Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about "Dc and ac dynamo-electric motors control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

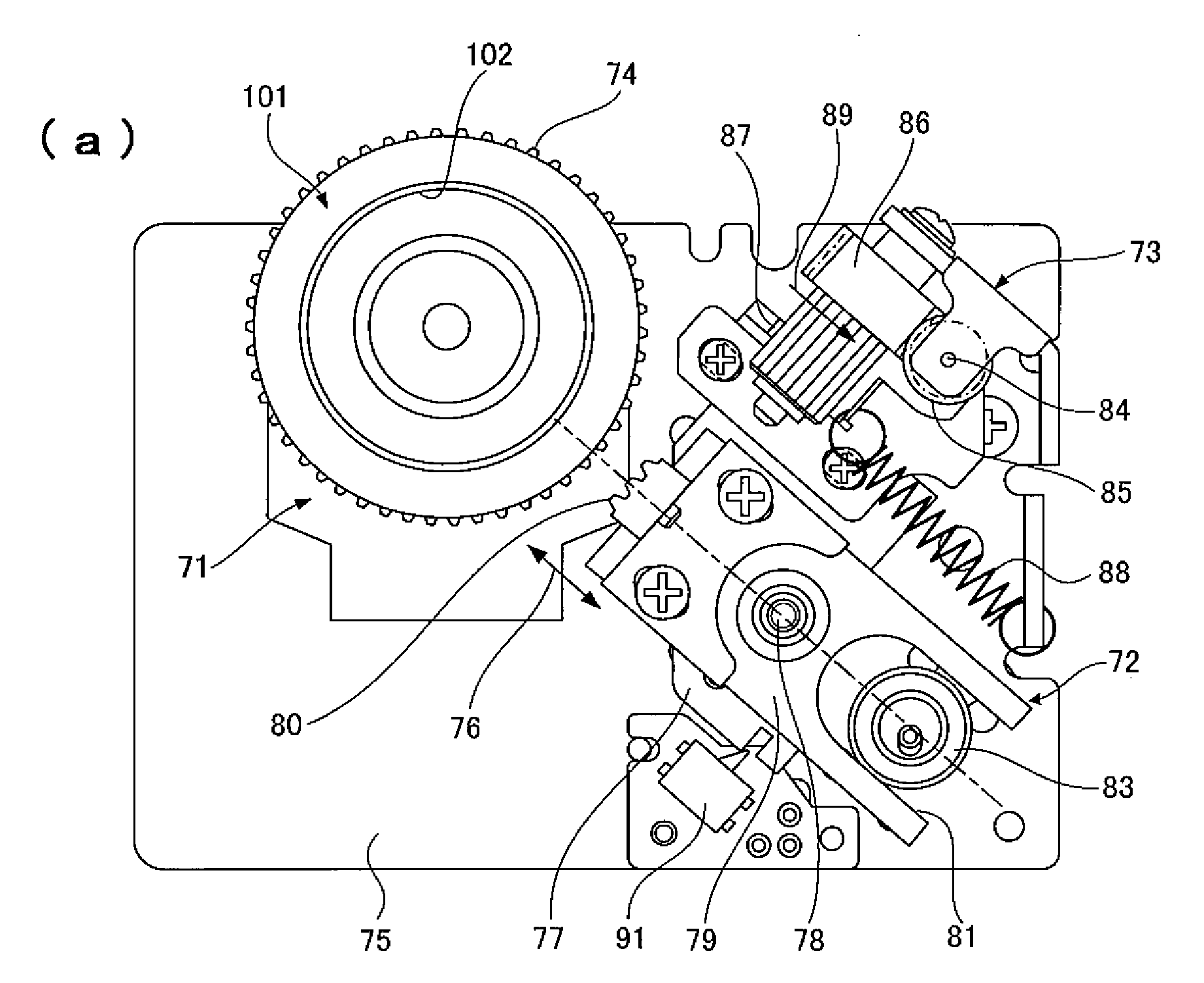

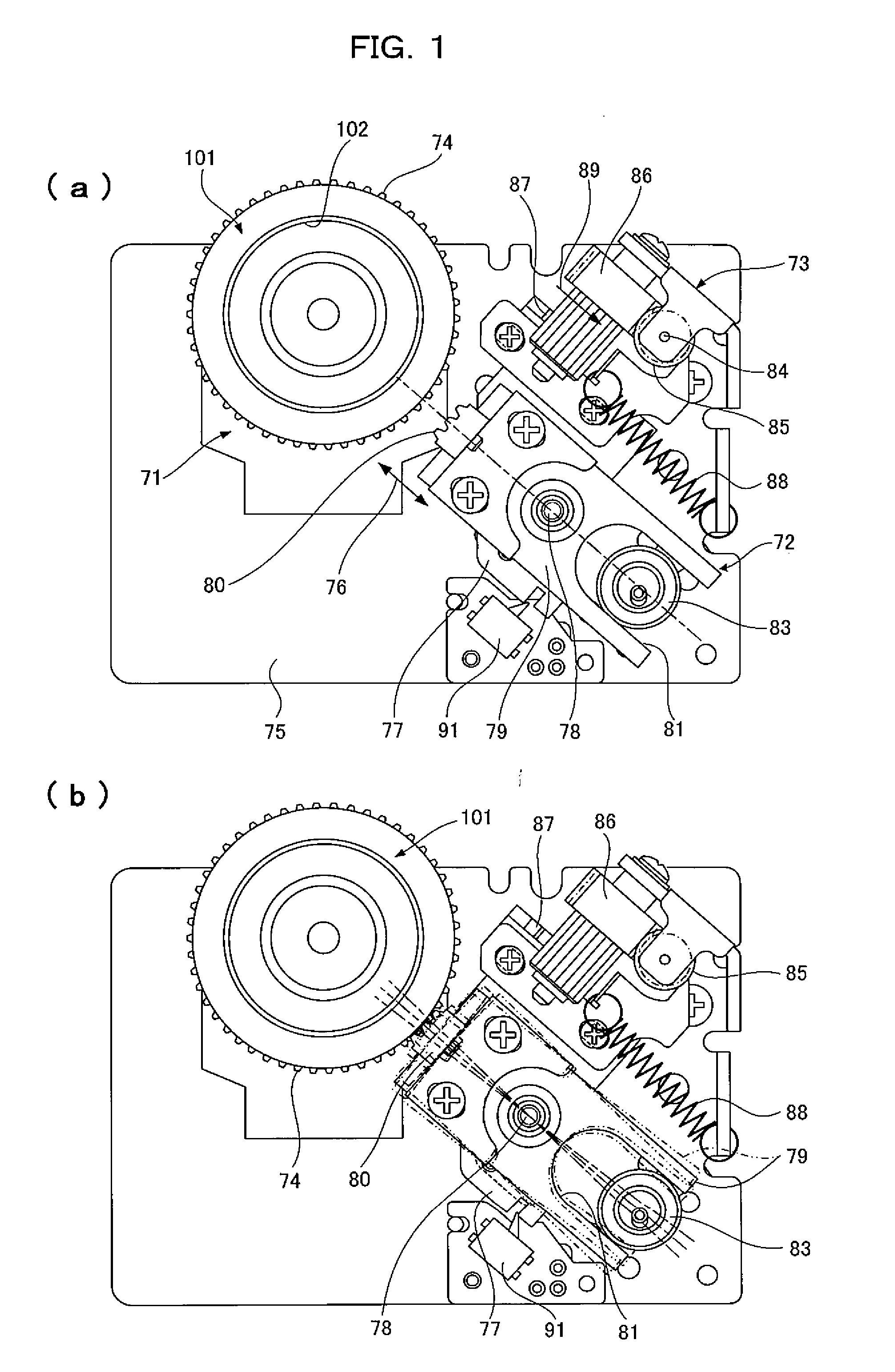

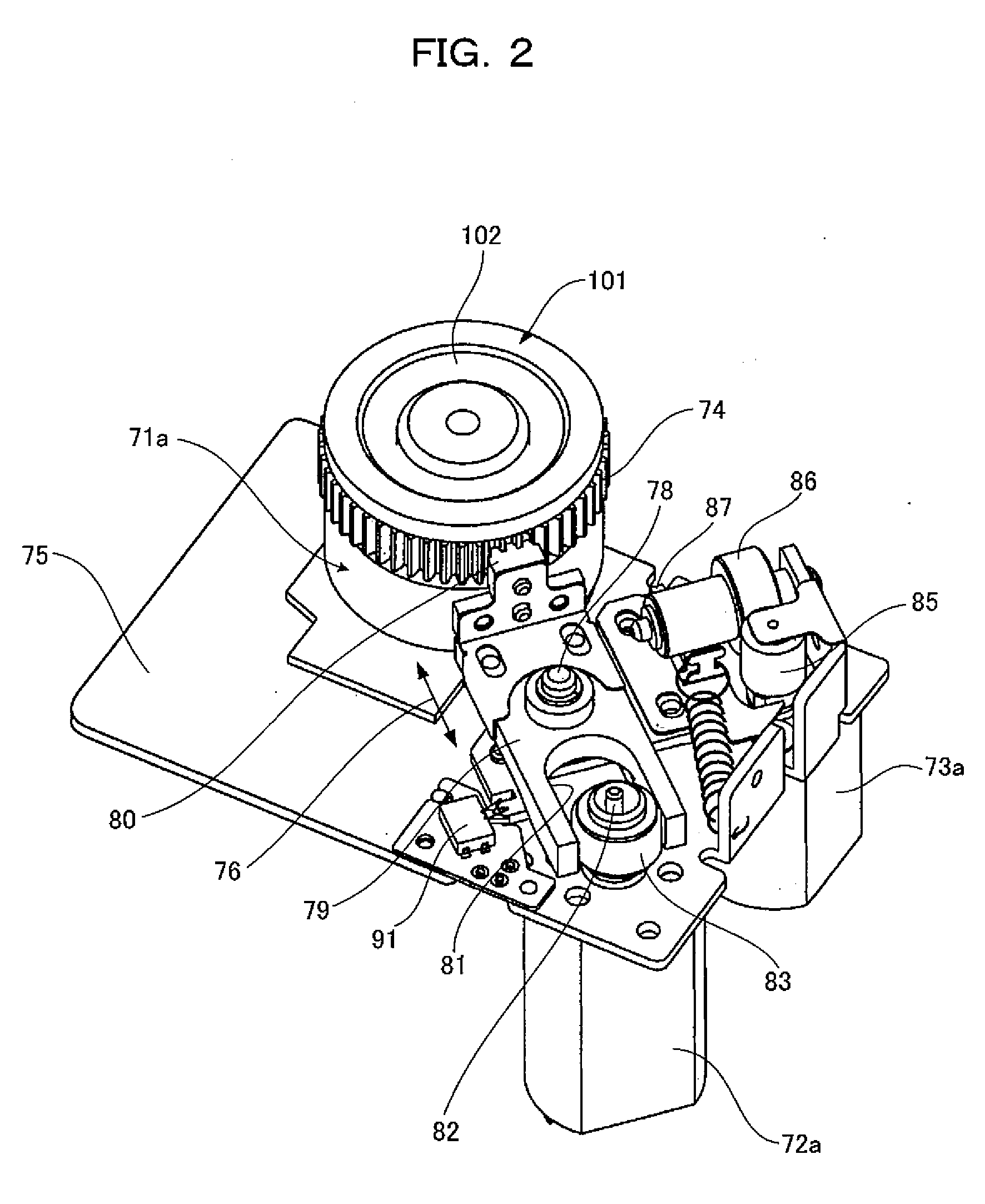

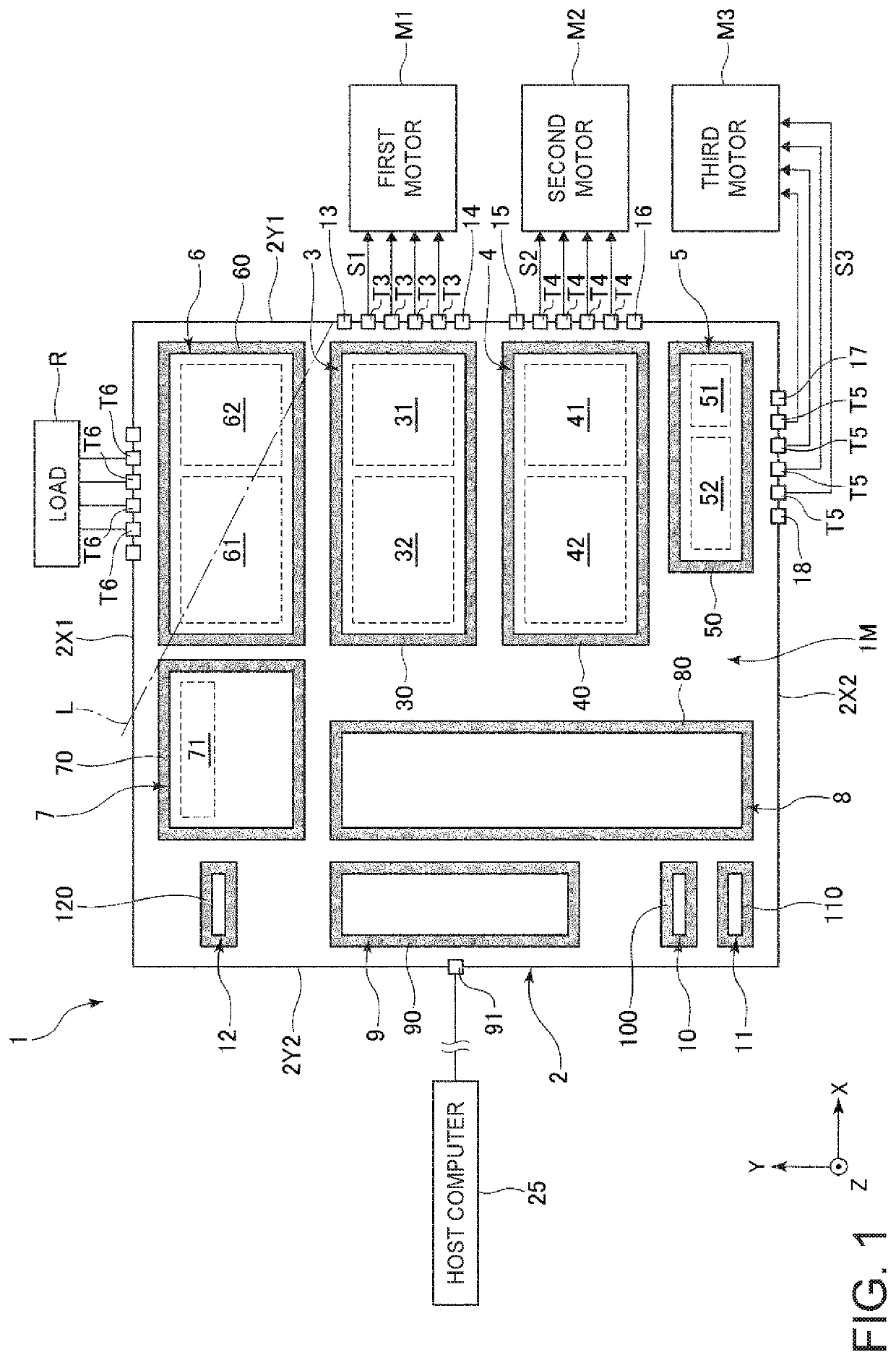

Analyzing apparatus

ActiveUS20100262389A1Reduce the impactGuaranteed stable engagementMaterial analysis using sonic/ultrasonic/infrasonic wavesShaking/oscillating/vibrating mixersReciprocating motionEngineering

Owner:PHC HLDG CORP

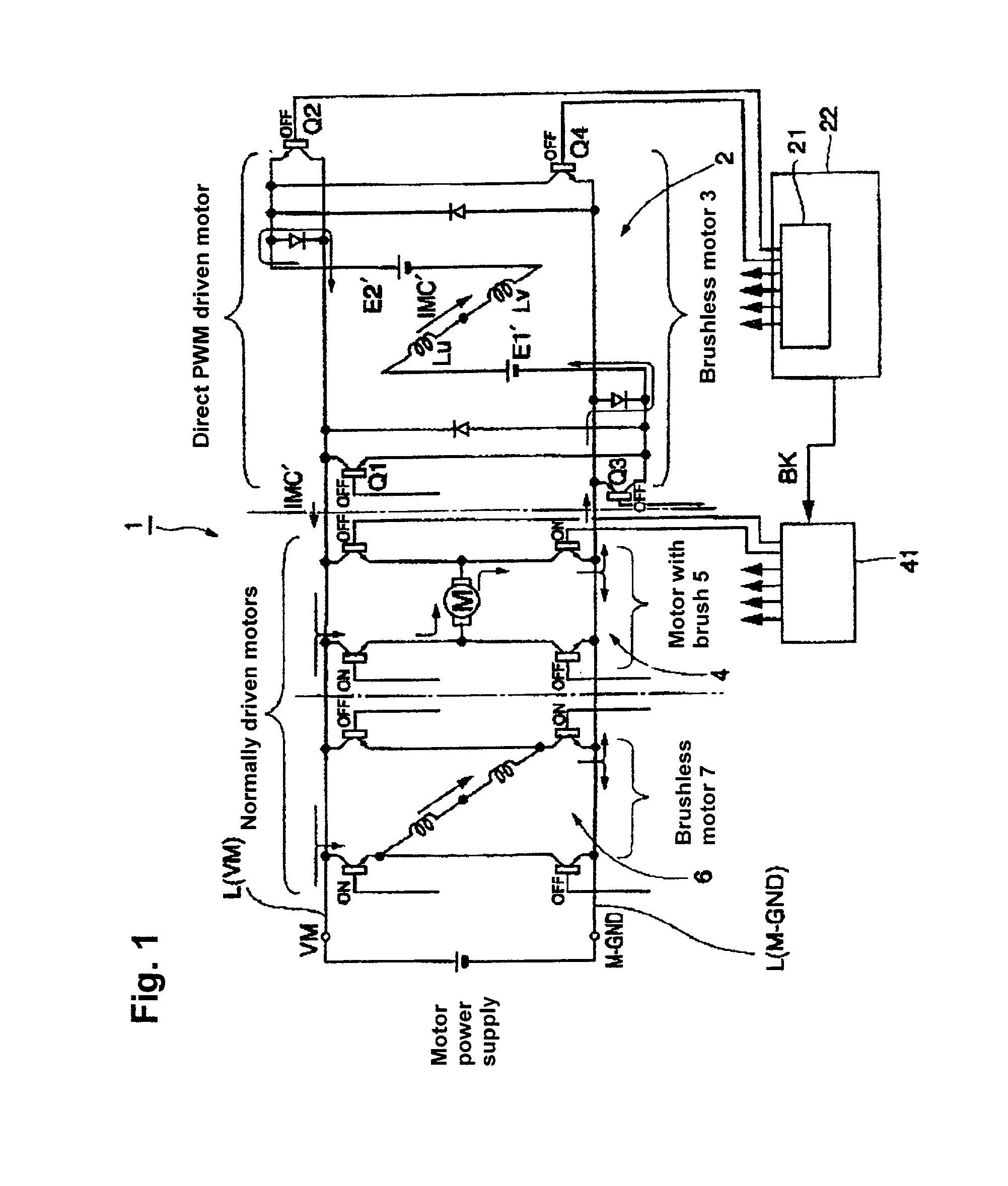

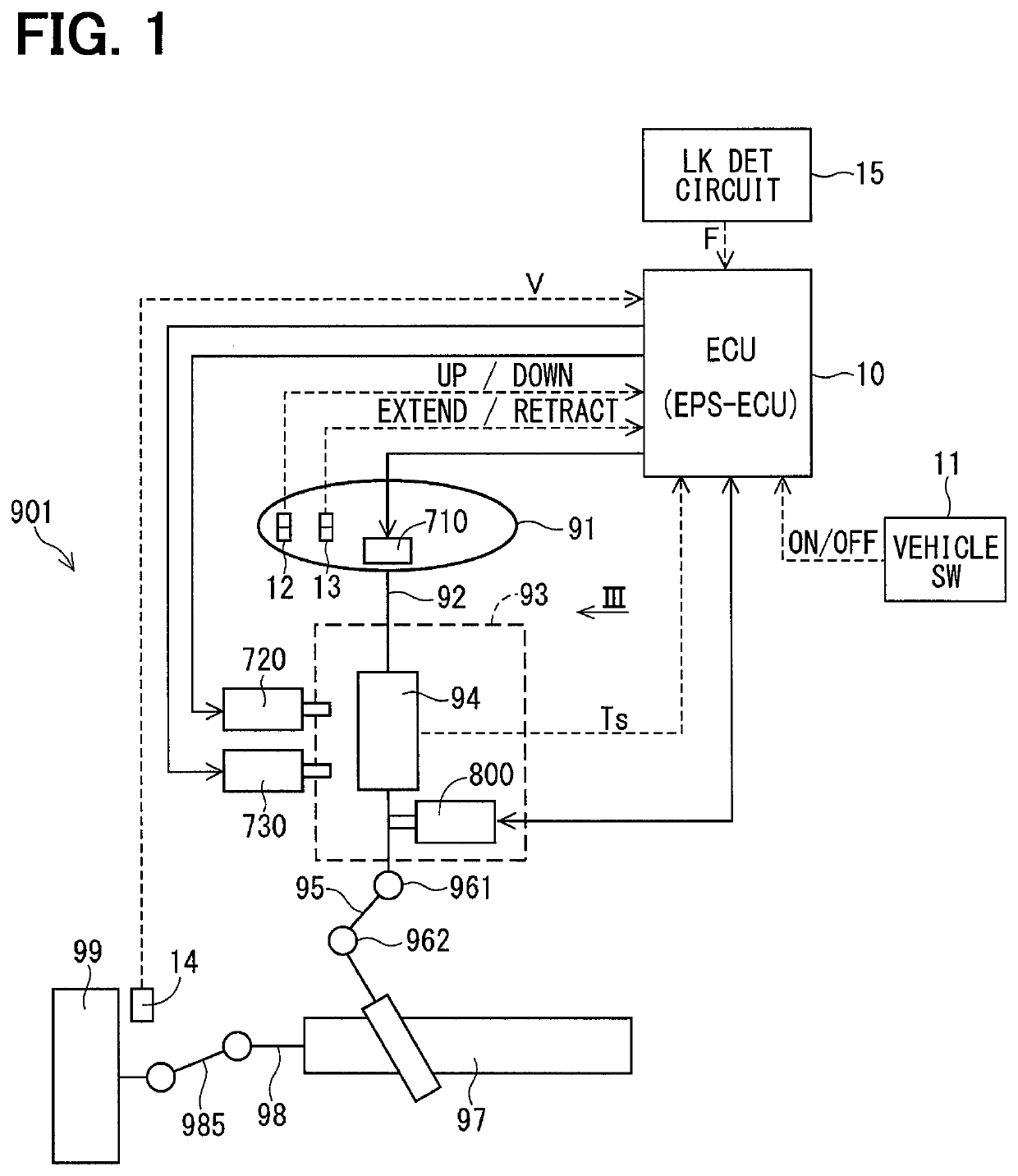

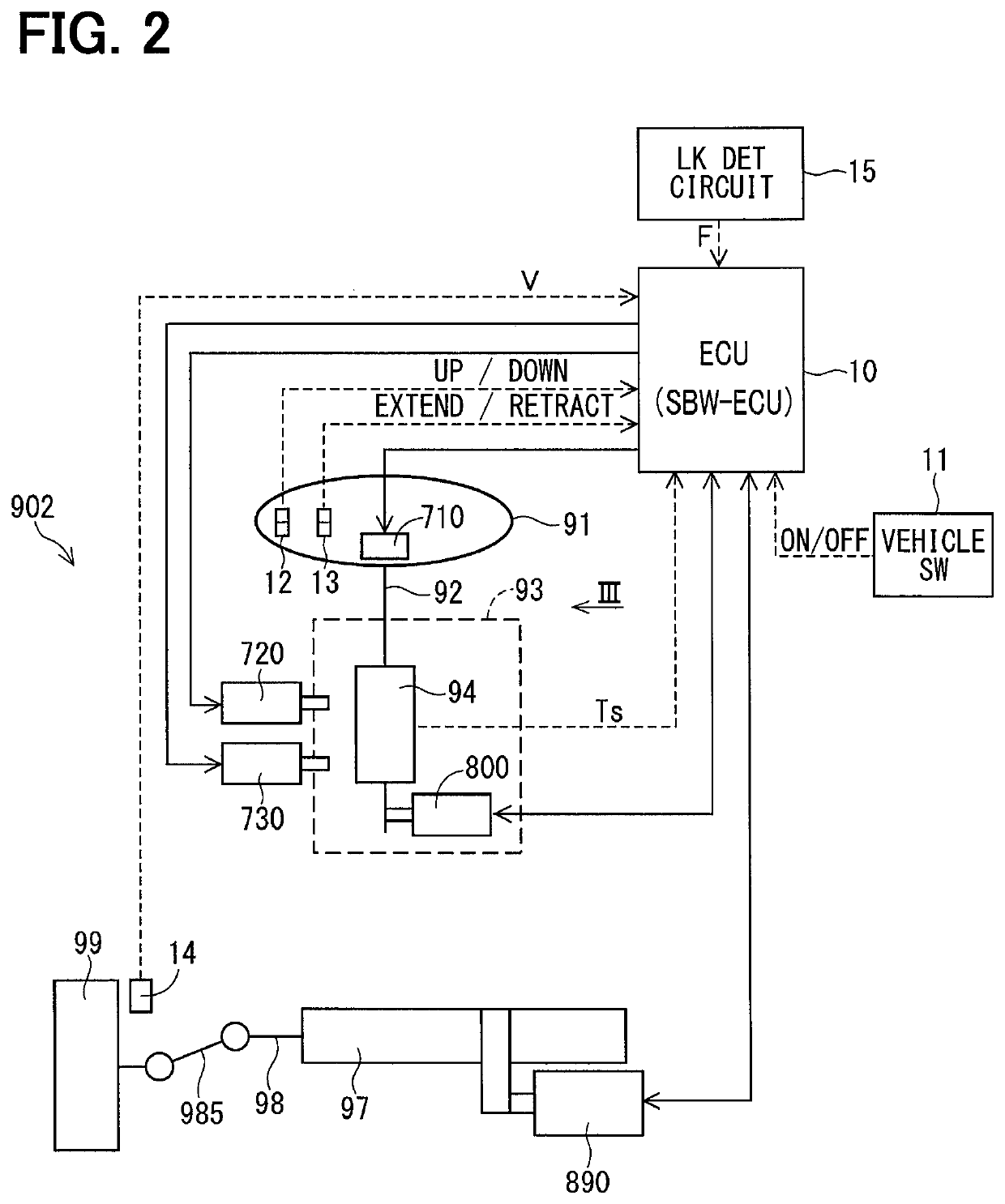

Method for driving motors and apparatus for driving motors

InactiveUS20010048277A1Commutation monitoringMotor/generator/converter stoppersBrushless motorsDrive motor

