Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about "Envelope closers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

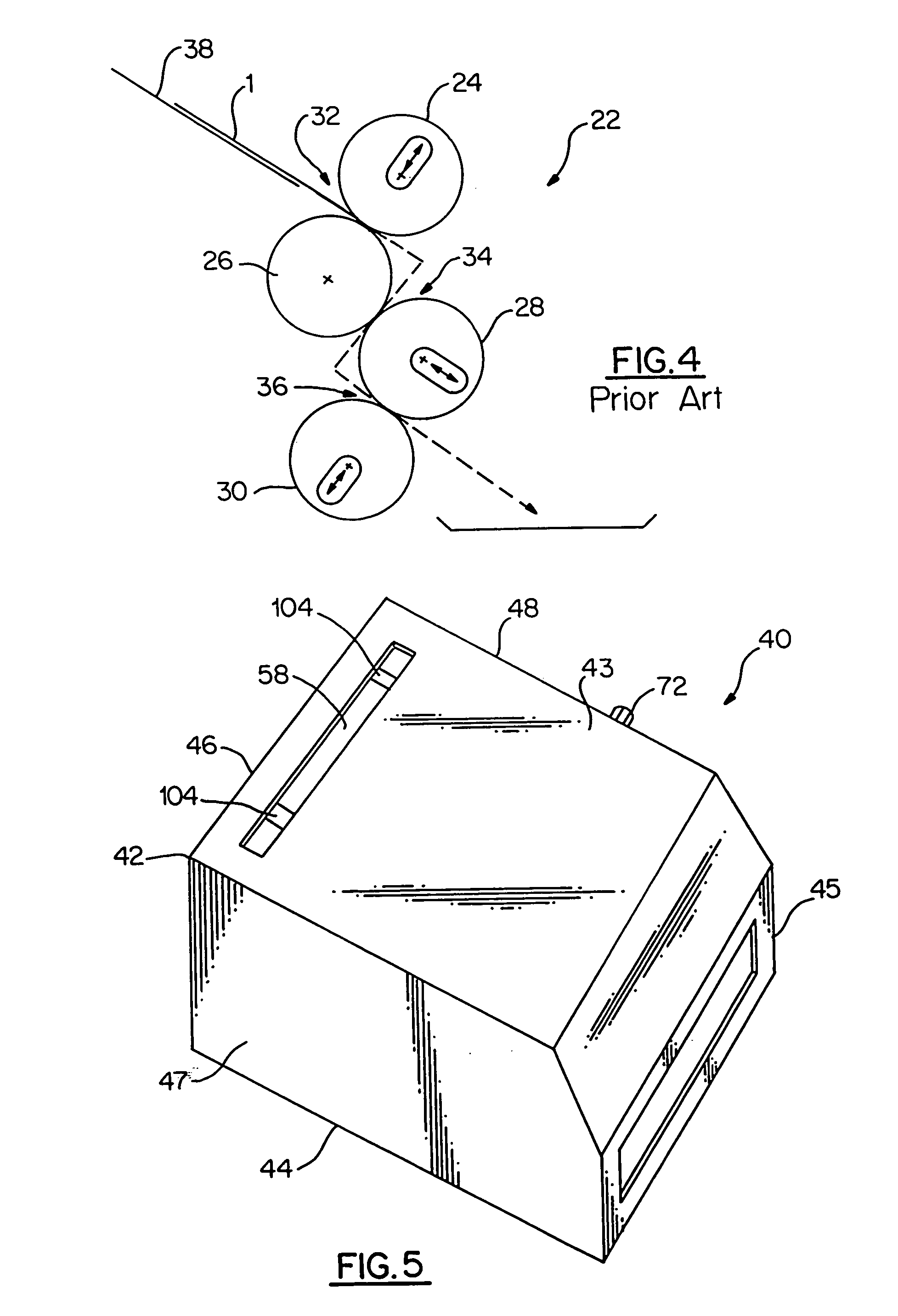

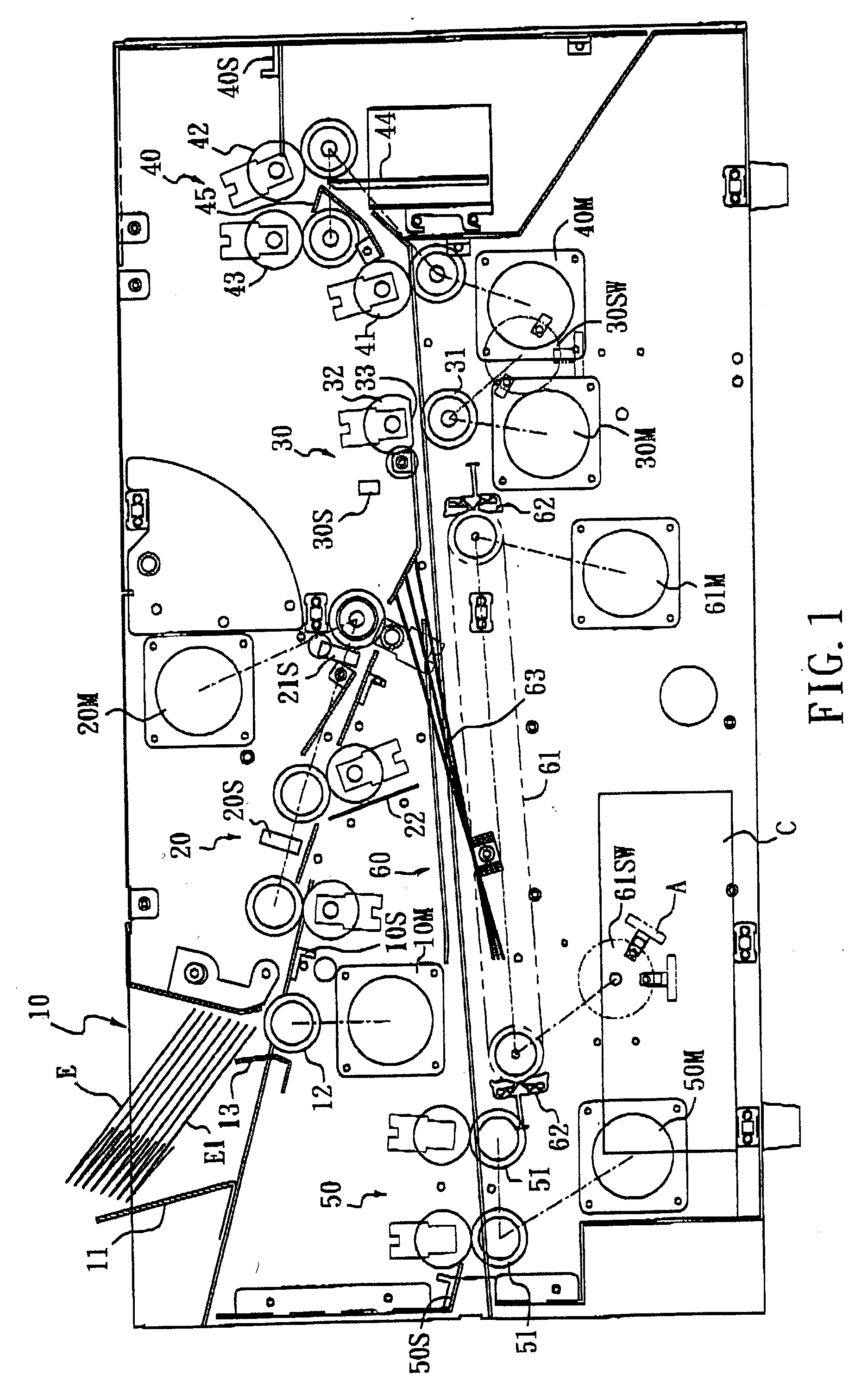

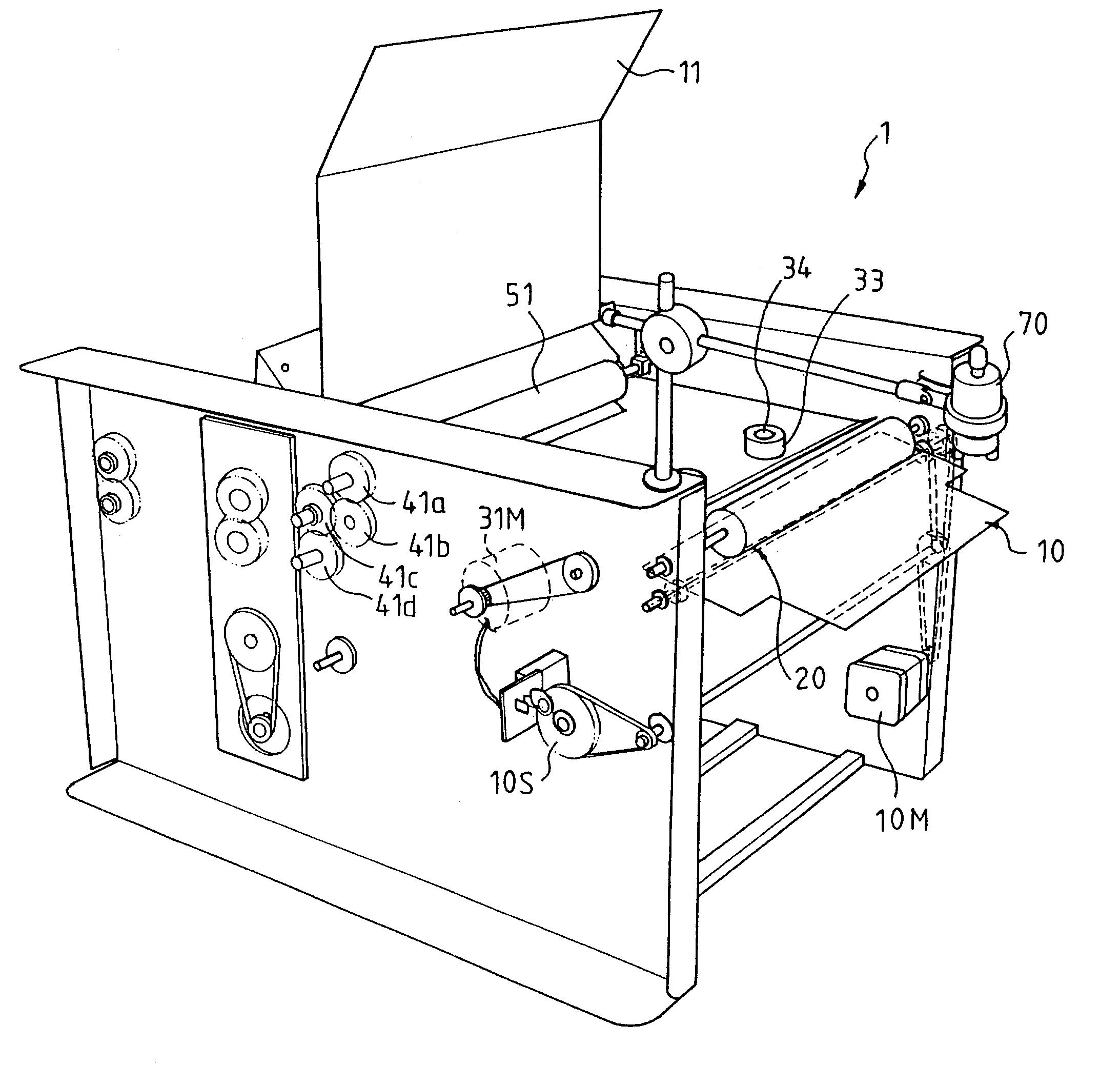

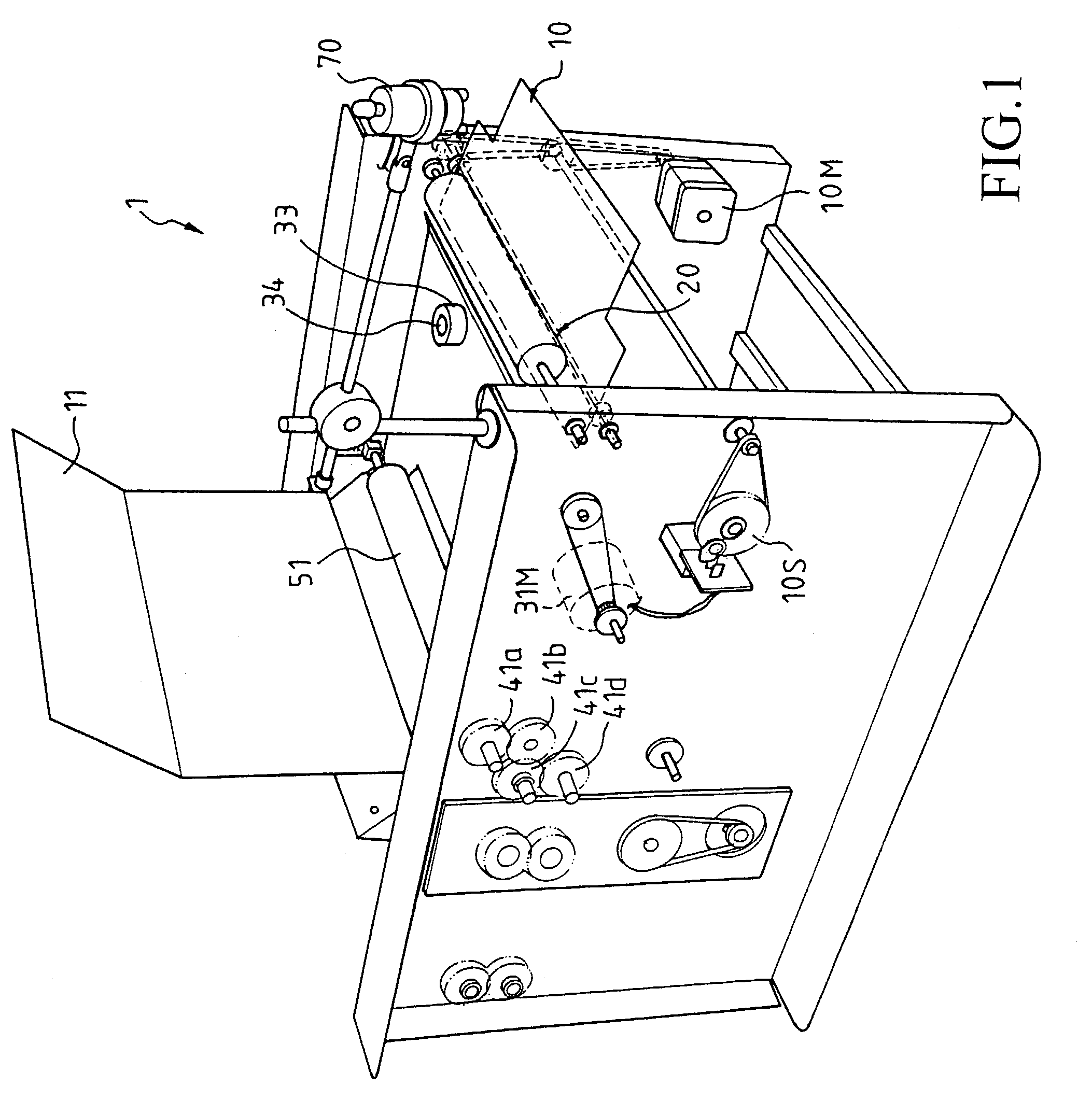

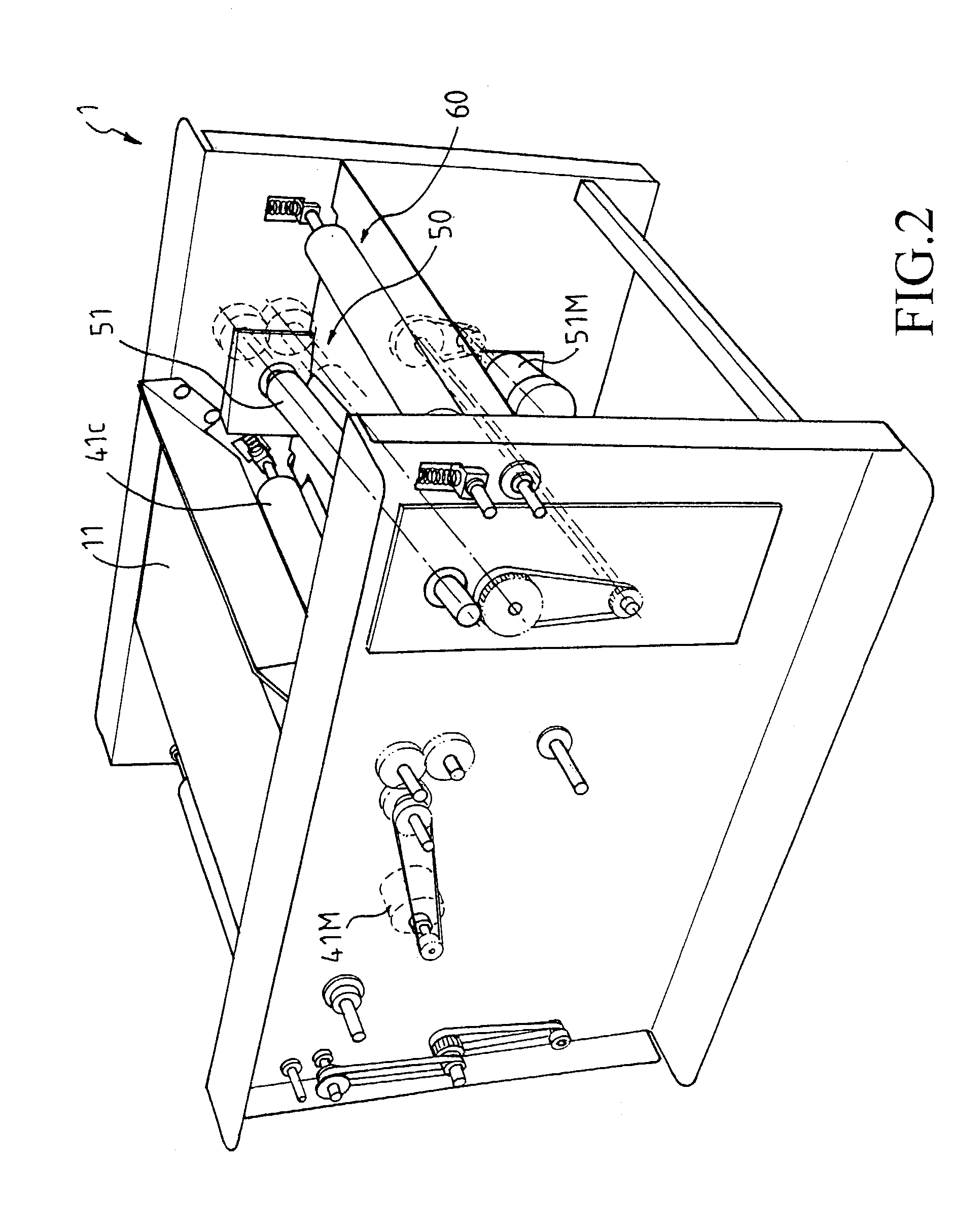

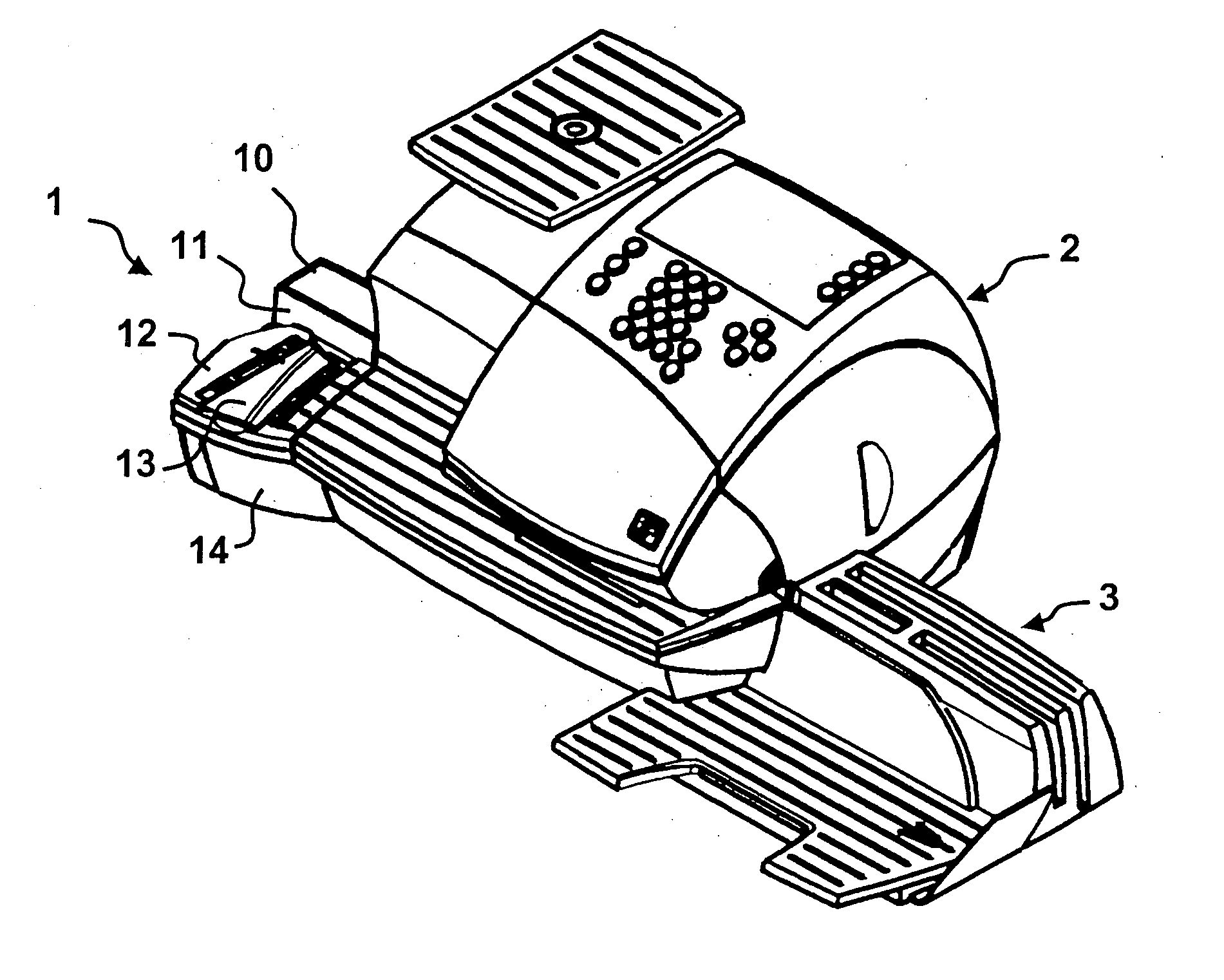

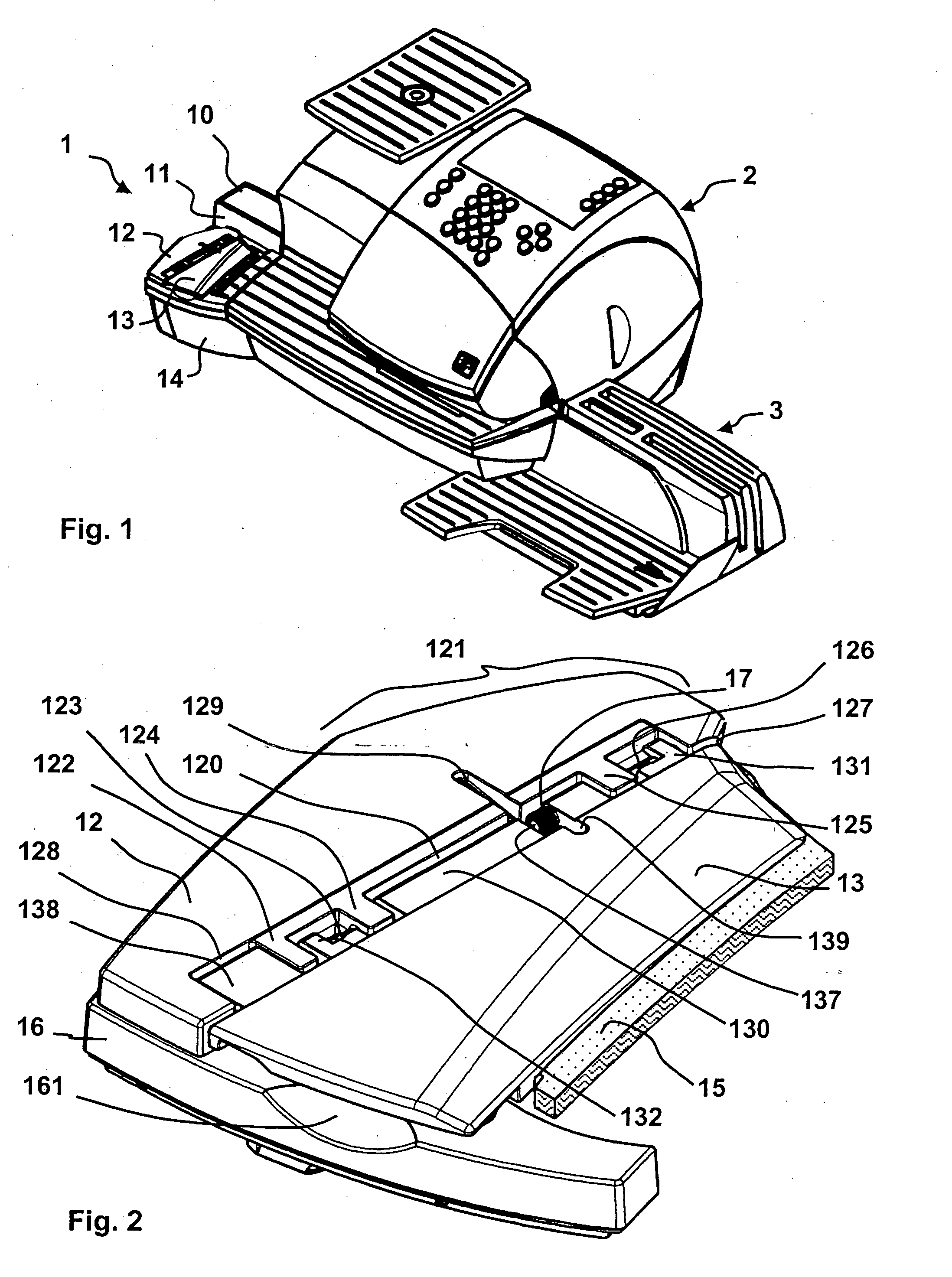

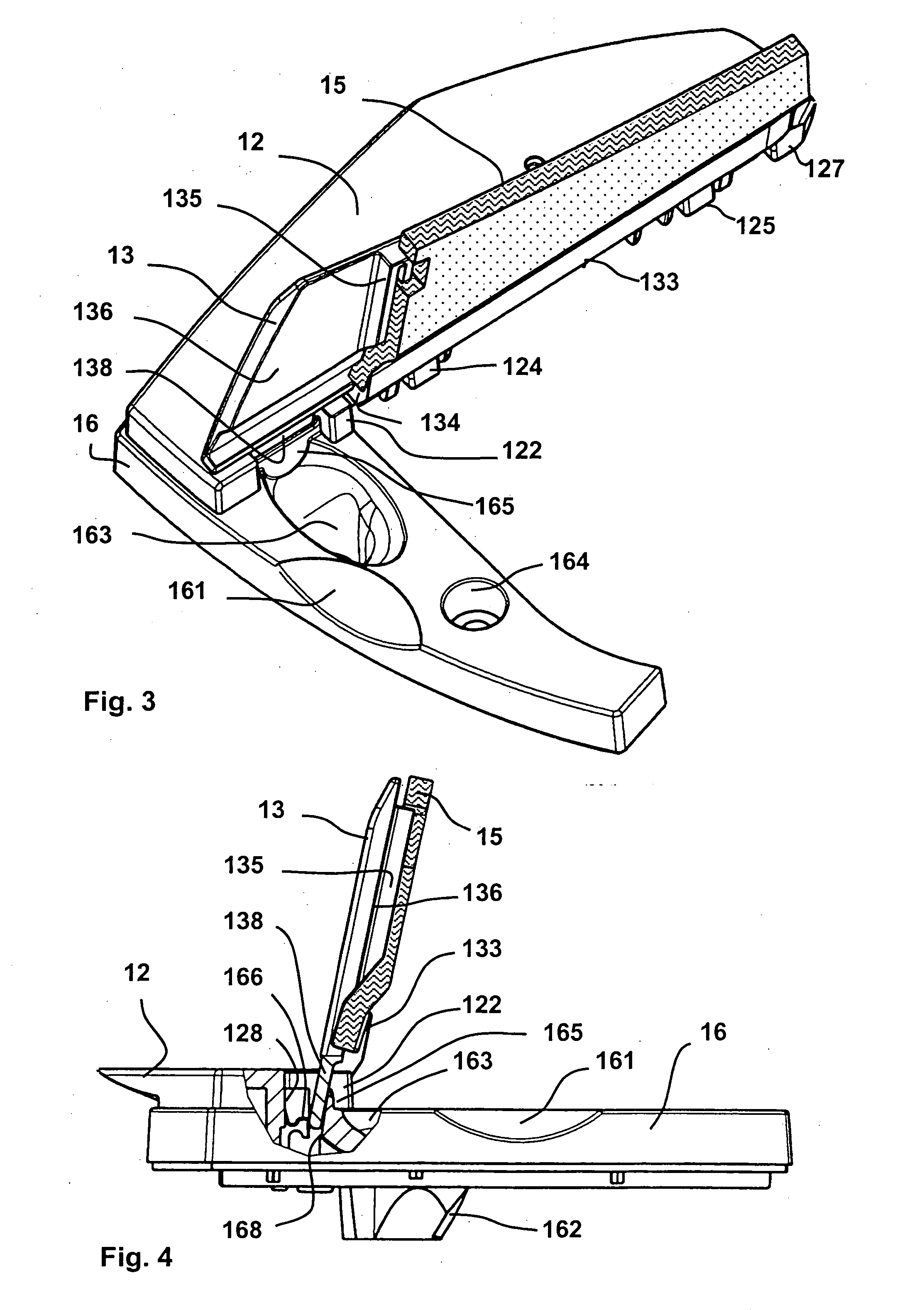

Automated fold and seal apparatus

InactiveUS20050092440A1Improve sealingSufficient sealing pressureMechanical working/deformationShaft and bearingsMotor driveFolded form

A folding and sealing apparatus supporting a feed platform for feeding a supply of pre-glued forms to the folding and sealing apparatus. The housing accommodating a first roller, a second roller, a third roller and a fourth roller, and the first and second rollers forming a first nip, the second and third roller forming a second nip and the third and fourth roller forming a third nip. A motor drives at least one of the rollers via a drive mechanism. At least one of the rollers having a resilient portion to accommodate an object mounted on a form, passing through the nips while maintaining appropriate folding and sealing pressure on the supporting form to provide a sufficient sealing pressure to the folded form, as the folded form passes through the nips to facilitate both folding and sealing of the folded form. A cleaning arm is provided adjacent one of the rollers to remove debris therefrom, and a collection bin is provided adjacent the third nip for collecting the folded and sealed forms upon exiting from the folding and sealing apparatus.

Owner:LINDSAY WAYNE R +1

Envelope reorientation device

A feed device for feeding a document folding and / or inserting machine with envelopes delivered by a general-purpose printer, said feed device comprising detection means for detecting the position of the envelope at the outlet of the printer and reorientation means for reorienting the envelope as a function of its position as determined by said detection means so as to enable documents to be inserted into the envelope. The detection means advantageously comprise a detector for detecting an edge of the envelope, and the reorientation means advantageously comprise a turntable.

Owner:NEOPOST IND

Card package production system with adhesive card attachment station and method

InactiveUS6902518B2Envelopes/bags making machineryLamination ancillary operationsAdhesiveElectrical and Electronics engineering

A card package production system (100) for producing card packages (115) composed of cards (128) attached to carriers (113) has an adhesive label attachment station (358, FIG. 34) with a heating platen (361) having a width for heating at least two labels (148) simultaneously that are passed over the platen (361) and a labeler downstream from the heating platen (361) with a pressing member (372) for pressing the heated adhesive label (128) against a card (128) at an attachment position. The heating platen (361) heats only an intermediate section of the adhesive to activate the adhesive and leaves end portions of the label relatively unheated and unactivated to facilitate subsequent removal of the label (148) from the card (128).

