Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about "Antimagnetic alloy usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

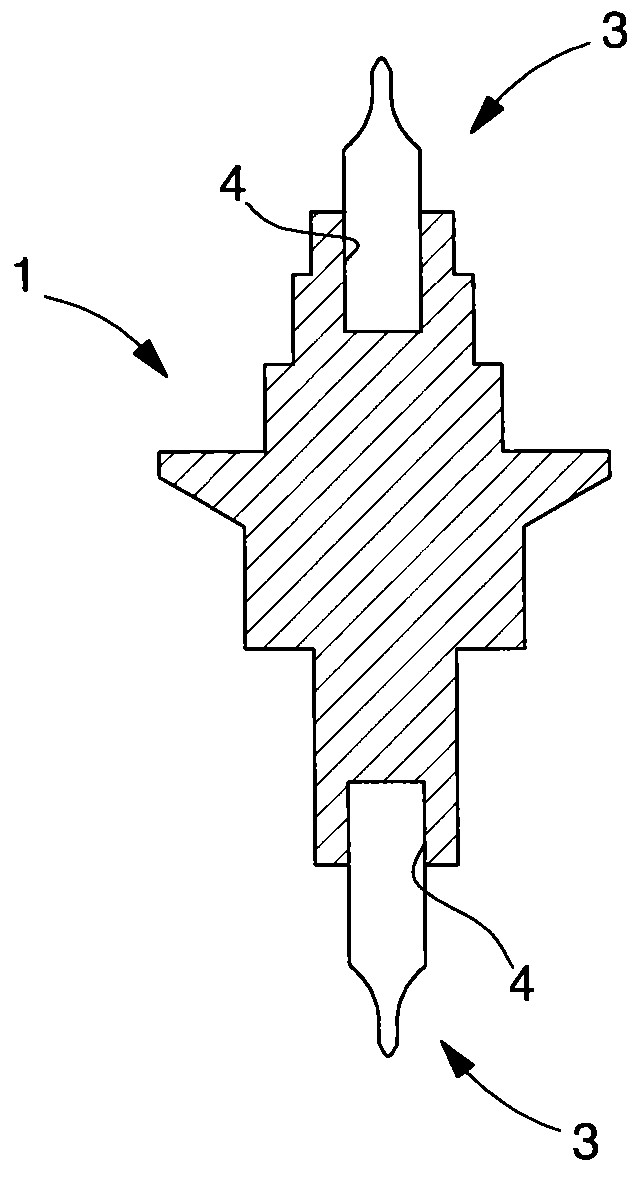

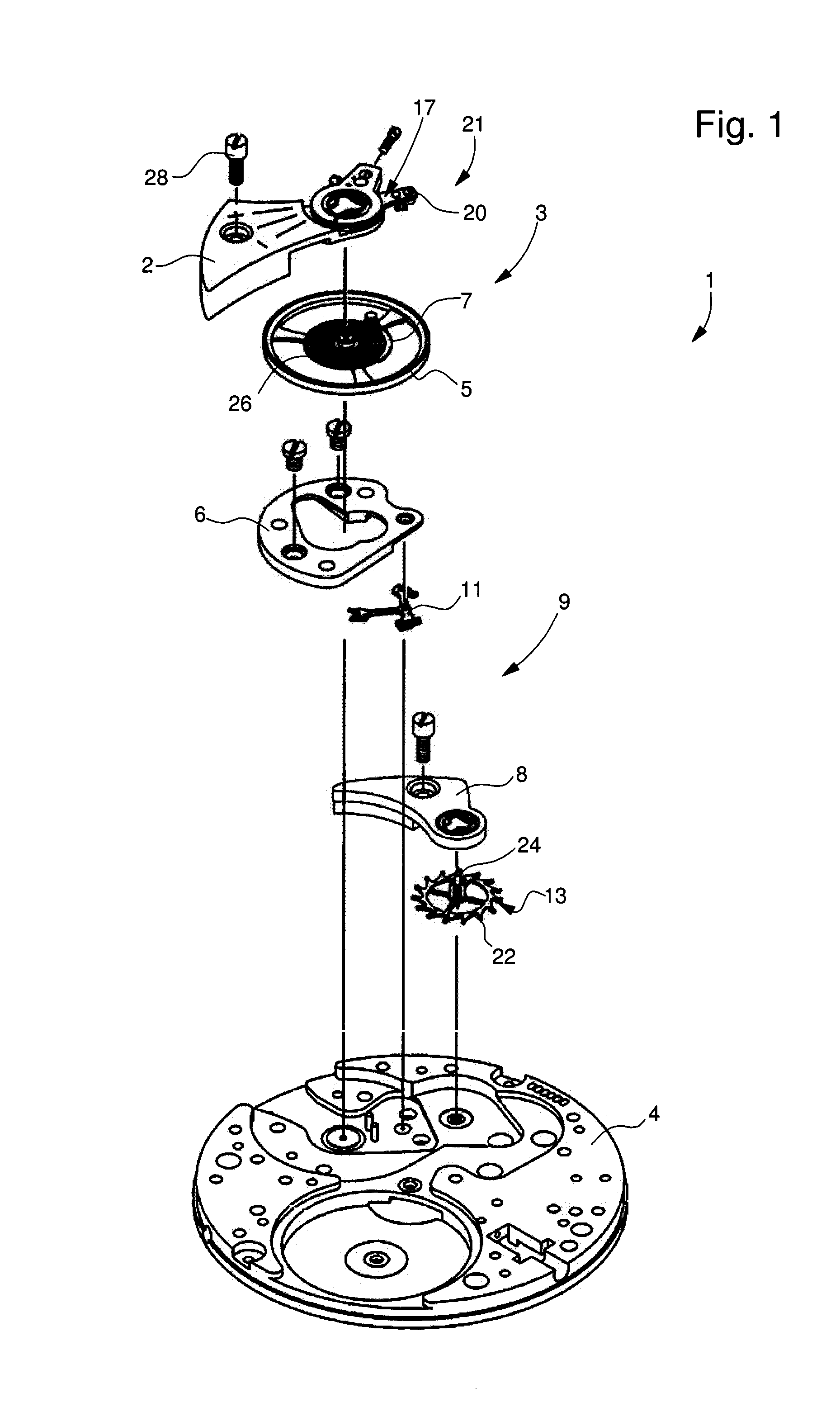

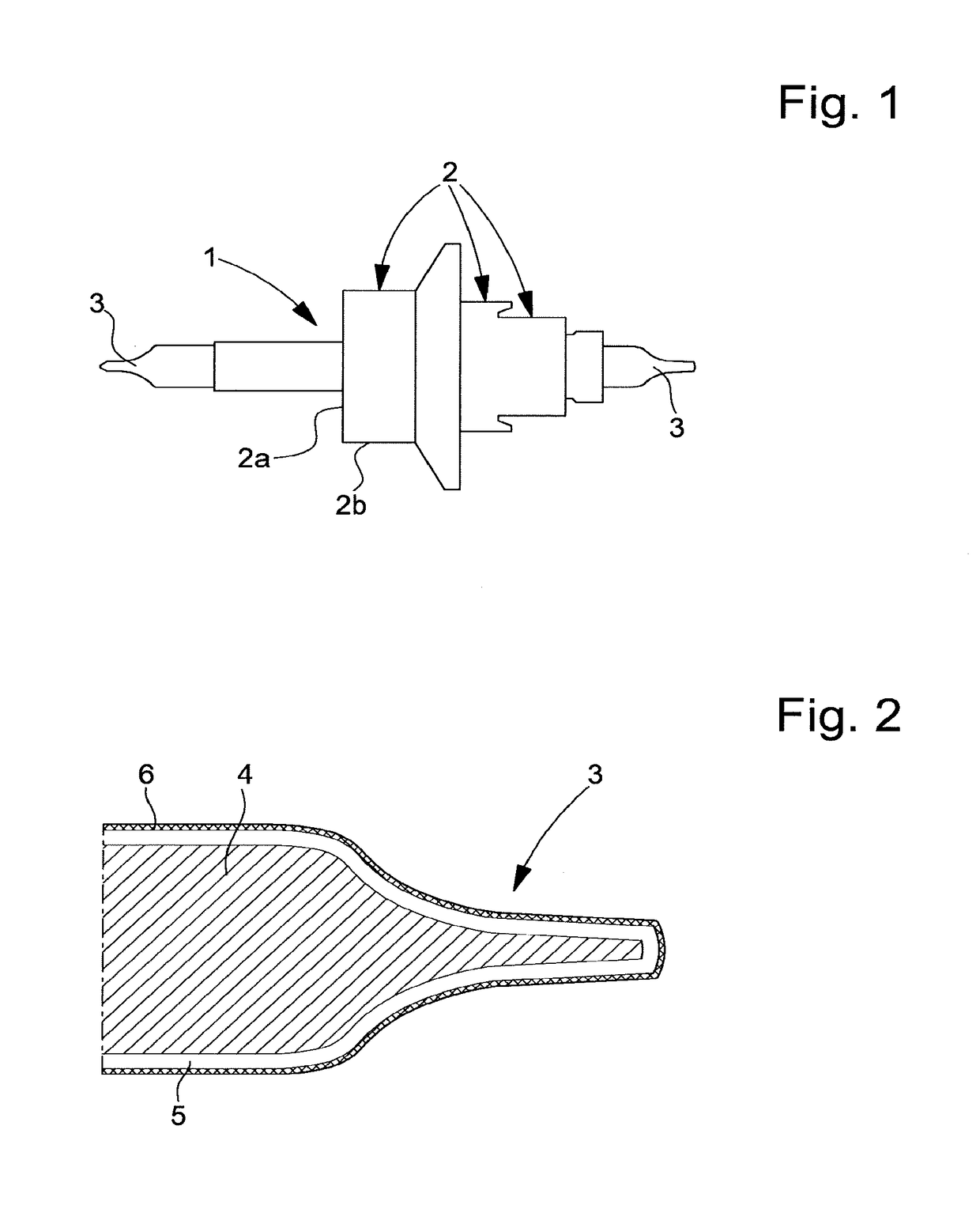

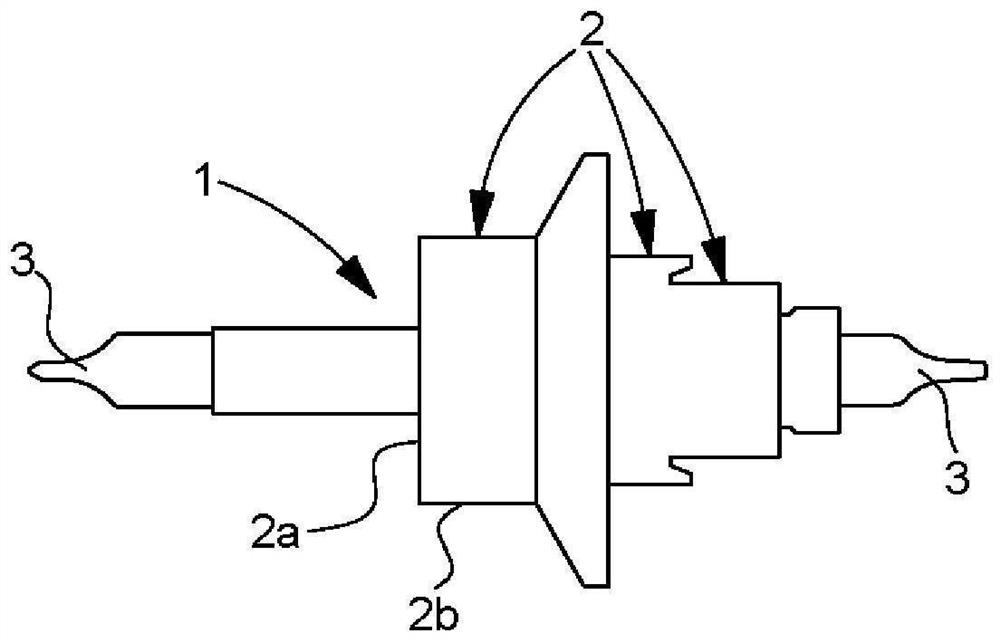

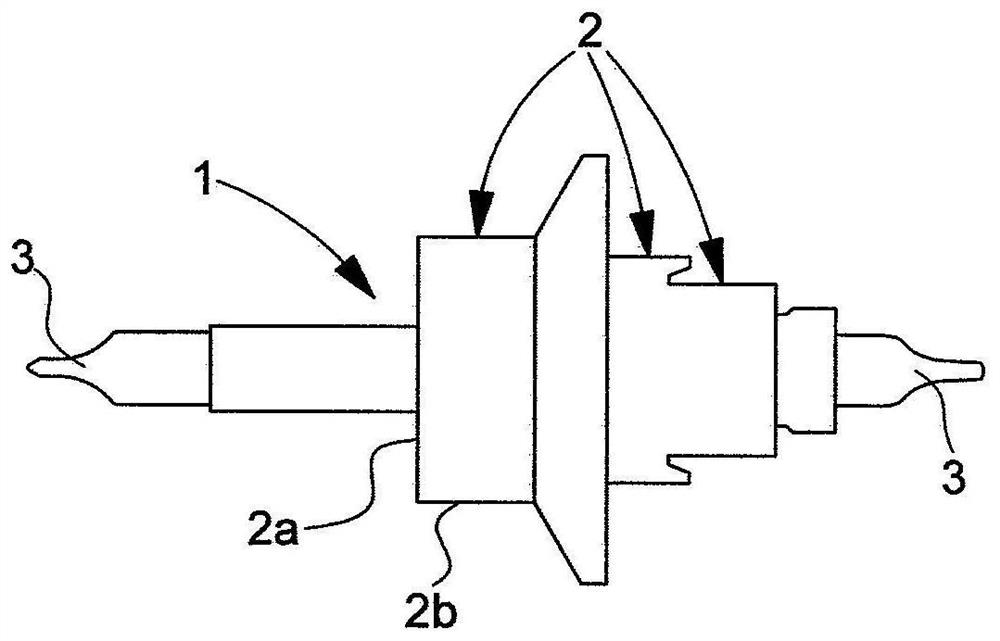

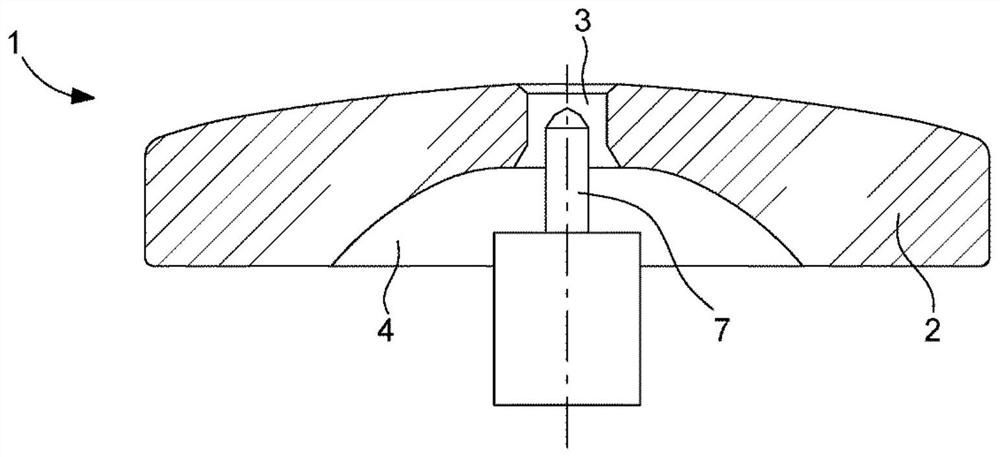

Part for clock movement

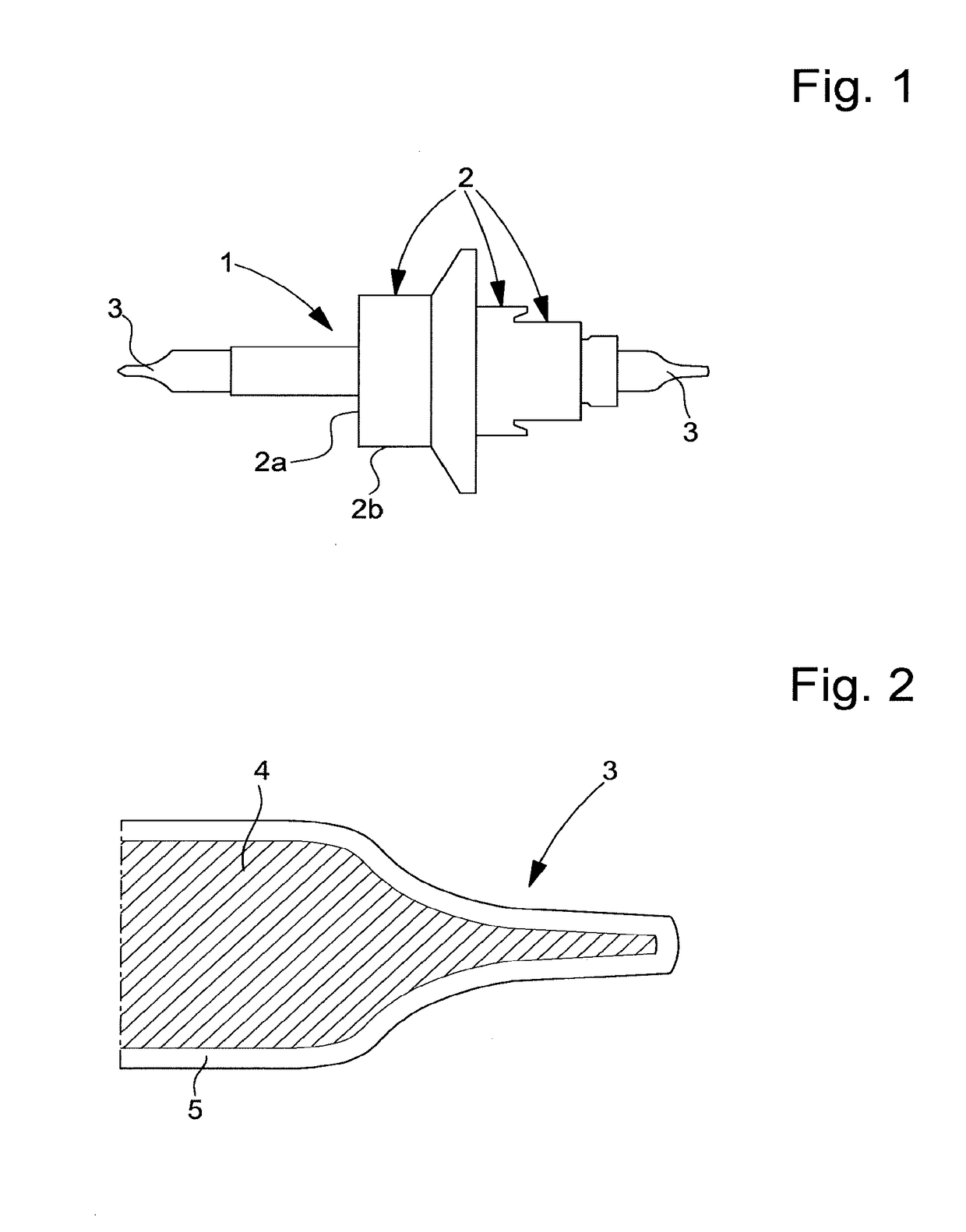

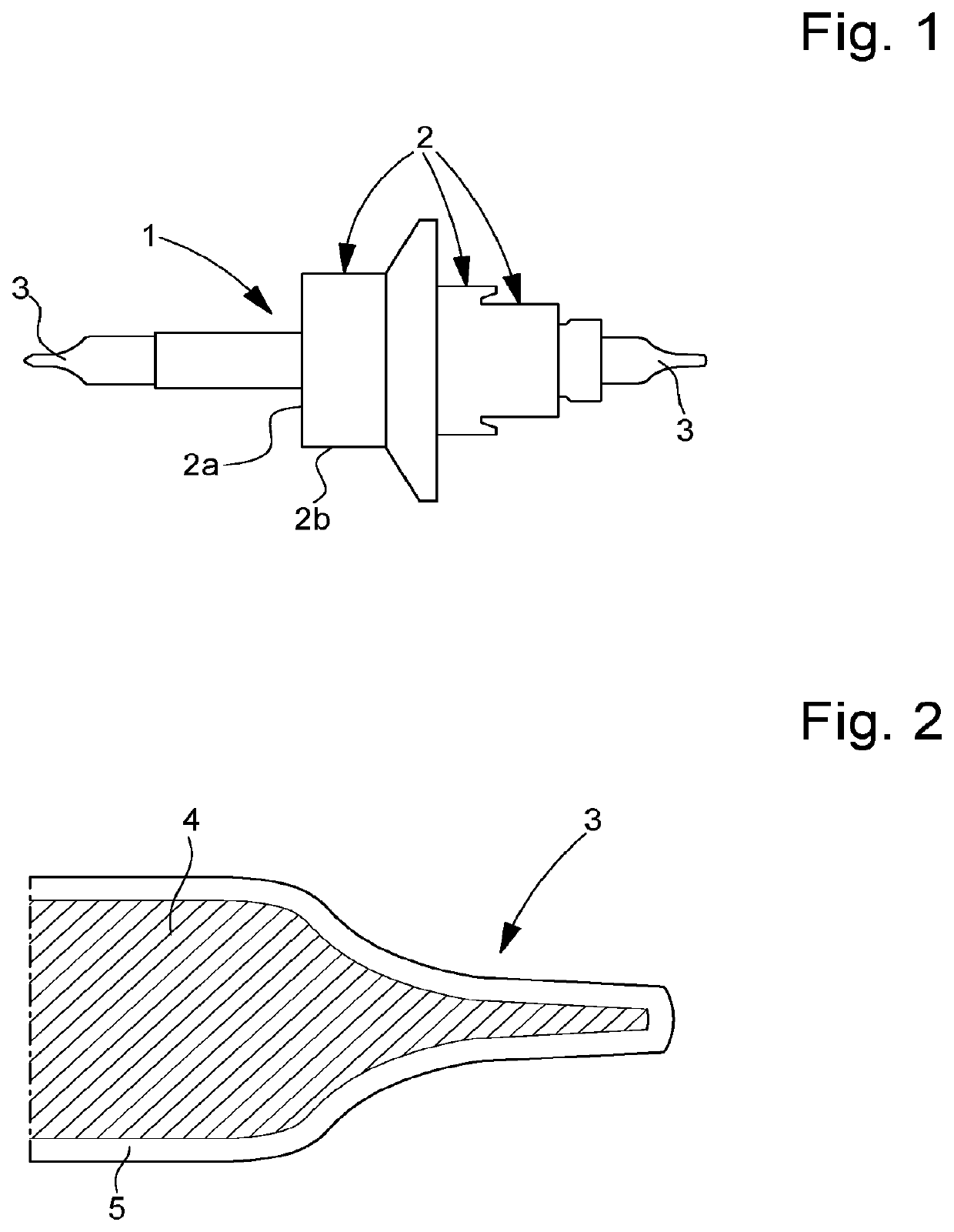

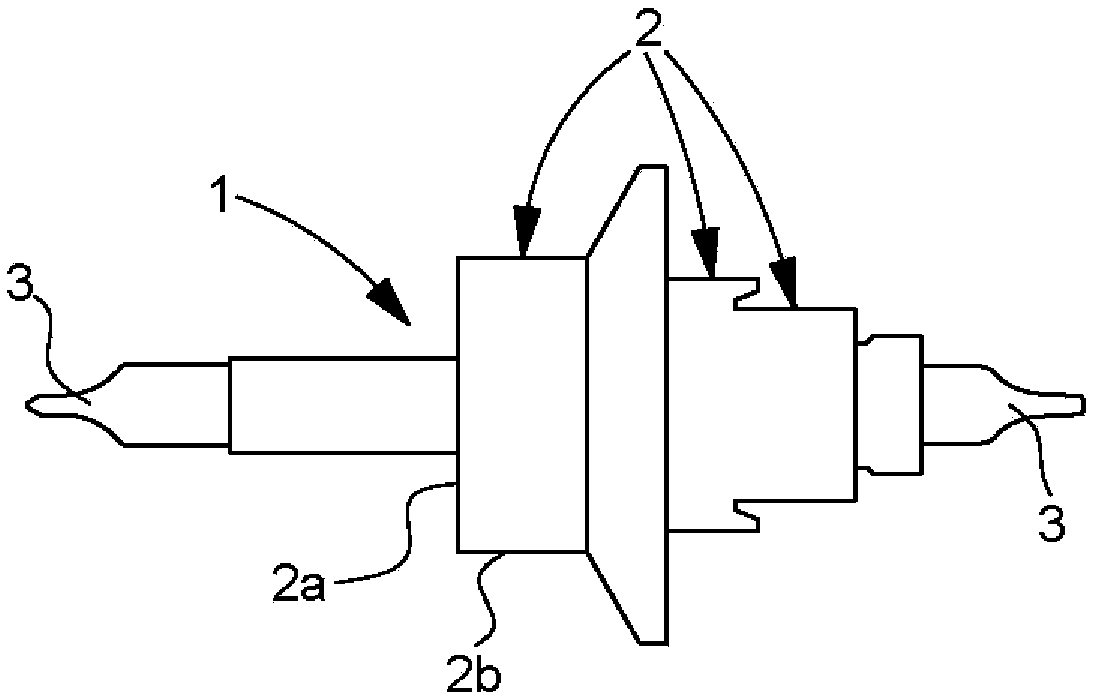

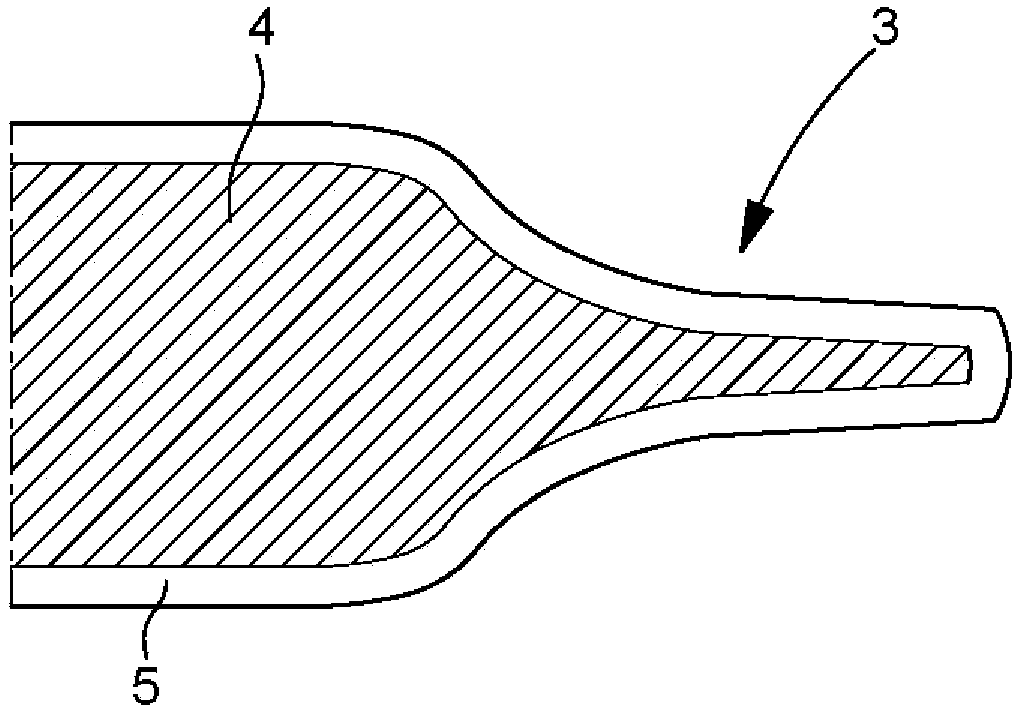

ActiveCN107632507AGood mechanical resistanceImprove friction performanceGearworksEscapementsPlatinumMetallic materials

