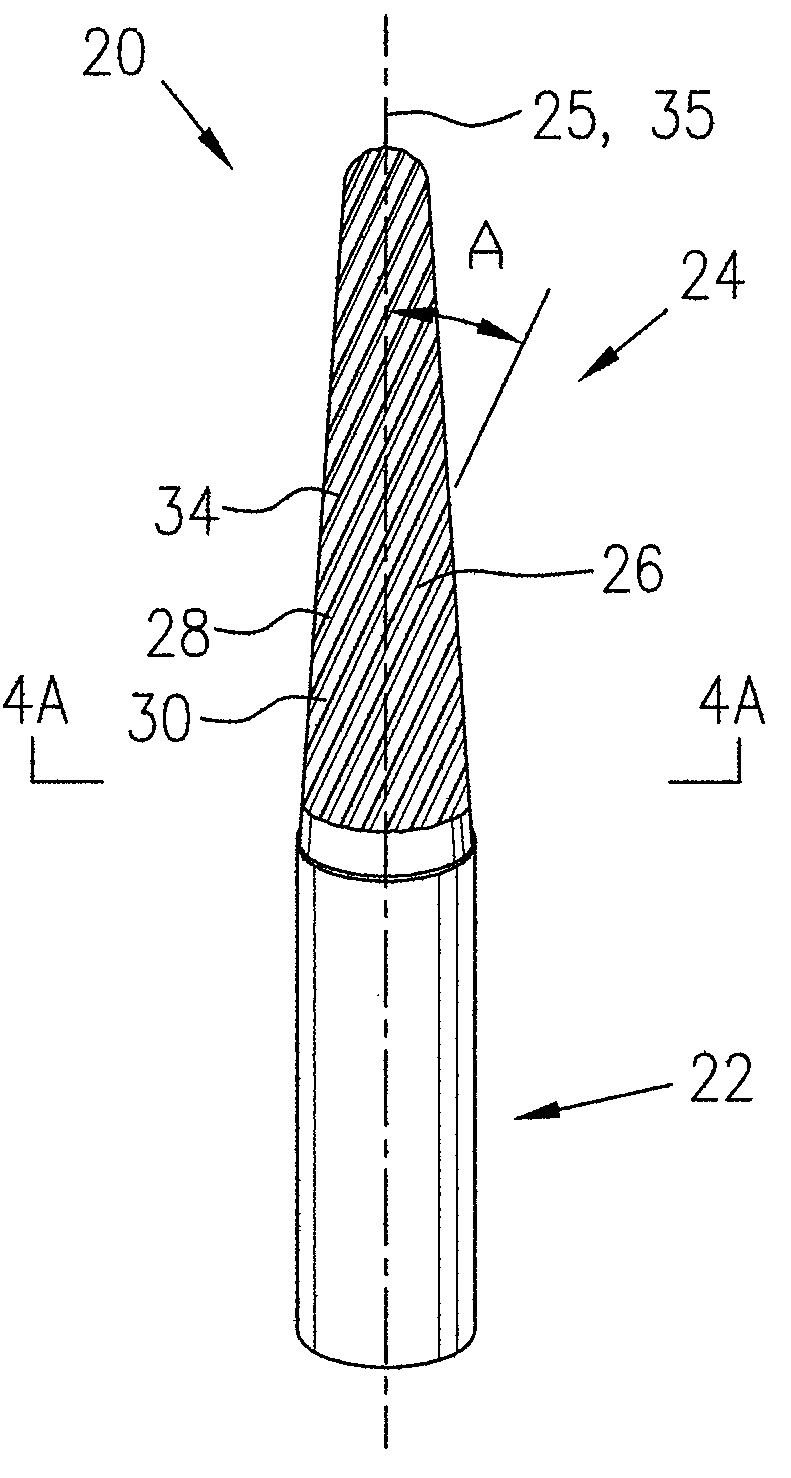

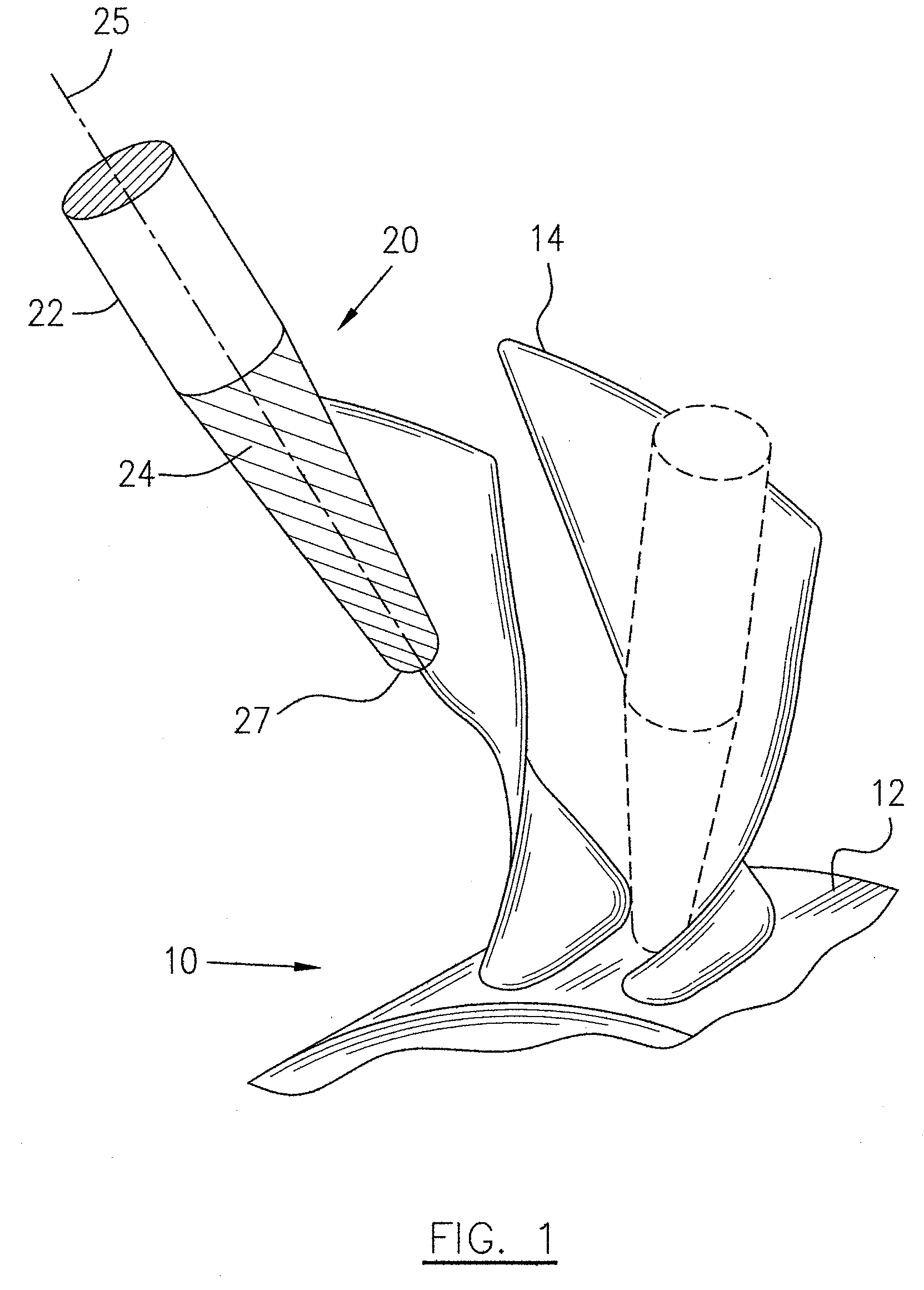

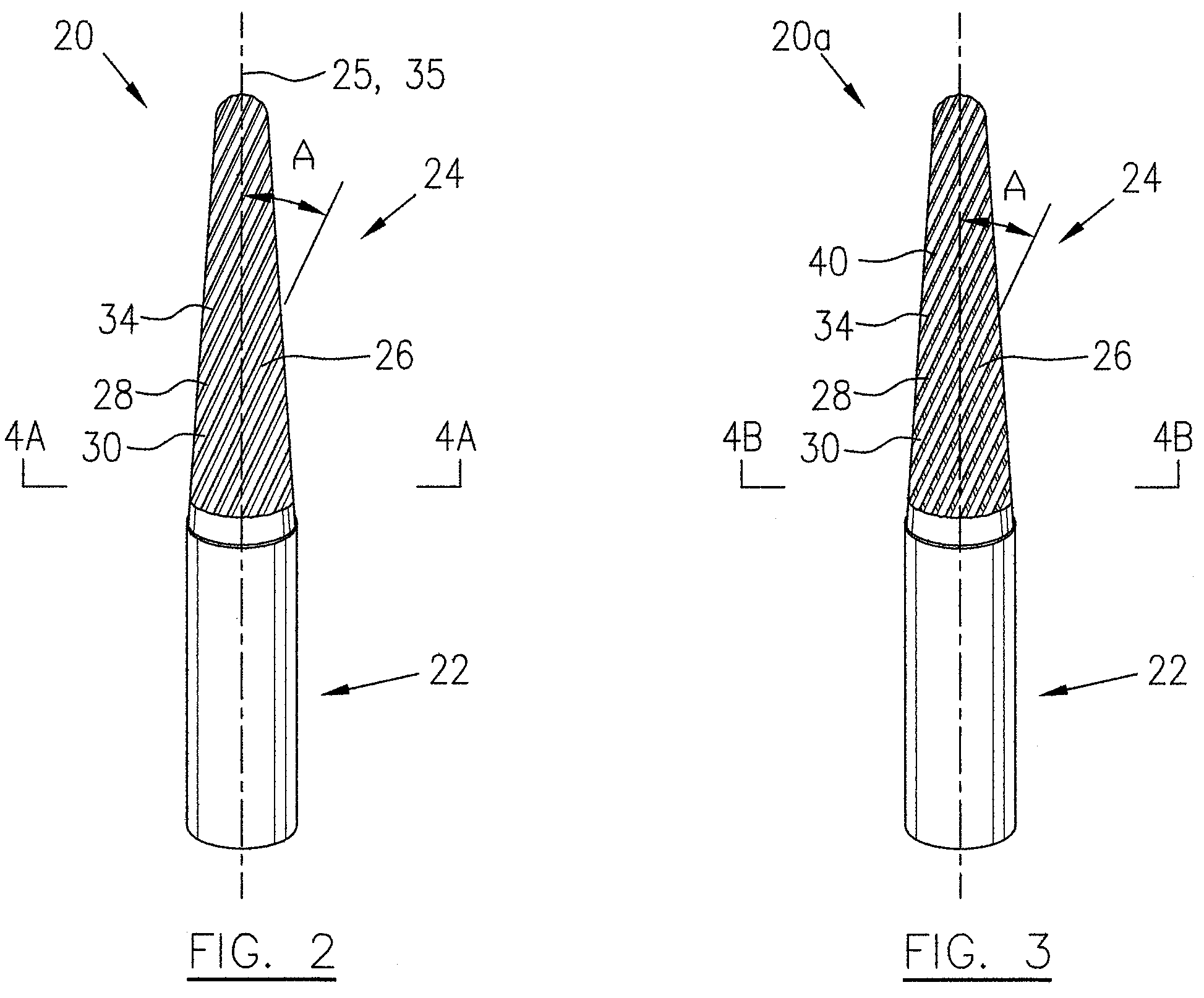

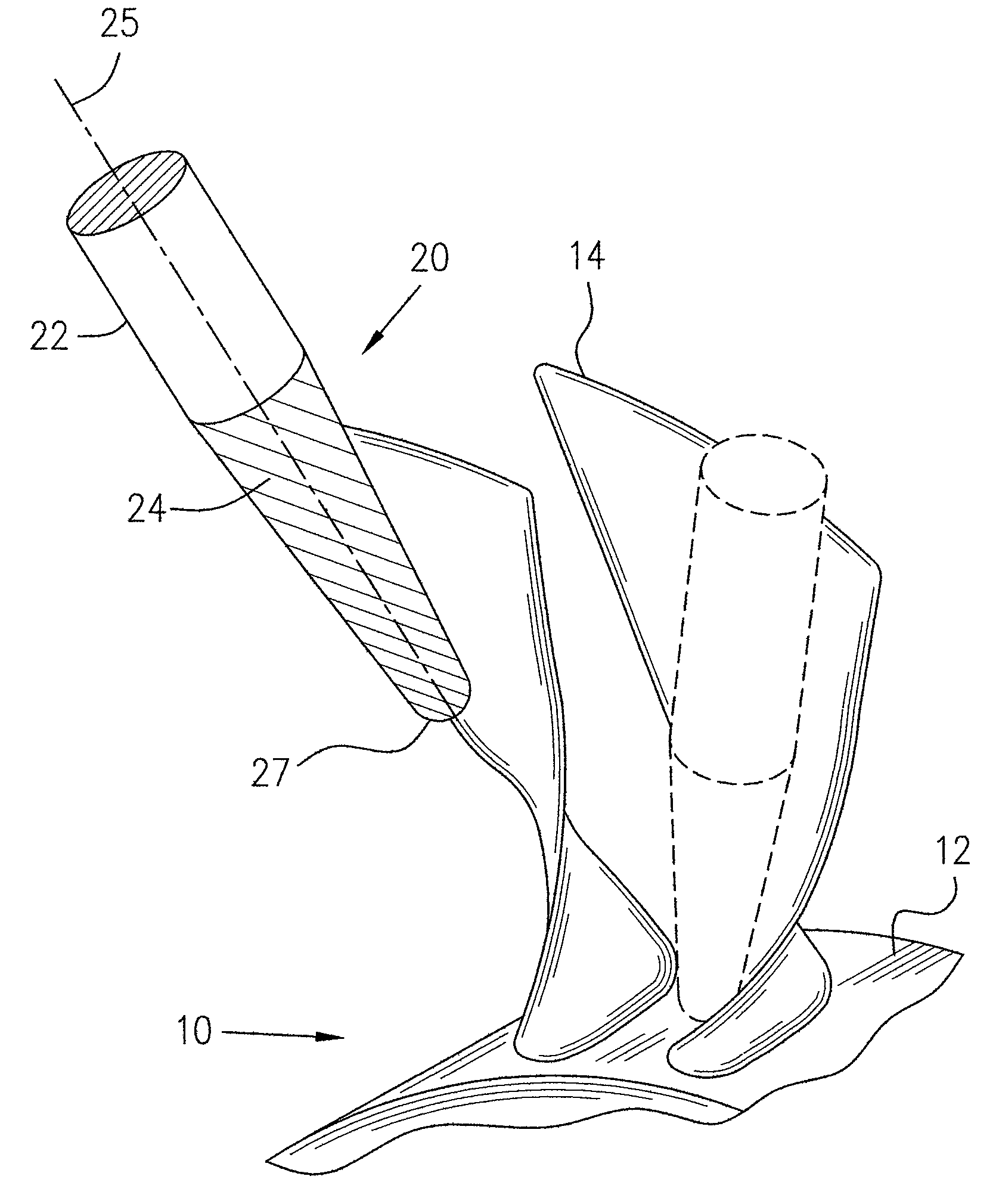

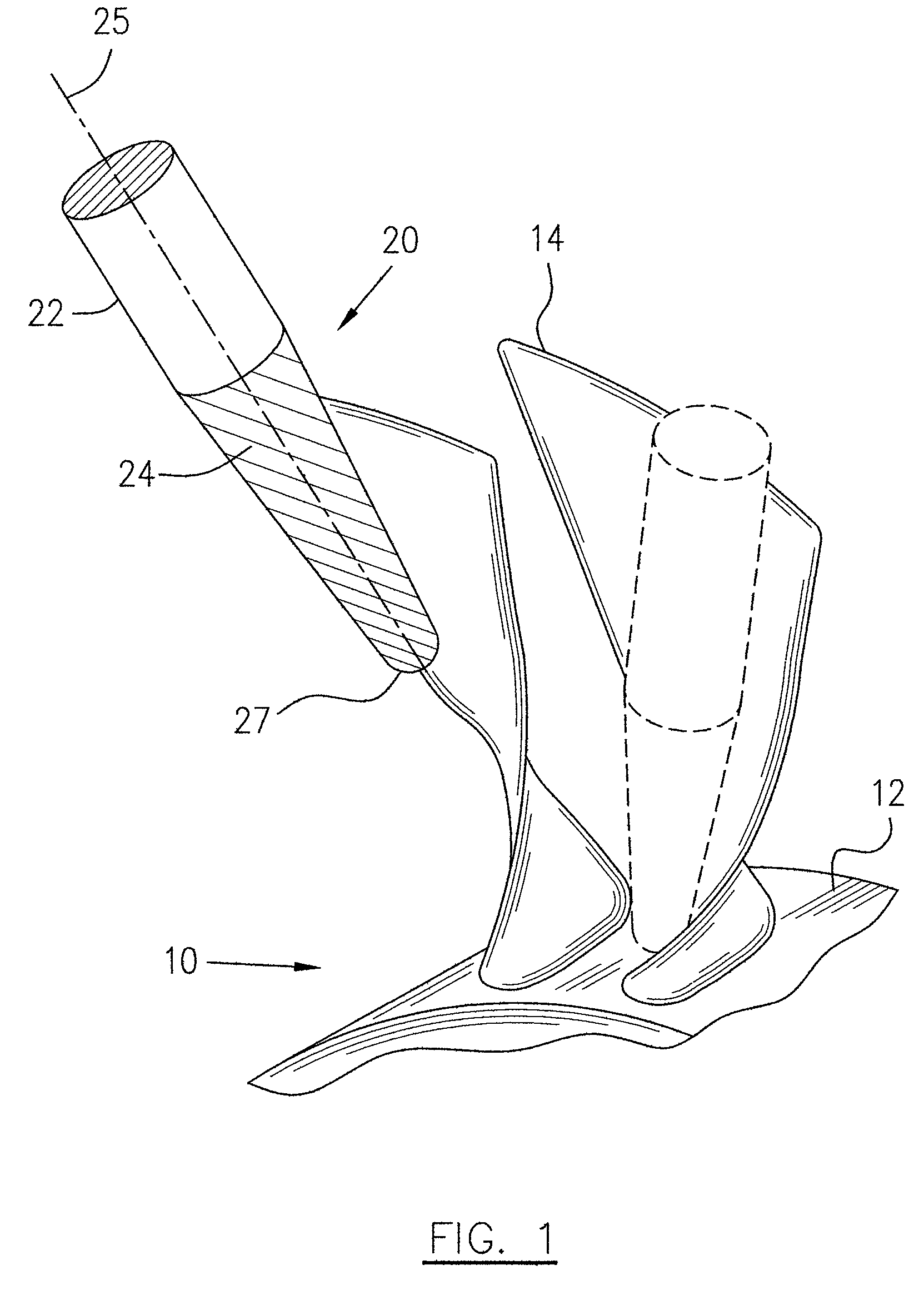

A routing tool for cutting material and an associated apparatus and method are provided. The tool includes a substantially cylindrical shaft member having a shank portion and a cutting portion. The cutting portion includes a plurality of cutting teeth disposed peripherally about a first helix and an intersecting second helix. Each cutting tooth defines a first cutting clearance on a first cutting edge and a first clearance on a first non-cutting edge. The cutting tooth defines a second cutting clearance on a second cutting edge and a second clearance on a second non-cutting edge. A flat extends on each cutting tooth resulting in a circular land on an outside diameter of the cutting portion.

Owner:THE BOEING CO

Combination tool

A combination tool is described that has a housing that includes a first side and an opposed second side, a third side and an opposed fourth side. The sides connect together to define the housing. The housing includes a first end portion and an opposed second end portion that define a longitudinal axis. The combination tool includes a razor mechanism that is connected to the housing. The razor mechanism receives and moves a cutting blade between a first position in the cavity and a second position wherein the cutting blade extends through the housing. The housing defines a channel that includes a floor, a first sidewall and a second sidewall. The first sidewall and the second sidewall have first edges that are connected to the floor and second edges that connect to the first side of the housing. The first sidewall includes a first slot and the second sidewall includes an opposed second slot. The first slot and second slot are positioned in fixed spaced relation from the floor and the second edge. The slots are configured to receive a rasp. The slots are positioned to recess a cutting surface of the rasp in the channel such that at least a portion of the sidewalls extend between the cutting surface and the second edges. A claw is defined in the housing that includes a first tong and a second tong. The claw extracts fasteners from soft materials.

Owner:MASSARO DANIEL J

Shaper router and method

ActiveUS7090442B2Reduce layeringHigh surface finishMilling cuttersFiling/rasping toolsEngineeringMechanical engineering

A routing tool for cutting material and an associated apparatus and method are provided. The tool includes a substantially cylindrical shaft member having a shank portion and a cutting portion. The cutting portion includes a plurality of cutting teeth disposed peripherally about a first helix and an intersecting second helix. Each cutting tooth defines a first cutting clearance on a first cutting edge and a first clearance on a first non-cutting edge. The cutting tooth defines a second cutting clearance on a second cutting edge and a second clearance on a second non-cutting edge. A flat extends on each cutting tooth resulting in a circular land on an outside diameter of the cutting portion.

Owner:THE BOEING CO

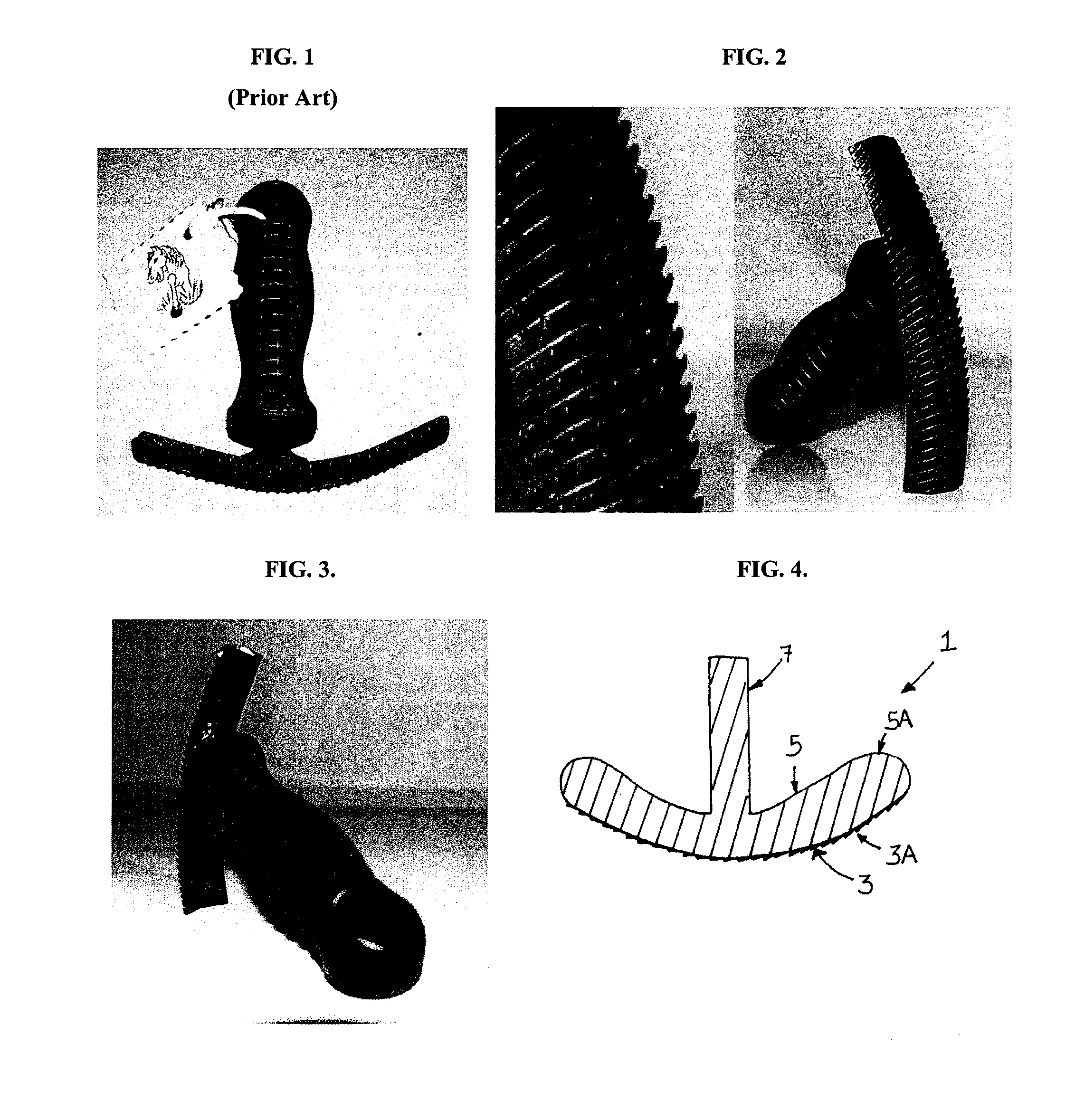

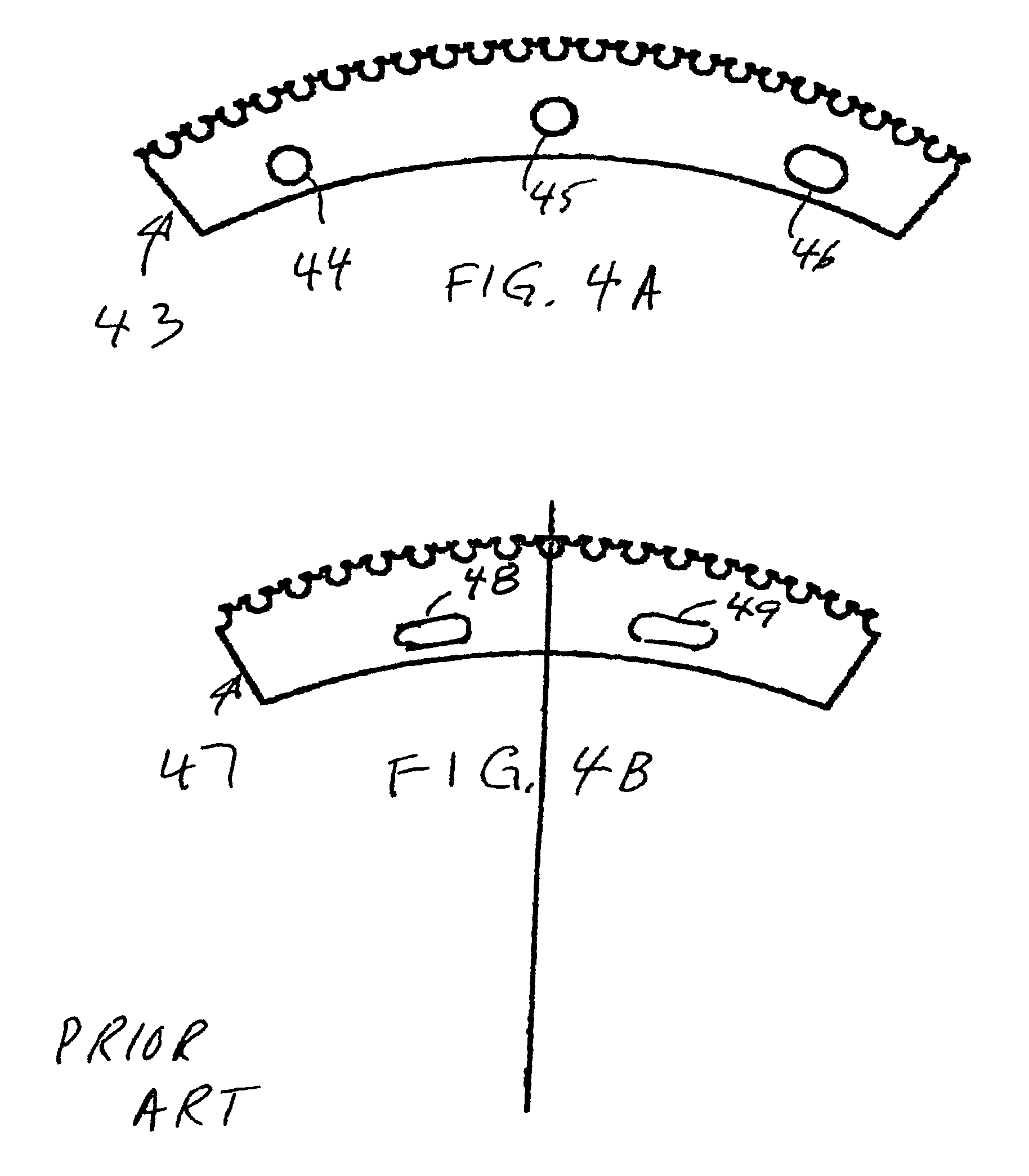

Convex rasp

An improved concave rasp that can be used to smooth any concave surface, such as under a hoof, having a handle approximately perpendicularly affixed at about the middle of a rasp that is convex both along its length and in cross section. The underside of the rasp has a rounded end, thus being suitable for applying pressure there against. Another embodiment of the invention is an improved tooth design, comprising a tooth blade, rather than individual teeth, thus providing much increased biting edge with increased durability.

