Claw pole motor driving system and method as well as fan driving system applying same

A technology of motor drive system and claw pole motor, which is applied in the field of fan drive system and claw pole motor drive system, can solve the problems of inability to use the same power supply and high production cost, and achieve the advantages of easy promotion and use, low cost, and improved safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

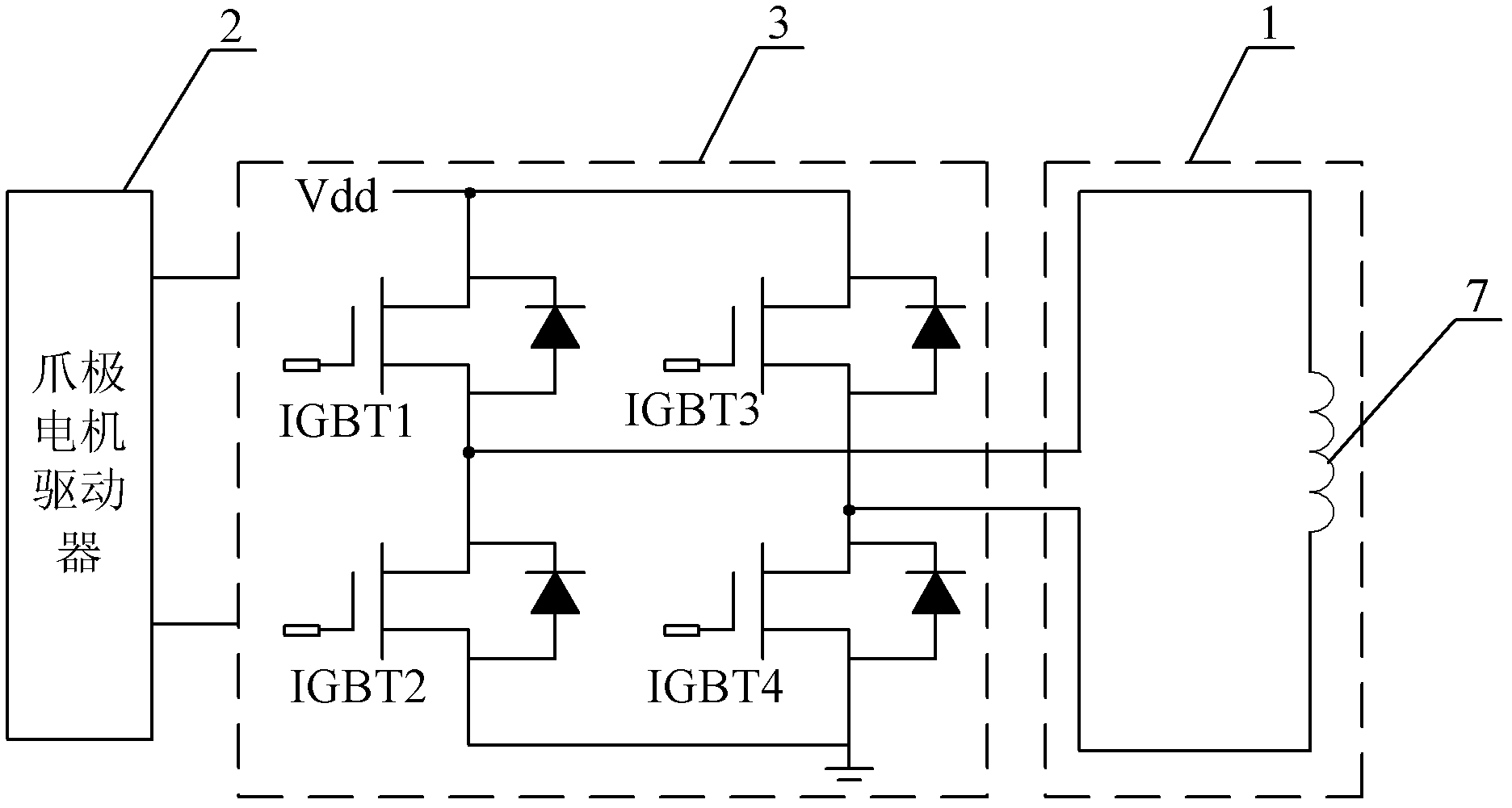

Method used

Image

Examples

Embodiment 1

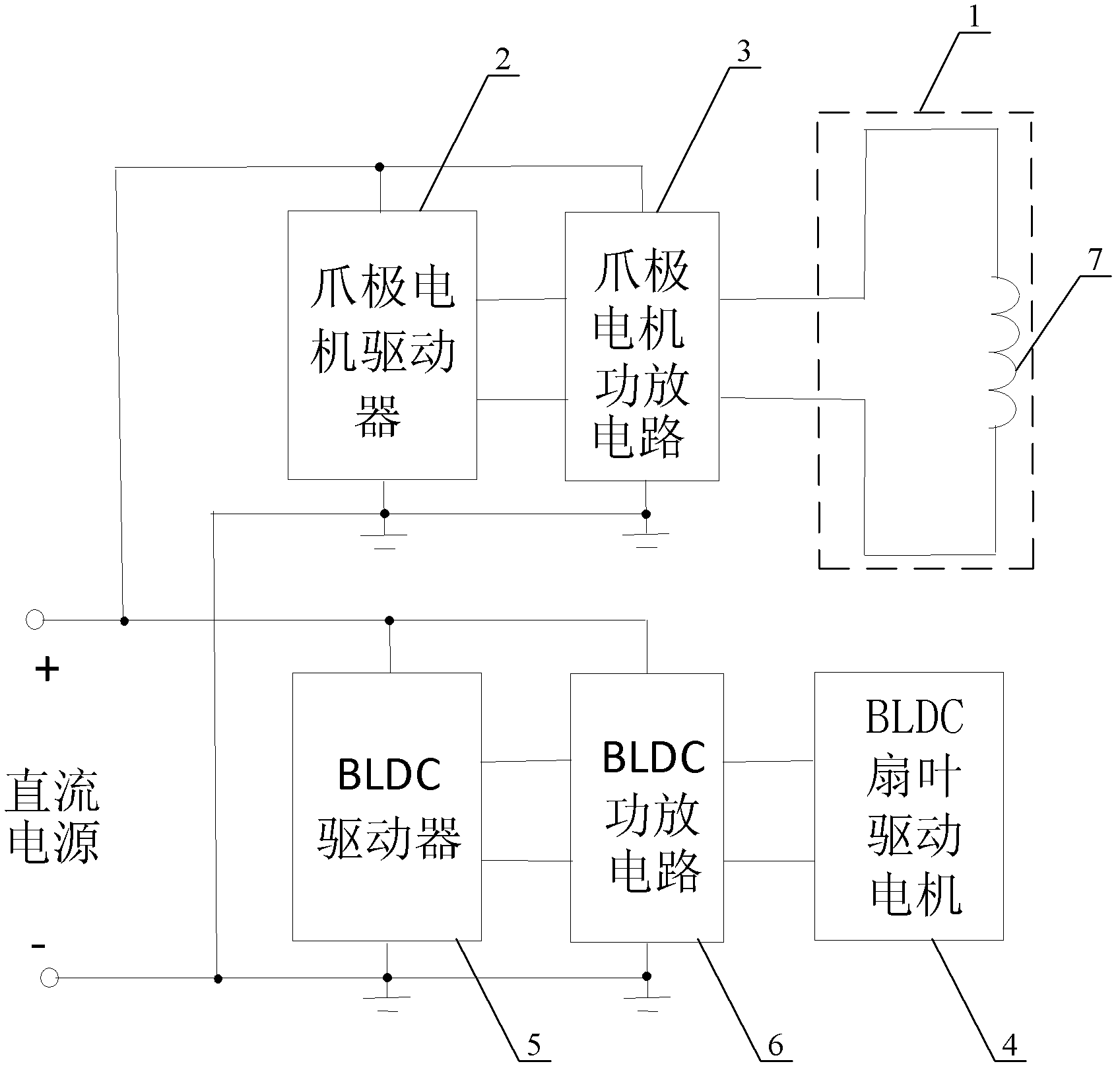

[0043] refer to figure 2 As shown, the present invention also discloses a fan driving system, which includes a BLDC motor driving system and the above-mentioned claw pole motor driving system, and the BLDC motor driving system and the claw pole motor driving system are respectively connected to a power supply.

[0044]In this embodiment, the BLDC driving system includes a traditional BLDC blade driving motor 4 , a BLDC driver 5 and a BLDC power amplifier circuit 6 connected in series between the BLDC driving motor 4 and the BLDC driver 5 . When connecting, the positive poles of the power supply of the claw pole motor driver 2 and the claw pole motor power amplifier circuit 3 need to be connected in parallel with the positive poles of the power supply of the BLDC driver 5 and the BLDC power amplifier circuit 6 and then connected to the positive pole of the external DC power supply, while the claw pole motor driver 2 and the The negative pole of the power supply of the claw pol...