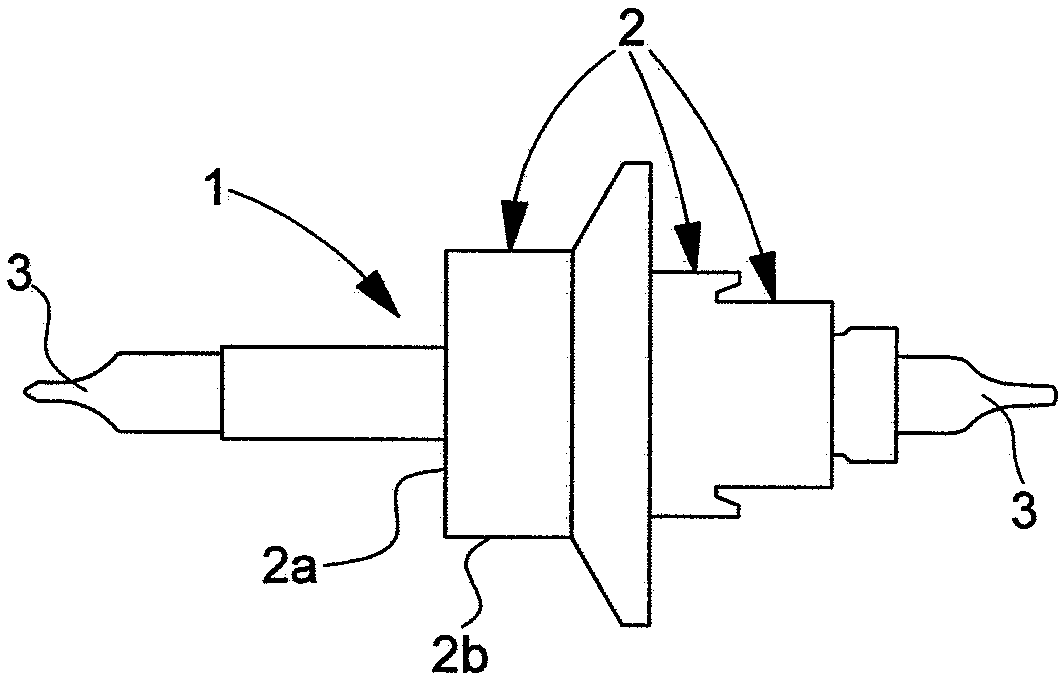

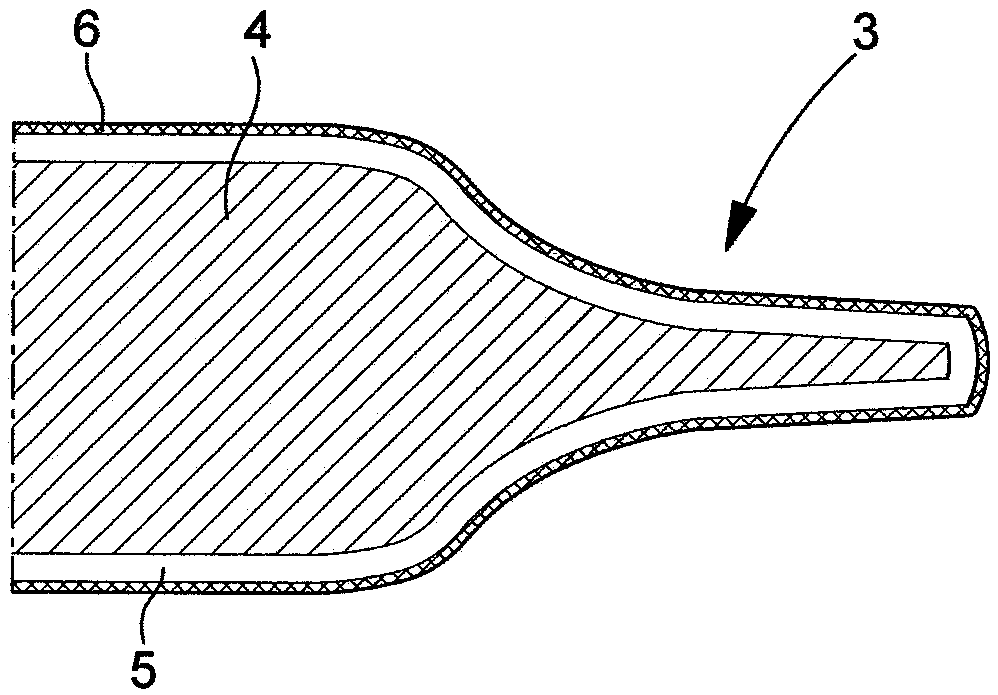

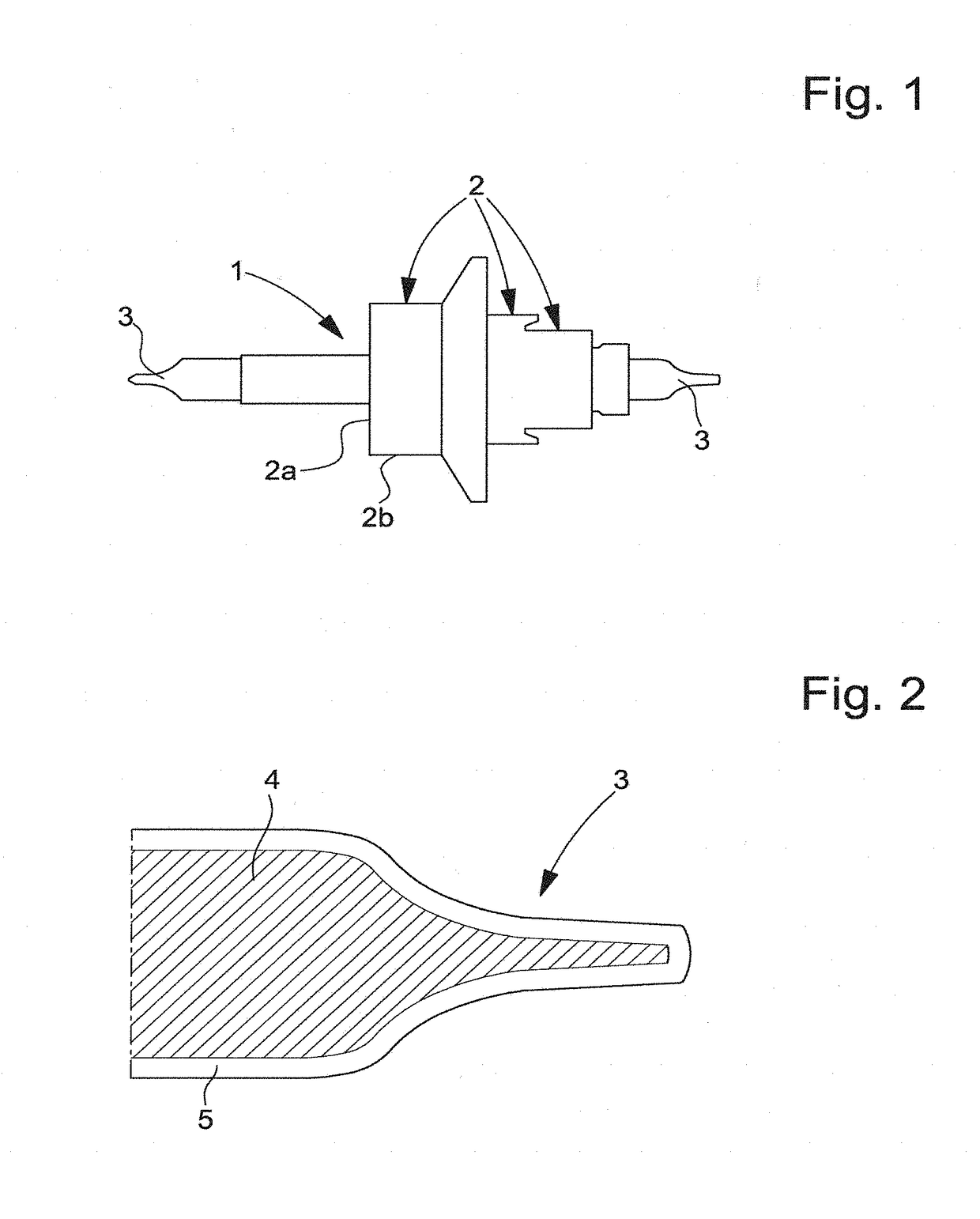

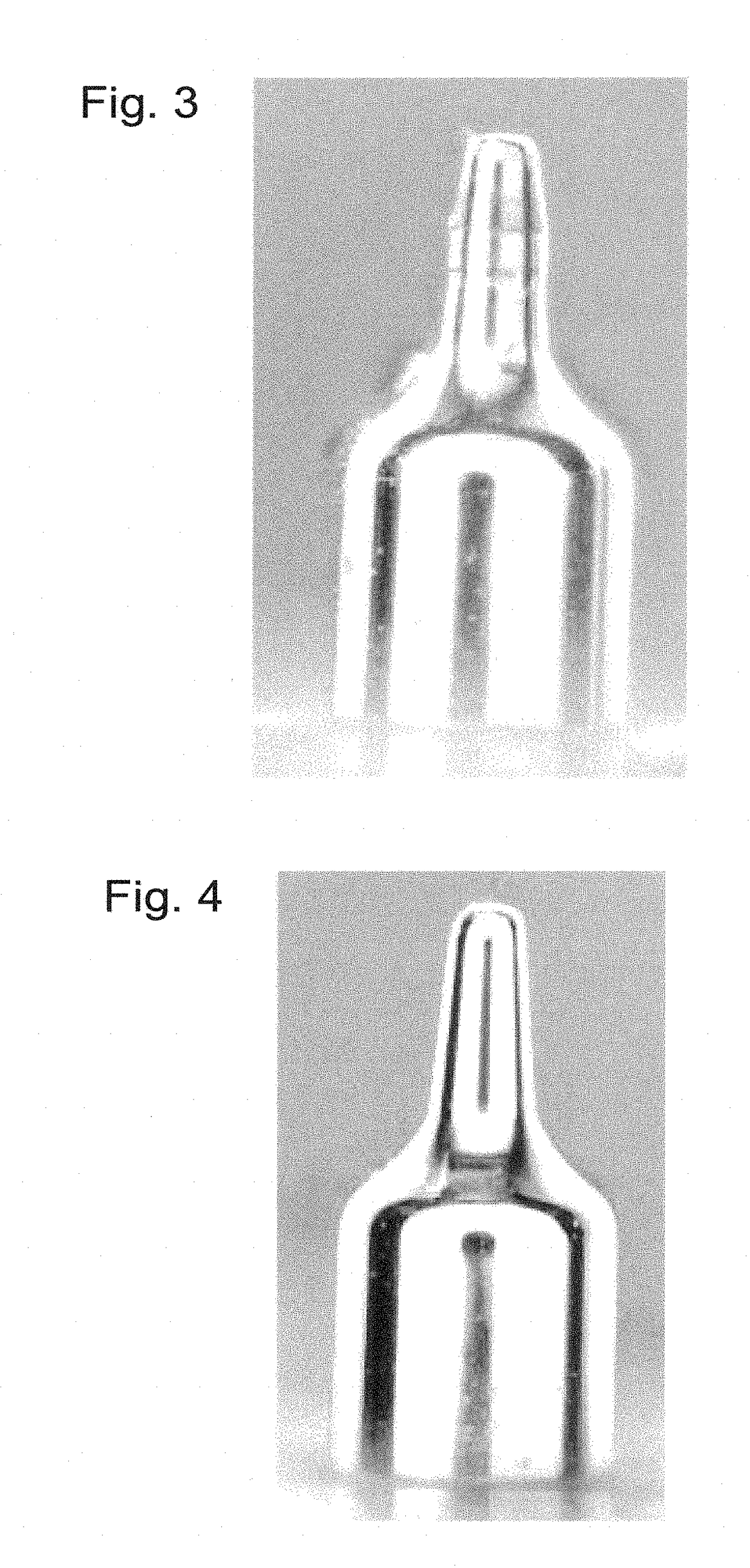

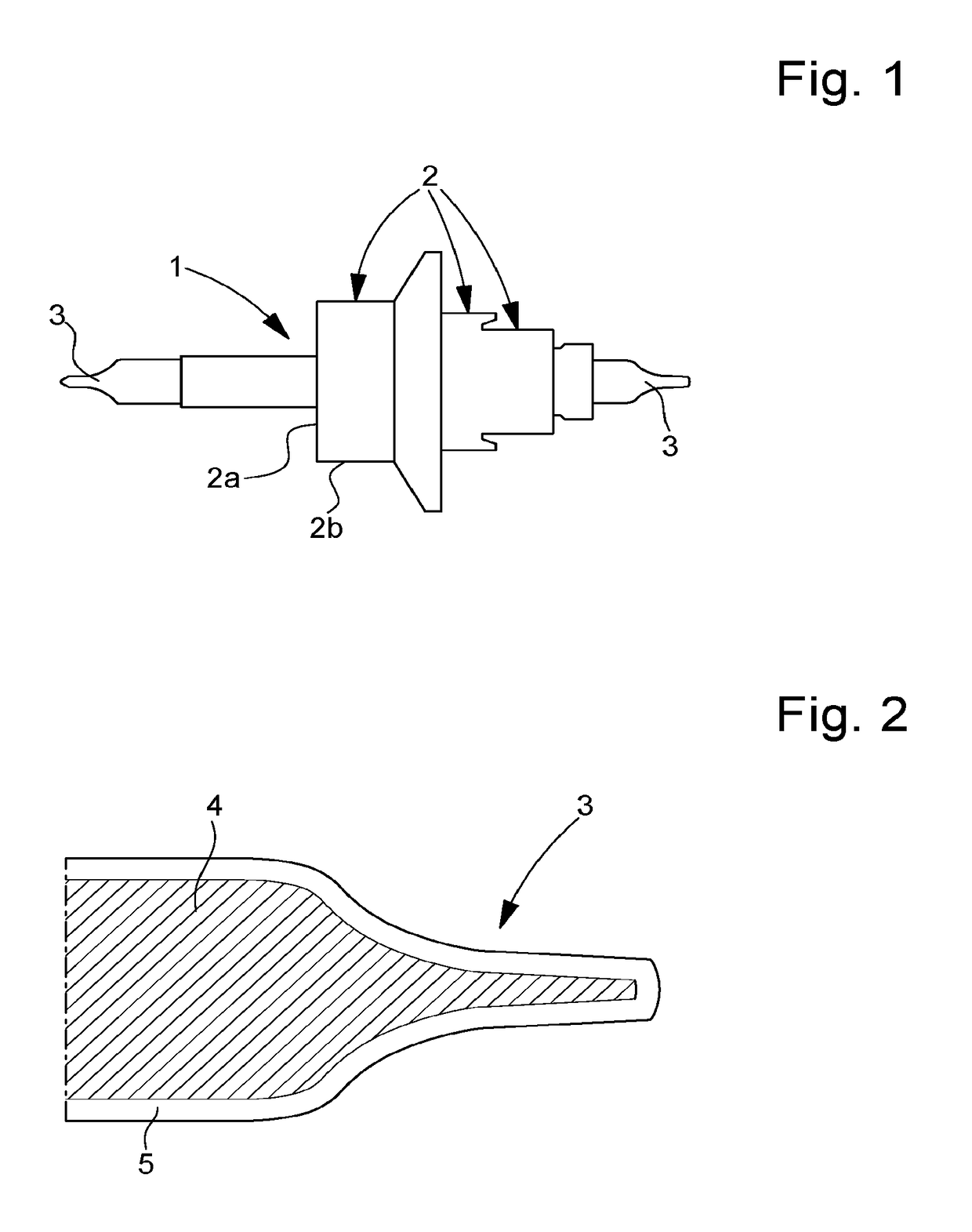

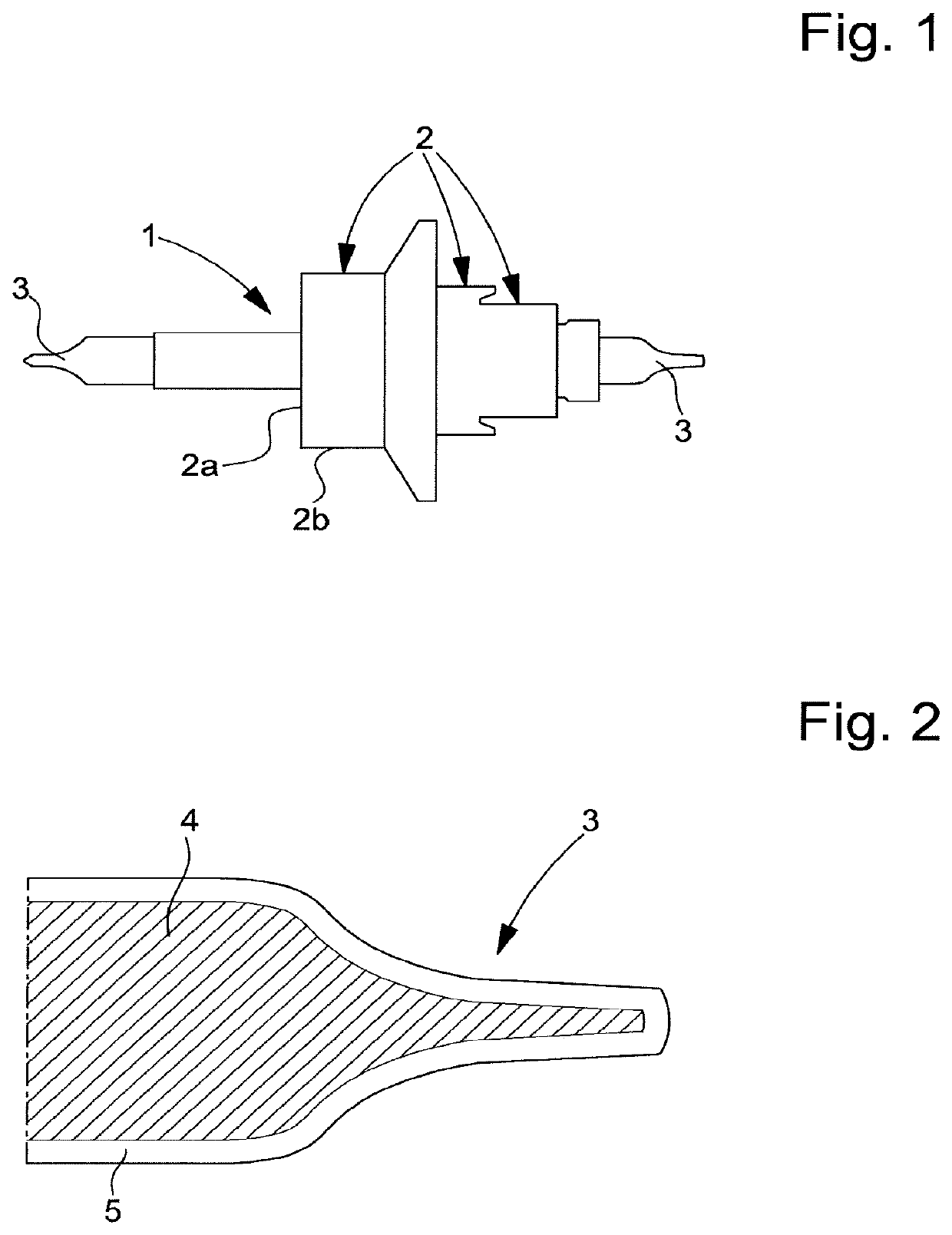

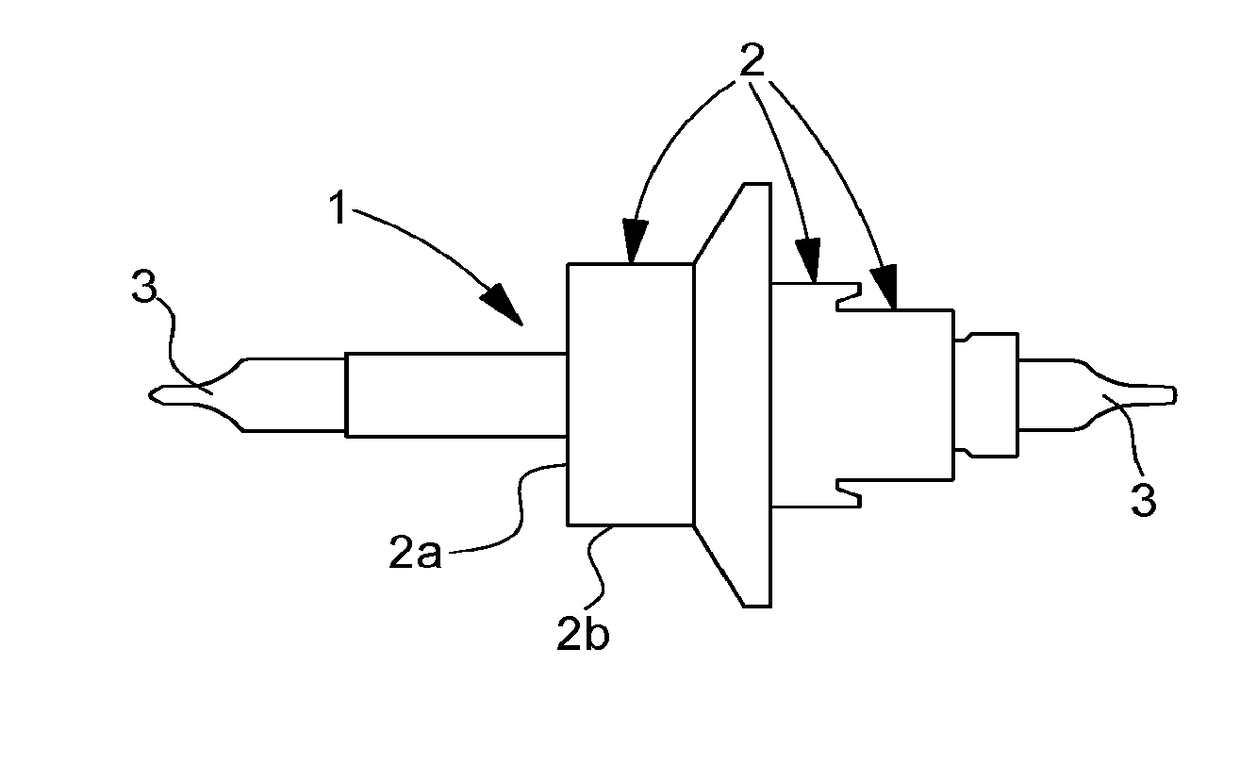

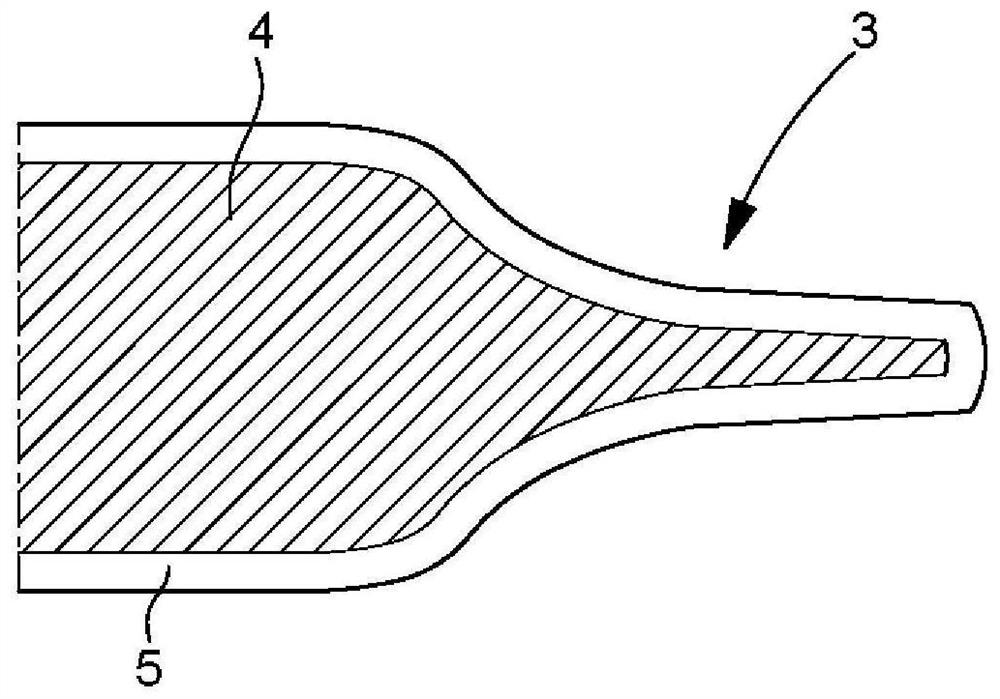

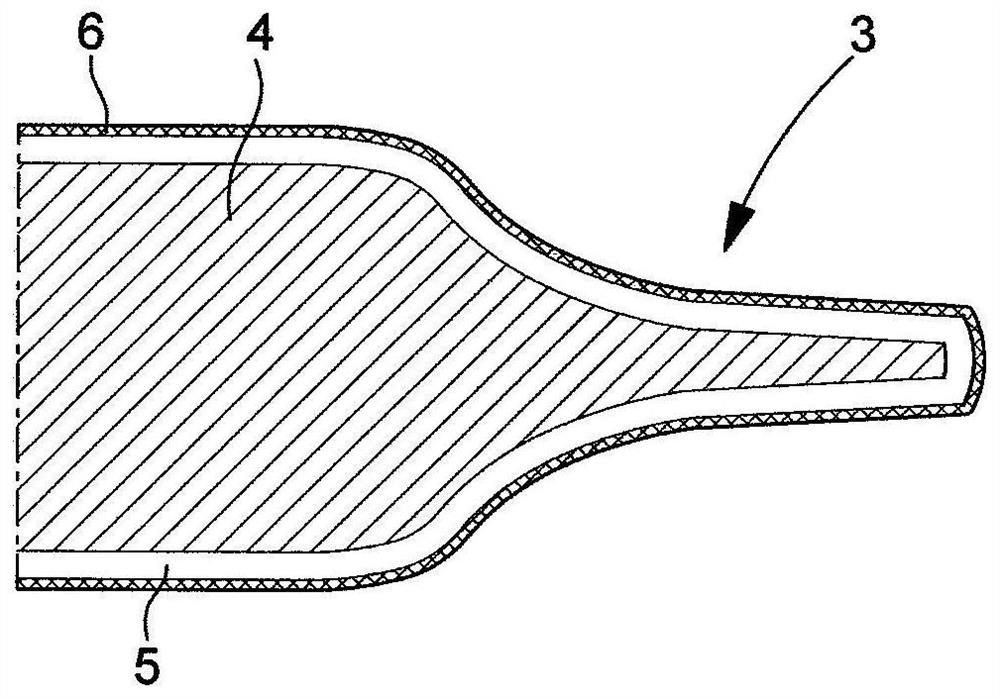

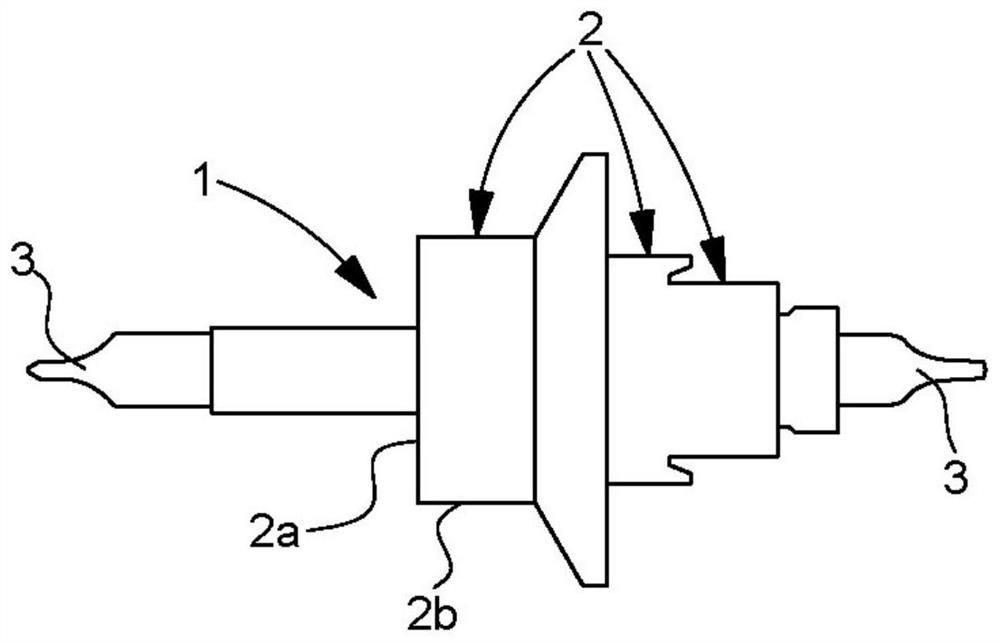

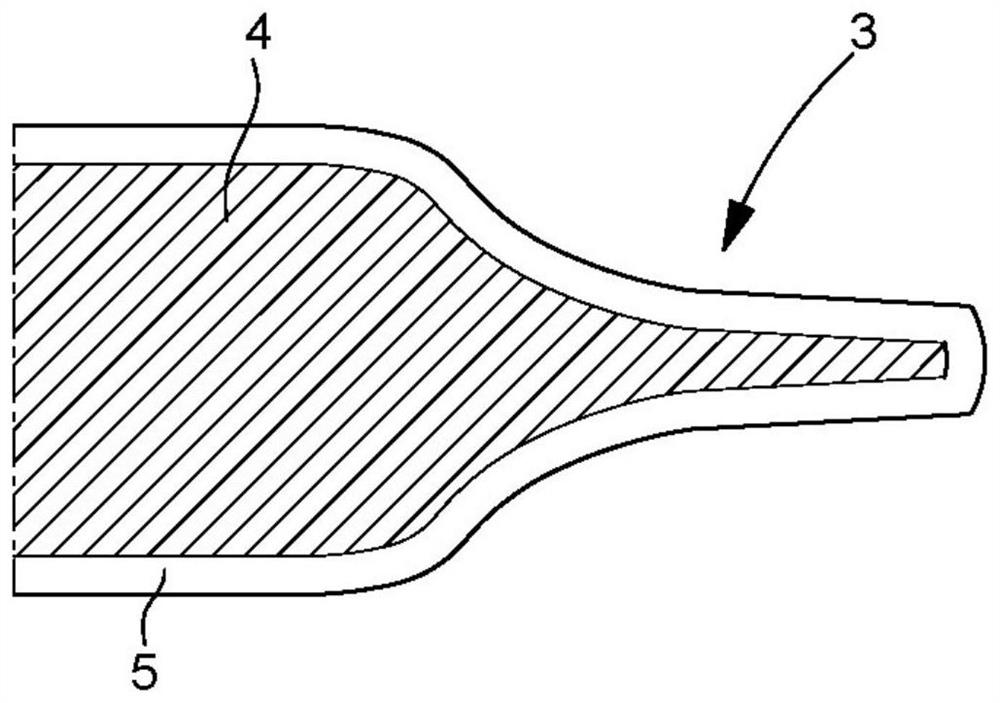

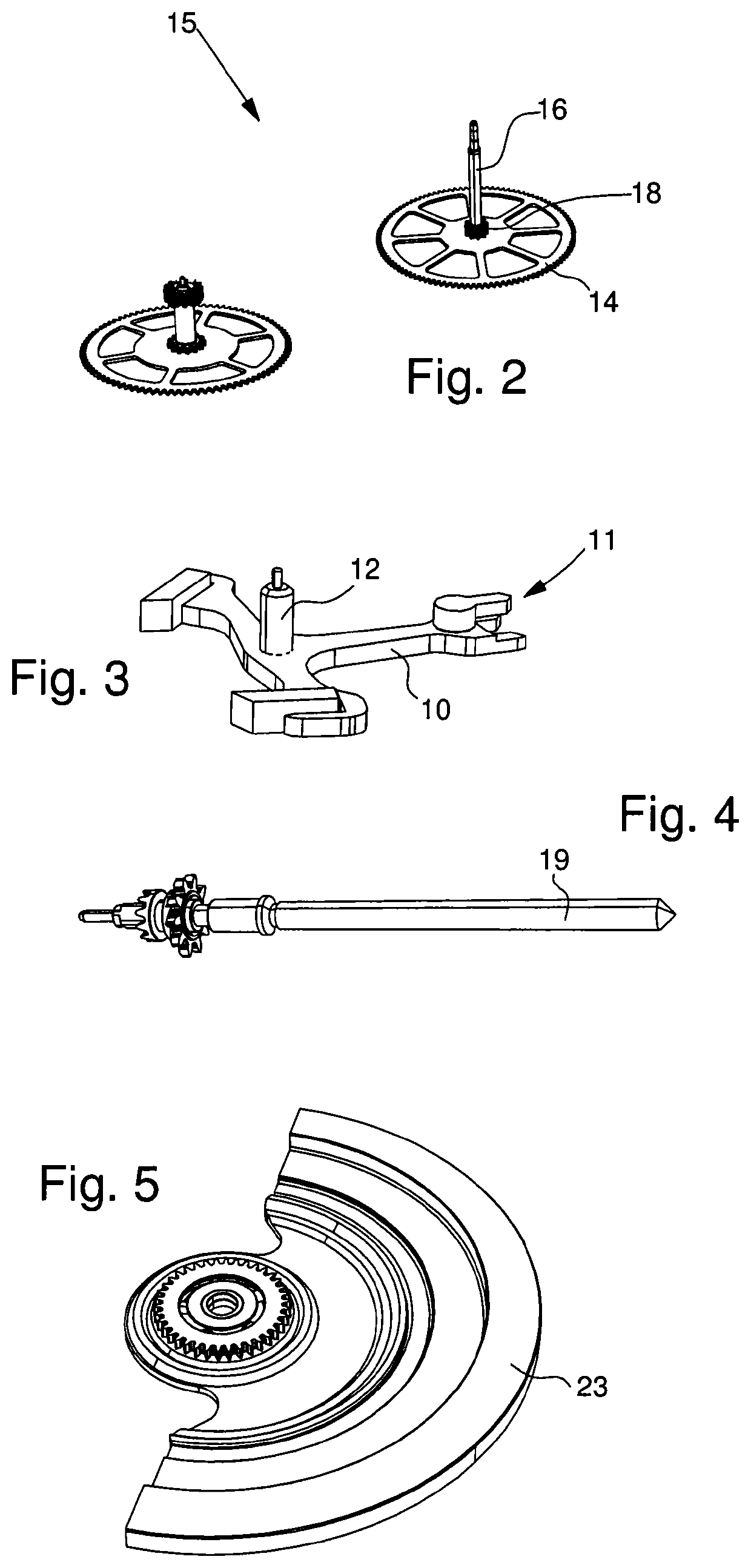

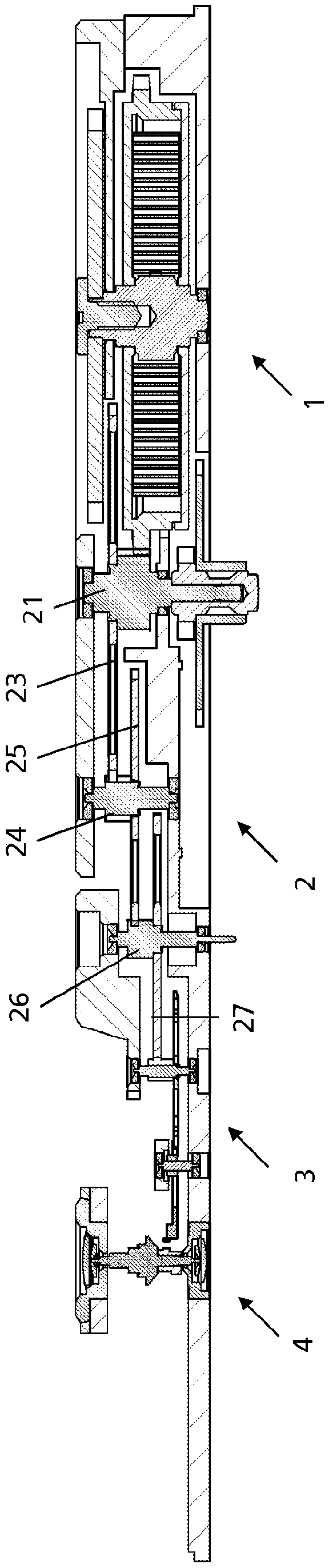

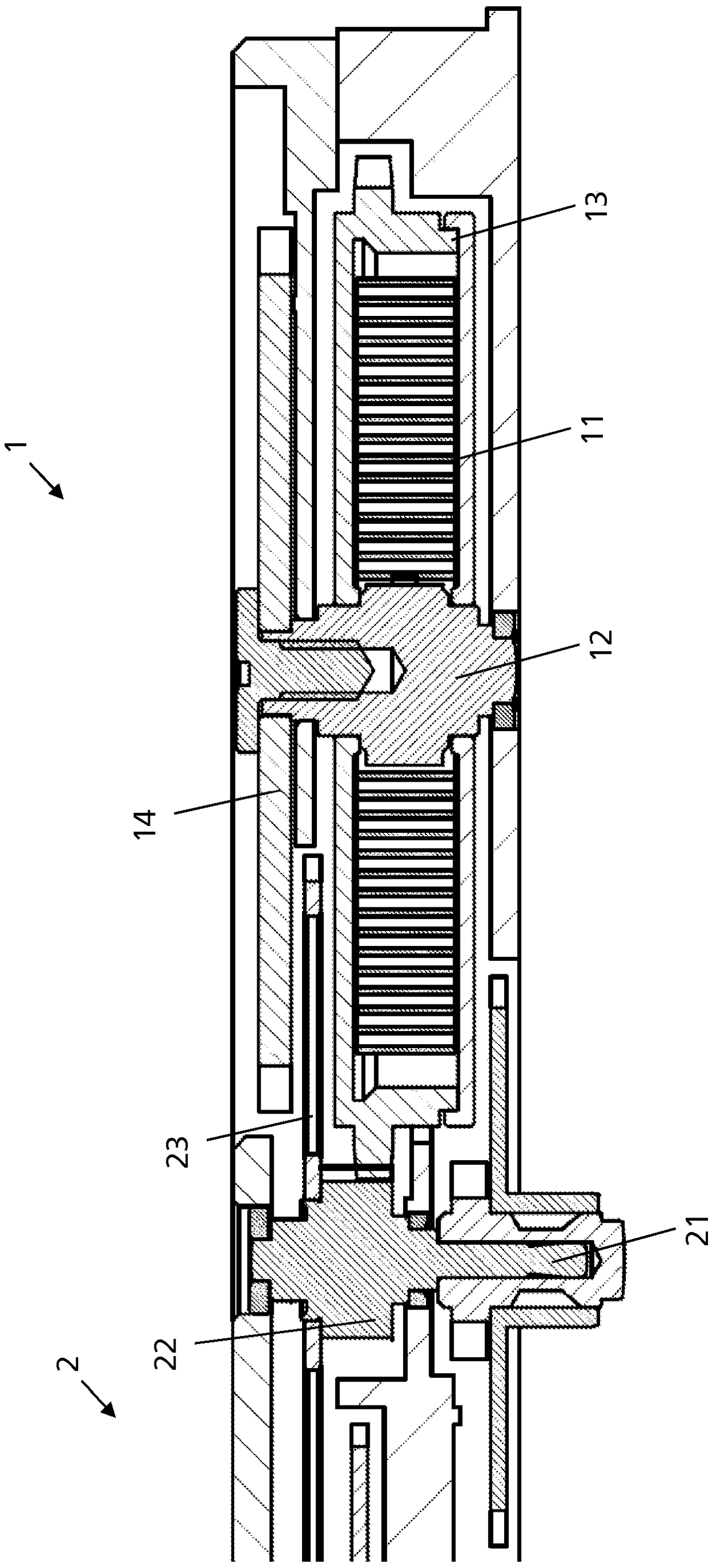

The invention relates to a pivot axis (1) for a watch movement. The pivot axis includes at least one pivot (3), which is made of a first non-magnetic metal material (4), at at least one of its ends inorder to limit its sensitivity to magnetic fields, at least the surface external of said pivot (3) being covered with a first layer (5) of a second material selected from the group comprising Ni, NiBand NiP, and preferably NiP chemical. At least the first layer (5) of the second material is at least partially covered with a second layer (6) of a third material selected from the group consistingof gold, silver, copper, platinum, rhodium, palladium and their alloys. The invention relates to the field of watch movements.

Owner:NIVAROX FAR

Magnetically insensitive, highly hard and constant-modulus alloy, and its production method, as well as hair spring, mechanical driving apparatus and watch and clock

ActiveUS20110286312A1Weakly magneticHigh Young 's modulusFrequency stabilisation mechanismFurnace typesWire rodYoung's modulus