Owner:DYNETICS ENG

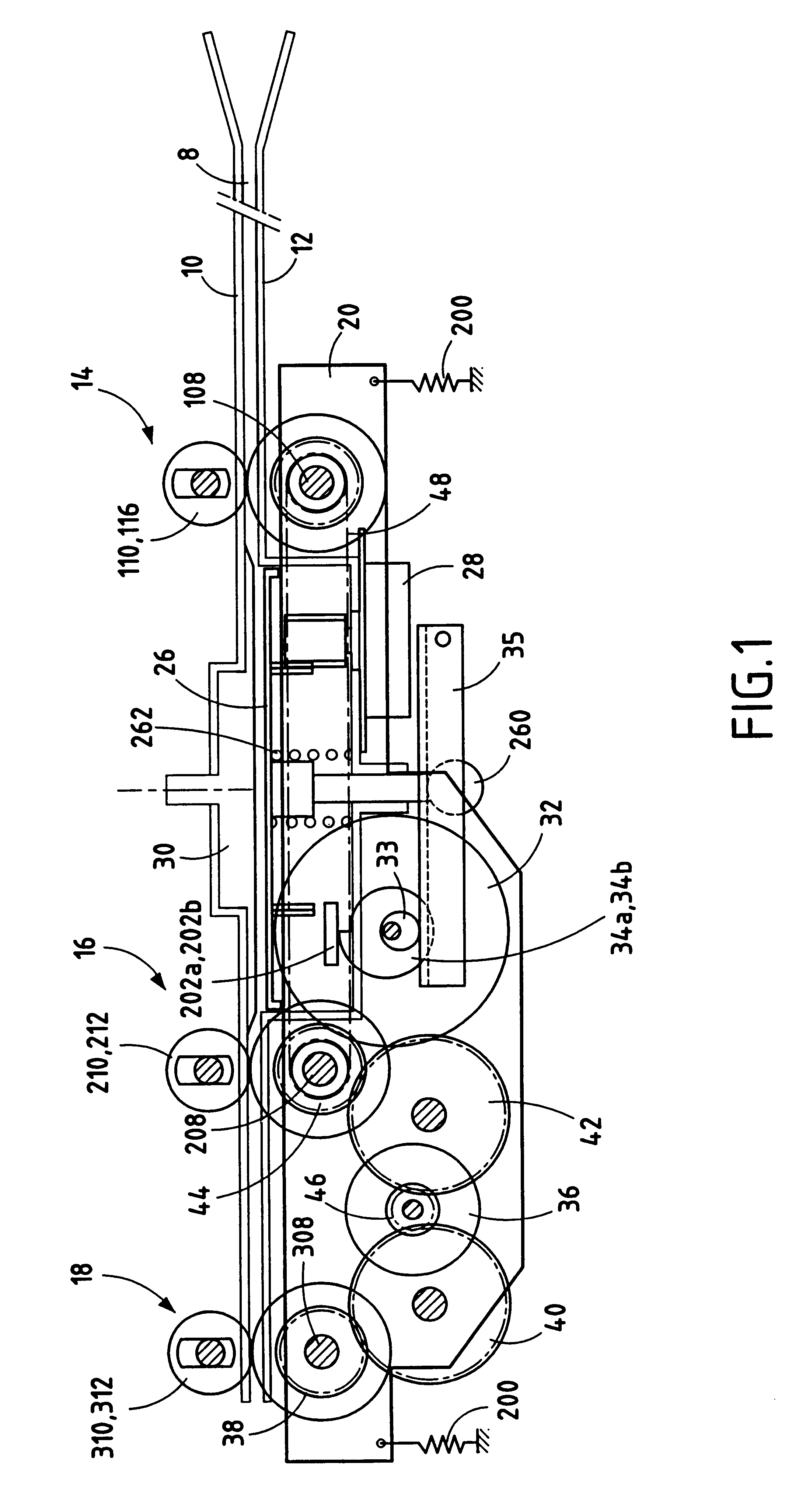

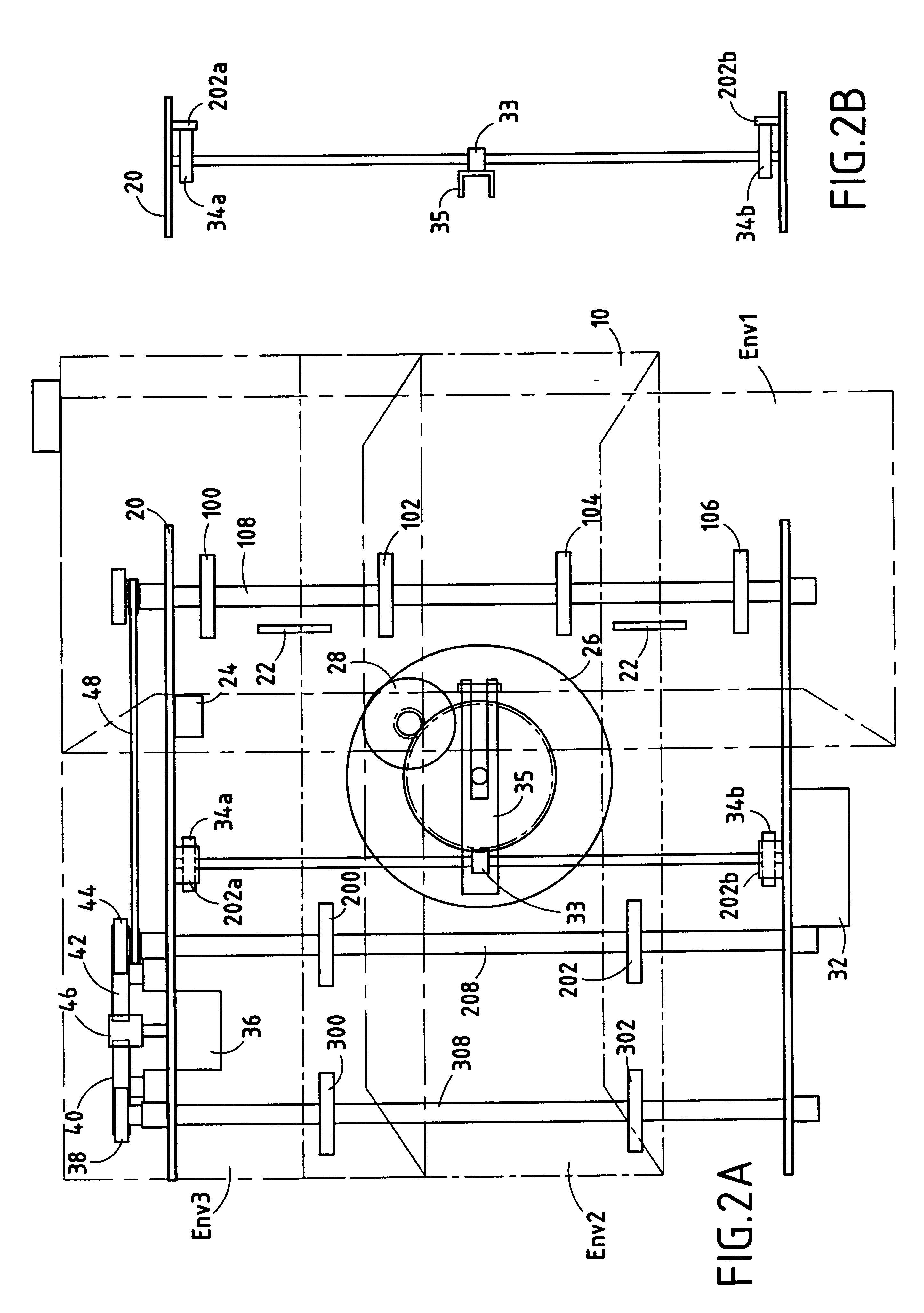

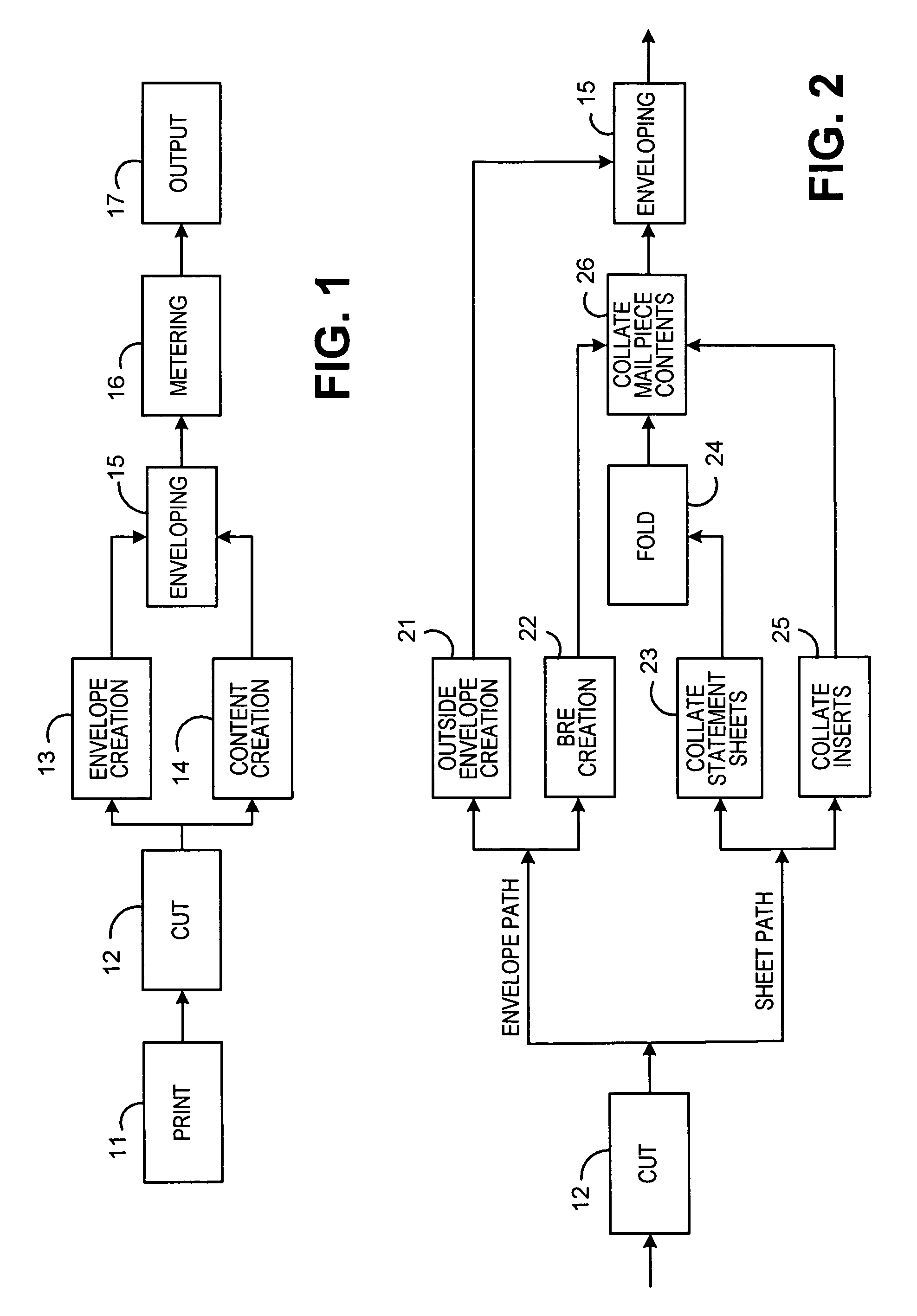

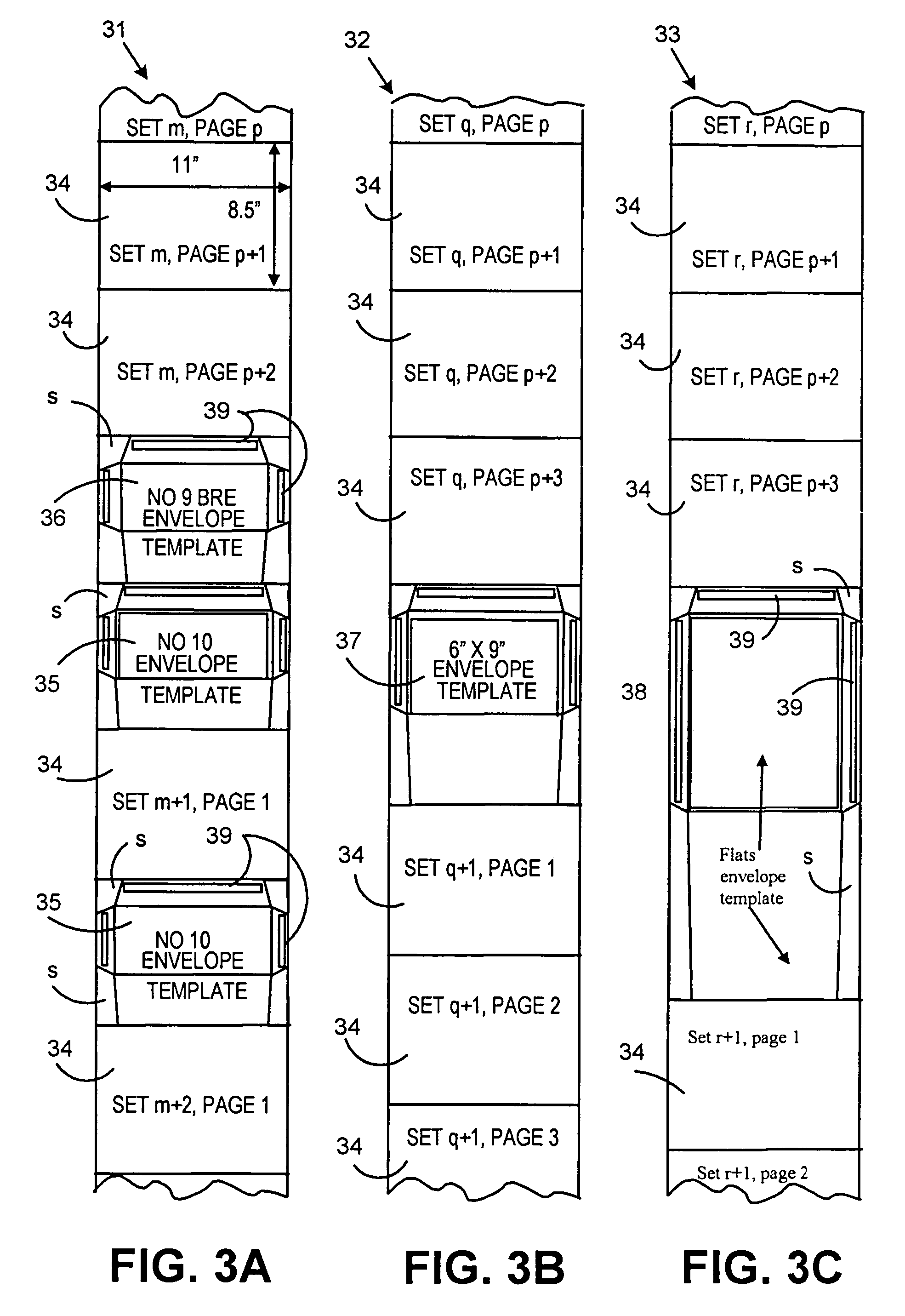

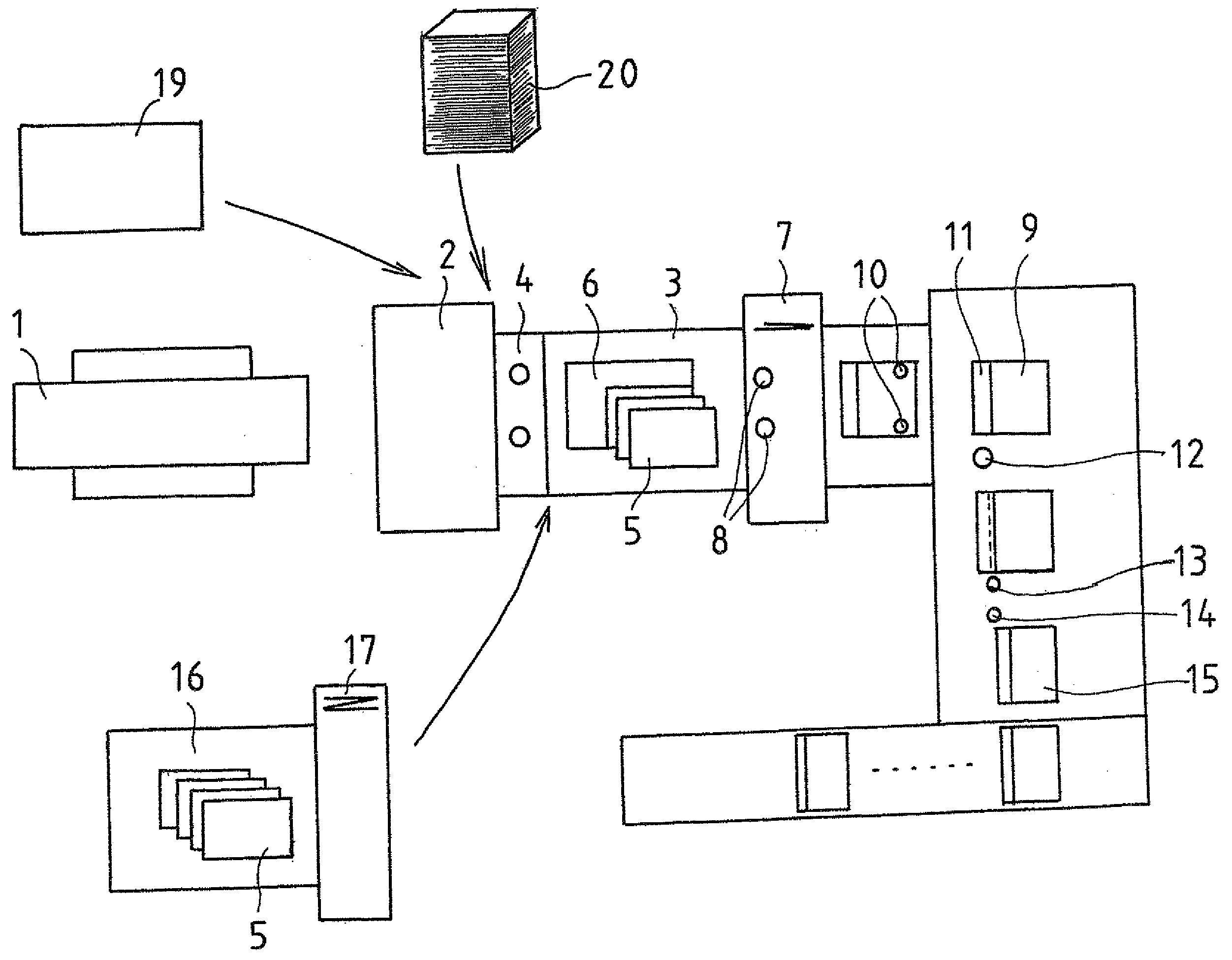

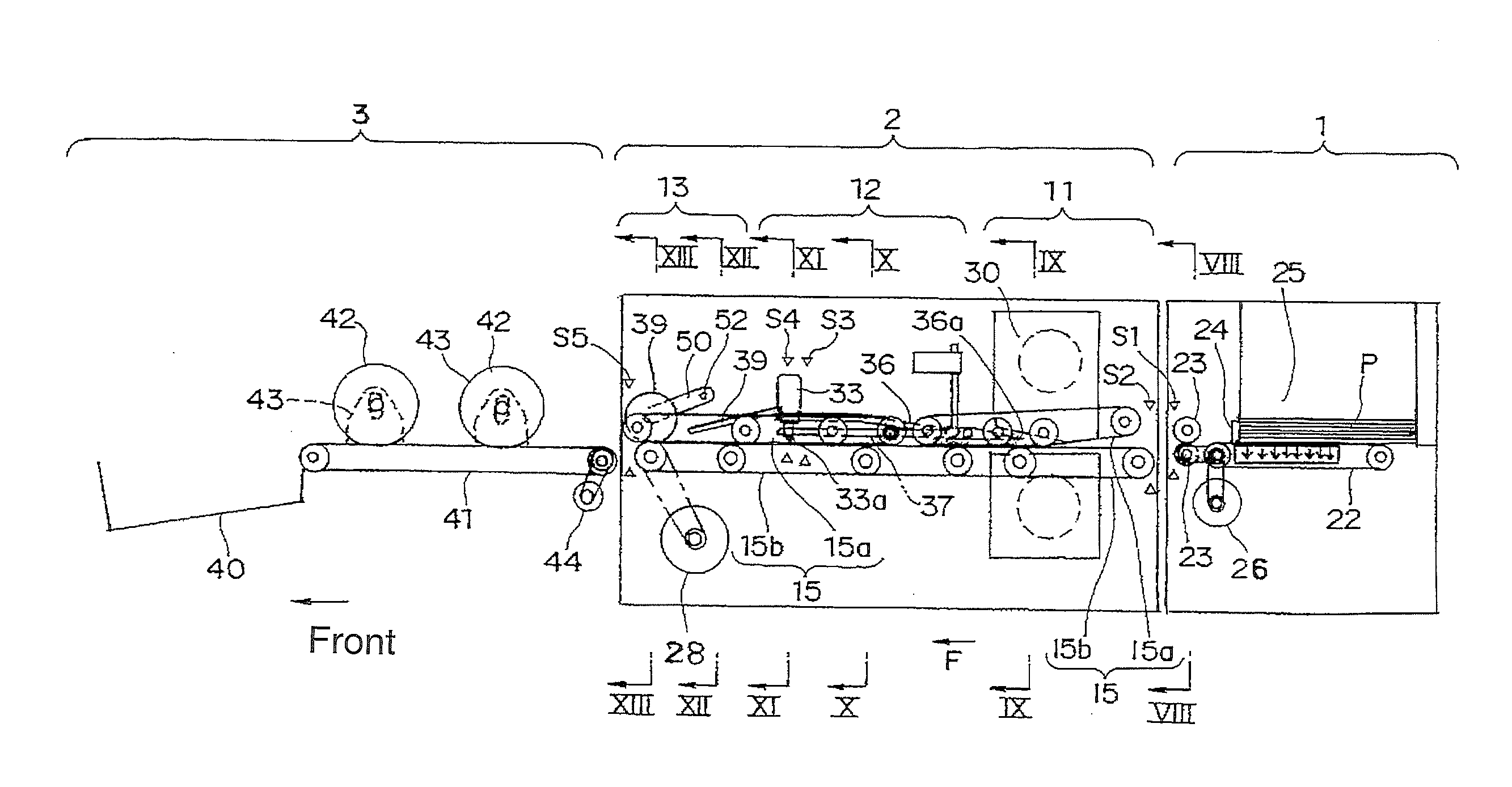

Method and system for creating mailpieces from a single continuous web of printed material

ActiveUS7254931B2Reduce unreliabilitySimple equipmentEnvelopes/bags making machineryBag making operationsEngineeringPaper sheet

A method for creating mailpieces from a single web of printed material. The web of printed material includes a continuous web having a width and a length, the length comprised of a series of attached sheets. The series of attached sheets is comprised of envelope sheets and content pages. The content pages are rectangular in shape and may be oriented relative to the envelope sheets in a number of different configurations. In some configurations, two sets of content pages and / or envelope sheets can be printed across the width of the web. The method starts with cutting consecutive attached sheets into separated sheets. The content pages belonging to a same mailpiece are accumulated together. The separated envelope sheet is transported, bypassing the accumulating and turning steps. The accumulated and turned content pages are then merged with the envelope sheet, and the envelope sheet is folded and closed around the accumulated content pages to form a finished enclosing envelope.

Owner:DMT SOLUTIONS GLOBAL CORP

Method of producing mailing covers and machine utilizing said method

InactiveUS20080172145A1Shorten the lengthEnsure integrityProgramme controlComputer controlSoftware engineeringIndustrial engineering

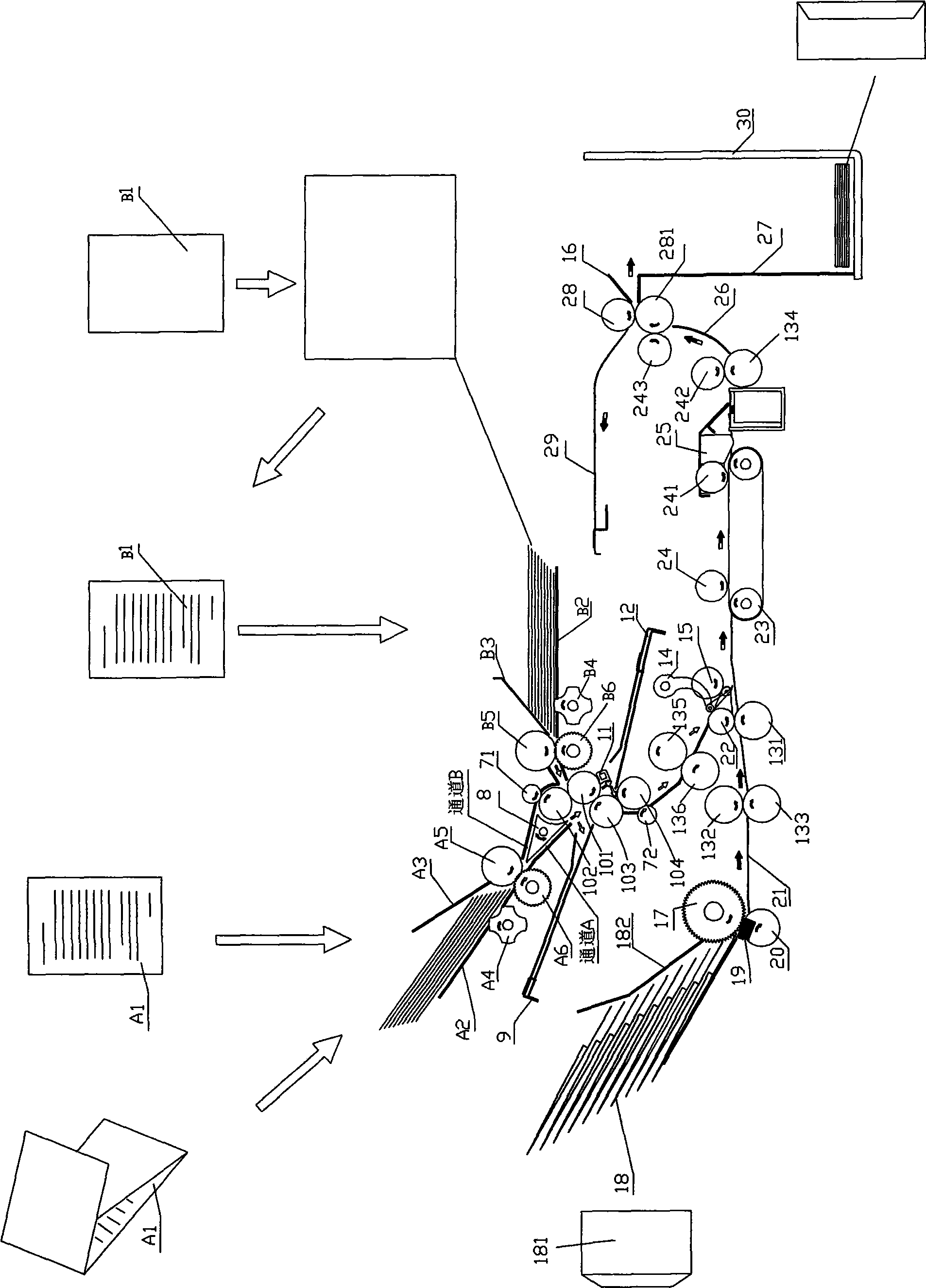

A method for producing unique and personalized pieces of mail, including integrating envelope production with the production of the documents for insertion within the envelopes. The machine for producing the pieces of mail includes a device for producing, from the same width of paper, both the documents and the envelopes designed to contain the documents. A longitudinal cutting device cuts the documents to the correct width and forms the flaps of the envelopes. A transverse