Owner:NATURHOV

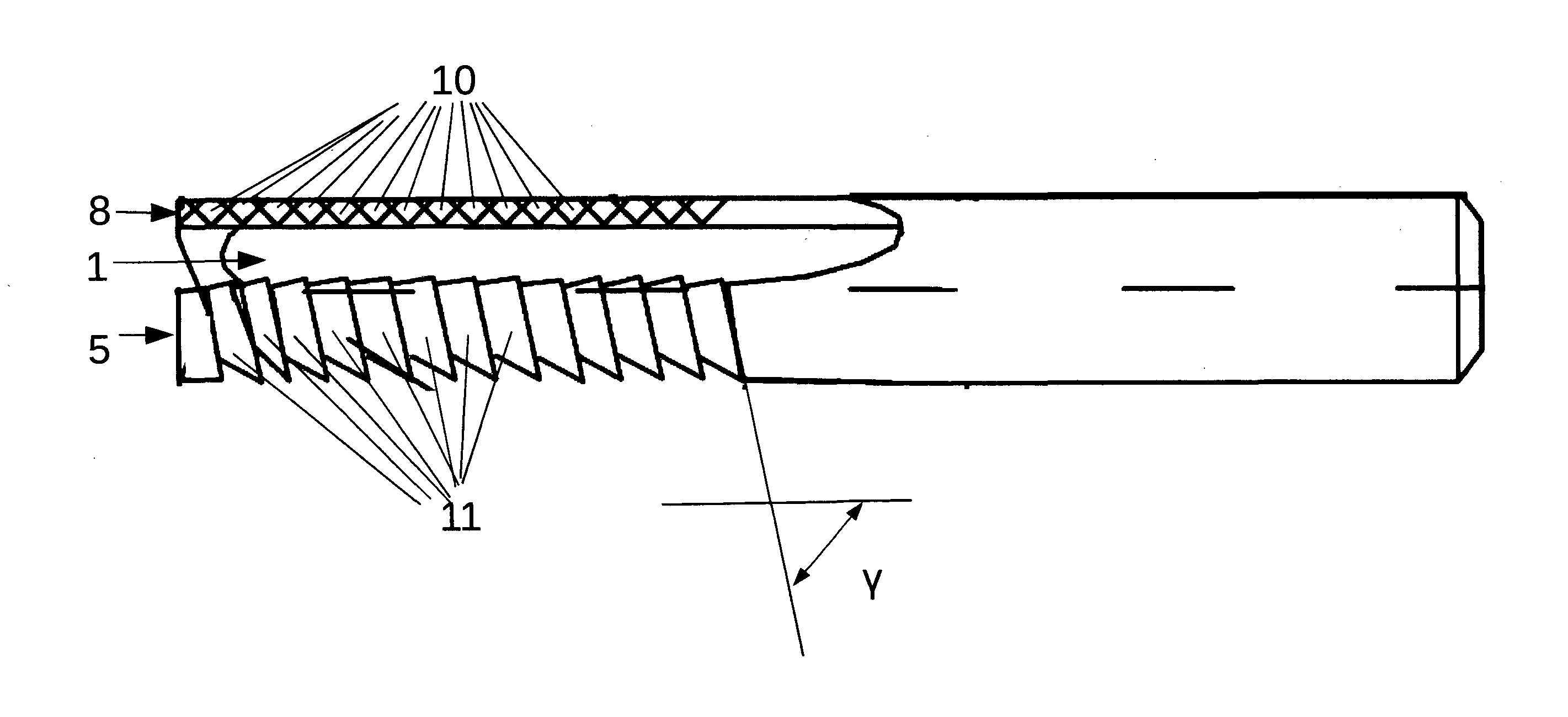

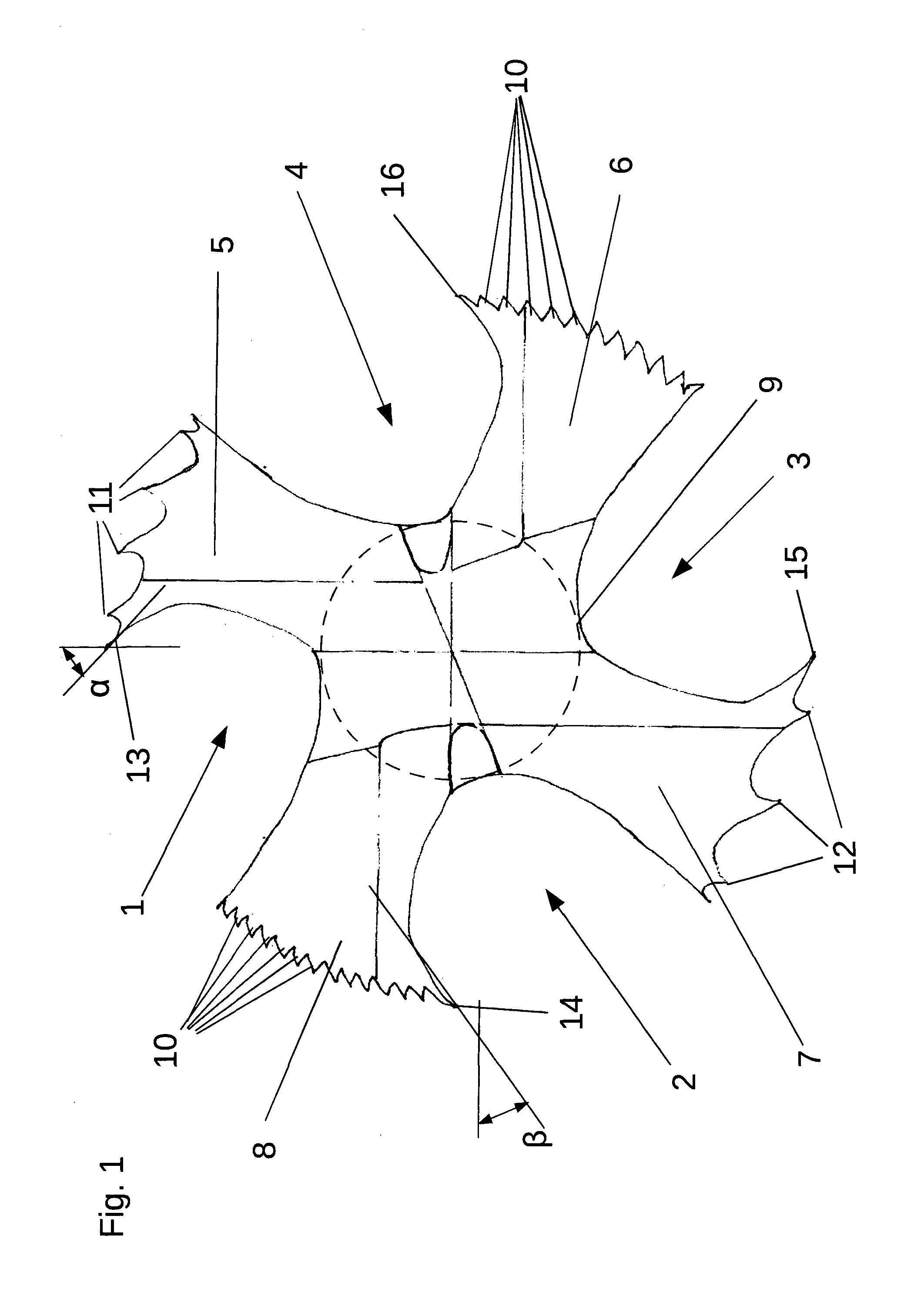

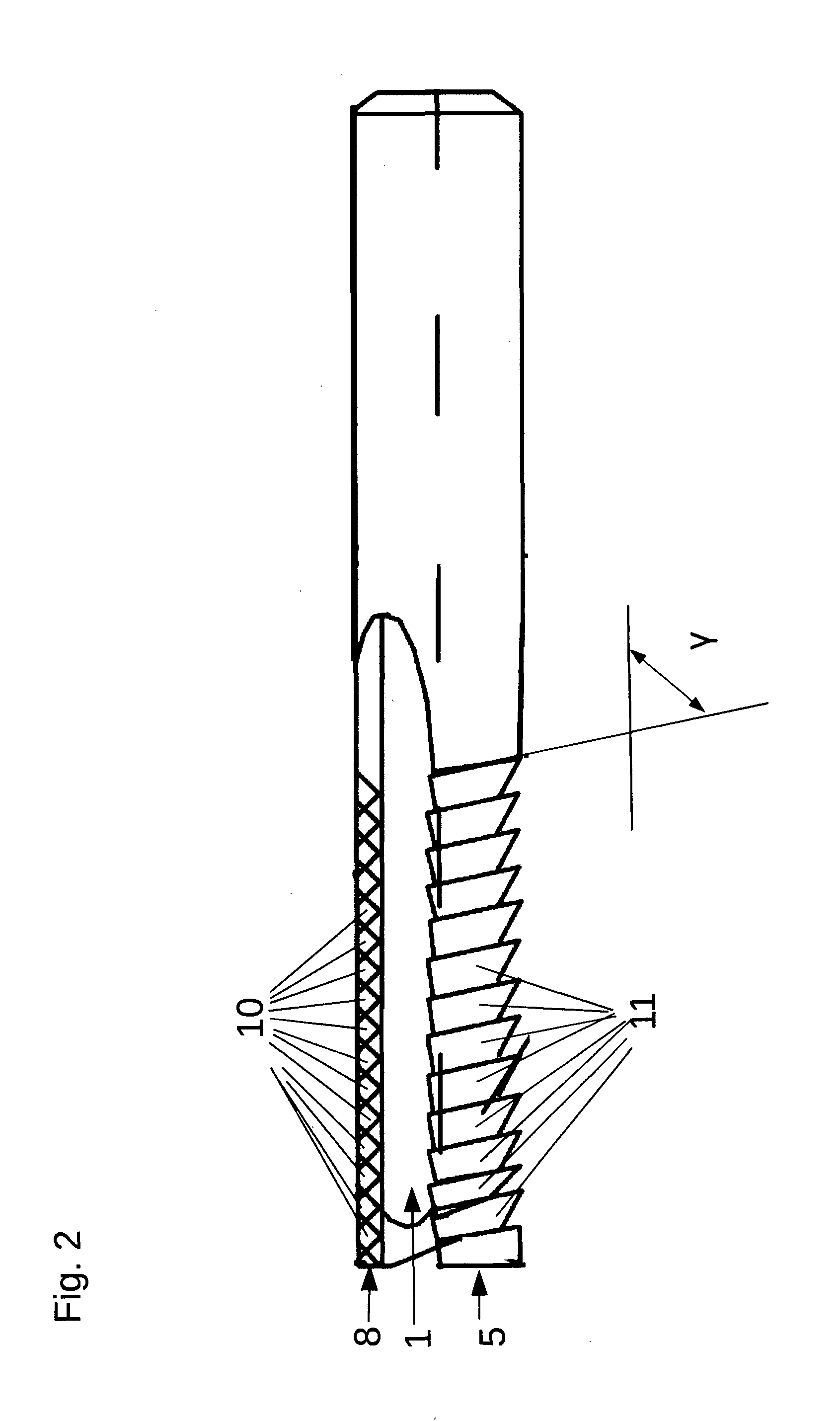

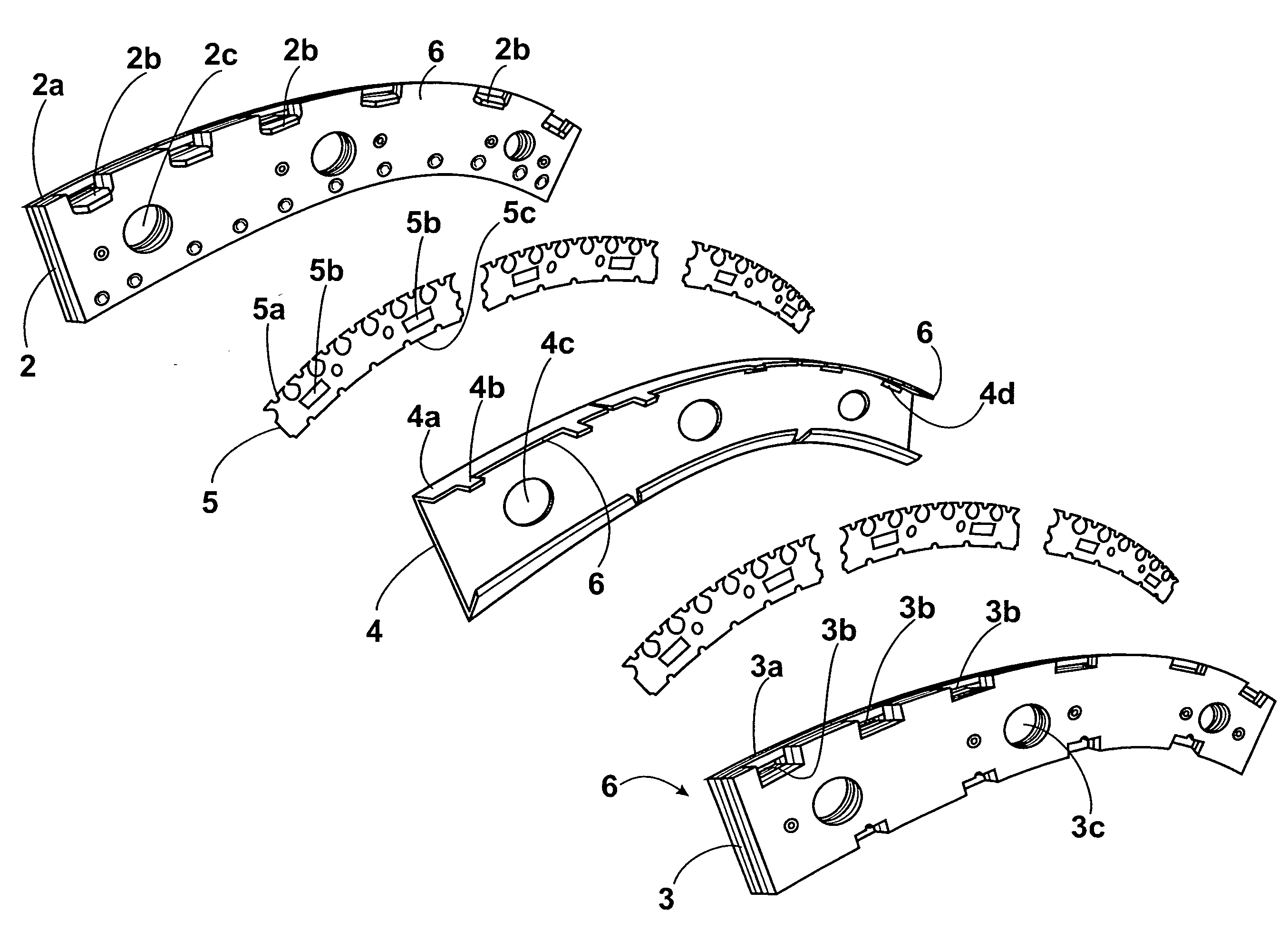

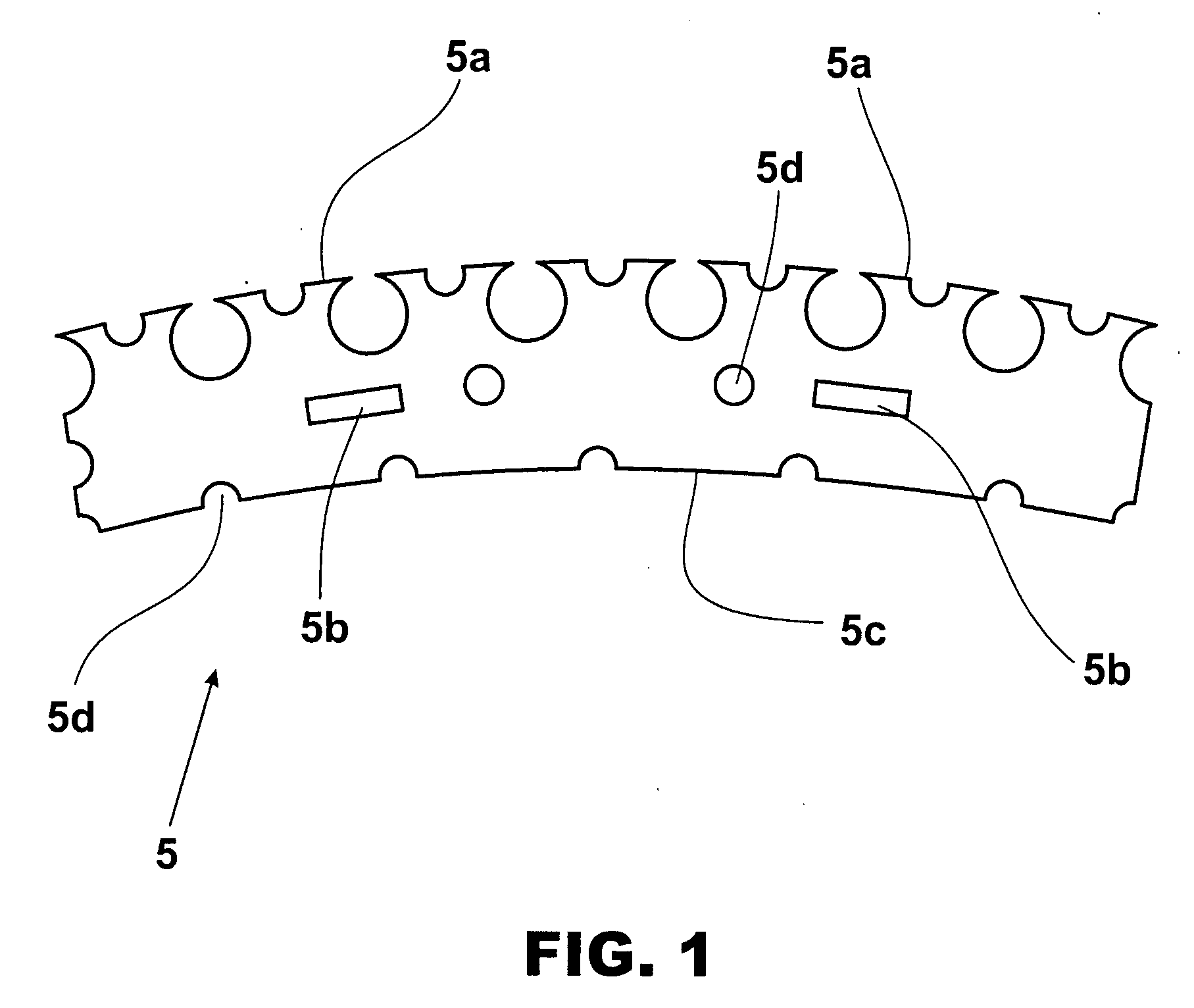

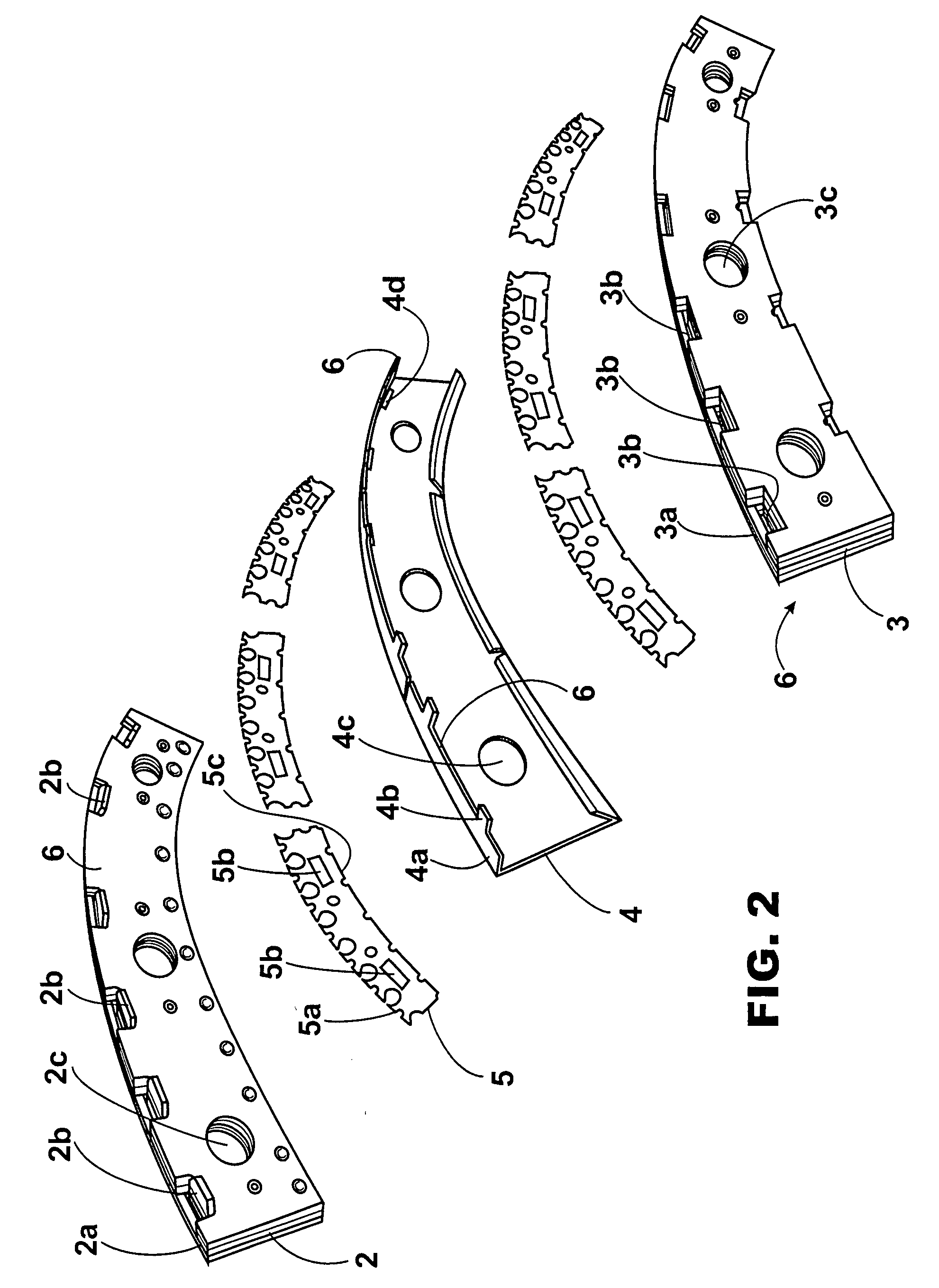

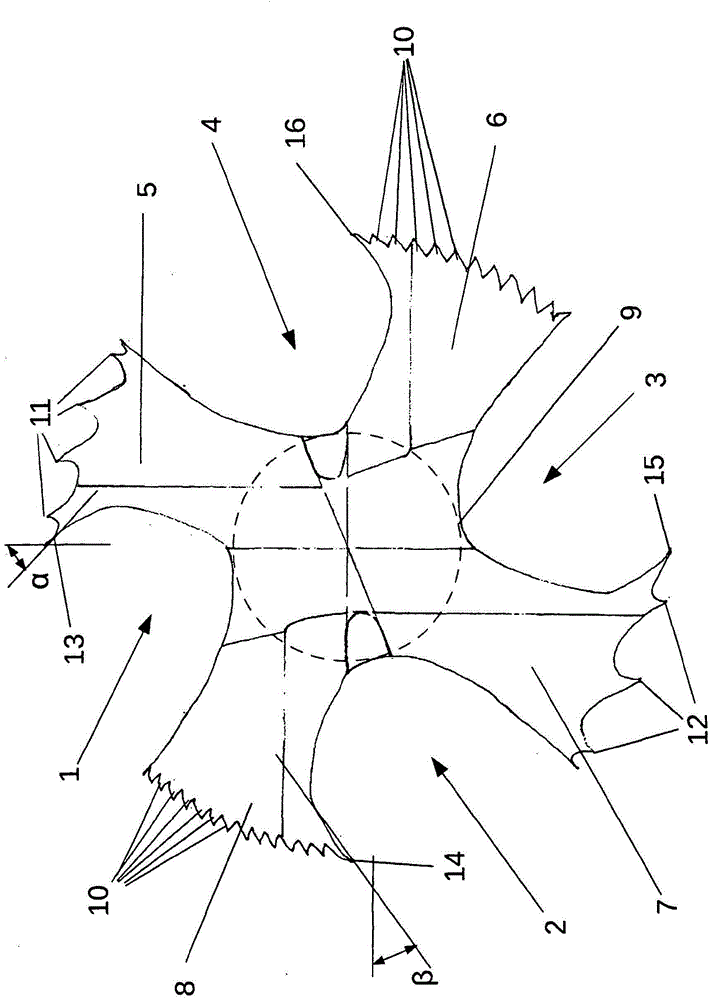

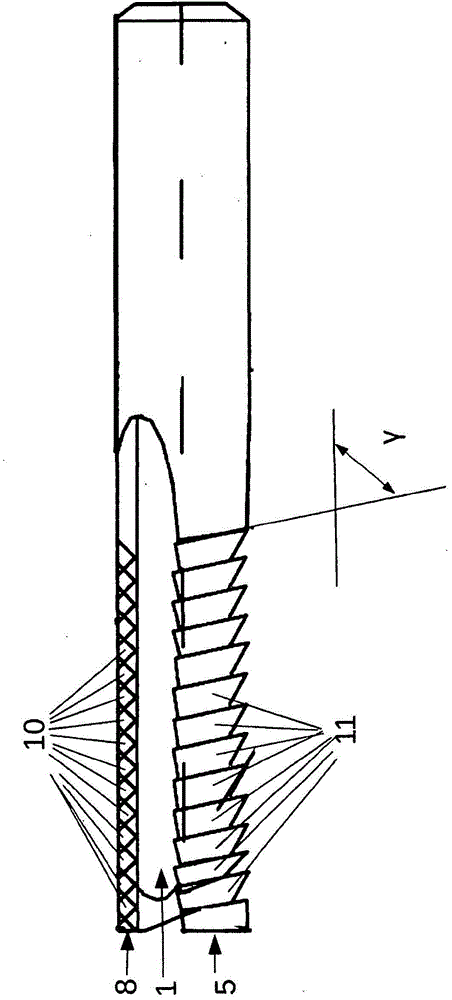

End milling cutter for processing of fiber-reinforced materials such as carobon fiber reinforced plastics (CFRP)

ActiveUS20150251253A1Short processing timeImprove surface qualityMilling cuttersWorkpiecesFluteGlass fiber

The invention concerns a machining tool for machining fiber-reinforced materials such as CFRP, glass-fiber-reinforced plastics or plastics reinforced with polyester threads. The machining tool comprises a plurality of flutes (1, 2, 3, 4) which distance lands (5, 6, 7, 8), disposed about a cylinder core segment (9), from each other in the peripheral sense. At least one of the lands (6, 8) is designed as a premachining land (6, 8) and at least one other of the lands (5, 7) is designed as a postmachining land (5, 7), each comprising a peripheral working region extending along, or with a twist and, in the form of a helical segment about, the tool axis. The working region of each premachining land (6, 8) is designed as a peripheral file with a plurality of teeth (10) which are incorporated in a cylinder surface segment-shaped outer surface of the working region, and provided in the working region of each postmachining land (5, 7) is a number of sharp cutting edges (11, 12, 13, 15) extending parallel to or with a twist and in the form of a helical segment about the tool axis. The invention is characterized in that the number of sharp cutting edges (11, 12, 13, 15) on at least one postmachining land (5, 7) comprises a plurality of cutting edges (11, 12) each provided on a peripheral casing groove, the casing grooves being incorporated in a cylinder surface segment-shaped outer face of the working region, parallel to each other and at a pitch relative to the flute (1, 3) leading at least one postmachining land (5, 7).

Owner:HUFSCHMIED ZERSPANUNGSSYST

Hacksaw frame having a file as an integral part thereof

A hacksaw having a frame that includes a back handle and an elongated beam that has a series of ridges on at least one or more surfaces of the elongated beam that form a file for reducing and smoothing surfaces of an article. The elongated beam has a first distal end coupled with a first back handle section. A hacksaw blade is coupled with the back handle and a fore piece coupled to a second distal end of the elongated beam.

Owner:ZAKARIAN ARTIN J

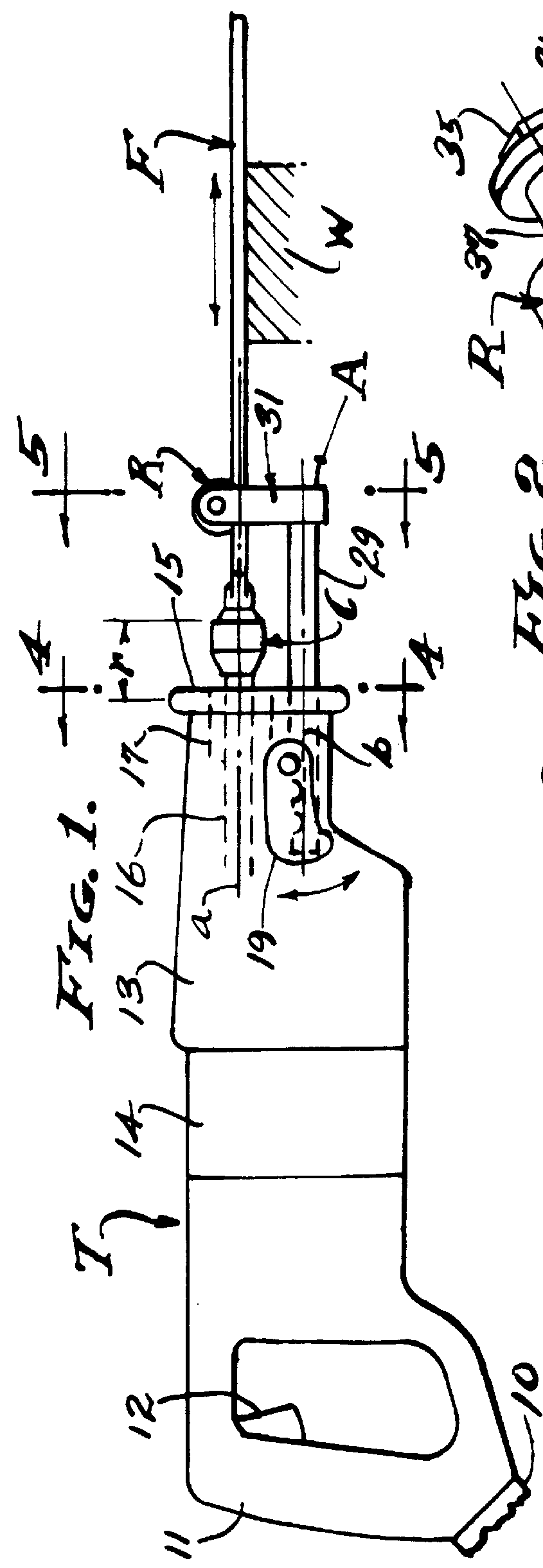

File adapter for power saw tool

A motor driven power hand tool and adapter reciprocating a modified hand file in pressured engagement with a work piece by manipulating a lever resistance intermediate the opposite ends of a file which becomes a second class lever operating with a fulcrum at its reciprocally driven end and with work force applied at its other end, the invention residing in the adapter that guides the file as an aftermarket device and in combination with the power hand tool.