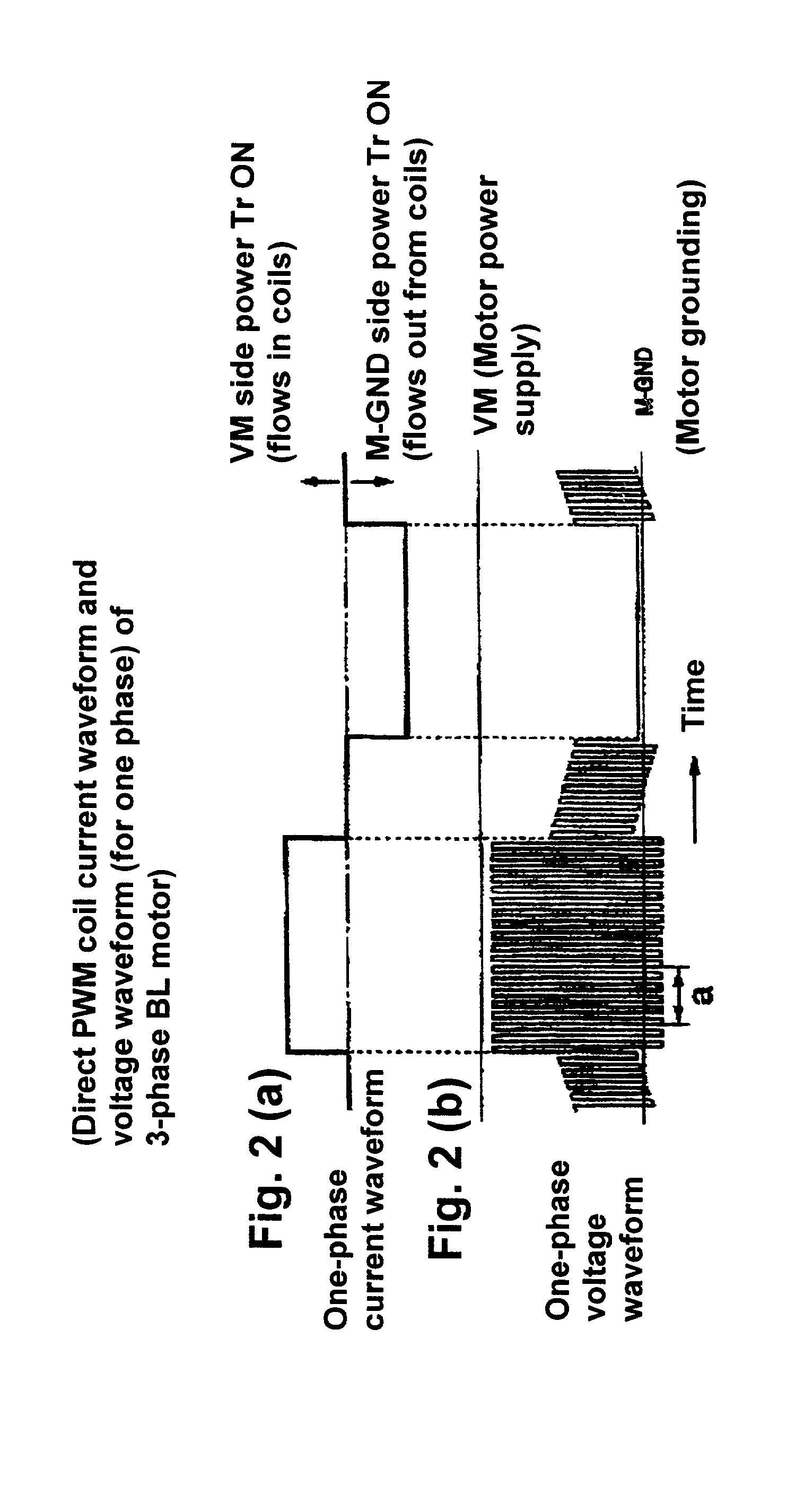

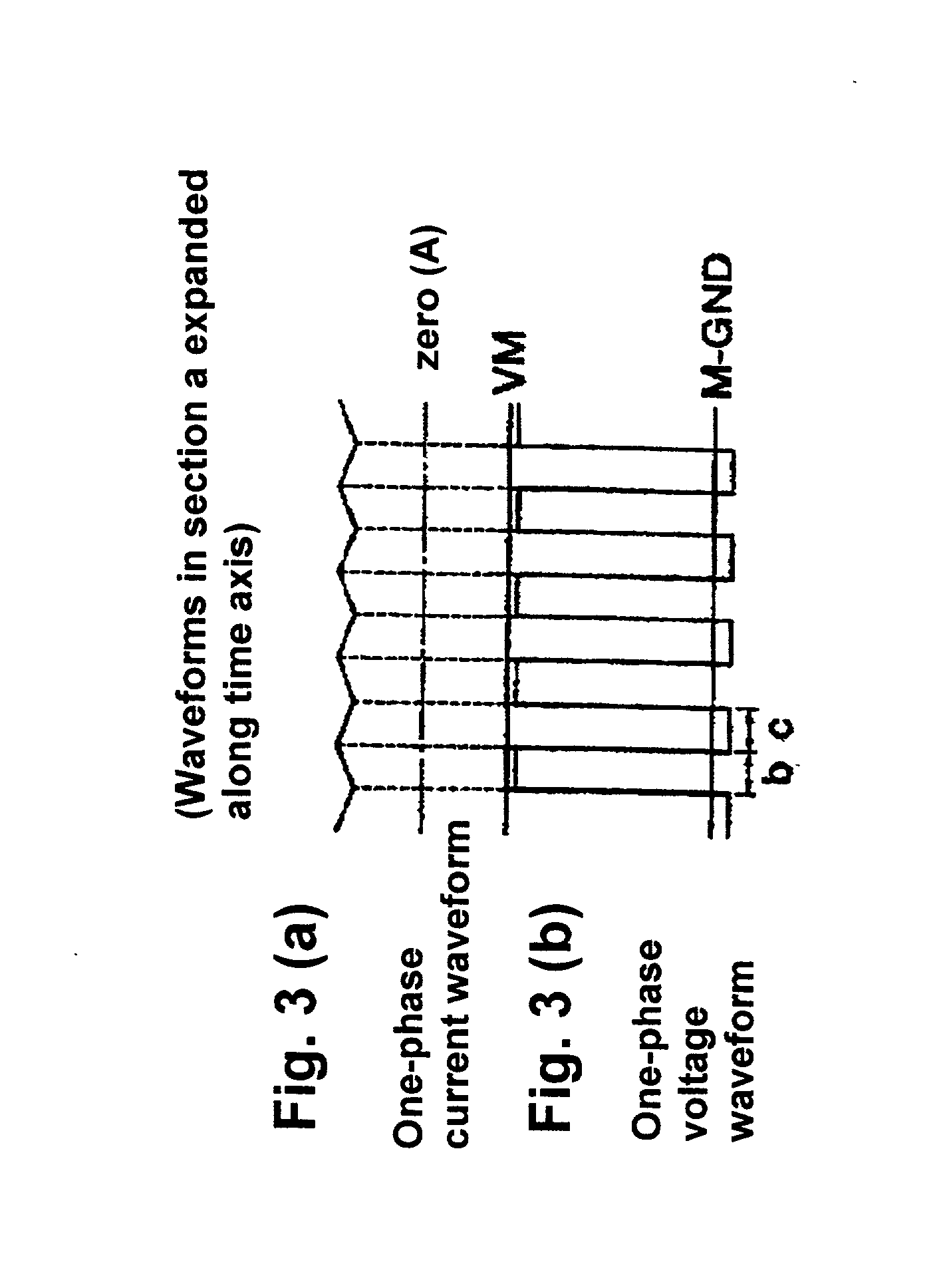

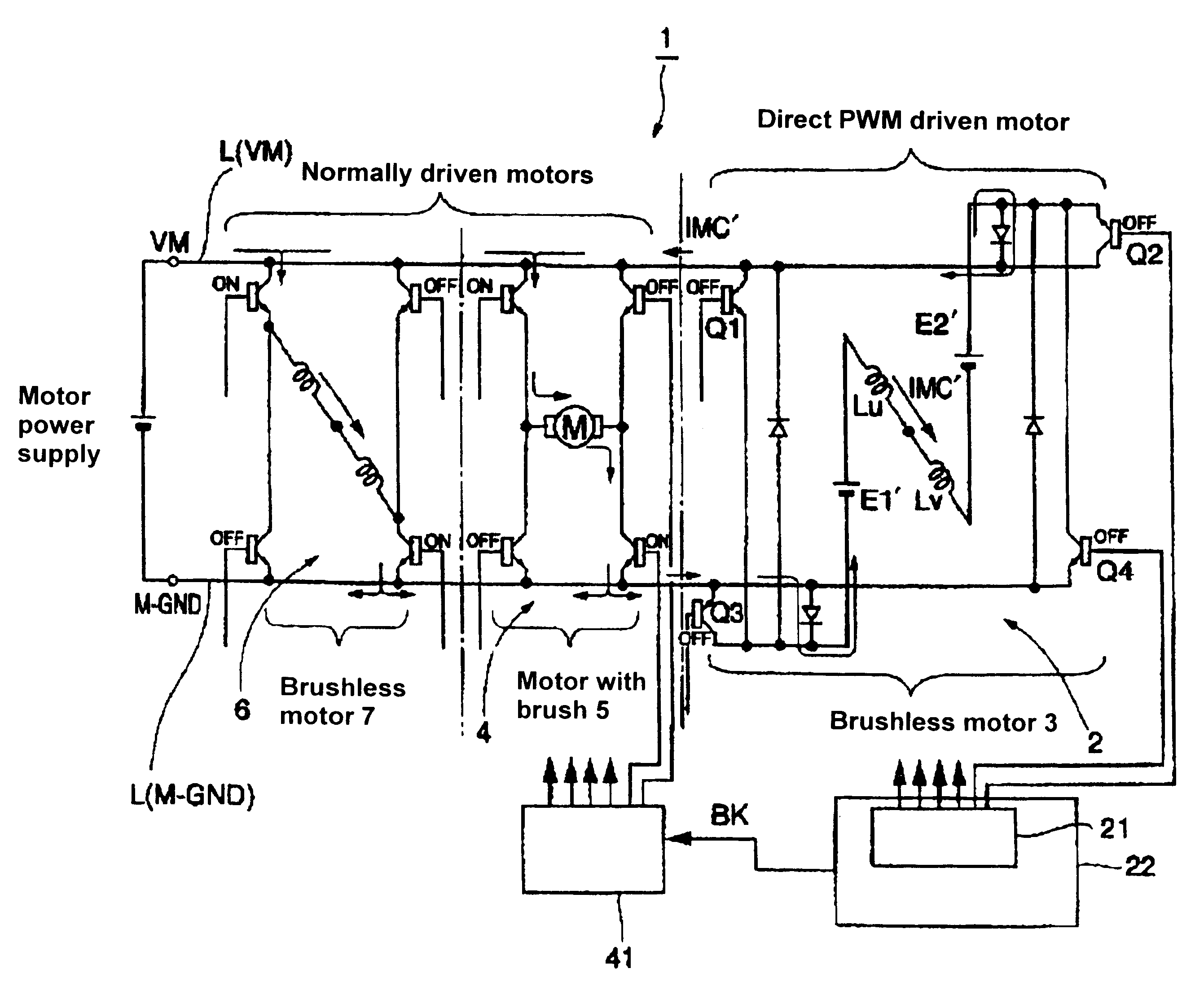

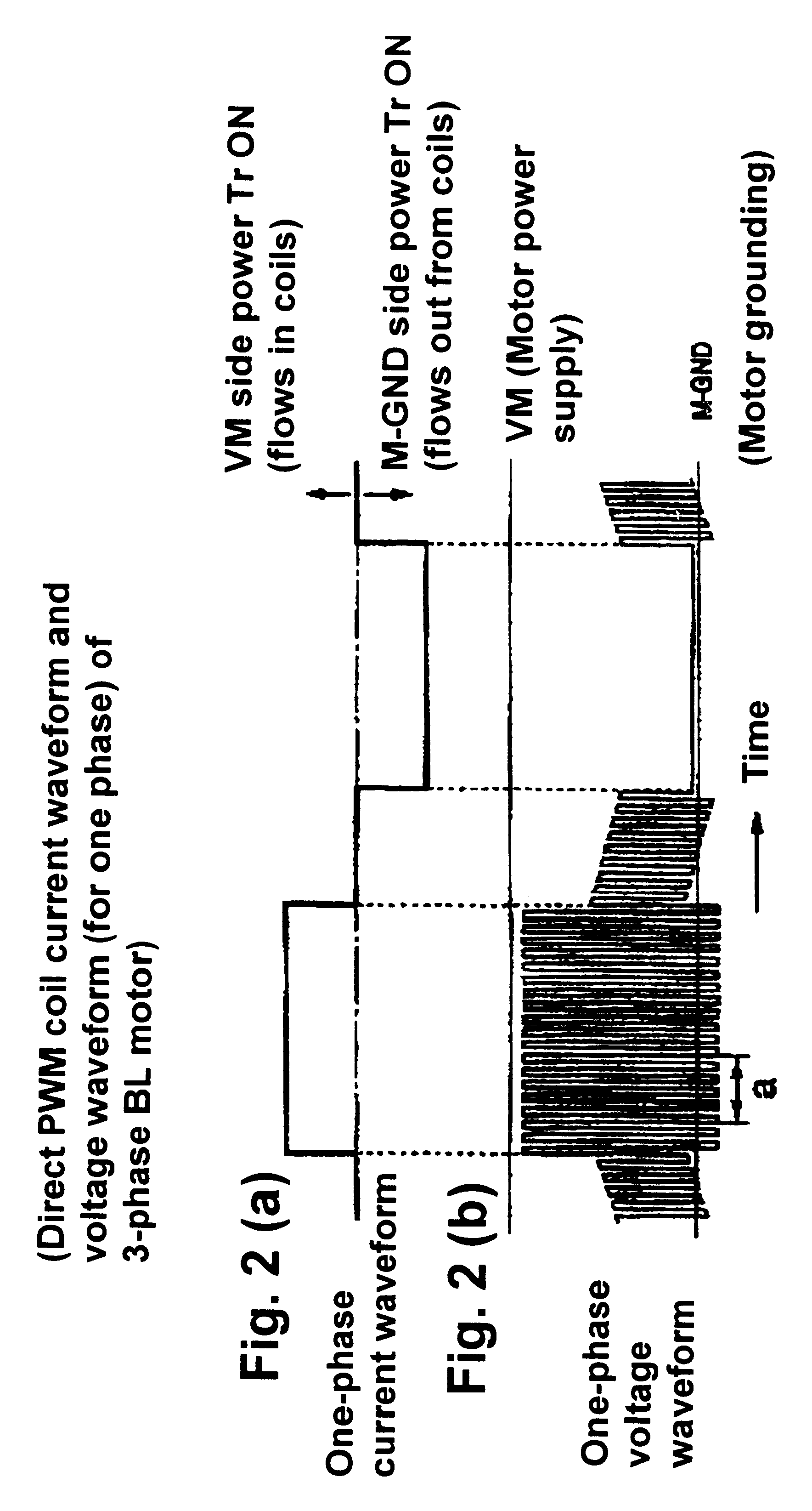

A method is provided for driving a motor apparatus having a first motor, a second motor, and a motor power supply commonly used for the first motor and the second motor. The first motor is a brushless motor. An electrical power is supplied from the motor power supply to driving circuits of the first motor and the second motor through a common motor power supply line. The first motor is driven by a direct PWM driving method, and the second motor is driven by a method different from the direct PWM driving method. A reverse regeneration current generated in the first motor is flown to the second motor through the common motor power supply line.

Owner:SANKYO SEIKI MFG CO LTD

Method for driving motors and apparatus for driving motors

InactiveUS6552505B2Commutation monitoringMotor/generator/converter stoppersBrushless motorsDrive motor

Owner:SANKYO SEIKI MFG CO LTD

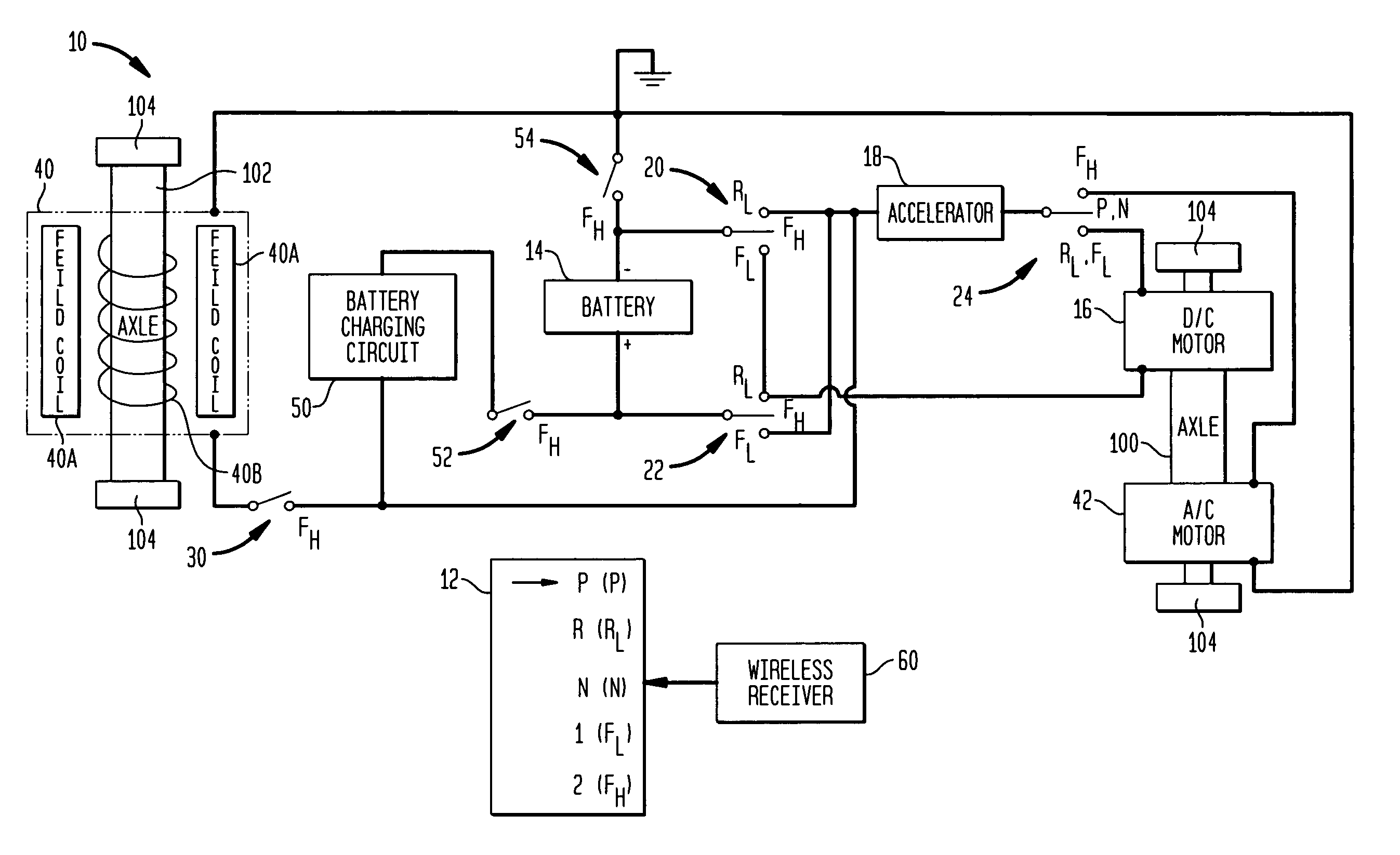

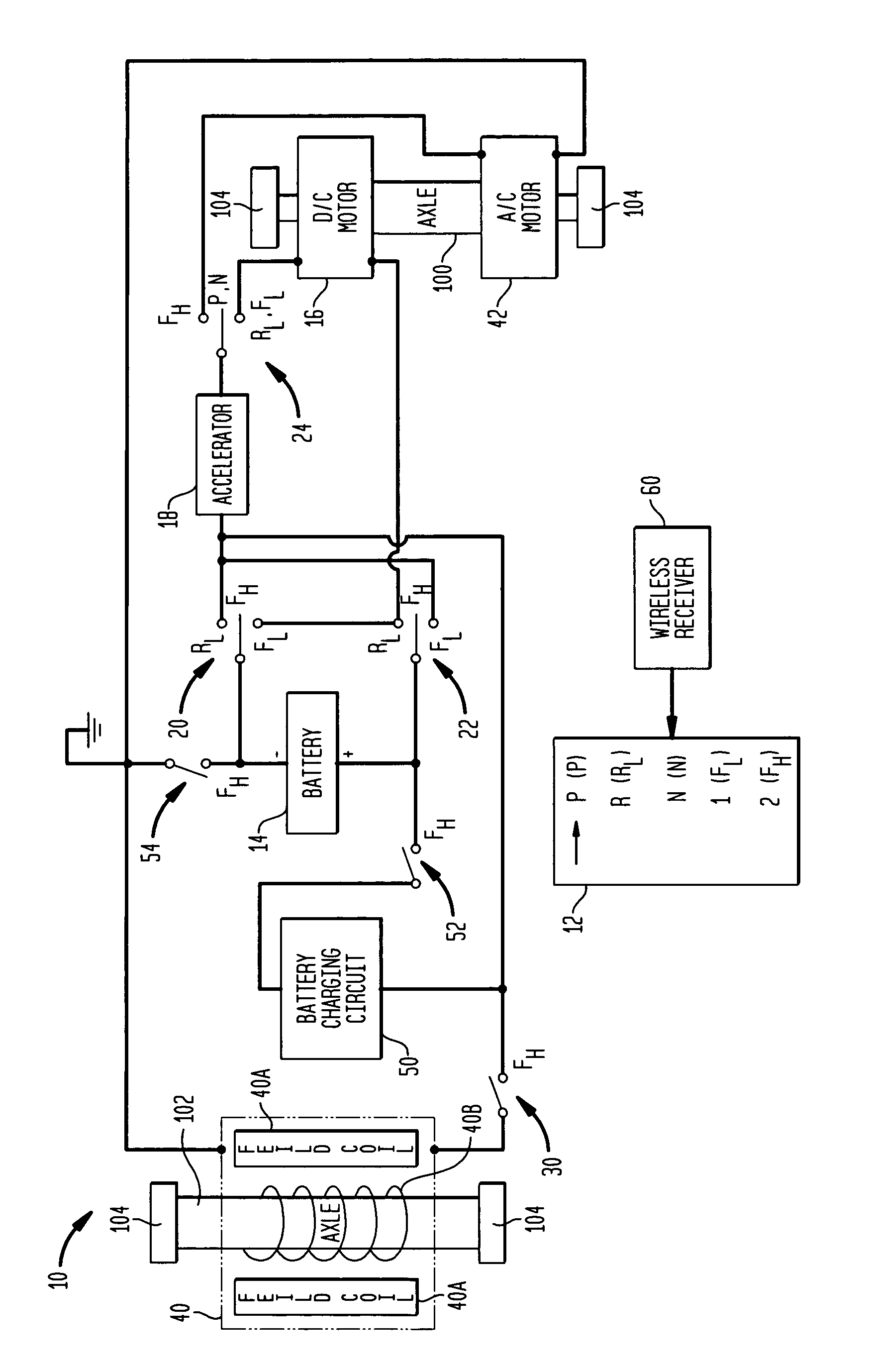

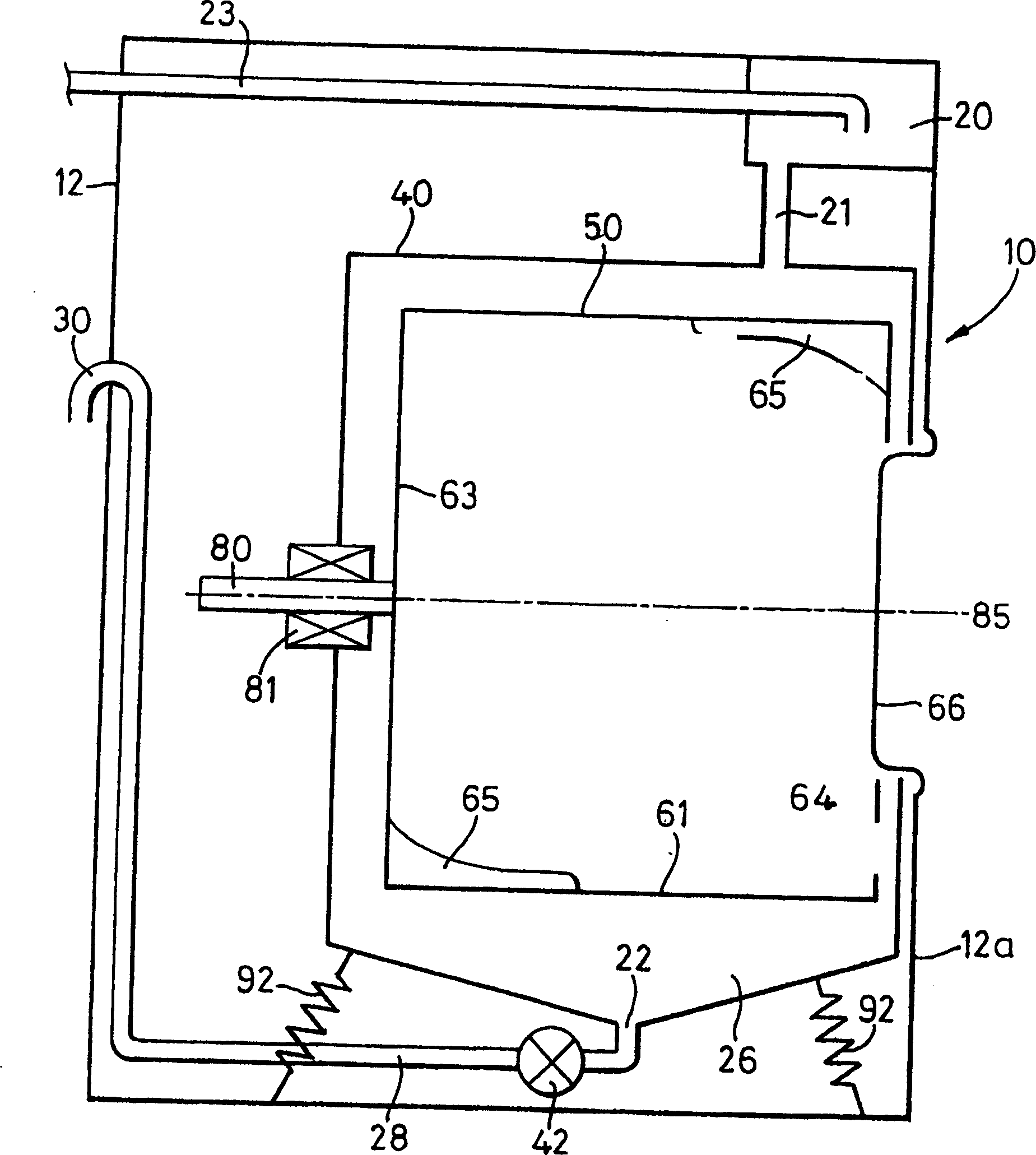

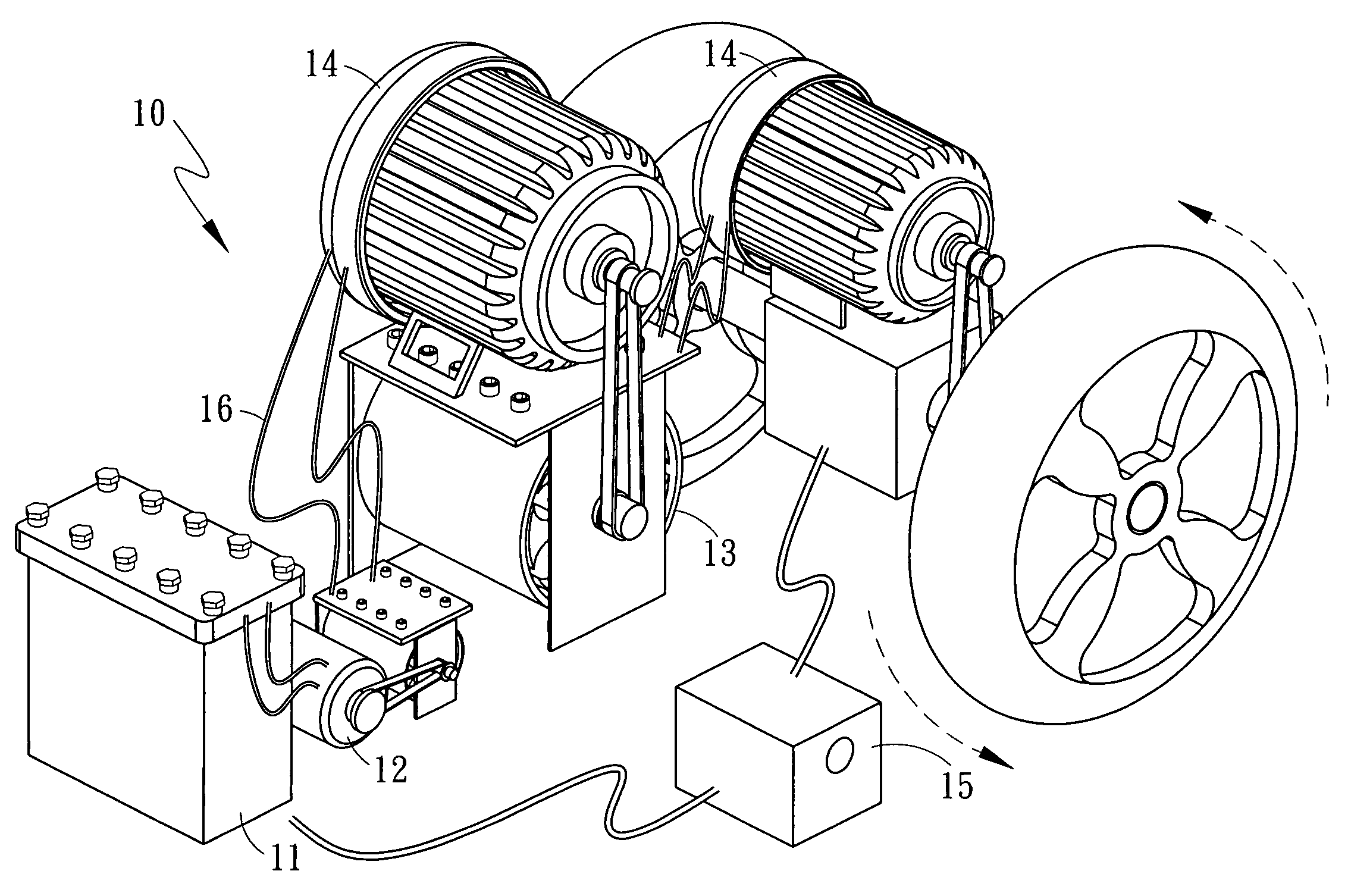

AC/DC system for powering a vehicle

A system for powering a vehicle includes a DC motor adapted to be coupled to a vehicle axle when the vehicle is to be driven in reverse or forward at a speed less than a threshold, and an AC motor adapted to be coupled to vehicle axle when it is to be driven forward at a speed exceeding the threshold. An AC turbine adapted to be driven by motion of the vehicle generates an AC current for powering the AC motor when the AC turbine is coupled thereto. An operator-controlled rheostat is used to control the speed of either the AC or DC motor. A switching system uncouples the AC turbine from the AC motor and couples a battery to the DC motor through the rheostat when the vehicle is driven in reverse or forward at a speed less than the threshold. The switching system also serves to uncouple the battery from the DC motor and couple the AC turbine to the AC motor through the rheostat when the vehicle is driven forward at a speed exceeding the threshold.