cutting device separates the documents from the envelopes and cuts them to the correct length. A device assembles the documents with the corresponding envelope. A gluing and folding device closes the envelope while a central processing unit regulates at least the cutting devices, according to the number and format of the documents, and the stuffed envelopes to be produced.

Owner:MEGASPIREA PRODION

Mail inserter

InactiveUS20040250517A1Without riskNeat appearanceIndividual articlesEnvelope closersAerospace engineering

A mail inserter for inserting a mail into an envelope having a flap and a throat, including: an envelope entry; an envelope carrier, provided downstream of the envelope entry; an envelope retainer, provided at the downstream of the envelope carrier; a mail entry, for advancing the mail into the mail inserter; a mail carrier, provided downstream of the mail entry; a sealer, provided downstream of the envelope retainer; wherein the envelope entry, envelope carrier, envelope retainer and sealer jointly form an envelope path, and the mail entry and the mail carrier jointly form a mail path that merges into the envelope path after the mail carrier.

Owner:HSIEH ELTON

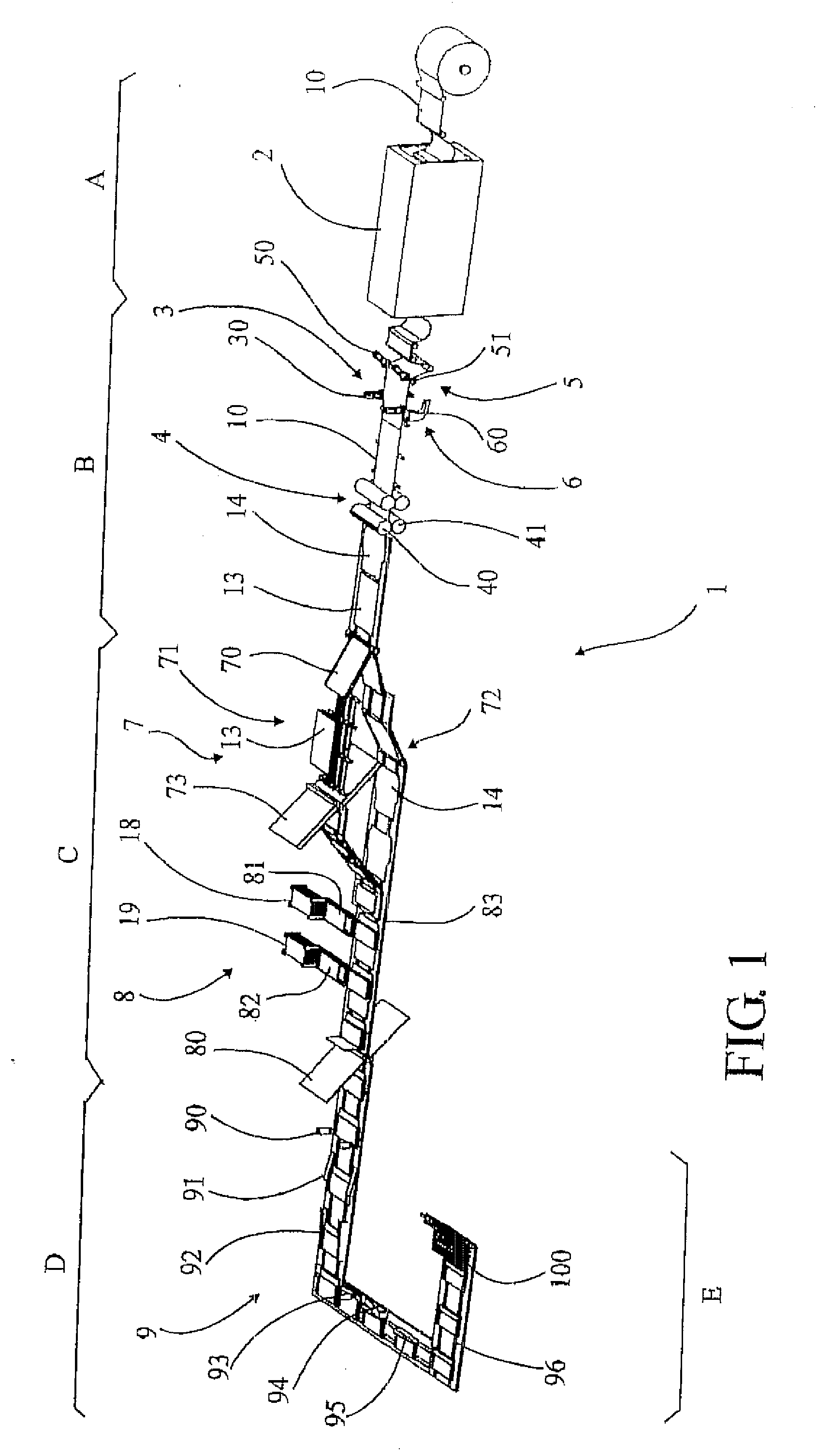

Sealed letter forming apparatus

ActiveUS20120260605A1Easy to checkEasy to identifyCapsCapping machinery safety/controlForm processingLettering

A sealed letter forming apparatus has a sheet feed unit containing an envelope sheet to be an envelope and a content sheet to be a content; a printer for printing on the respective sheets supplied from the paper feed unit; an enclosing and sealing unit for folding the respective sheets printed by the printer, and enclosing and sealing the respective sheets; and a controller to control the enclosing and sealing unit to stop the sealed letter forming processing when an error related to the envelope sheet or the content sheet in an n-th article occurs, and to perform the sealed letter forming processing without sealing a sealed letter of the n-th article as a sealed letter to be checked by a user when the error is canceled. A sealed letter forming processing is performed on each article which is a combination of the envelope sheet and the content sheet.