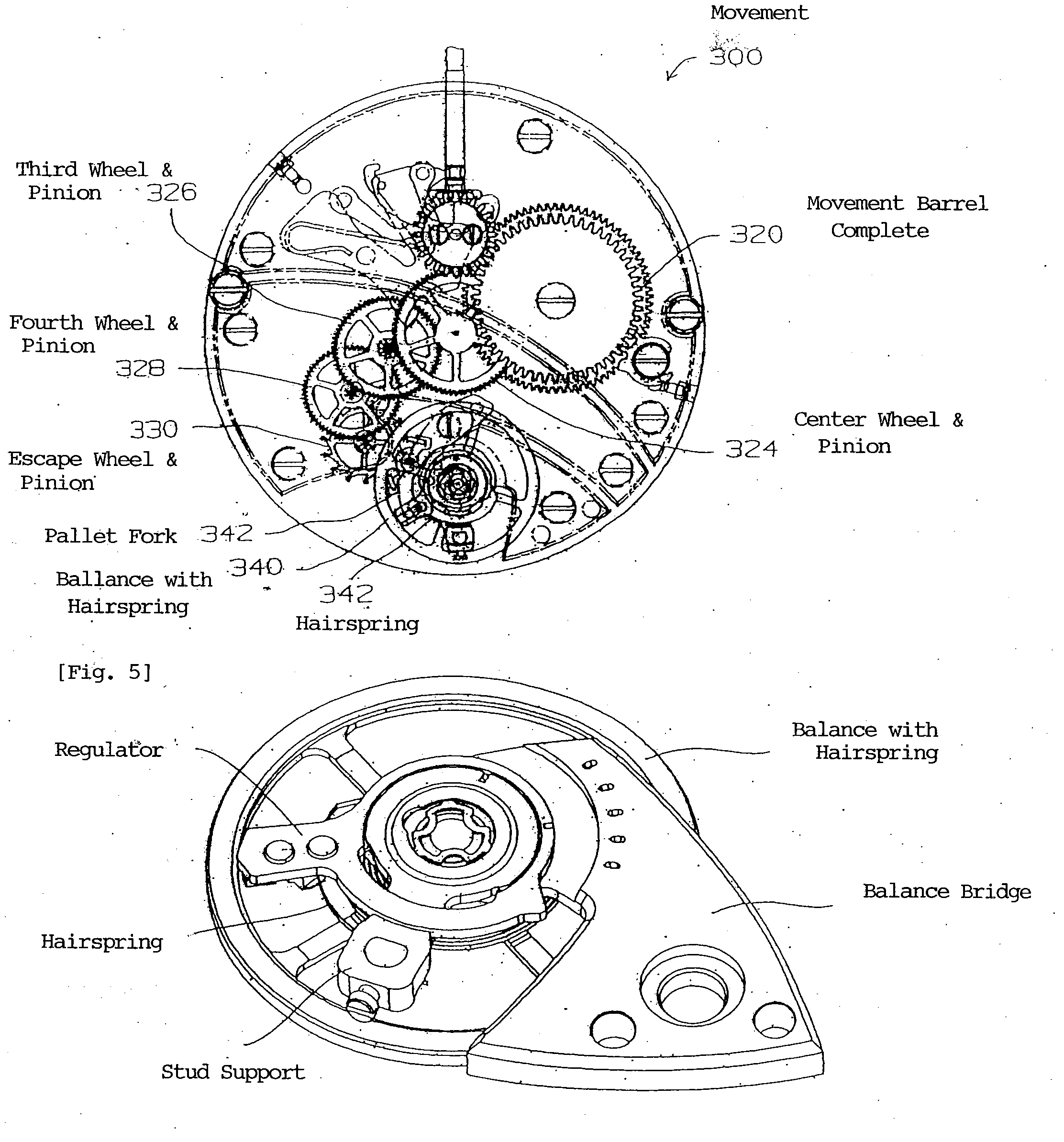

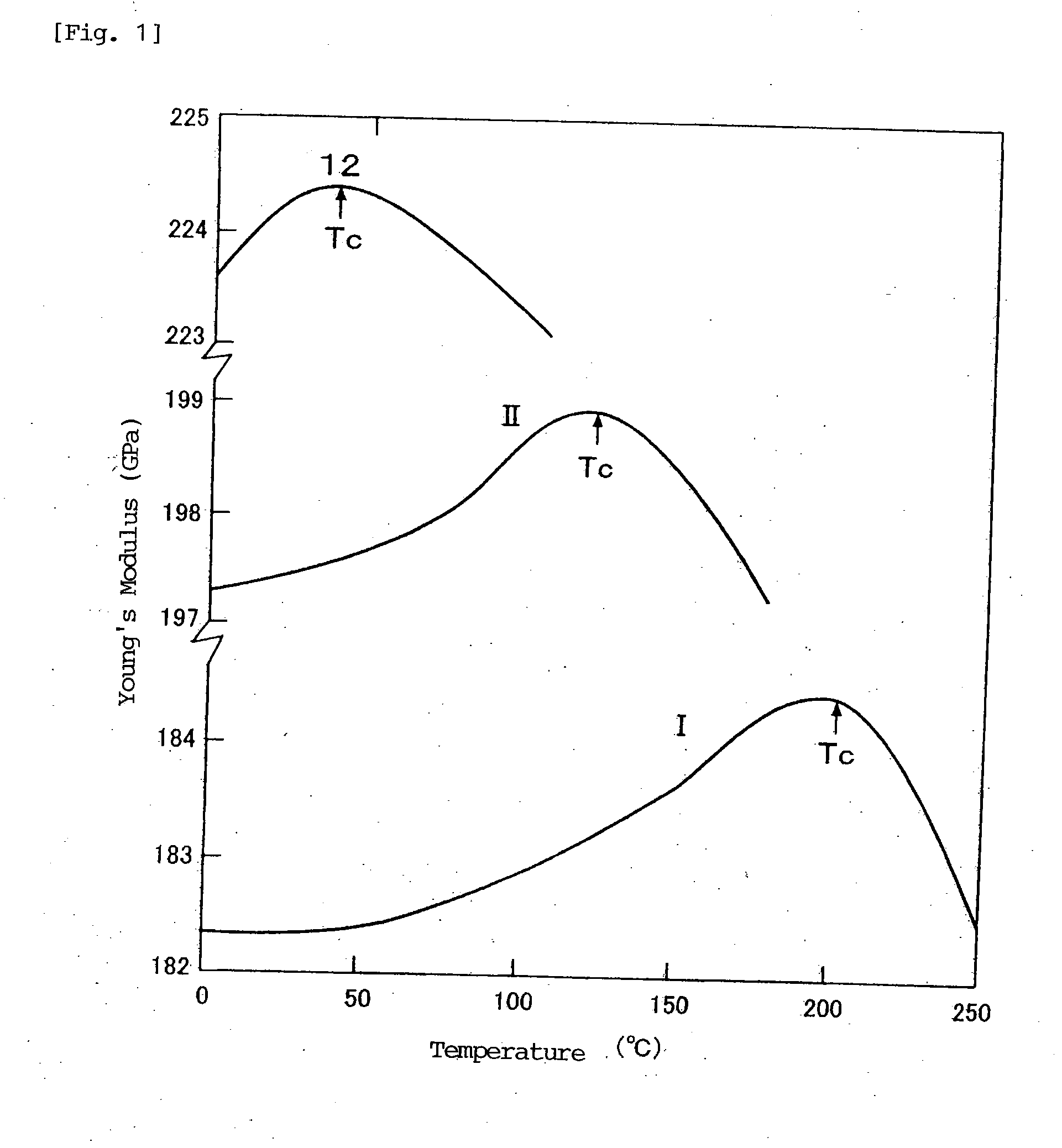

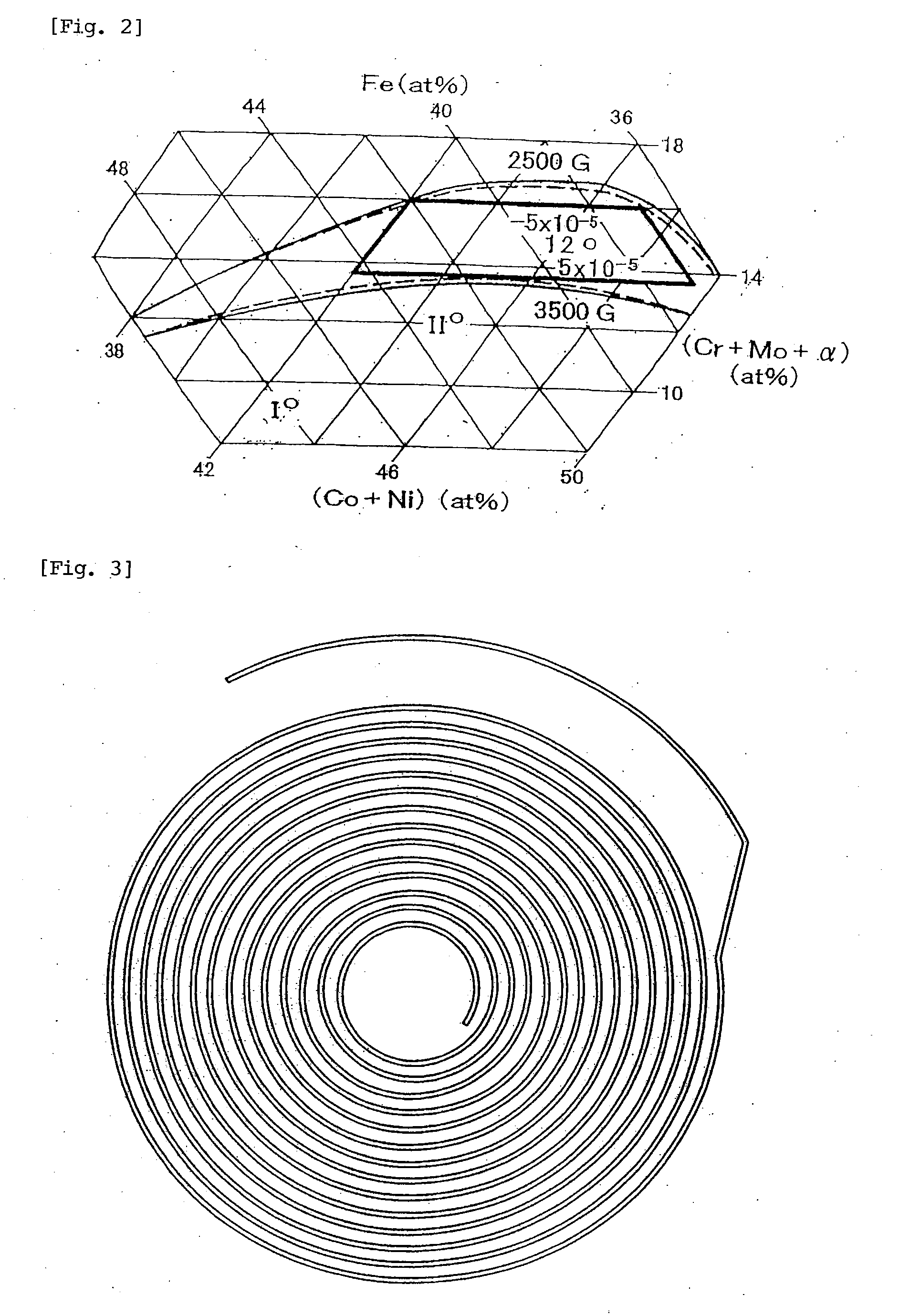

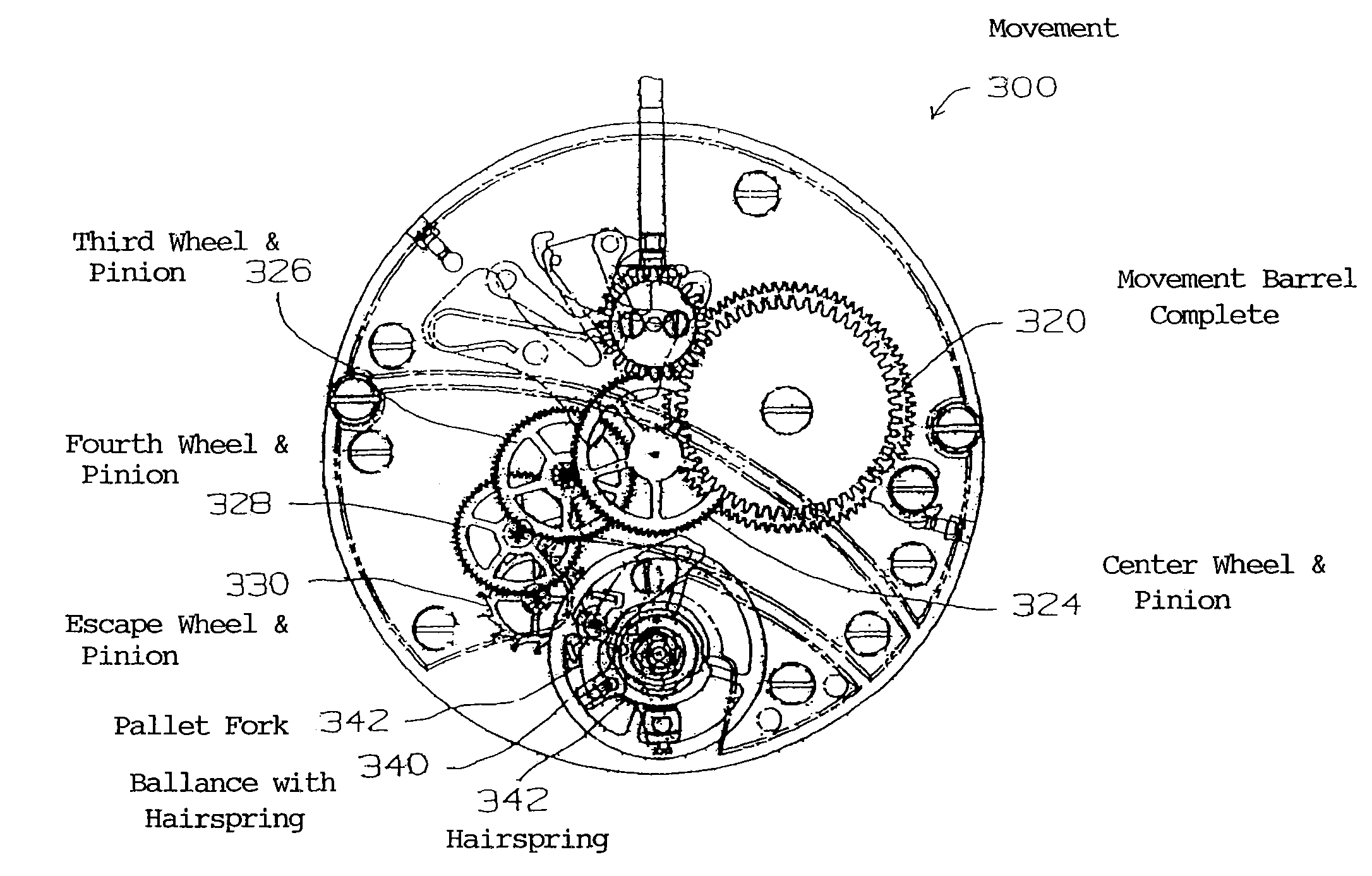

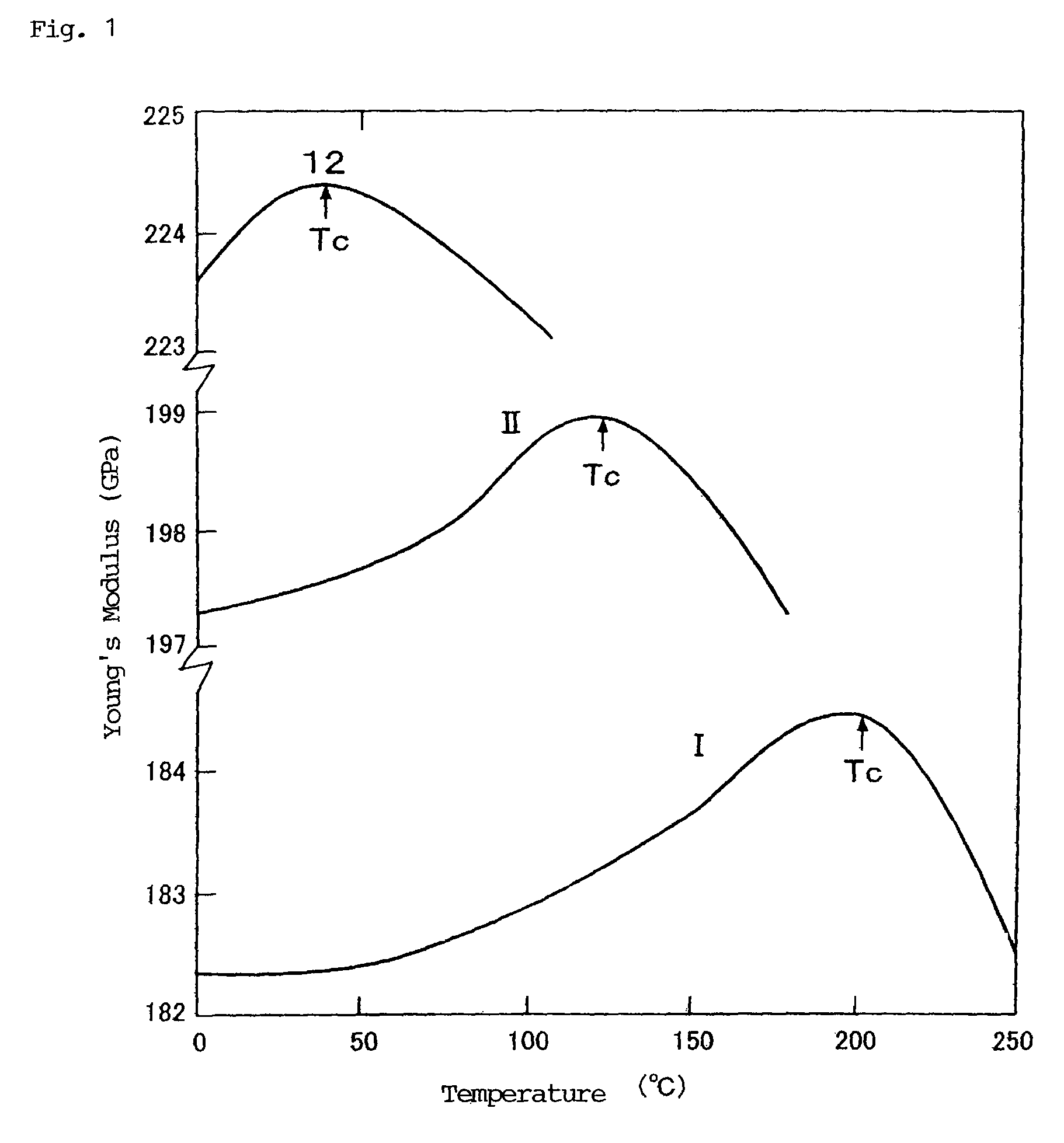

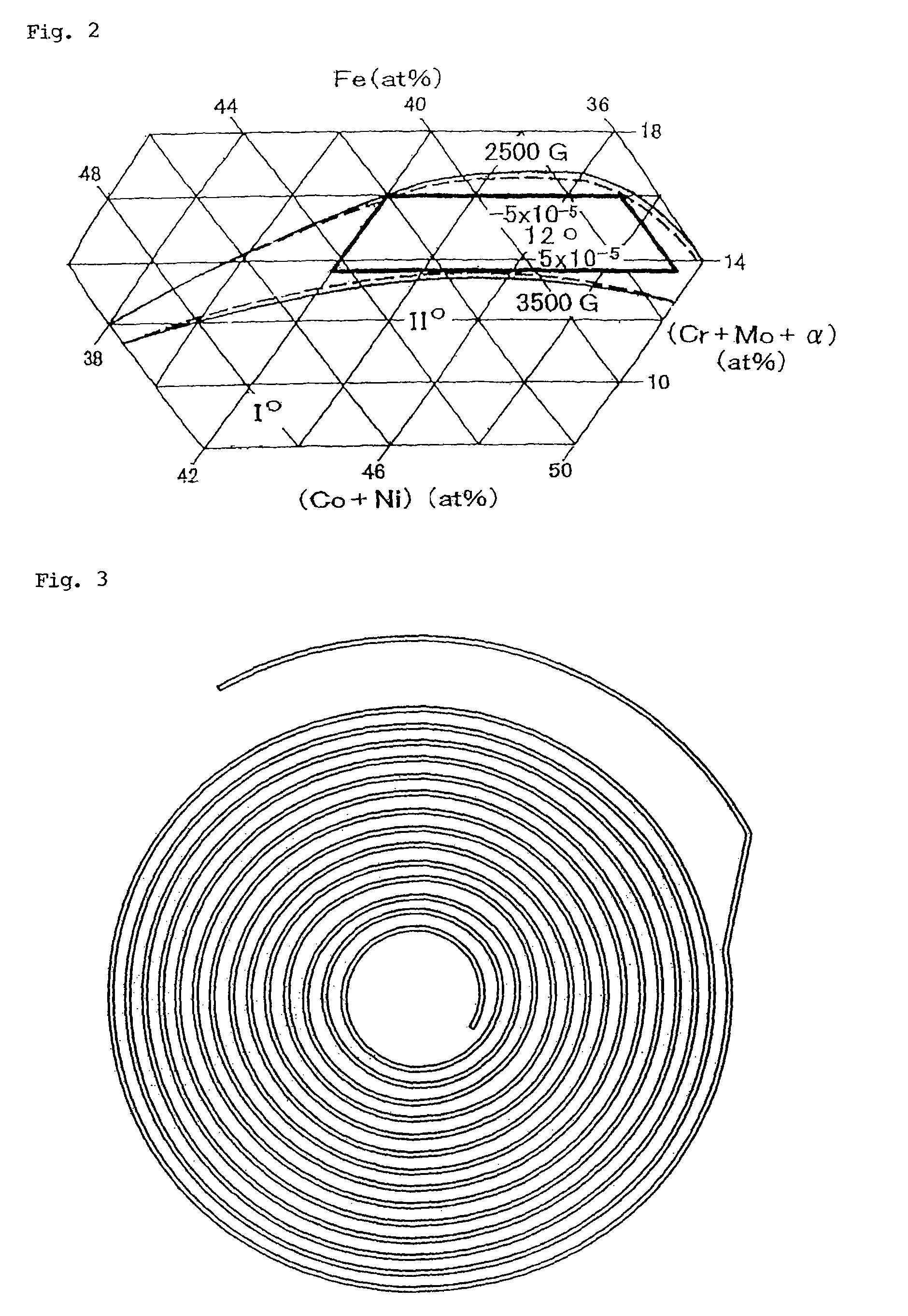

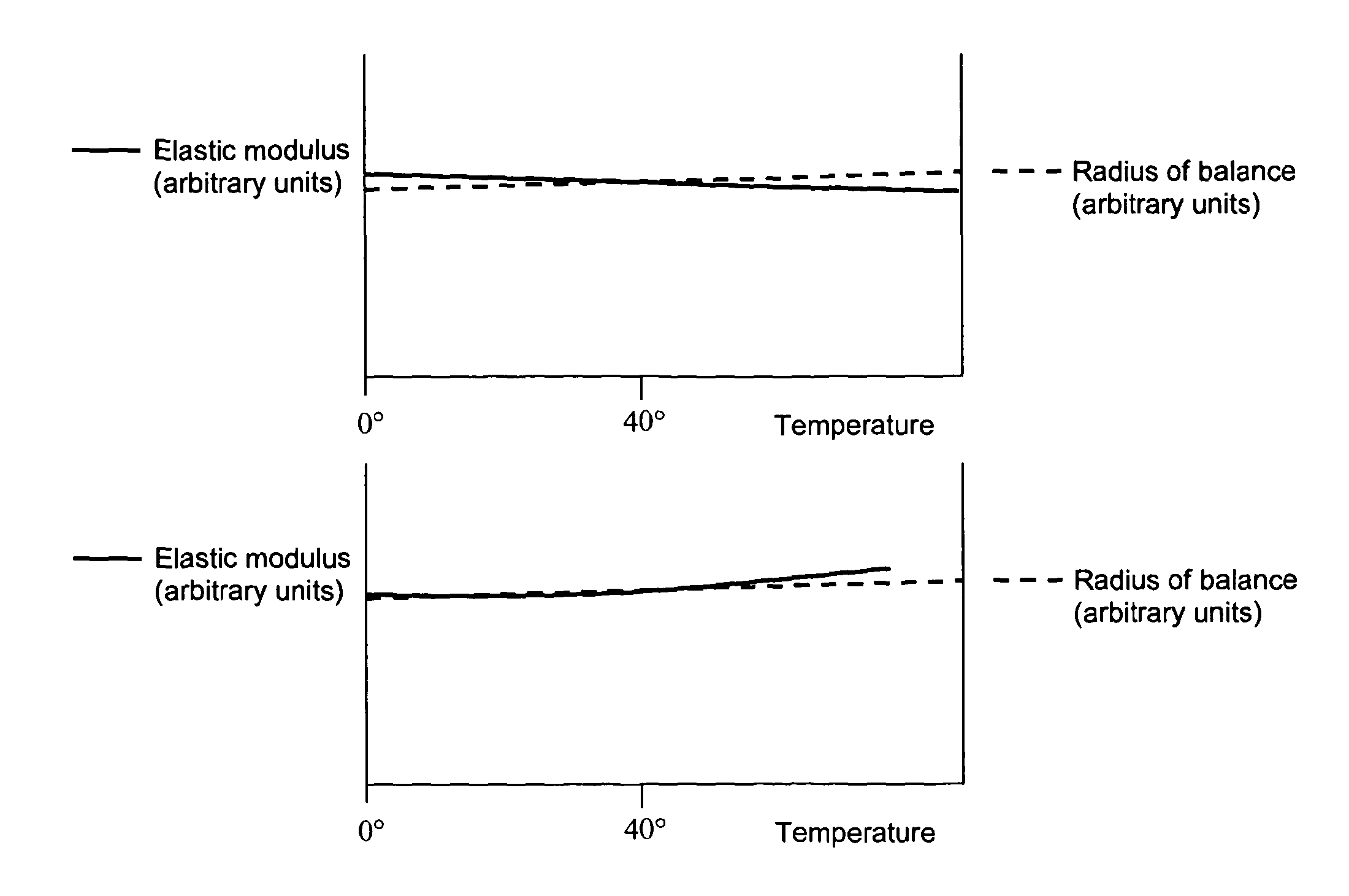

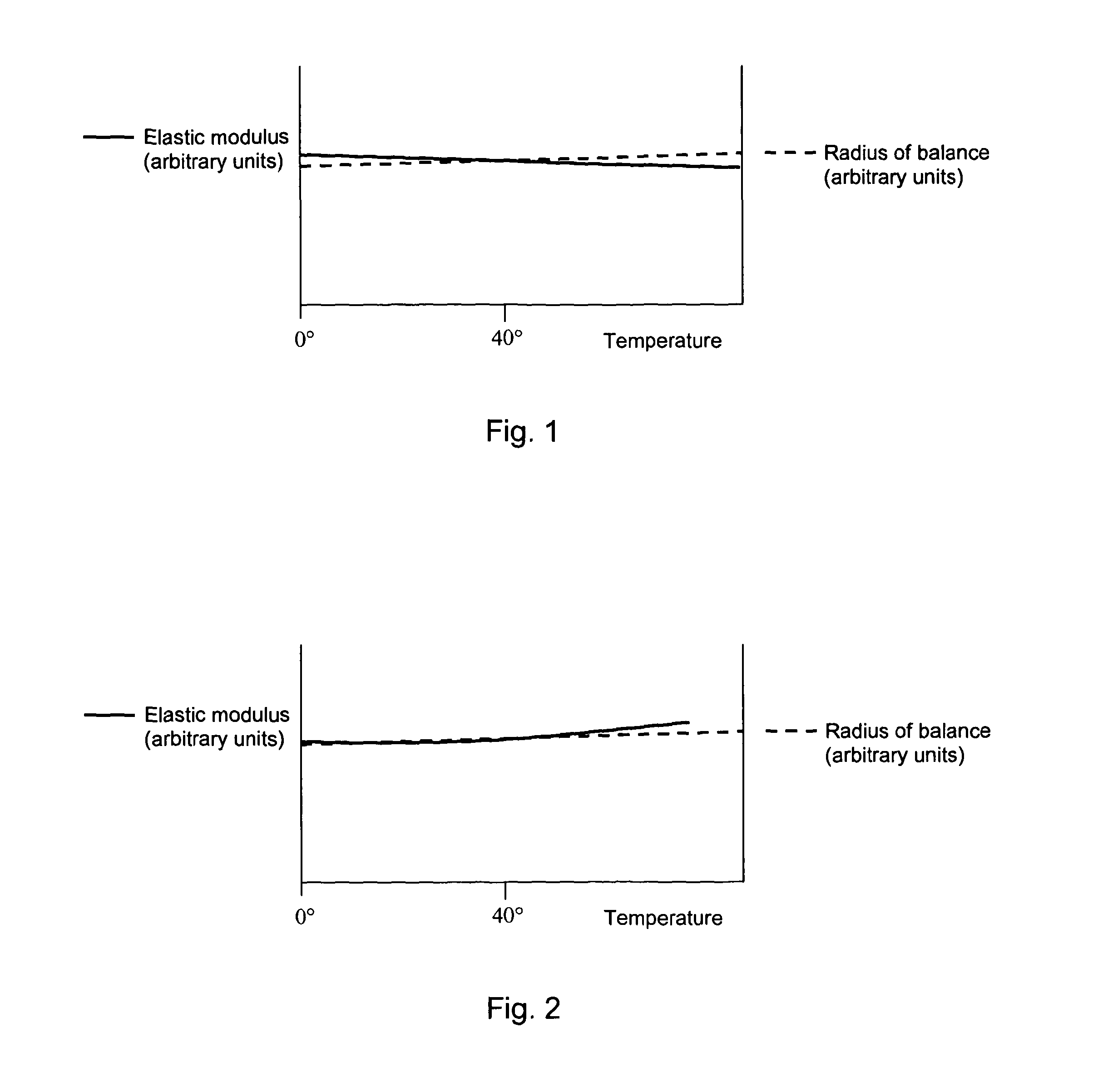

[Task] A constant-modulus alloy, which has a low saturation magnetic flux density to provide weakly magnetic properties, a high Young's modulus, a low temperature coefficient of Young's modulus, and high hardness, is provided. A hairspring, a mechanical driving apparatus and a watch and clock, in which the alloy is used, are provided.[Means for Solution]The alloy consists essentially of, by atomic weight ratio, 20 to 40% Co and 7 to 22% Ni, with the total of Co and Ni being 42.0 to 49.5%, 5 to 13% Cr and 1 to 6% Mo, with the total of Cr and Mo being 13.5 to 16.0%, and with the balance being essentially Fe (with the proviso that Fe is present in an amount of 37% or more) and inevitable impurities. The alloy is heated to a temperature of 1100 degrees C. or higher and lower than the melting point, followed by cooling. The alloy is subsequently subjected to repeated wiredrawing and intermediate annealing at 800 to 950 degrees C., thereby forming a wire at a working ratio of 90% or more. The resultant wire has a fiber structure having a <111> fiber axis. The wire is subsequently cold rolled at a rolling reduction of 20% or more, thereby obtaining a sheet, followed by heating the sheet at a temperature of 580 to 700 degrees C. The obtained magnetically insensitive, highly hard, constant modulus alloy has a {110}<111> texture. 2500 to 3500 G of saturation flux density, (−5˜+5)×10−5 degrees C−1 of temperature coefficient of Young's modulus as measured at 0 to 40 degrees C., and 350 to 550 of Vickers hardness

Owner:RESEARCH INSTITUTE FOR ELECTROMAGNETIC MATERIALS +1

Method for manufacturing a balance spring for a timepiece movement

InactiveUS20190196406A1Improve deformationEasy to roll processingFrequency stabilisation mechanismFurnace typesSurface layerNiobium

A method for manufacturing a balance spring for a balance, which includes creating a blank from an alloy containing: niobium: the remainder to 100 wt %, titanium: between 40 and 60 wt %, traces of elements selected from the group formed of O, H, C, Fe, Ta, N, Ni, Si, Cu, Al, between 0 and 1600 ppm by weight individually, and less than 0.3 wt % combined; β-quenching the blank, such that the titanium of the alloy is essentially in solid