Owner:STEGER ANDREW A +1

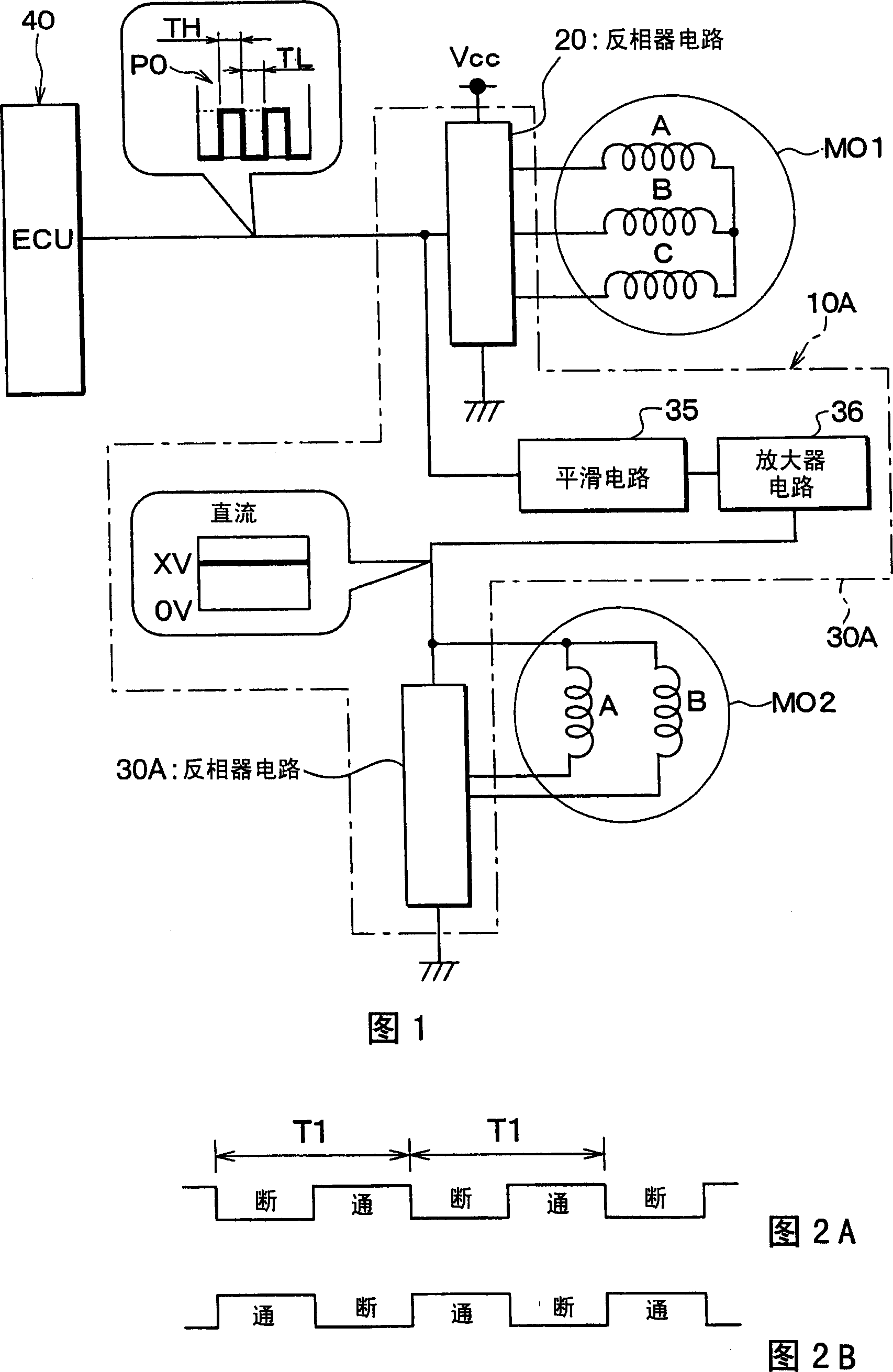

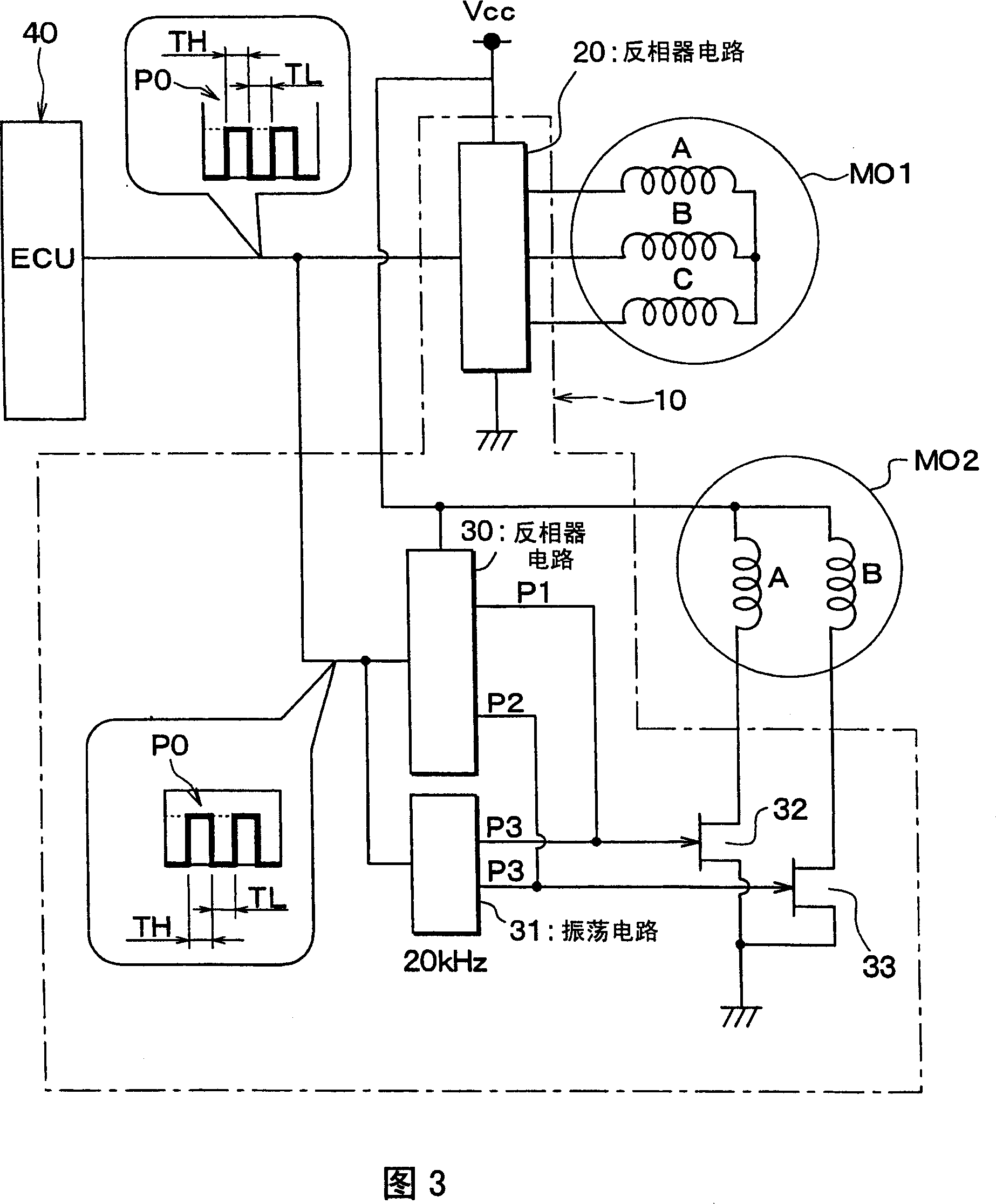

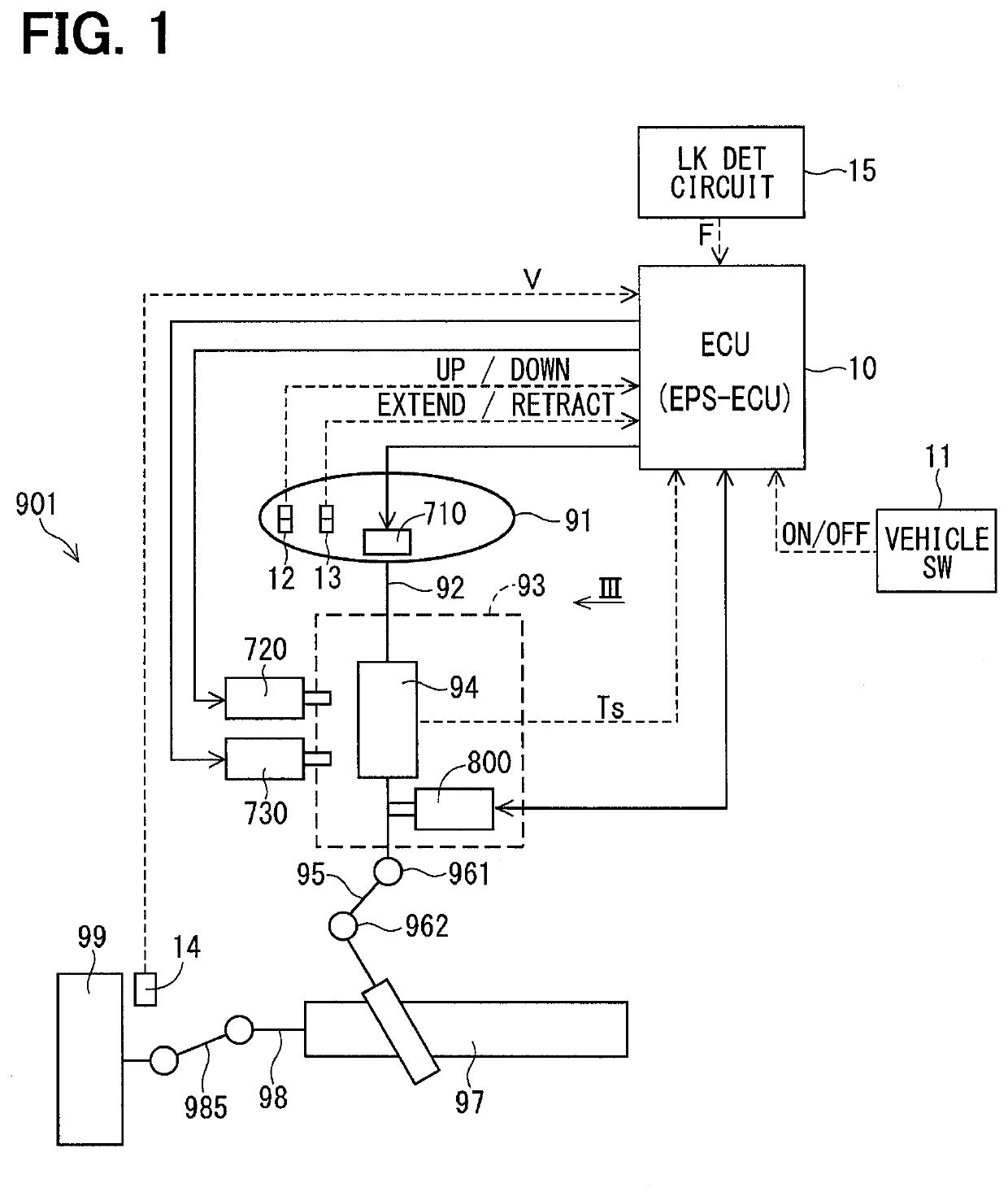

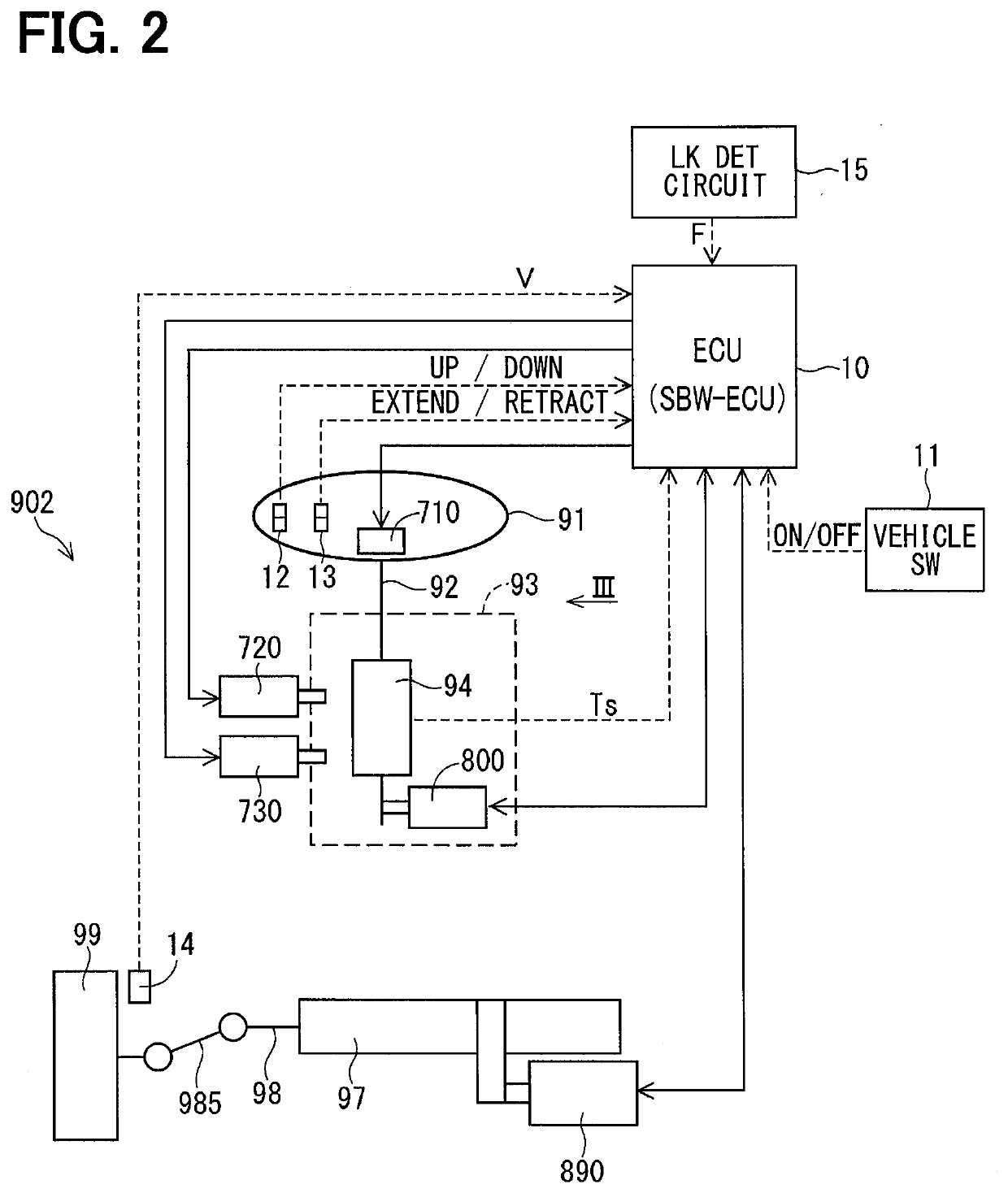

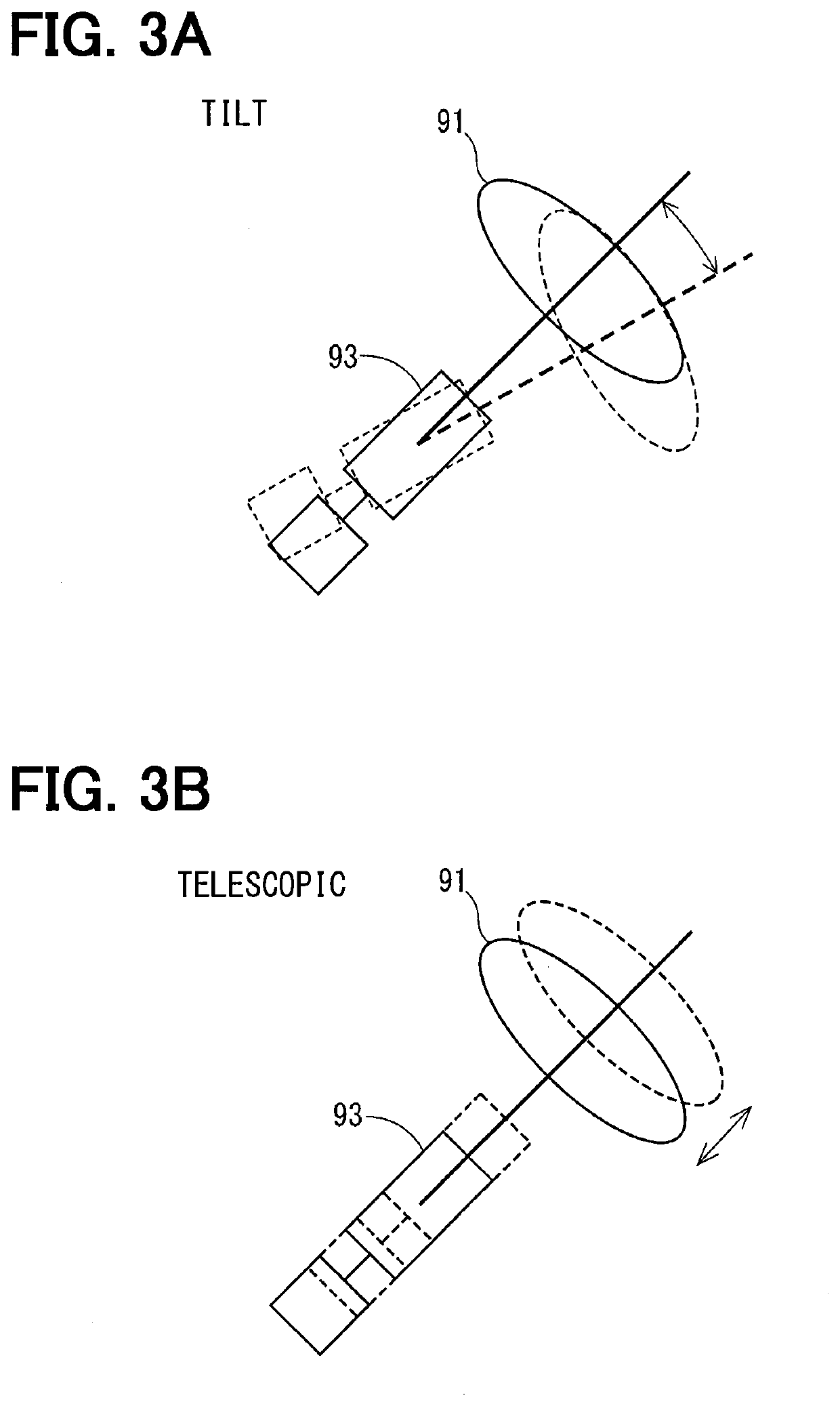

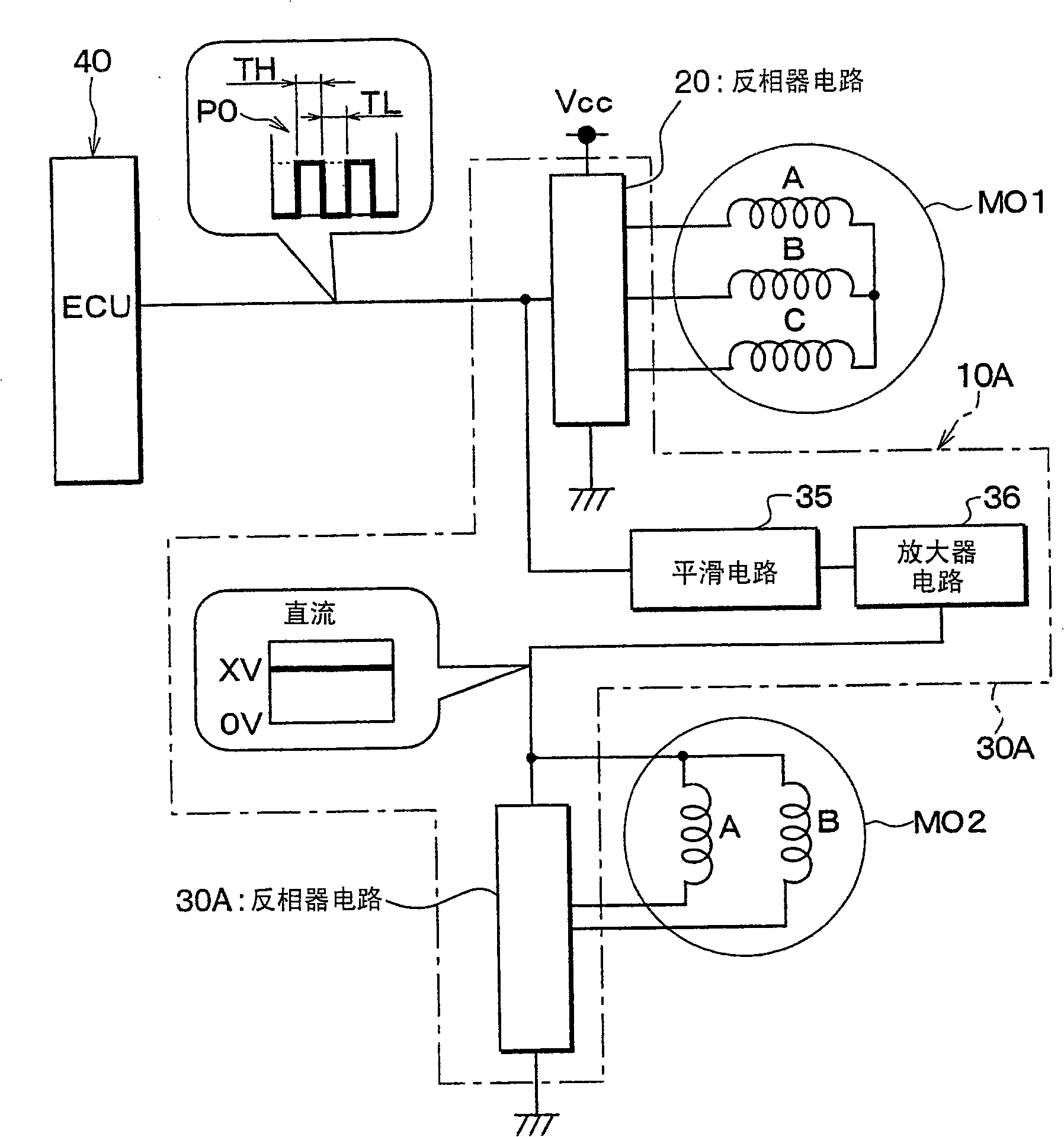

Motor driving device

InactiveCN1972111AIncrease speedMultiple ac dynamo-electric motors controlDc and ac dynamo-electric motors controlMotor driveElectric machine

A motor driving device is disclosed that includes a first drive circuit that drives a first electric motor and increases a rotational speed of the first electric motor according to an increase in a duty ratio of a pulse signal output from an electronic control unit. The motor driving device also includes a second drive circuit that drives a second electric motor and increases the rotational speed of the second electric motor according to the increase in the duty ratio of the pulse signal. The second drive circuit smooths the pulse signal from the electronic control unit to produce a direct-current voltage. Also, the second drive circuit supplies electric power to the second electric motor by applying the direct-current voltage to the second electric motor.

Owner:DENSO CORP

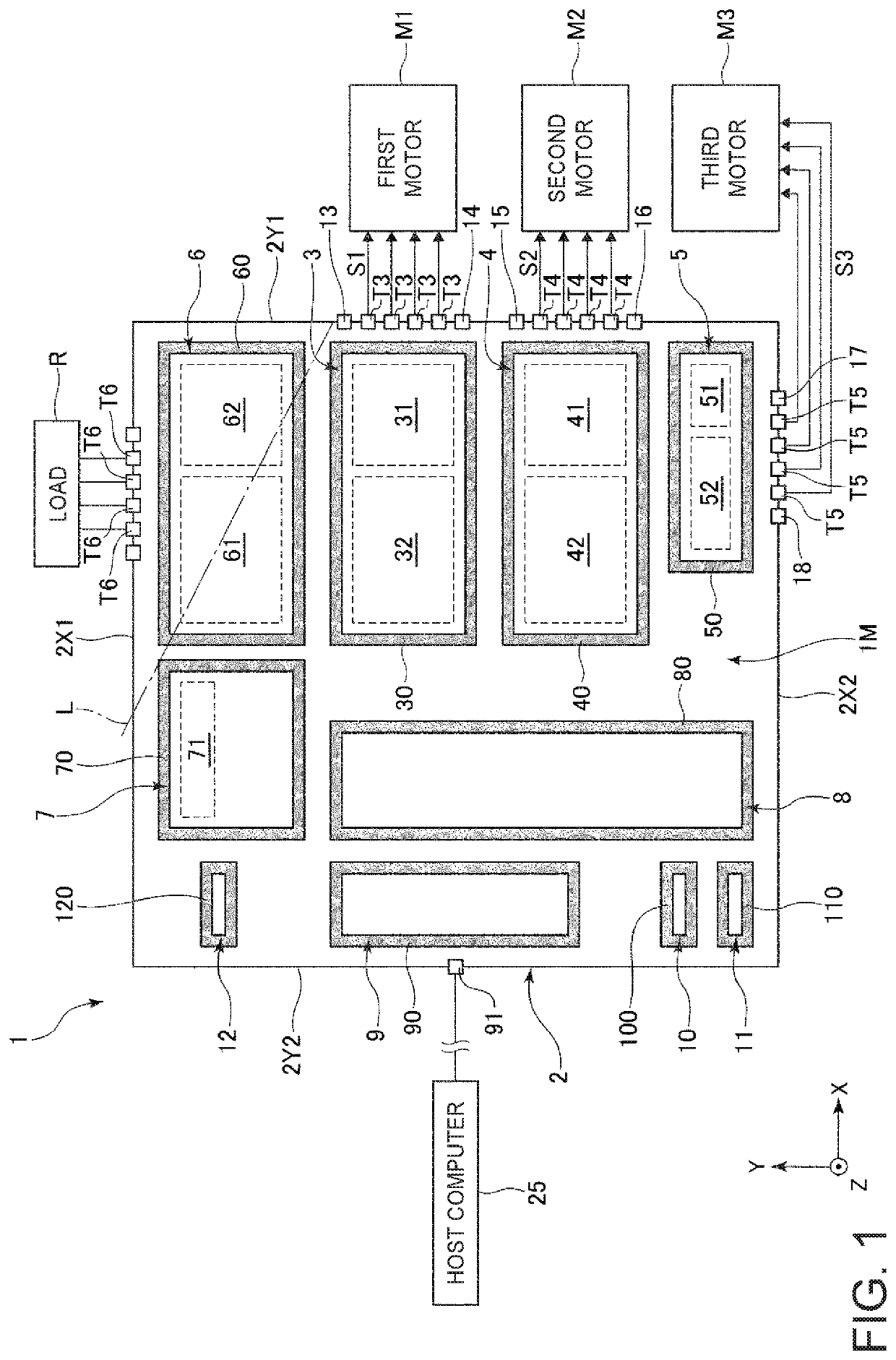

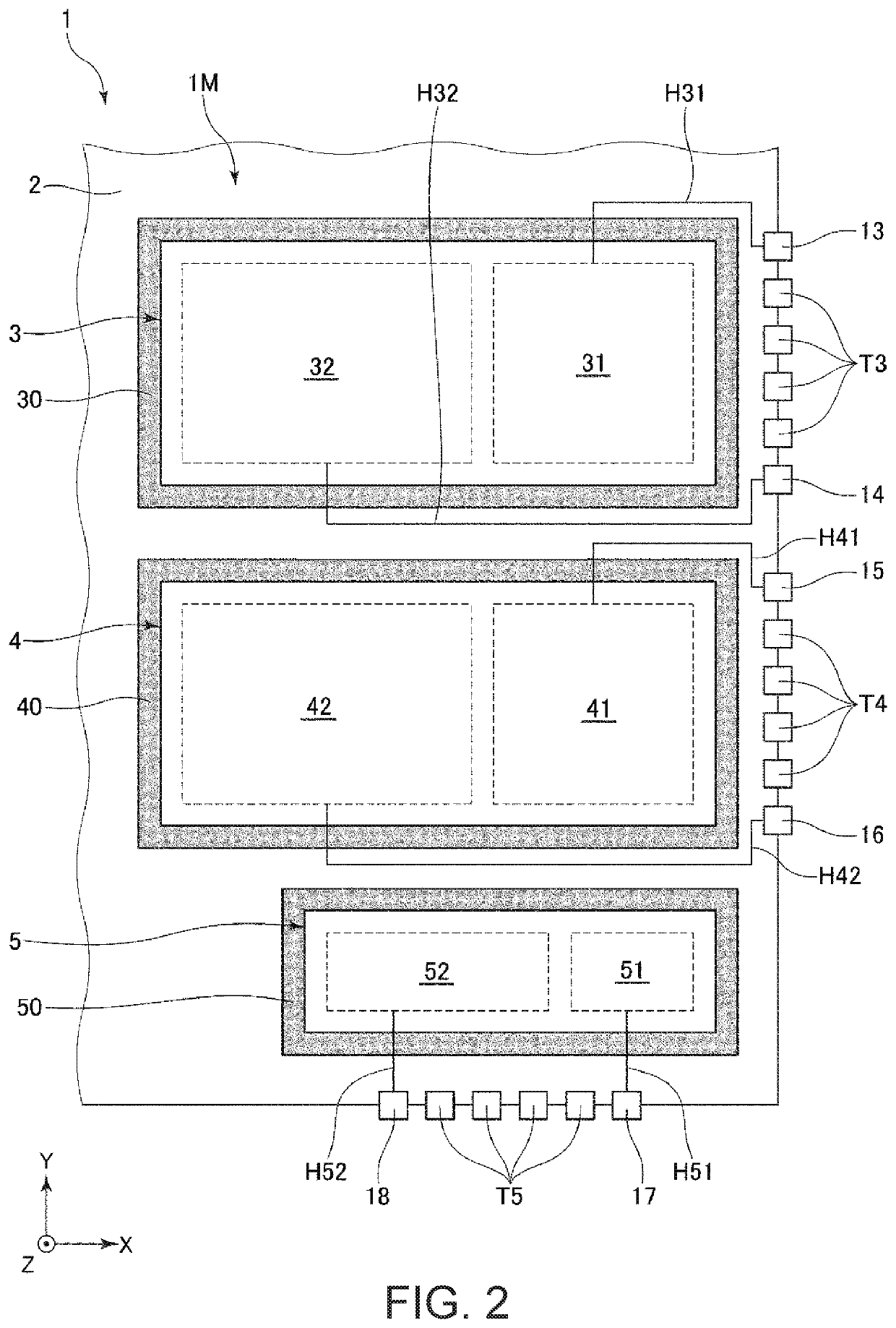

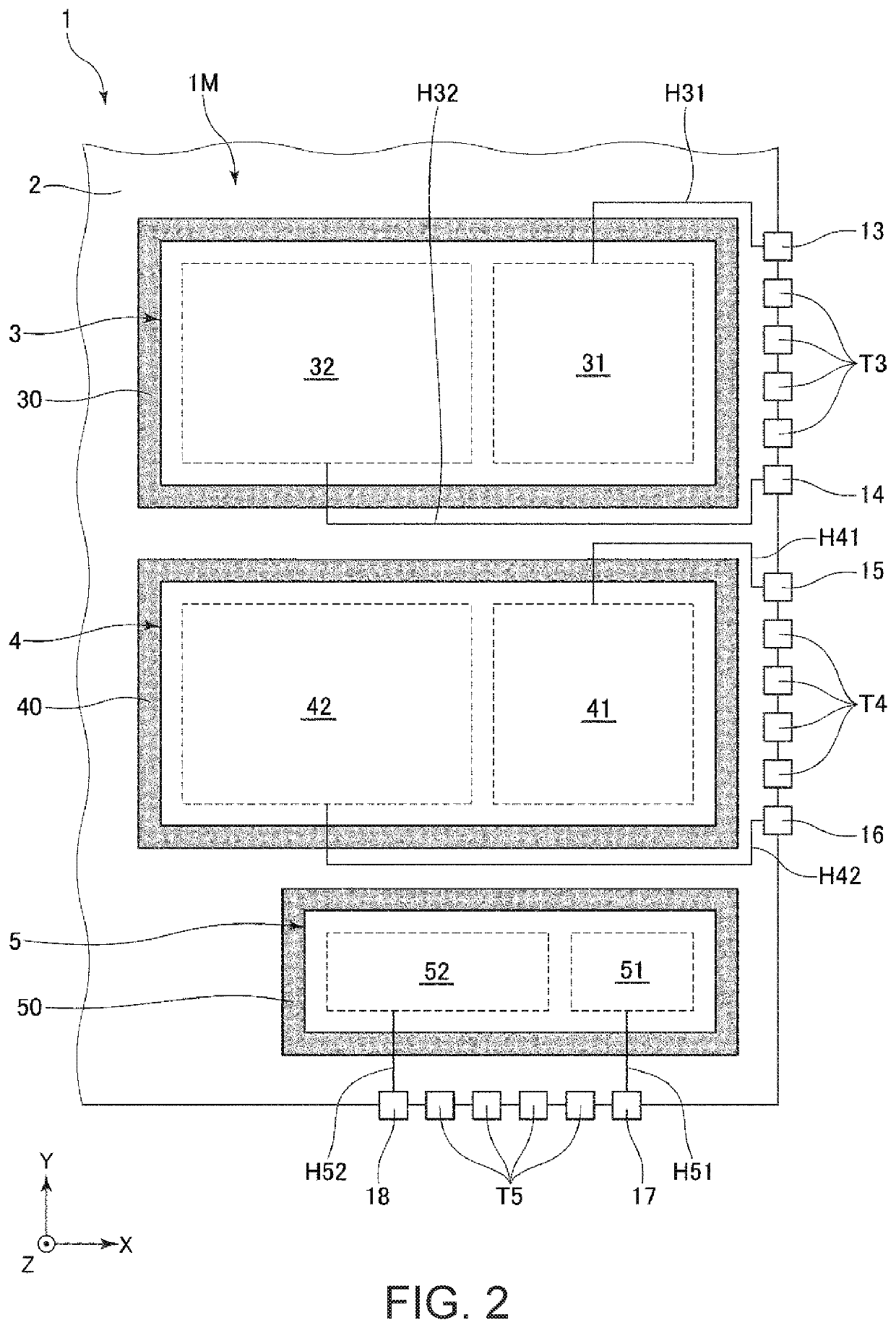

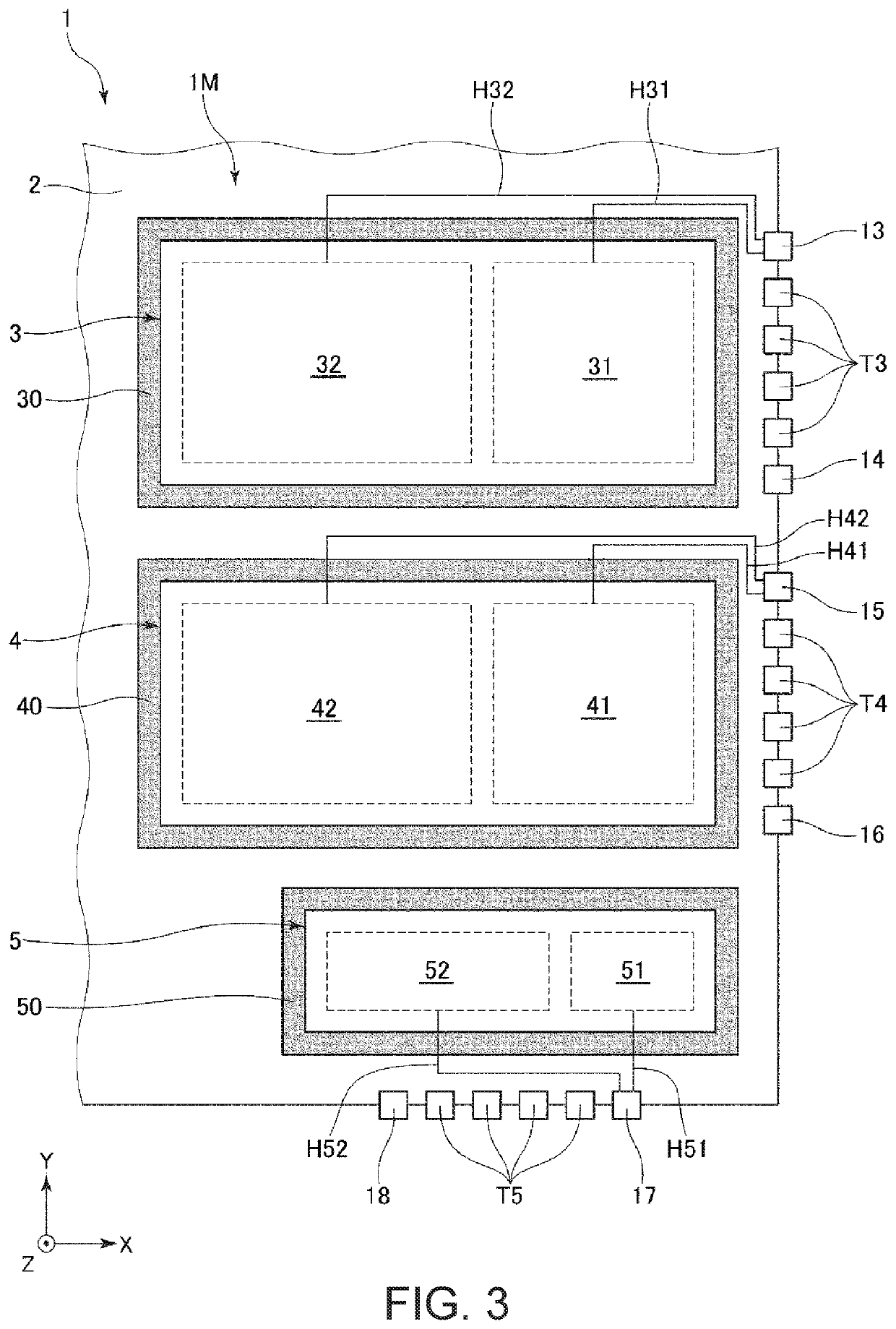

Rotating machine controller

An electronic control unit, for example, a rotating machine controller, is capable of driving one three-phase motor including a first set of three-phase winding and a second set of three-phase winding and one to three direct current motors. The direct current motor is connected to a position between one phase of the first set of three-phase winding and one phase of the second set of three-phase winding without redundancy. Inverters convert a direct current electric power to a three-phase alternating current electric power by an operation of bridge-connected plural switching elements, and apply a voltage to each phase in two sets of three-phase winding. A control unit controls a supply of electric power to the three-phase motor and to the direct current motor by controlling an operation of the switching elements.