Owner:RISO KAGAKU CORP

Method and system for creating mailpieces from a single continuous web of printed material

ActiveUS7231750B2Reduce unreliabilitySimple equipmentEnvelopes/bags making machineryBag making operationsEngineeringPaper sheet

A method for creating mailpieces from a single web of printed material. The web of printed material includes printed matter to be used on envelopes, and other printed matter to be used on mail content to be included in the envelopes. The content pages are rectangular in shape and may be oriented relative to the envelope sheets in a number of different configurations. In some configurations, two sets of content pages and / or envelope sheets can be printed across the width of the web. The method starts with cutting consecutive sections of the web into separated sheets. Some of the separated sheets are envelope sheets including envelope printed matter, and some of the sheets are mail content sheets including mail content printed matter. The method includes cutting variable sized sheets depending on whether a sheet is a mail content sheet, or an envelope sheet. The method further includes cutting variable sized envelope sheets depending on the size of the mailpieces. In a preferred embodiment, the web includes business return envelopes (BREs). The BRE sheets are transported to an envelope creation path and in the envelope creation path where the sheets are formed into envelopes. The envelope creation path is then merged back with a content processing path whereby finished BRE's are stacked with their respective accumulations of folded content sheets to form a complete content stack. BRE's are then enclosed with the content sheets by the enclosing envelope sheets.

Owner:DMT SOLUTIONS GLOBAL CORP

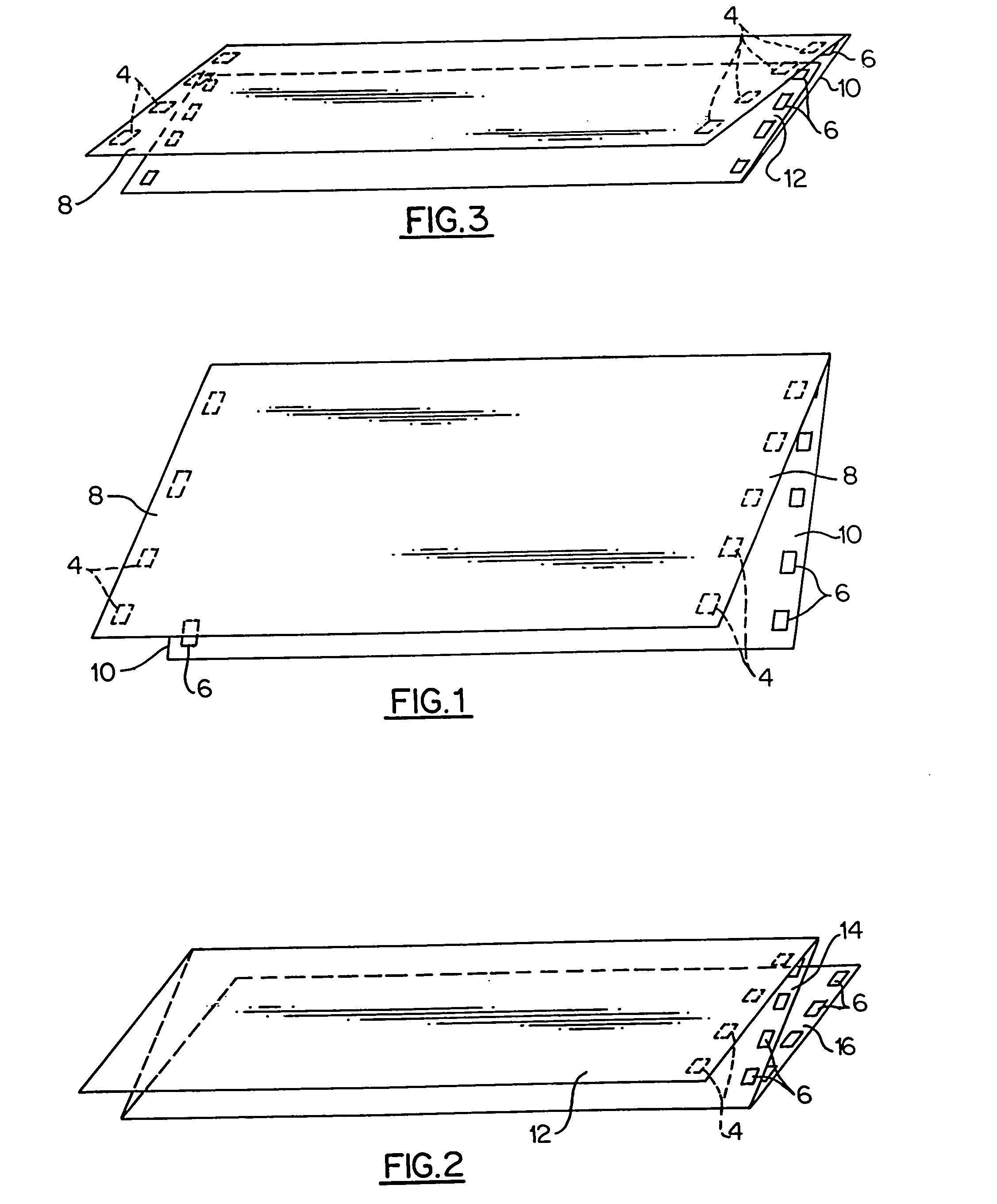

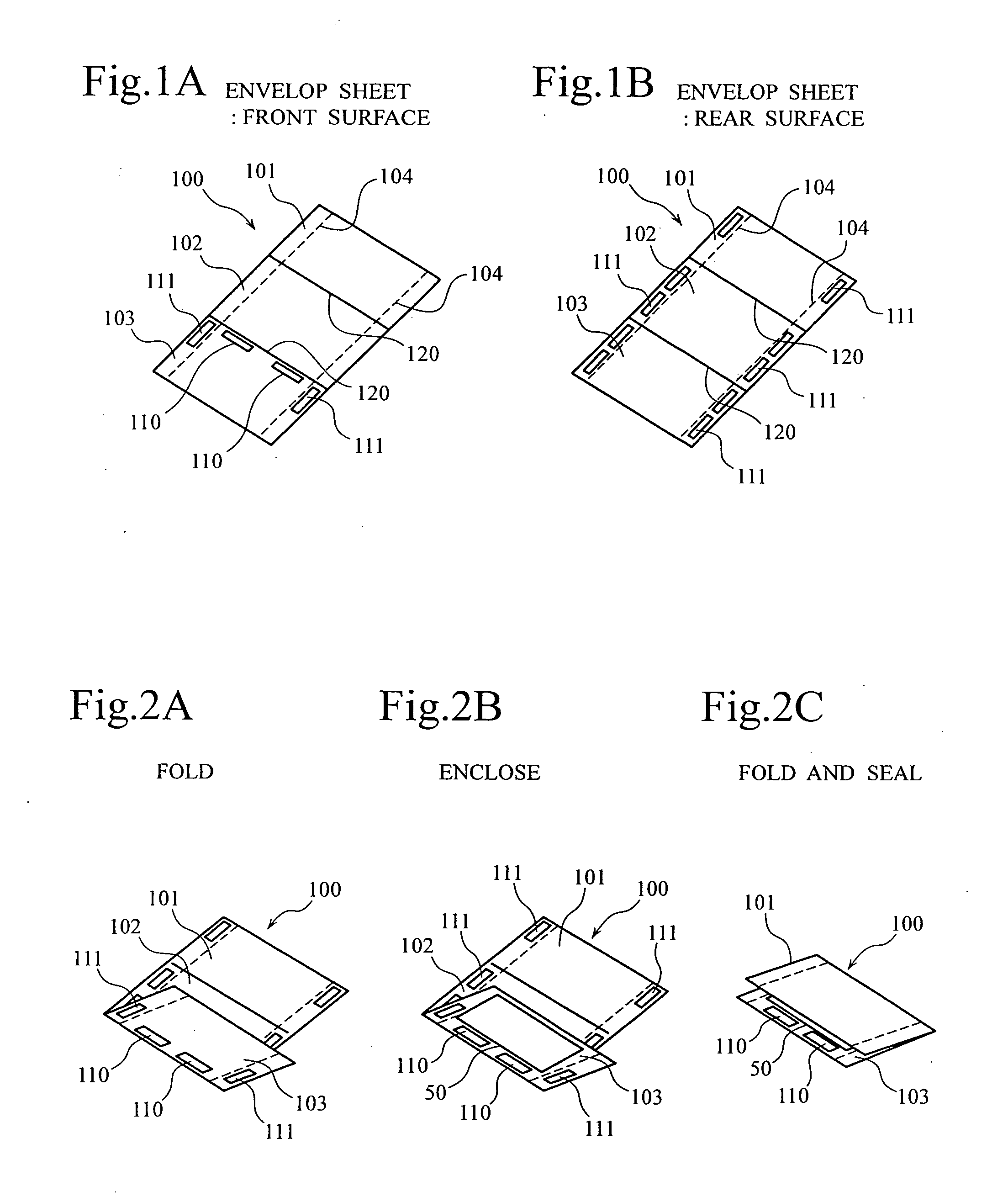

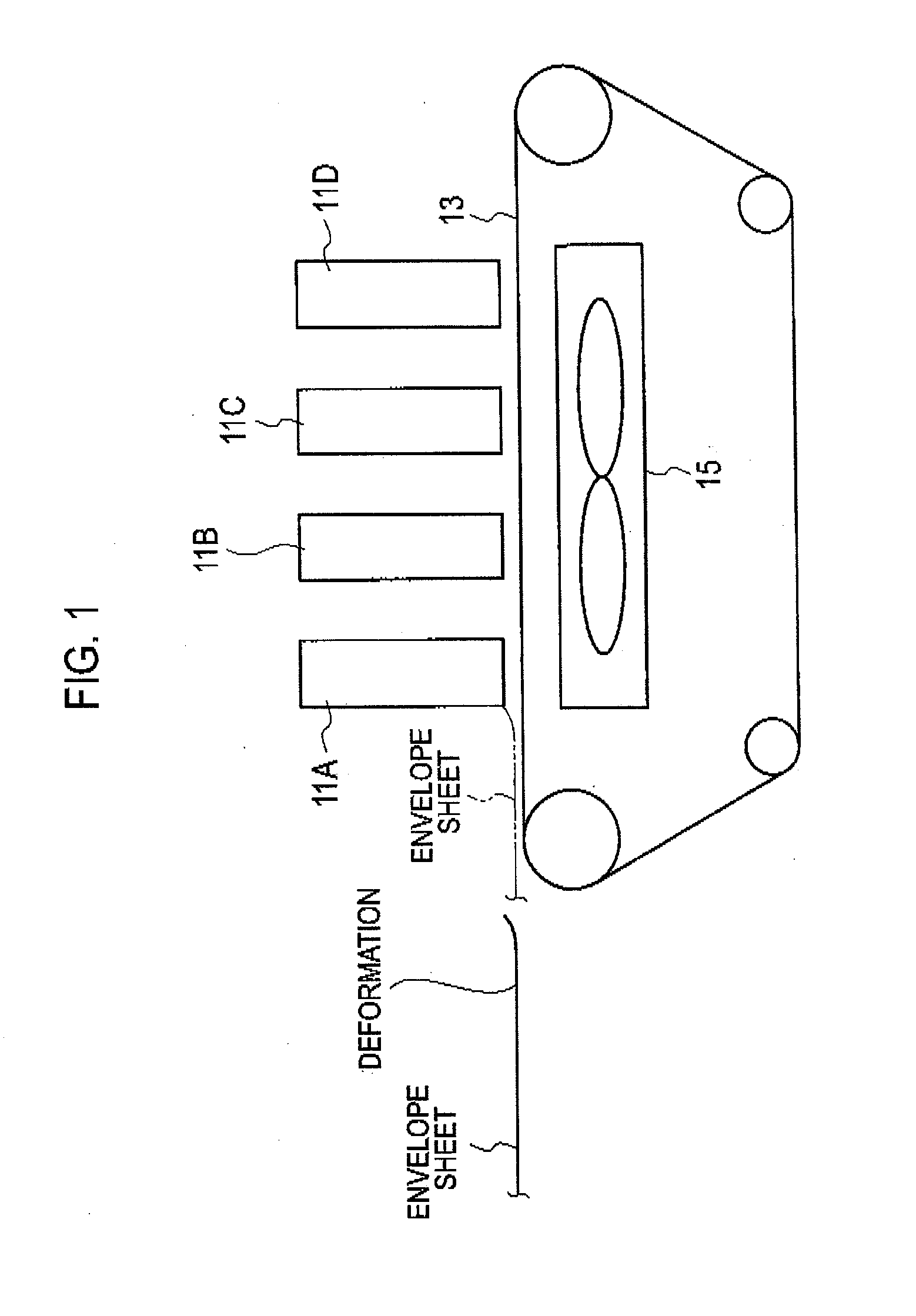

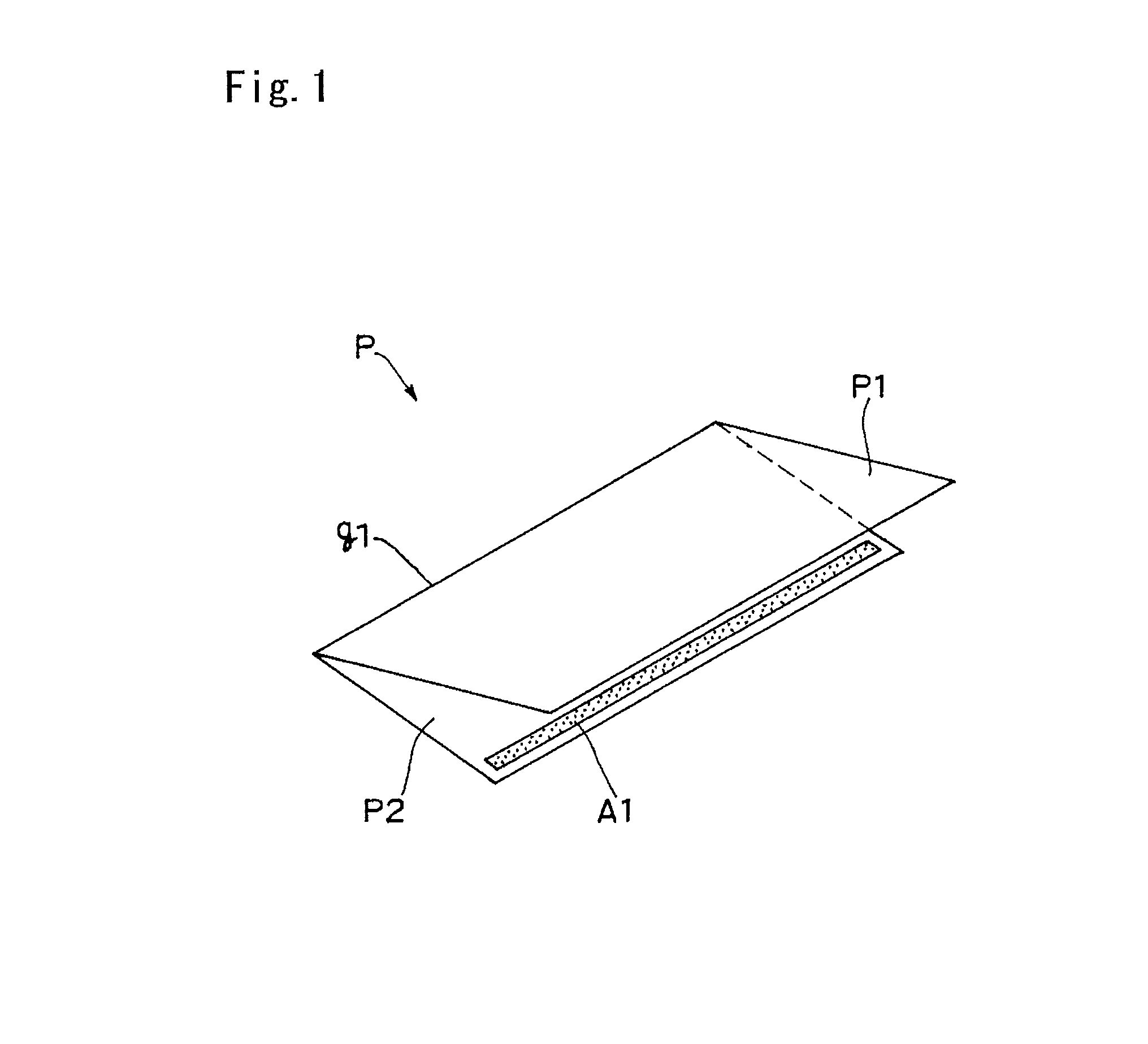

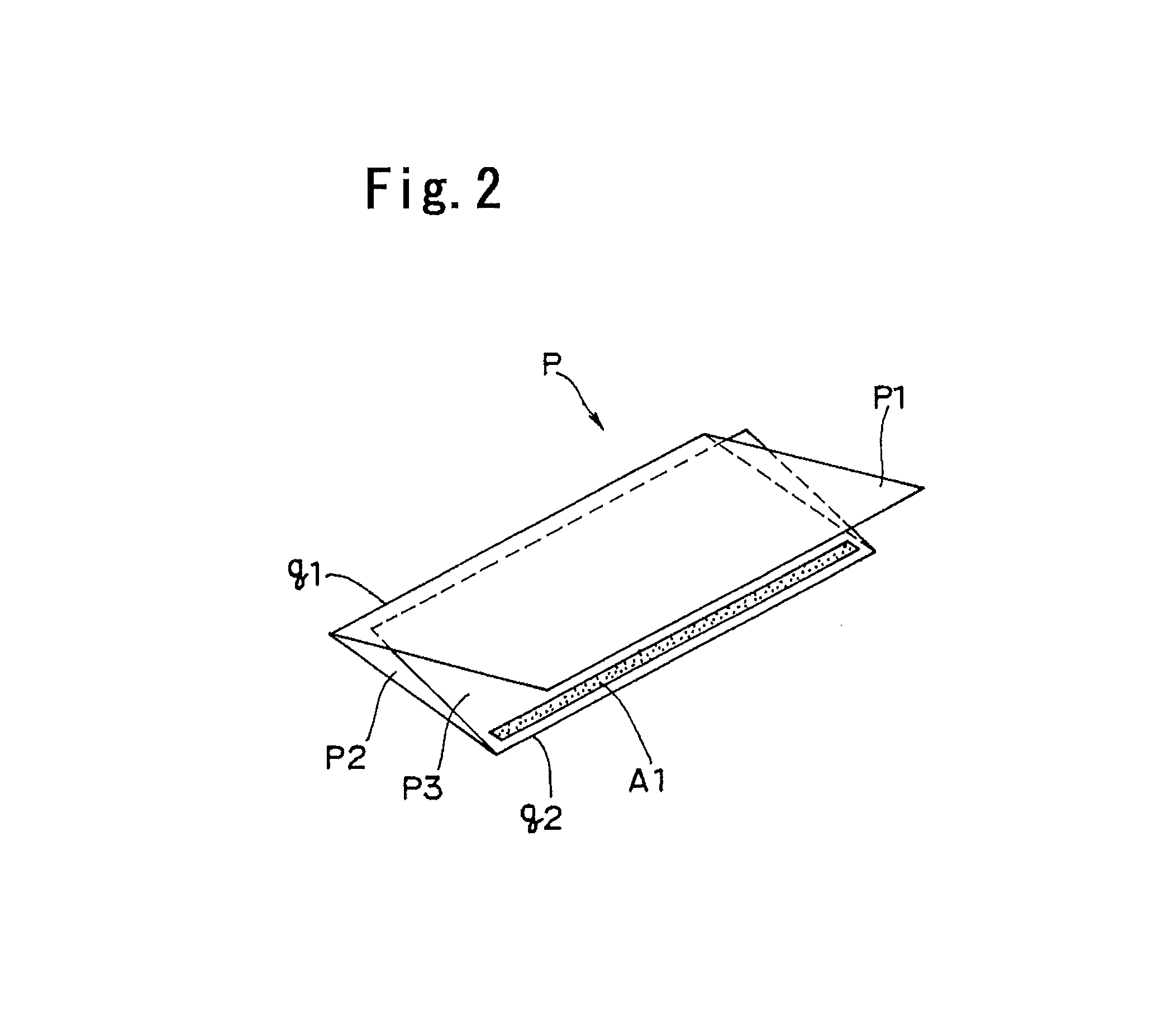

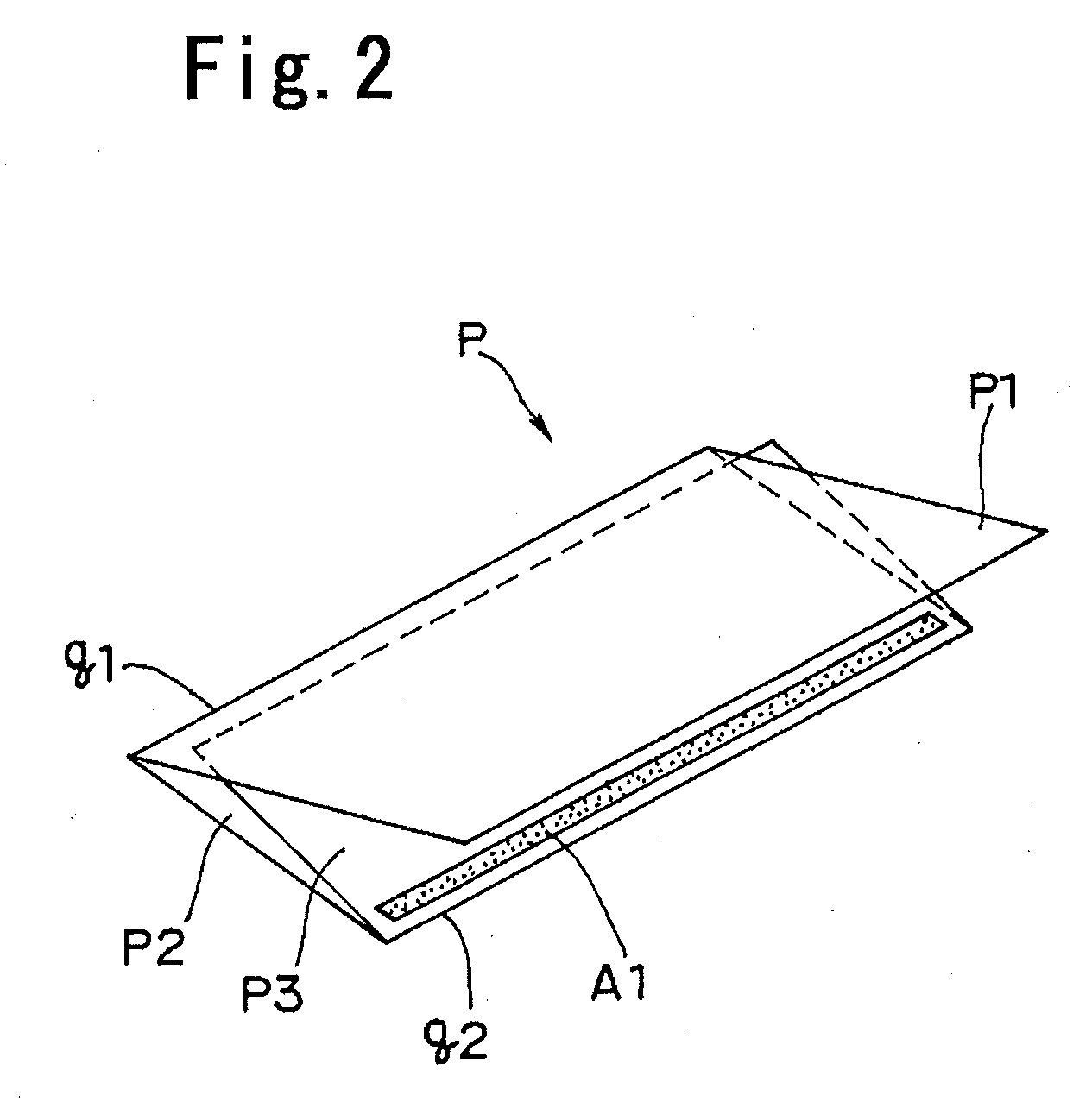

Envelope sheet

ActiveUS20130206824A1Correction of deformationReduce stiffnessEnvelopesEnvelope closersPaper sheetCoating

Another coating part is formed along a sheet short side direction, on a region which is a part of an envelope outer side of a third component sheet and which contacts a flap by folding along a second folding line. A first cutout part and a second cutout part which respectively extend in an extension direction of a first coating part and a second coating part, are respectively formed on both side fringes in the sheet short side direction in the third component sheet. The minimum width of each of the first cutout part and the second cutout part in the sheet short side direction is set longer than a length from the side fringe of the envelope sheet in the sheet short side direction to the inner side fringe of each of the first coating part and the second coating part.