Owner:FUSCO IVALEE

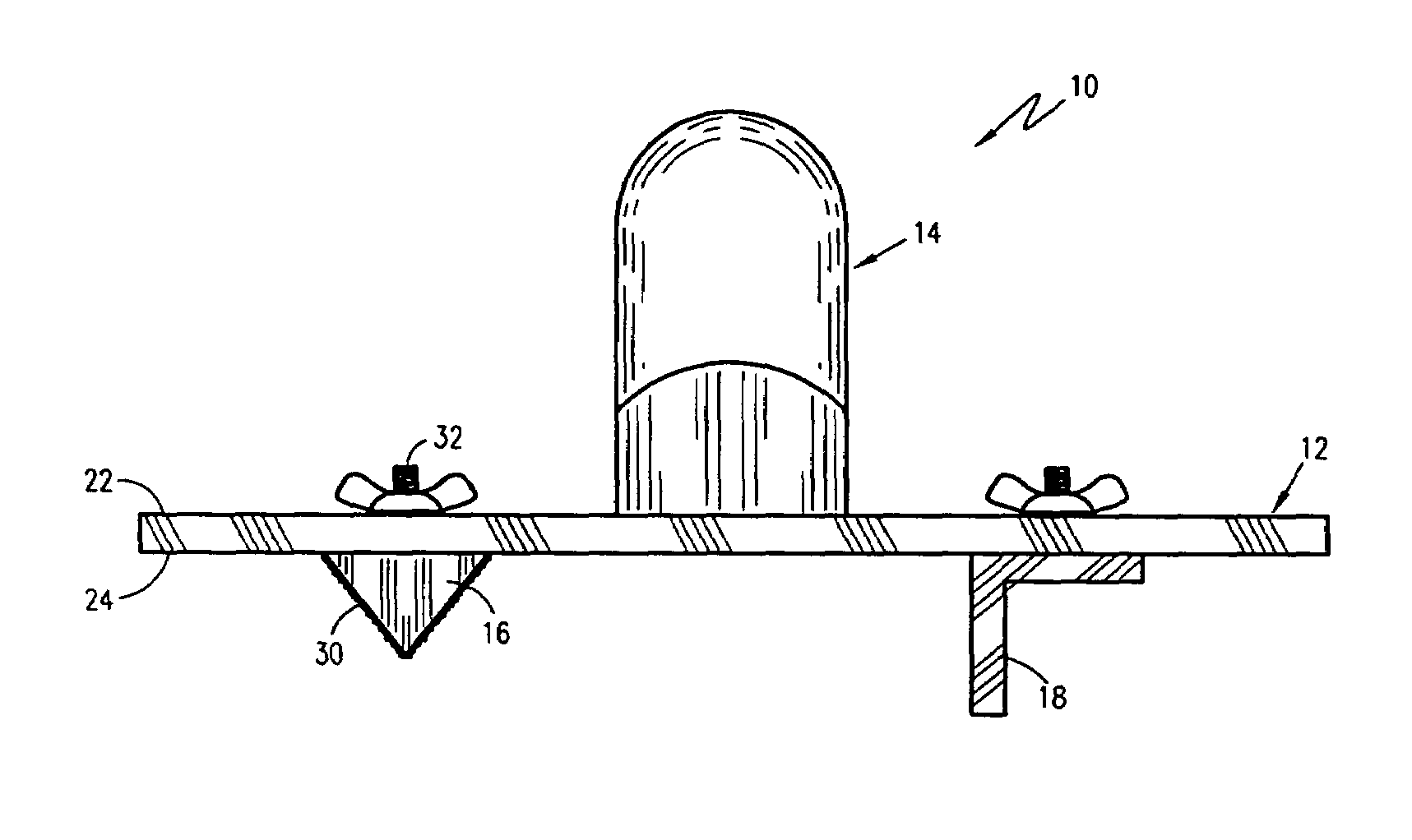

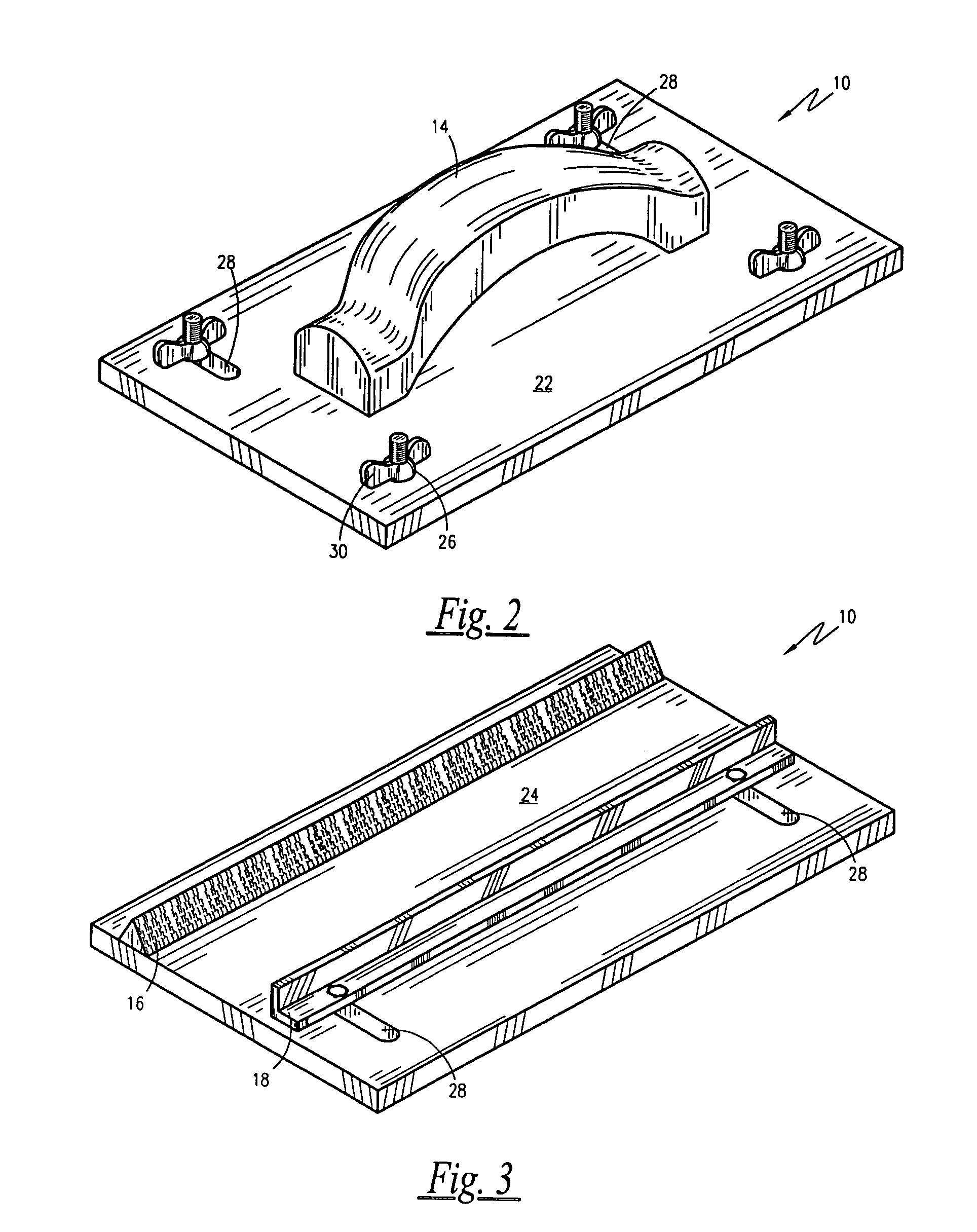

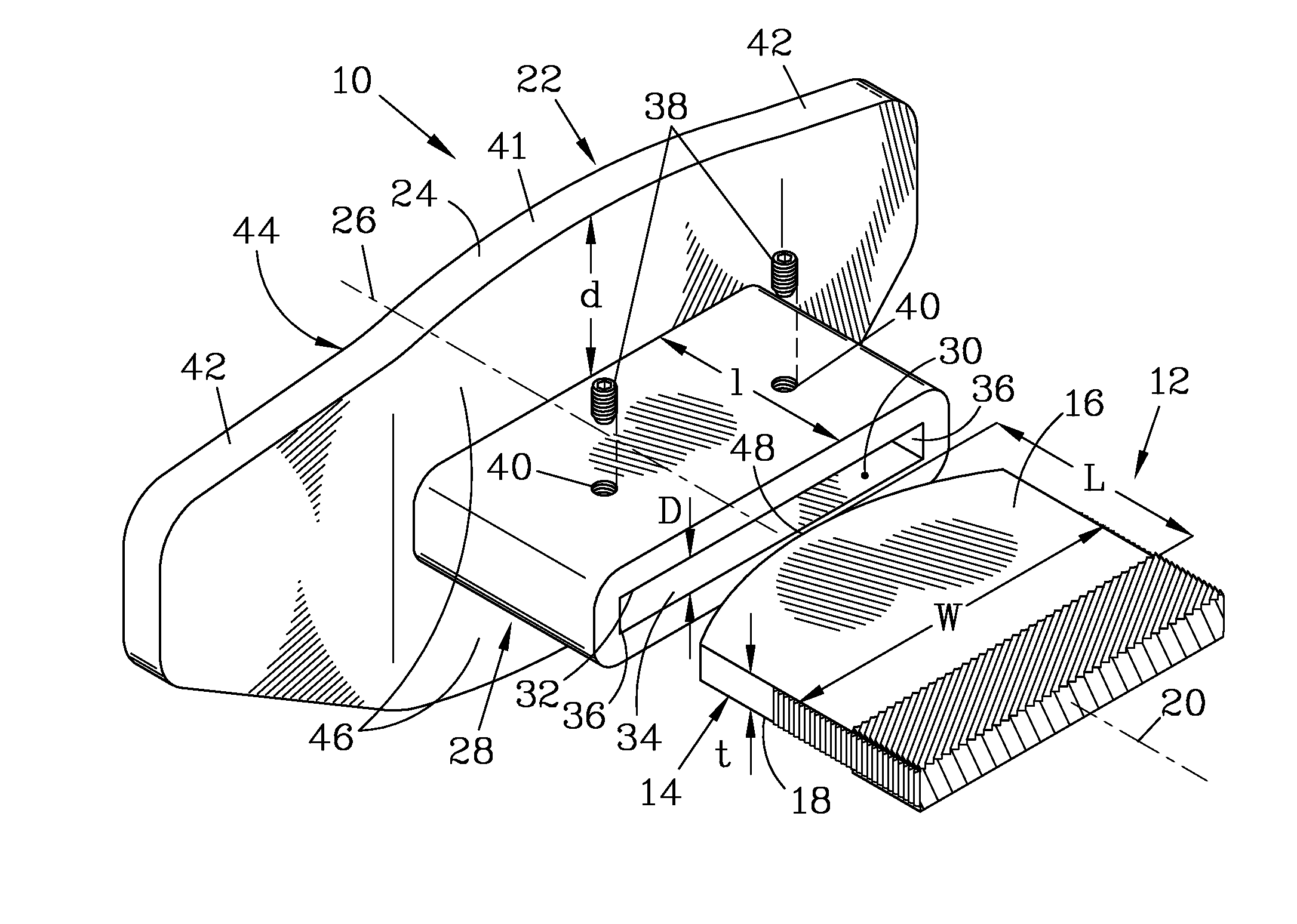

Hand rasp with groove blade and adjustable guide for scoring construction material

ActiveUS6905290B1Improve versatilitySmoothly start scoringMulti-purpose machinesFlat surfacing machinesRaspAnterior surface

An improved hand rasp comprises a planar plate with an anterior surface and an opposing posterior surface. An ergonomic handle is affixed to the anterior surface of the plate. A groove blade is removably affixed to the posterior surface of the plate by attachment means. The groove blade may have a variety of geometric configurations and varying in width and depth to accommodate the imagination of the user or designer. The groove blade includes an abrasive surface on the exterior surface of the groove blade. A guide is also removably affixed to the posterior surface of the plate by attachment means, positioned parallel to the groove blade. The guide is adjustable about apertures formed in the plate to position the guide closer to or farther away from the groove blade.

Owner:CASCIATO JR ANDREW

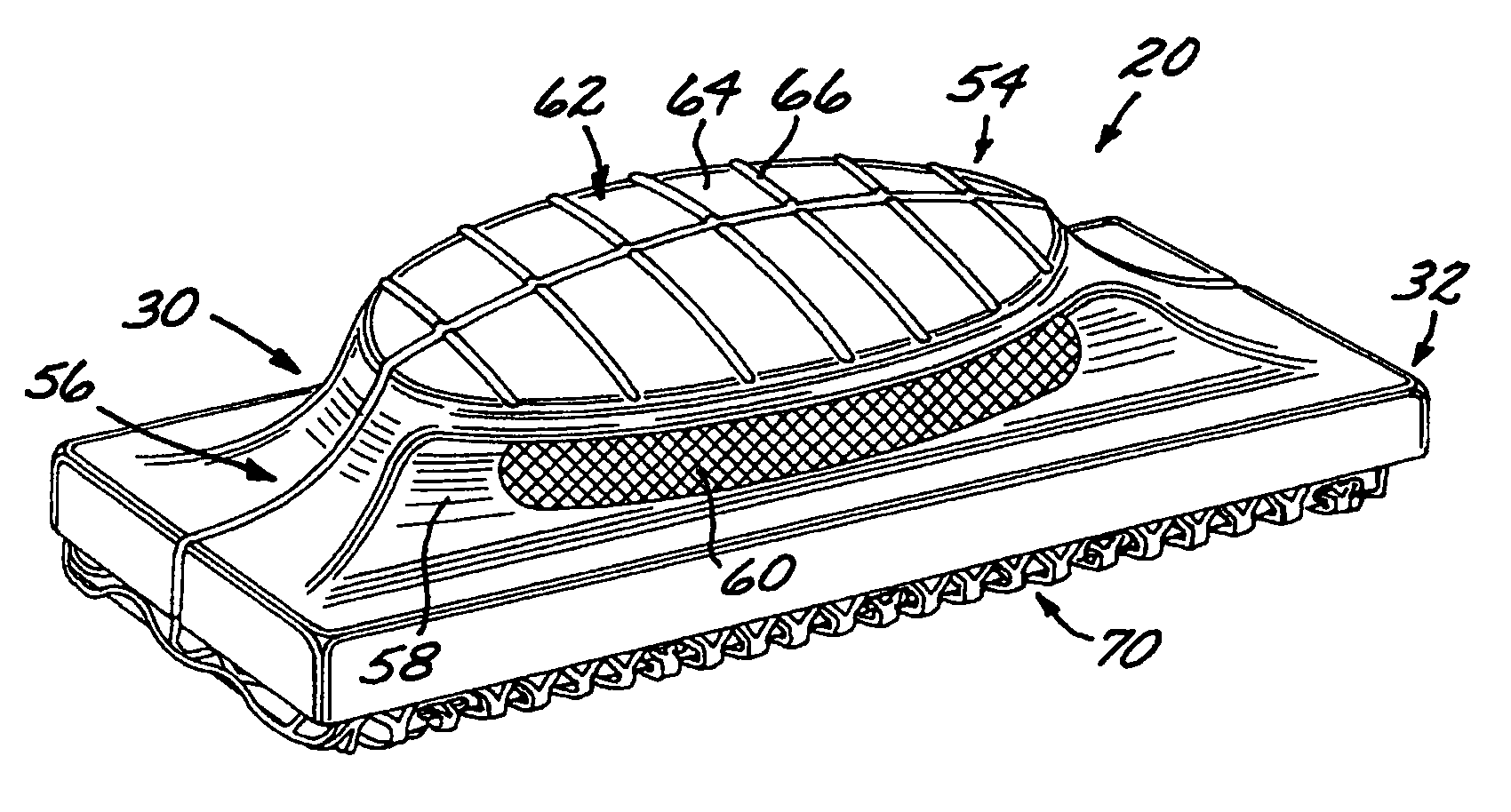

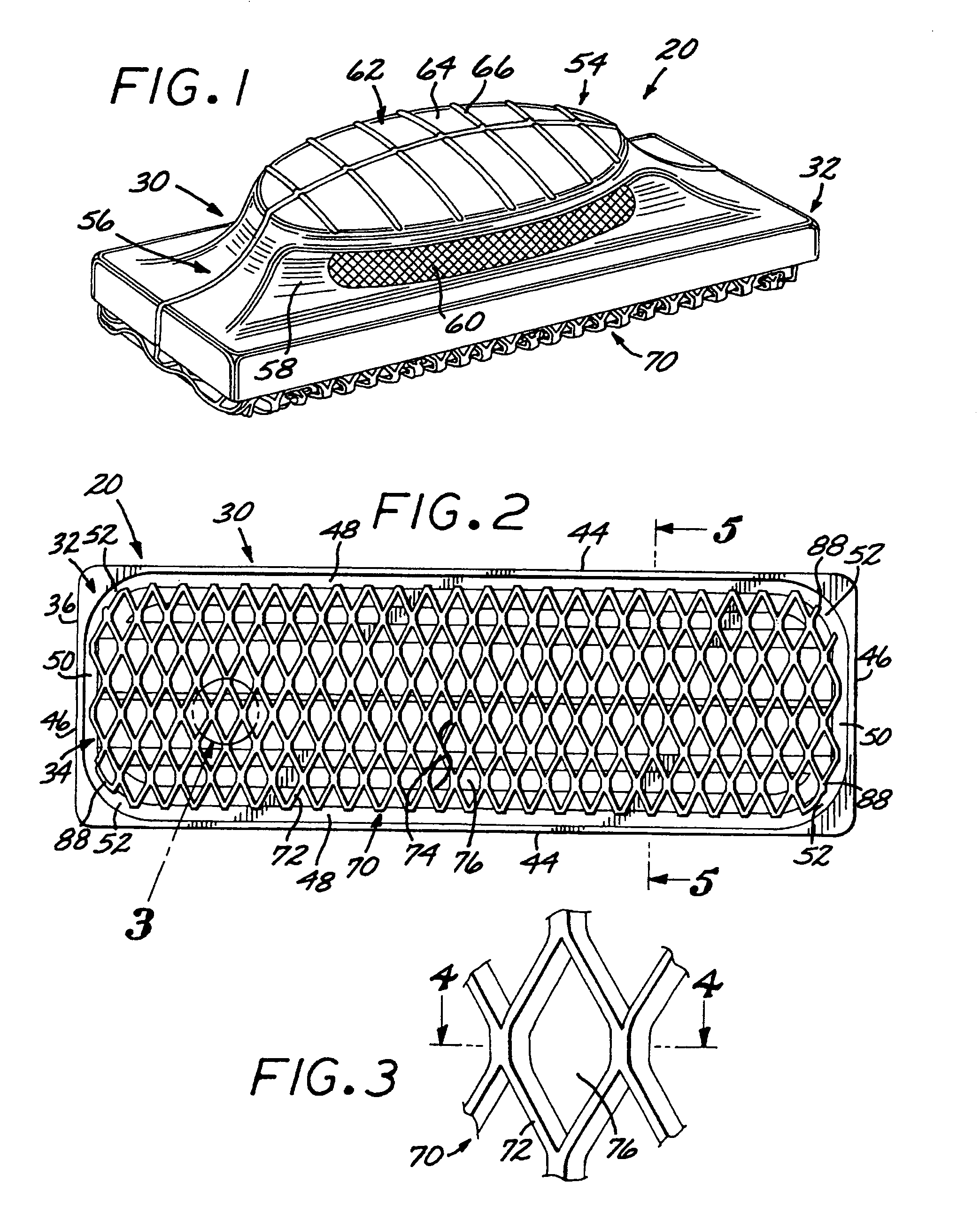

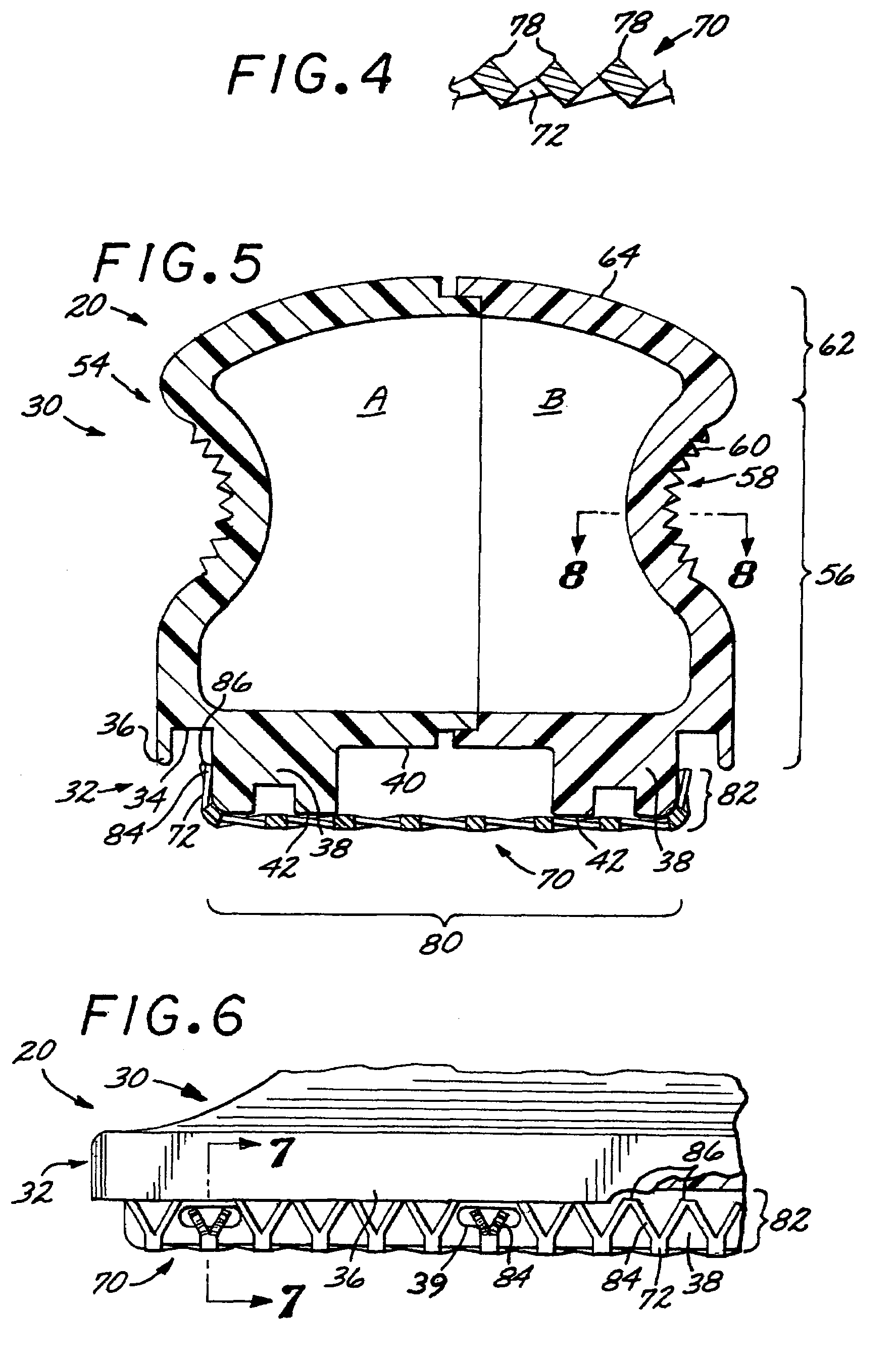

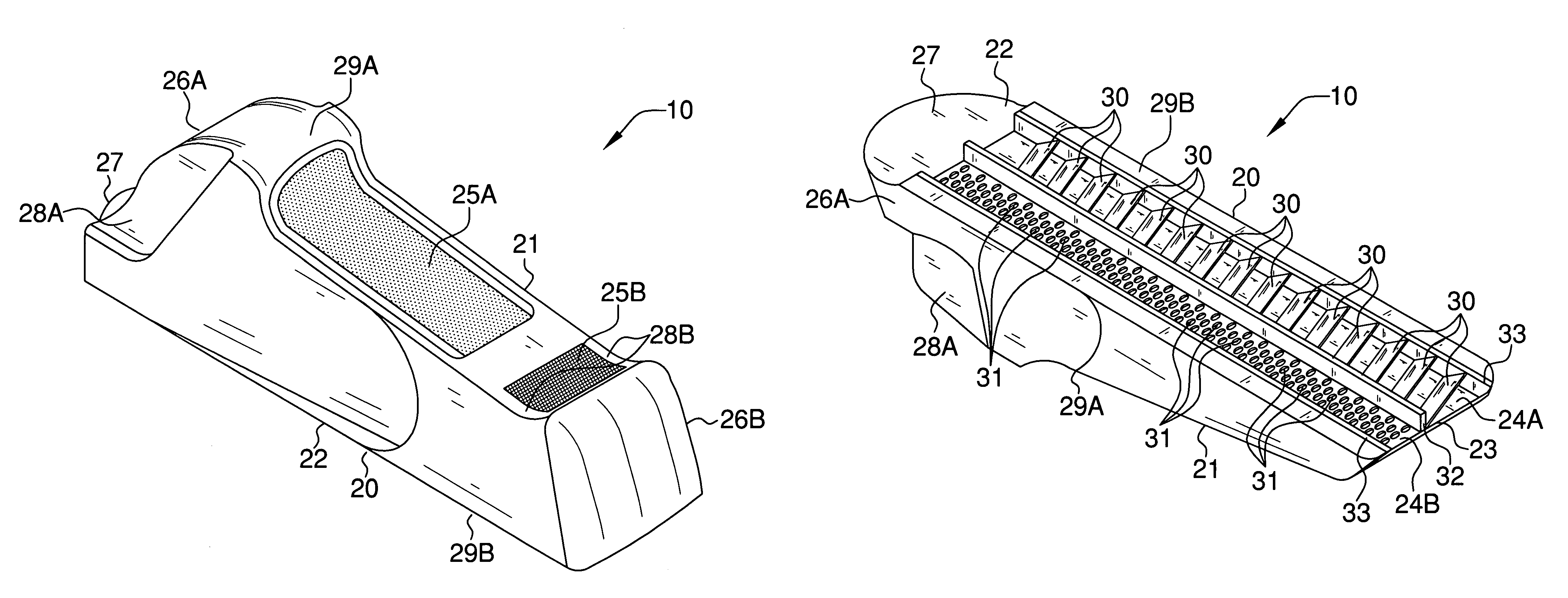

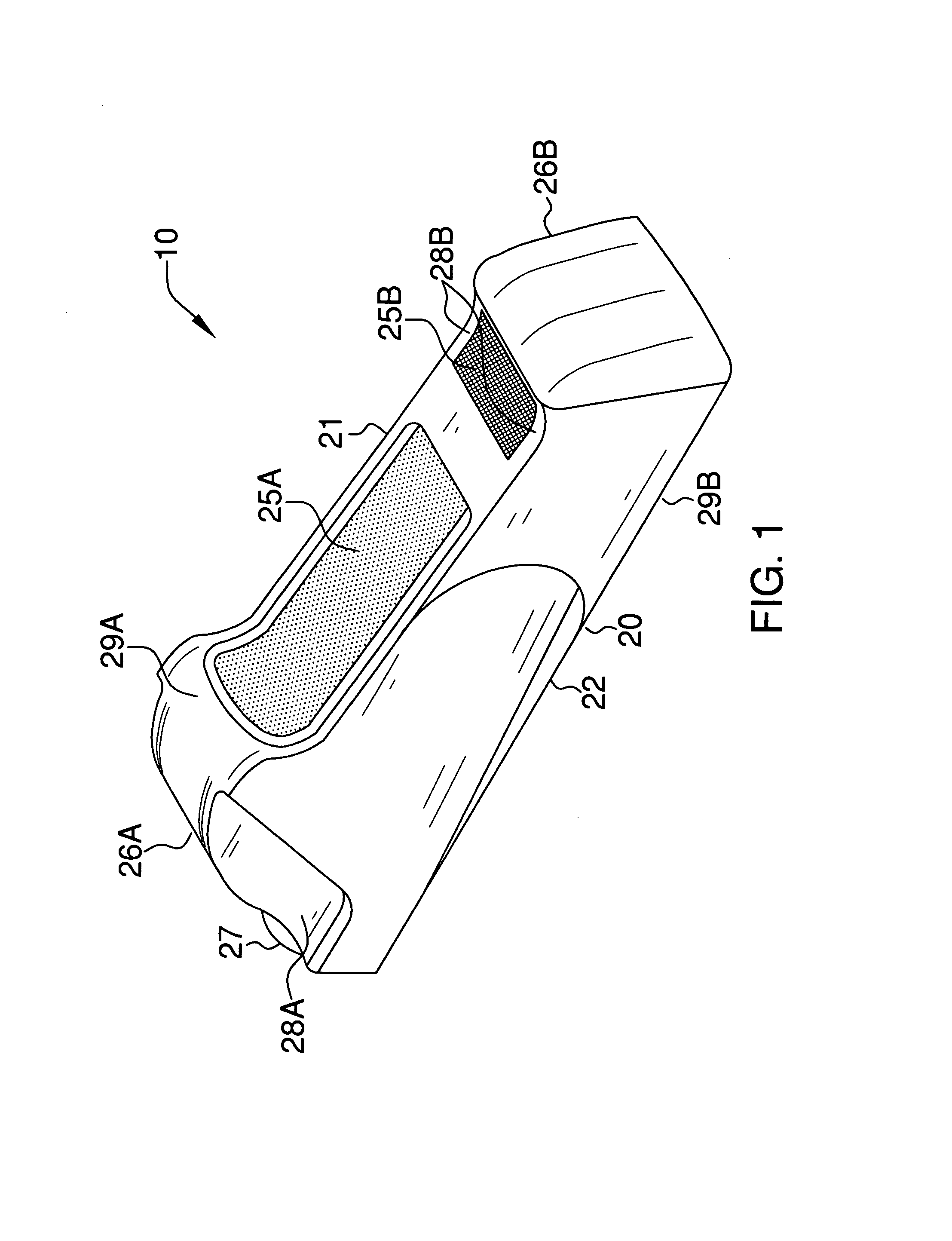

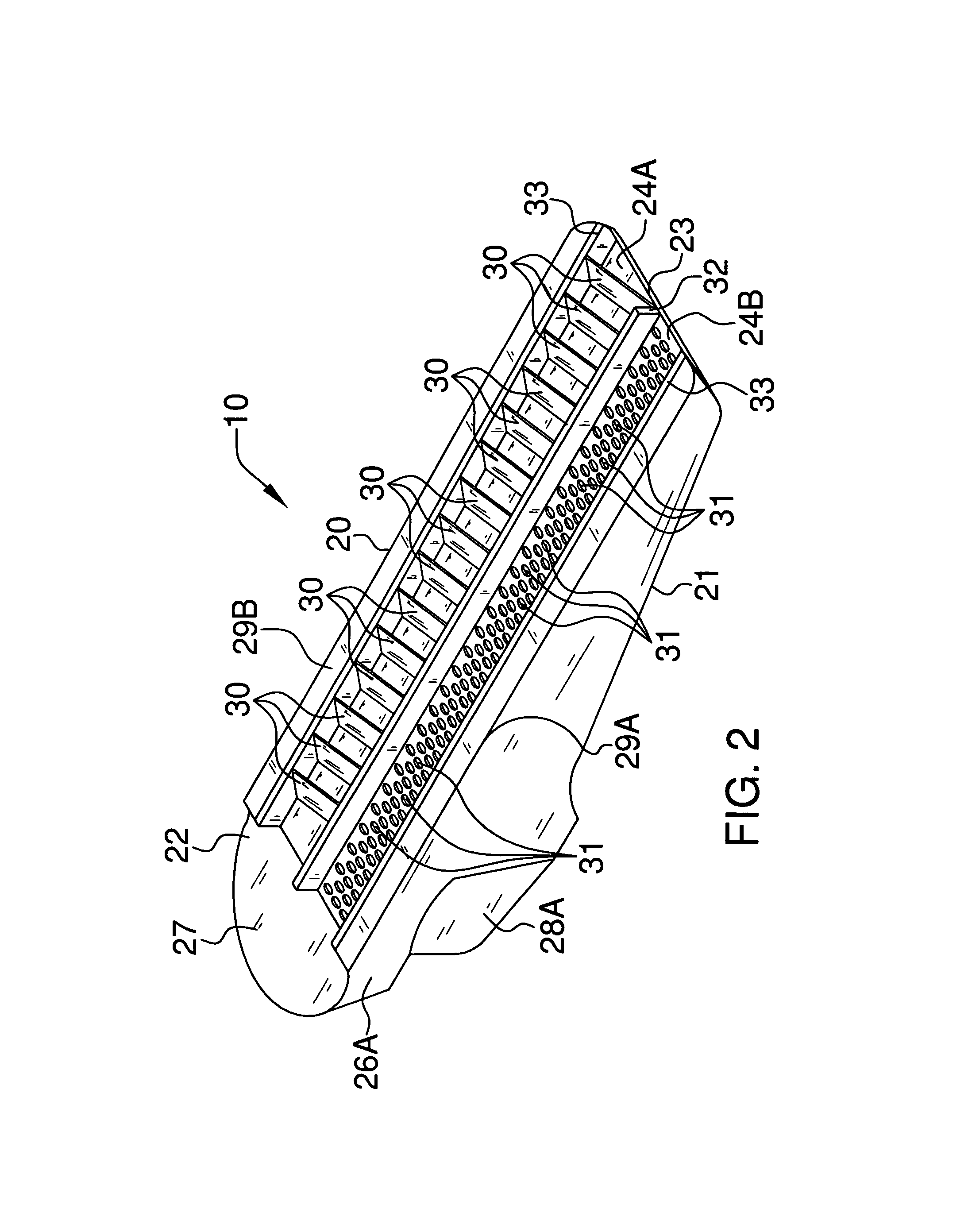

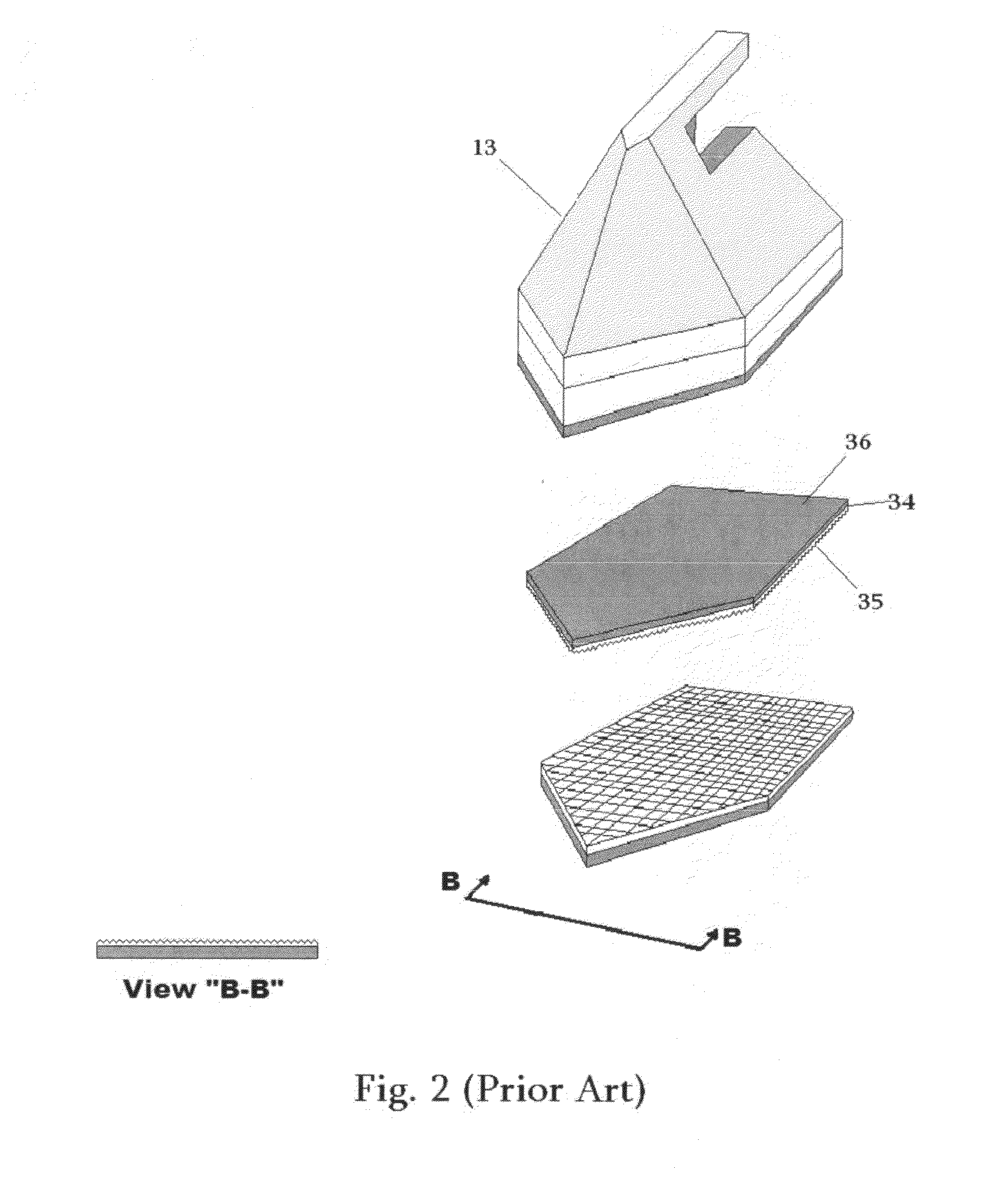

Wallboard rasp

InactiveUS6957934B2Prevent inadvertent cutEliminate dangerLiquid surface applicatorsCarpet cleanersRaspMechanical engineering

A wallboard rasp having an expanded metal blade mounted to a molded plastic handle. The handle is configured with a downwardly-opening receiving groove for receipt of an upwardly-curved perimeter portion of the blade. Sections of the blade's perimeter may be crimped or heat staked within the groove. The groove may be formed between a downwardly-projecting outer lip and one or more downwardly-projecting inner ribs. Where the blade is formed with a substantially planar central portion, the ribs may have substantially planar downwardly-facing surfaces against which the blade's central portion may be supported when mounted on the handle. The grip portion of the handle is configured as a contoured, upwardly-extending body having a base with opposite knurled inset surfaces and a convex top flanged surface with spaced-apart grip ribs.