Owner:DENSO CORP

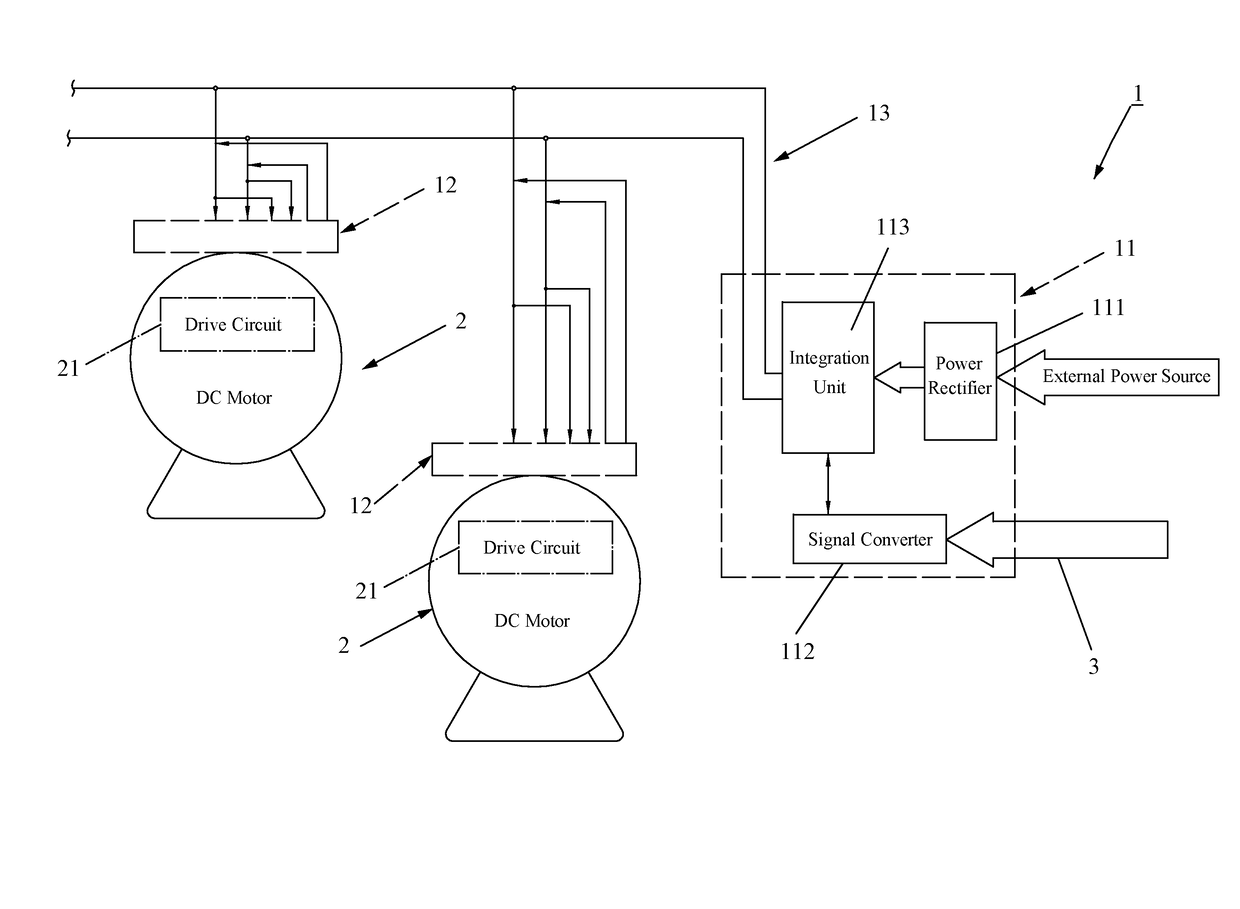

Electrical serially-connected control system

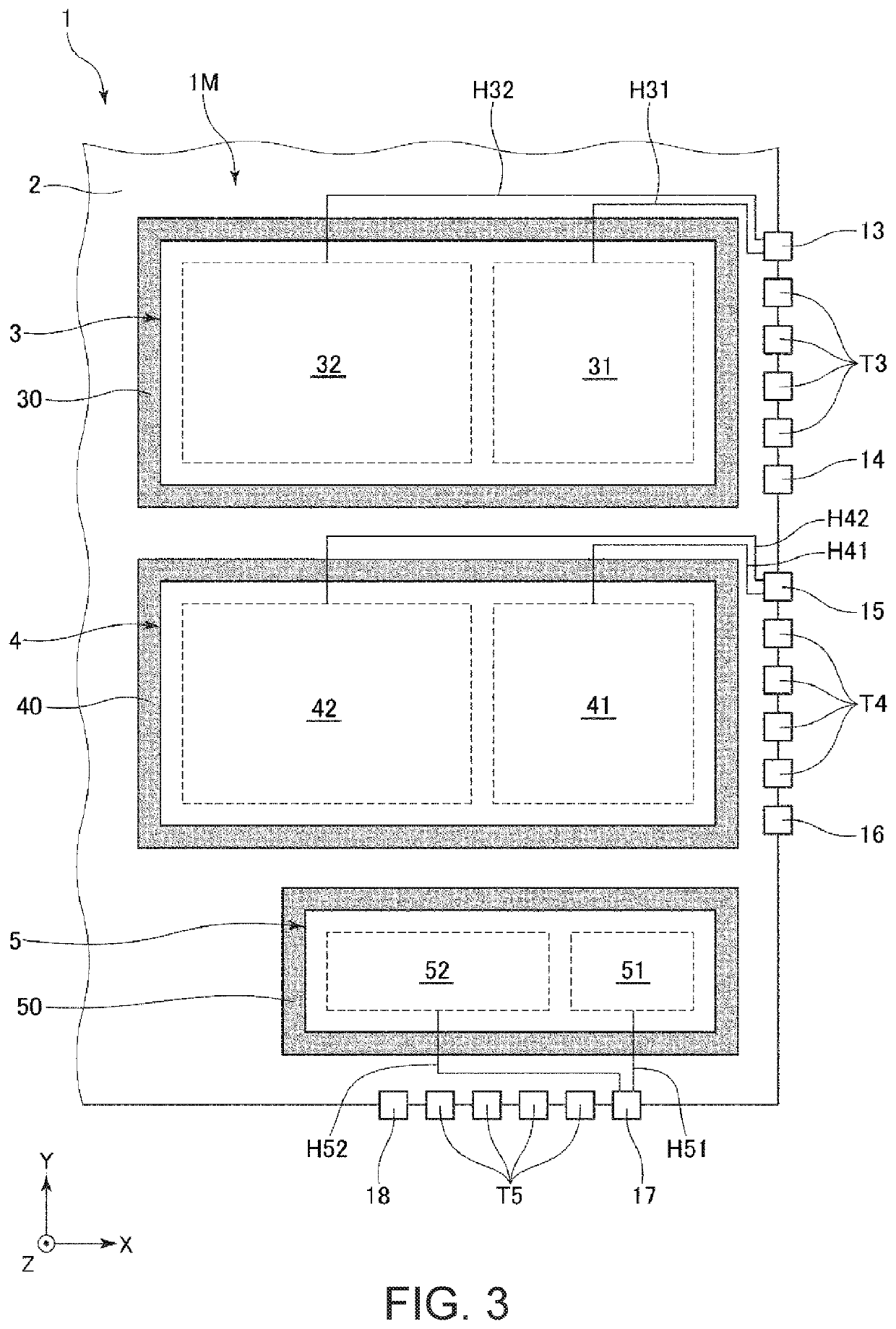

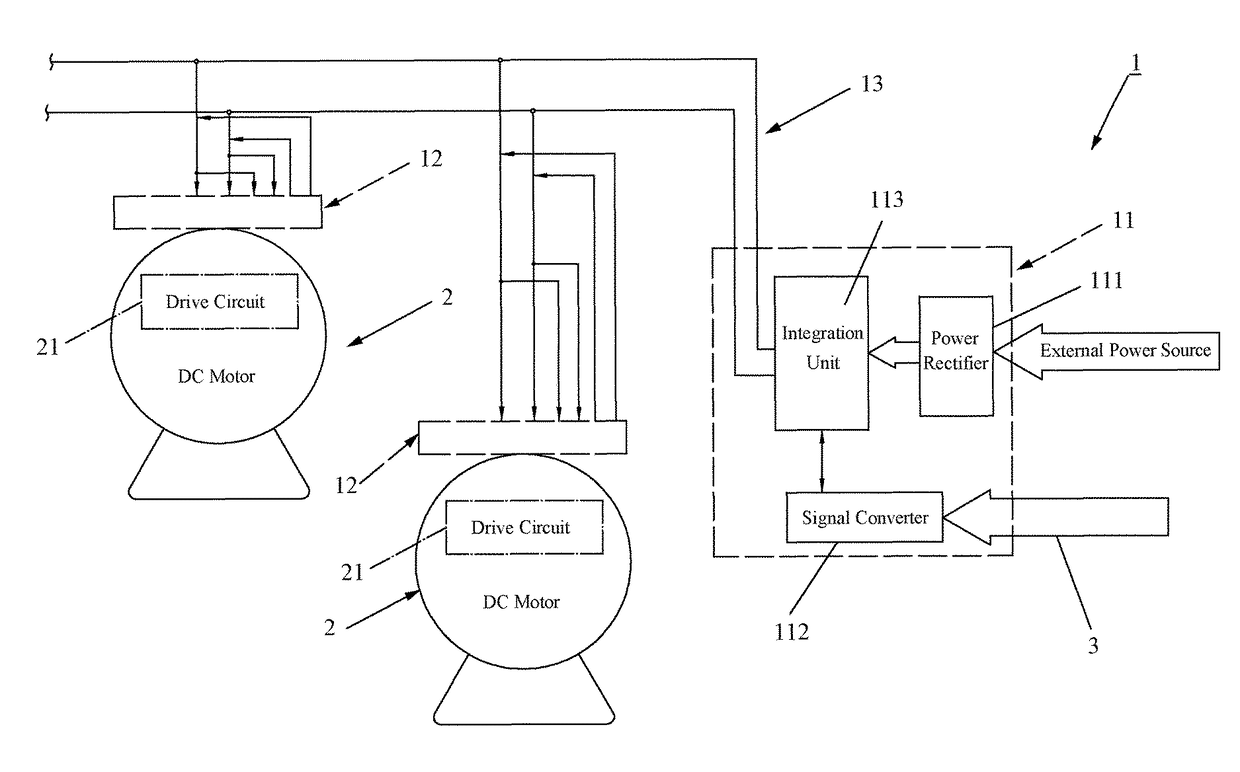

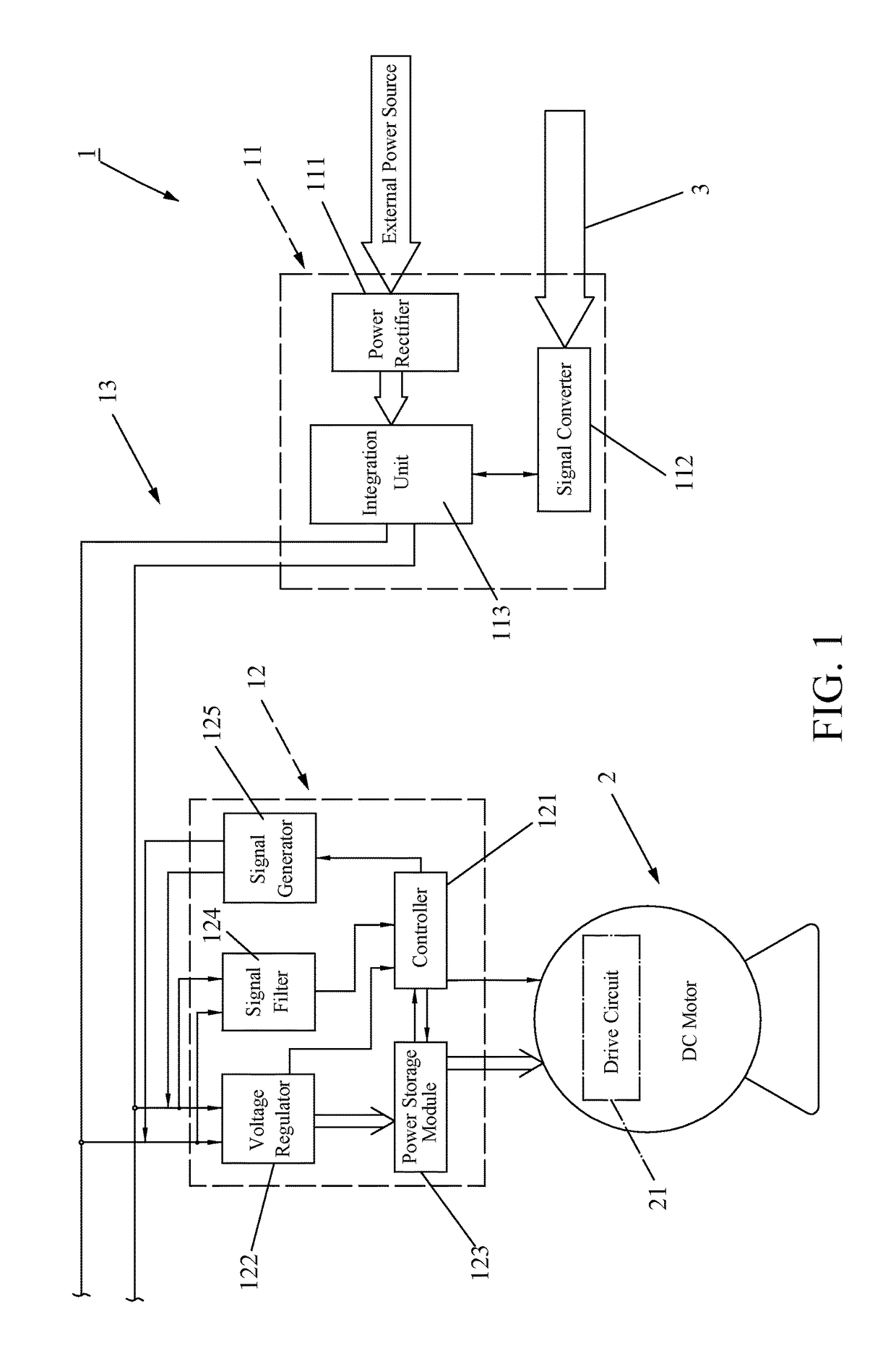

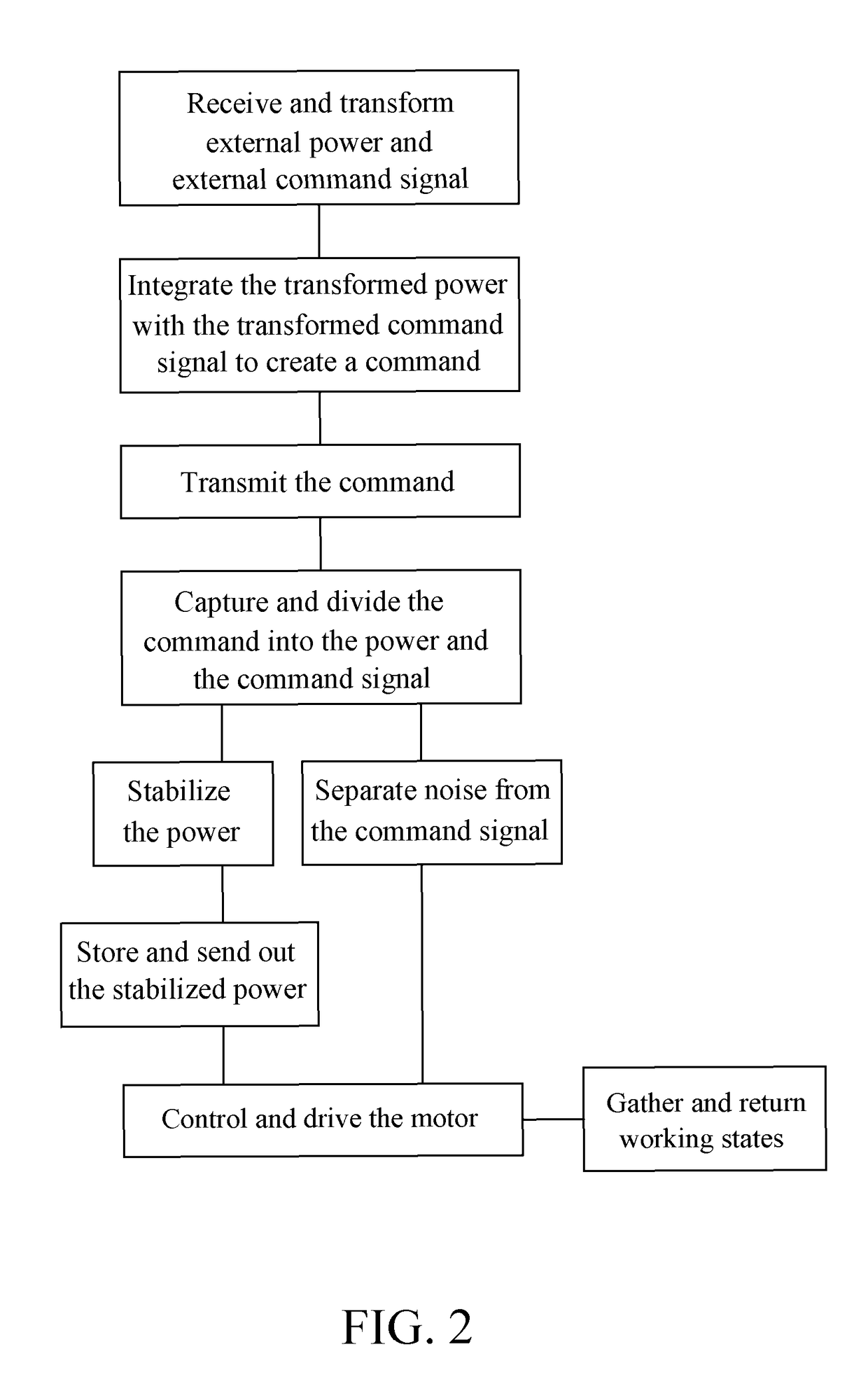

InactiveUS20180006586A1Easy to operateConvenience of drive controlMultiple ac dynamo-electric motors controlDc and ac dynamo-electric motors controlControl systemVoltage regulation

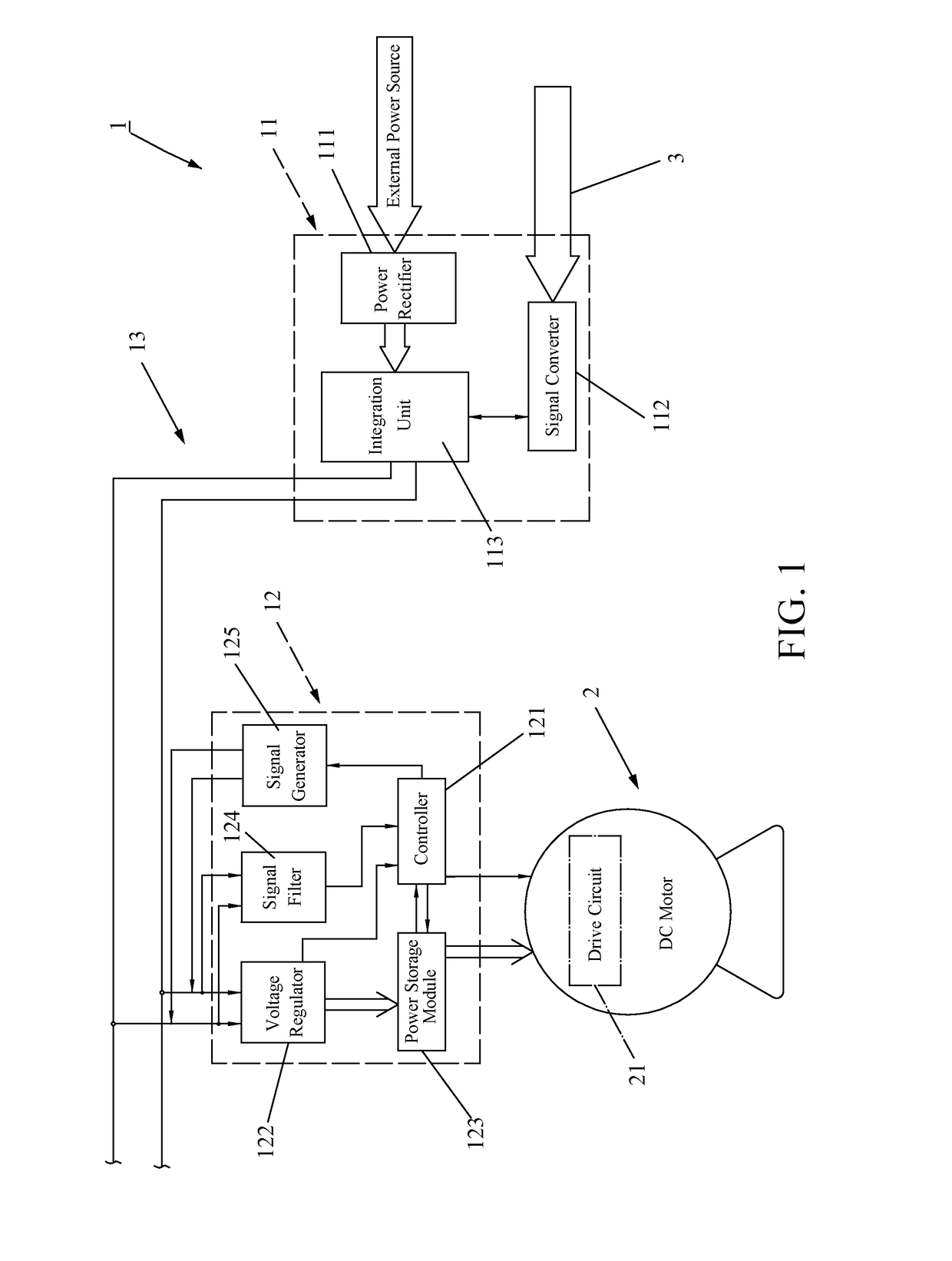

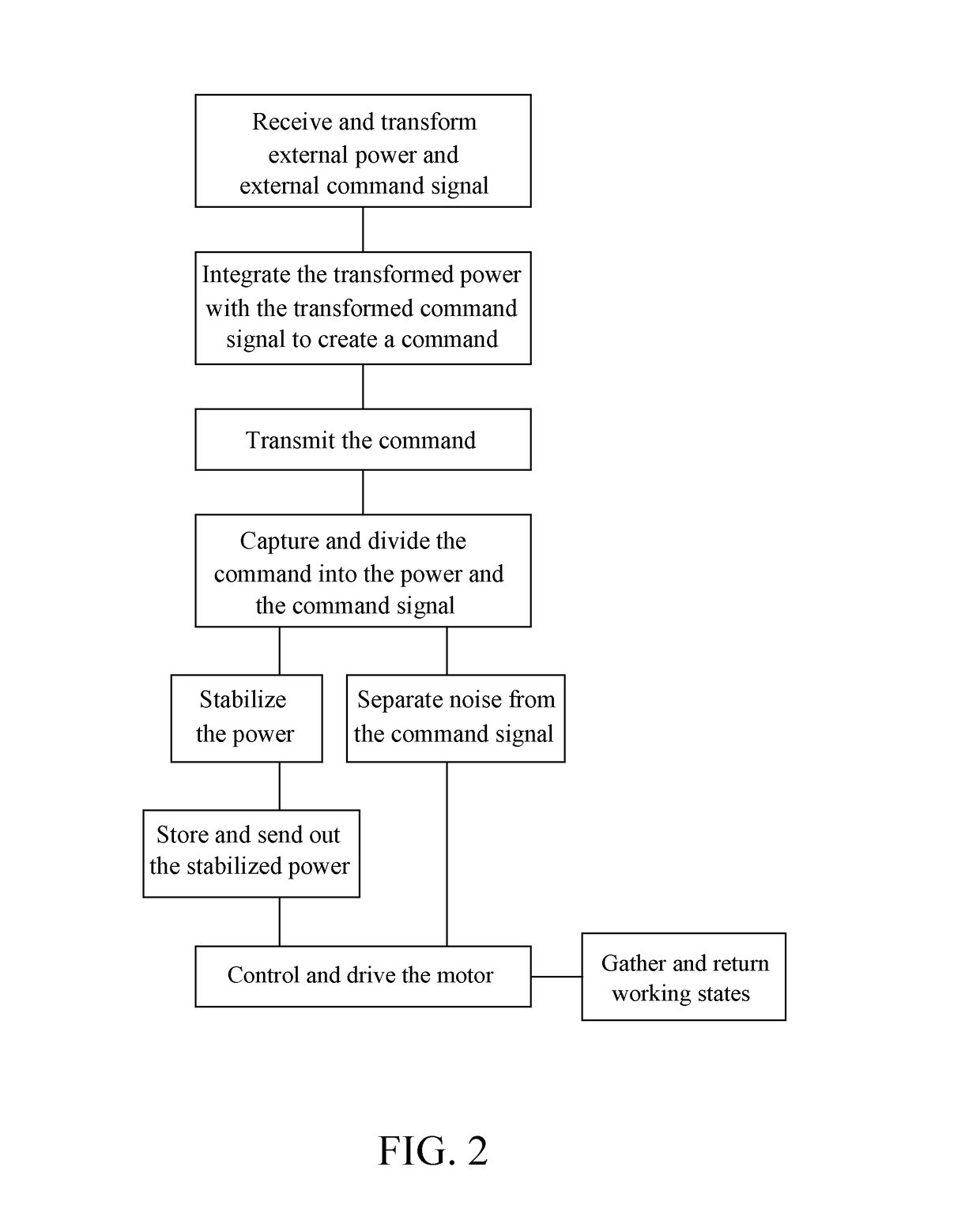

An electrical serially-connected control system for driving motors in series includes a control device, at least one processing device, and a transmission medium connected between the two devices for mutual communication. The control device includes a power rectifier transforming an external power, a signal converter converting each external command signal, and an integration unit connected to the rectifier and the converter for integrating the transformed power with each converted command signal to create commands. The processing device includes a voltage regulator connected to the transmission medium for stabilizing the power come from the command, a power storage module connected to the voltage regulator and each motor, a signal filter connected to the transmission medium for processing the command signal come from the command, a controller connected with the voltage regulator, the power storage module and the signal filter, and a signal generator connected to the controller.

Owner:NAT CHIN YI UNIV TECH

Hybrid power rotary cultivator

PendingCN106576446AReduce noiseNo emissionsTilling equipmentsDc and ac dynamo-electric motors controlCurrent meterEngineering

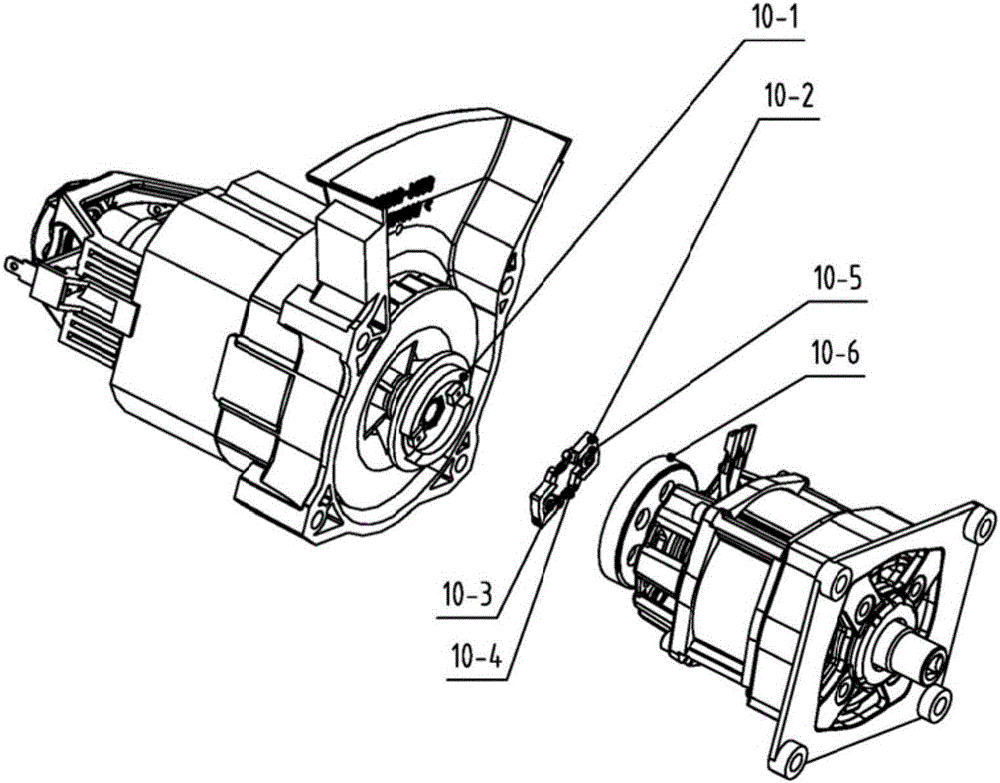

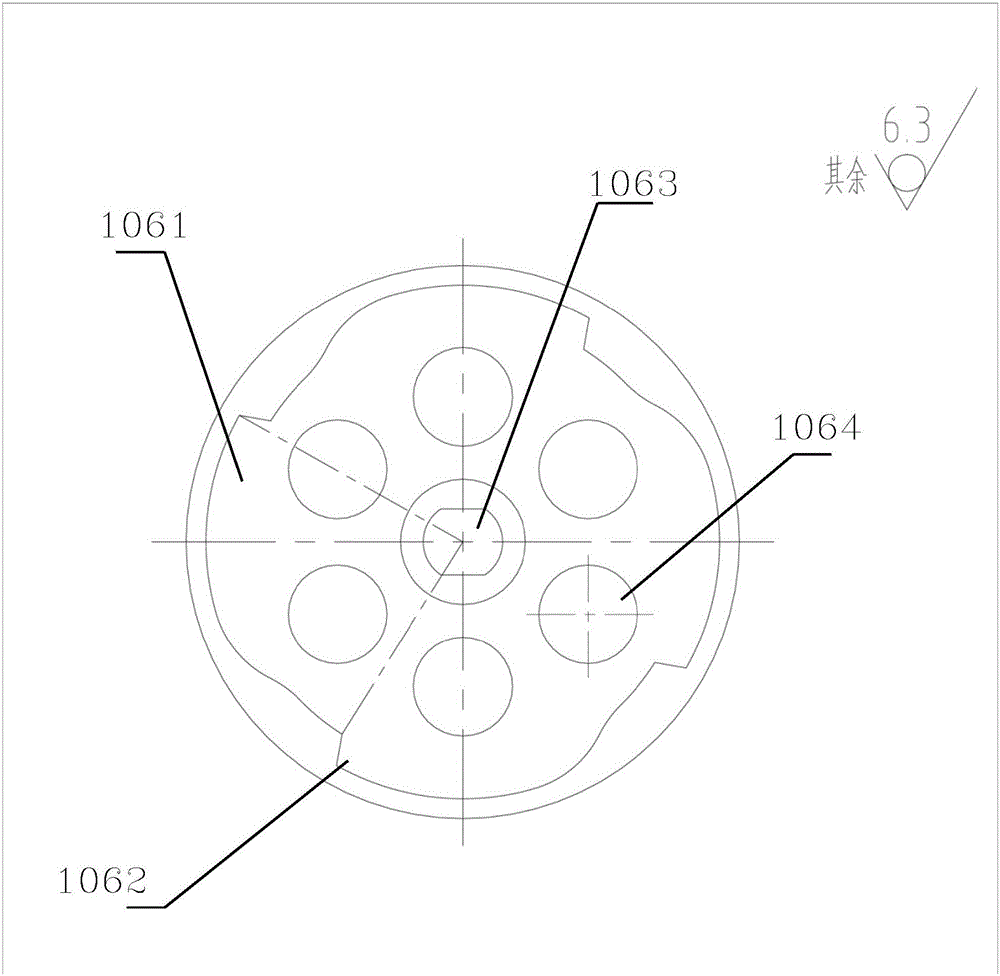

The invention discloses a hybrid power rotary cultivator. The hybrid power rotary cultivator includes an alternating current plug (1), a direct current power supply (2), a switch (3), a direct current controller (4), a direct current motor (5), an alternating current motor (6), an alternating current motor access end (7), a direct current motor access end (8), an LED lamp (9), an alternating current motor and direct current motor connector (10), and a working portion (11). The rotary cultivator includes a direct current power supply system and an alternating current power supply system which are independent working systems; and the two working systems can be simply changed by the alternating current motor and direct current motor connector, respective advantages of the two working systems are integrated together, and the problem that the conventional rotary cultivator is loud in noise, results in serious pollution, and is short in time of endurance can be solved.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