Owner:RISO KAGAKU CORP

Method and system for creating mailpieces from a single continuous web of printed material

ActiveUS20060186592A1Simple processImprove reliabilityEnvelopes/bags making machineryBag making operationsEngineeringContent page

A method for creating mailpieces from a single web of printed material. The web of printed material includes a continuous web having a width and a length, the length comprised of a series of attached sheets. The series of attached sheets is comprised of envelope sheets and content pages. The content pages are rectangular in shape and may be oriented relative to the envelope sheets in a number of different configurations. In some configurations, two sets of content pages and / or envelope sheets can be printed across the width of the web. The method starts with cutting consecutive attached sheets into separated sheets. The content pages belonging to a same mailpiece are accumulated together. The separated envelope sheet is transported, bypassing the accumulating and turning steps. The accumulated and turned content pages are then merged with the envelope sheet, and the envelope sheet is folded and closed around the accumulated content pages to form a finished enclosing envelope.

Owner:DMT SOLUTIONS GLOBAL CORP

Envelope sealing apparatus

InactiveUS6948540B2Controlling laminationAdhesive processes with surface pretreatmentAdhesiveControl system

Owner:PITNEY BOWES INC

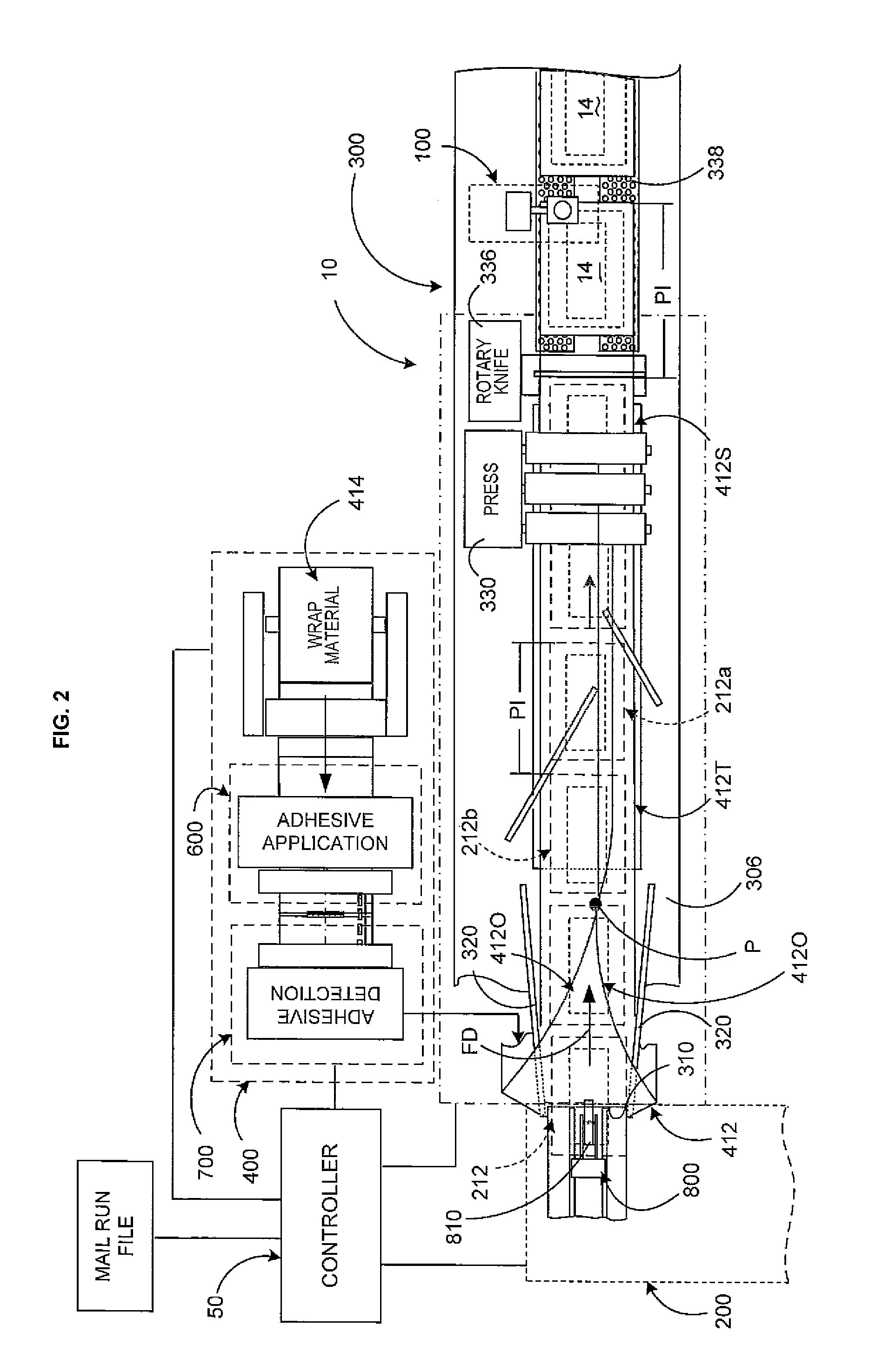

System and method for ensuring cutting accuracy in a mailpiece wrapper

ActiveUS20150174848A1Wrapping material feeding apparatusBox making operationsEngineeringMechanical engineering

An improved mailpiece fabrication system assembles finished mailpieces from content materials and from wrapping materials. The wrapping materials include printed cut quality marks at predetermined positions relative to cut lines. Content materials are placed on the continuous web. The continuous web is then folded and sealed around the content materials to form a continuous tube enclosing the content materials. A cutter downstream of the conveyance deck cuts individual envelopes from the continuous tube of folded wrapping material. A downstream imaging device captures image data indicative of a cut quality mark on the individual envelopes. A controller receives the captured image data from the imaging device and compares an actual dimension of an imaged cut quality mark with an expected dimension of a cut quality mark. An error signal is produced if the difference is not within a predetermined tolerance.

Owner:DMT SOLUTIONS GLOBAL CORP

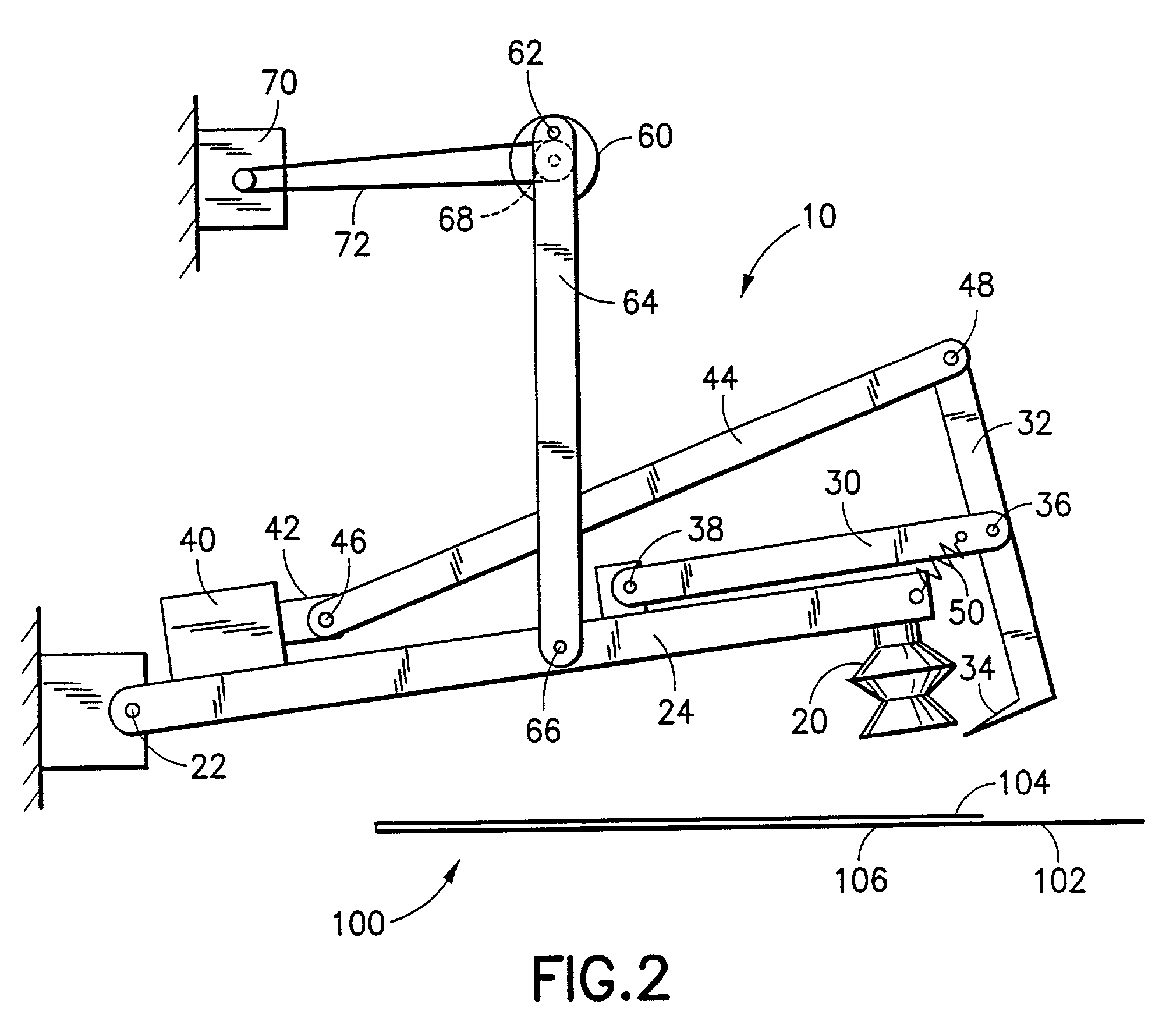

Method and device for maintaining the opening position of an envelope

A device to lift a throat of an envelope to spread open the envelope. The device comprises a suction cup mounted to a pitching arm; a hook movably mounted adjacent to the suction cup; means for lowering the pitching arm to allow the suction cup to seal with the throat with a suction force, and raising the pitching arm to allow the suction cup to lift the throat; and an actuation device for placing the hook under the throat after the throat has been lifted by the suction cup so as to mechanically maintain the lifted position of the throat. Accordingly, the method of maintaining the lifted position of a throat includes the steps of: 1) positioning the suction cup over the throat; 2) pressing the suction cup against the throat to seal with the throat; 3) raising the suction cup to lift the throat; and 4) placing the hook under the lifted throat to mechanically maintain the lifted position of the throat. It is preferred that the suction force can be provided by a vacuum pump, and preferably a piston operated vacuum pump.

Owner:PITNEY BOWES INC

Apparatus and method for inserting documents into envelopes

InactiveUS6038835AReserve is fewShort fillWrappingWrapper twisting/gatheringEngineeringDocumentation

In an inserting apparatus an envelope holder comprises a first envelope support connecting to a document feed path, for holding an envelope in a filling position in or against a first surface, and a second envelope support connecting to an envelope discharge path, for carrying another envelope in or against a second surface and in an overlapping relation with an envelope simultaneously held in the filling position. Also described is a method in which an envelope to be filled is brought into the filling position before the preceding, filled envelope has left a feed-through path and this envelope brought into the filling position temporarily overlaps the filled envelope. The proposed apparatus and method enable an increased processing capacity.