Owner:WALLBOARD TOOL

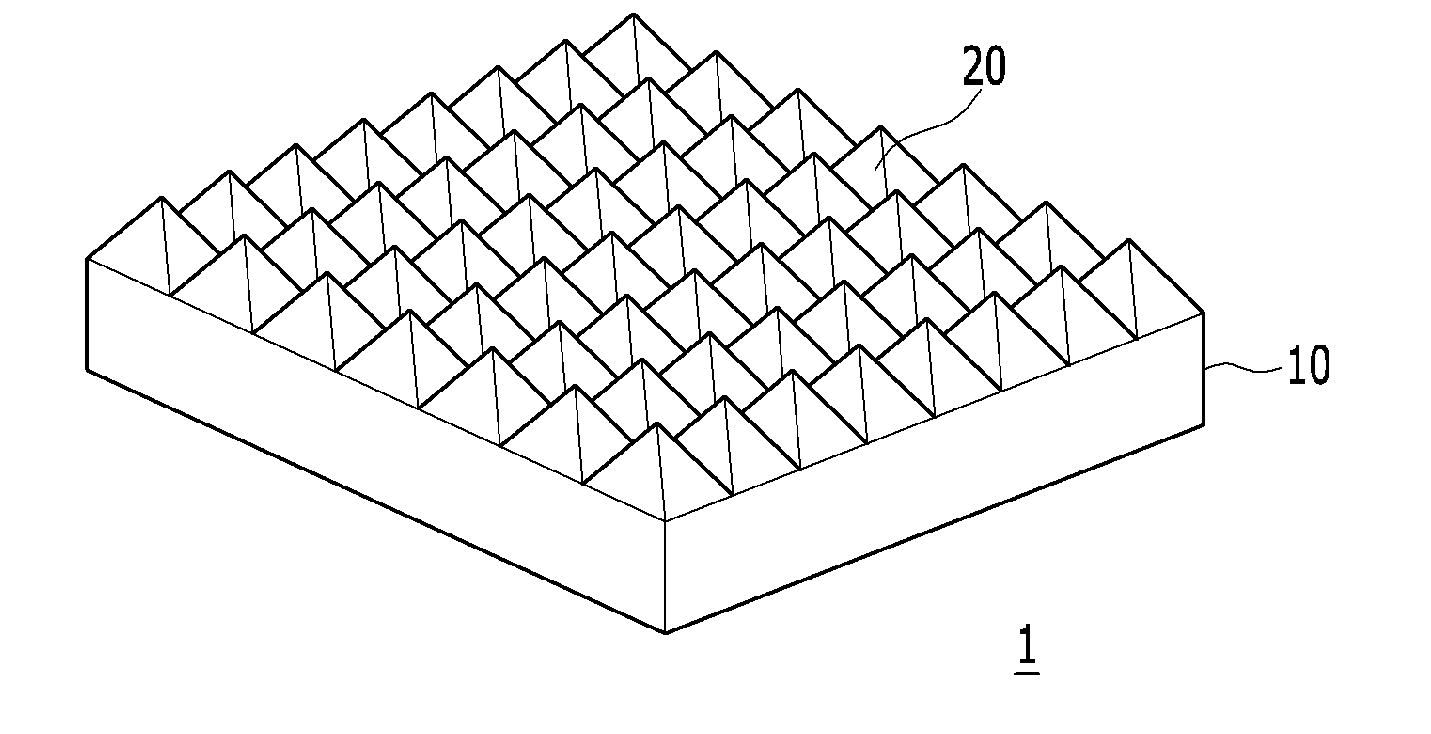

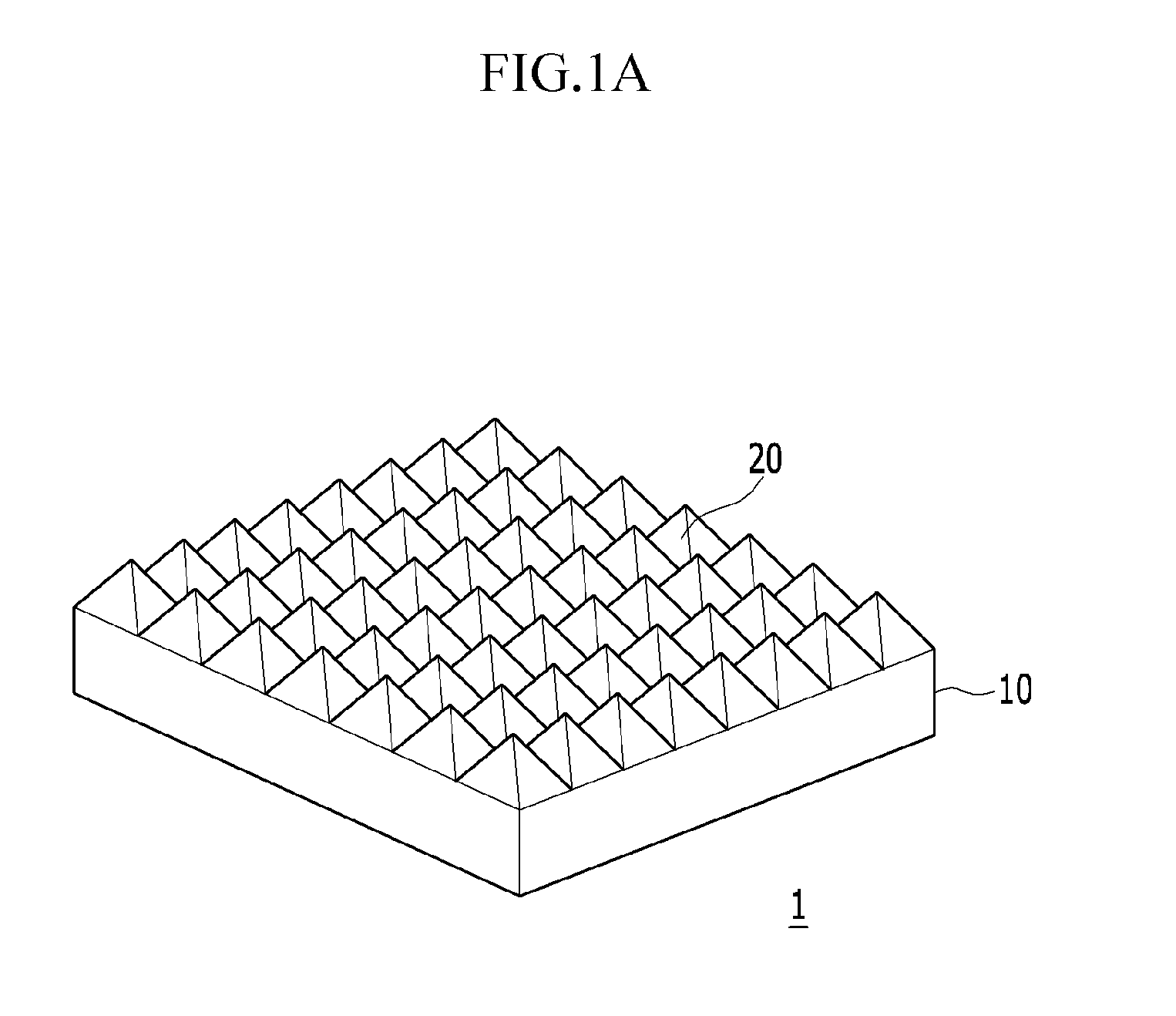

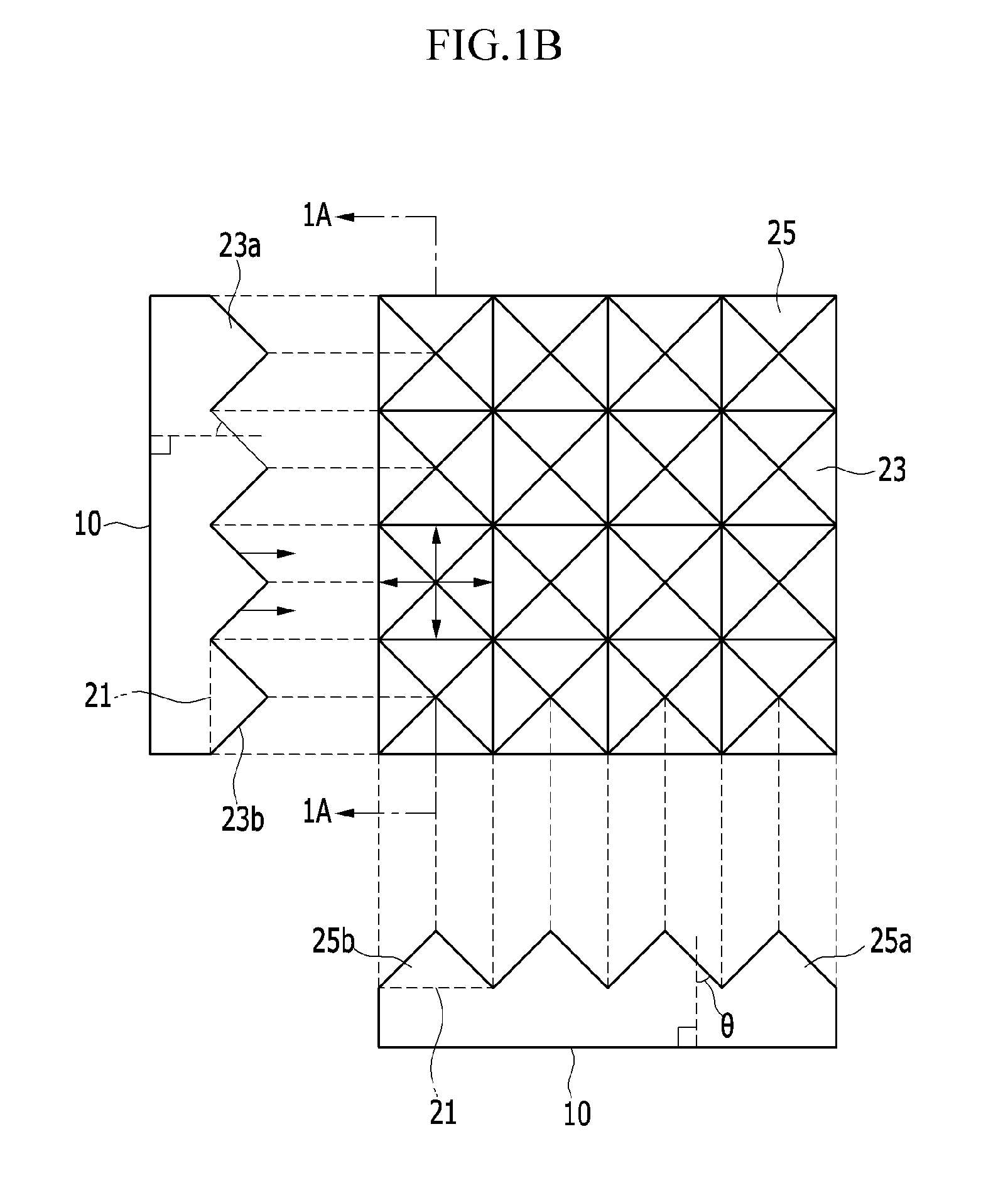

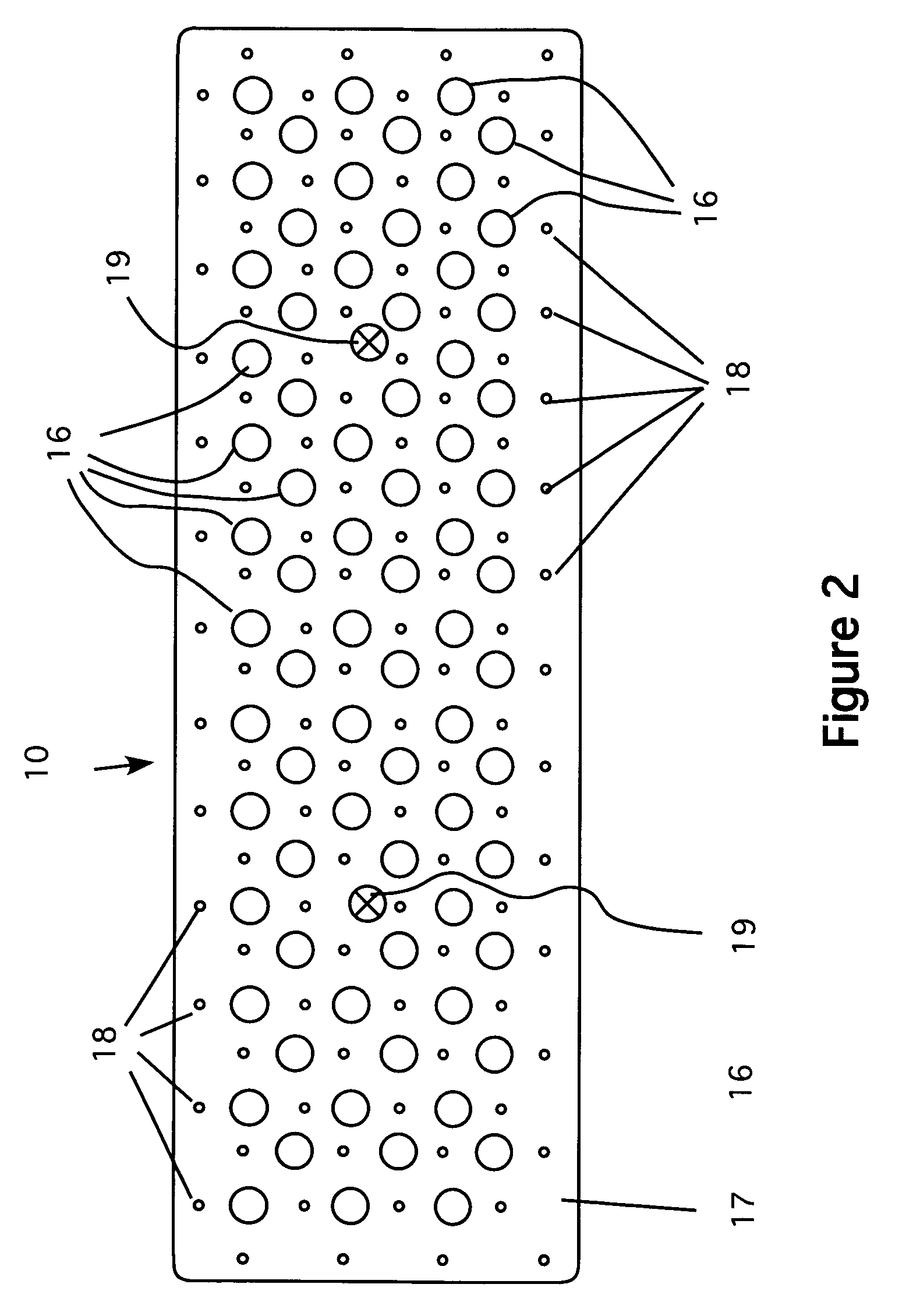

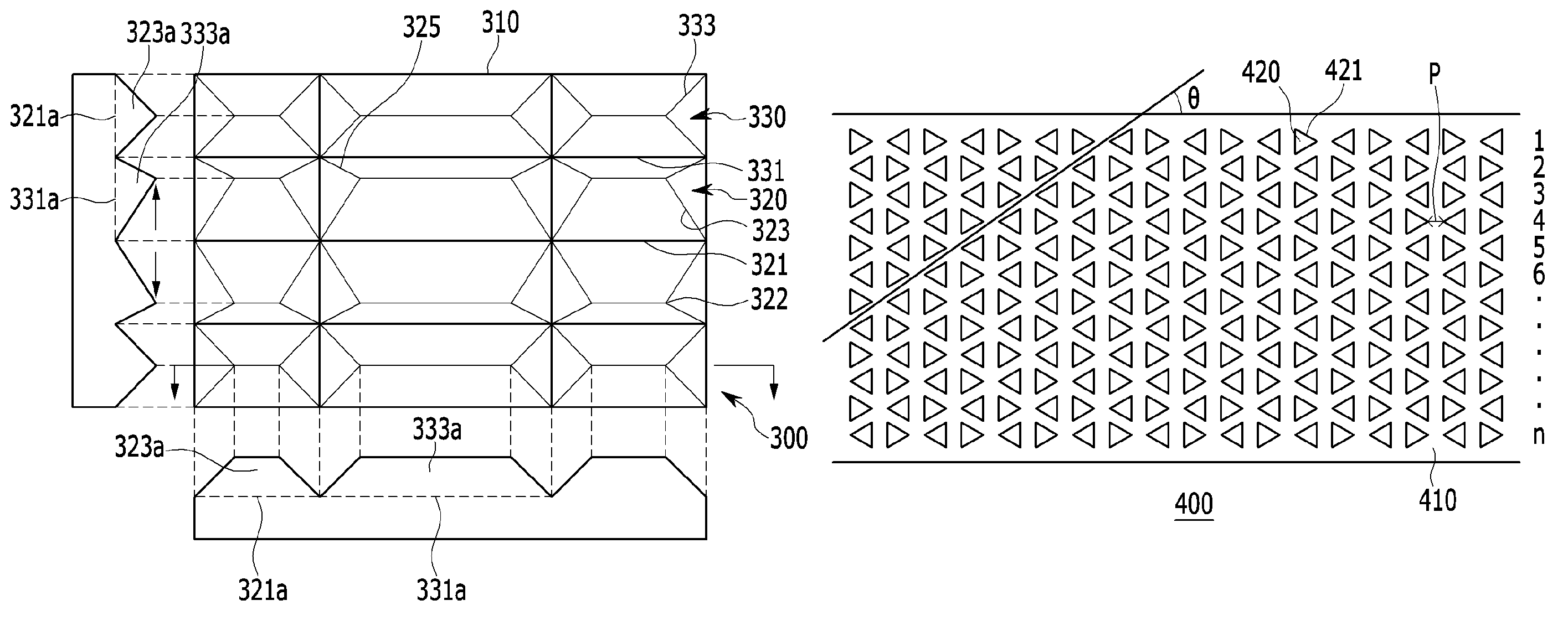

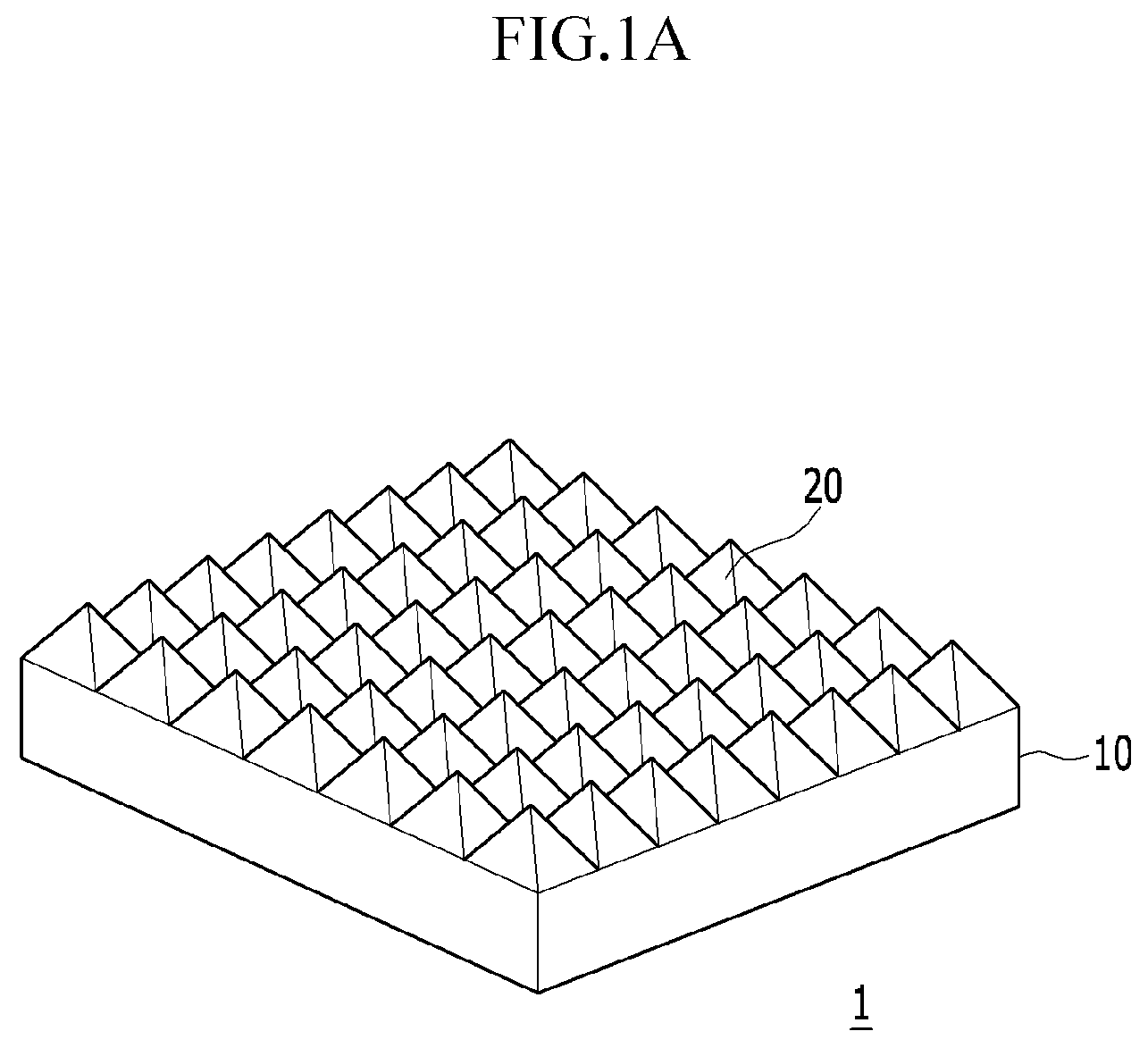

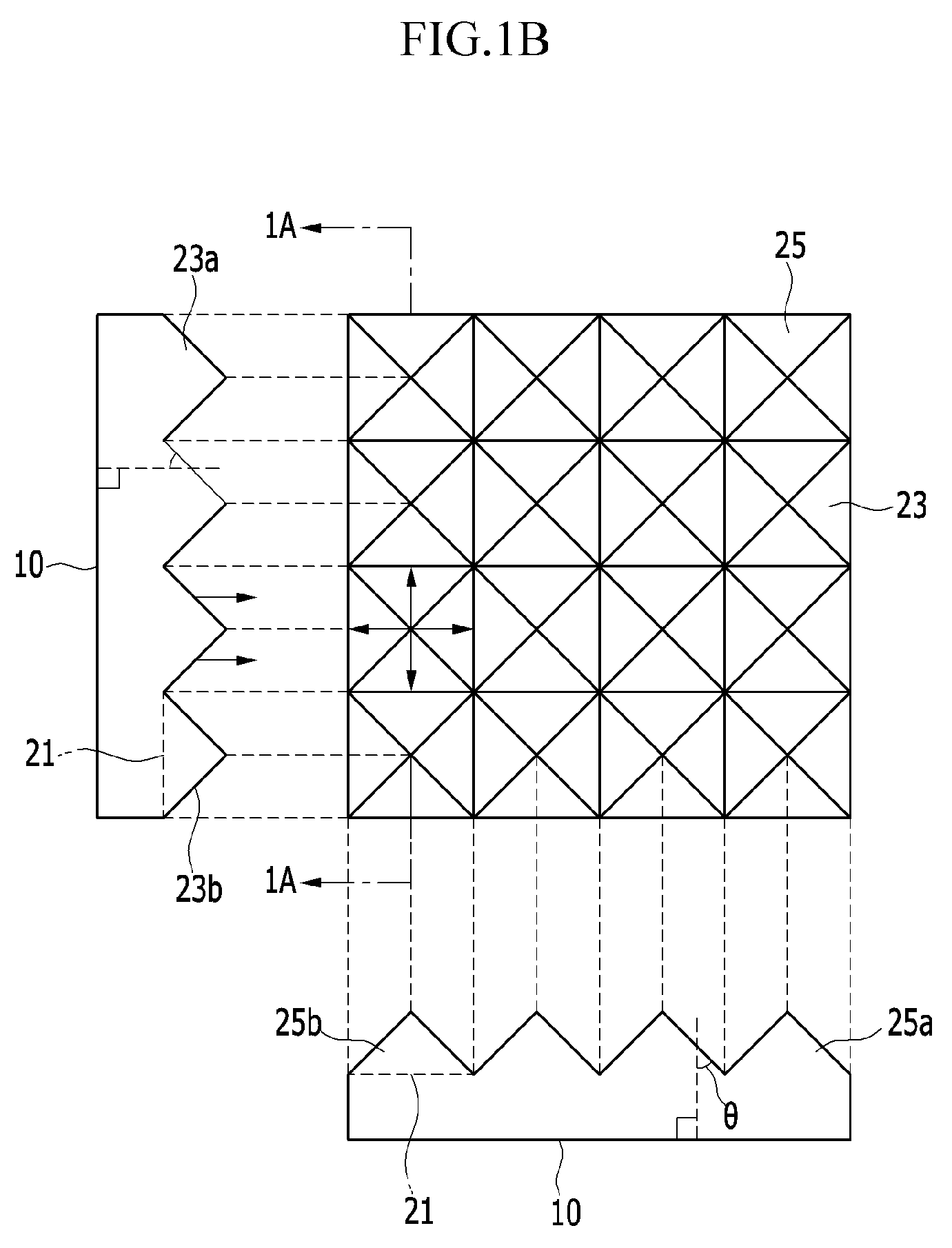

Abrasive article having multi-directional abrasion protrusion

ActiveUS20130280994A1Increased durabilityIncrease resistancePigmenting treatmentOther chemical processesParticulatesLoad resistance

An abrasive article having a multi-directional abrasion protrusion according to an exemplary embodiment of the present invention includes a flexible base substrate, and a plurality of abrasion protrusions integrally molded with the base substrate and having at least three sides forming a triangle, in which a plurality of abrasion protrusions has a directional property by grouping.According to this constitution, loading resistance and durability are excellent, there are no attachment materials attached to an abraded surface in the case where a flat surface is abraded, abrasion can be efficiently and evenly performed in a predetermined shape even though abrasion particles are not enlarged to perform abrasion or abrasion is not repeated several times by using particulates, and abrasion performance can be improved.