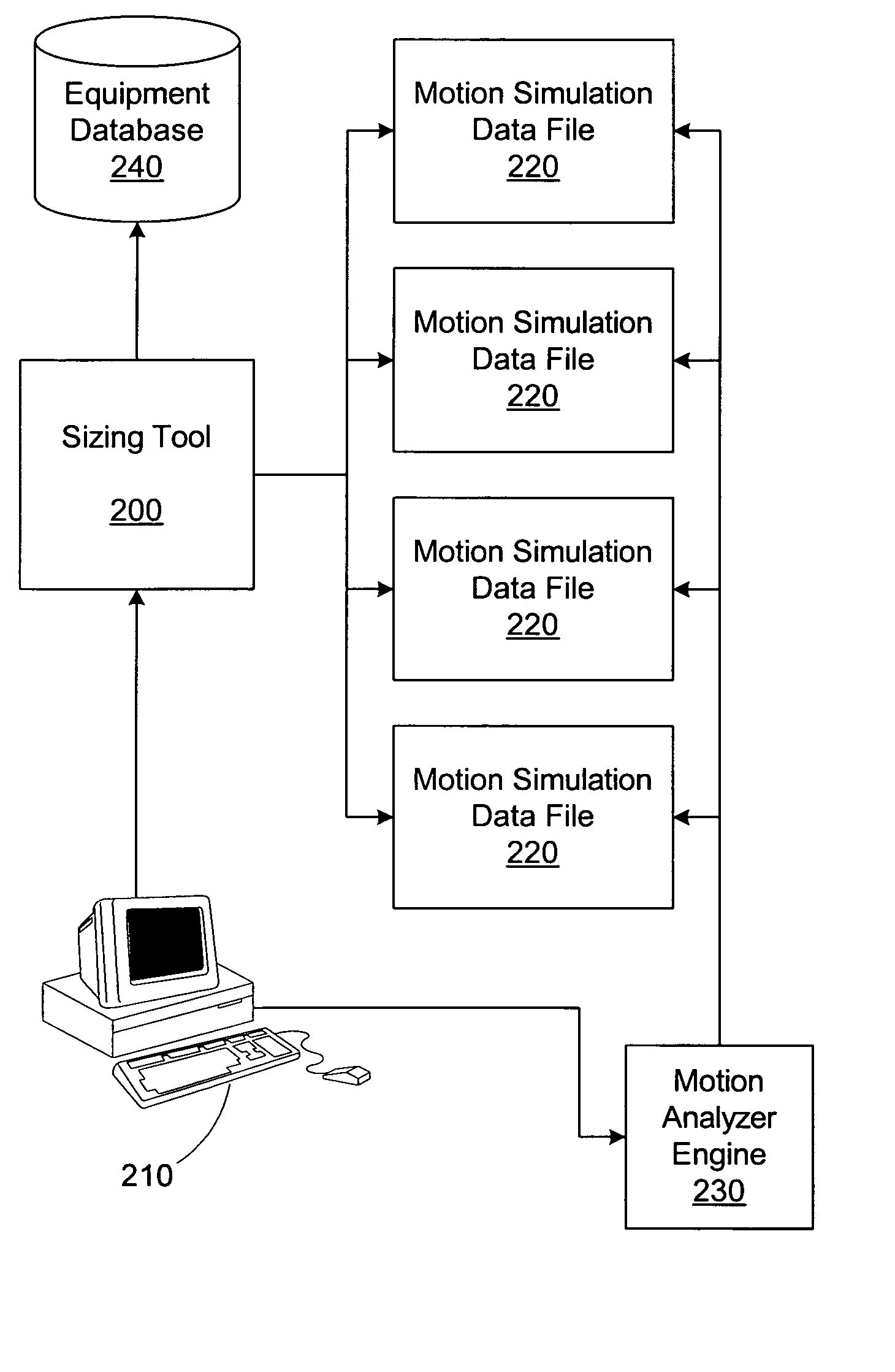

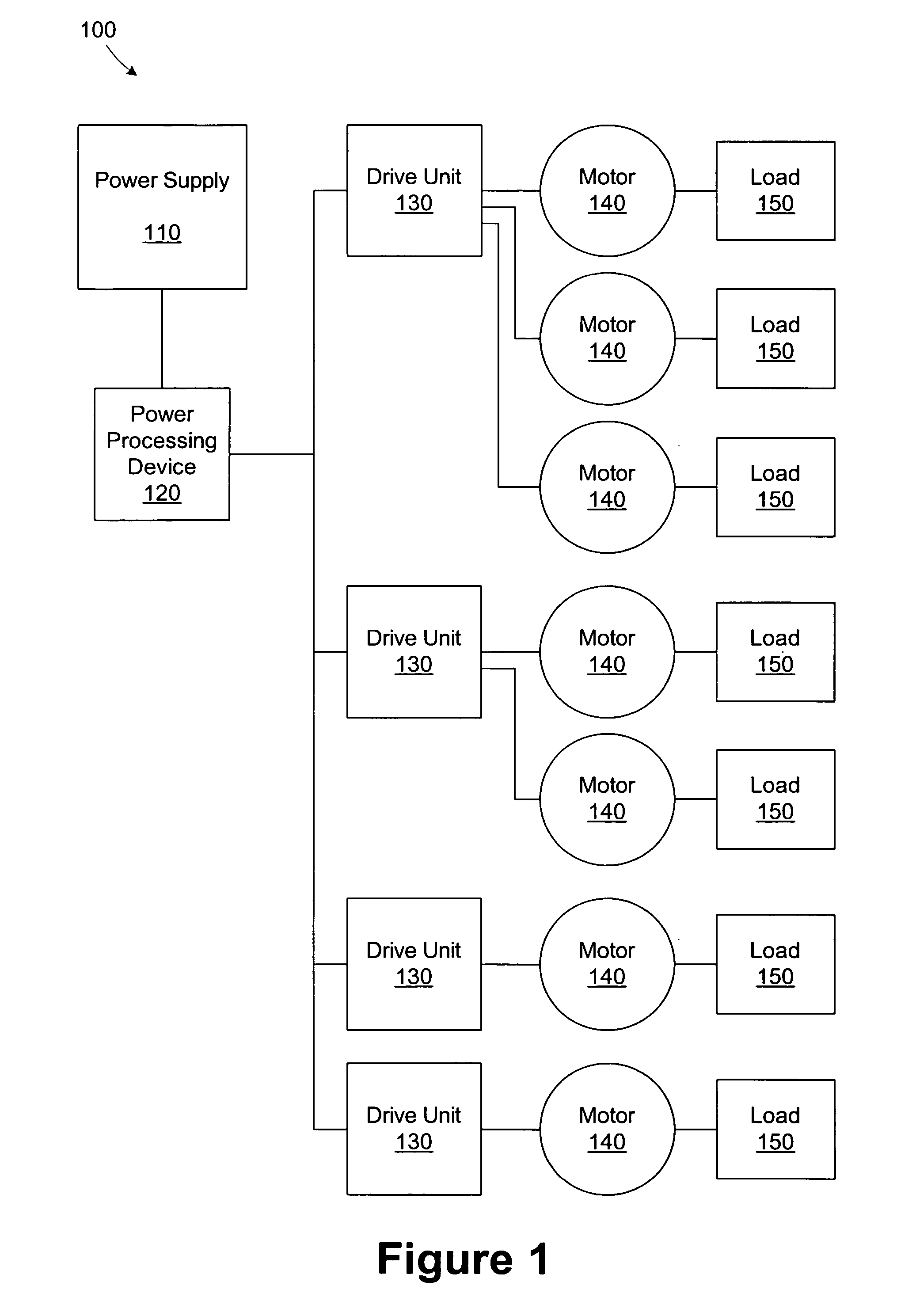

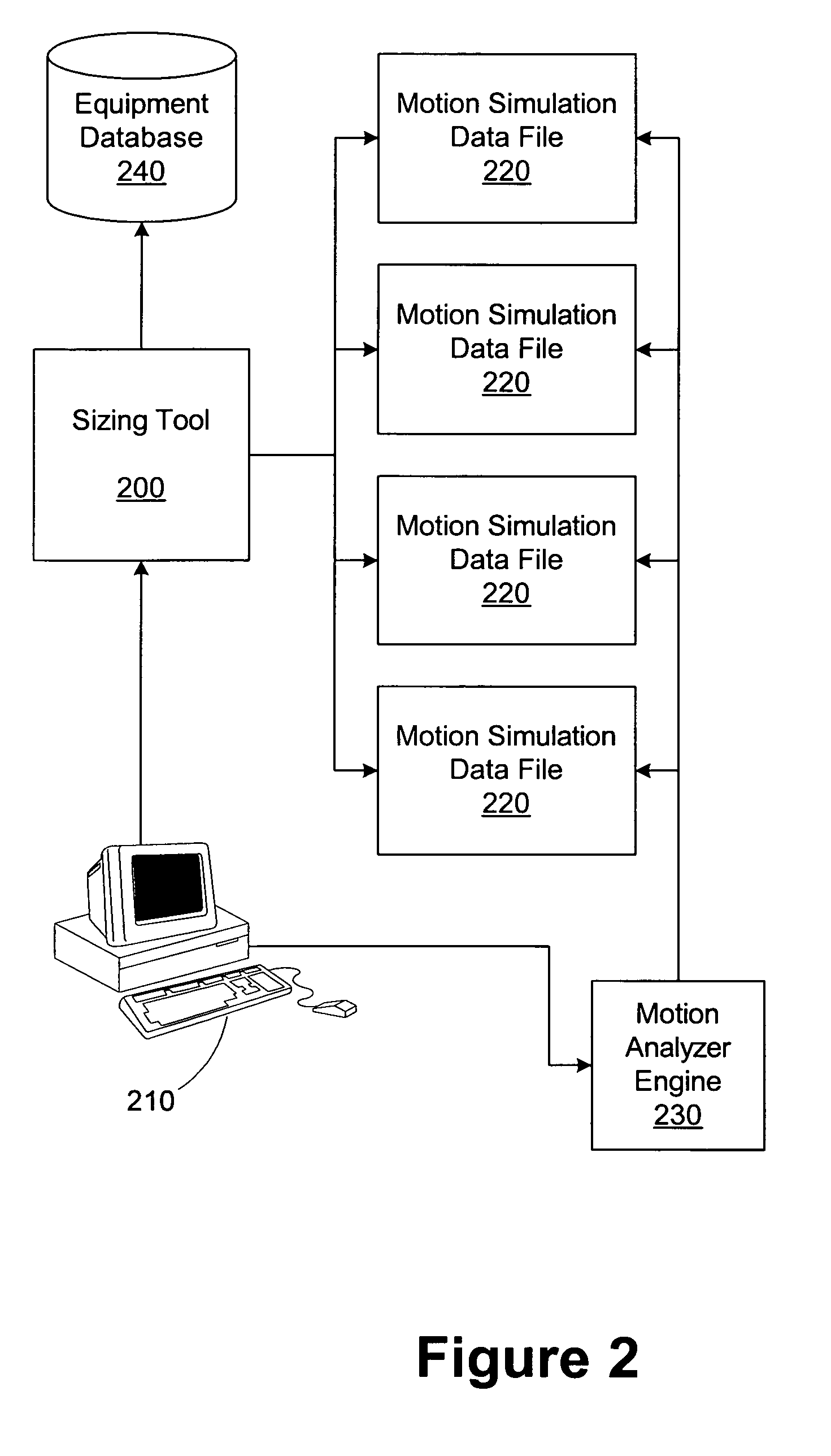

Method and apparatus for sizing a power processing device serving multiple drive units

ActiveUS7113887B2Small sizeLow ratedDC motor speed/torque controlElectric motor controlControl systemElectric machine

A method for determining supply requirements for a motor control system includes determining a performance profile for each of a plurality of drive units. A power supply parameter for each drive unit is generated based on the performance profiles. The power supply parameters for the drive units are combined to generate a rating parameter for the motor control system. In some embodiments, instructions for implementing the method may be encoded on a program storage device or programmed into a processing device for execution.

Owner:ROCKWELL AUTOMATION TECH

Motor driving device

InactiveCN100421348CIncrease speedMultiple ac dynamo-electric motors controlDc and ac dynamo-electric motors controlMotor driveElectric machine

A motor driving device is disclosed that includes a first drive circuit that drives a first electric motor and increases a rotational speed of the first electric motor according to an increase in a duty ratio of a pulse signal output from an electronic control unit. The motor driving device also includes a second drive circuit that drives a second electric motor and increases the rotational speed of the second electric motor according to the increase in the duty ratio of the pulse signal. The second drive circuit smooths the pulse signal from the electronic control unit to produce a direct-current voltage. Also, the second drive circuit supplies electric power to the second electric motor by applying the direct-current voltage to the second electric motor.

Owner:DENSO CORP

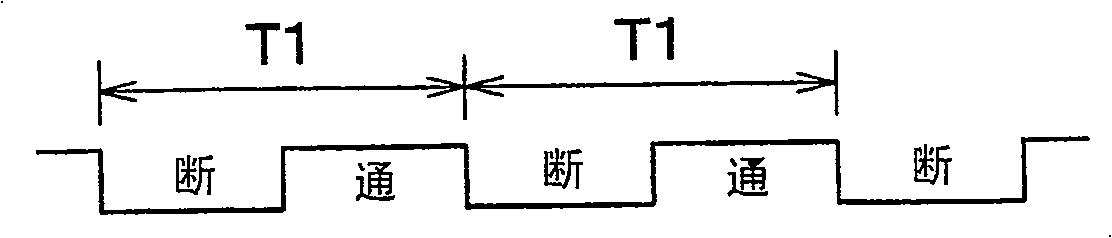

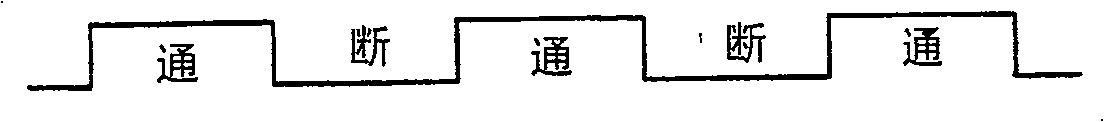

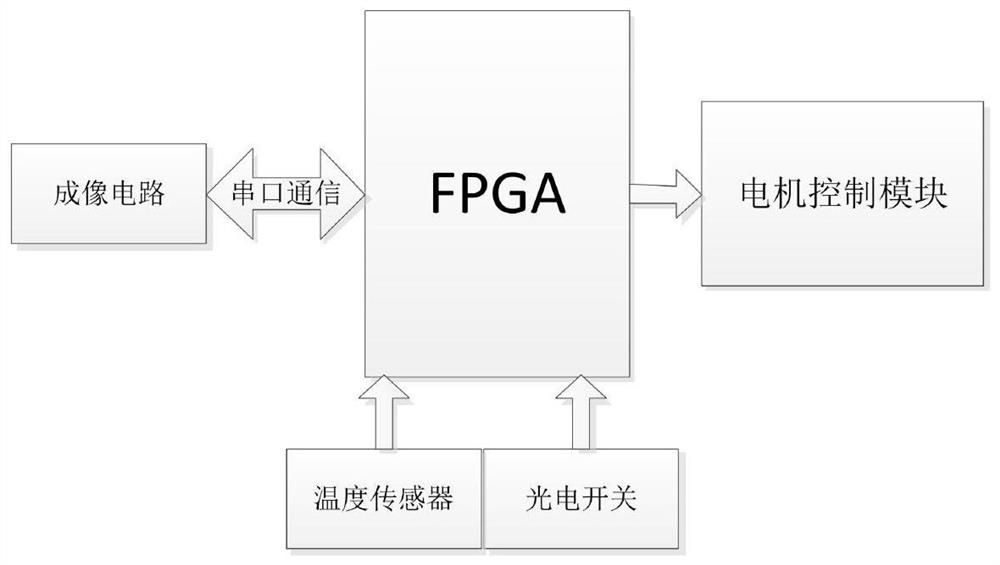

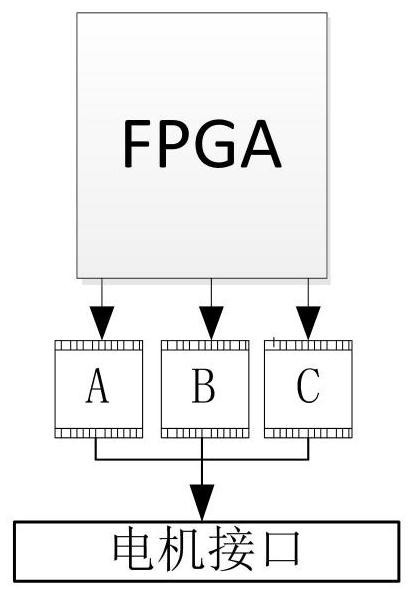

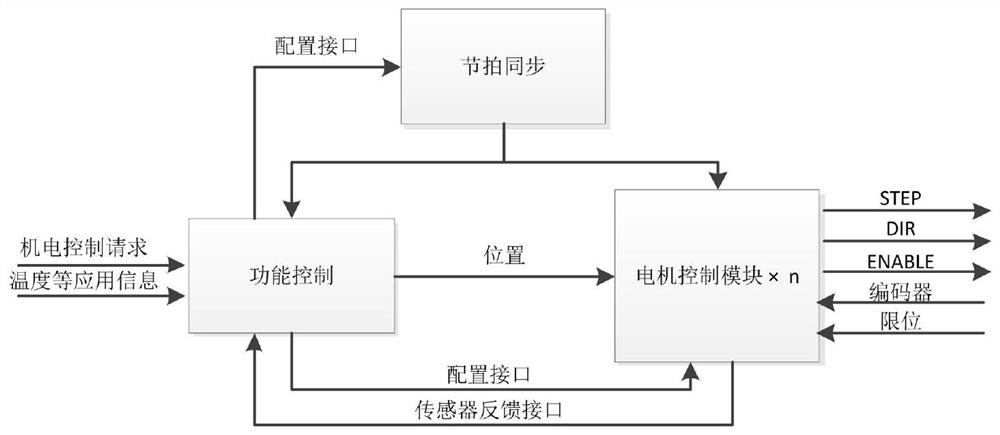

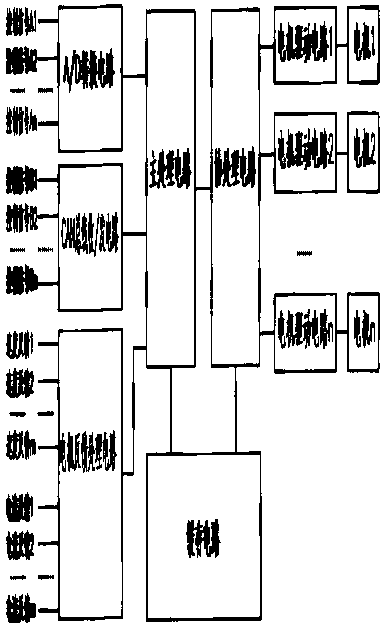

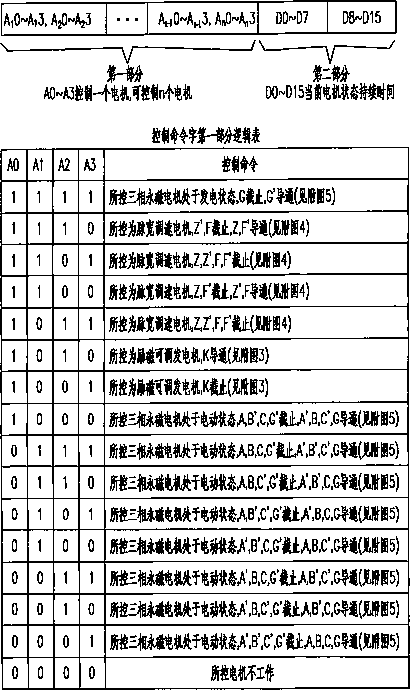

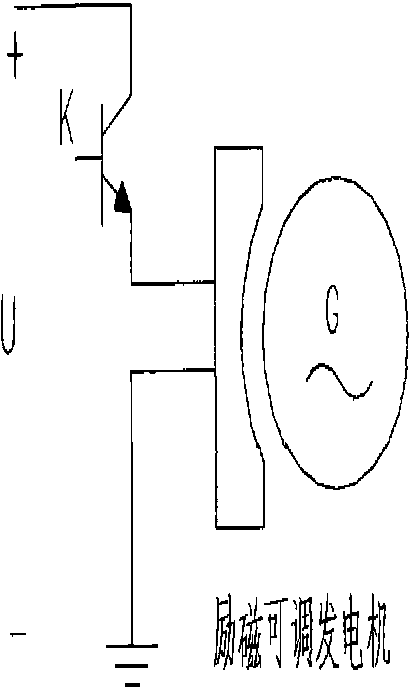

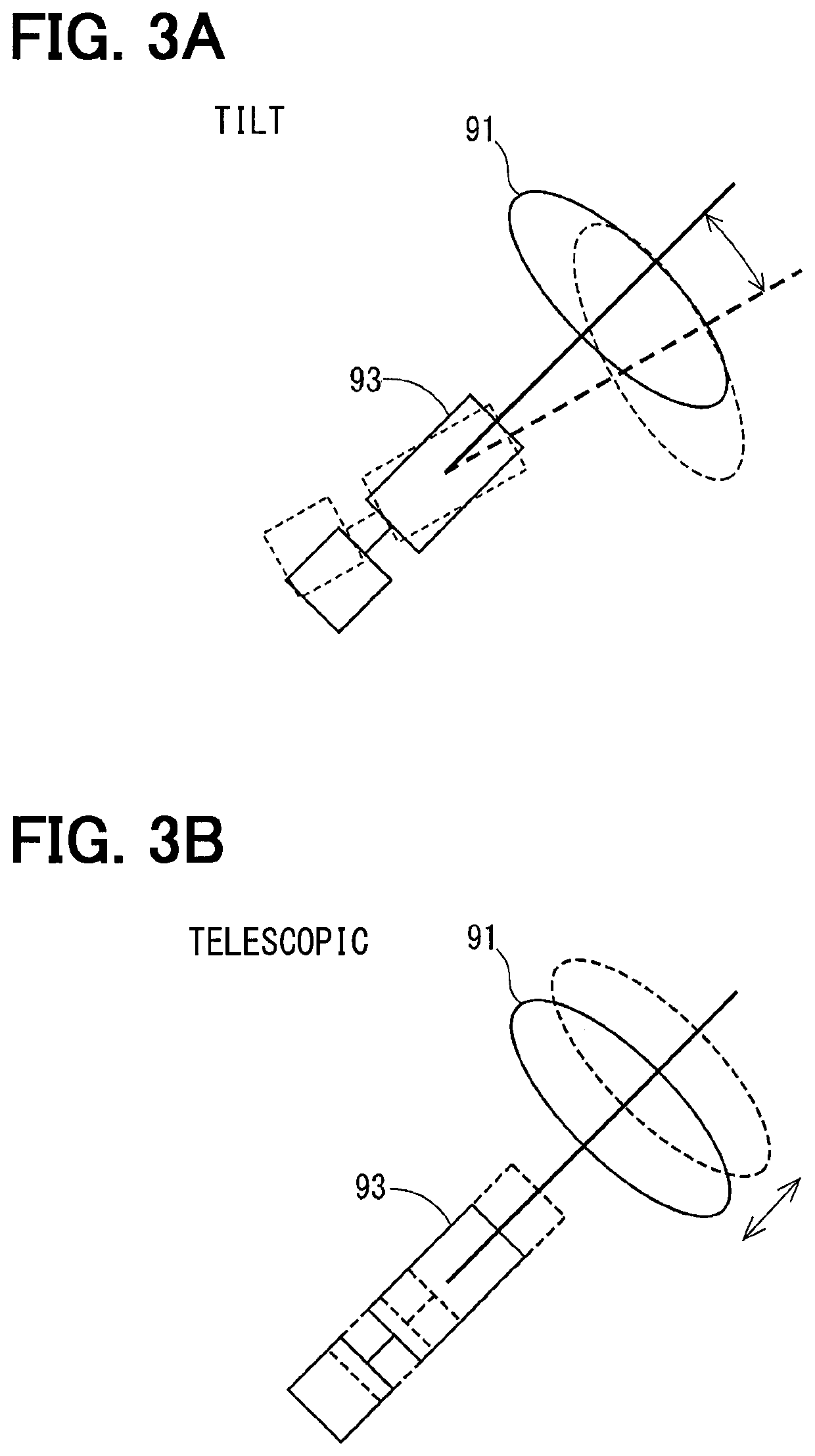

Multi-motor control circuit of thermal infrared imager

PendingCN112600465AFunction increaseDynamo-electric converter controlDc and ac dynamo-electric motors controlPhotoswitchElectric machinery

The invention discloses a multi-motor control circuit of a thermal infrared imager. The multi-motor control circuit is applied to a multi-type thermal infrared imager, can complete the control of eachmotor of the thermal infrared imager and is matched with a motor control software program; and the multi-motor control circuit, a related motor, a mechanical structure, a photoelectric switch and thelike are cooperatively matched and controlled. By means of the above design, multi-motor cooperative control with time precision reaching the levelo f 0.01 microsecond and position precision reachingthe level of 0.01 millimeter can be completed; the functions of the multi-motor control circuit are diversified; a unified motor interface is adopted, so subsequent updating and maintenance are facilitated; and the design has important significance in research of a continuous zoom system and motor control.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

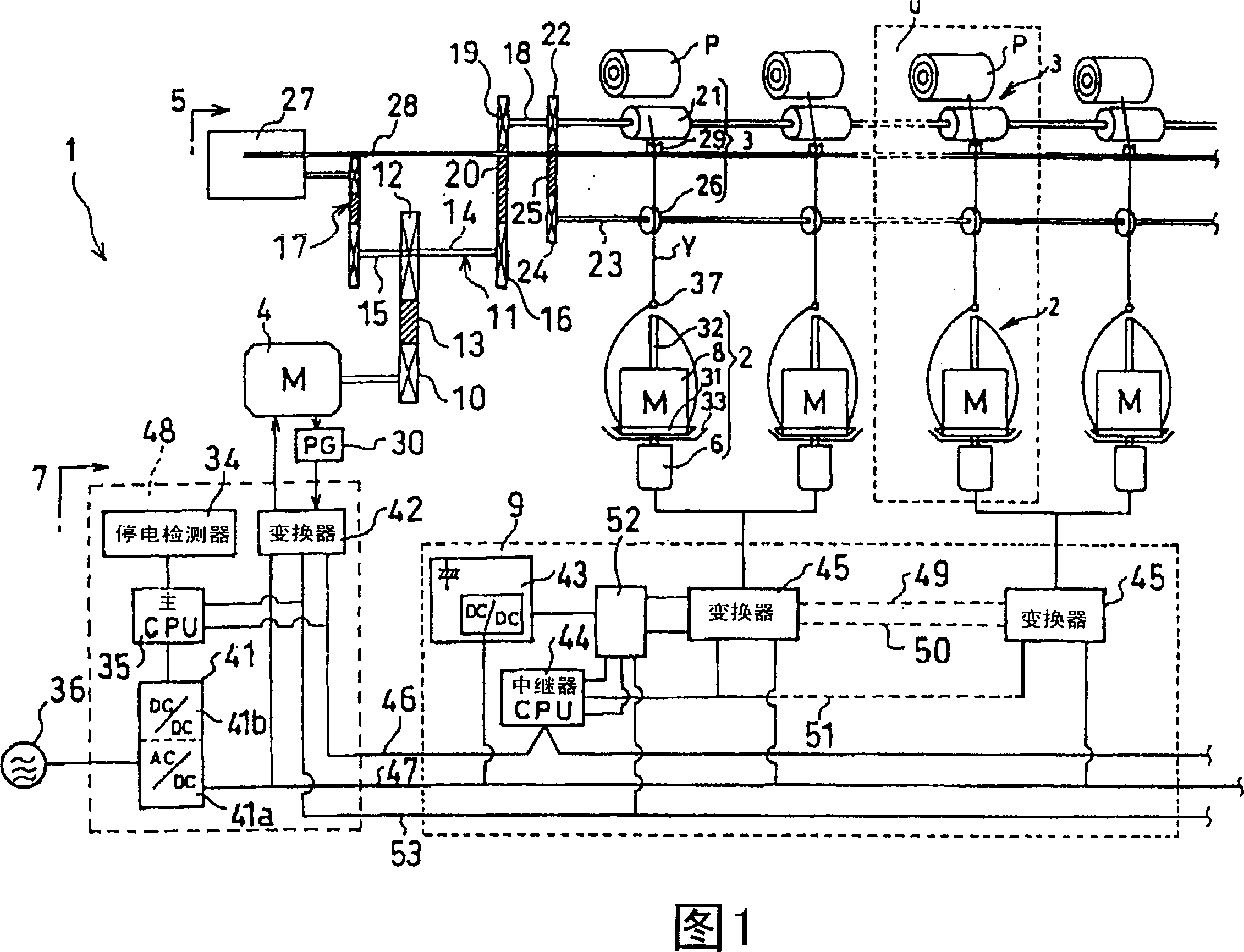

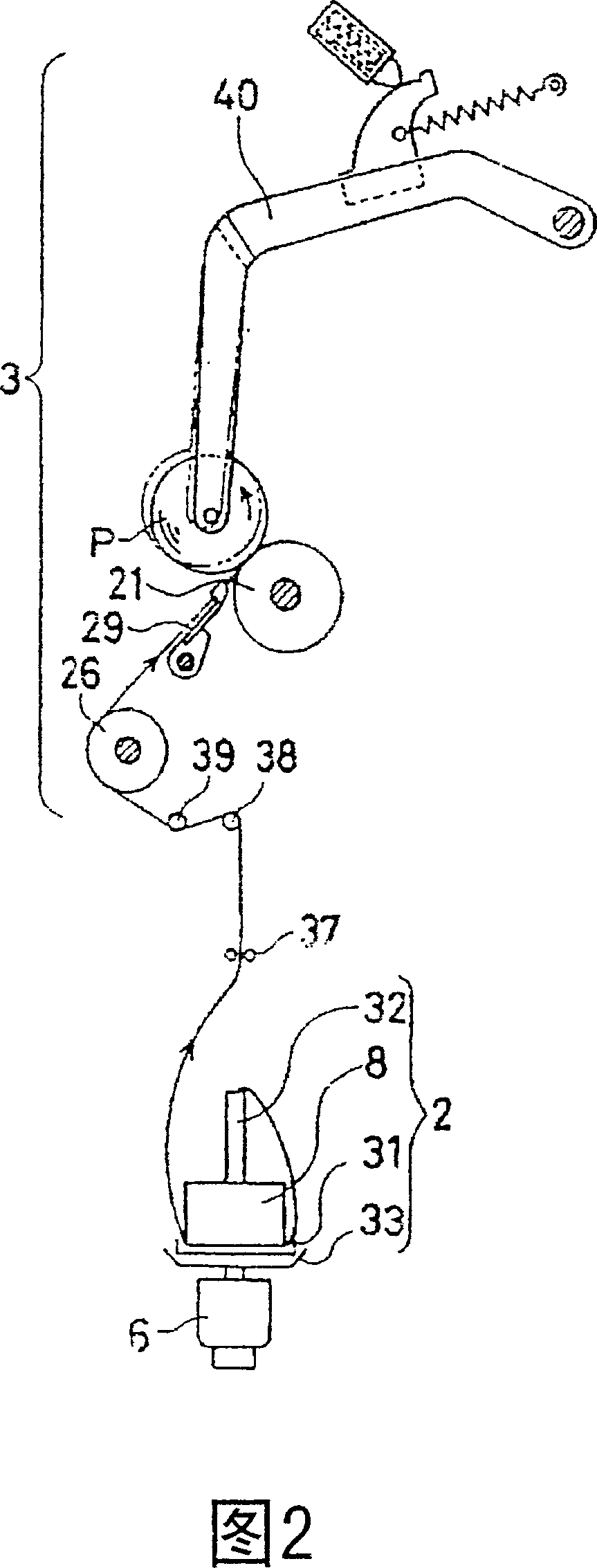

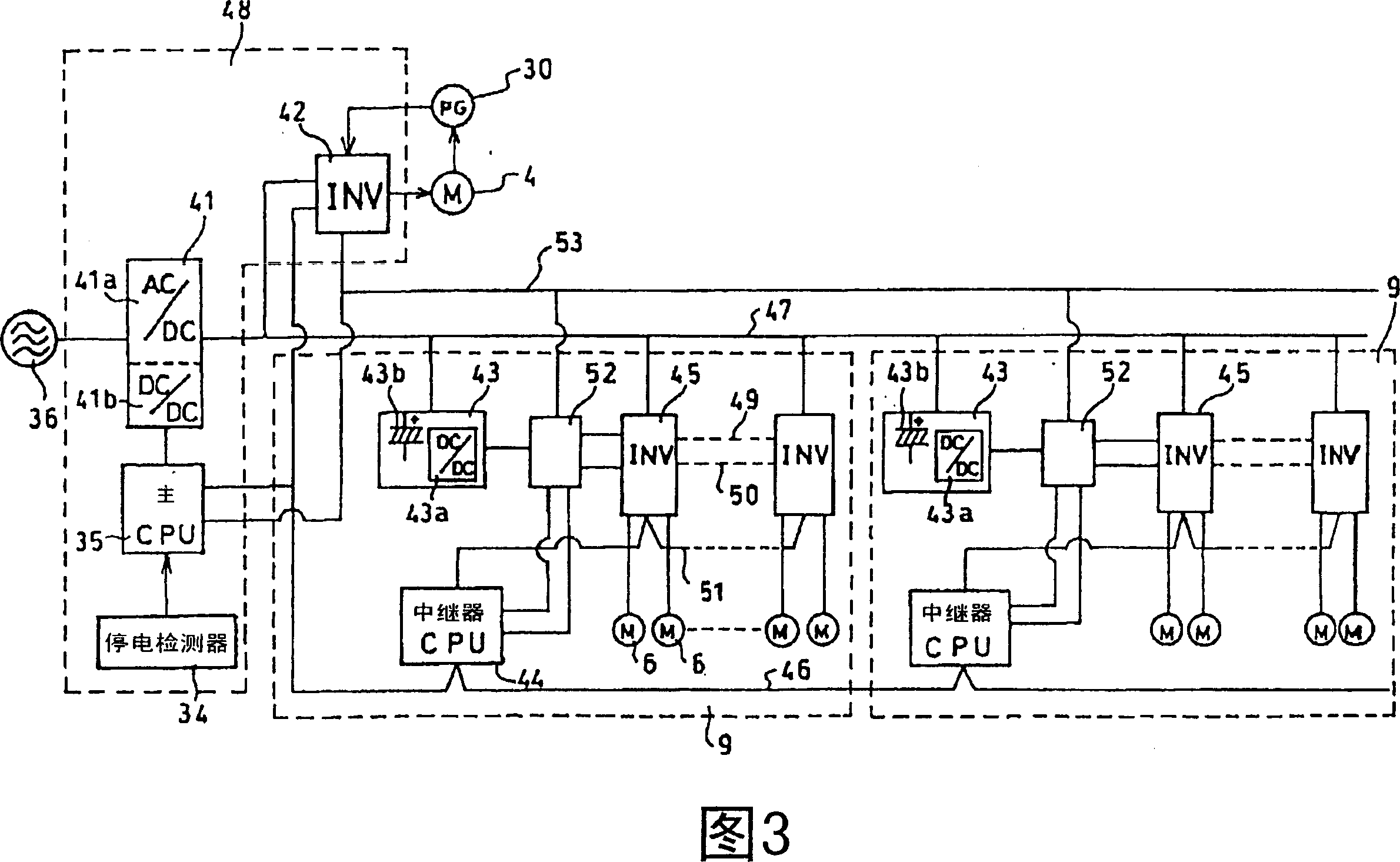

Individual-spindle-drive type textile machine

InactiveCN1970858AAvoid voltage dropMotor/generator/converter stoppersMultiple motor speed/torque controlFiberStop time

This invention provides an apparatus for treating power failure capable of decelerating and stopping spindle driving system motors and drum driving system motors while synchonizing both with simple control at the time of the power failure. This apparatus for treating power failure of a multiple twister drives the plural spindle driving motors installed for each spindle and the winding drum driving motors common to the plural spindles with inverters, respectively. The apparatus is equipped with a power failure detecting means for detecting the power failure when the voltage is reduced by a prescribed value or above, stop commanding means for outputting stop commands to respective inverters when detecting the power failure and the stopping means for performing feedback control so as to stop each of motors at a predetermined stopping time based on the stop commands.