Owner:NEOPOST

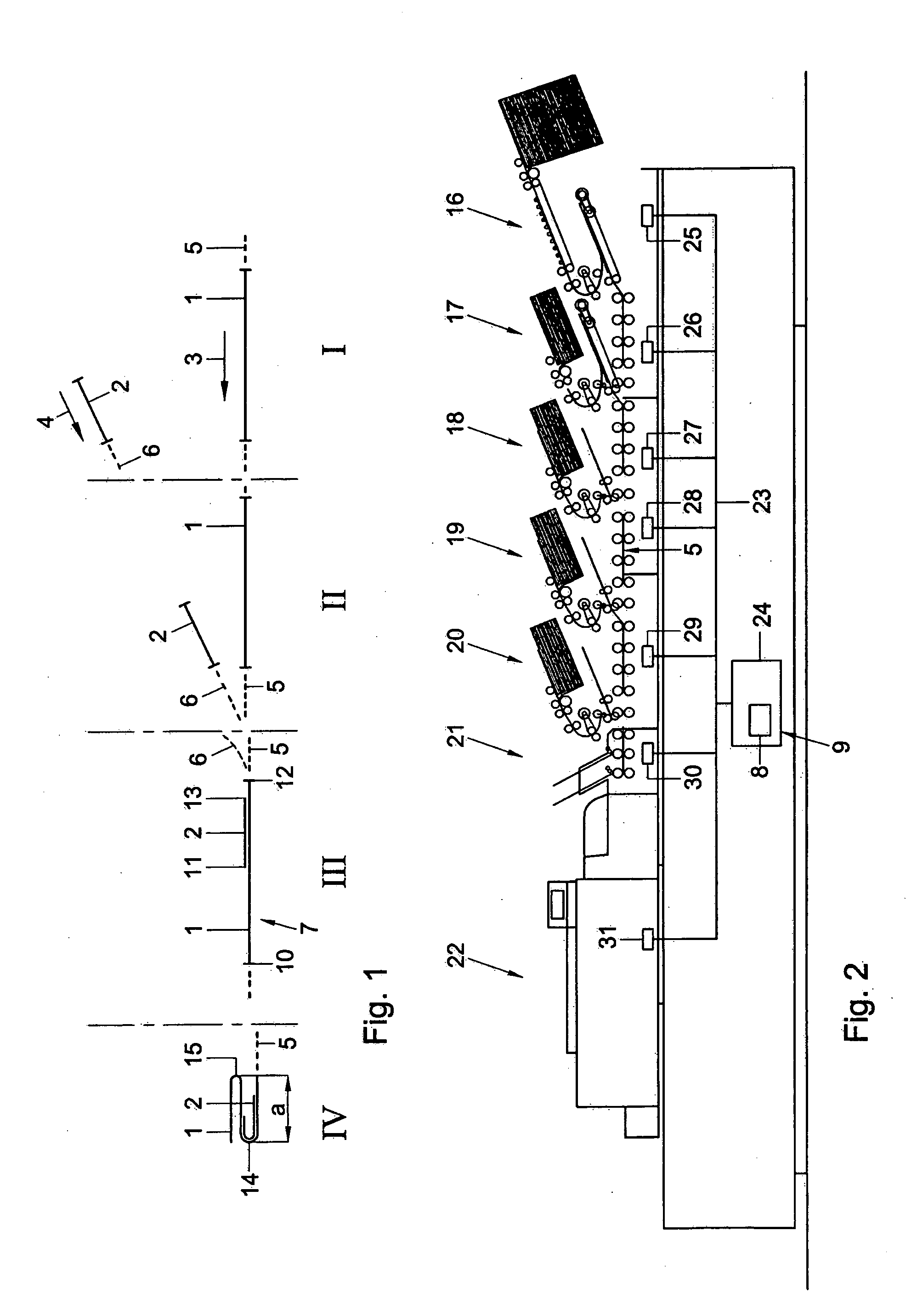

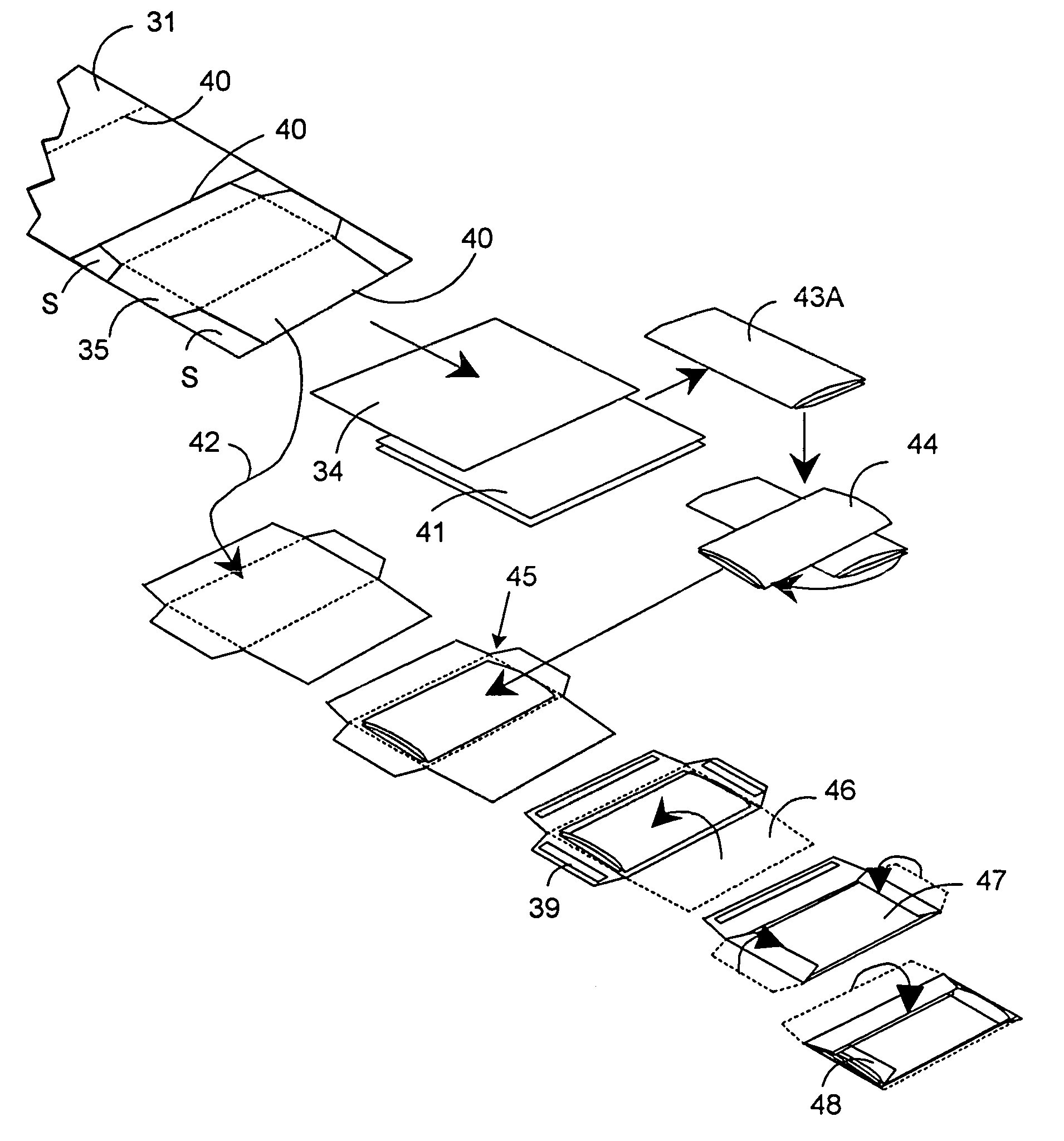

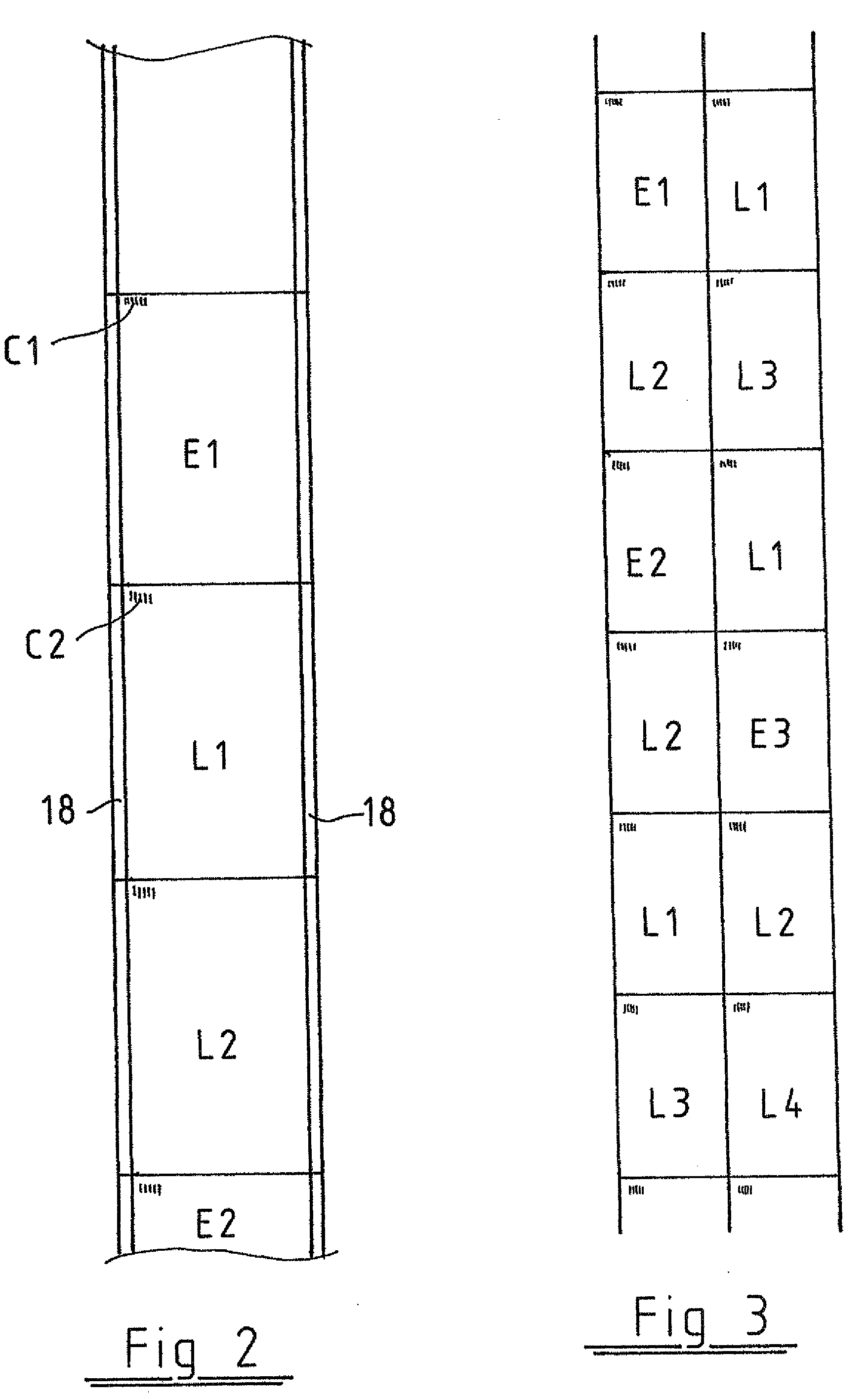

Method for forming individual letters provided with envelopes

InactiveUS20090282783A1Quick and reliableReduce wasteWrappingLiquid materialLetteringBiomedical engineering

The invention relates to a method for forming individual letters provided with envelopes from printed same-size sheets, comprising pre-printed envelope forms for forming the envelopes, and in the immediate vicinity of each envelope form one or more letter forms for forming a letter or letters and inserting them in the envelope. In accordance with the invention, the envelope form is led as such to envelope formation; the letter forms are cut at least on one side into letters which are smaller than the letter forms; the letters are brought to contact with the envelop form; the envelope form is folded in two around the letters and glued at the side edges to form an open envelope; and the open flap of the envelope is glued and folded so that a sealed letter provided with an envelope is formed.

Owner:MSH FINLAND

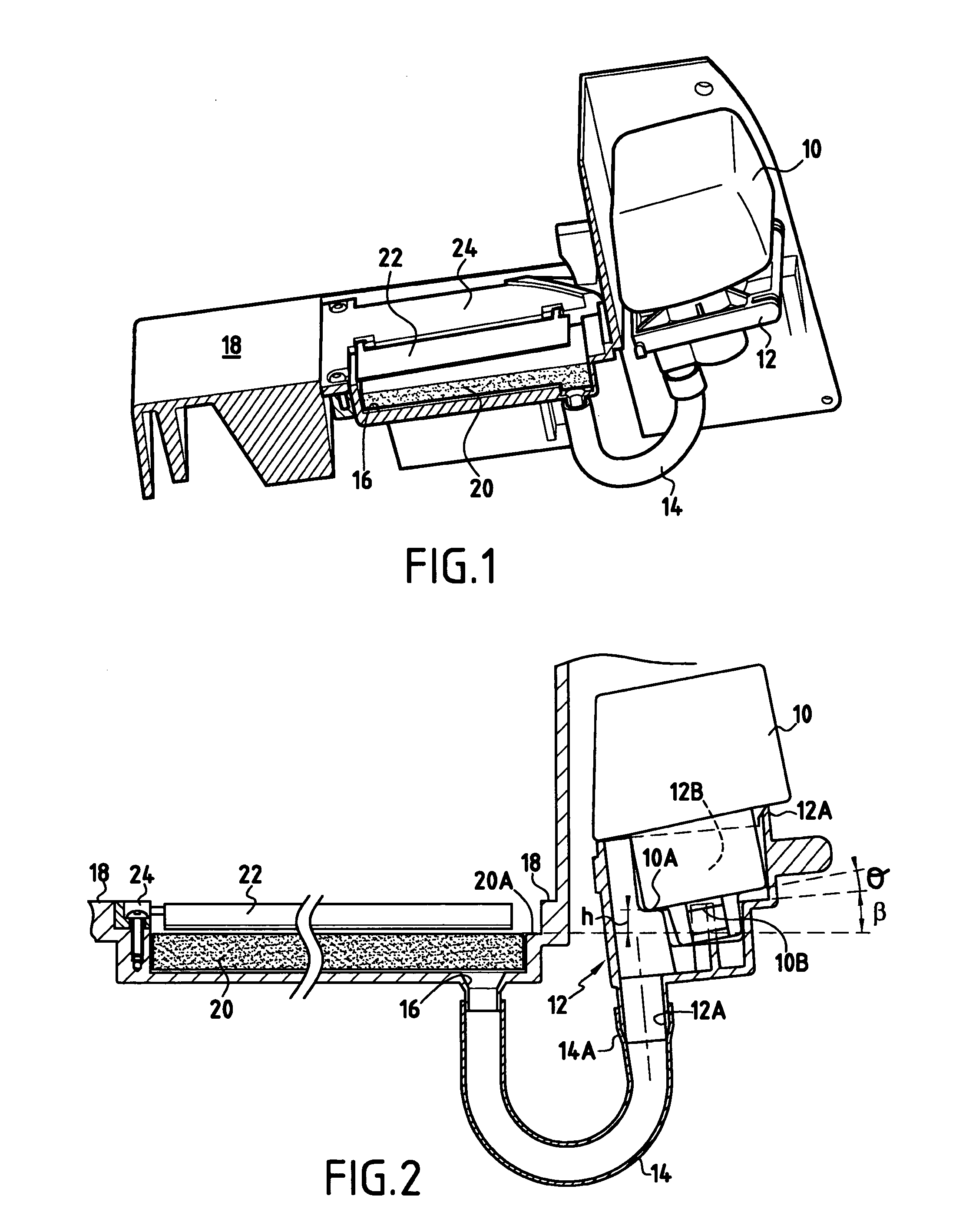

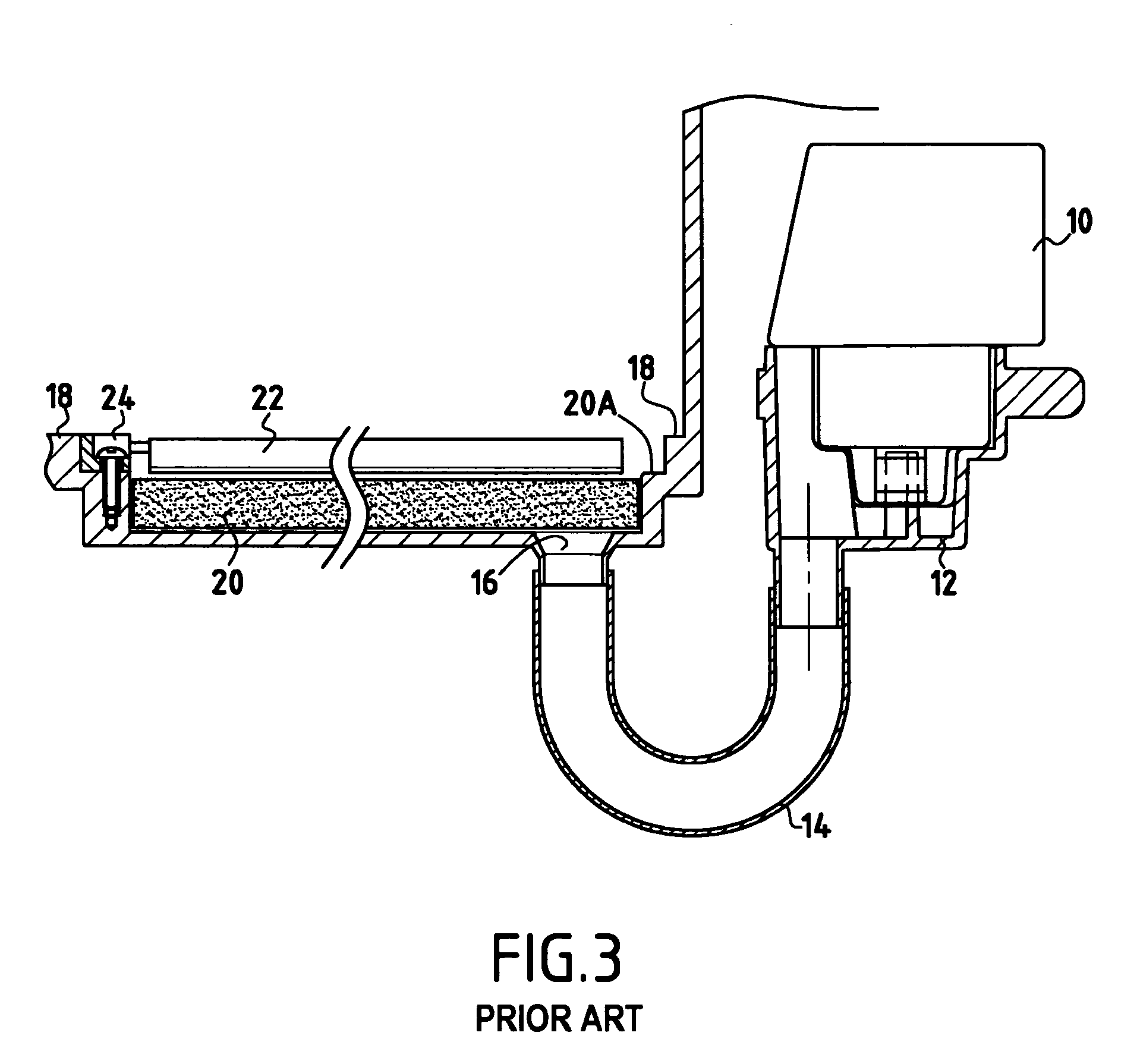

Water feed device for a moistener of a mail handling machine

InactiveUS7364621B2Mitigate such drawbackWithout significantly altering the current structure of mail handling machinesLiquid surface applicatorsManual label dispensersWater flowWater reservoir

A water feed device for feeding water to a moistener for moistening envelope flaps, which moistener is incorporated into a mail handling machine, the water feed device including a water tank which is mounted on a support and from which a quantity of water flows through a water feed pipe to a water reservoir in which part of a piece of foam is dipped, the quantity of water serving to impregnate the piece of foam for moistening the envelope flaps as they pass between a top surface of the piece of foam and a moistener brush, the water tank support being tilted at a determined angle β relative to a horizontal reference plane, and the water tank itself being tilted at a determined angle θ relative to the water tank support.

Owner:NEOPOST TECH SA

Apparatus and method for moistening envelope flaps

InactiveUS20090252870A1Reliably seal envelopesSufficient amountCoatingsSpecial surfacesBiomedical engineeringSkin flap

An apparatus for moistening flaps of envelopes has a liquid dispenser for dispensing liquid to the envelope flap of each envelope to be moistened. A liquid sensor is provided for sensing liquid carried by the dispenser and generating a humidity signal indicating an amount of the liquid held by the dispenser. A method for moistening flaps of envelopes is also described.

Owner:NEOPOST TECH SA

Apparatus and method for sealing paper with paste

ActiveUS8152152B2Easy to checkSwiftly sealing an open endFranking apparatusArticle feedersAdhesiveEngineering

Owner:DUPLO SEIKO CORP

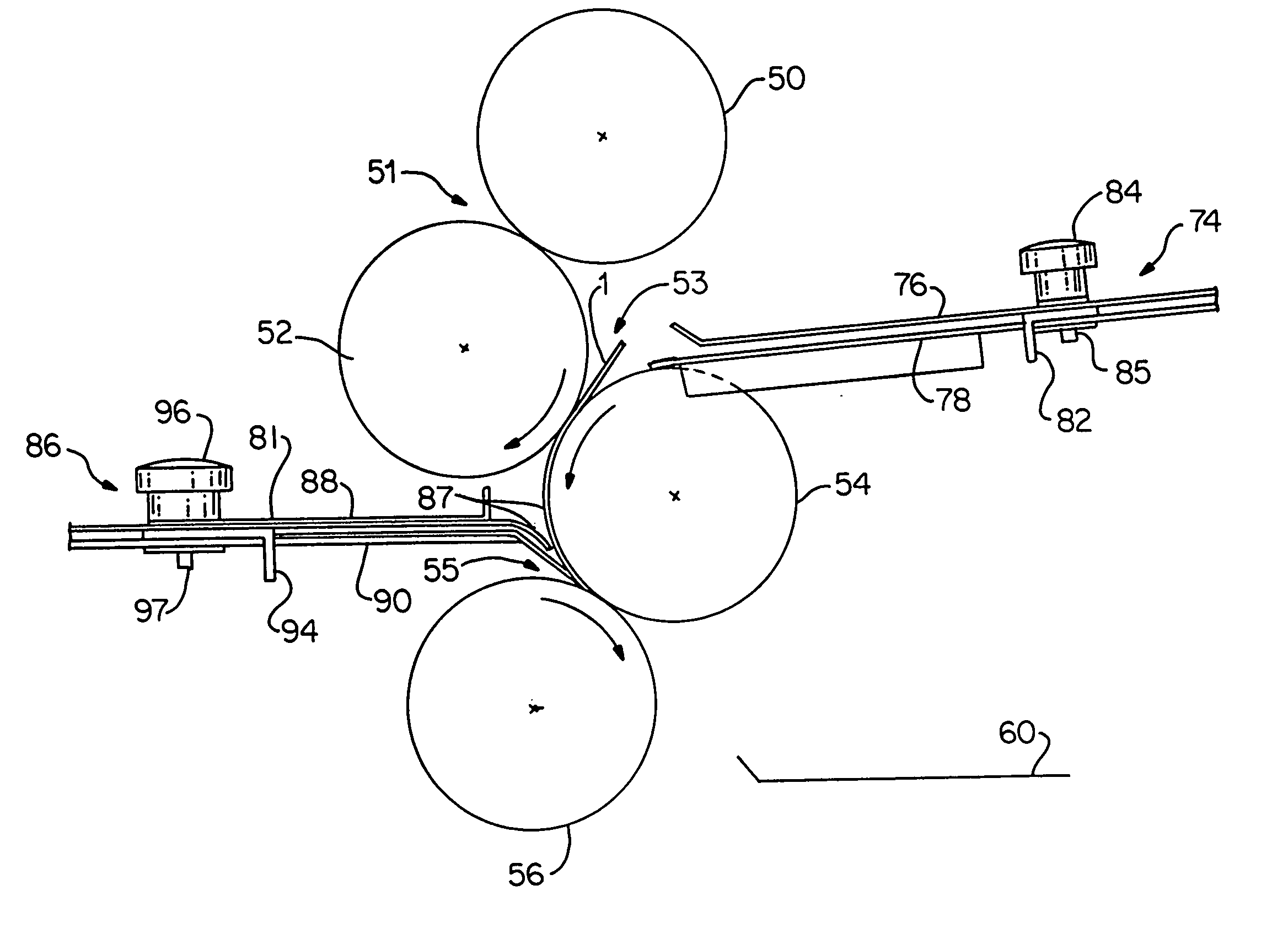

Pressure sealer apparatus

InactiveUS7018507B2Prevent system shutdownMeet needsMechanical working/deformationAdhesivesFree rotationPulp and paper industry

Owner:PRINTMAIL SOLUTIONS

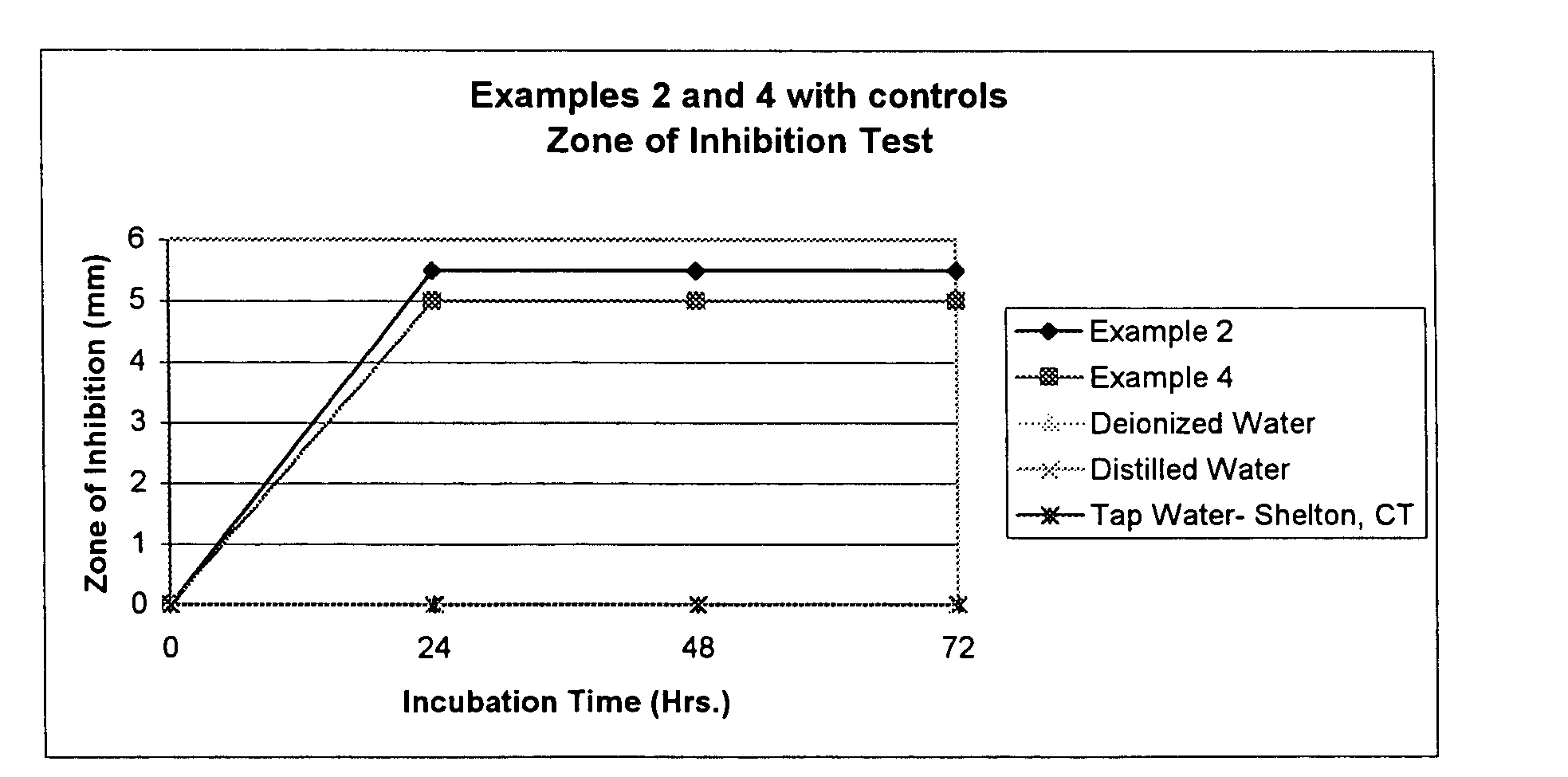

Moistening fluids that destroy and/or inhibit the growth of biological organisms

InactiveUS20060124246A1Destroys their abilityImprove abilitiesBacterial antigen ingredientsLavatory sanitoryAdhesiveFungal microorganisms

Moistening fluids are disclosed that are capable of being used in mail processing machines and systems. Mail processing equipment can automatically feed and moisten envelopes at slow to very high speeds of 30 inches per second. The moistening system becomes contaminated with paper dust, talc, and common envelope adhesives. The moistening fluids kill many types of bacteria, fungi, and inhibit the growth of other types of bacteria, fungi, and algae. The moistening fluids of this invention are safe for use in an office environment, i.e., they are non-toxic and non-flammable and may be transported by common carriers without any safety precautions. The moistening fluid contains: detergent, biocide, alcohol, dye and distilled water.