Owner:DEERFOS

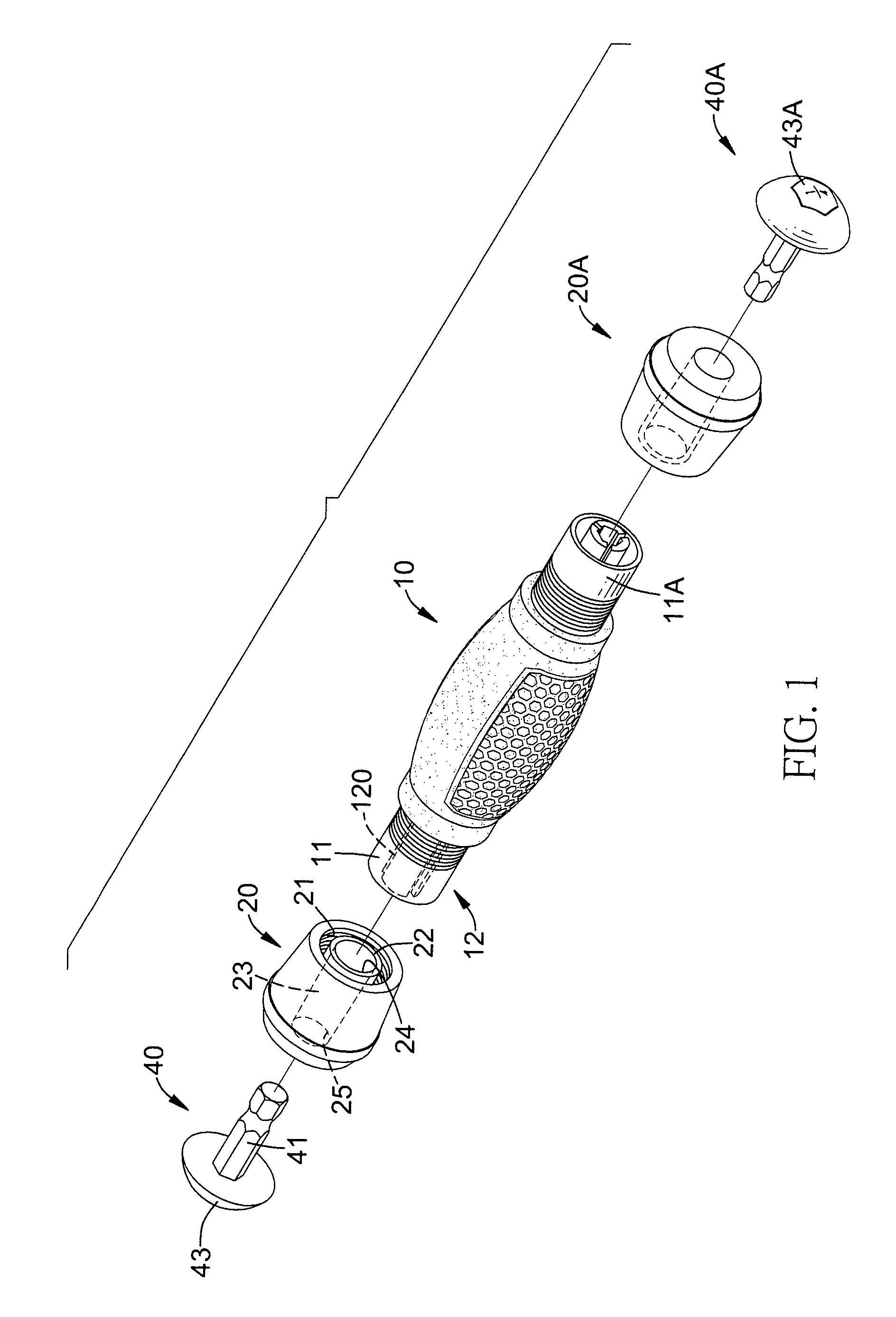

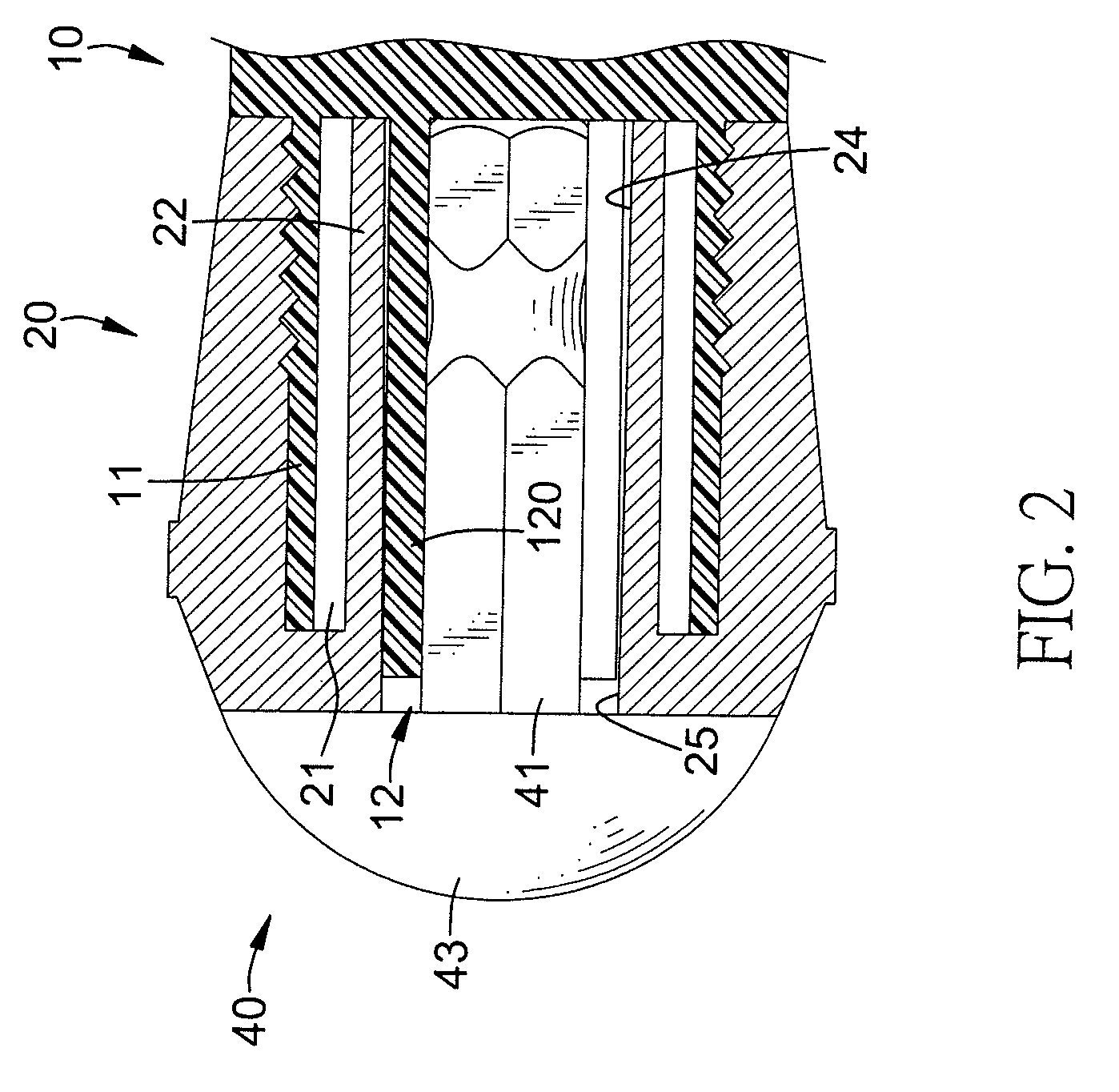

Apparatus for cleaning male electrical pins

ActiveUS8214961B2Easy and convenient to clean dirtEasy and convenient to clean dirt and corrosionHousehold cleanersCleaning machinesEngineeringMechanical engineering

Owner:VINCI IAN R +2

Foam rasp

InactiveUS7748933B1Eliminate the effects ofEasy to disassembleBuilding constructionsFiling/rasping toolsRaspEngineering

A rasp that has a mounting plate with a number of debris vent ports formed in it. The debris vent ports are formed to allow dust and debris to escape, thereby eliminating a hydroplaning effect on the abrasive surfaces while using the rasp, as well as making the tool lighter. A number of sharp pointed screws are screwed into the plate so that the points extend below the base of the plate. The screw tips become the abrasive rasping surface. The screws can be turned in or out to raise or lower the tips, to change the amount of rasping action from fine to aggressive. The screws can also be easily removed when they become worn so that the abrasive surface is always uniform and fresh. Finally, unlike the other tools, the screws can be removed to clean the base of the plate thoroughly to remove dried or caked mud.

Owner:EDWARDS KERRI

Transition Metal Nitride Coated File

InactiveUS20070147963A1Metallic material coating processesFiling/rasping toolsGallingCeramic coating

A hand operated file is provided with a thin ceramic coating of a transition metal nitride, such as vanadium nitride and / or zirconium nitride, on its teeth. The coating may be 20 um or less, thereby not altering the macro dimensions of the file. The coating may be applied using a vapor deposition process such as physical vapor deposition, and advantageously via a physical vapor deposition process where the file body does not exceed a temperature of about 300° F. The coating helps prevent galling, thereby increasing the useful life of the file.

Owner:COOPER BRANDS

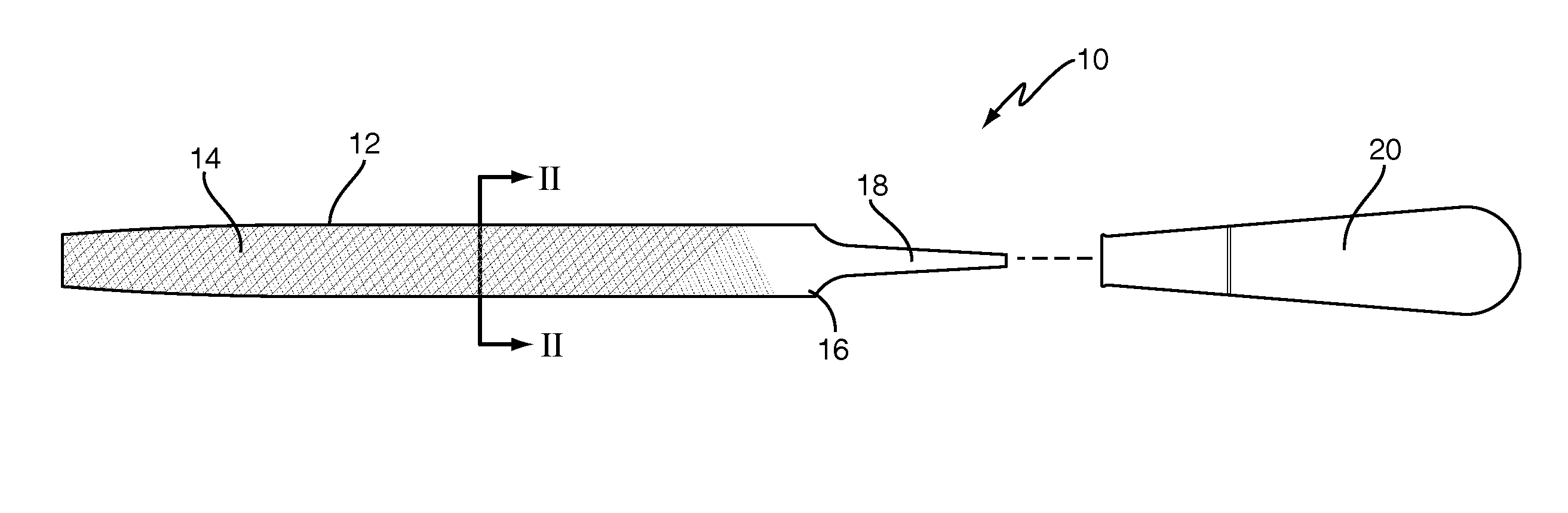

File handle

InactiveUS8006350B2Improve convenienceImprove versatilityTravelling carriersHoldersMechanical engineeringEngineering

A file handle has a handle and a connector. The handle has a sleeve formed on one end and having a clamp and a shaft hole. The clamp has multiple resilient claws. The shaft hole is formed in the clamp. The connector is detachably mounted on the sleeve of the handle and adjustably presses the clamp to selectively adjust the clamp. A blade may be a file, rasp or chisel and has a shaft corresponding to and being mounted in the shaft hole of the clamp and being securely clamped by the clamp. Therefore, the file handle can be carried easily and may be used with a file, rasp, chisel or the like for improved convenience and portability.

Owner:CHEN KUN CHEN +1

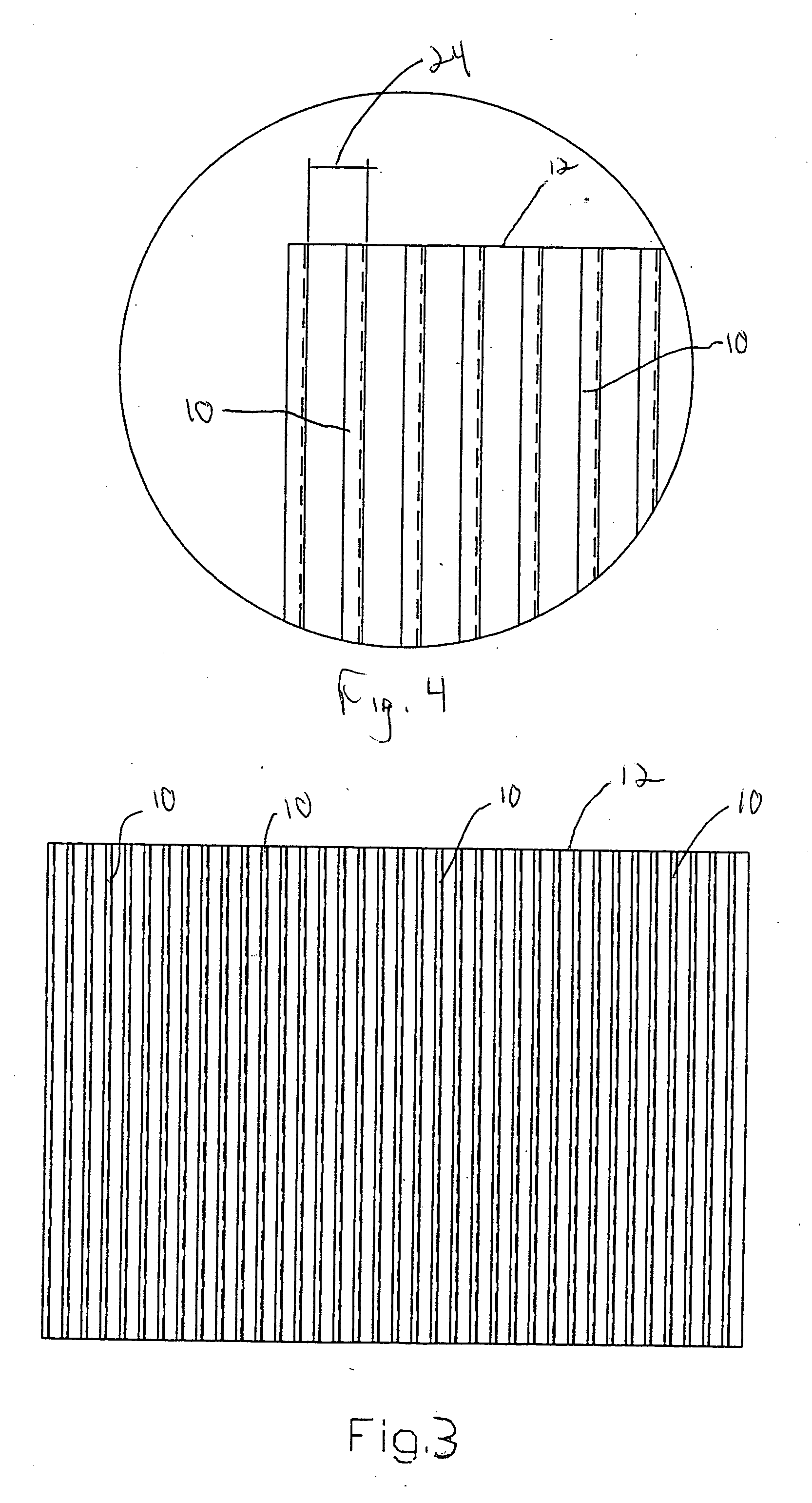

Continuous shearing edges made of brazed carbide grits for use on a tool

InactiveUS20070243029A1Improved edge cutting structureEfficient processGrinding devicesFiling/rasping toolsCarbideEngineering

A preformed continuous or interrupted shearing machining edges that are composed of hard substance grits and are brazed together and to steel grinding wheels or other tool members. The parallel edges may be interrupted by voids between teeth of the edges. The edges have selectable edge rakes and clearance angles, edge tooth widths, edge spacing and mounting angles to the tool members or grinding wheel work surfaces.

Owner:L R OLIVER

Drywall rasp

A rasp includes a body including upper, lower, front and rear portions. The lower portion has a groove that has first and second sections extending along a length thereof. The first section includes equidistantly spaced coextensive cutting blades extending downwardly therefrom. The blades have front and rear surfaces that have a rectangular shape engageable along a portion of drywall. The second section includes randomly spaced protrusions that have arcuate shapes and extend downwardly therefrom. The protrusions are engageable with drywall for removing imperfections therefrom. A divider bifurcates the first and second sections and extends downwardly from the body. The divider has a height equal to that of the sidewalls. Coextensive sidewalls are conjoined with the body and oppositely spaced from the divider. The sidewalls protrude downwardly from the bottom surface and terminate coplanar with the divider. The first and second sections are recessed from the divider and the sidewalls.

Owner:MORRIS JEFFREY R

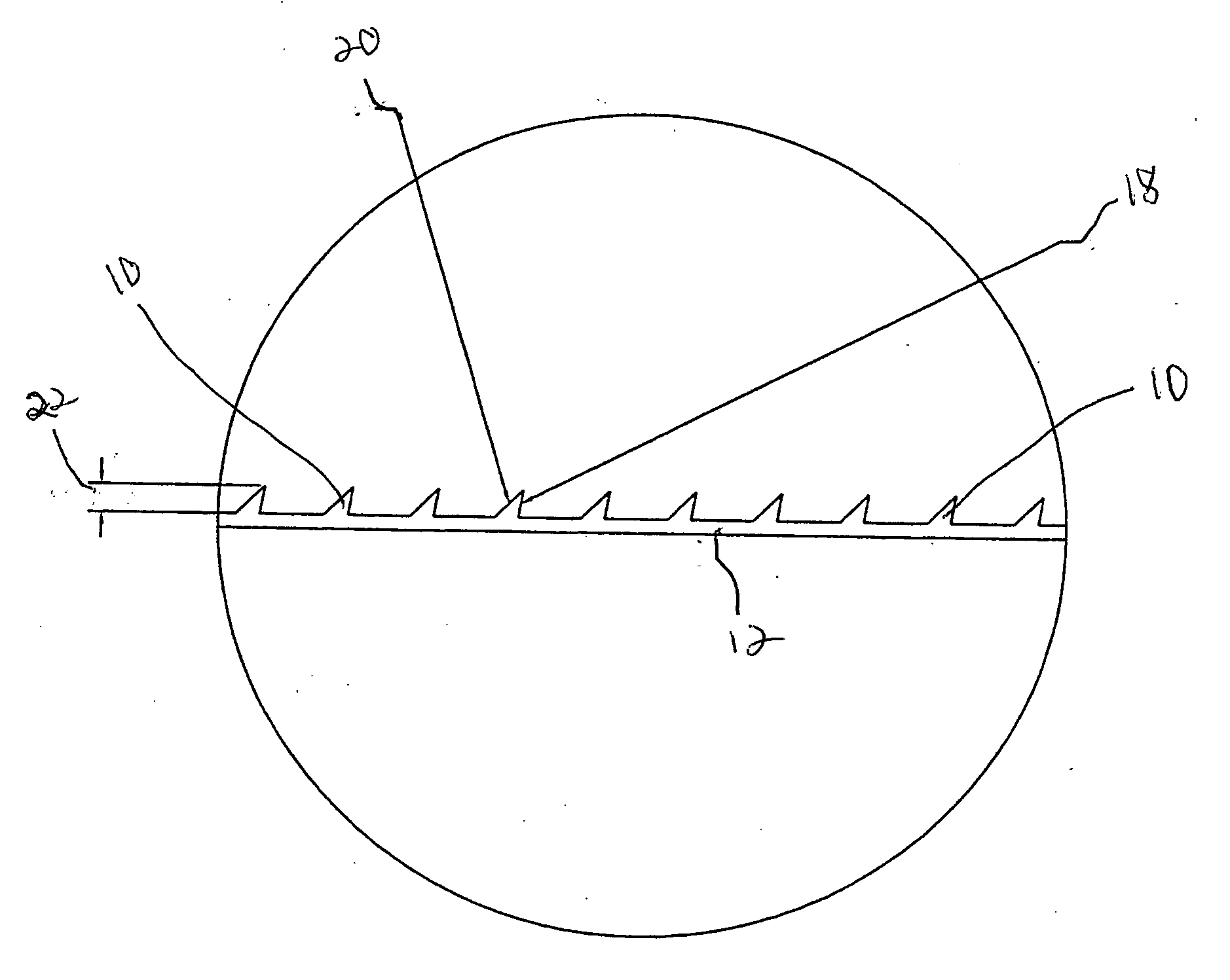

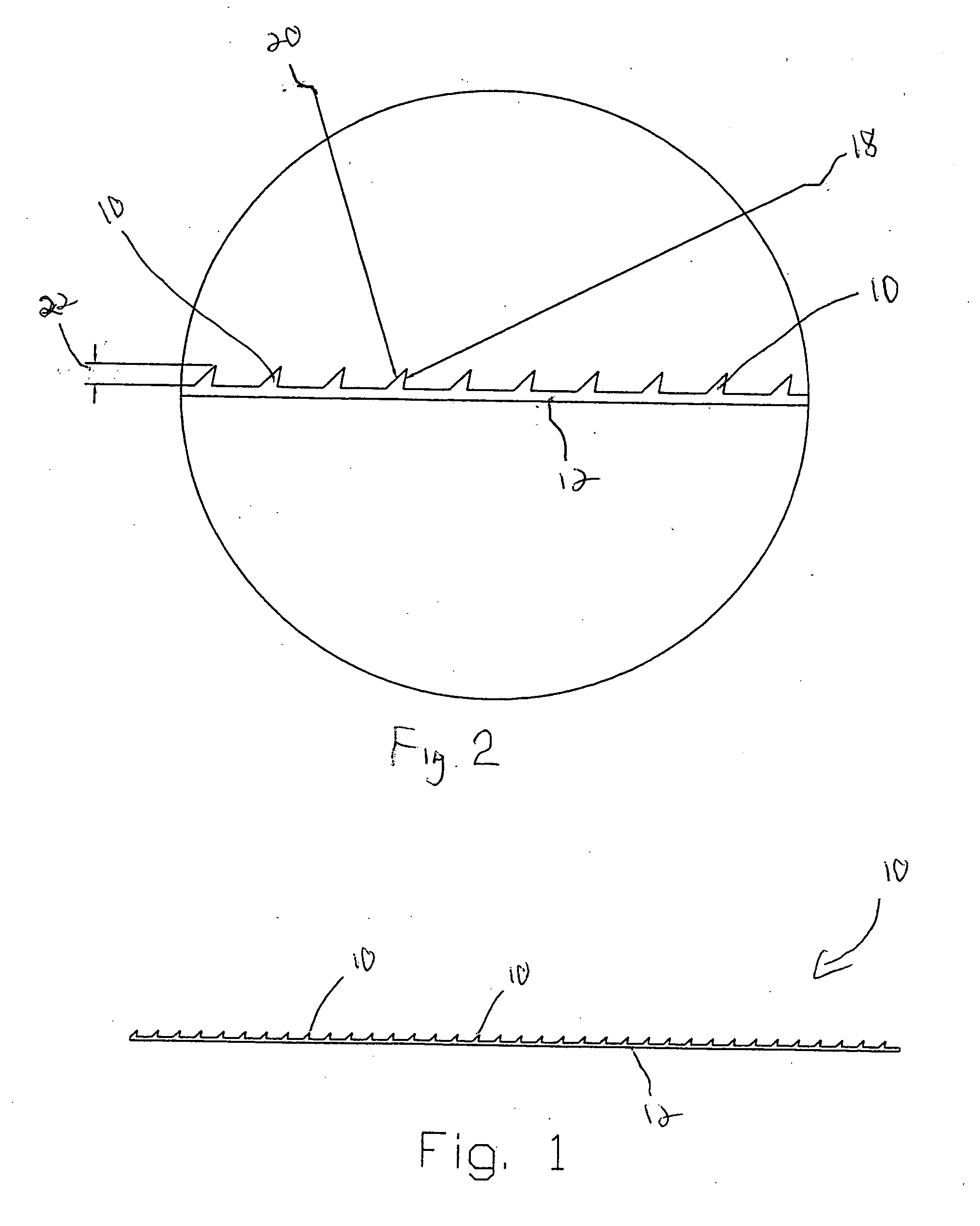

Device for smoothing the surfaces of hard or soft materials

InactiveUS20080171496A1Few clogging problemEasy to slideOven incrustations prevention/removalFiling/rasping toolsSanderEngineering

The present invention is a finishing plate and method of fabricating a finishing plate. The finishing plate can be fabricated to various shapes, and can be used with various surfacing machines. In a preferred mode, the present invention is a disc cutting plate which can be used with a random orbital sander, and can be used to replace traditional abrasive sheets such as sandpaper. The present invention can be used in smoothing various materials including wood, painted wood, plastic, and various metals.

Owner:GELFUSO RUSSELL

Tire rasp drawknife and mounting therefore

The mini drawknife body has one or more fixing openings which allow its assembly in the adjacency of the support periphery; from the notched rim, the body extends briefly right across until reaching such a width that the rim opposite to the notched rim cannot interfere with the openings and assembly bolts on the support. The invention also refers to an adaptation device for the assembly of the mini drawknife in a rotary support for tires roughing. This adaptation device comprises fixing sets integrated by bases and lateral retaining covers, among which intermediate separators can be placed; all these means have fixing members and openings which, in addition to forming jaws in the joint area, fasten to the roughing drawknives passing through some fastening openings of their body.

Owner:PEREZ RICARDO DANIEL

Abrasive article having multi-directional abrasion protrusion

ActiveUS9044842B2Increased durabilityIncrease resistancePigmenting treatmentOther chemical processesParticulatesLoad resistance

According to this constitution, loading resistance and durability are excellent, there are no attachment materials attached to an abraded surface in the case where a flat surface is abraded, abrasion can be efficiently and evenly performed in a predetermined shape even though abrasion particles are not enlarged to perform abrasion or abrasion is not repeated several times by using particulates, and abrasion performance can be improved.

Owner:DEERFOS

Face cutter for machining fibre-reinforced materials such as carbon-fibre-reinforced plastics (cfrp)

ActiveCN104837585APrevent pull outAvoid spreadingTransportation and packagingMilling cuttersPolyesterFiber

The invention concerns a machining tool for machining fibre-reinforced materials such as CFRP, glass-fibre-reinforced plastics or plastics reinforced with polyester threads. The machining tool comprises a plurality of flutes (1, 2, 3, 4) which distance lands (5, 6, 7, 8), disposed about a cylinder core segment (9), from each other in the peripheral sense. At least one of the lands (6, 8) is designed as a premachining land (6, 8) and at least one other of the lands (5, 7) is designed as a postmachining land (5, 7), each comprising a peripheral working region extending along, or with a twist and in the form of a helical segment about, the tool axis. The working region of each premachining land (6, 8) is designed as a peripheral file with a plurality of teeth (10) which are incorporated in a cylinder surface segment-shaped outer surface of the working region, and provided in the working region of each postmachining land (5, 7) is a number of sharp cutting edges (11, 12, 13, 15) extending parallel to or with a twist and in the form of a helical segment about the tool axis. The invention is characterized in that the number of sharp cutting edges (11, 12, 13, 15) on at least one postmachining land (5, 7) comprises a plurality of cutting edges (11, 12) each provided on a peripheral casing groove, the casing grooves being incorporated in a cylinder surface segment-shaped outer face of the working region, parallel to each other and at a pitch relative to the flute (1, 3) leading at least one postmachining land (5, 7).

