Method of producing mailing covers and machine utilizing said method

a technology of mailing covers and machines, applied in the field of producing mail pieces, can solve the problems of unsatisfactory current use techniques, confidentiality problems, and no method for producing unique mail pieces, and achieve the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008]The aim of the present invention is to overcome these disadvantages by proposing a method to produce personalized and unique mails, offering a complete solution beginning with a roll of paper and ending with a sealed piece of mail, integrating envelope production with document production, allowing production at higher speeds than are currently possible, ensuring the integrity and confidentiality of the mail thus produced, and reducing the global unit cost of the mail.

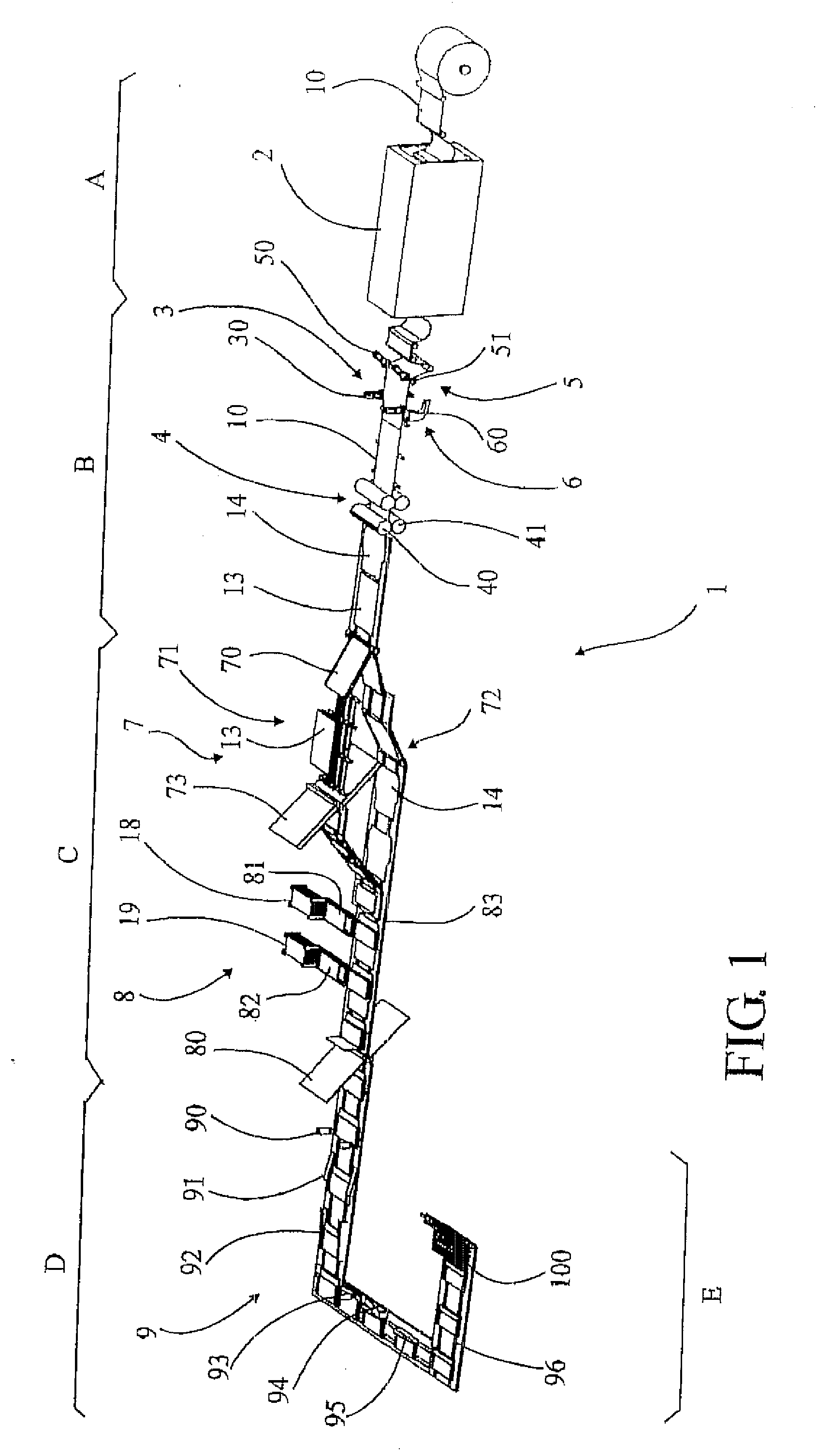

[0009]For this purpose, the invention concerns a production method of the type indicated in the preamble in which the documents to be enclosed and the envelopes destined to contain them are printed on the same width of material, one after the other in the order of insertion, each envelope being preceded or followed by the documents it will contain; the longitudinal edges of the width of material are trimmed to make the documents the correct width and to form the envelope flaps; the width of material is cut transve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com