Owner:MURATA MASCH LTD

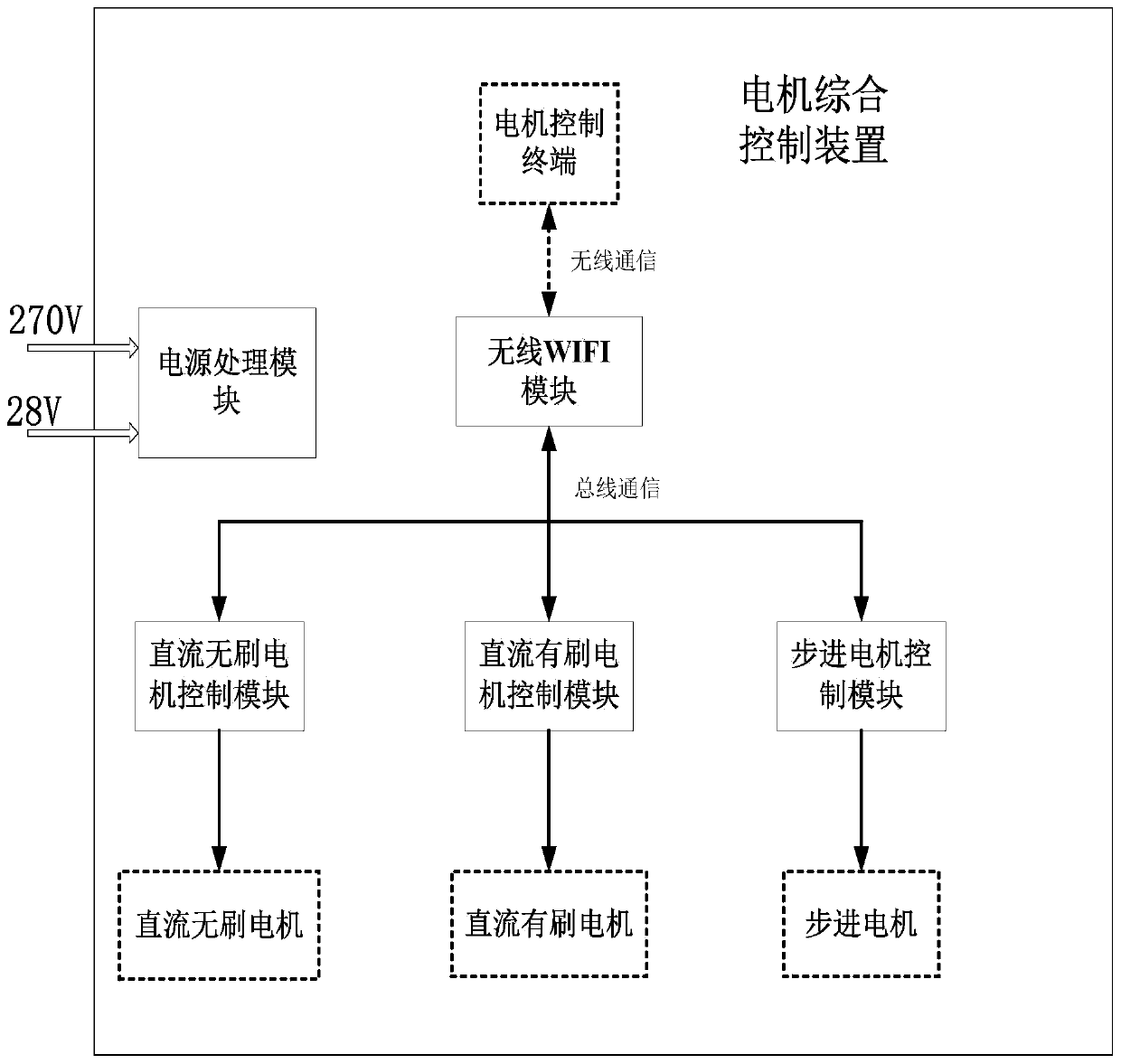

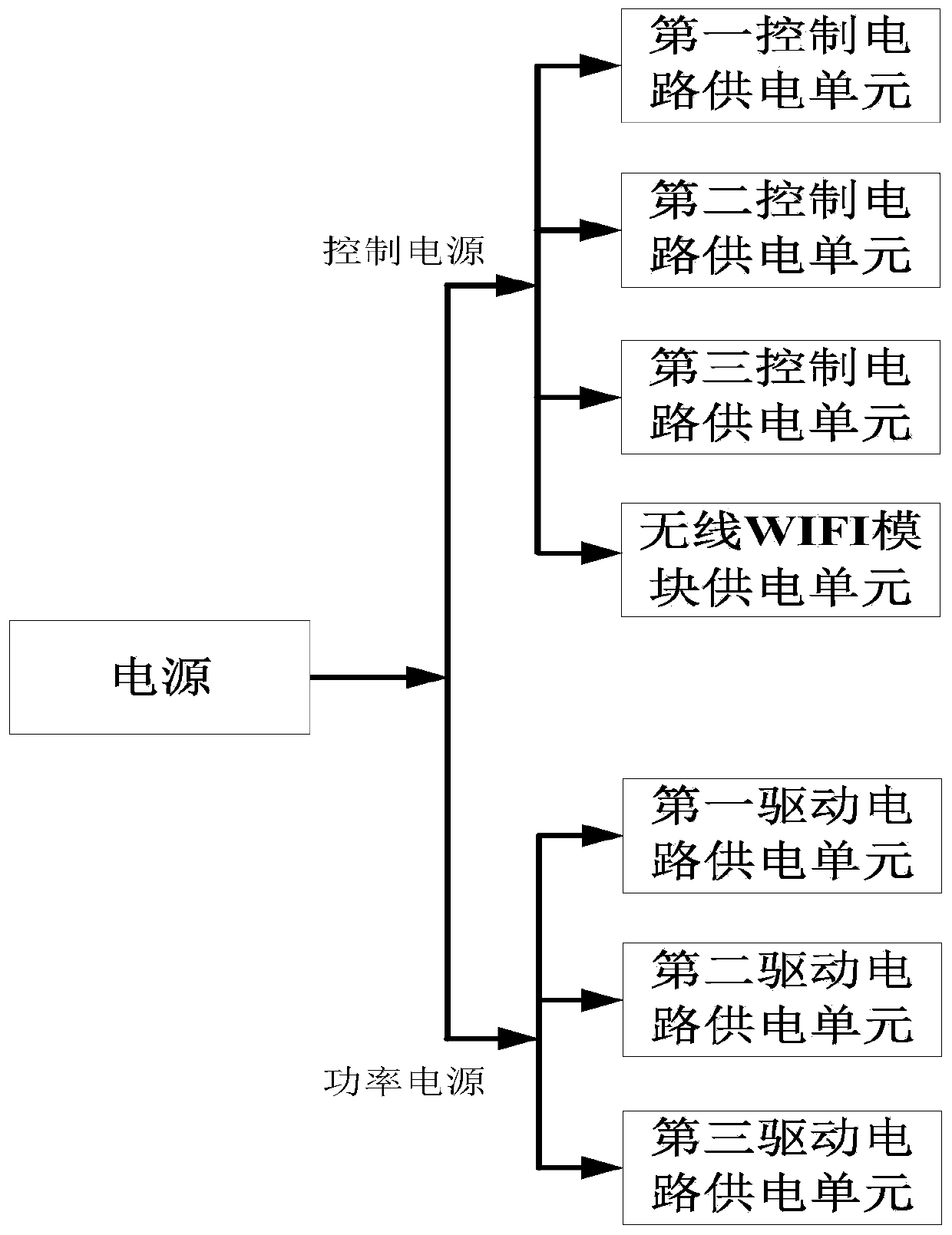

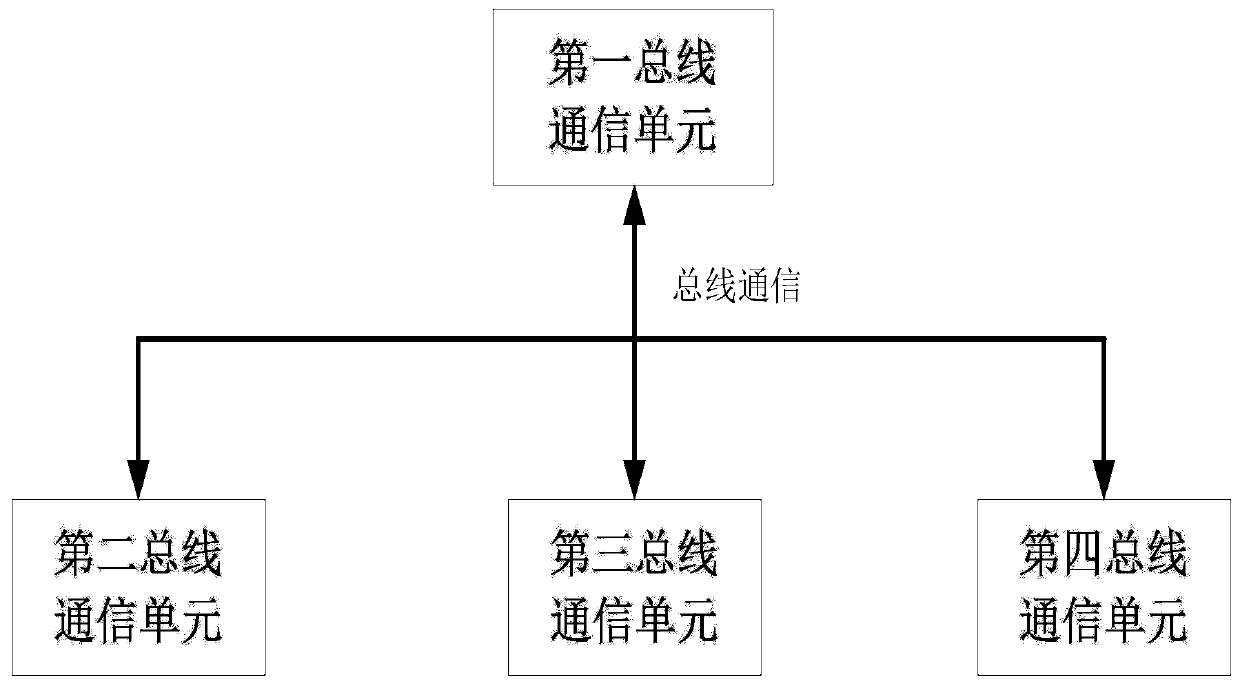

Comprehensive control device based on wireless WIFI

PendingCN110808696AEasy to read workEasy to monitor operationTransmission systemsDc and ac dynamo-electric motors controlBrushless motorsControl engineering

The invention provides a comprehensive control device based on wireless WIFI. A wireless WIFI module receives a motor working instruction sent by a motor control terminal through a wireless WIFI signal; the wireless WIFI module is used for identifying and processing the motor working instruction, the motor working instruction is transmitted to a direct-current brushless motor control module or a direct-current brush motor control module or a stepping motor control module in the form of bus signals; and the direct-current brushless motor control module or the direct-current brush motor controlmodule or the stepping motor control module operates the processed motor working instruction and outputs a corresponding motor control signal so as to control the direct-current brushless motor or thedirect-current brush motor or the stepping motor to work. Data transmitted can run in the device for a long time, the running condition of the motor control device can be monitored more conveniently,and the motor control device can be simplified and intelligentized.

Owner:XIAN AVIATION BRAKE TECH

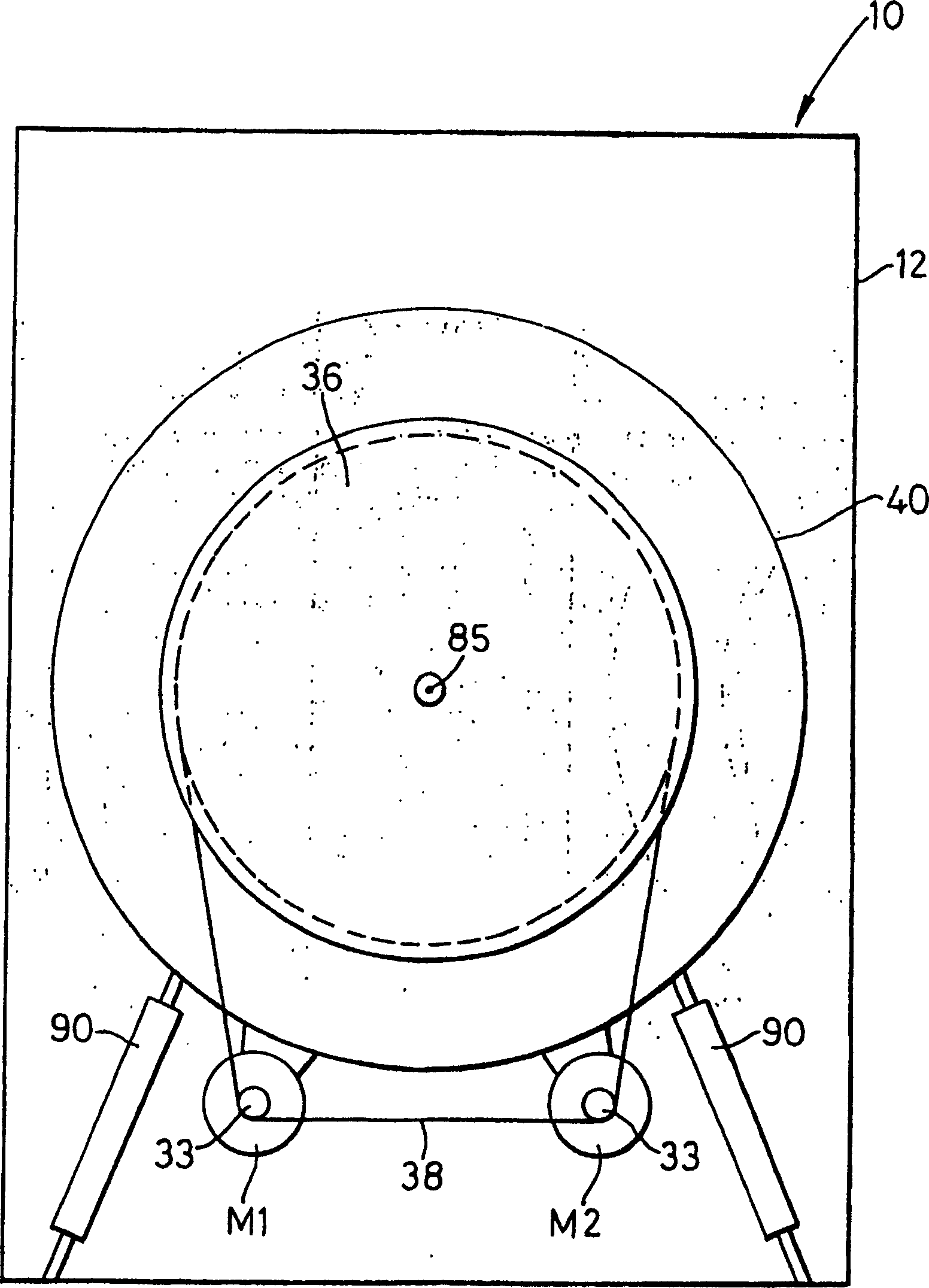

Motor control device for two motors and method

InactiveCN1201477CShort lifeExtend your lifeDC motor speed/torque controlMultiple motor speed/torque controlLaundry washing machineControl engineering

A load in an electrical apparatus is driven by two motors M1, M2. Switching means (R1, R2) switches the motors M1, M2 between: a series configuration, in which the motors M1, M2 are connected in series across a power supply and driven with a dc supply; and a parallel configuration in which the motors M1, M2 are connected in parallel across the power supply and driven with an ac supply. In the series configuration, a bridge rectifier BR is switched across the ac supply to provide the dc supply for the motors M1, M2 and in the parallel configuration, the rectifier BR is removed from the circuit. The arrangement can be used to drive a drum of a washing machine or a load in some other kind of appliance.

Owner:DYSON TECH LTD

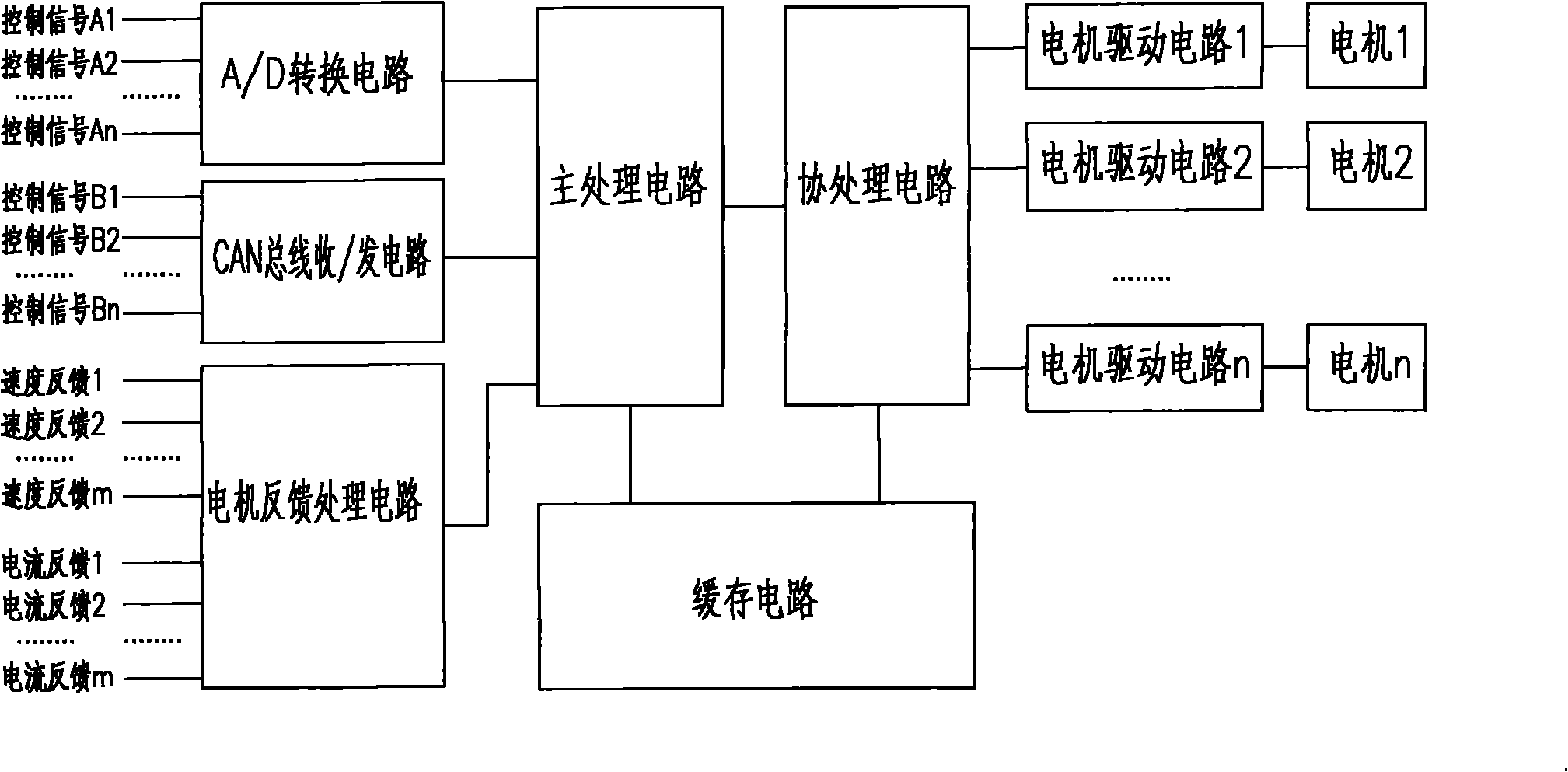

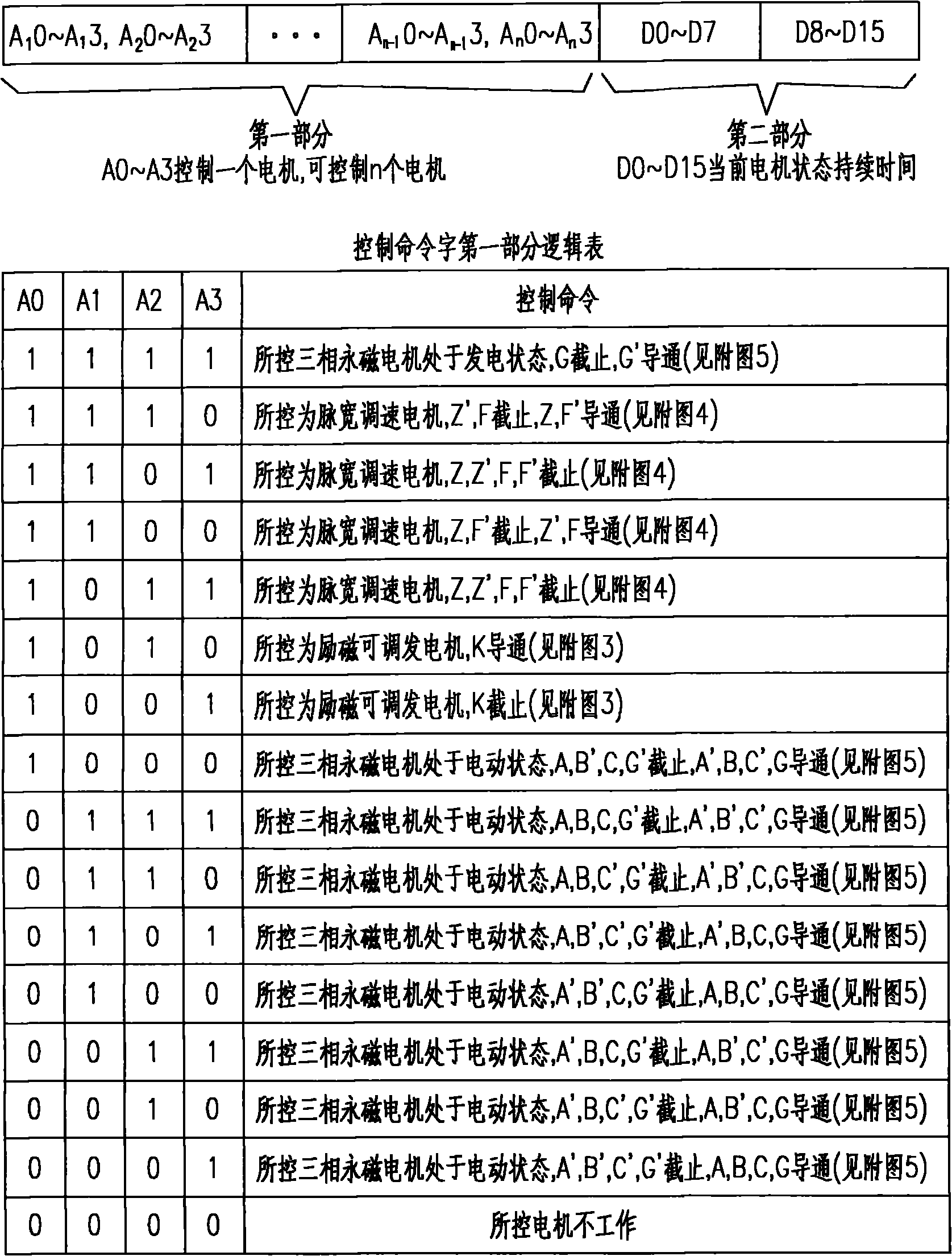

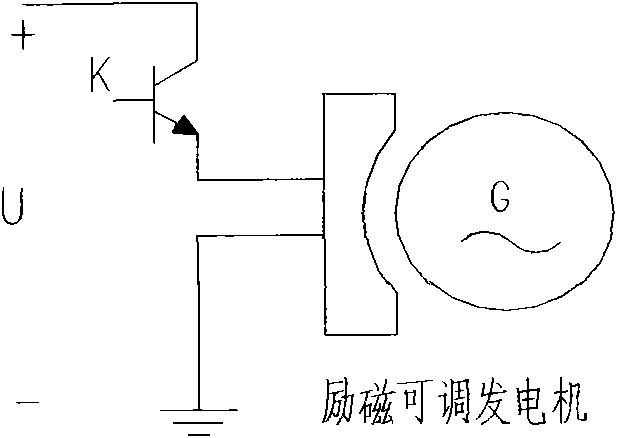

Multi-motor cluster driving control technology

InactiveCN101895242ALow costReduce volumeDc and ac dynamo-electric motors controlCoprocessorMotor drive

The invention relates to a multi-motor cluster driving control technology which comprises a peripheral signal receiving circuit, a main processor circuit, a buffer circuit, a coprocessor circuit and N motor-driven circuits. A main processor is used for receiving control signals and speeds and current feedback signals of motors and respectively carrying out corresponding operation processing. The switching-on / switching-off times of all the power switching pipes of the motors are sequenced from front to back by adopting unified time, thereby generating the control command words of all the motors. The multi-motor cluster driving control technology has the advantages of low cost, small size, light weight and high precise control degree for the motors.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

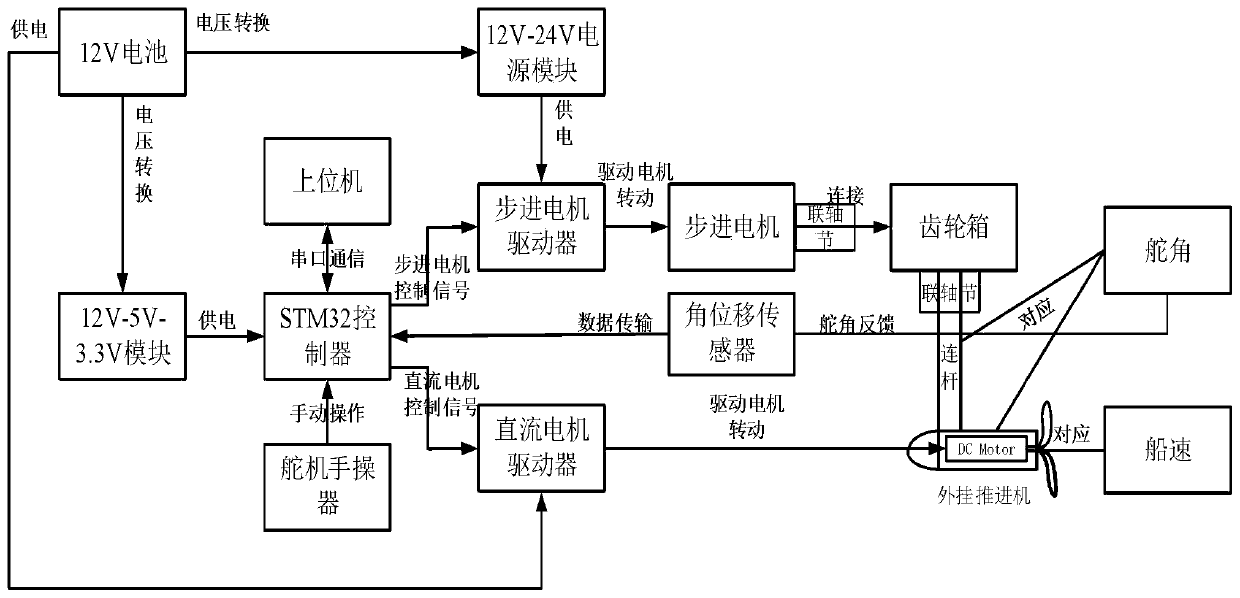

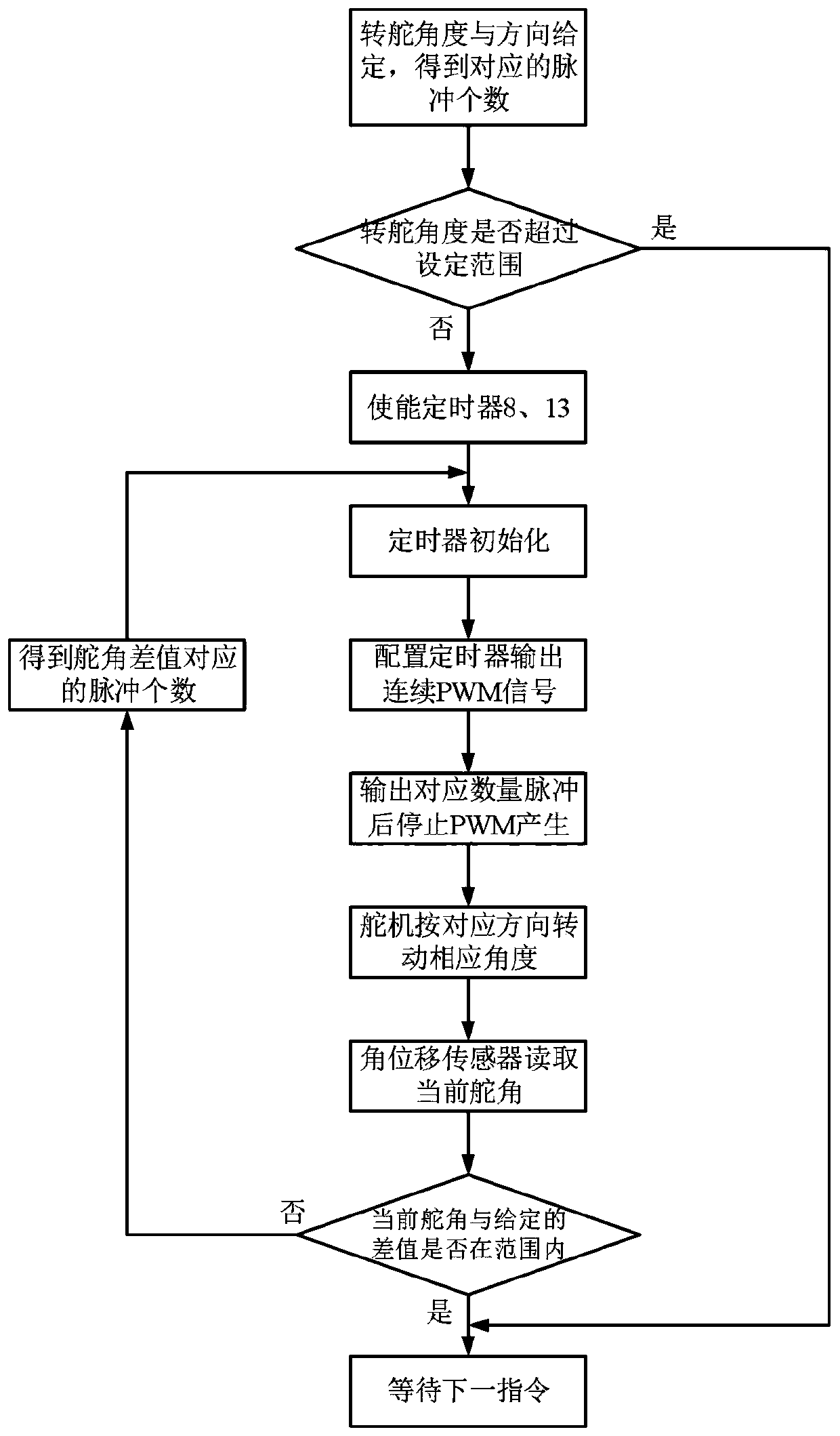

Electric steering engine servo device for ship

InactiveCN111232177AEasy to controlSteering ruddersField or armature current controlSTM32Electric machinery

The invention discloses an electric steering engine servo device for a ship. The device comprises the components of an upper computer which outputs a control rudder angle value of a motor driver of aship; an STM32 controller which receives the rudder angle value transmitted by the upper computer; the STM32 controller transmits the rudder angle value to the stepping motor driver and stores the rudder angle value; the output end of the stepping motor driver is connected with the stepping motor; an output shaft of the stepping motor is connected with the gear box, and rotation of the gear box iscontrolled according to the received rudder angle value. The device further comprises an angular displacement sensor used for detecting actual rudder angle information of the ship. The angular displacement sensor transmits a detected actual rudder angle value to the STM32 controller; and the STM32 controller compares the rudder angle value given by the upper computer with the actual rudder angleto obtain a rudder angle difference value, performs rudder angle compensation control on the stepping motor according to the rudder angle difference value, and stops the rudder angle compensation control until the actual rudder angle is equal to the given rudder angle value.