solution form with β-phase niobium, the α-phase titanium content being less than or equal to 5% by volume, at least one deformation step of the alloy alternated with at least one heat treatment step such that the niobium and titanium alloy obtained has an elastic limit higher than or equal to 600 MPa and a modulus of elasticity lower than or equal to 100 GPa, a winding step to form the balance spring being performed prior to the final heat treatment step, prior to the deformation step, a step of depositing, on the alloy blank, a surface layer of a ductile material such as copper, to facilitate the wire shaping process, the thickness of the deposited ductile material layer is chosen such that the ratio of the area of ductile material to the area of NbTi alloy for a given cross-section of wire is less than 1.

Owner:NIVAROX FAR

Magnetically insensitive, highly hard and constant-modulus alloy, and its production method, as well as hair spring, mechanical driving apparatus and watch and clock

ActiveUS8684594B2Weakly magneticHigh Young 's modulusFrequency stabilisation mechanismInorganic material magnetismWire rodAlloy

A constant-modulus alloy, which has a low saturation magnetic flux density to provide weakly magnetic properties, a high Young's modulus, a low temperature coefficient of Young's modulus, and high hardness, is provided. A hairspring, a mechanical driving apparatus and a watch and clock, in which the alloy is used, are provided. The alloy consists of Co, Ni, Cr, Mo. and Fe. The alloy is healed and cooled before being subjected to repeated wiredrawing and intermediate annealing, forming a wire with a fiber structure having a <111> fiber axis. The wire is then cold rolled into a sheet and heated to obtain optimal magnetic insensitivity and hardness.

Owner:RESEARCH INSTITUTE FOR ELECTROMAGNETIC MATERIALS +1

Part for a timepiece movement

The invention relates to a pivot pin for a timepiece movement including at least one pivot at at least one of the ends thereof, characterized in that said at least one pivot is formed of a composite material having a metallic matrix including at least one metal selected from among nickel, titanium, chromium, zirconium, silver, gold, platinum, silicon, molybdenum, aluminum or an alloy of the above metals, said matrix being charged with hard particles selected from among WC, TiC, TaC, TiN, TiCN, Al2O3, ZrO2, Cr2O3, SiC, MoSi2, Al N or a combination thereof, so as to limit the sensitivity of the pin to magnetic fields.The invention concerns the field of timepiece movements.