Owner:HUFSCHMIED ZERSPANUNGSSYST

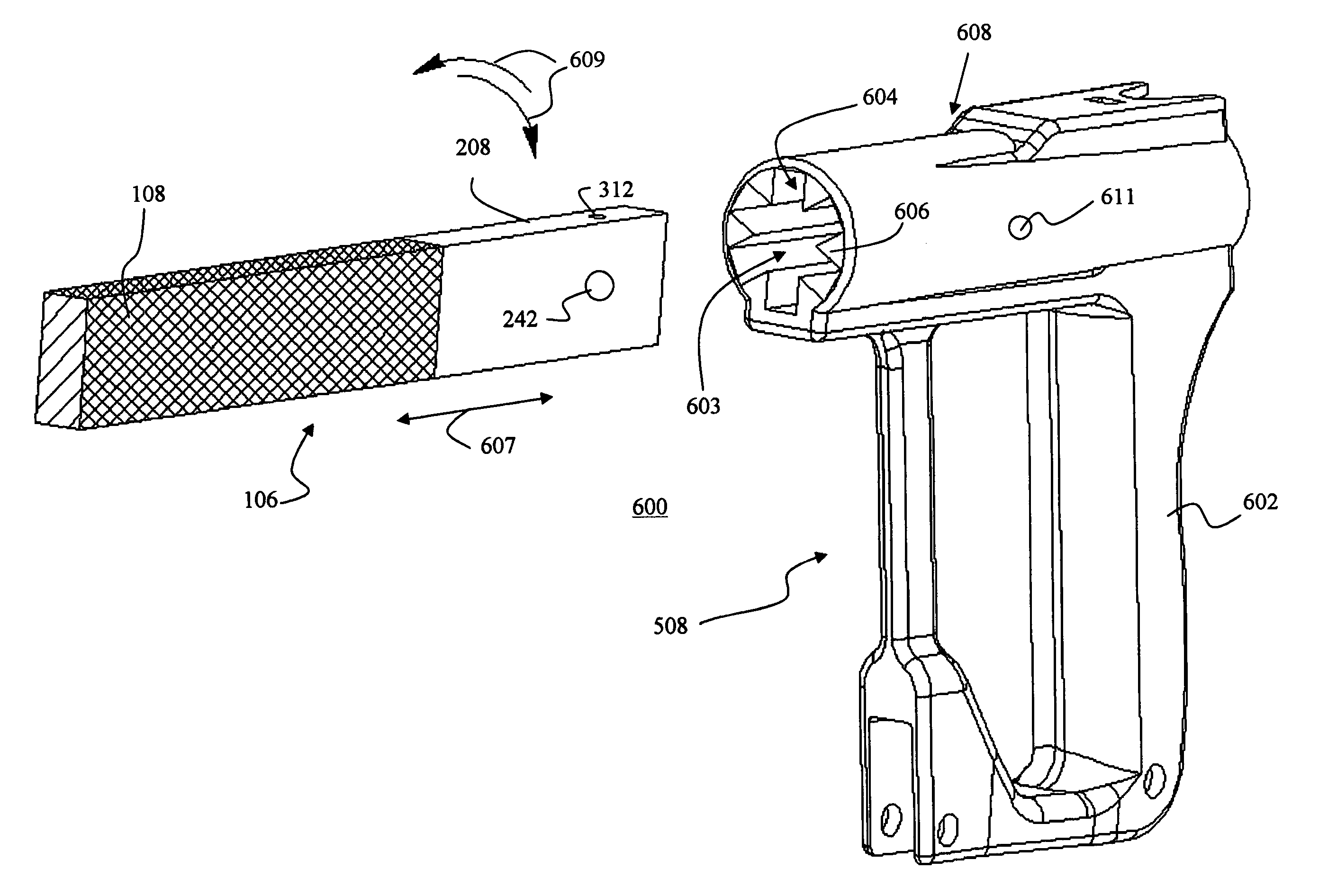

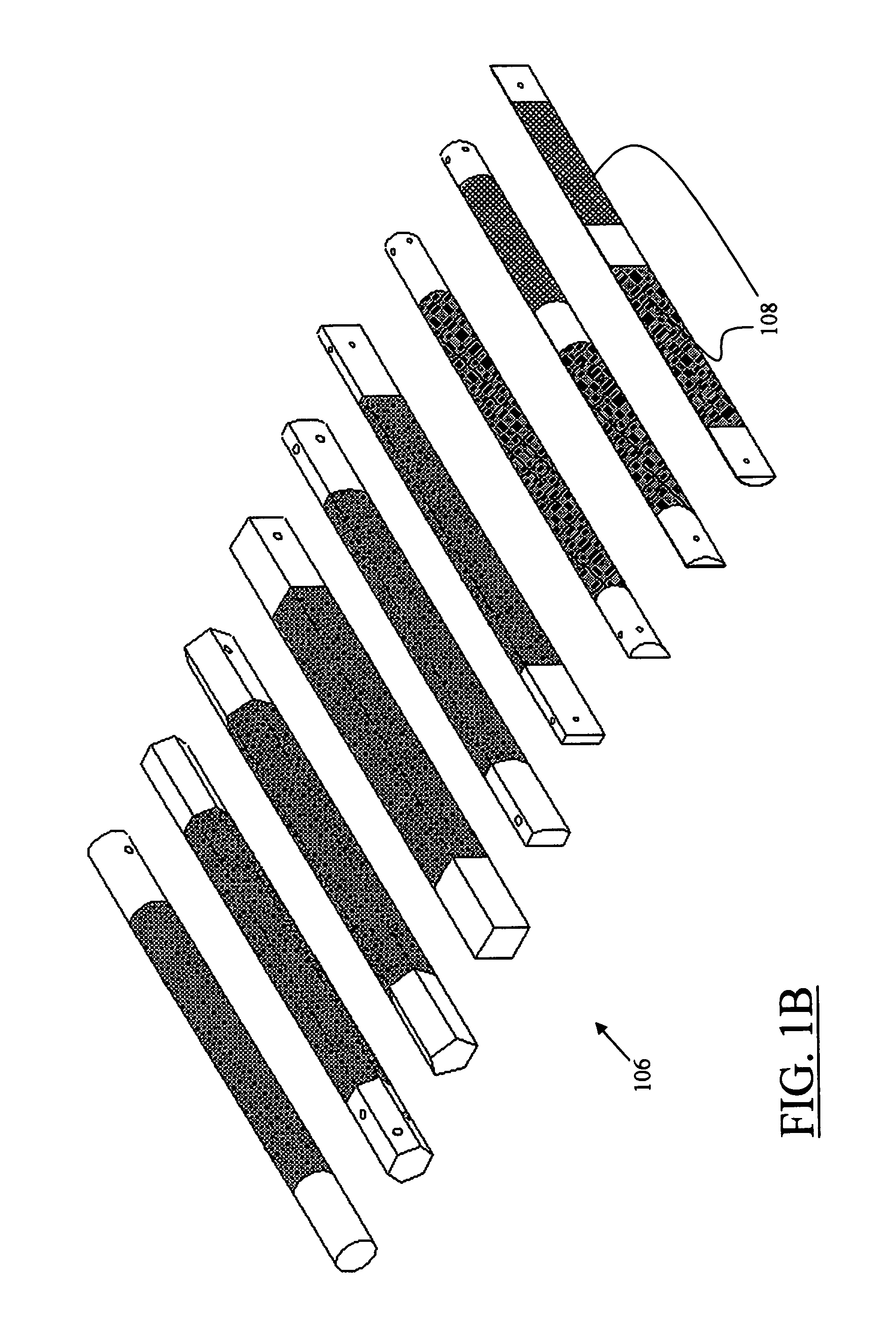

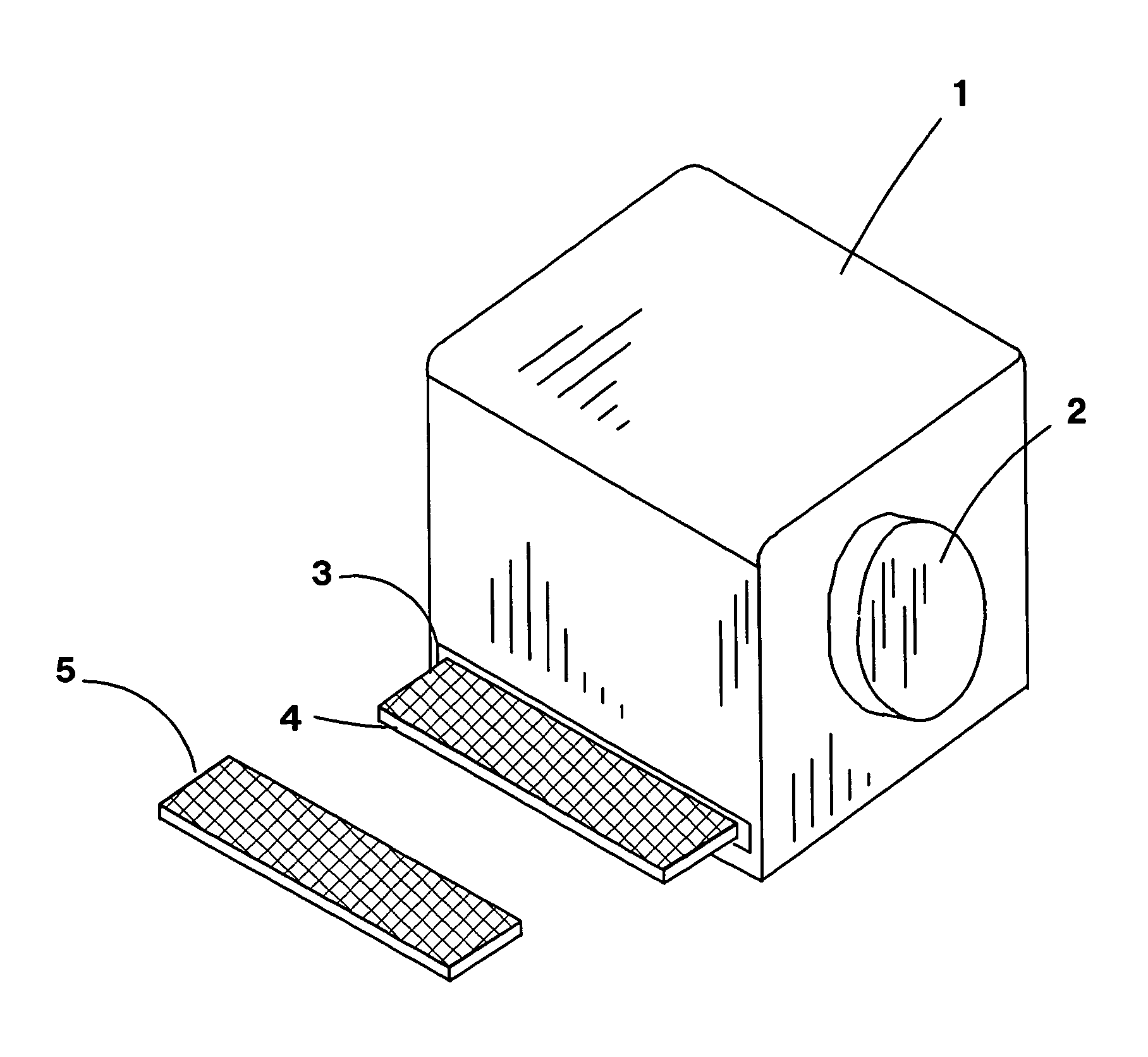

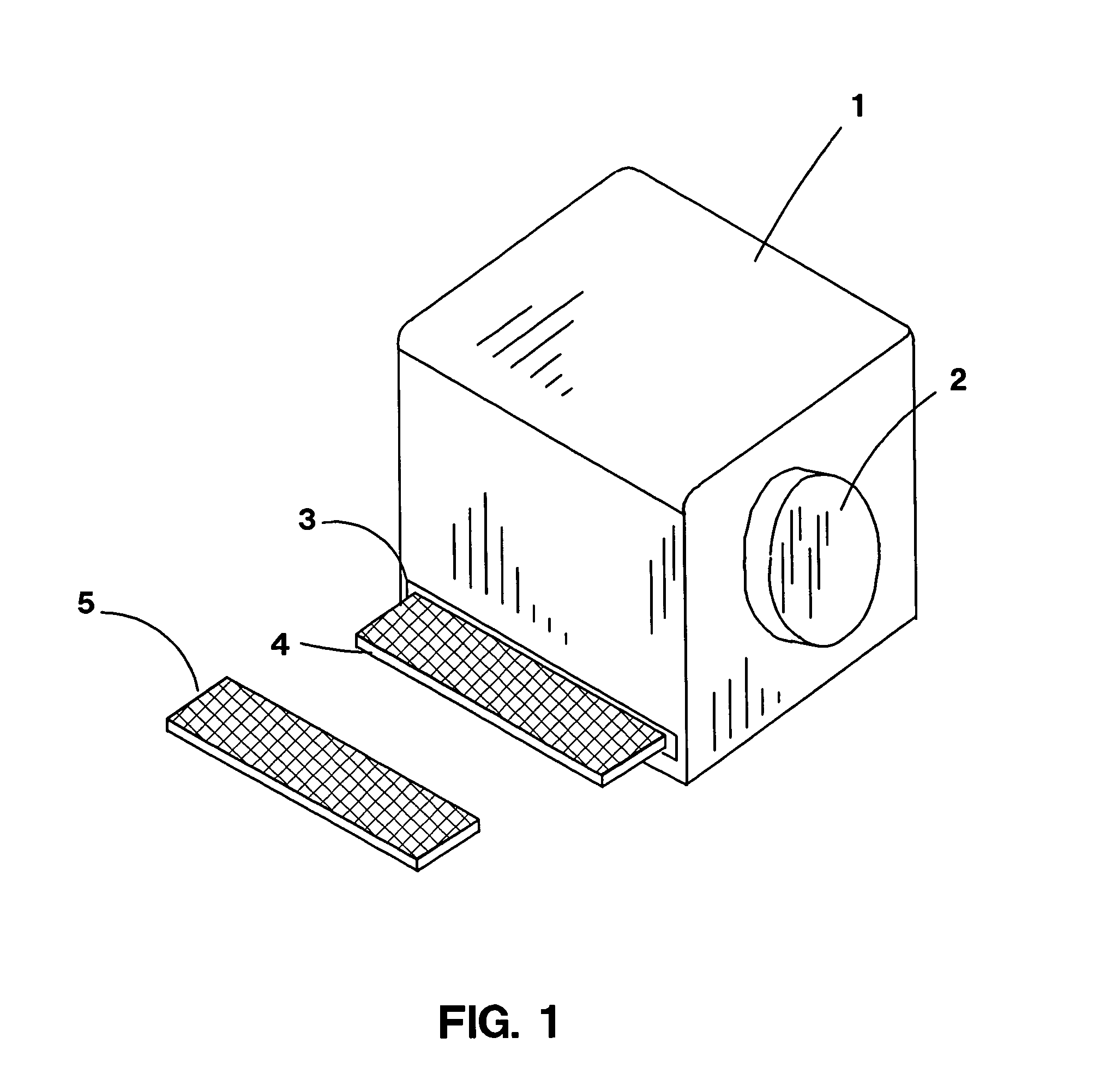

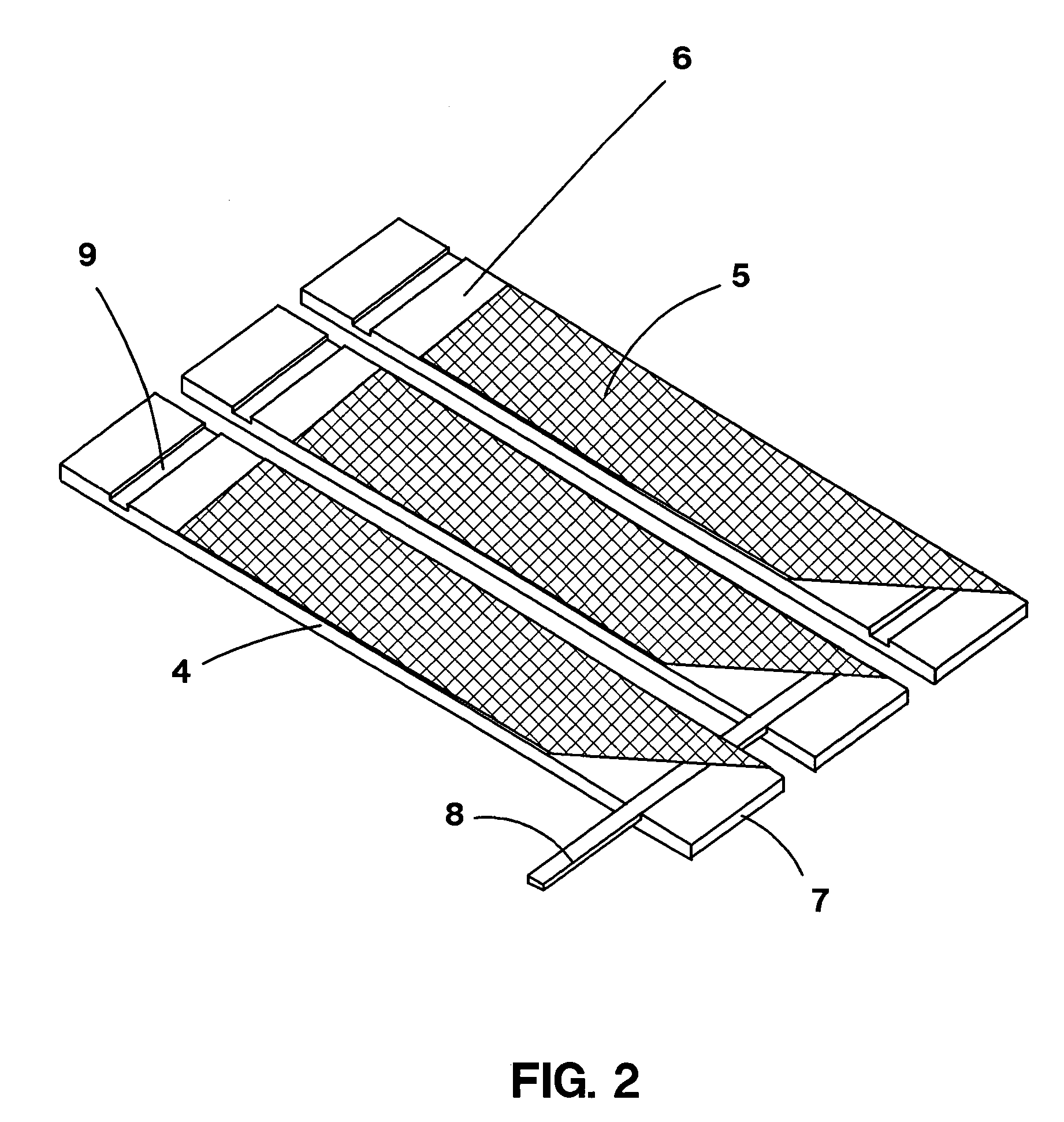

Flexible file and file dispenser system

InactiveUS7077737B2Easy to useEasy rolling outAbrasion apparatusFlat article dispensingFile allocationFile system

A flexible file system for providing abrasive files that can be used for wood or metal working that can be supplied in different sizes, stiffness and with different types of abrasive surfaces in different cross-sections. These flexible files can be attached to form a web that can be loaded into a dispenser either on a spindle or folded for easy dispensing of files as they are needed. The dispenser can have optional blades for separating the files as they are dispensed. Various methods can be used to attach the files into a web for easy dispensing and later separation including attach strips with cut or break points.

Owner:MANIGEL GUENTER

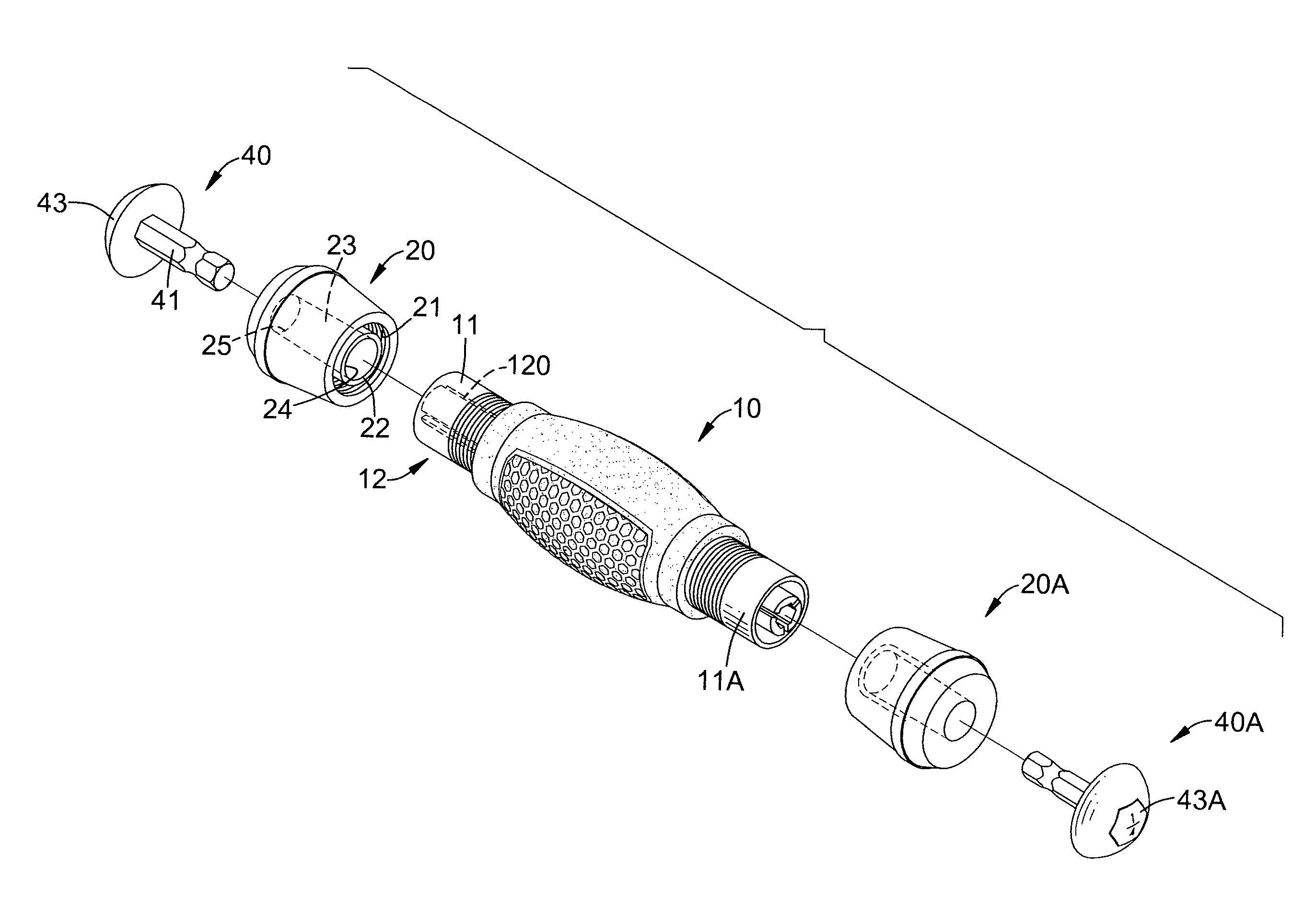

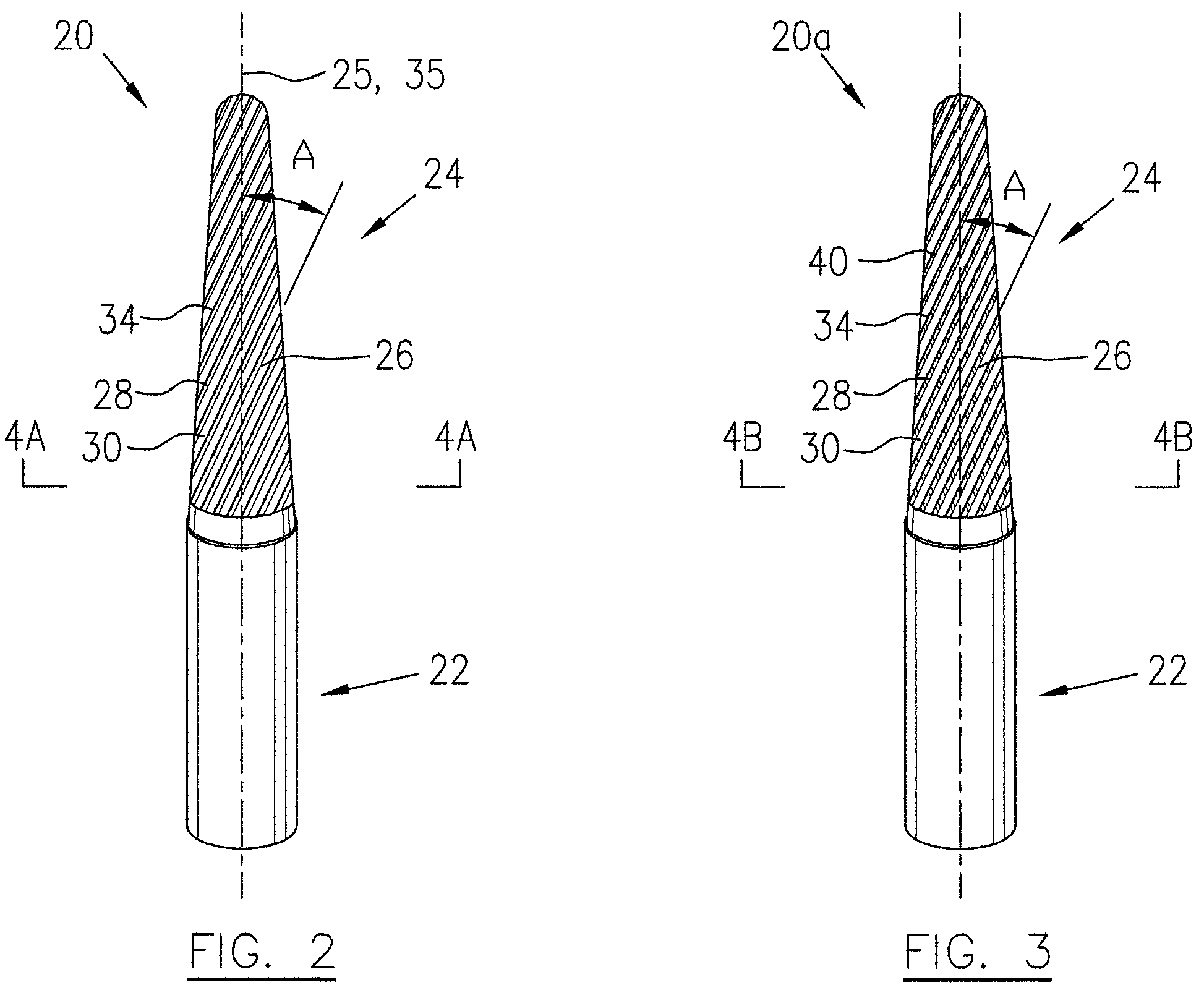

Ice screw sharpener

ActiveUS20140099169A1Easy to handleMaintain performanceFiling/rasping devicesMountaineeringEngineeringKnife blades

A sharpener for an ice screw with a tubular shank and a bit, comprising:a fixed sharpening support equipped with a file in the form of an elongate blade,a positioning slide of the ice screw at predefined angles with respect to the file, said slide being able to move in translation astride the two opposite surfaces of the file,and guiding and stopping means of the bit in the slide comprising at least one opening for inserting the shank and a securing stud salient from the associated opening.

Owner:ZEDEL CORP

Multi-flute ball endmill for airfoil machining

A milling cutter comprises a shank section joined to a cutting section. The cutting section includes a plurality of peripheral teeth separated by a plurality of flutes to form cutting edges extending around the cutting section in a helix direction. The number of respective teeth and flutes is more than 12.

Owner:PRATT & WHITNEY CANADA CORP

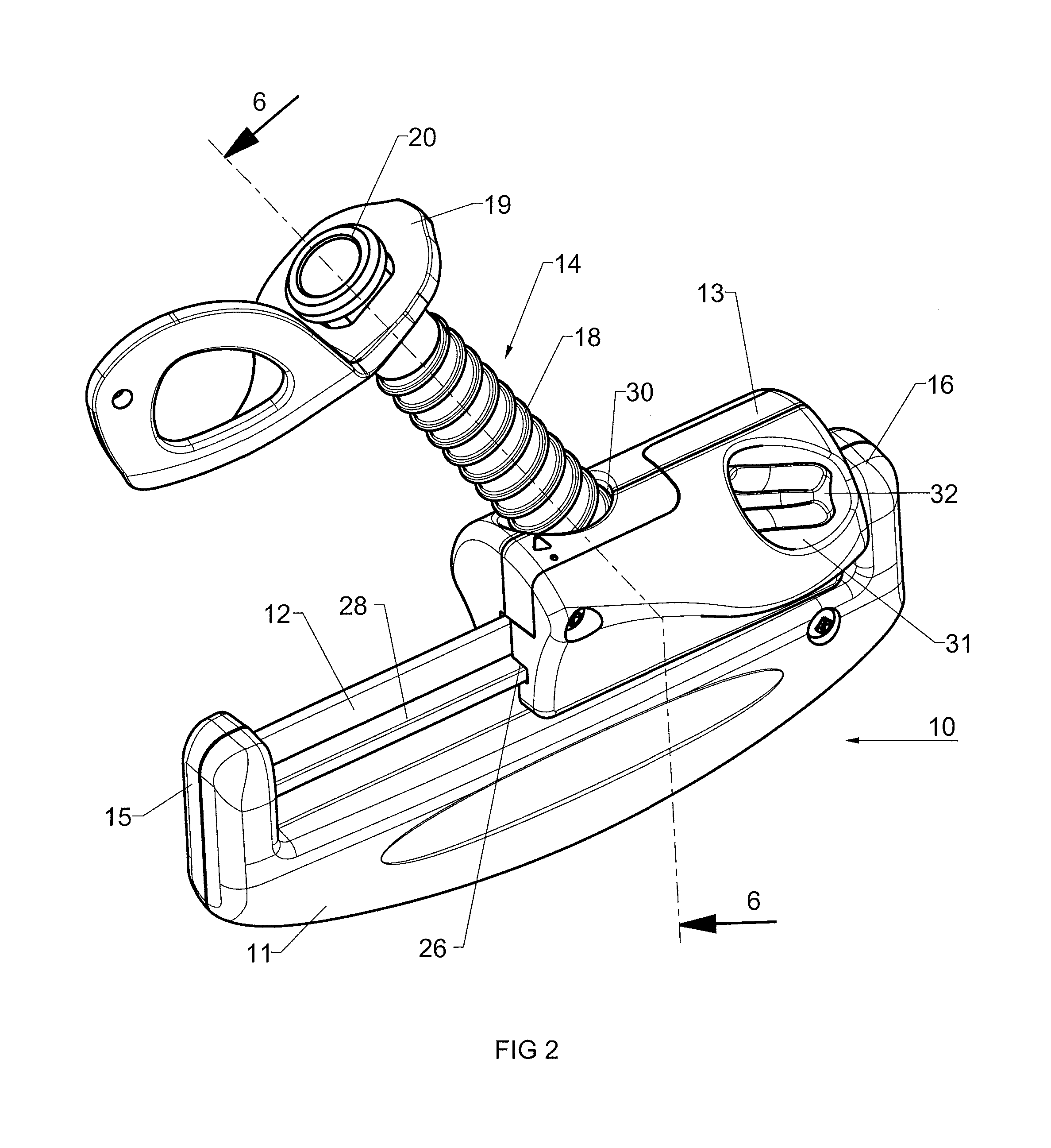

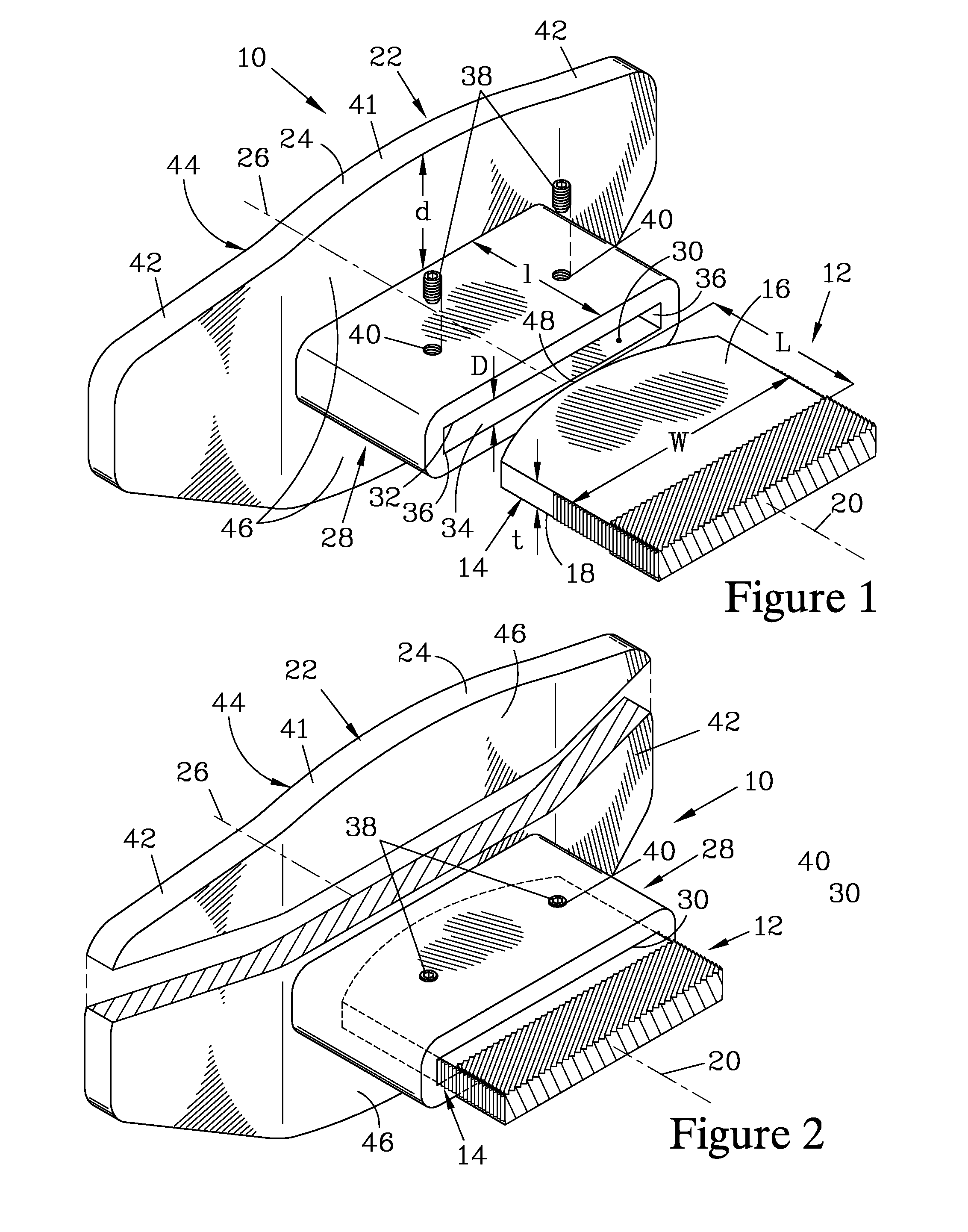

Auxiliary Hand Grip for Rasp

InactiveUS20120230783A1Easy to controlIncrease engagementAnimal shoeingFiling/rasping toolsSet screwRasp

The auxiliary hand grip attaches to a conventional rasp to provide the user with an additional grip, allowing the user to better control the rasp when used to reconfigure a hoof. The auxiliary hand grip has a plate affixed to a socket element, the socket element extending along an axis and the plate extending substantially normal to the axis. The socket has inner surfaces spaced to accept a distal end extension of the rasp, and is aligned with the rasp so as to align the axis of the auxiliary hand grip with a longitudinal axis of the rasp. Clamping elements such as set screws extending through the socket serve to affix the auxiliary hand grip onto the distal end extension of the rasp.