Owner:DALIAN MARITIME UNIVERSITY

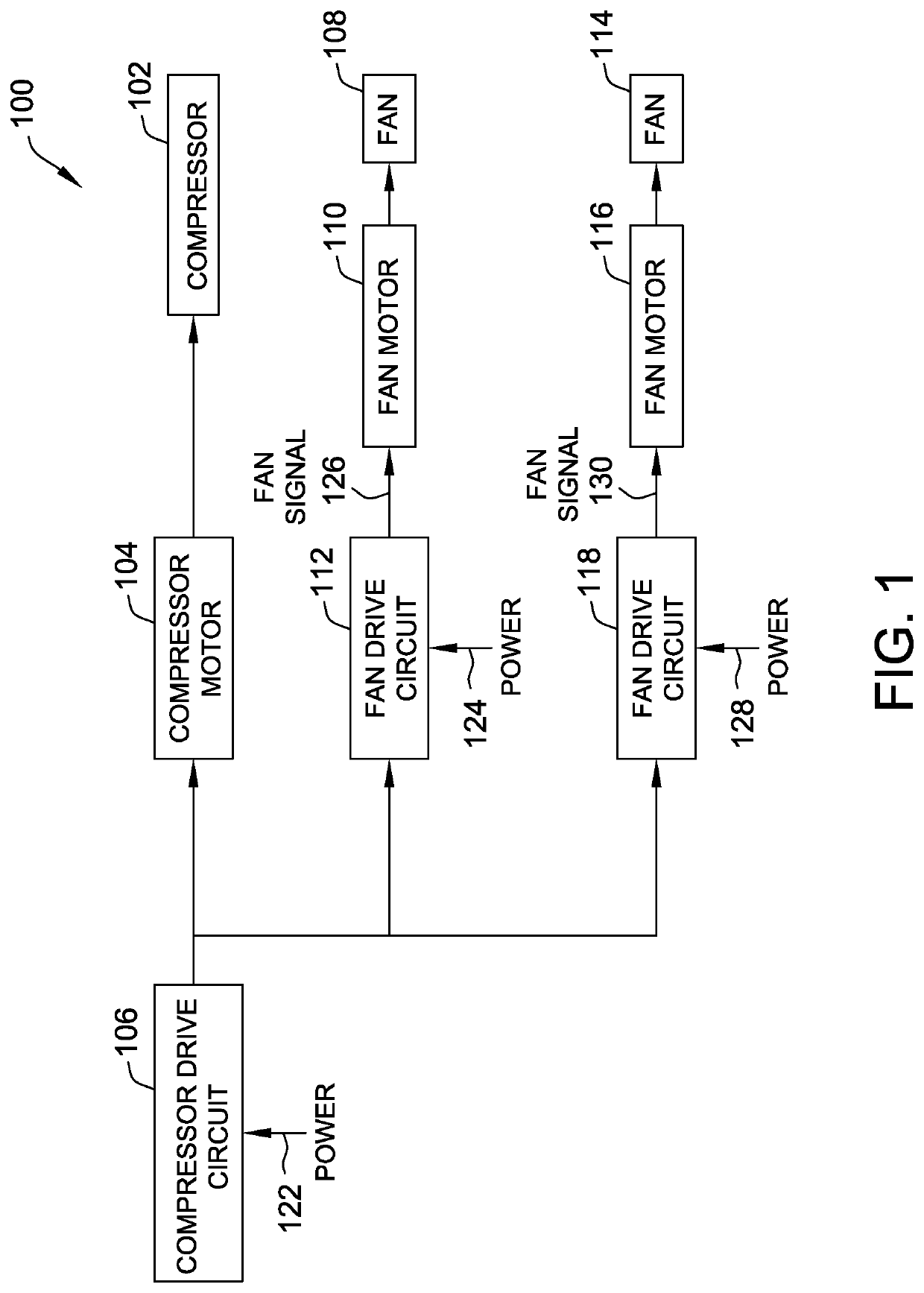

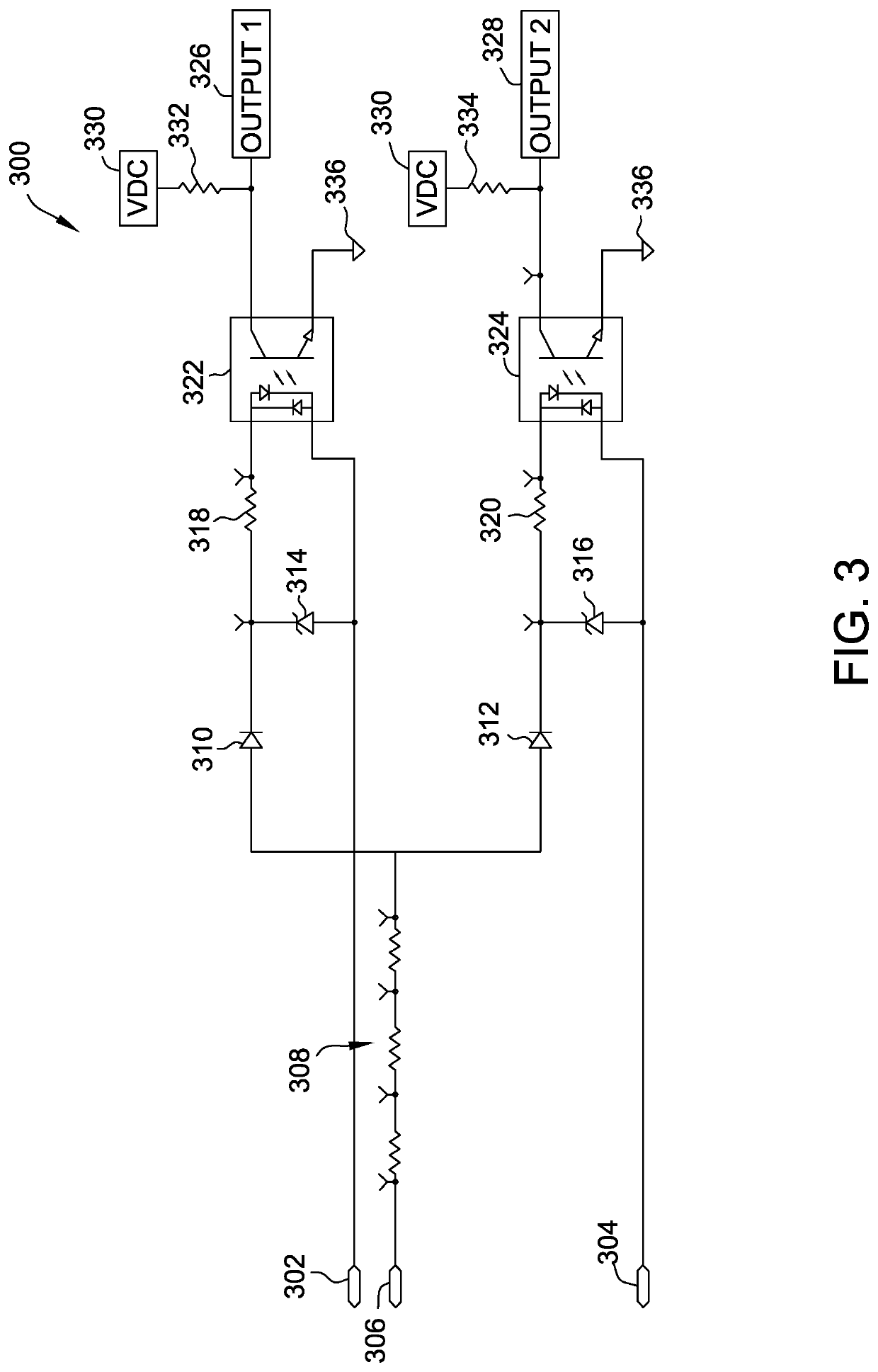

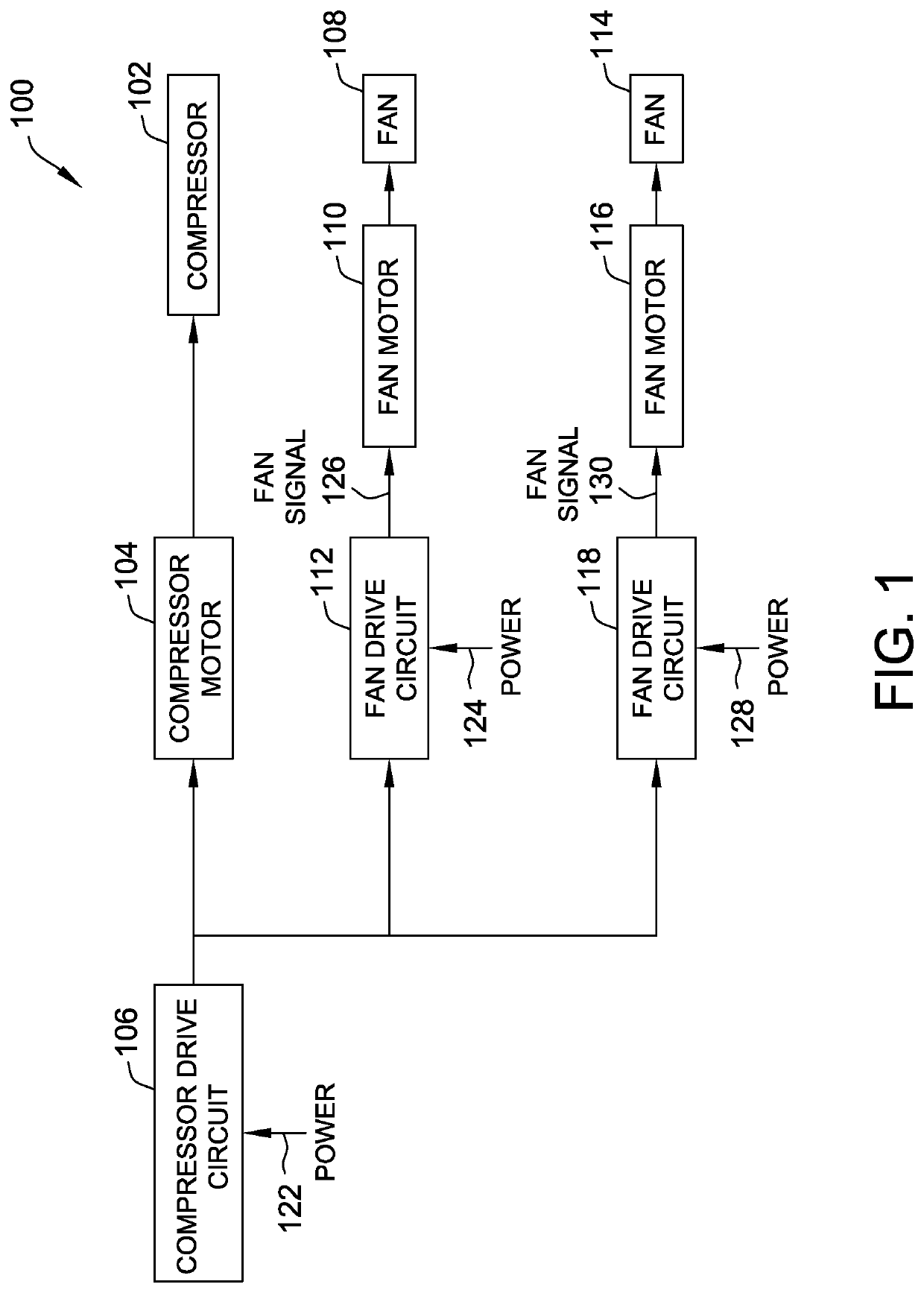

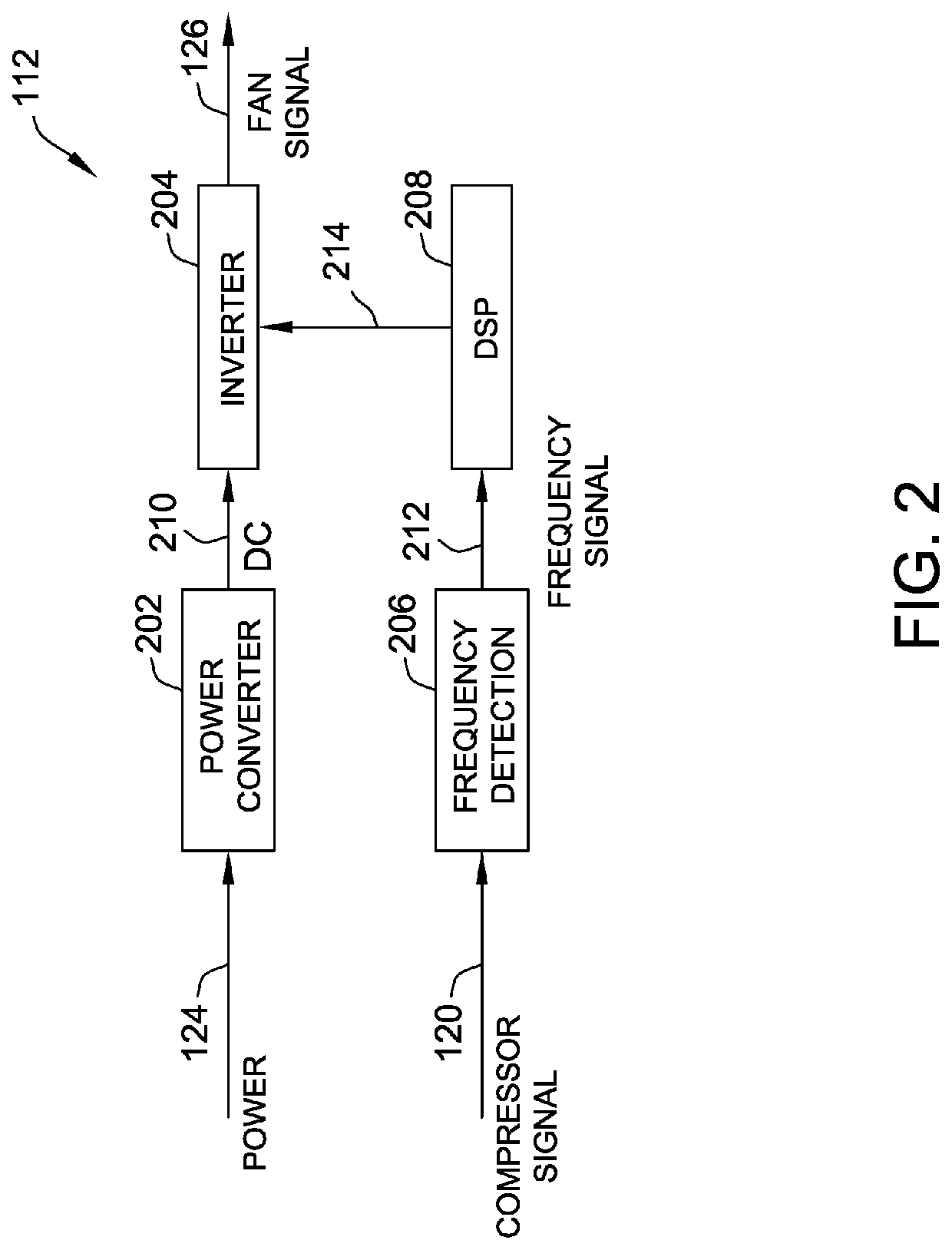

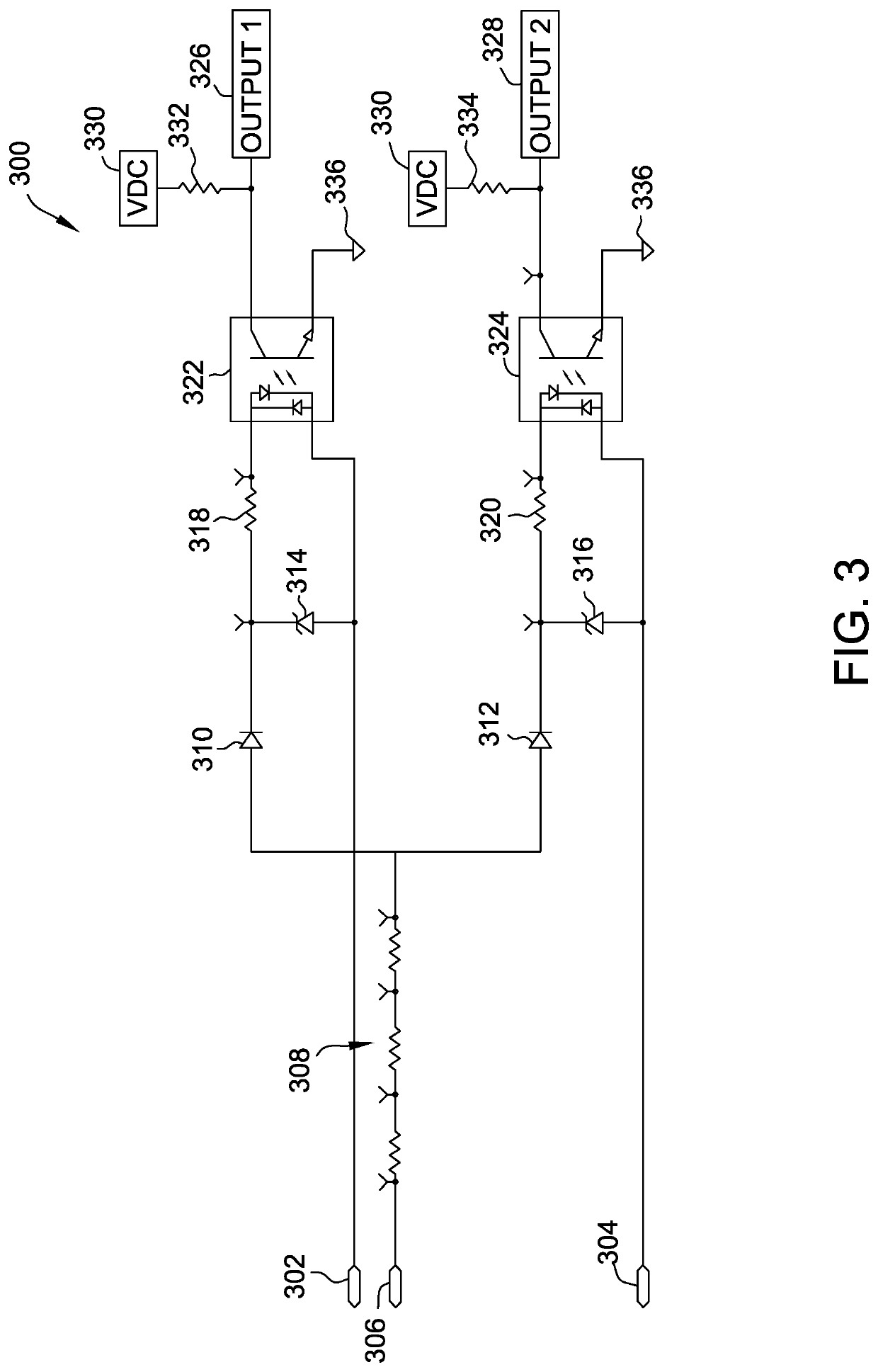

Drive circuit for a variable speed fan motor

A fan drive circuit for a variable speed fan motor in a cooling system, includes an inverter configured to supply a current signal to stator windings of the variable speed fan motor, a frequency detection circuit coupled to an output stage of an inverter of a compressor motor of the cooling system and configured to detect a first frequency of a compressor current signal at the output stage of a variable speed compressor drive circuit and generate a frequency signal, and a digital signal processor (DSP) coupled to the inverter and the frequency detection circuit. The DSP is configured to receive the frequency signal corresponding to the first frequency from the frequency detection circuit, select a second frequency corresponding to the first frequency at which to operate the variable speed fan motor, and transmit control signals to the inverter to supply current to the stator windings at the second frequency.

Owner:REGAL BELOIT AMERICA

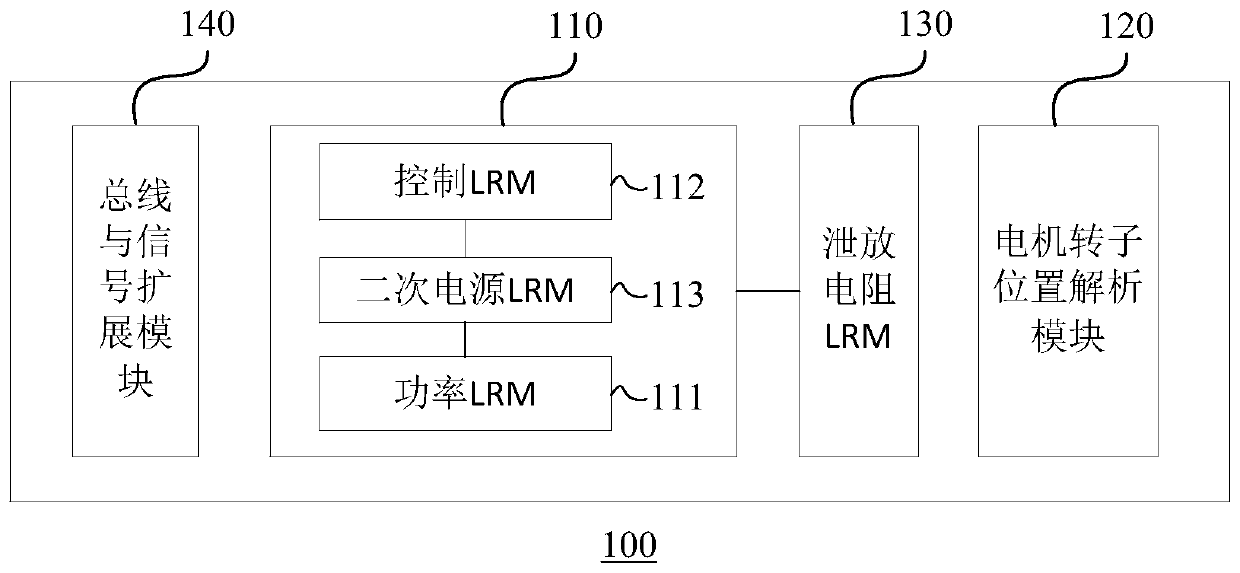

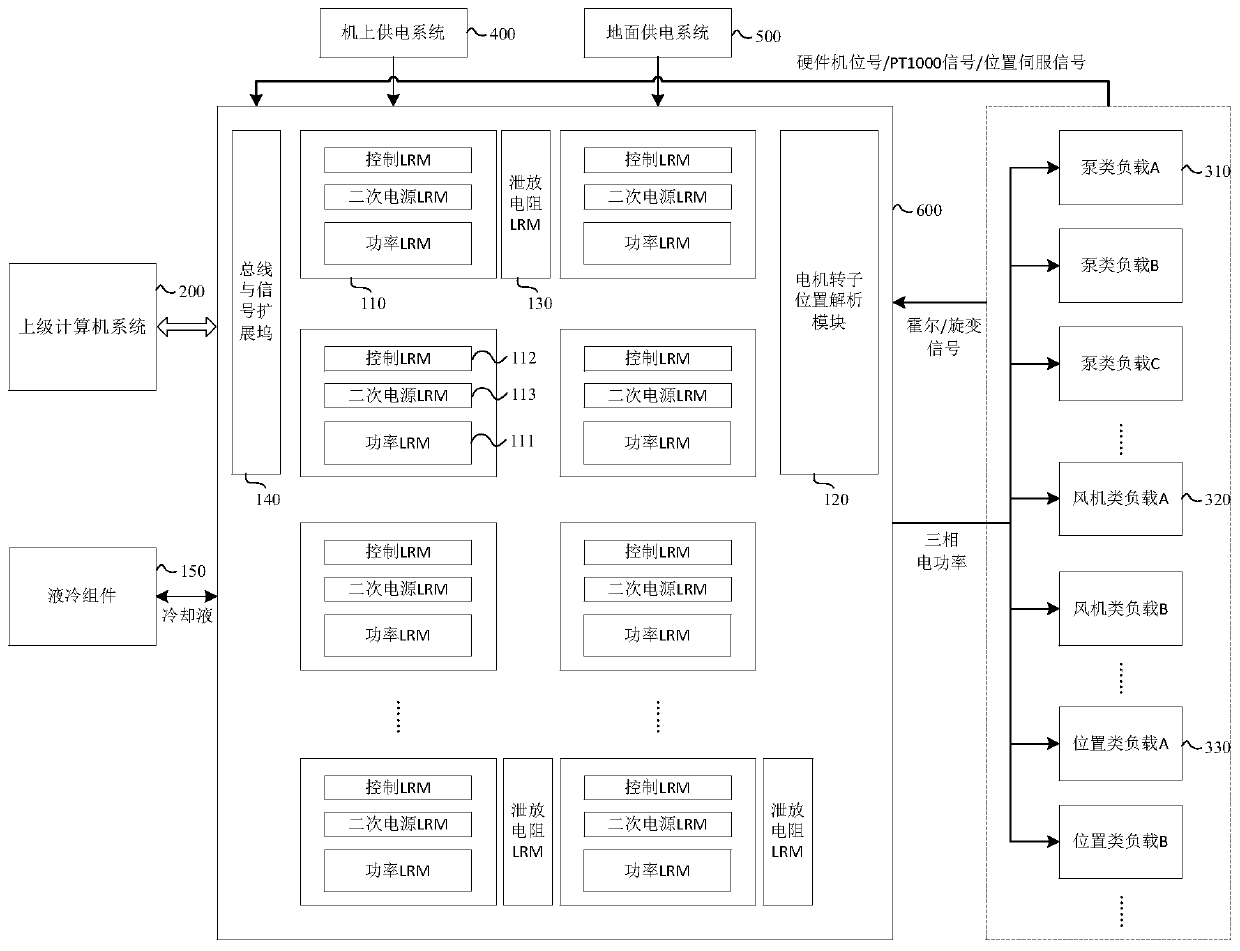

Airborne motor drive control system

PendingCN111525842ASimplified species specificationImprove versatilityElectric motor controlDc and ac dynamo-electric motors controlControl powerElectric machine

The embodiment of the invention relates to an airborne motor drive control system. The airborne motor drive control system comprises N drive control units and a motor rotor position analysis module, wherein the N drive control units are used for identifying a specific load and loading a control method; wherein N is an integer greater than or equal to 1. Each drive control unit comprises a power LRM, a control LRM and a secondary power supply LRM which are electrically connected with one another. The motor rotor position analysis modul is used for detecting a position signal of the load, the control LRM is used for controlling the operation state of the load, the power LRM is used for providing alternating current required by each phase of winding for the load, and the secondary power supply LRM is used for providing driving voltage for a drive control unit hardware board card of the load. According to the embodiment of the invention, universal and centralized control of various electromechanical loaders in a certain area of the fuselage of the aircraft is realized, the number, type and specification of airborne motor controllers are simplified, the purchase and use cost is reduced,and the field maintenance efficiency is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Energy-efficient transmission method

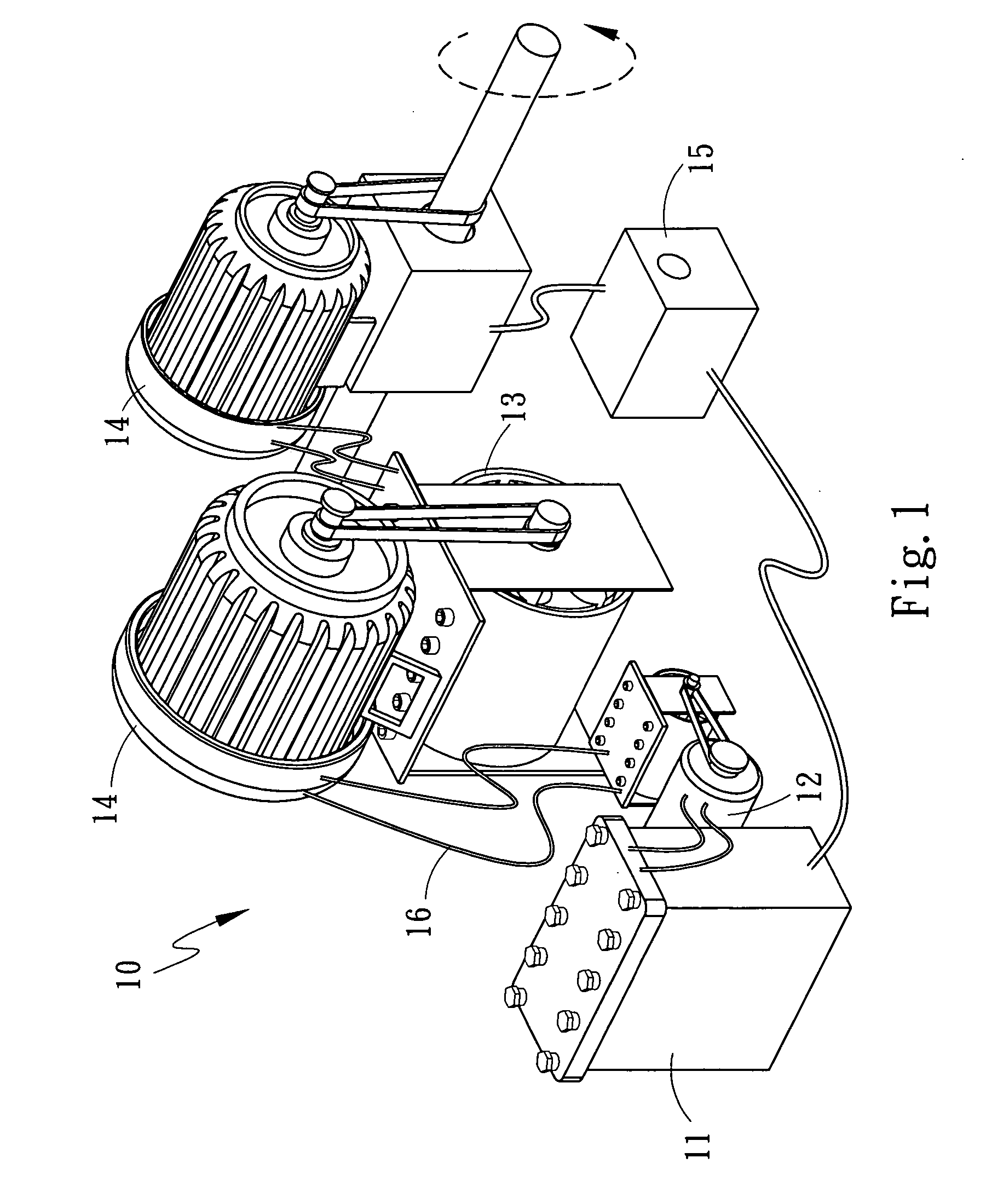

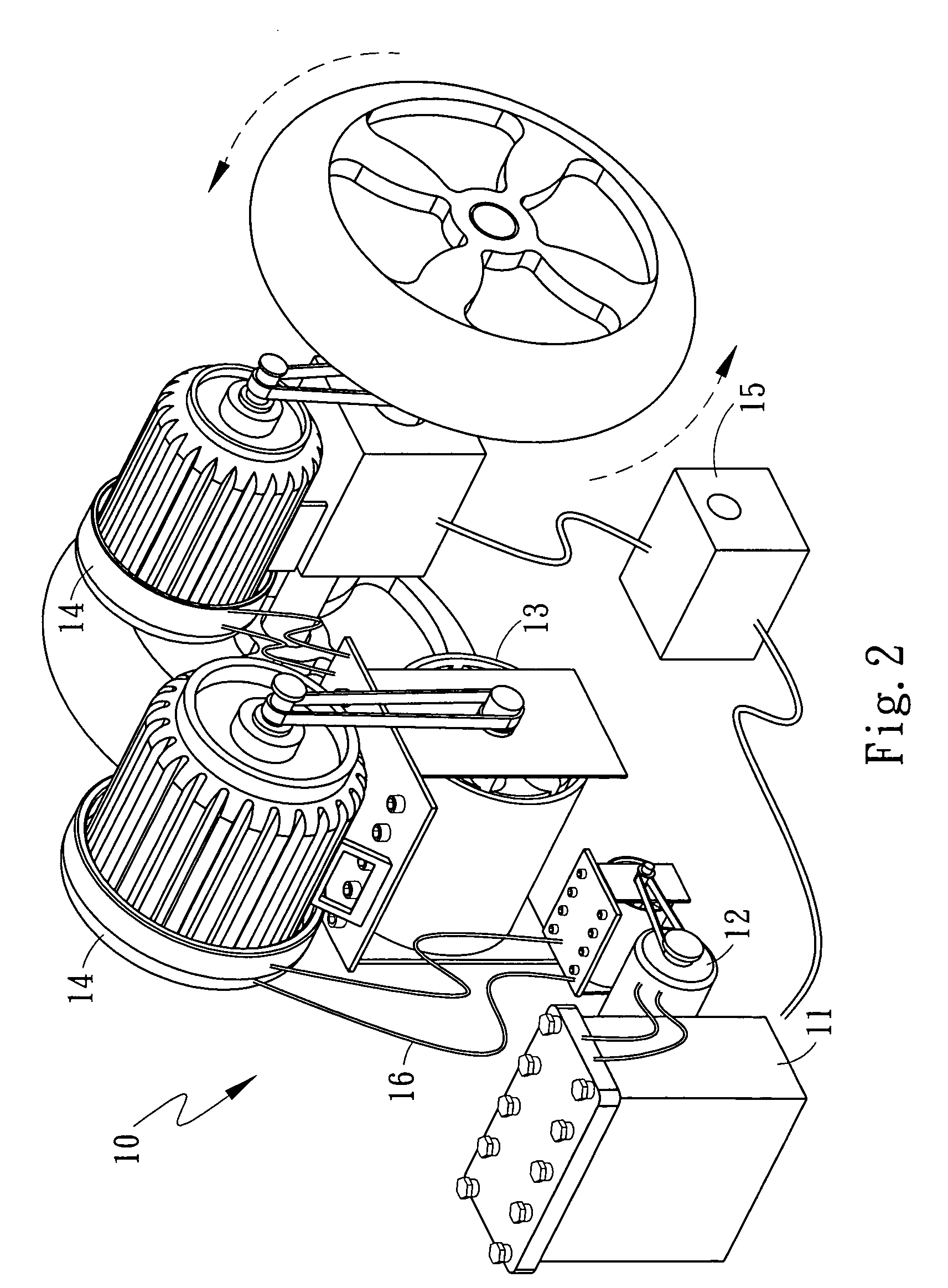

ActiveCN106712592BImprove reliabilityReasonable implementation of transmissionDc and ac dynamo-electric motors controlMechanical energy handlingMotor driveCharge discharge

The invention relates to an efficient and energy-saving transmission method, which comprises the steps that: a transmission platform is established in advance, wherein the transmission platform comprises a motor, a standby motor, a current detection module, a motor driving module, a battery, a control module, a charge-discharge switching module, a motion control module and a variable speed gear box; the control module is electrically connected with the motor driving module, the current detection module, the variable speed gear box, the charge-discharge switching module and the motion control module; the motor driving module can drive the motor and the standby motor to rotate; the motor and the standby motor are connected with the variable speed gear box; the variable speed gear box drives the load to move; and the charge-discharge switching module is connected with the motor and the battery. The efficient and energy-saving transmission method has the advantages of good reliability and low cost, and can realize efficient and energy-saving transmission reasonably.

Owner:苏州市相城区黄桥工业园经济发展有限公司

Drive circuit for a variable speed fan motor

A fan drive circuit for a variable speed fan motor in a cooling system, includes an inverter configured to supply a current signal to stator windings of the variable speed fan motor, a frequency detection circuit coupled to an output stage of an inverter of a compressor motor of the cooling system and configured to detect a first frequency of a compressor current signal at the output stage of a variable speed compressor drive circuit and generate a frequency signal, and a digital signal processor (DSP) coupled to the inverter and the frequency detection circuit. The DSP is configured to receive the frequency signal corresponding to the first frequency from the frequency detection circuit, select a second frequency corresponding to the first frequency at which to operate the variable speed fan motor, and transmit control signals to the inverter to supply current to the stator windings at the second frequency.