Embodiment 2

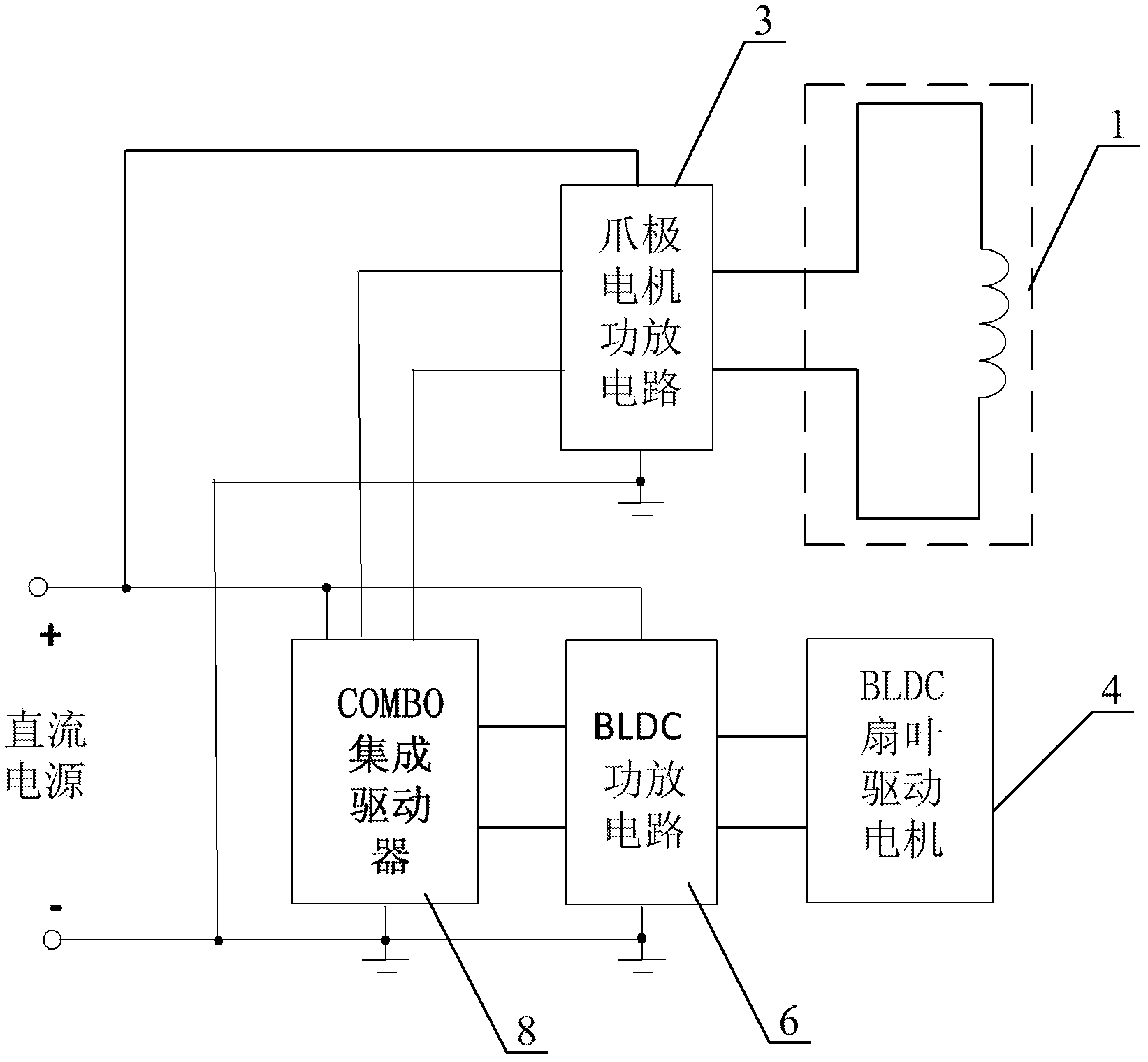

[0048] According to actual needs, the fan drive system described in Embodiment 1 can also be properly adjusted as follows, that is, the claw pole motor driver 2 and the BLDC driver 5 are integrated on one chip to realize, that is, a drive control chip controls the claw pole at the same time Pole motor 1 and BLDC drive motor 4, the structure of which is as follows image 3 shown.

[0049] That is, the positive poles of the claw pole motor power amplifier circuit 3 and the BLDC power amplifier circuit 6 are both connected to the positive pole of the external DC power supply, and the negative poles of the power supply are connected to the negative pole of the external DC power supply. Since the claw pole motor driver 2 and the BLDC driver 5 need to be integrated on one chip, this embodiment is preferably realized by using a COMBO chip. At this time, in order to distinguish it from the previous claw-pole motor driver 2 and BLDC driver 5 , in this embodiment, the COMBO chip integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com