Owner:OMEGA SA

Clock movement with low magnetic sensitivity

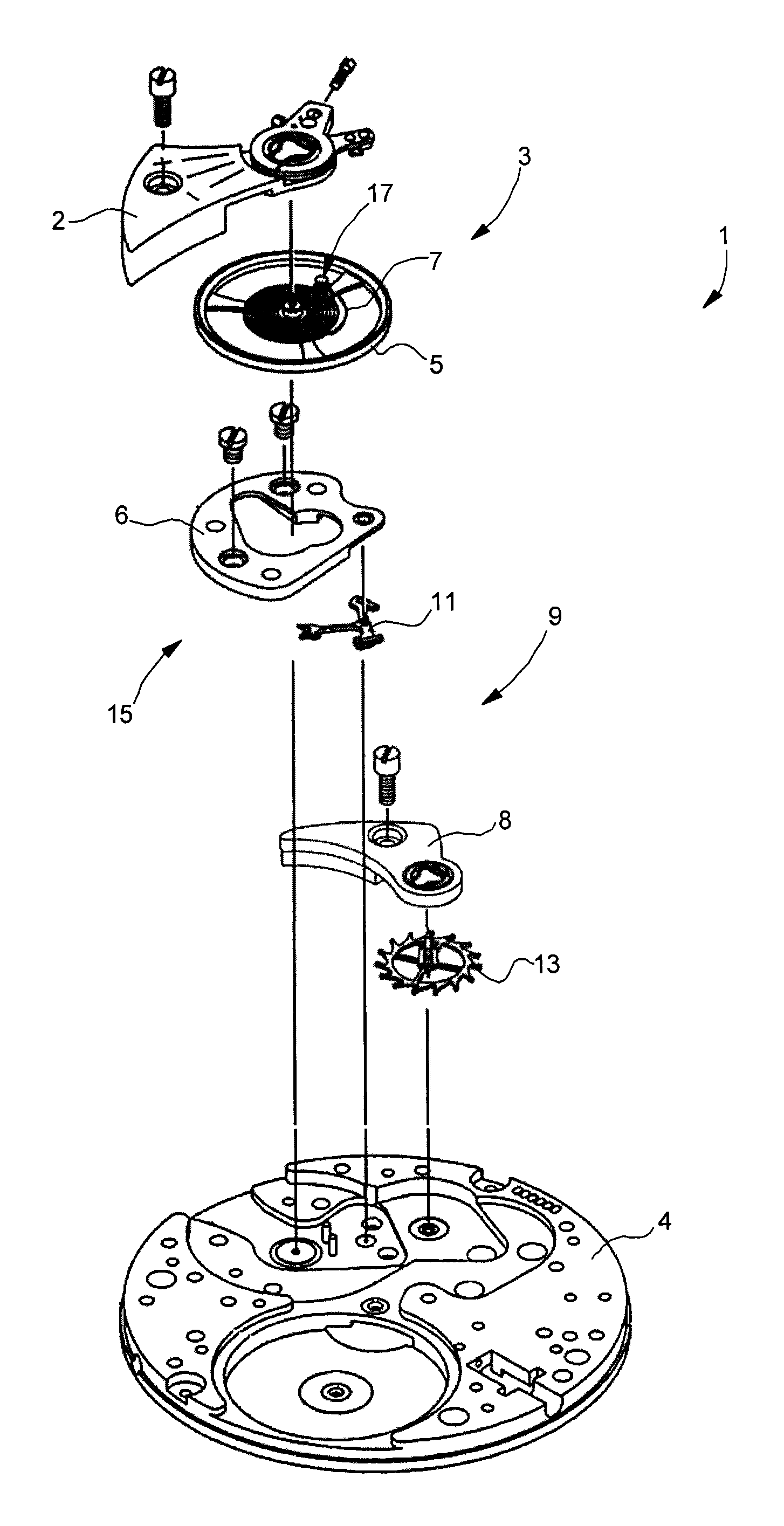

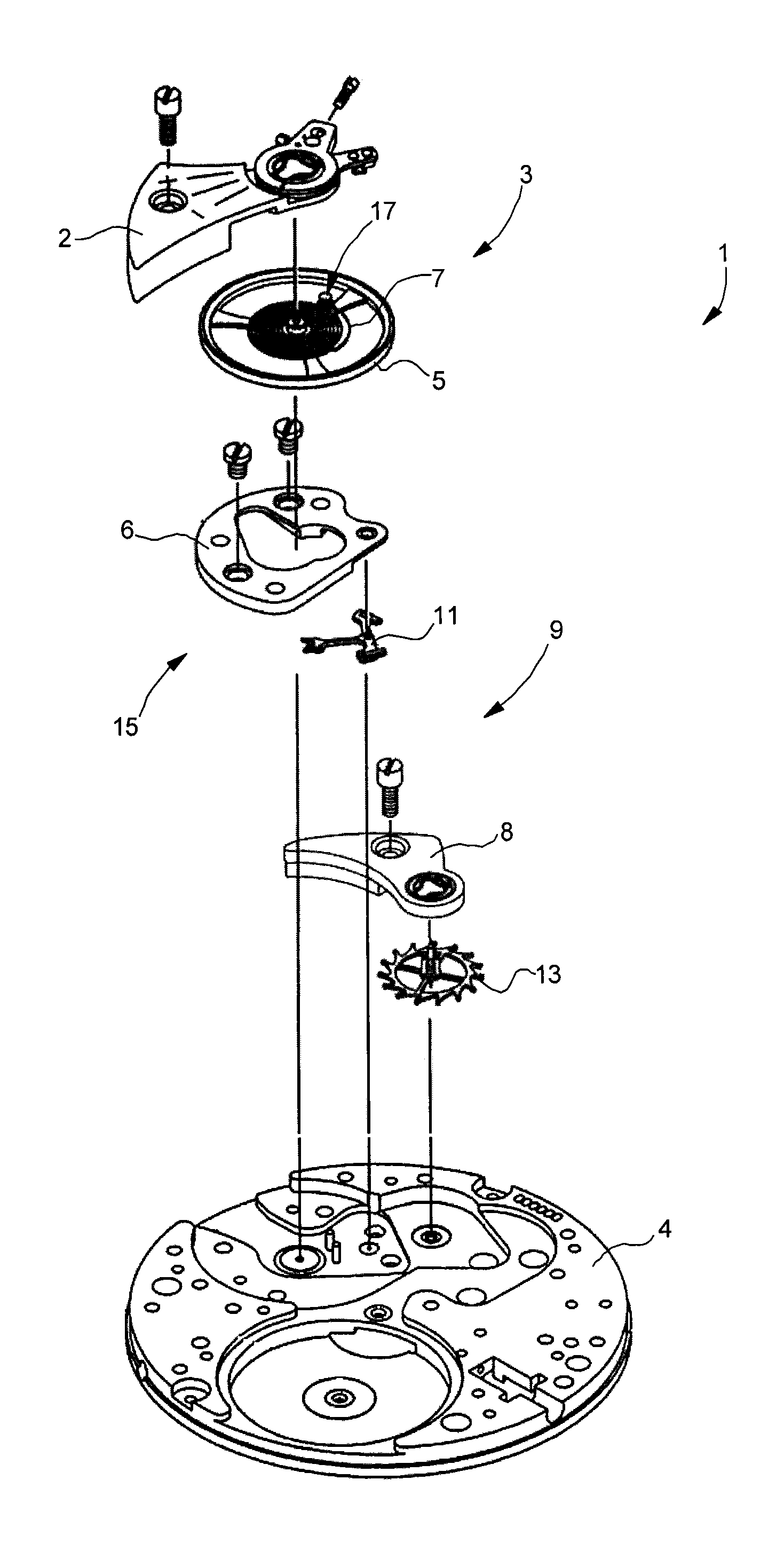

The invention relates to a timepiece movement (1) comprising a sprung (7) balance (5) resonator (3) mounted between a bar (2) and a bottom plate (4) wherein the balance (7) is formed from a ferromagnetic material. According to the invention, the timepiece movement includes a magnetic polarising device (15) for said balance spring for maintaining a predefined state of polarisation in the balance spring (7) and including permanent magnetising means which forms a magnetic field in the plane of the balance spring so as to totally or almost totally magnetically saturate the balance spring (7) in the absence of an external magnetic field. The invention concerns the field of timepieces.

Owner:NIVAROX FAR

Component for a timepiece movement

A micromechanical component for a timepiece movement including a metal body formed using a single material. The single material is of high-interstitial austenitic steel type including at least one non-metal as the interstitial atom in a proportion between 0.15% and 1.2% with respect to total mass of the material.

Owner:NIVAROX FAR

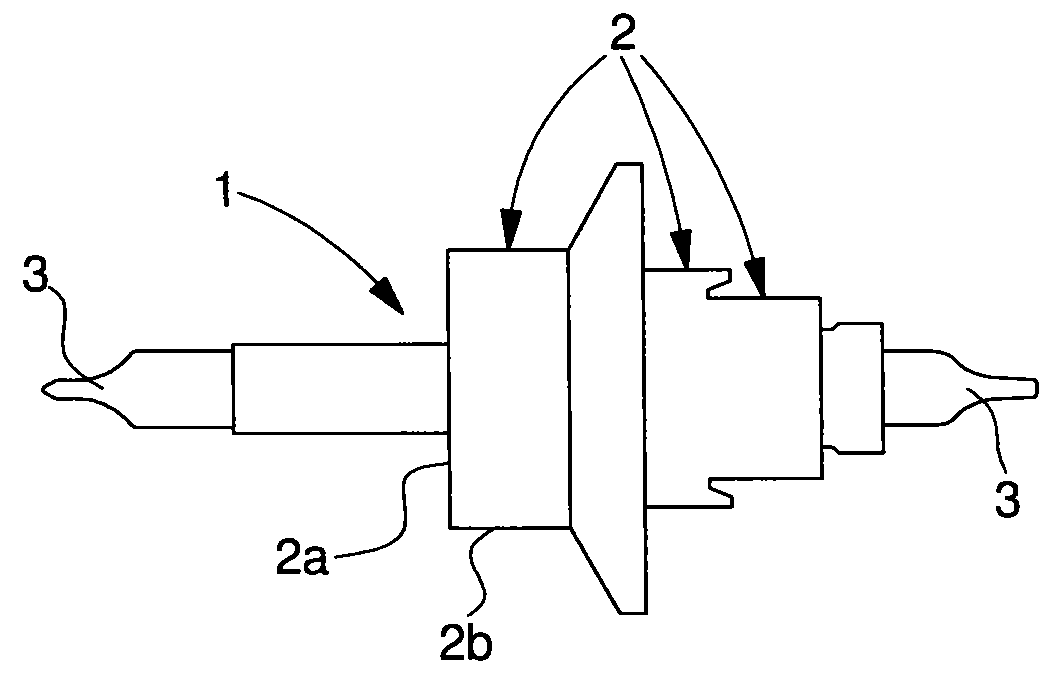

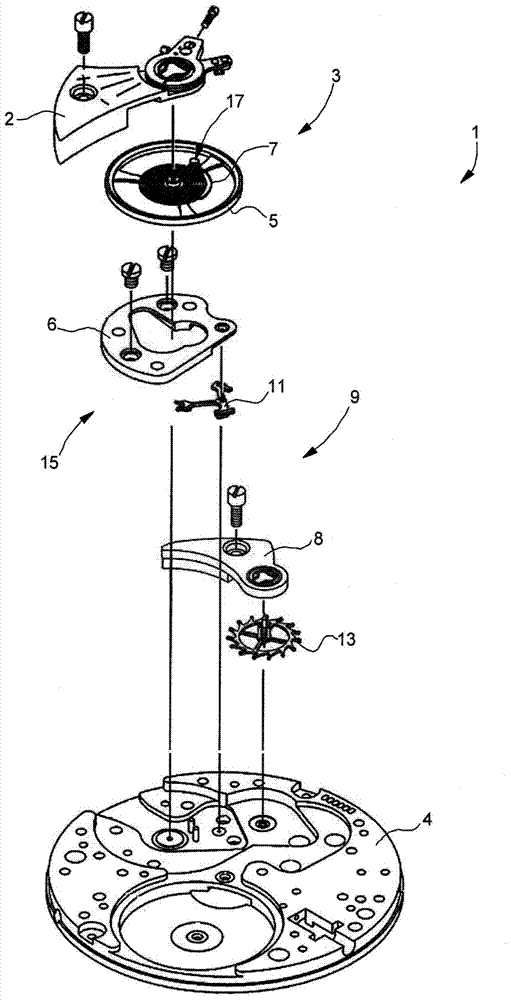

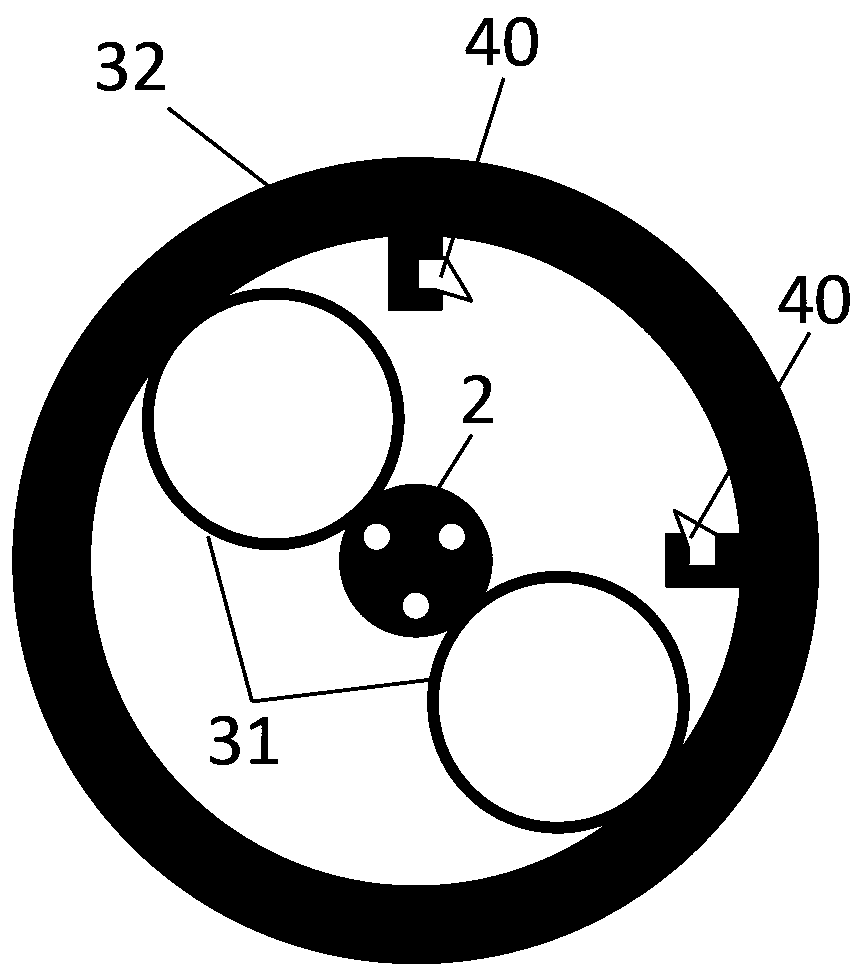

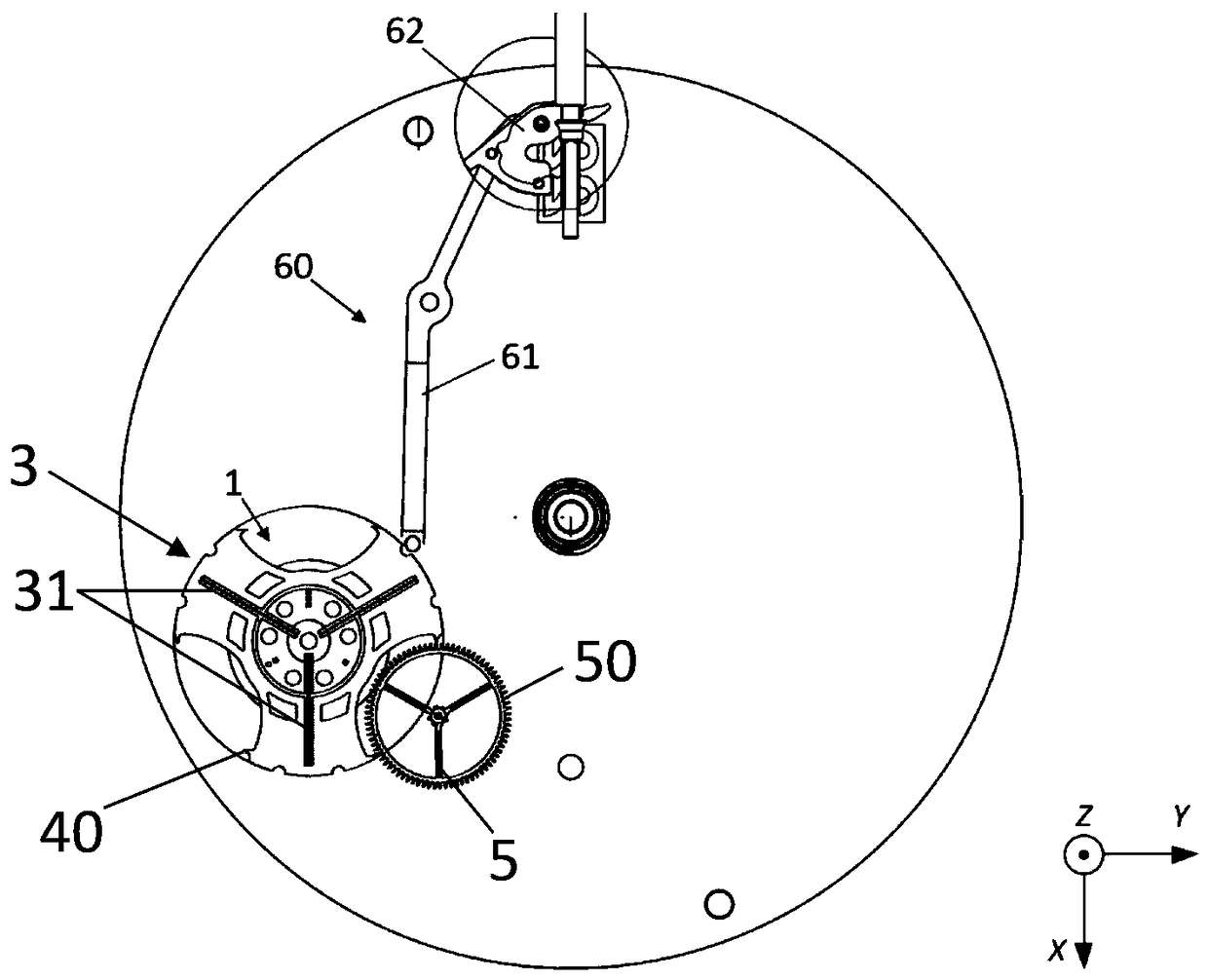

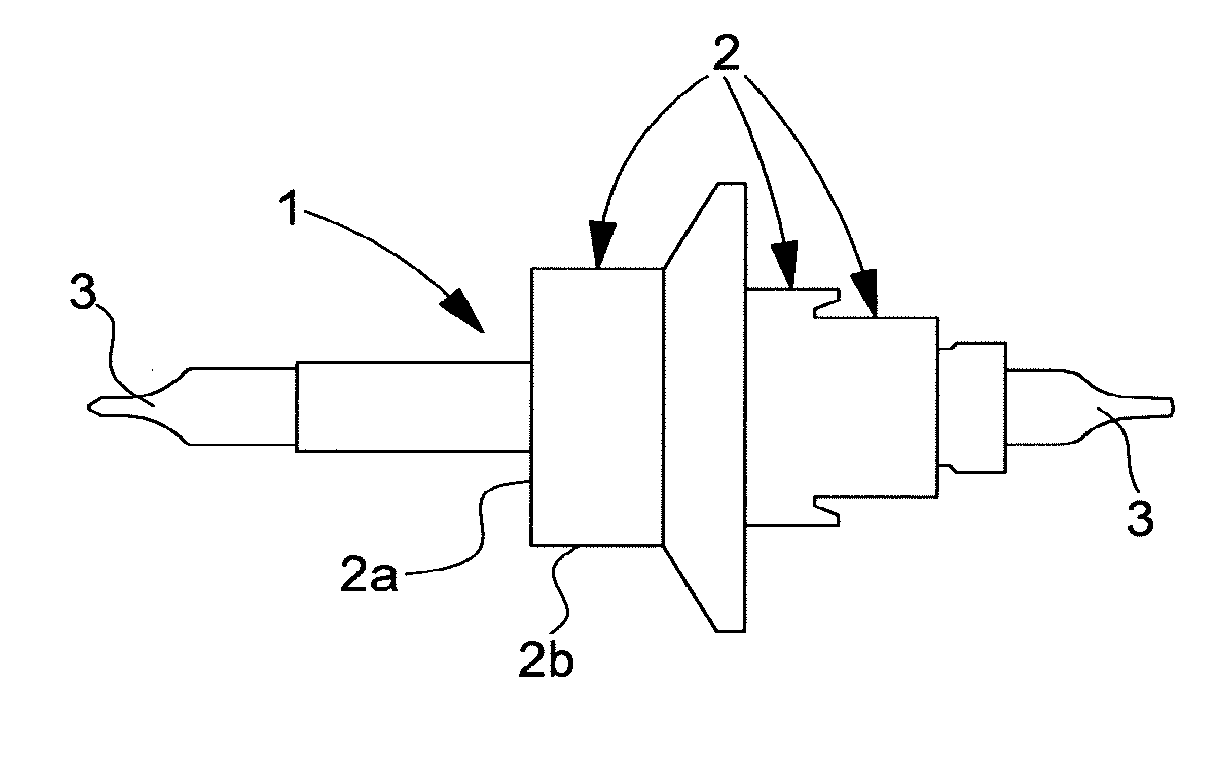

Oscillator for a mechanical timepiece movement

ActiveCN108139712AImprove stabilityImprove running accuracyEscapementsFrequency stabilisation mechanismMass elementResonator