Owner:REGAL BELOIT AMERICA

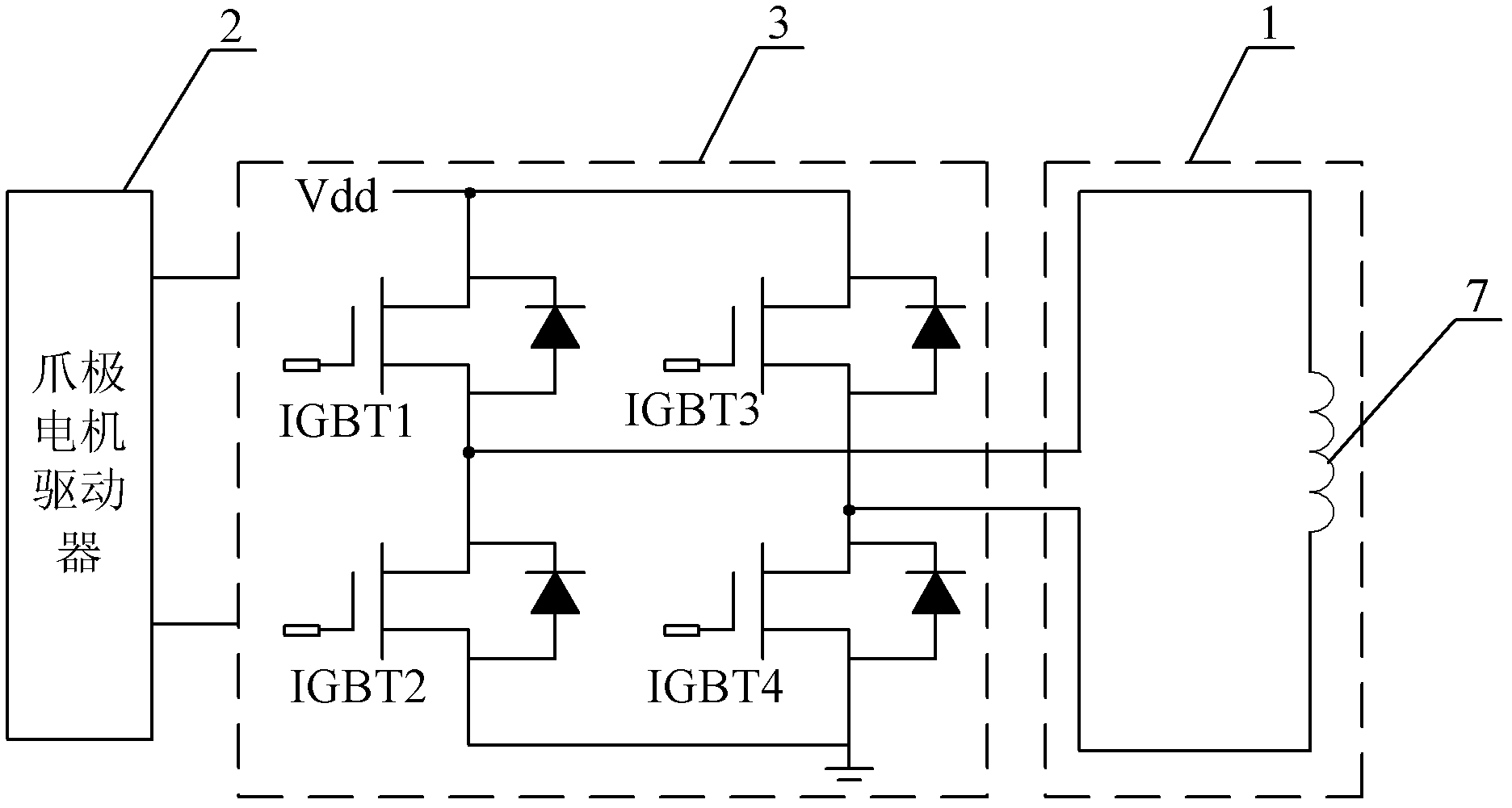

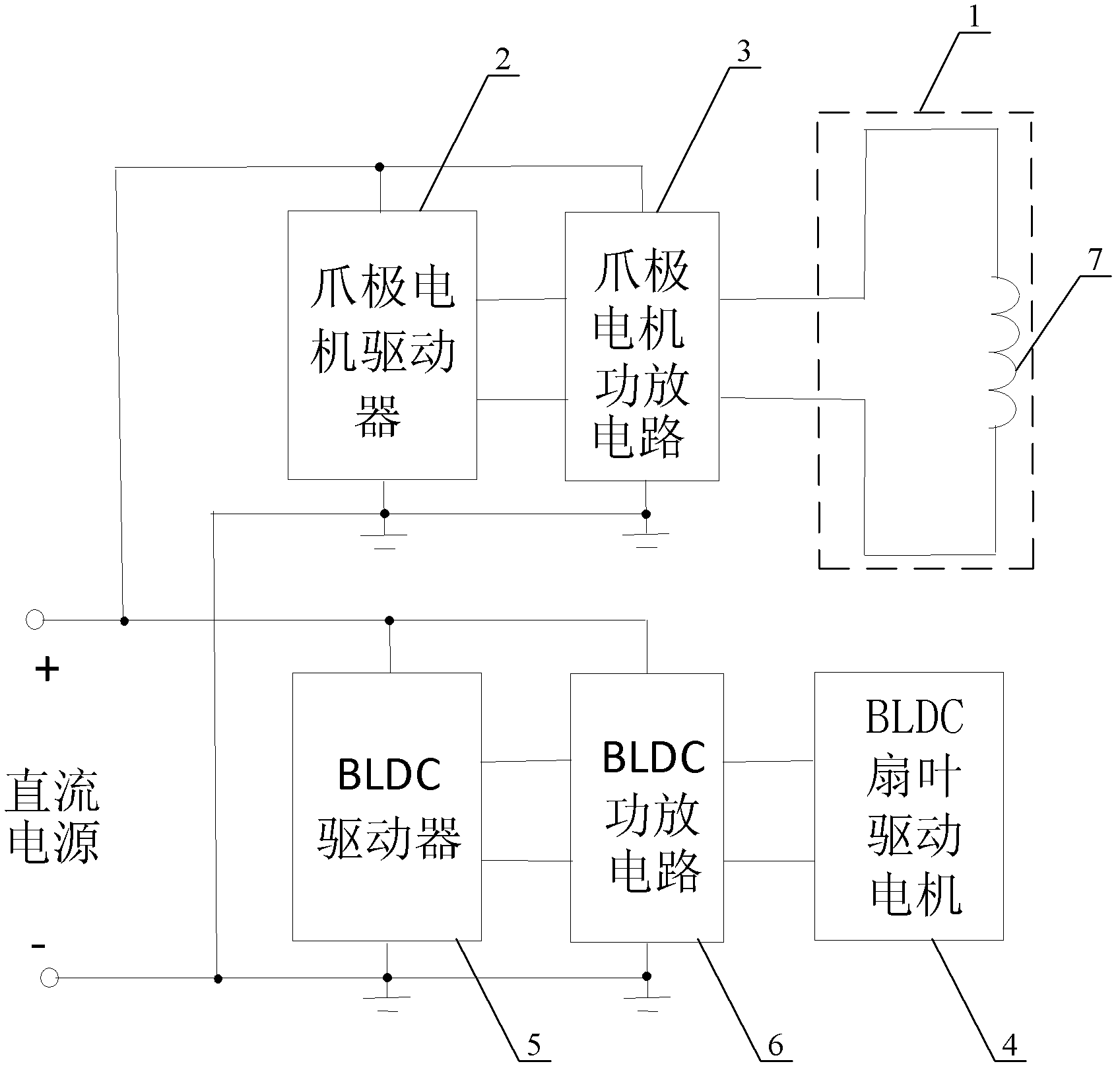

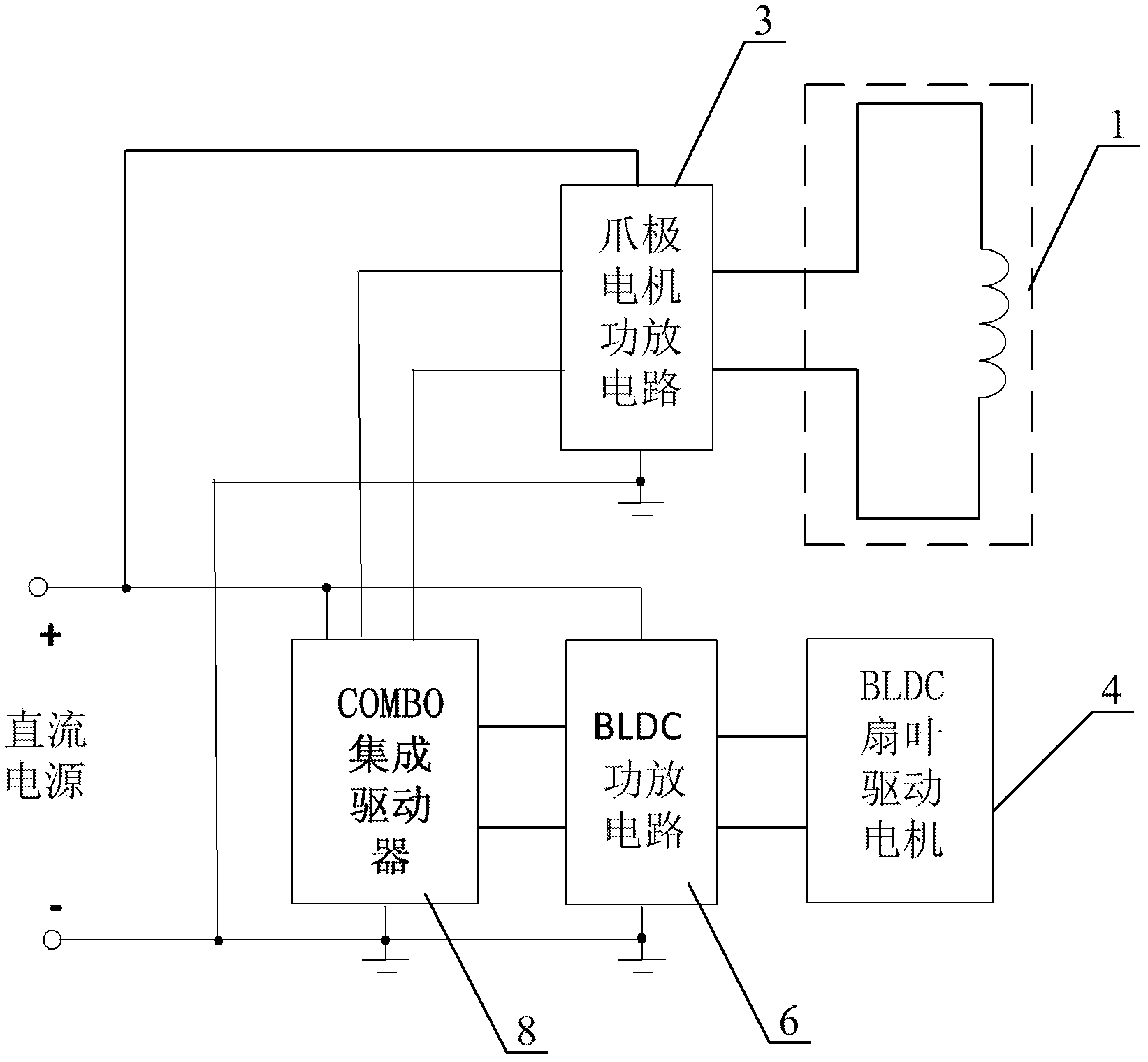

Claw pole motor driving system and method as well as fan driving system applying same

InactiveCN103051259ASimple structureLow costAC motor controlDc and ac dynamo-electric motors controlMotor driveMotor power

The invention discloses a claw pole motor driving system and a claw pole motor driving method used for oscillation of an electric fan as well as a fan driving system applying the same. The law pole motor driving system mainly consists of a claw pole motor and a claw pole motor driver; and a claw pole motor power amplification circuit is connected in series between the claw pole motor and the claw pole motor driver. The fan driving system comprises a BLDC (Brushless Direct-Current) motor driving system and a claw pole motor driving system; and the BLDC motor driving system and the claw pole motor driving system are respectively connected with a power source. The claw pole motor driving system provided by the invention not only is very simple in whole structure, but further can also realize a fan oscillating function with the coordination of a brushless direct-current motor. The claw pole motor driving system provided by the invention has the advantages of very low cost, and convenience in popularization and use.

Owner:FORTIOR TECH SHENZHEN

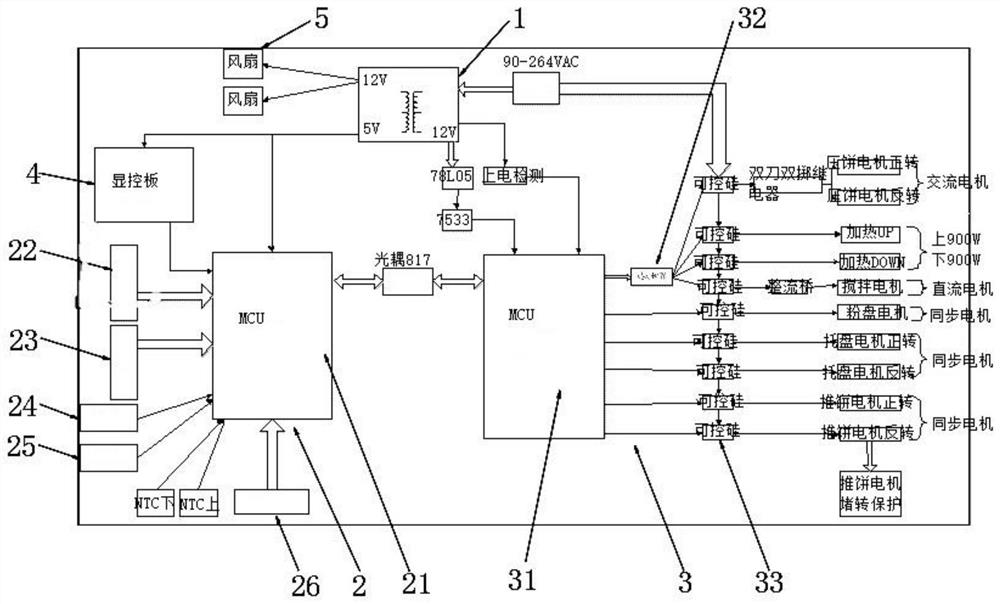

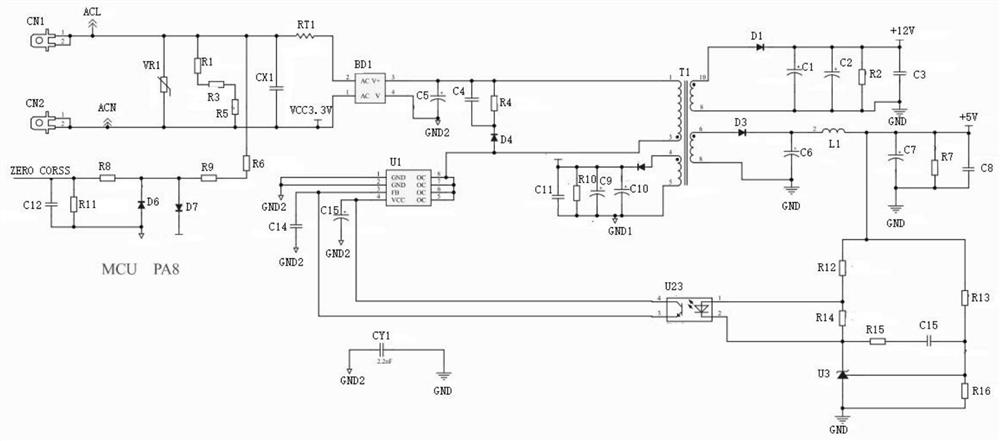

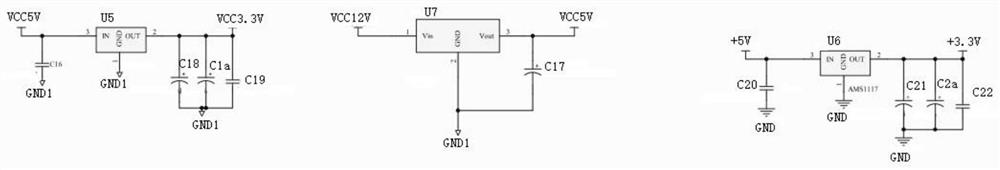

Main control board circuit of full-automatic pancake baking machine

PendingCN113037054AAutomatic control timeEasy to operateAc-dc conversion without reversalTemperatue controlSilicon-controlled rectifierControl engineering

The invention discloses a main control board circuit of a full-automatic pancake baking machine, which relates to the field of pancake baking machines and comprises a power supply module, a sensor control module, a silicon controlled rectifier control module and a display control board, wherein the sensor control module, the silicon controlled rectifier control module and the display control board are all electrically connected with the power supply module; and the display control board is electrically connected with the sensor control module. According to the main control board circuit of the full-automatic pancake baking machine, after an operation instruction is given out through the display control board, a first main control chip in the sensor control module receives a signal and transmits the signal to a second main control chip through communication, and the second main control chip drives on-off of a silicon controlled rectifier by giving a high-low level driving signal to a Darlington tube, and thus, the motor and the heating tube are thus controlled to work; the motor works to a designated position, the operation is simple and convenient, pancakes can be automatically made, and the time of the pancake baking machine can be automatically controlled when the pancakes are baked.

Owner:CHINA KEY SYST & INTEGRATED CIRCUIT

AC power driving apparatus

InactiveUS20090153080A1Versatile in its utilityBatteries circuit arrangementsMultiple dynamo-motor startersEngineeringAC power

An AC power driving apparatus includes at least a DC input end, a DC motor, a plurality of AC output coils, a plurality of AC motors, a power chargeback device and a plurality of wires. The DC input end is connected to one side of the DC motor through the wires to supply driving power to the DC motor. The DC motor has another side connecting to one AC output coil through the wires to output AC power to one AC motor connected to another side of the AC output coil. The AC motor drives another AC output coil connected to one side thereof to generate amplification to be output. Thereby the another AC output coil is able to supply power to another AC motor to provide driving power.

Owner:LEE CHING CHUNG

Motor driving circuit, integrated circuit device, and electronic apparatus

ActiveUS20210135607A1Dc and ac dynamo-electric motors controlDC motor rotation controlElectric machineryControl theory

A motor driving circuit includes a first motor driving circuit that controls driving of a first motor is disposed, a second motor driving circuit that controls driving of a second motor is disposed, and a constant current generation circuit that generates a constant current is disposed, and the constant current generation circuit is disposed at a position deviating from between the first motor driving circuit and the second motor driving circuit.

Owner:SEIKO EPSON CORP

Electrical serially-connected control system

InactiveUS9985558B2Easy to operateReduce convenienceMultiple dynamo-motor startersMultiple ac dynamo-electric motors controlDrive motorEngineering

An electrical serially-connected control system for driving motors in series includes a control device, at least one processing device, and a transmission medium connected between the two devices for mutual communication. The control device includes a power rectifier transforming an external power, a signal converter converting each external command signal, and an integration unit connected to the rectifier and the converter for integrating the transformed power with each converted command signal to create commands. The processing device includes a voltage regulator connected to the transmission medium for stabilizing the power come from the command, a power storage module connected to the voltage regulator and each motor, a signal filter connected to the transmission medium for processing the command signal come from the command, a controller connected with the voltage regulator, the power storage module and the signal filter, and a signal generator connected to the controller.

Owner:NAT CHIN YI UNIV TECH

Excavator motor dynamic control technology

InactiveCN108242901AReduce weightLow costDc and ac dynamo-electric motors controlCoprocessorControl signal

The invention relates to an excavator motor dynamic control technology. The excavator motor dynamic control technology is composed of a peripheral signal receiving circuit, a main processor circuit, acaching circuit, a coprocessor circuit and N motor driving circuits. A main processor receives the control signals and speeds and the current feedback signals of motors, and carries out correspondingmathematical operation. The control command words of all the motors are generated by sorting the on / off time of all the power switching tubes of the motors based on a unified time. The excavator motor dynamic control technology has the advantages of low cost, small size, low weight and high motor control precision.

Owner:天津兴扬瑞迪科技有限公司

Motor driving circuit, integrated circuit device, and electronic apparatus

ActiveUS11404979B2Dc and ac dynamo-electric motors controlDC motor rotation controlElectric machineryControl theory

A motor driving circuit includes a first motor driving circuit that controls driving of a first motor is disposed, a second motor driving circuit that controls driving of a second motor is disposed, and a constant current generation circuit that generates a constant current is disposed, and the constant current generation circuit is disposed at a position deviating from between the first motor driving circuit and the second motor driving circuit.

Owner:SEIKO EPSON CORP

Rotating machine controller

An electronic control unit, for example, a rotating machine controller, is capable of driving one three-phase motor including a first set of three-phase winding and a second set of three-phase winding and one to three direct current motors. The direct current motor is connected to a position between one phase of the first set of three-phase winding and one phase of the second set of three-phase winding without redundancy. Inverters convert a direct current electric power to a three-phase alternating current electric power by an operation of bridge-connected plural switching elements, and apply a voltage to each phase in two sets of three-phase winding. A control unit controls a supply of electric power to the three-phase motor and to the direct current motor by controlling an operation of the switching elements.

Owner:DENSO CORP

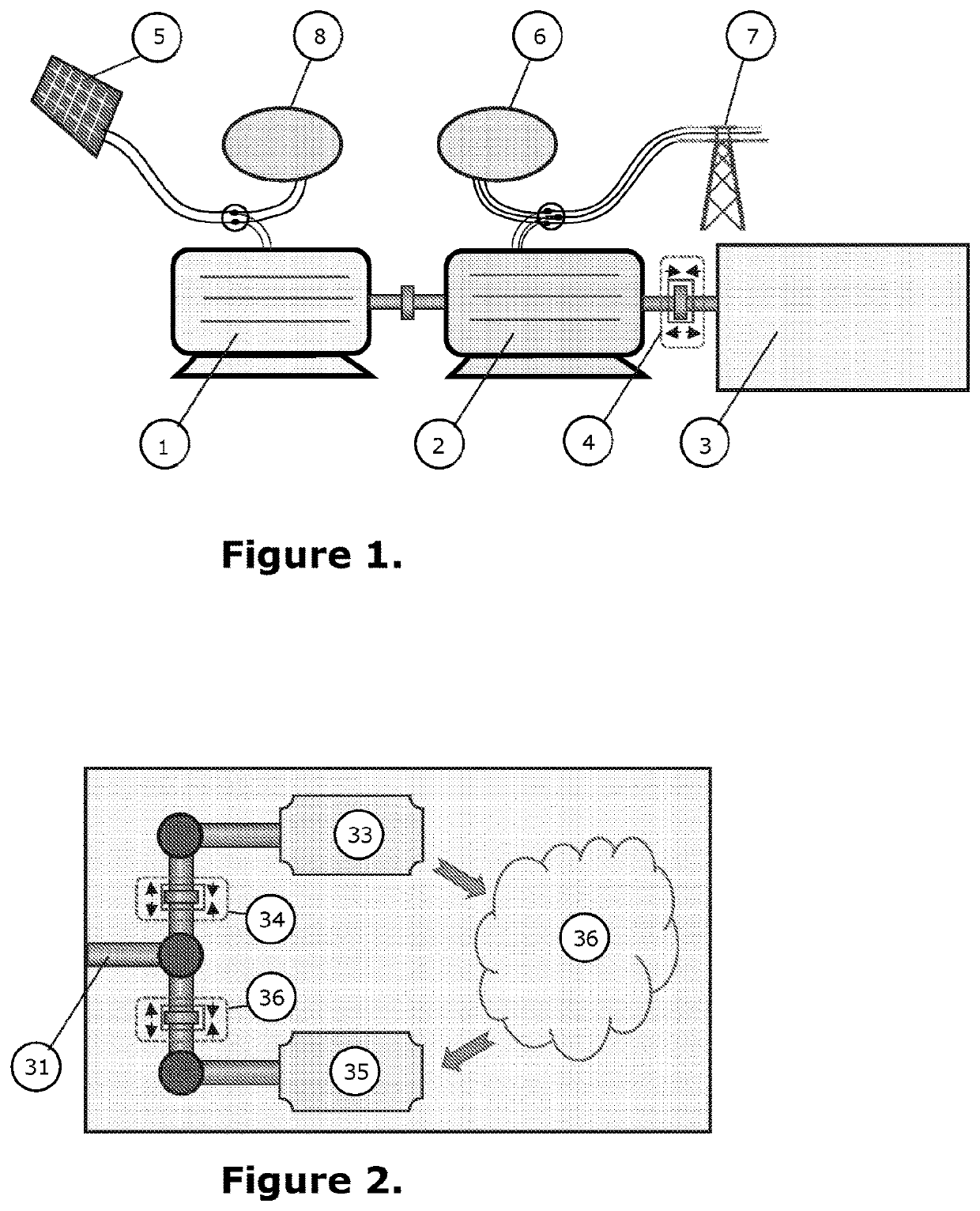

System for Power Conversion and Energy Storage

PendingUS20220149629A1Low costCost advantageElectrical storage systemDc and ac dynamo-electric motors controlElectrical batteryRotor (electric)

A system for power conversion and energy storage is described. In an embodiment the system comprise a DC rotating electrical machine (1) comprising a DC rotor; an AC rotating electrical machine (2) comprising an AC rotor; and a (thermo-) mechanical energy storage system (known as a TMESS) (3). The TMESS comprises a central shaft, said central shaft charged and discharged with shaft power and selectively mechanically coupled to the DC rotor and to the AC rotor via clutch (4) to form a shaft train. Some source of DC generation such as photovoltaic cells (5) feeds electrical power into the DC electrical machine (1). There may also be local DC loads (8) supported by the system. The AC electrical machine (2) may deliver power to local AC loads (6), or draw power from the AC electrical grid (7).

Owner:CHEESECAKE ENERGY LTD

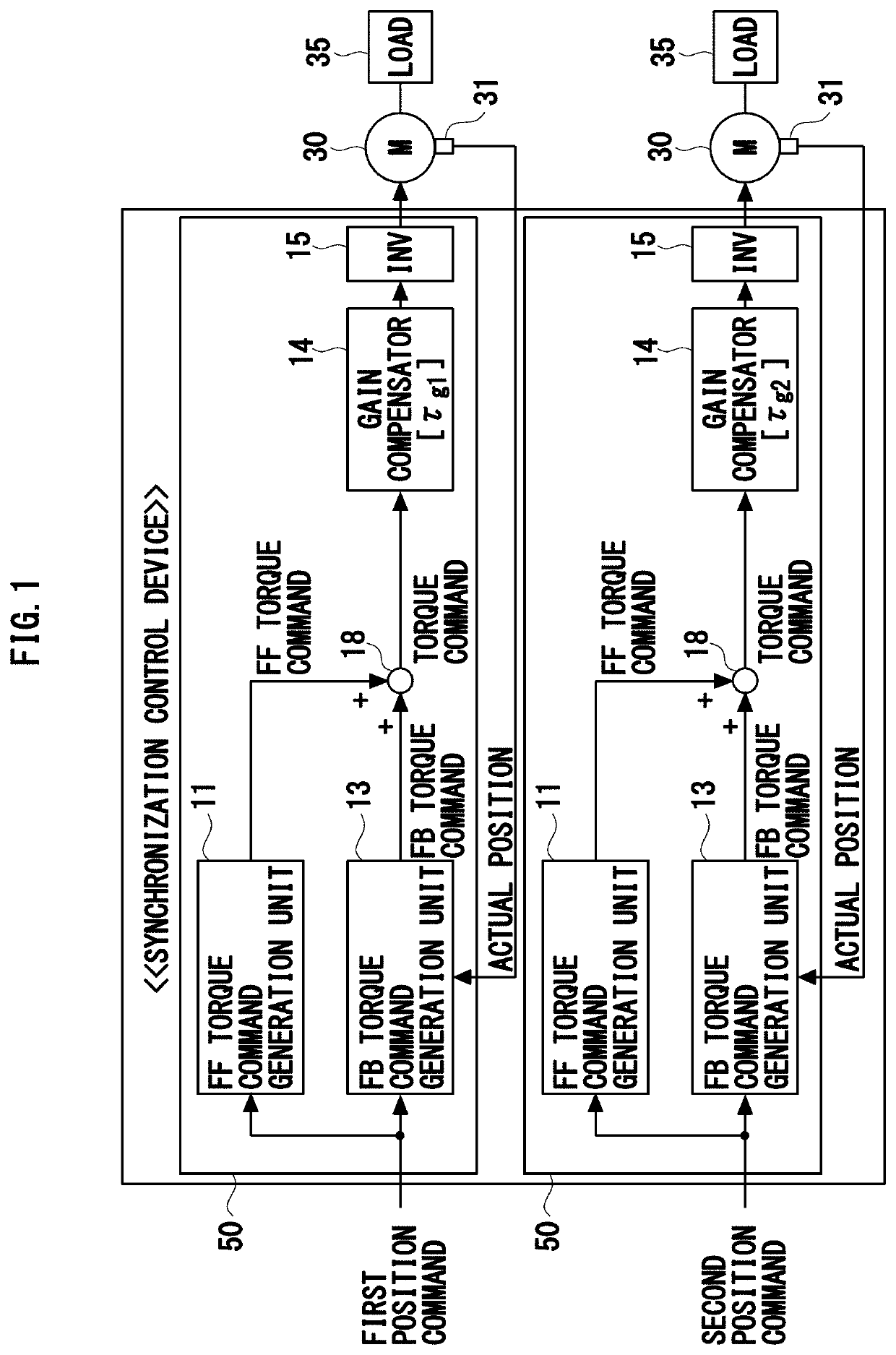

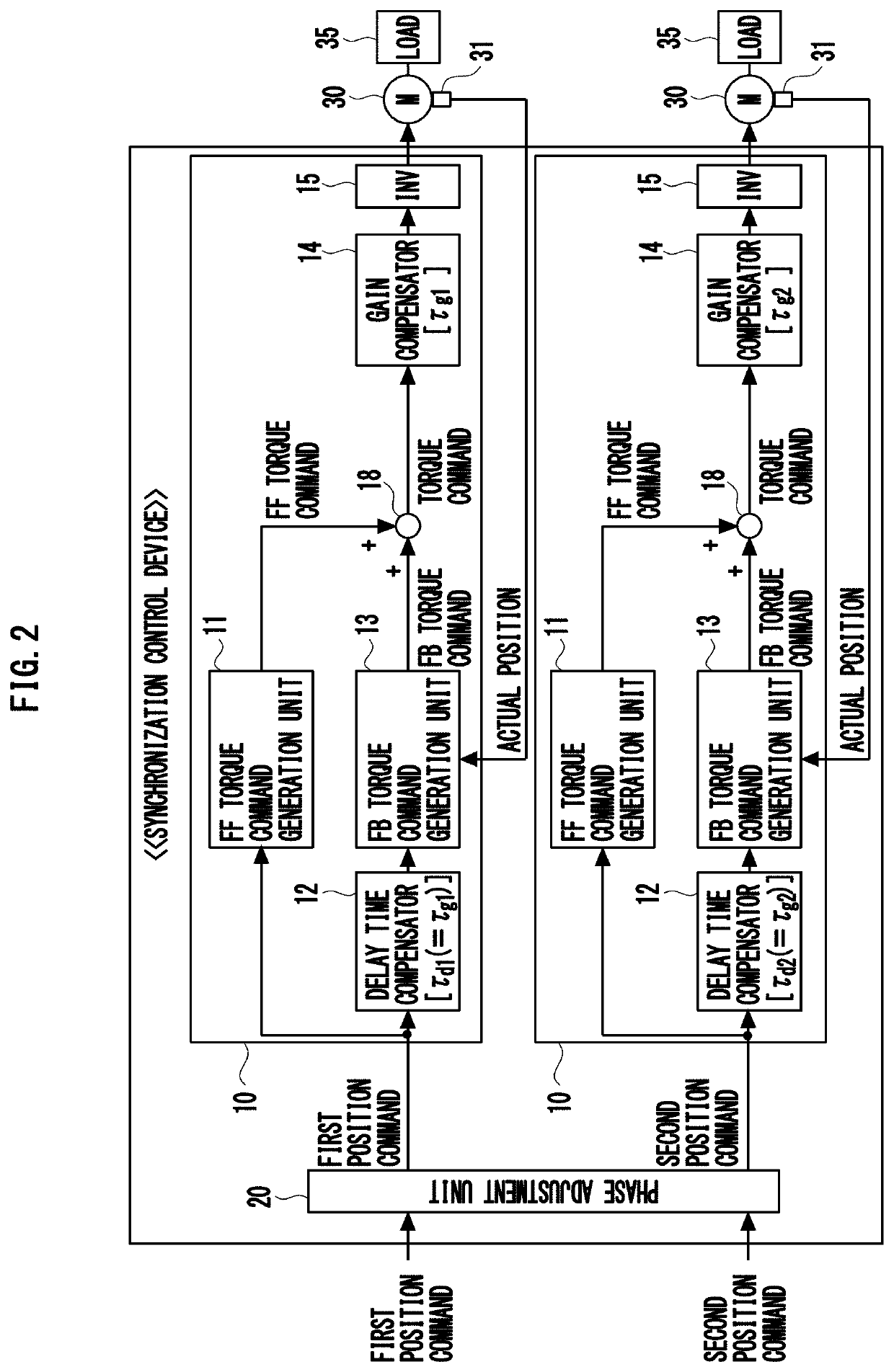

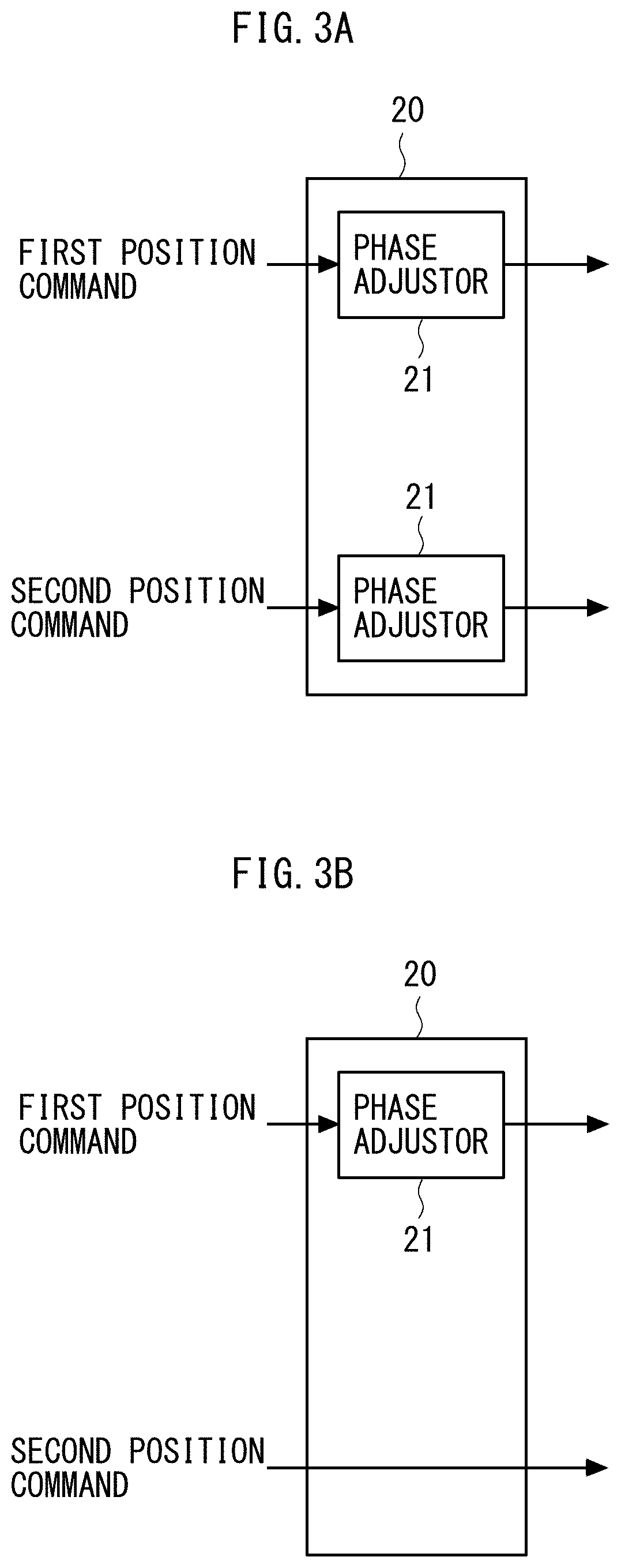

Synchronization control device

ActiveUS20200403538A1Good track followabilityDc and ac dynamo-electric motors controlControl using feedbackSynchronous controlControl engineering

Provided is a synchronization control device that can control a mechanical system with good track followability. A control unit for each shaft of the synchronization control device includes: a delay time compensator which delays a position command to an FB torque command generation unit, and of which equivalent time constant is approximately the same as an equivalent time constant as a gain compensator. The synchronization control device also includes a phase adjustment unit, which adjusts a phase of at least one of the position commands, in a previous stage of each control unit, so that the time until the position command, input to each control unit, is output from the delay time compensator, becomes approximately the same.

Owner:ORMON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com