Owner:PITNEY BOWES INC

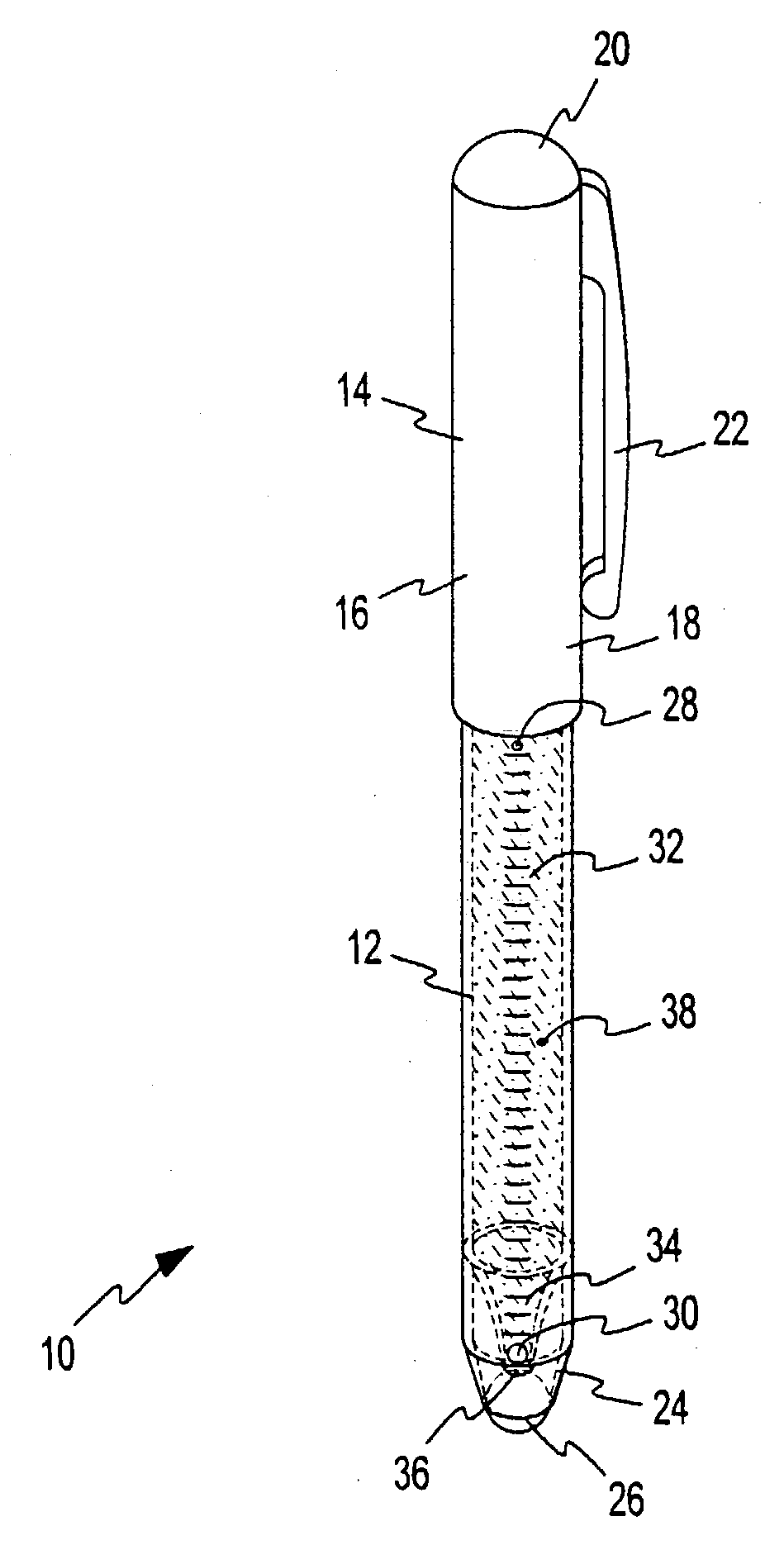

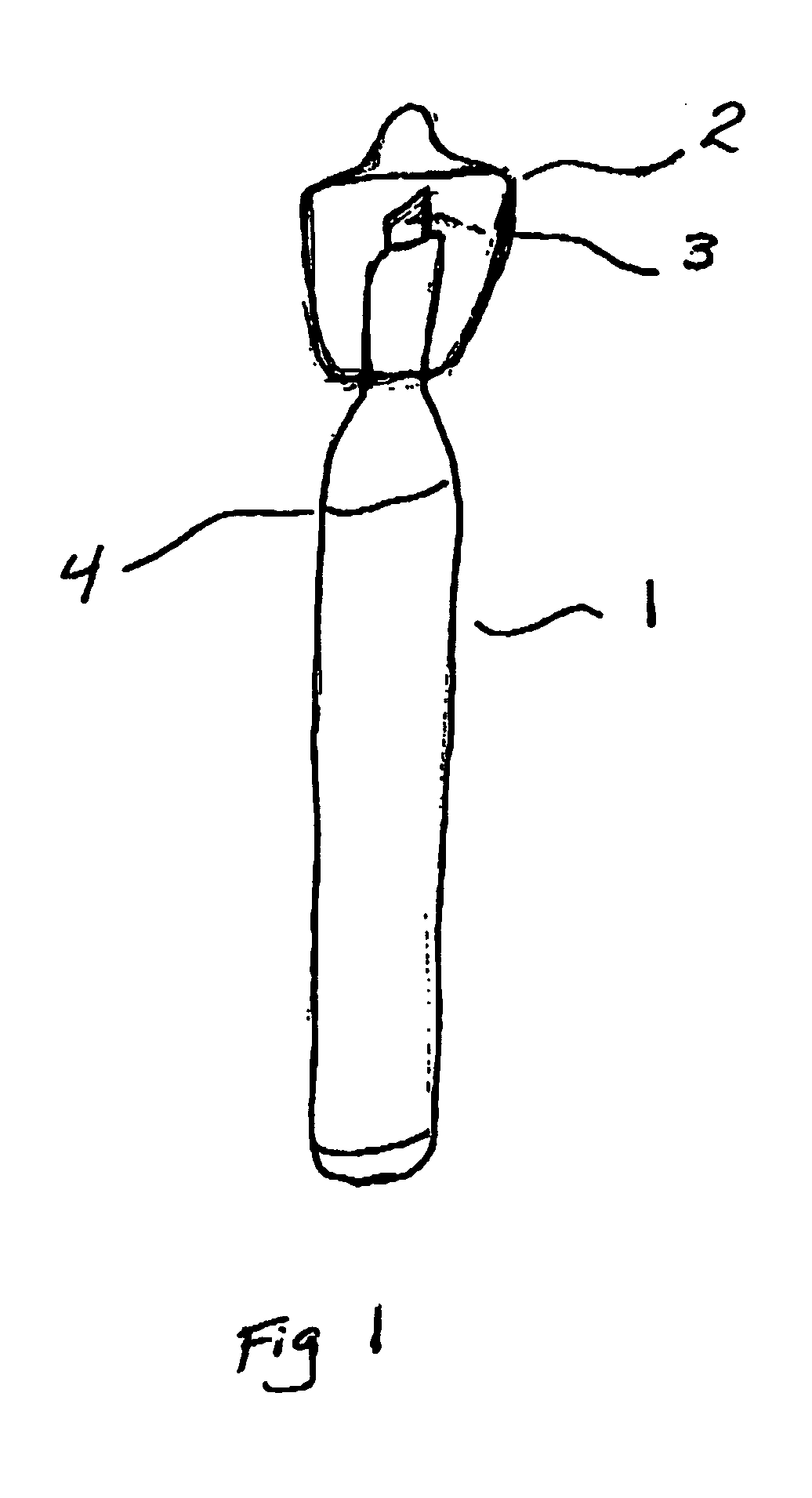

Applicator pen

InactiveUS7179008B2Economical to acquire and manufactureEasy to manufactureWriting connectorsBall-point pensAdhesiveHand held

A device for applying liquid adhesive to seal a variety of parcel post items such as, containers, packages, boxes, envelopes and stamps. The device includes a hand-held pen-shaped housing having a roller ball therein for dispensing the adhesive. The device further includes a vent and a drain hole in the housing.

Owner:HOLCOMB DAVID L

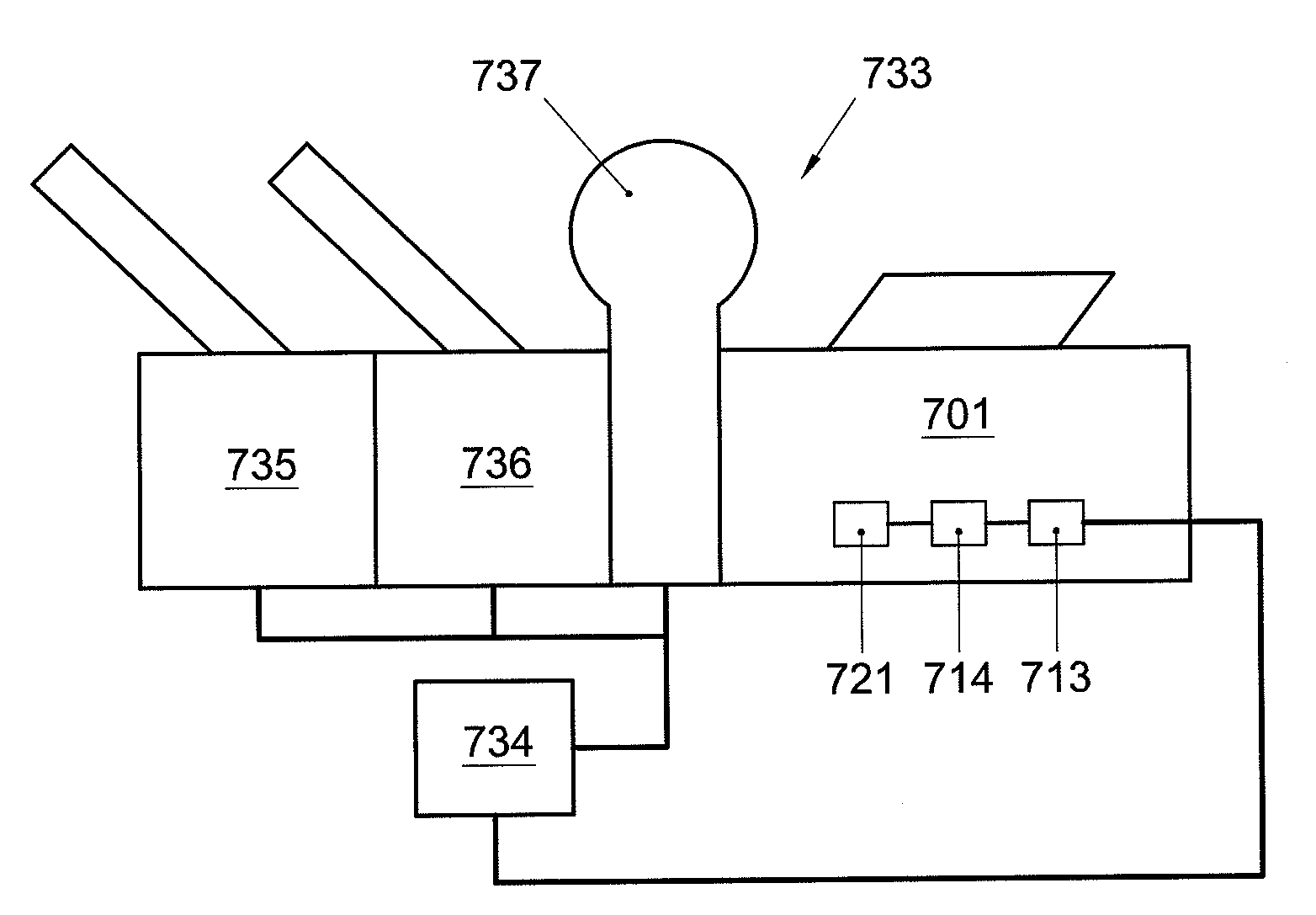

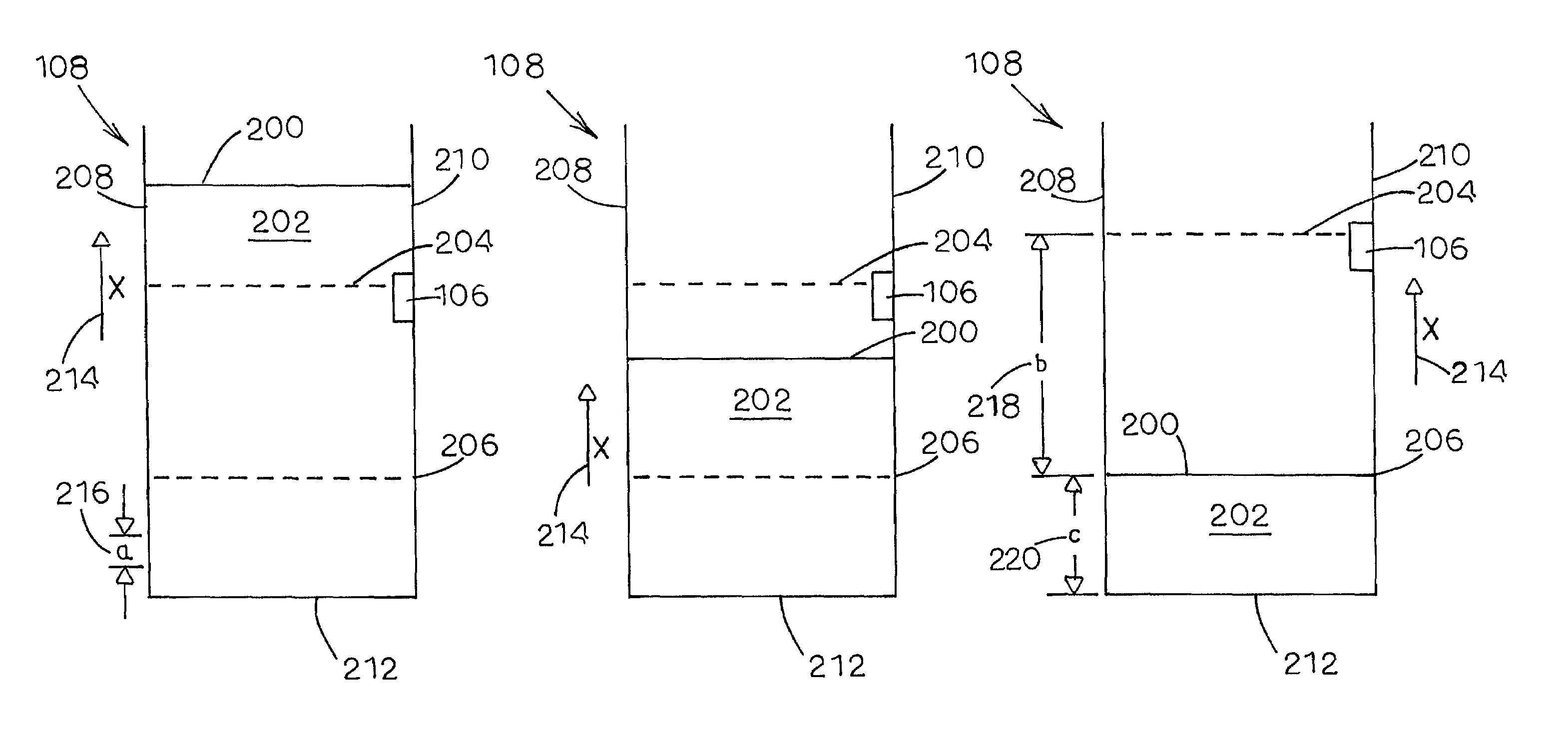

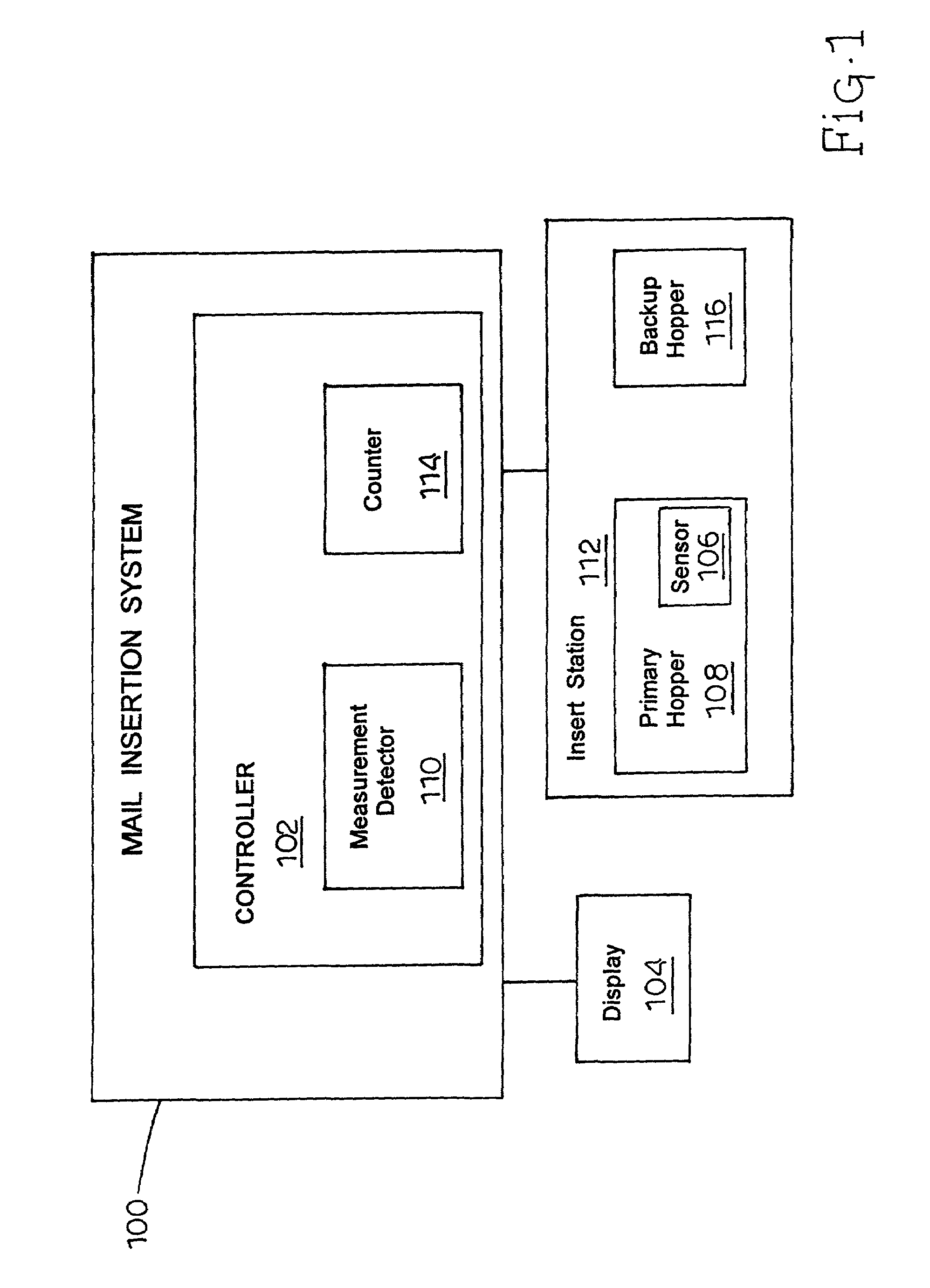

System and method for monitoring grouped resources

System and method for monitoring grouped resources. A system and method of monitoring resource units in a stack is provided. The system and method includes providing a group of resource units and determining a thickness of one or more of the resource units. The system and method also includes indicating when the group of resource units reaches a predetermined size after one or more of the resource units has been moved from the group.