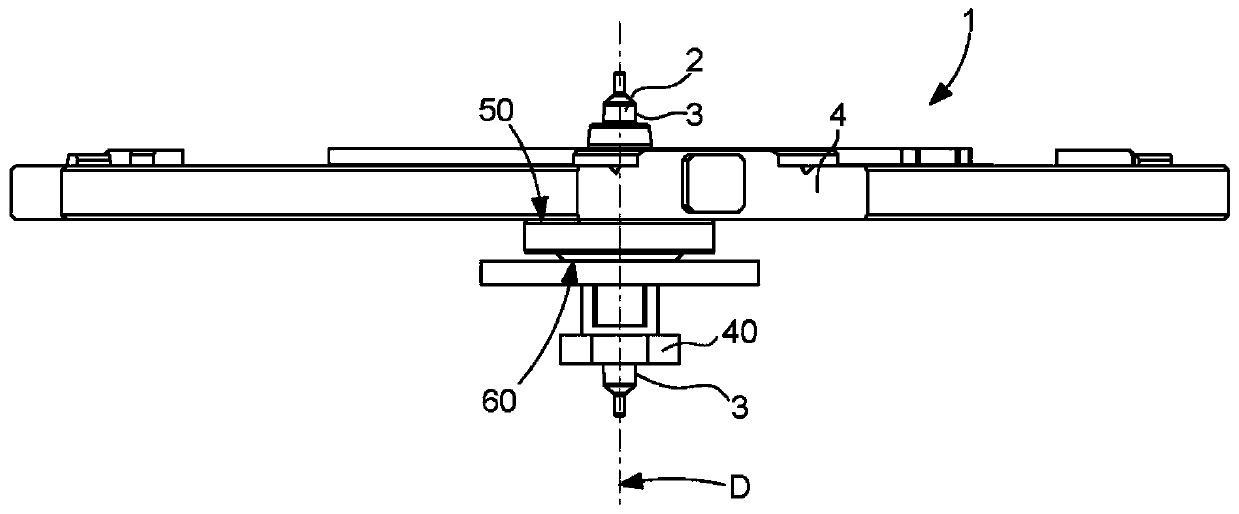

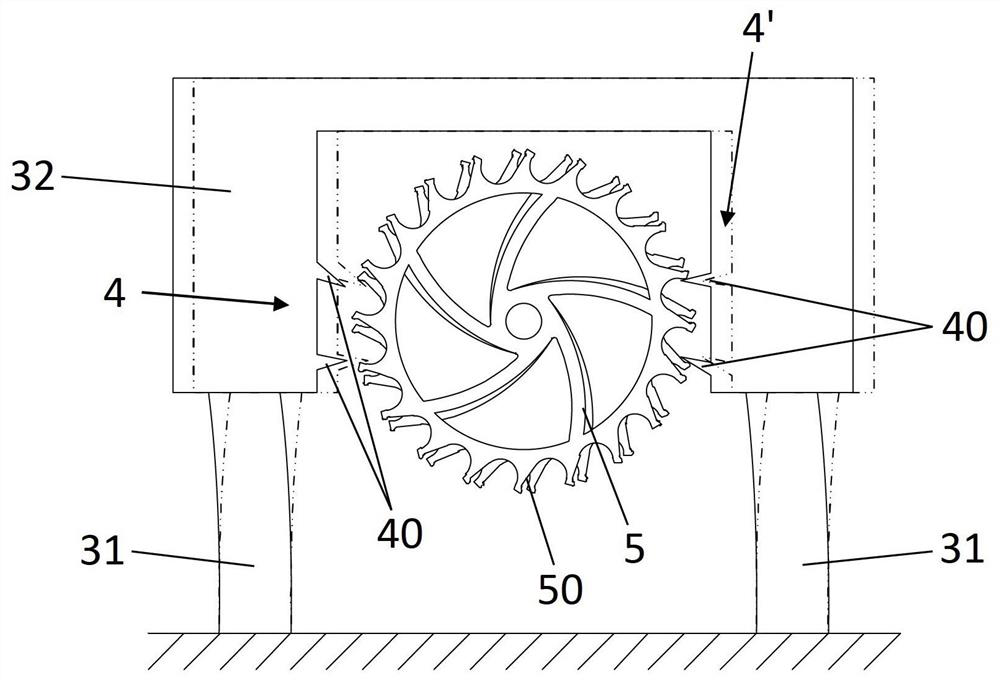

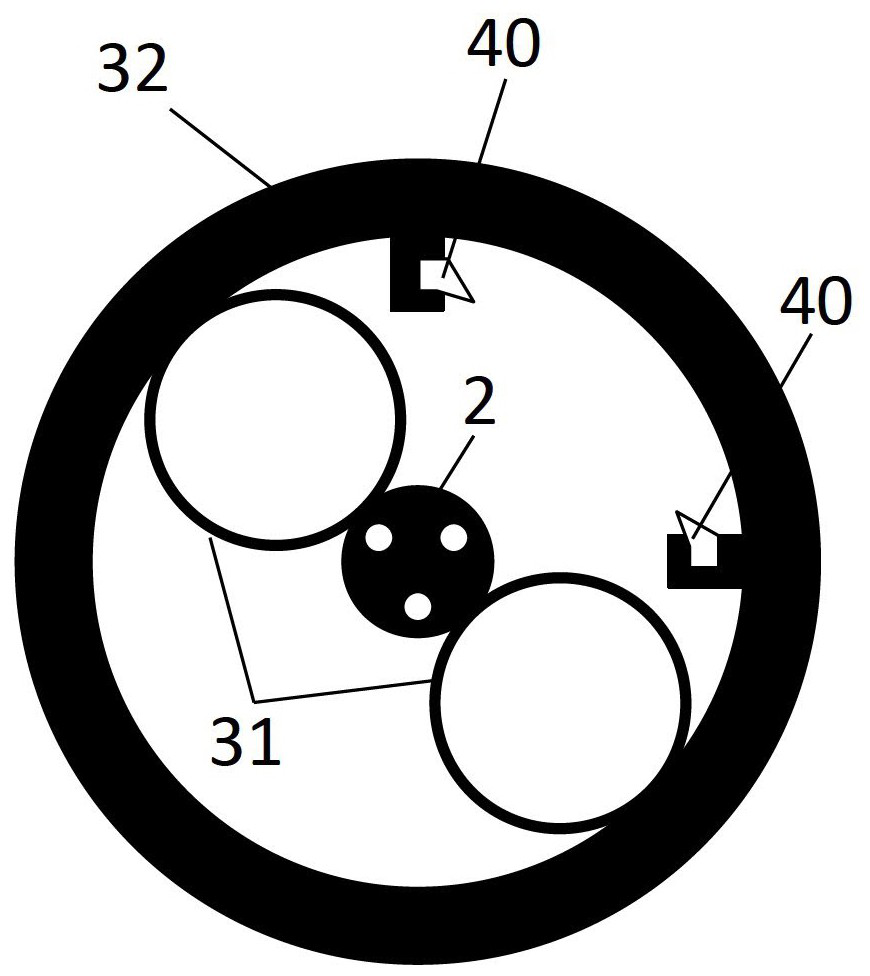

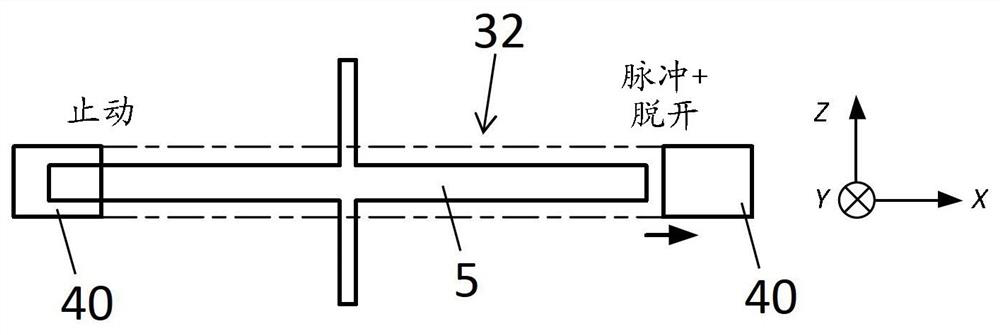

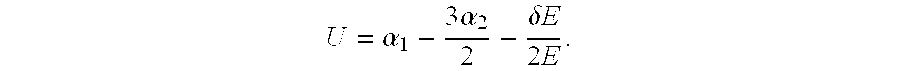

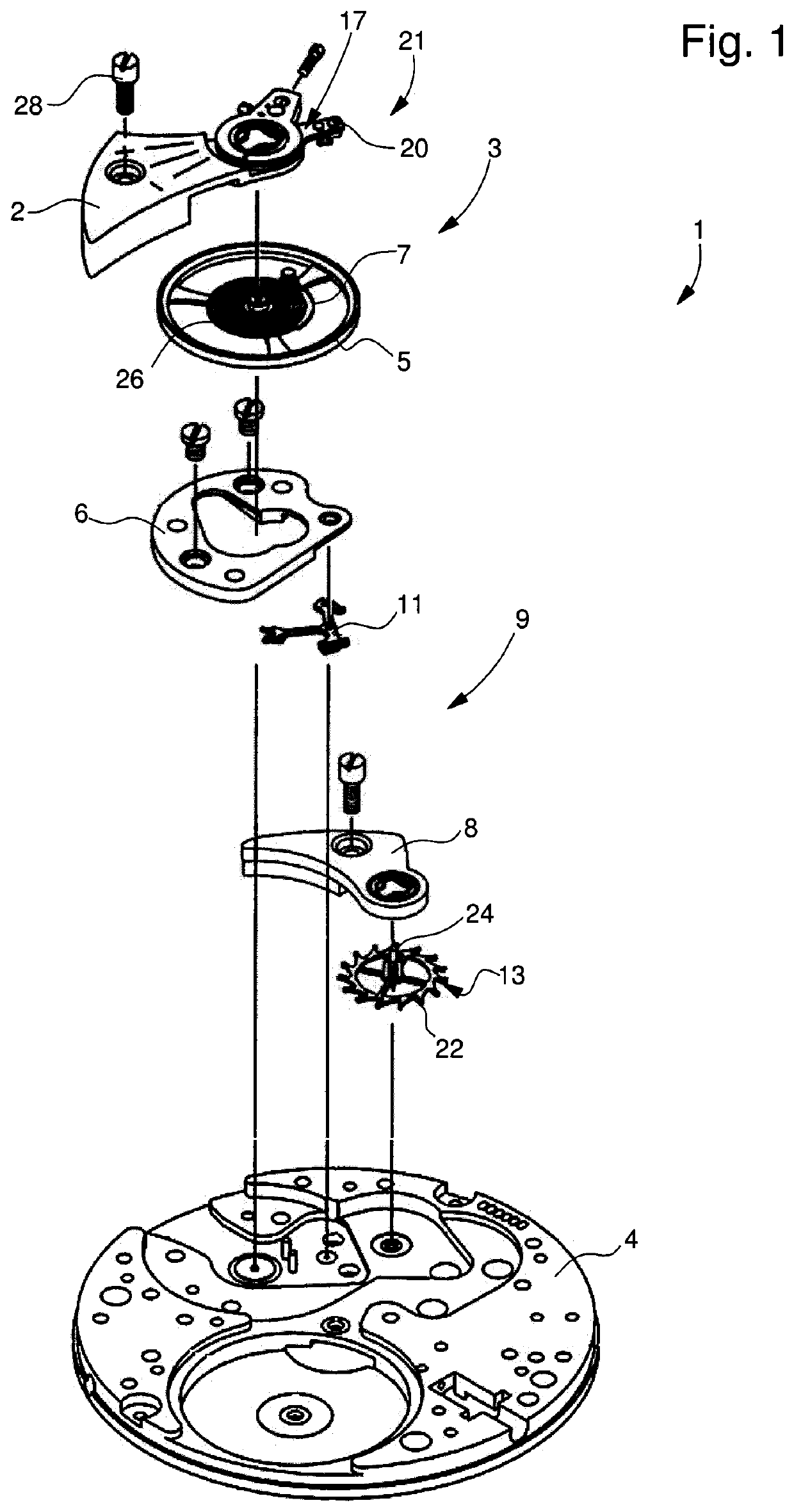

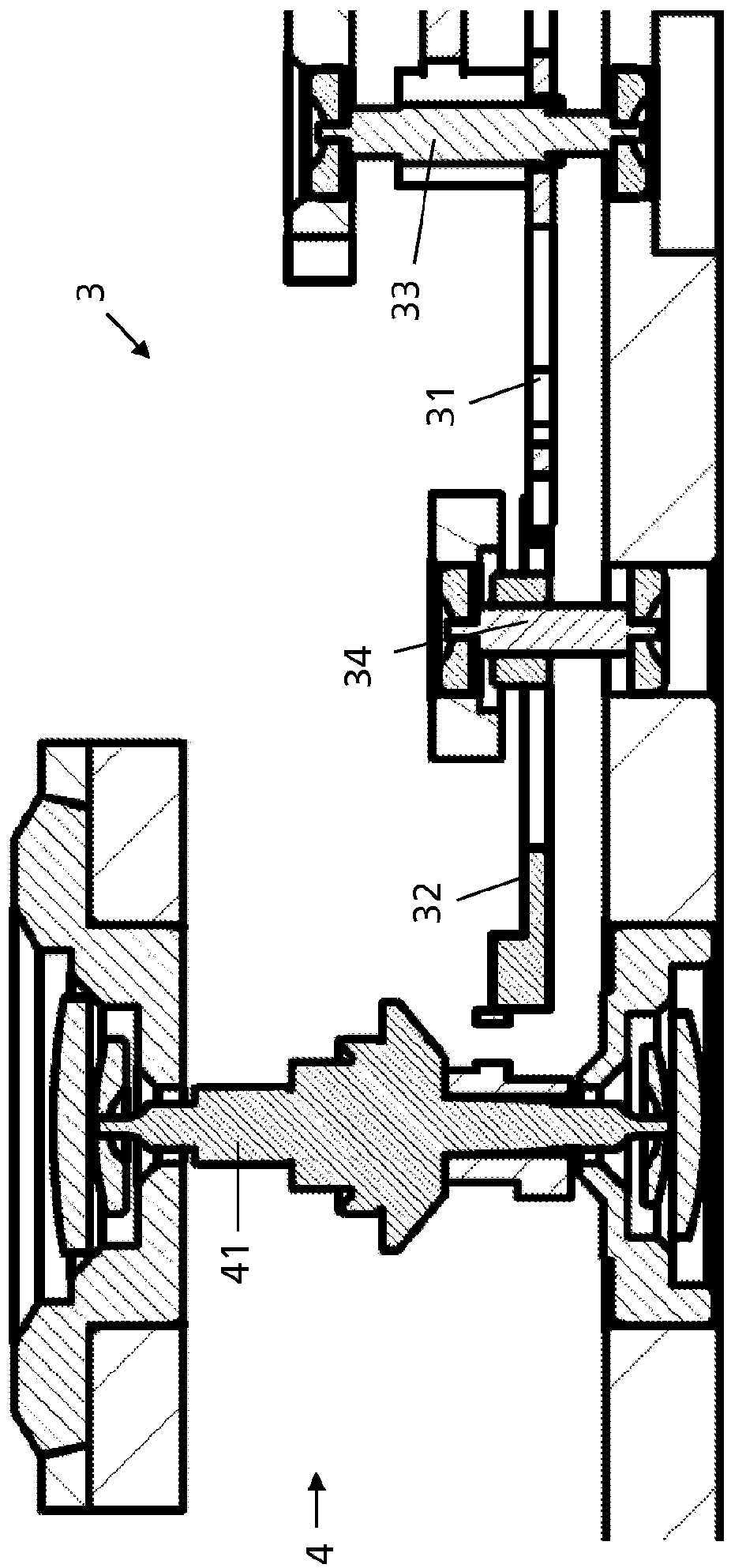

The present invention relates to an oscillator for adjusting a mechanical timepiece movement. The oscillator (1) comprises an escapement wheel (5) and a resonator (3) that forms the time base of the oscillator (1); the resonator (3) includes a mass element (32) that is kept in oscillation by at least two vibrating elements (31); the mass element (32) includes at least one anchor portion (4) that is rigidly connected to the mass element (32), and is configured so as to directly engage with the escapement wheel (5) in order to maintain oscillations of the resonator (3), and so as to allow the escapement wheel (5) to move with each alternation of the oscillations; the first resonator (3) also includes a base (2) that is intended to be mounted in a stationary or movable manner on the timepiecemovement; and the mass element (32) is supported only by the base (2) via the vibrating element (31).

Owner:RICHEMONT INT

Component for a timepiece movement

ActiveUS20180024502A1Reduce sensitivitySimply and economically manufacturedGearworksEscapementsEngineeringNon magnetic

The invention relates to a pivot arbor (1) for a timepiece movement comprising at least one pivot (3) made of a first non-magnetic metal material (4) at one of the ends thereof in order to limit the sensitivity thereof to magnetic fields. At least the outer surface of said pivot (3) is coated with a layer (5) of a second material selected from the group comprising Ni and NiP, and preferably chemical NiP.The invention concerns the field of timepiece movements.

Owner:NIVAROX FAR

Part for clock movement

PendingCN107632509ALimit sensitivityLow sensitivity to magnetic fieldsGearworksEscapementsStructural engineeringMechanical engineering

