Motor control device for two motors and method

A motor and switching device technology, applied in motor generator control, motor speed or torque control, multiple motor speed/torque control, etc., can solve the problem of brush wear, large current, large harmonic content, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

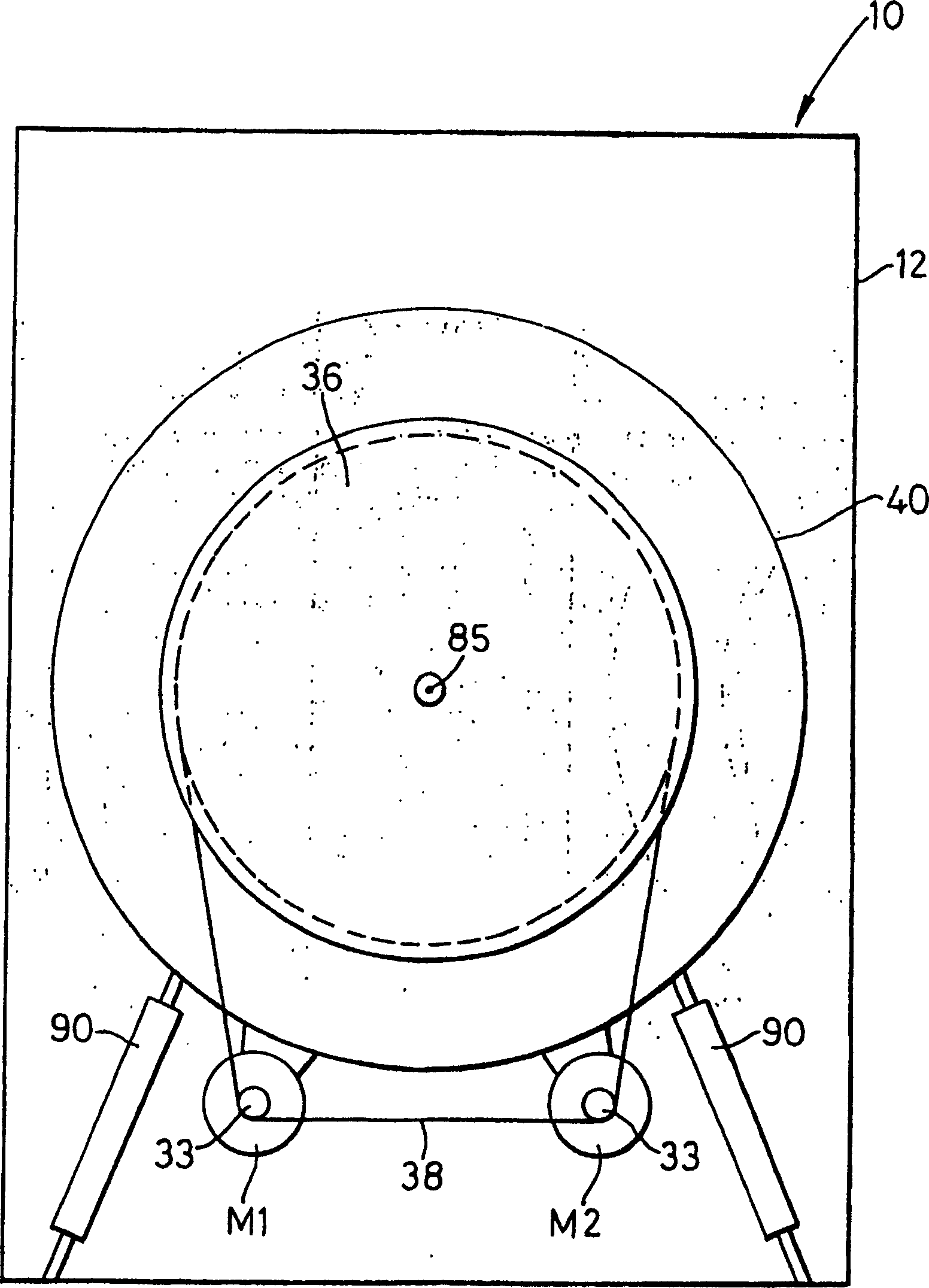

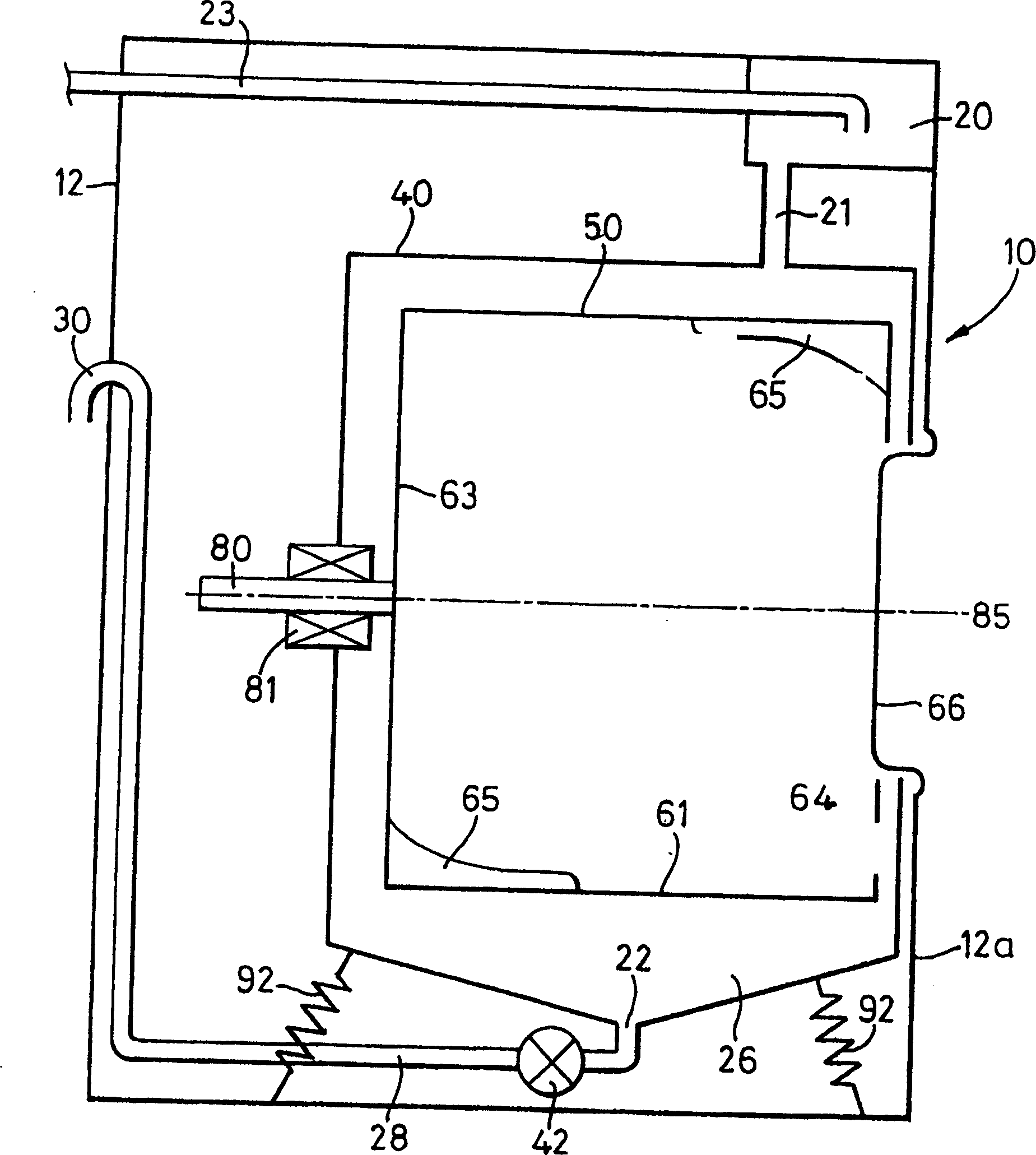

[0027] The following examples illustrate how the invention can be applied to washing machines. figure 1 and 2 A washing machine 10 is shown comprising a housing 12 in which a stationary tub 40 is disposed. The drum 50 is mounted inside the tub 40 so as to be rotatable about an axis 85 along a shaft 80 . Bucket 40 is also supported inside housing 12 by suspension struts 90 . Barrel 40 is sealed except for inlet 21 and outlet 22 . The washing machine 10 includes a soap tray 20 capable of receiving detergent in a well known manner. At least one water inlet 23 communicates with the soap tray 20 and provides suitable means for connecting to a water source in the environment in which the washing machine 10 is used. A conduit 21 is provided between the soap tray 20 and the tub 40 to guide water into the tub 40 through the inlet 23 . The tub 40 has a sump 26 installed under the drum 50 . Drain 28 communicates with sump 26 and directs water to outlet 30 through which water can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com