Owner:BELL & HOWELL CO

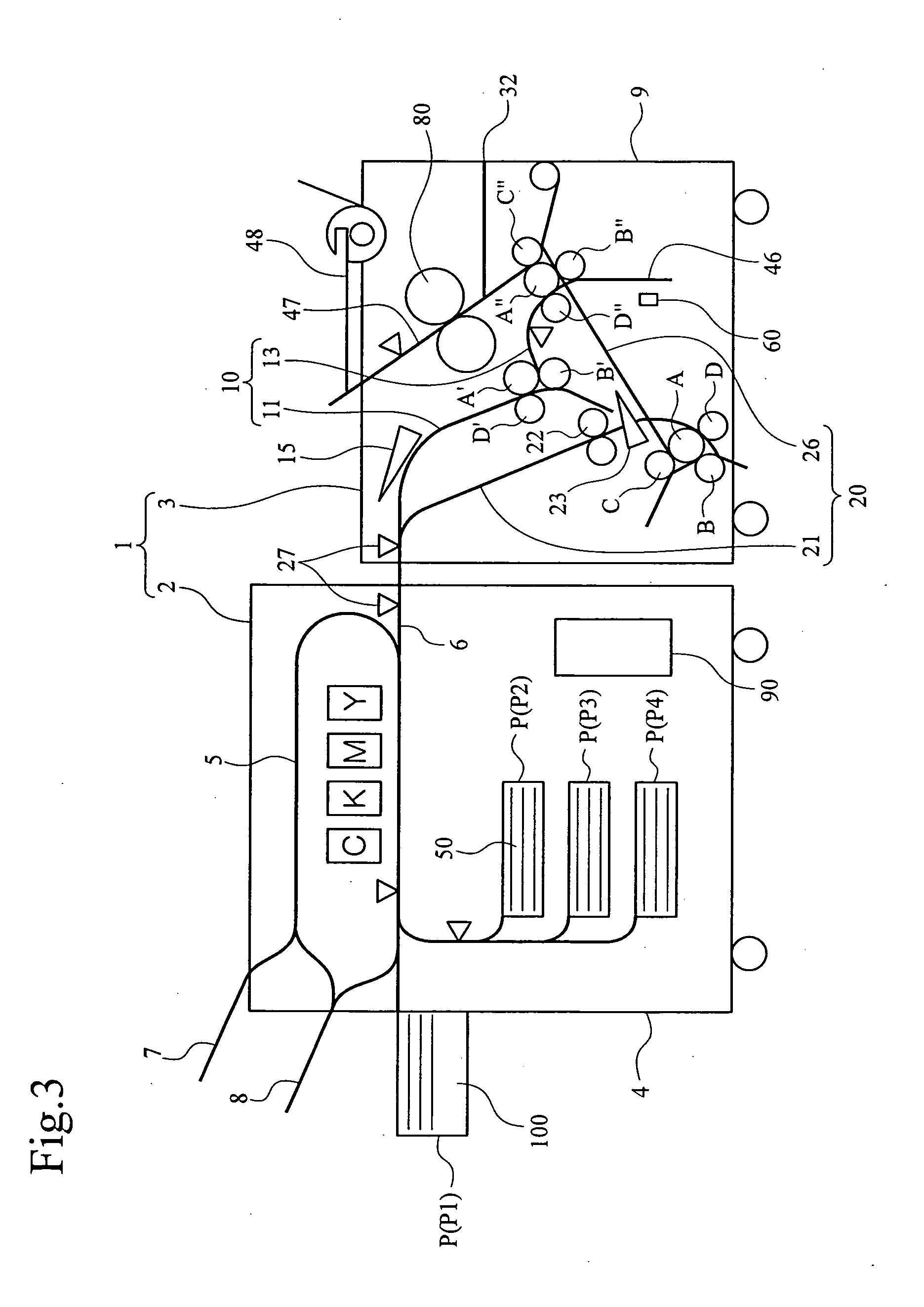

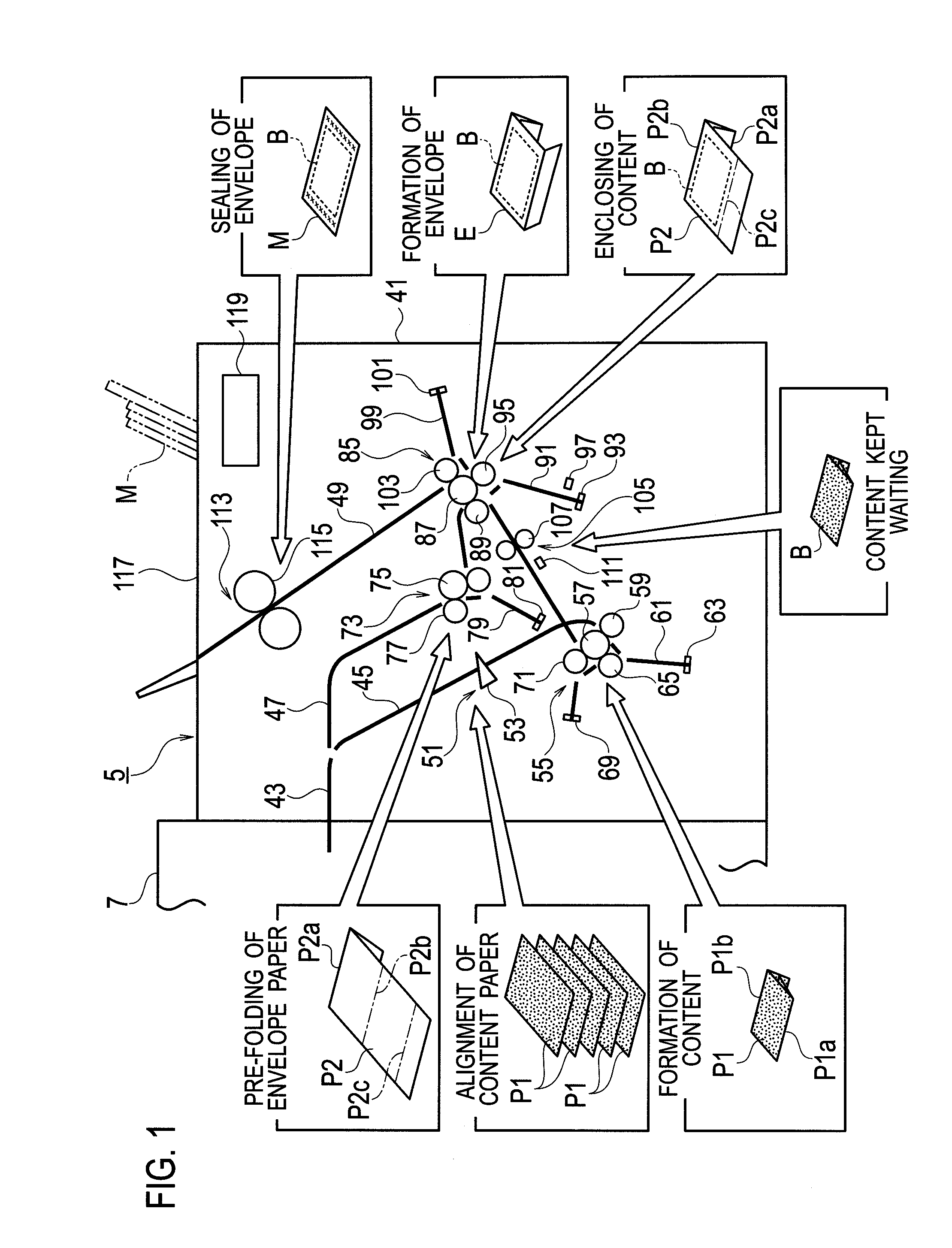

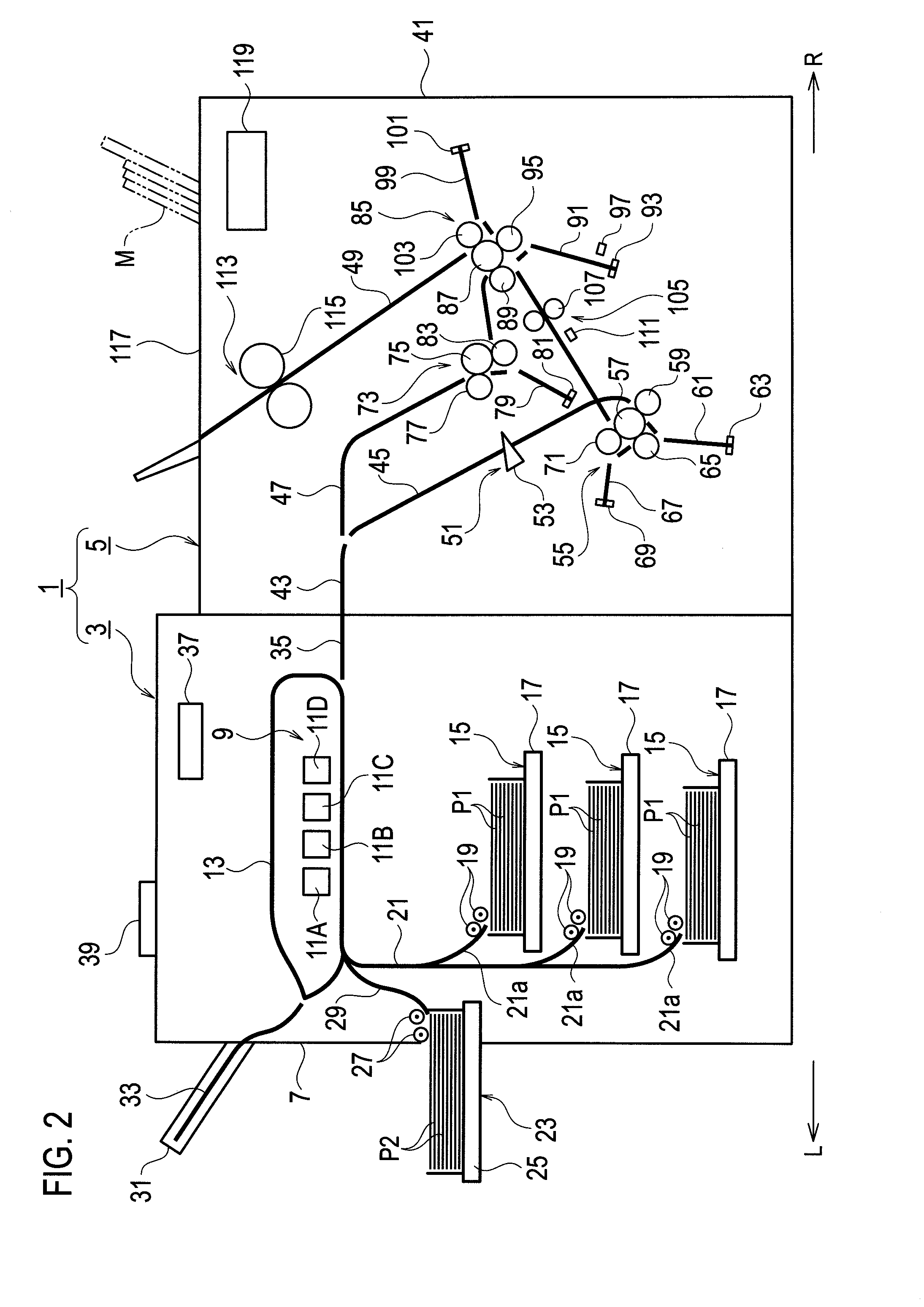

Enclosing-sealing device and image formation system having the same

ActiveUS20120159899A1Suppress degradation of folding qualityAvoid failurePackaging cigaretteWrapper folding/bending apparatusImage formationEngineering

An enclosing-sealing device for preparing a sealed matter by sealing an envelope with a content enclosed in the envelope includes a content formation unit, an envelope formation unit, a content delivery unit, a seal unit, a delivery timing determiner, and a delivery controller. The content delivery unit delivers the content delivered from the content formation unit to the envelope formation unit such that the content is enclosed in a sheet of envelope paper while being folded. The seal unit seals the envelope delivered from the envelope formation unit with the content enclosed in the envelope. The delivery timing determiner determines a delivery timing of the content by the content delivery unit based on inputted information about at least one of the content and the envelope. The delivery controller controls the content delivery unit to deliver the content to the envelope formation unit in accordance with the determined delivery timing.

Owner:RISO KAGAKU CORP

Fragranted moistening fluids that destroy and/or inhibit the growth of biological organisms while minimizing a tacky build up

Moistening fluids are disclosed that are capable of being used in mail processing machines and systems. Mail processing equipment can automatically feed and moisten envelopes at slow to very high speeds of 30 inches per second. The moistening system becomes contaminated with paper dust, talc, and common envelope adhesives. The moistening fluids kill many types of bacteria, fungi, and inhibit the growth of other types of bacteria, fungi, and algae. The moistening fluids of this invention are safe for use in an office environment, i.e., they are non-toxic, not tacky, have a pleasant odor, are non-flammable, have no residue build up and may be transported by common carriers without any safety precautions. The moistening fluid contains: detergent, biocide, alcohol, dye, de-ionized water and a fragrance.

Owner:PITNEY BOWES INC

Apparatus and method for sealing paper with paste

ActiveUS20110057377A1Easy to checkSwiftly sealing an open endFranking apparatusRotary pressesAdhesivePaper sheet

An apparatus for sealing paper with paste includes a paper-feeding unit, a pasting main body which seals open ends of a sheet of paper by an adhesive, and a paper-receiving unit on which the sealed sheets of paper are loaded. The pasting main body includes an opening mechanism which opens a closed sheet of paper, an adhesive applying mechanism which applies a peelable temporary adhesive in a streaky form to a lower folded piece of the opened sheet of paper, a sealing mechanism which superposes an upper folded piece on the lower folded piece, and which temporarily adheres the open ends of the upper and lower folded pieces, and a conveying mechanism.

Owner:DUPLO SEIKO CORP

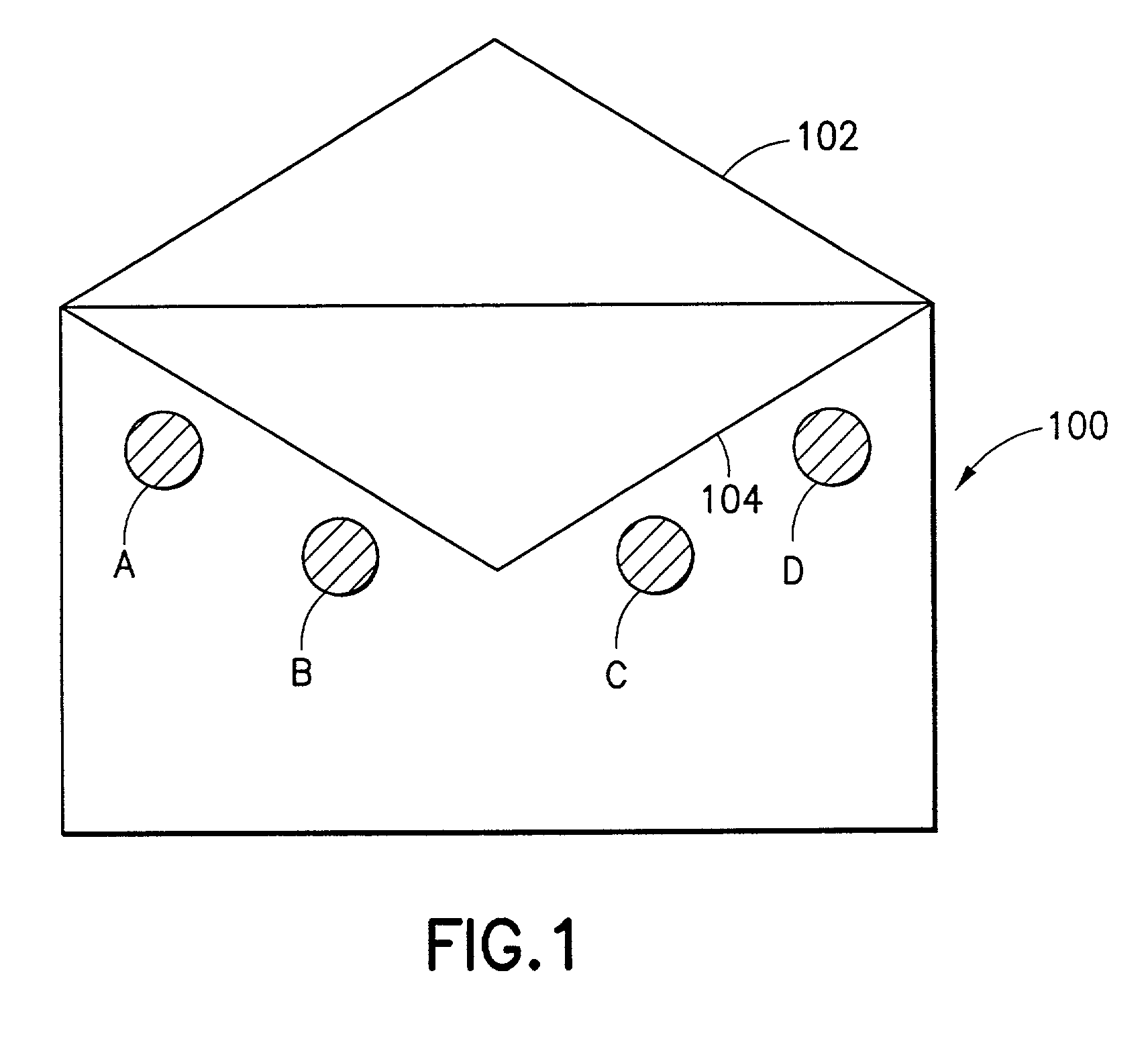

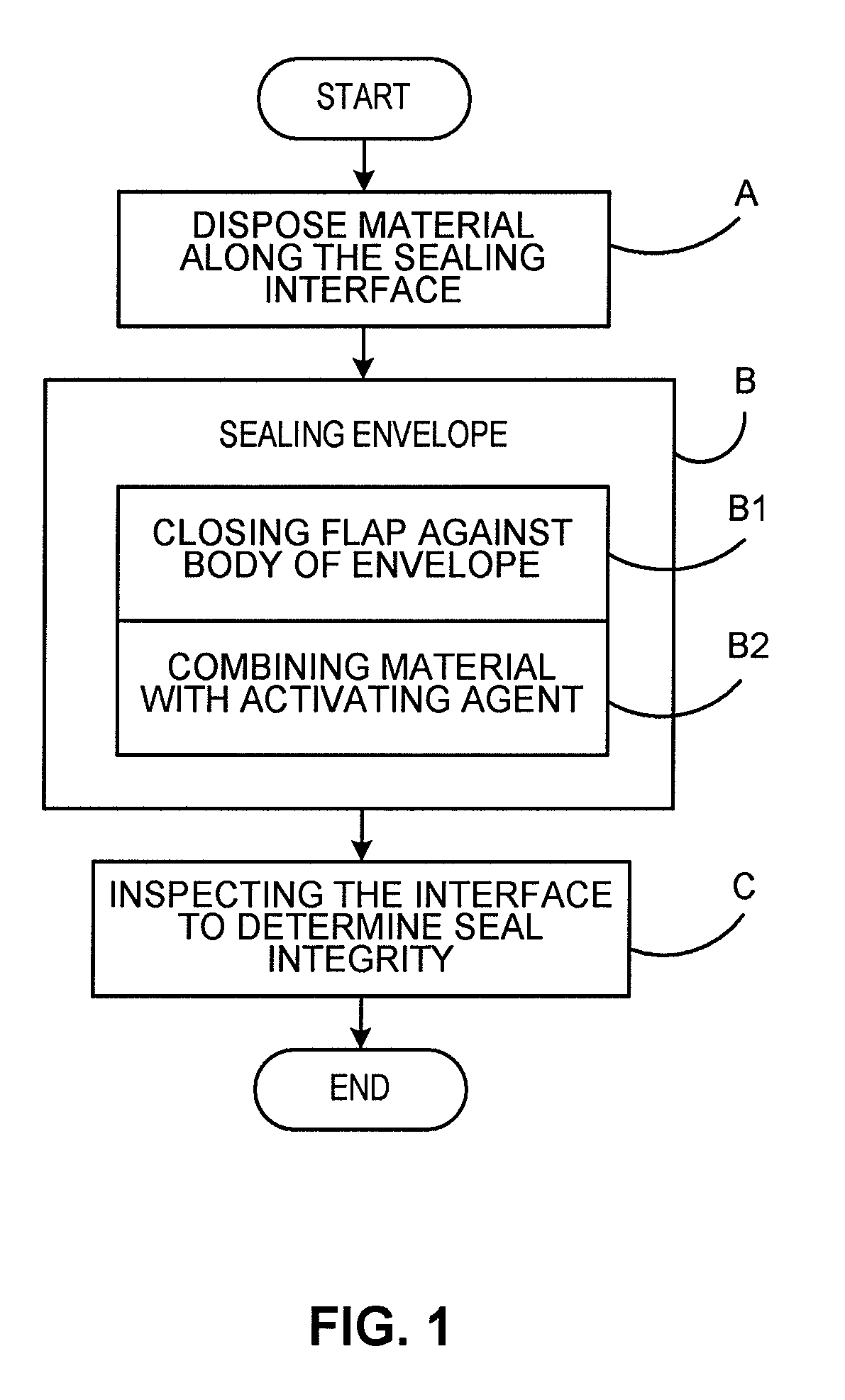

Method, system and article for producing a mailpiece envelope having improved seal integrity

InactiveUS20100089986A1Improves seal integrityEnvelopes/bags making machineryBag making operationsEngineeringMechanical engineering

A method, system and article for producing an envelope having improved seal integrity. The method comprises the steps of disposing at least one material at the interface of the adhesive seal between the flap and the body portion of the envelope, which material exhibits a characteristic property when combined with an activating agent. The envelope is then sealed by closing the flap onto the body portion of the envelope such that the activating agent combines with the material along the sealing interface. The sealing interface is inspected to determine whether the material exhibits the characteristic property thereby confirming that a seal has been produced between the flap and body portion of the envelope. The system and article are directed to the various modules of a mailpiece fabrication system employed to produce the mailpiece including an inspection module for confirming that a seal has been formed.

Owner:DMT SOLUTIONS GLOBAL CORP

Manually operated moistener for items with a water-activated glue

InactiveUS20060011303A1Easy maintenanceReduce evaporationAddressing machinesLiquid surface applicatorsEngineeringWater transfer

A manually-operated moistener, to which a mail piece is supplied lying flat with a down-turned but not yet adhered flap on the underside of the envelope, has a blade in an upper part and a moistener rocker that can be opened upwardly and can be rotated with at least one locking contour on an associated hinge on the blade so as to be spring-supported as well as locked in a maintenance position. The upper part and a lower part of the moistener are connected by connection elements that can be detached only from above. An antibacterial upper moistening element is disposed in the upper part with a clamping region thereof in a clamping groove of the moistener rocker. A water transfer element protrudes into the lower part, which element is curved at its other, upper end. Both possess a shared contact surface for water transfer that is enlarged by the curvature.

Owner:FRANCOTYP POSTALIA

Non-glue based moisturizing device

A non-glue-based moisturizing device for moistening surfaces that are pre-coated with a dry adhesive. The moisturizing device of the invention includes a body that stores an aqueous solution, a tip capable of absorbing, holding and applying the aqueous solution to the pre-coated adhesive surface of the object, and a cap that covers and protects the tip when not in use. The aqueous solution contains water as a major constituent, does not contain colorants, and has a viscosity greater than water.

Owner:HOUTAN MINA

Intelligent correspondence and file encapsulation mechanism

The invention discloses an intelligent correspondence and file encapsulation mechanism, which comprises an envelope conveying device, a paper folding flush overlaying mechanism, an envelope opening brush mechanism and an envelope encapsulation mechanism which are matched. The envelope conveying device comprises an envelope tray for placing empty envelopes, the front end of the envelope tray is assembled with a letter pressing wheel, and the upper part of the front end of the letter pressing wheel is provided with a letter opening rod and a feed roller; the envelope opening brush mechanism comprises a transport device matched with a belt, a first driving wheel and a second driving wheel which is assembled with a brush moving frame; the envelope encapsulation mechanism comprises an envelope collecting basket for transferring stored and sealed unit envelopes arranged at an output end of the envelope opening brush mechanism; a deployed letter sorting driving wheel and a letter sorting assistant driving wheel automatically convey the envelopes at the same time of conveying each envelope; the position of the letter pressing wheel is provided with a light control detection switch module to control the next operation for the correspondences; and by using the principle of a cam mechanism, the unit envelope is not wetted and the pasting effect is achieved.

Owner:宁波市诚邦办公设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com