Owner:JOHNS JEREMY C

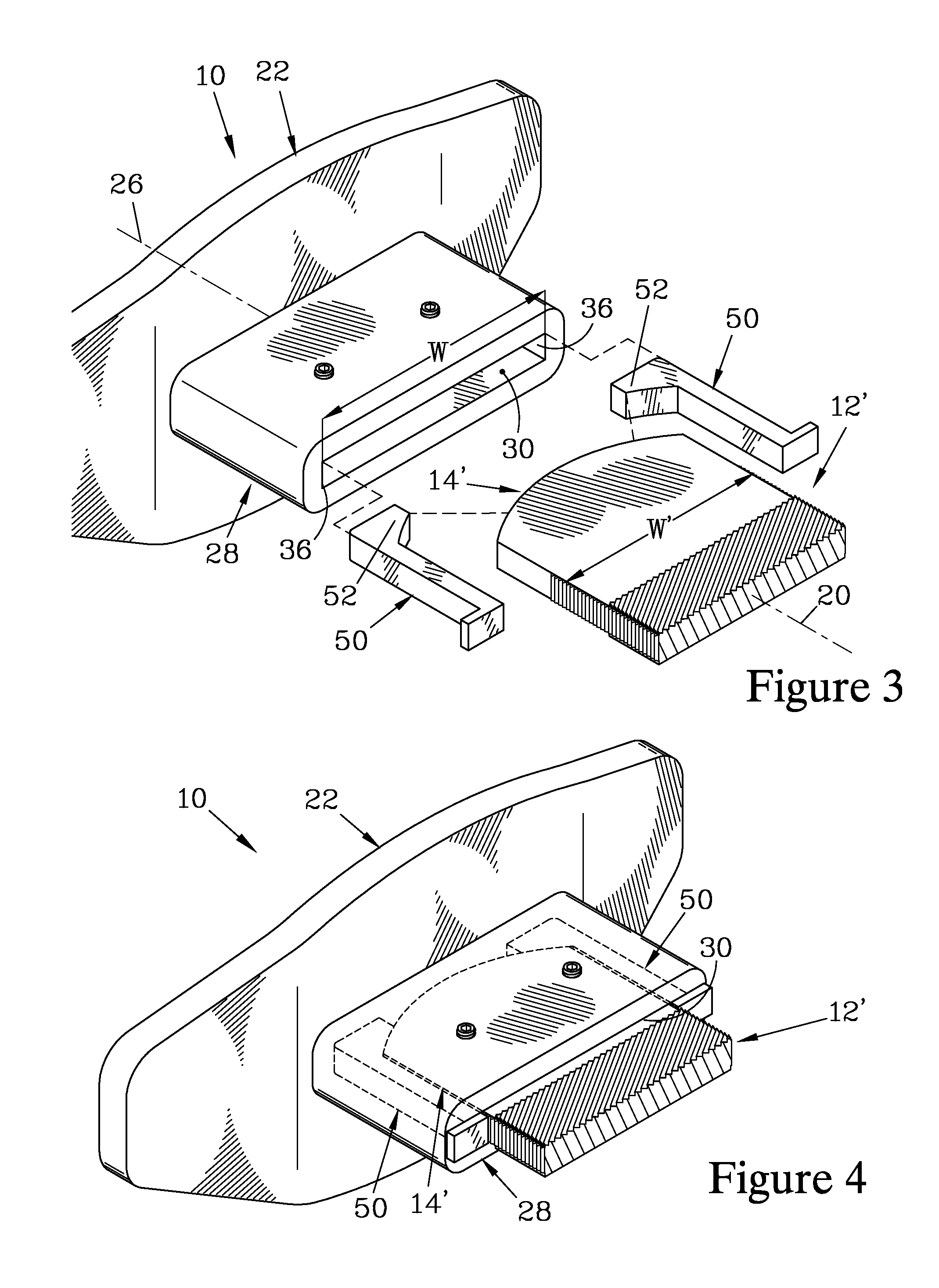

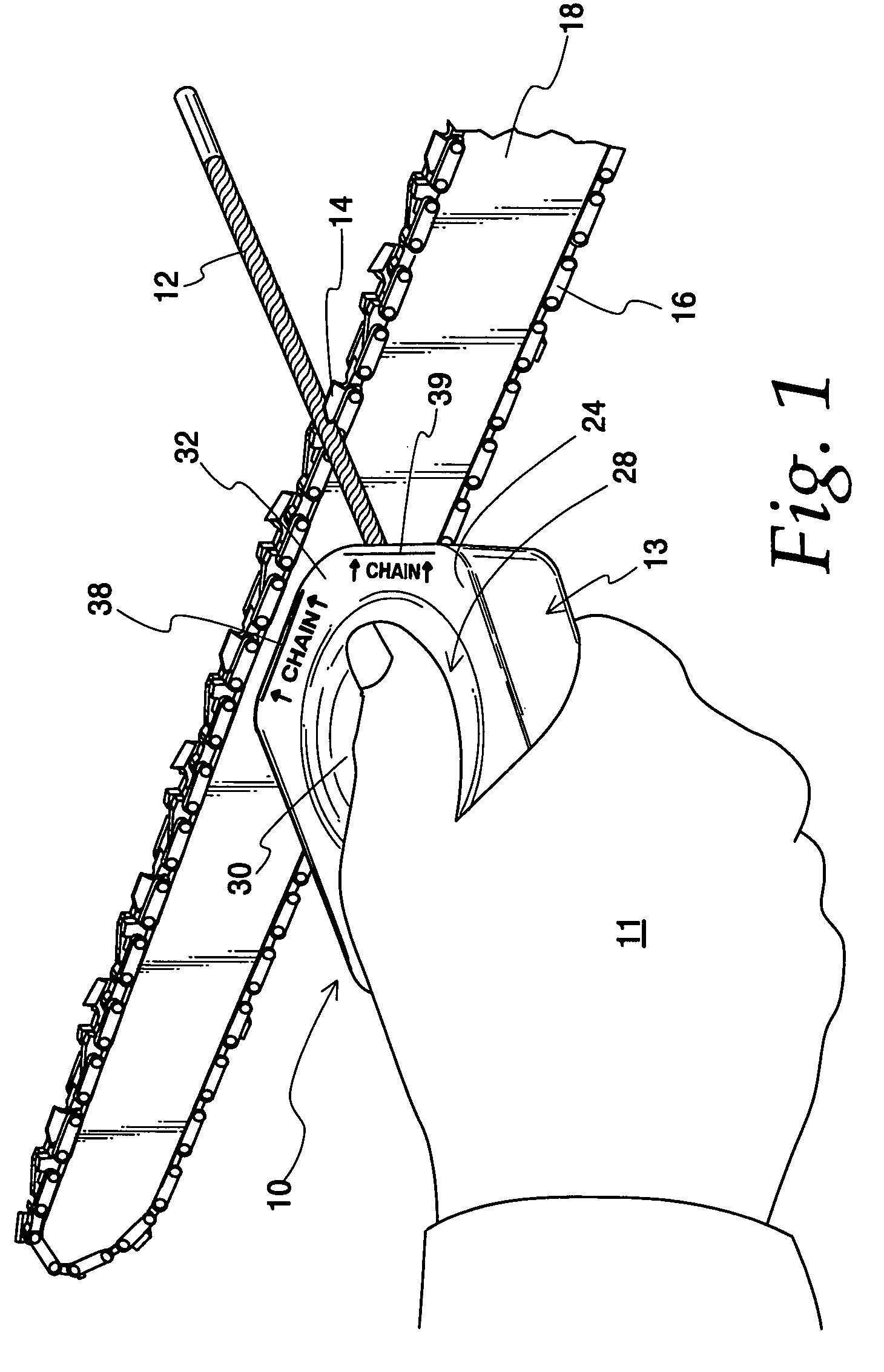

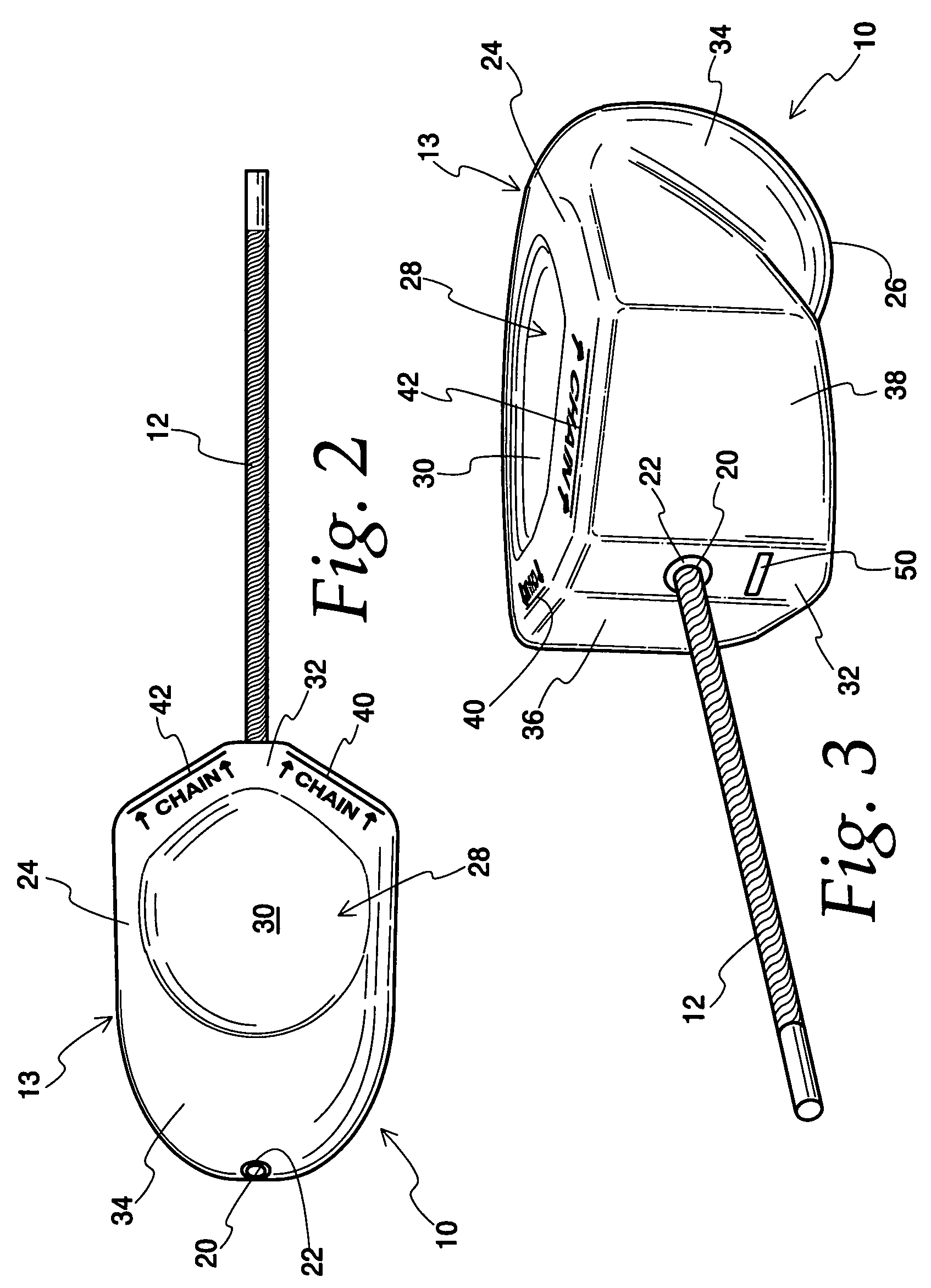

Ergonomic handle for a hand-held tool

An ergonomic handle for a hand-held tool, e.g., a chain saw sharpening file, is sized and shaped for cooperative engagement with the hand of a user and comprises an oblong, contoured body having a distal portion and a bulbous proximal portion integral therewith. A tool is received into a central opening that extends along the longitudinal axis of the oblong body.

Owner:HOOSER STEVEN M

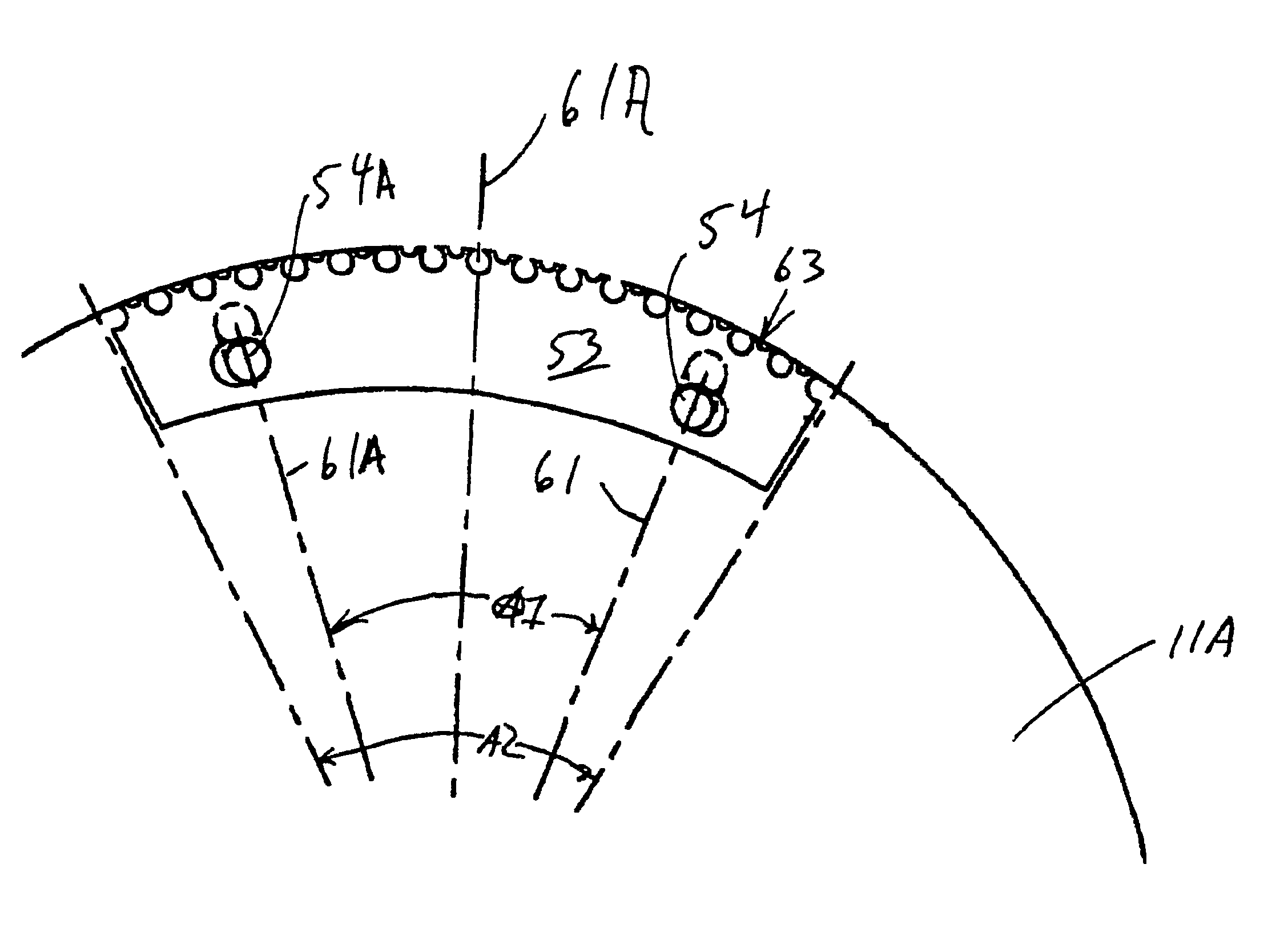

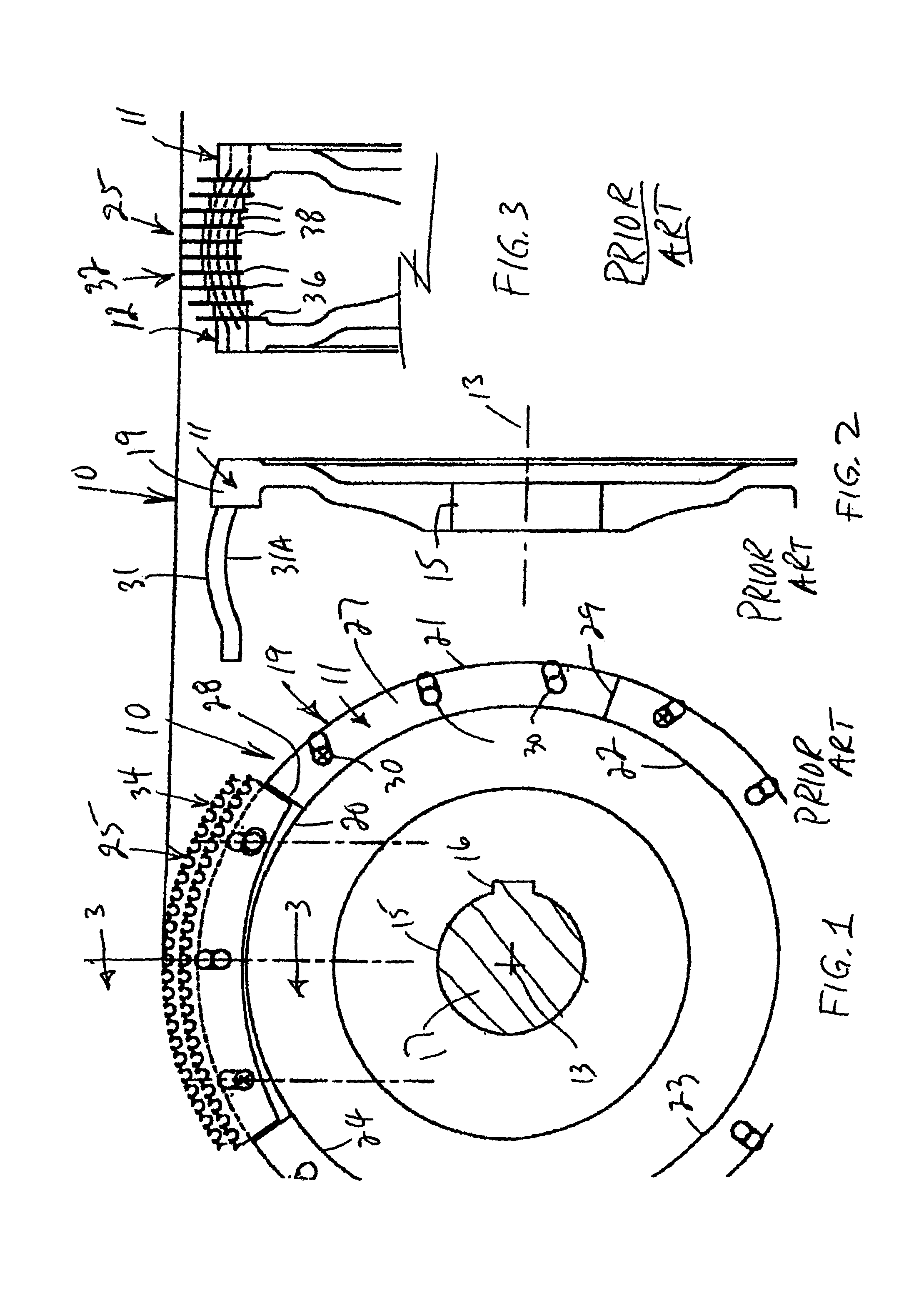

Rasp hub for tire retreading machine

InactiveUS7891915B2High concentricityImprove consistencyPlastic recyclingTyresRaspAerospace engineering

A rasp hub for use in tire retreading machines includes two side plates with mounting pins extending between the plates. Rasp blades arranged in stacks are mounted on the mounting pins. The stacks extend end-to-end circumferentially about the hub. The center portion of the mounting pins is curved so that the cut profile of the blades is convex. The blades are inclined relative to a plane perpendicular to the axis of rotation to define a cut angle. The center planes of the mounting pins intersect, preferably close to the axis of rotation of the hub, to reduce deviation of the blades from the concentricity.

Owner:B&J ROCKET AMERICA INC

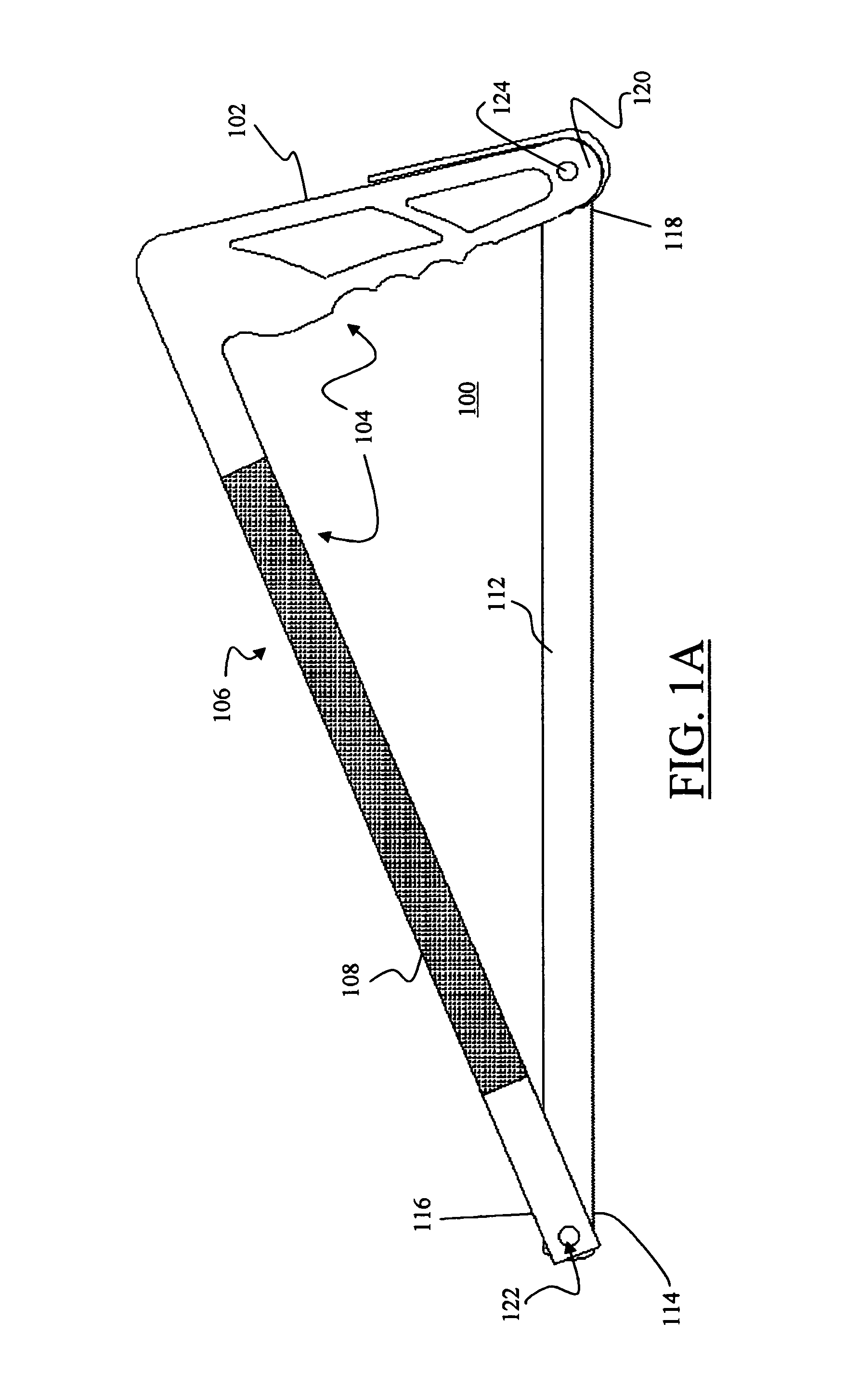

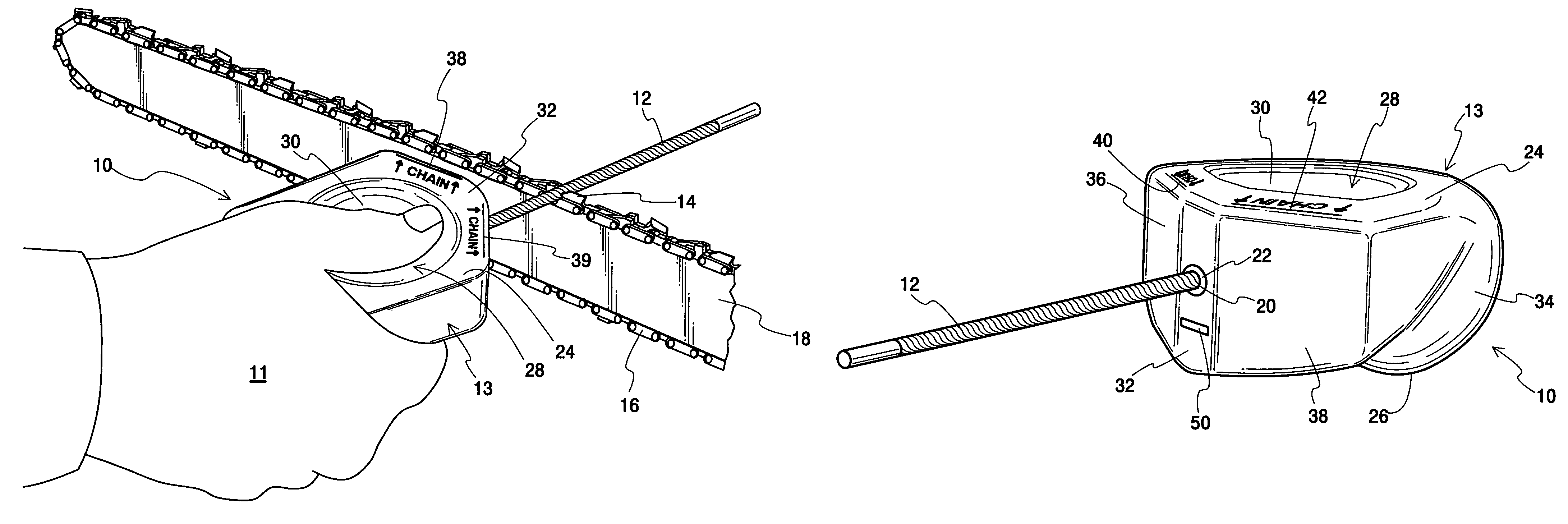

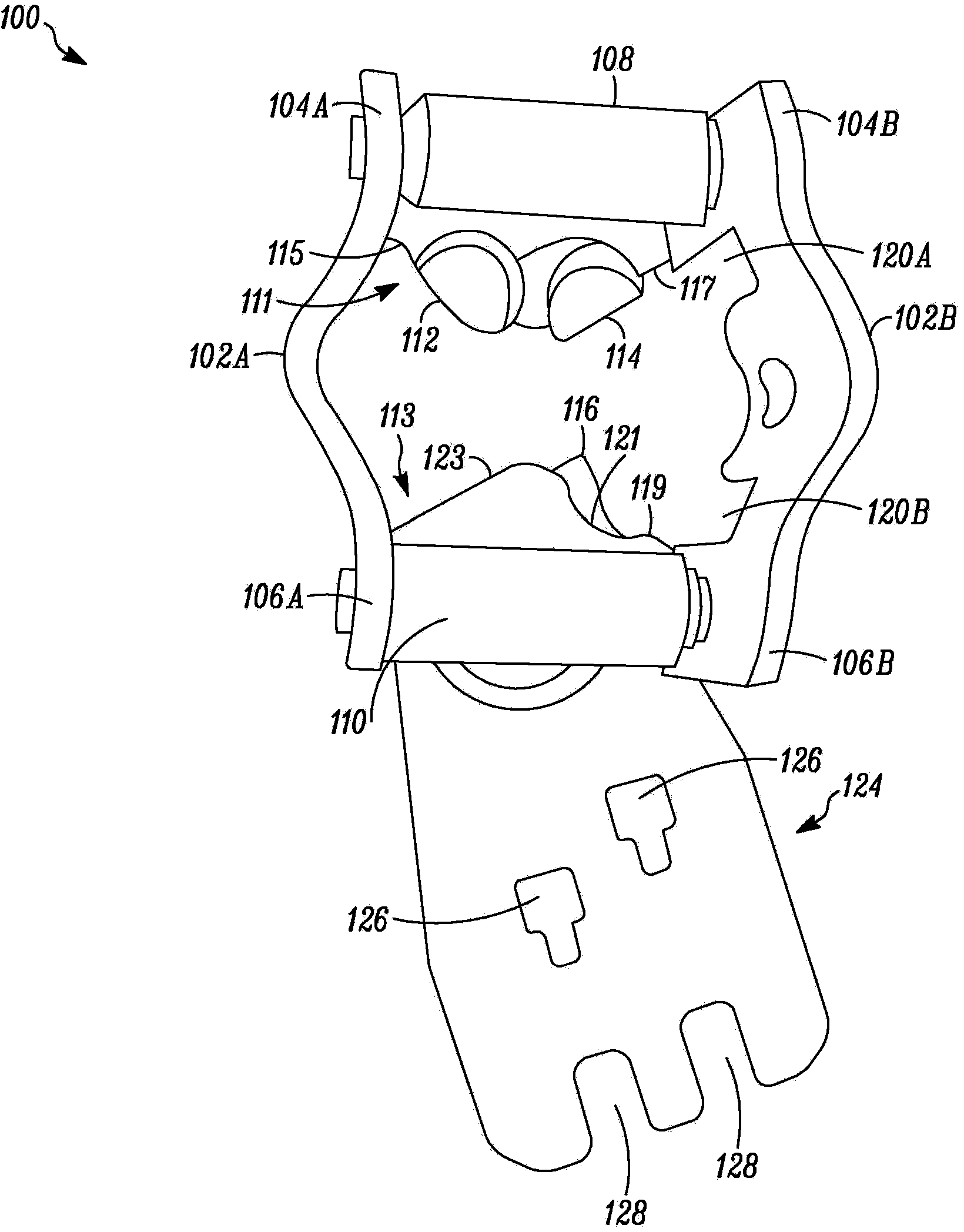

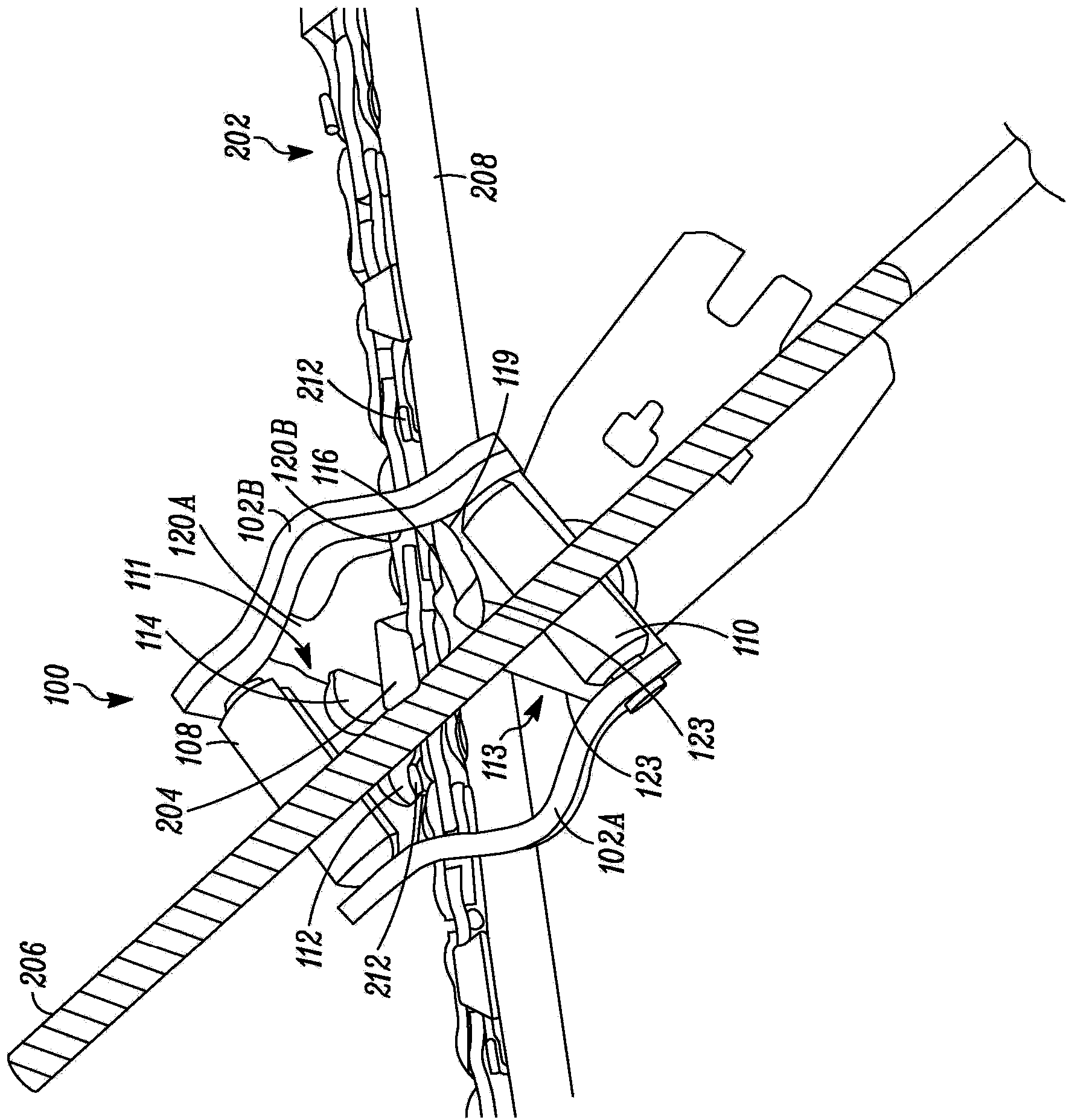

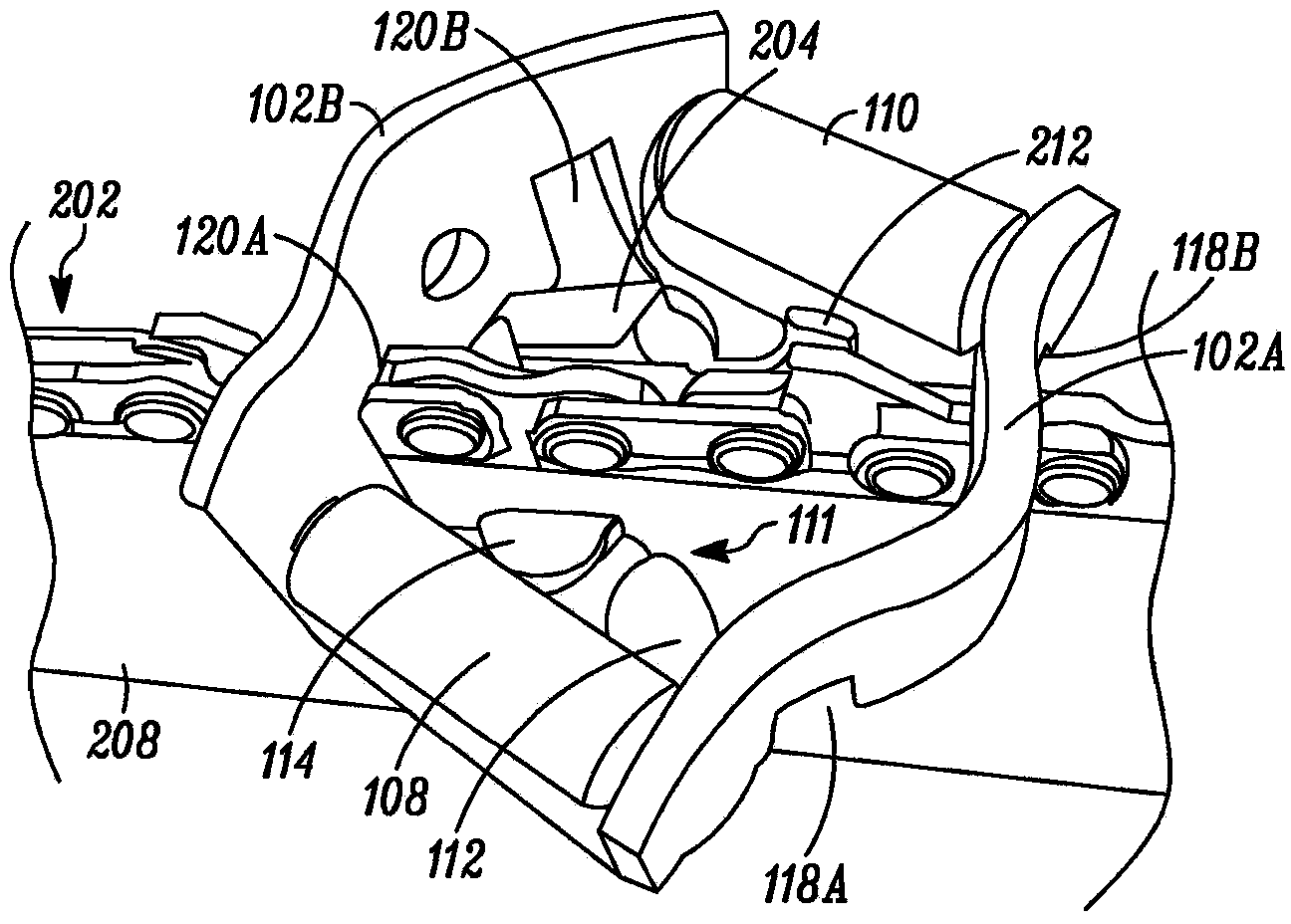

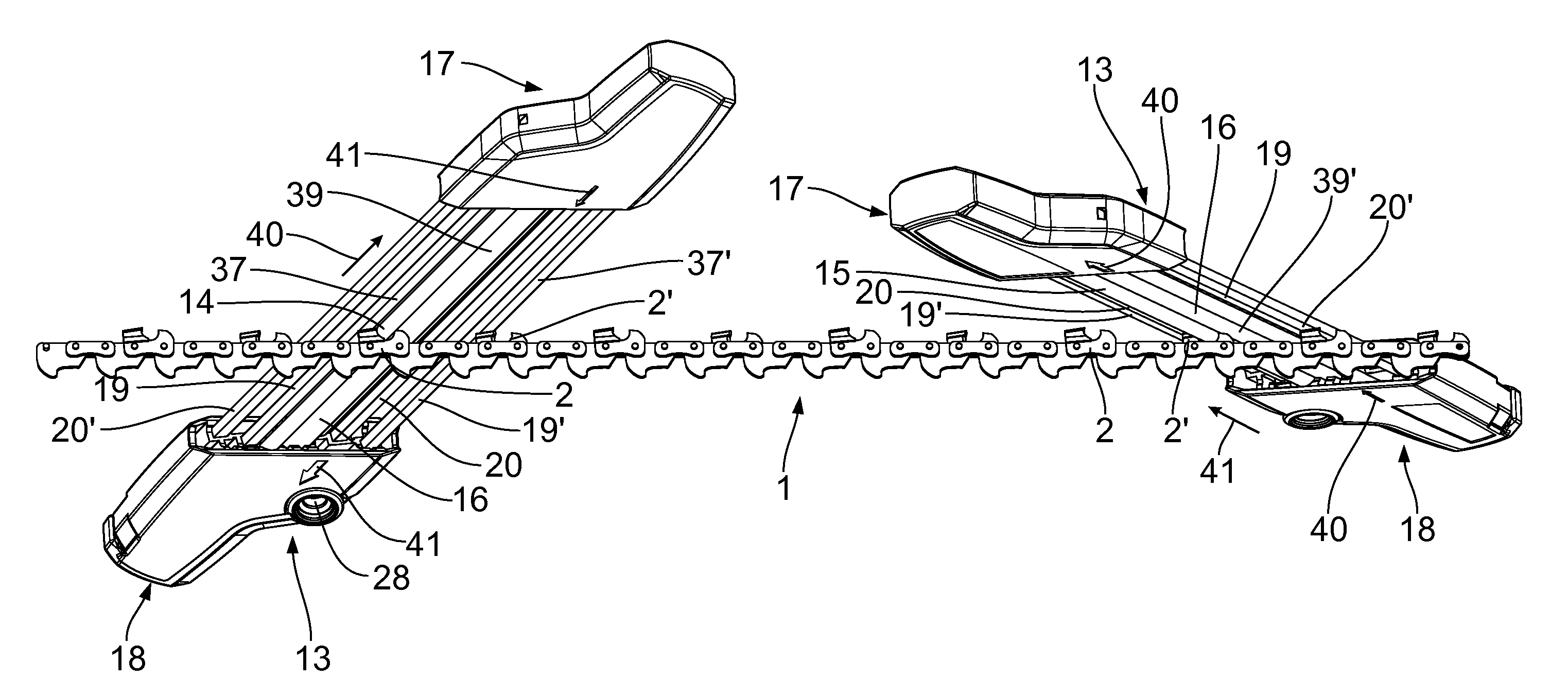

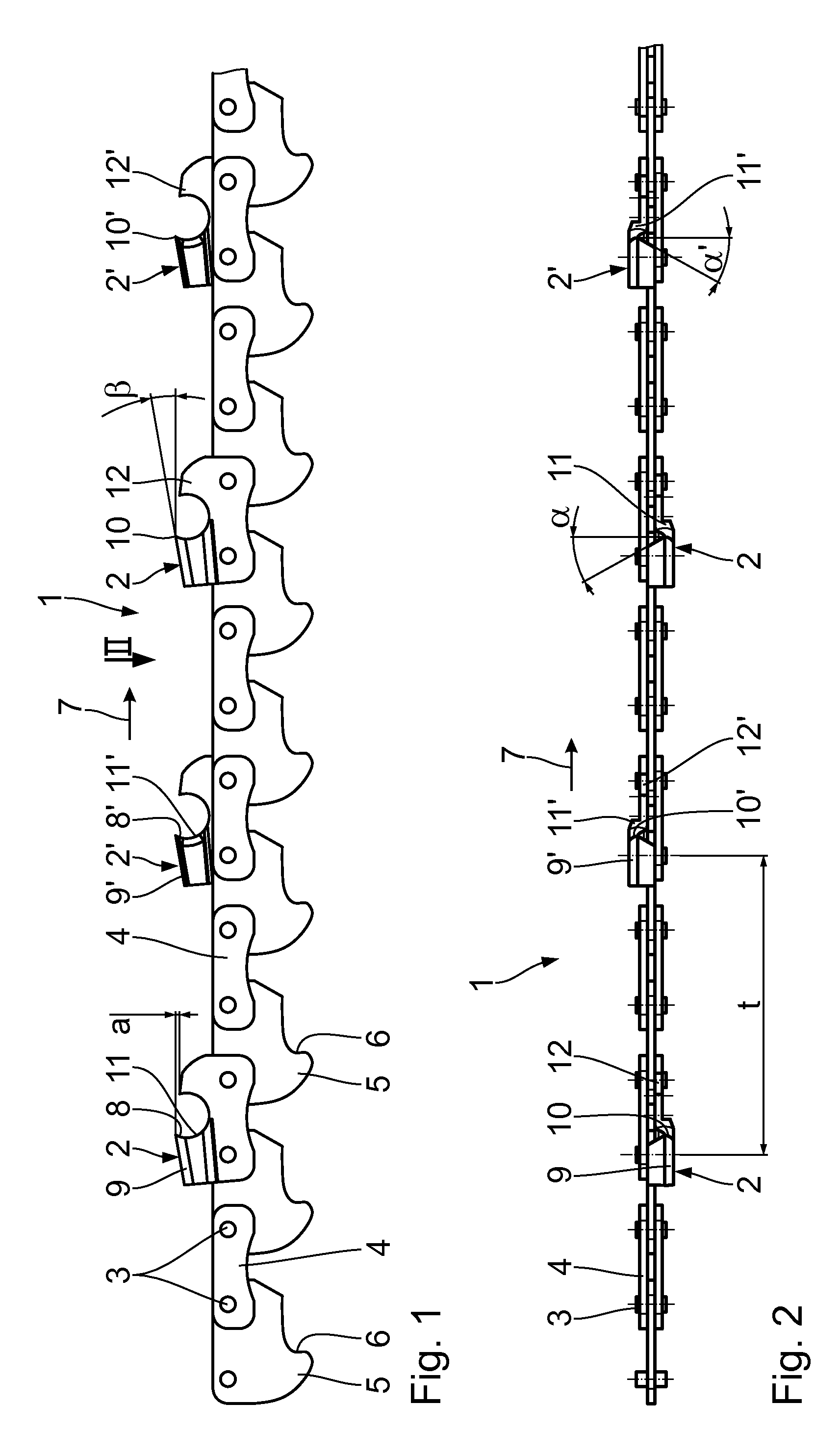

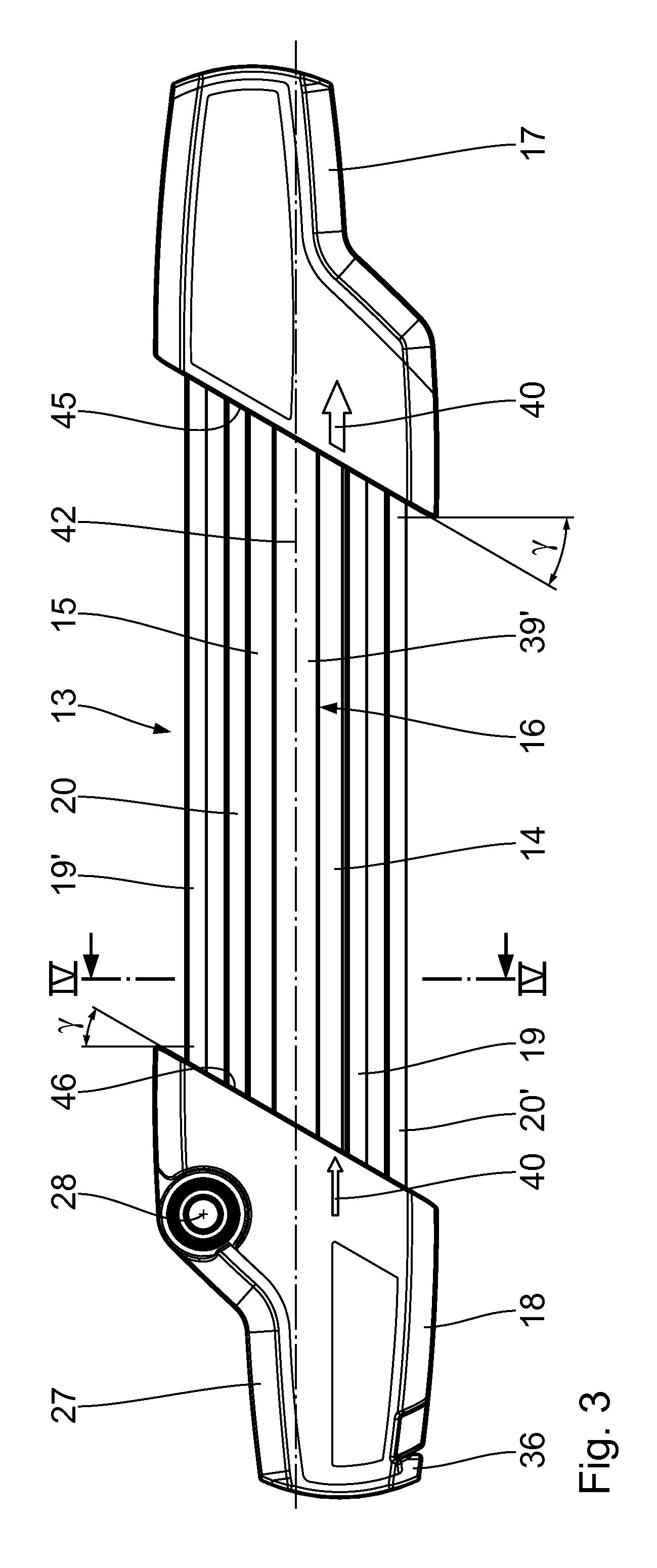

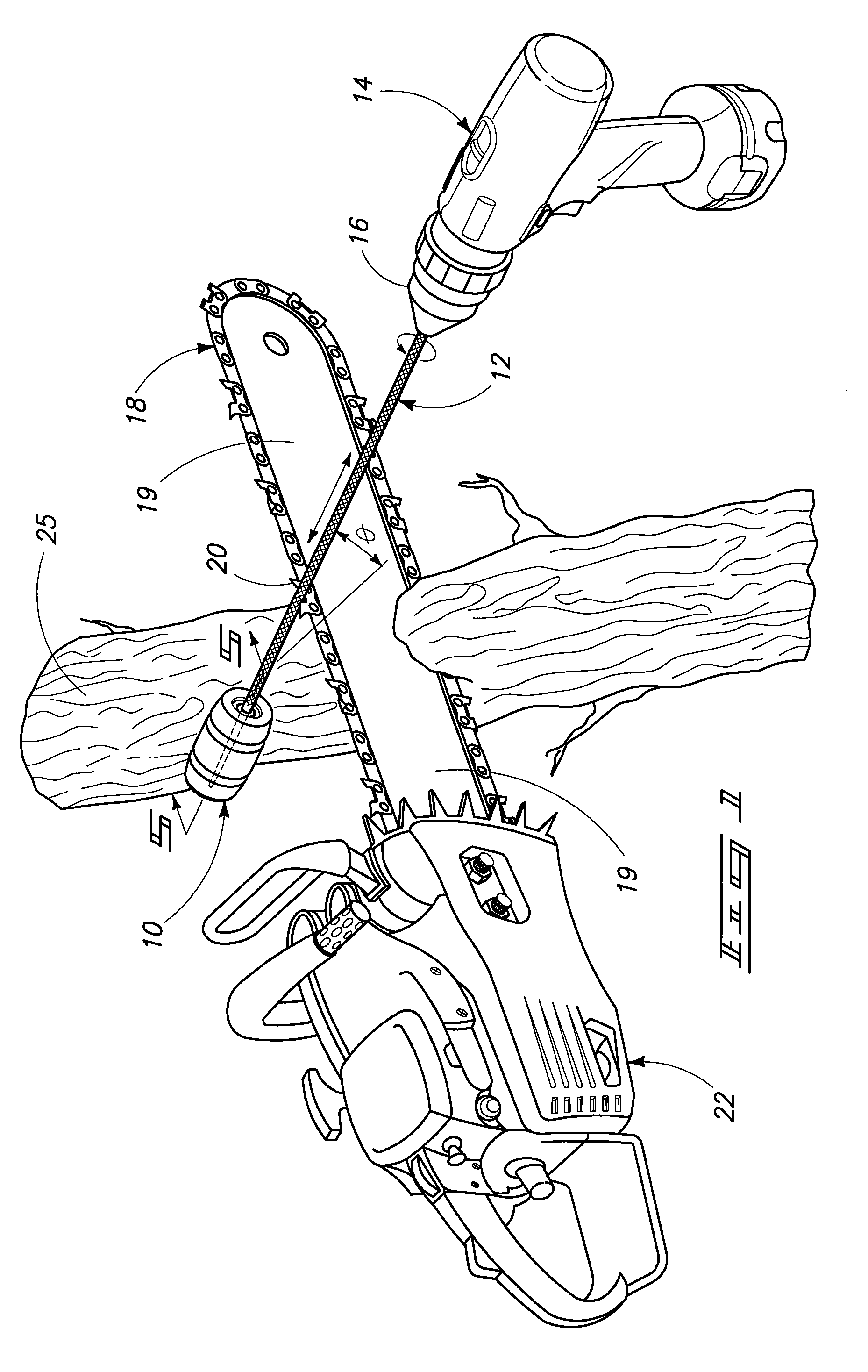

Filing fixture

ActiveCN104271297AClamp firmlySecurely and firmly clampedSawing tools dressing arrangementsFileEngineeringCam

The present invention discloses a fixture (100) configured to file a chain (202) of a chain saw. The fixture (100) includes at least one pair of flanges (102A, 102B), wherein each flange of the at least one pair of flanges (102A, 102B) has a first end (104A, 104B) and a second end (106A, 106B). Further, a first connecting portion (111) connects the flanges (102A, 102B) at their first ends (104A, 104B), and a second connecting portion (113) connects the flanges (102A, 102B) at their second ends (106A, 106B). Further, the first connecting portion (111) includes a pair of counter holds (112, 114) configured to provide area contact with a guide bar (208) of the chain saw. The fixture (100) also includes a cam portion (116) pivotally coupled to the second connecting portion (113), wherein the cam portion (116) and at least one of the counter holds (112, 114) simultaneously secure the fixture (100) to the guide bar (208).

Owner:HUSQVARNA AB

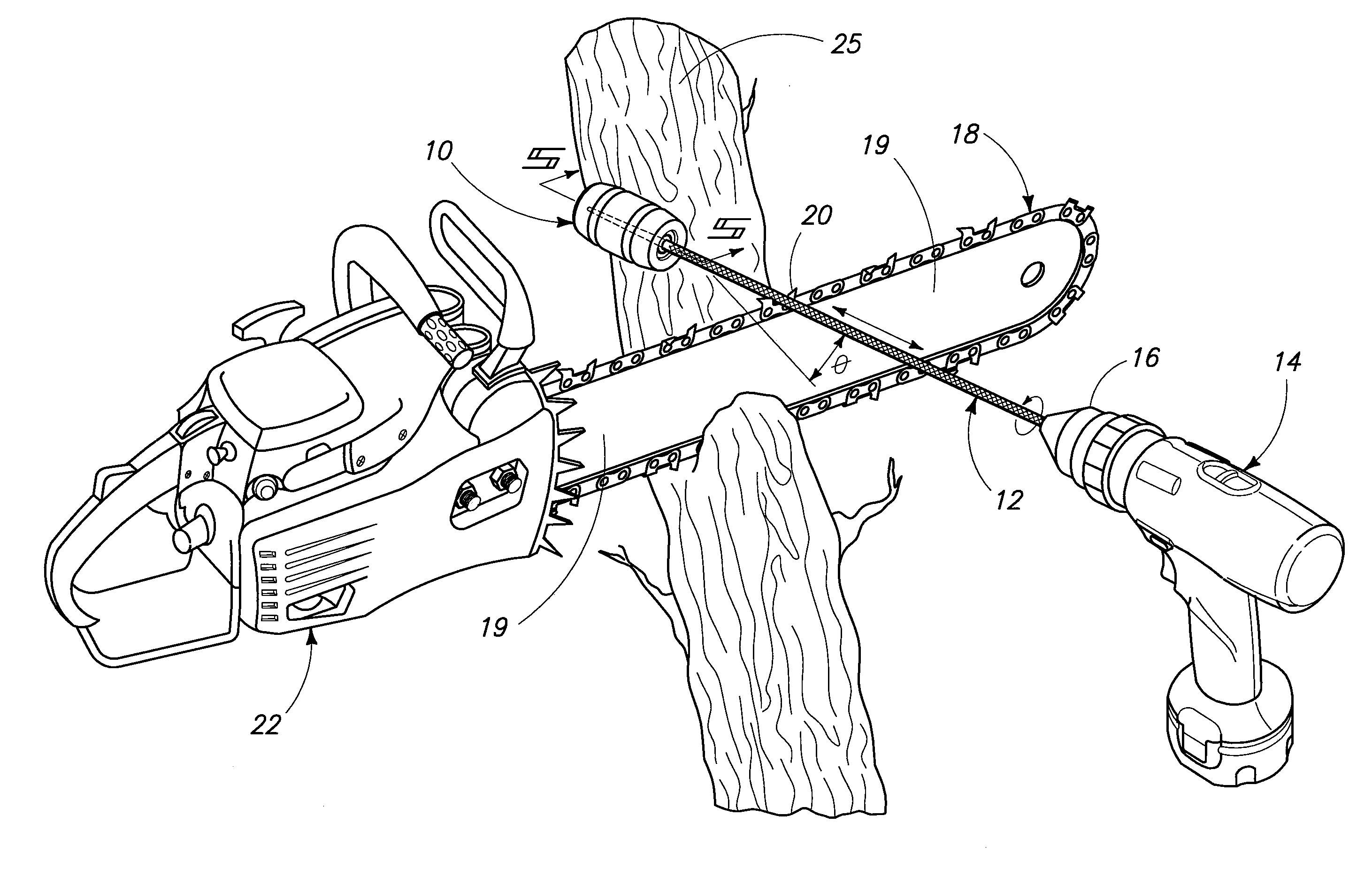

Sharpening device for manually sharpening the cutting teeth of saw chains for chain saws

A sharpening device for manually sharpening the cutting teeth of saw chains for chain saws has a frame, which has two head parts (spaced apart from one another and two pairs of guide rods which are, in each case, arranged parallel to one another and to a longitudinal axis and rigidly connect the head parts to one another. Parallel to the longitudinal axis, round files and two file faces are held without play, but exchangeably in the head parts. The pairs of guide rods and the respective associated round files and the respective file faces are arranged rotationally symmetrically with respect to the longitudinal axis.

Owner:FA AUGUST RUGGEBRERG

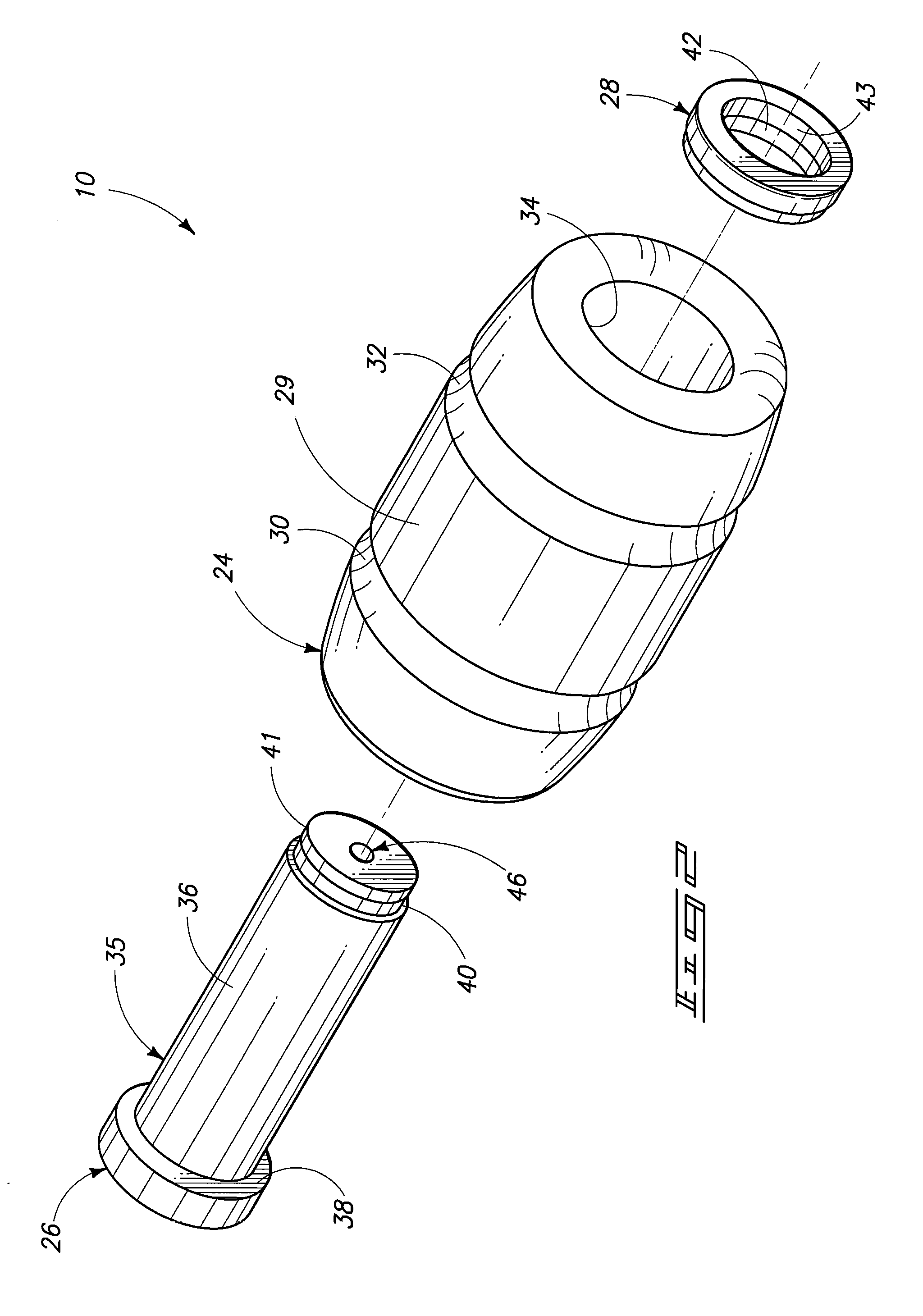

Chainsaw Sharpening Tool

InactiveUS20090071297A1Quickly and efficiently sharpeningEasy to useSawing tools dressing arrangementsFiling/rasping toolsEngineeringBearing surface

A file guide is provided having a tubular handle, a spindle, and a retainer. The tubular handle has a central bore with an inner bearing surface and an outer gripping surface. The spindle has a cylindrical outer bearing surface configured to mate in complementary, rotatable relation with the inner bearing surface of the handle, a head at a proximal end, a lock portion at a distal end, and a central receptacle configured to receive a file shank. The retainer has an inner surface with a complementary lock portion configured to interlock with the lock portion of the spindle

Owner:OVENTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com