Owner:NIVAROX FAR

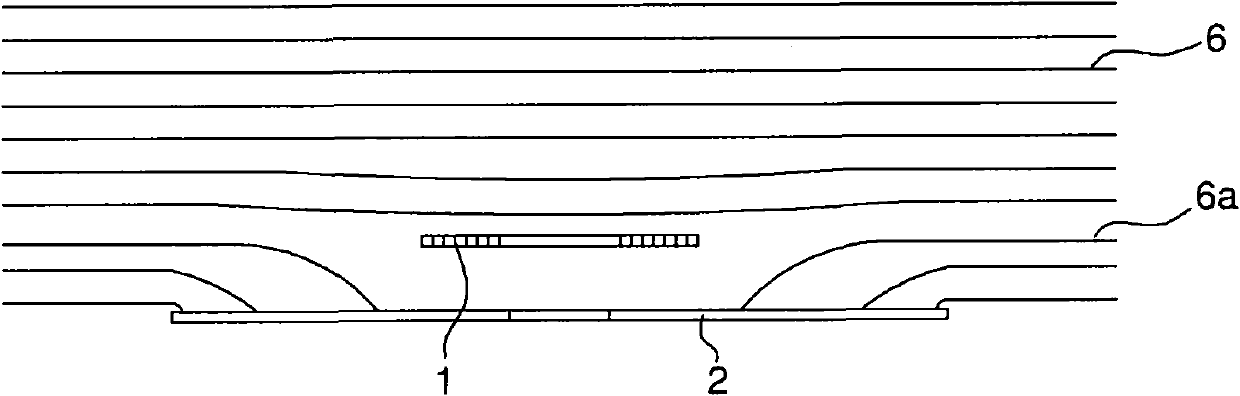

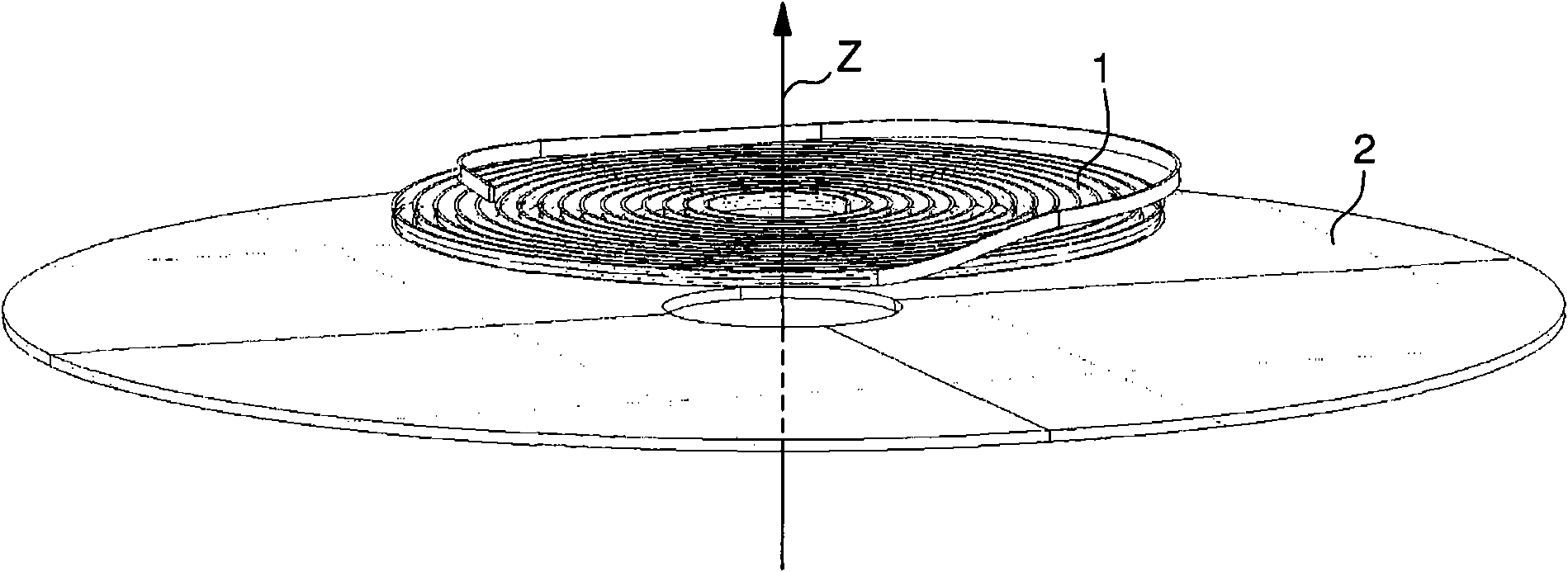

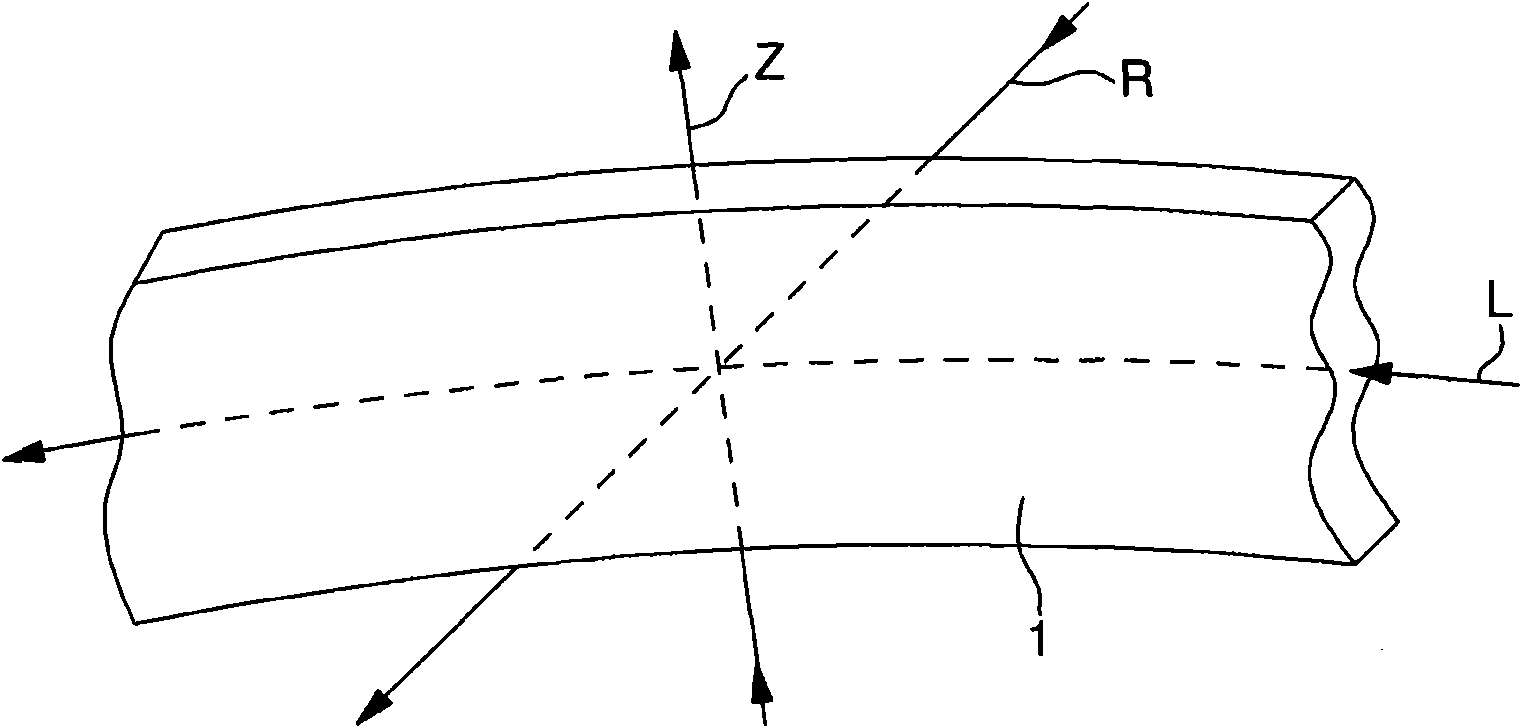

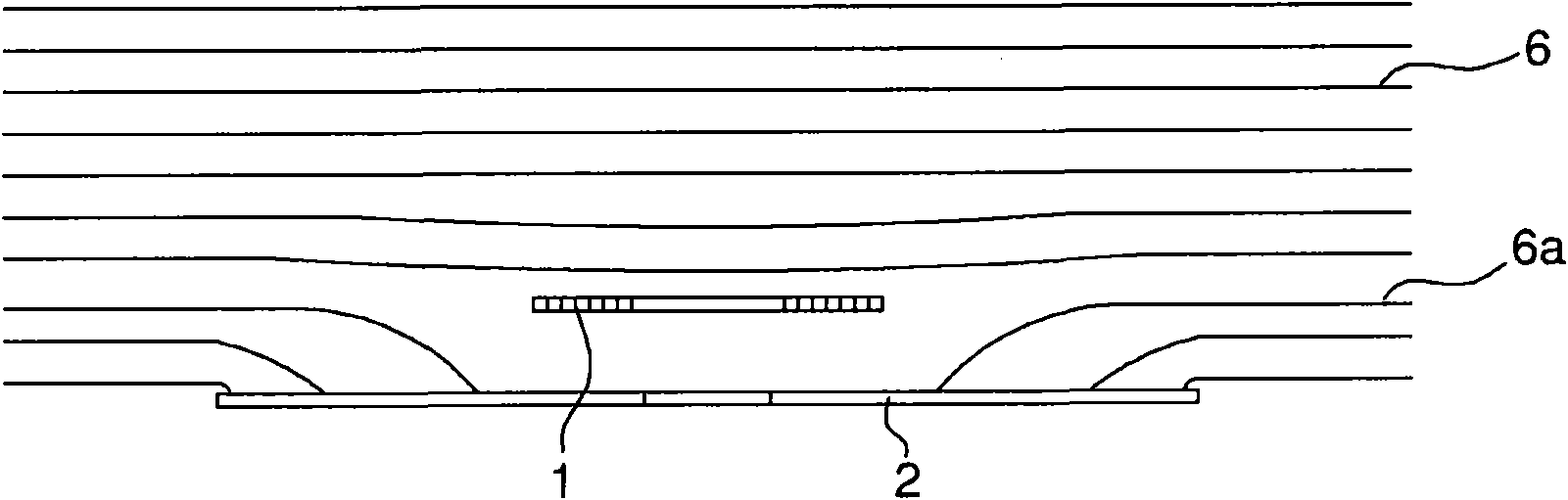

Magnetic protection for timepiece balance spring

ActiveCN101995814AFrequency stabilisation mechanismAntimagnetic alloy usageEngineeringBalance spring

The device for protecting a timepiece balance spring (1) from stray magnetic fields includes at least one disc (2) with high magnetic permeability, arranged in a parallel plane to the plane of the balance spring, wherein the disc (2) and the balance spring are mounted coaxially with each other.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

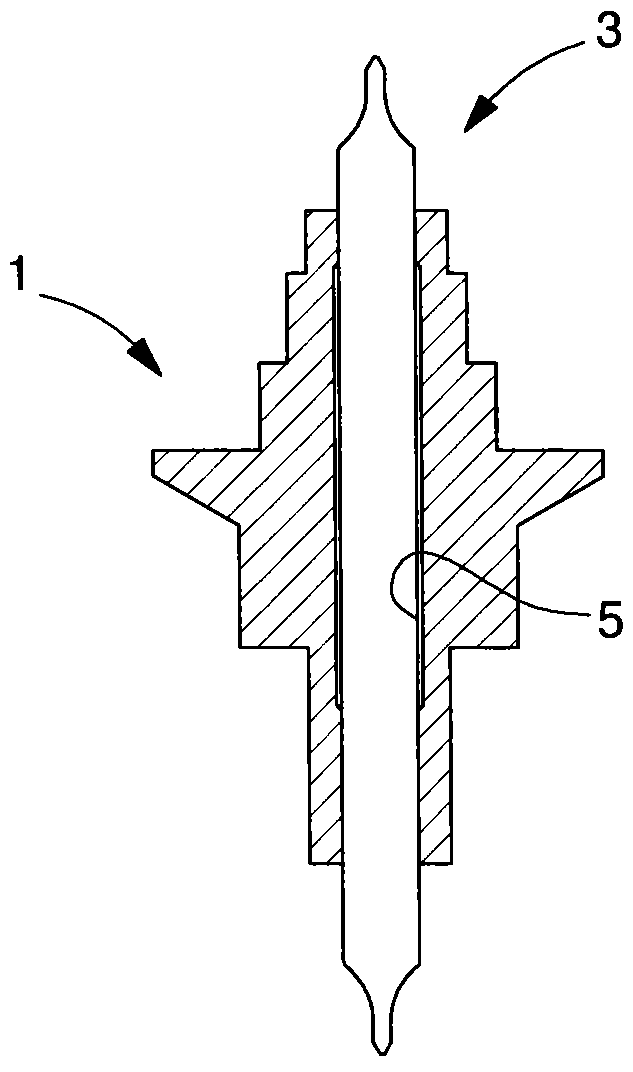

Component for a timepiece movement

ActiveUS20180024501A1Reduce sensitivitySimply and economically manufacturedGearworksEscapementsPlatinumEngineering

The invention relates to a pivot arbor (1) for a timepiece movement comprising at least one pivot (3) made of a first non-magnetic metal material (4) at at least one of the ends thereof in order to limit the sensitivity thereof to magnetic fields, at least the outer surface of said pivot (3) being coated with a first layer (5) of a second material selected from the group comprising Ni, NiB and NiP, and preferably chemical NiP. At least the first layer (5) of second material is at least partially coated with a second layer (6) of a third material selected from the group comprising gold, silver, copper, platinum, rhodium, palladium and their alloys.The invention concerns the field of timepiece movements.

Owner:NIVAROX FAR

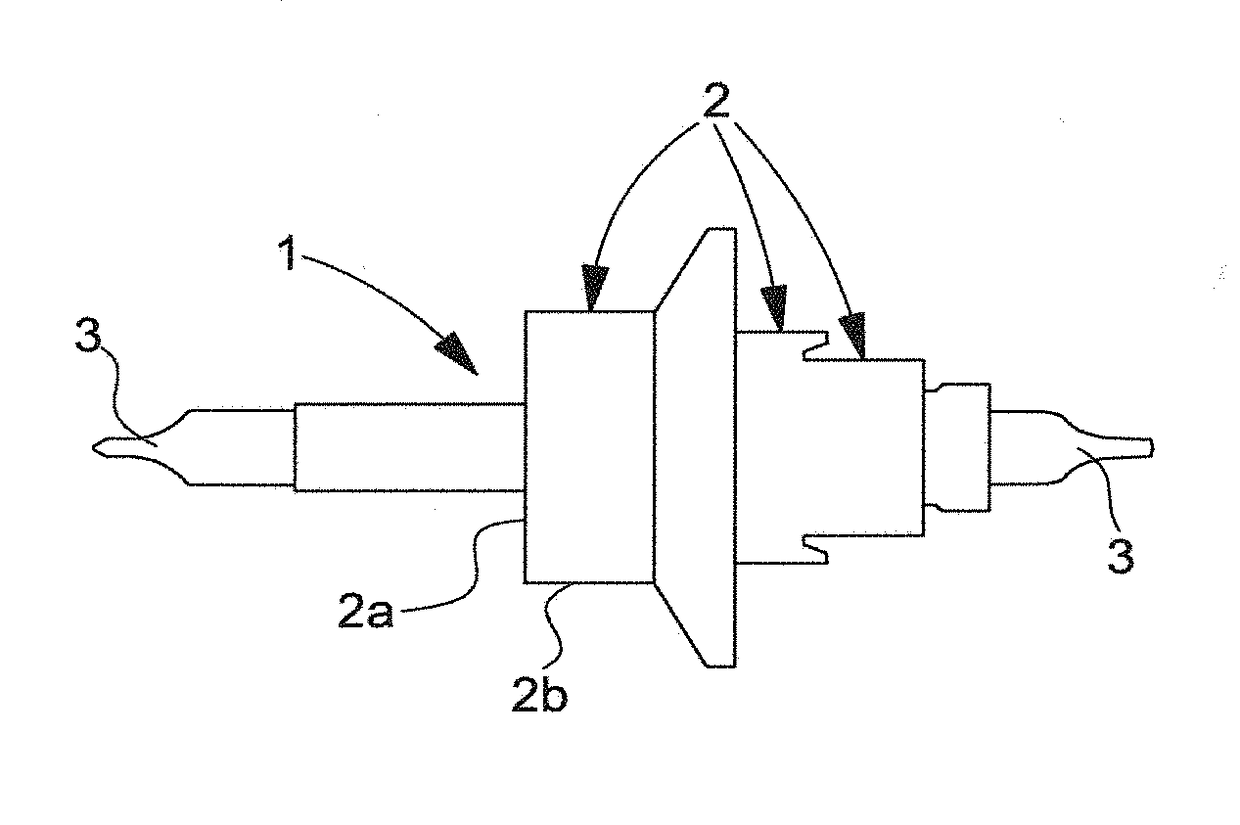

Component for a timepiece movement

The invention relates to a pivot arbor comprising a metal pivot (3) at each of its ends. The metal is a non-magnetic copper alloy in order to limit its sensitivity to magnetic fields, and at least the outer surface (5) of one of the two pivots (3) is deep-hardened to a predetermined depth with respect to the rest of the arbor to harden the pivot or pivots (3).The invention concerns the field of timepiece movements.

Owner:NIVAROX FAR

Component for a timepiece movement

ActiveUS10761482B2Limited sensitivityHigh hardnessGearworksEscapementsEngineeringMechanical engineering

The invention relates to a timepiece component (1) comprising at least one portion (3) machined by chip removal. Said portion (3) is made of a non-magnetic copper alloy in order to limit its sensitivity to magnetic fields, said copper alloy containing between 10 wt % and 20 wt % of Ni, between 6 wt % and 12 wt % of Sn, X wt % of additional elements, wherein X is comprised between 0 and 5, and the remainder is Cu.The invention concerns the field of timepiece movements.

Owner:NIVAROX FAR

Balance spring for timepiece movements and method for manufacturing the same

ActiveUS11137721B2Help shapeEasy to processFrequency stabilisation mechanismVacuum evaporation coatingTitaniumTitanium alloy

A balance spring for a balance with a blank containing: niobium: the remainder to 100 wt %, titanium: between 40 and 60 wt %, traces of elements selected from the group formed of O, H, C, Fe, Ta, N, Ni, Si, Cu, Al, between 0 and 1600 ppm by weight individually, and less than 0.3 wt % combined, a step of β-quenching the blank with a given diameter, such that the titanium of the alloy is essentially in solid solution form with β-phase niobium, the α-phase titanium content being less than or equal to 5% by volume, at least one deformation step of the alloy alternated with at least one heat treatment step such that the niobium and titanium alloy obtained has an elastic limit higher than or equal to 600 MPa and a modulus of elasticity lower than or equal to 100 GPa, a winding step to form the balance spring being performed prior to the final heat treatment step, prior to the deformation step, a step of depositing, on the alloy blank, a surface layer of a ductile material such as copper, the surface layer of ductile material being retained on the balance spring, the thermoelastic coefficient of the niobium and titanium alloy being adapted accordingly.

Owner:NIVAROX FAR

Component for a timepiece movement

The invention relates to a pivot arbor comprising a metal pivot (3) at each of its ends. The metal is a non-magnetic aluminium alloy in order to limit its sensitivity to magnetic fields, and at least the outer surface (5) of one of the two pivots (3) is deep-hardened to a predetermined depth with respect to the rest of the arbor to harden the pivot or pivots (3).

Owner:NIVAROX FAR

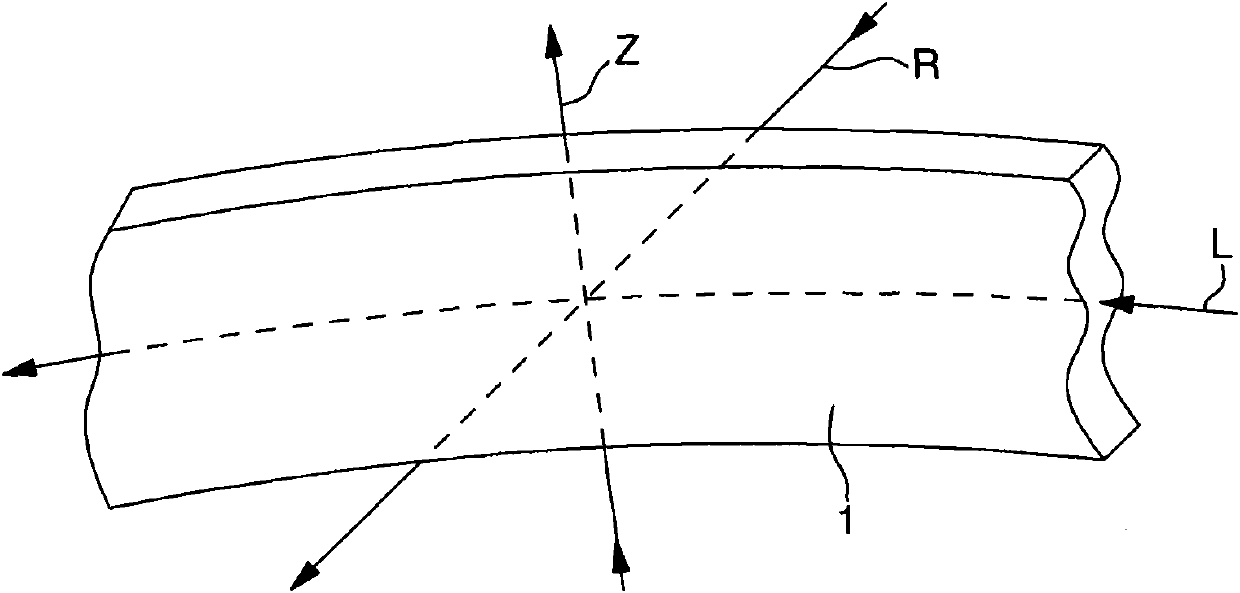

Timepiece component having shaft-like portion made of non-magnetic alloy

The invention relates to a timepiece component (1) comprising a shaft-like portion (2) comprising at least one pivot (3) about a pivot axis (D), at least the material forming the shaft-like portion (2) being a non-magnetic alloy comprising at least silver and palladium and having a Vickers hardness greater than 450 HV.

Owner:BLANCPAIN SA

Components for clock movements

Owner:NIVAROX FAR

Components for clock movements

ActiveCN107632507BLow sensitivity to magnetic fieldsImprove impact resistanceGearworksEscapementsPlatinumMetallic materials

Owner:NIVAROX FAR

Oscillators for mechanical watch movements

ActiveCN108139712BImprove stabilityImprove running accuracyEscapementsFrequency stabilisation mechanismEngineeringHorology

The present invention relates to an oscillator for adjusting a mechanical timepiece movement, the oscillator (1) comprising an escapement wheel (5) and a resonator (3) that forms the time base of the oscillator (1); the resonator (3) including a mass element (32) that is kept in oscillation by at least two vibrating elements (31); the mass element (32) including at least one anchor portion (4) that is rigidly connected to the mass element (32), and is configured so as to directly engage with the escapement wheel (5) in order to maintain oscillations of the resonator (3), and so as to allow the escapement wheel (5) to move with each alternation of the oscillations; the first resonator (3) also including a base (2) that is intended to be mounted in a stationary or movable manner on the timepiece movement; the mass element (32) being supported only by the base (2) via the vibrating element (31).

Owner:RICHEMONT INT

Timepiece movement with low magnetic sensitivity

A timepiece movement comprising including a sprung balance resonator mounted between a bar and a bottom plate wherein the balance is formed from a ferromagnetic material. The timepiece movement includes a magnetic polarizing device for the balance spring for maintaining a predefined state of polarization in the balance spring and including a permanent magnetizing device which forms a magnetic field in the plane of the balance spring so as to totally or almost totally magnetically saturate the balance spring in the absence of an external magnetic field.

Owner:NIVAROX FAR

Pivot mandrel of adjustment member

The invention relates to a timepiece component for a timepiece movement, and in particular to a pivot mandrel of an adjustment member of a mechanical timepiece movement. The pivot mandrel is made of an alloy comprising the following components by weight: 25% to 55% of palladium; 25% to 55% of silver; 10% to 30% of copper; 0.5% to 5% of zinc; two elements of gold and platinum with a total content of 15% to 25%; 0% to 1% of one or two elements selected from the group consisting of boron and nickel; 0% to 3% of one or two elements selected from rhenium and ruthenium; no more than 0.1% of one or more elements selected from iridium, osmium and rhodium; and no more than 0.2% of other impurities, the sum of the amounts of the components being set to no more than 100%. The invention also relates to a method for producing a timepiece component for a timepiece movement.

Owner:NIVAROX FAR

Magnetic protection for timepiece balance spring

#CMT# # / CMT# The device has a disk with high magnetic permeability, arranged in a plane parallel to a plane of a balance spring. The disk and the balance spring are mounted coaxially with each other while allowing magnetic field to reach the balance spring in a direction of the magnetic field. A ring (3) with the high magnetic permeability is mounted on the disk. The ring is arranged around the balance spring in a coaxial manner. The disk is made to fit with a set of branches (4) made of the same material as the disk and arranged in a star-form. #CMT#USE : # / CMT# Protecting device mounted in a tourbillon (claimed), for protecting a balance spring of a timepiece from stray / parasitic magnetic fields originating from outside timepiece. #CMT#ADVANTAGE : # / CMT# The device is designed to align field lines in more or less orthogonal and radial configuration to the plane of the balance spring, thus protecting the balance spring from the stray magnetic fields, using more compact and lighter structure. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a plan view of a device for protecting a timepiece balance spring. 3 : Ring 4 : Branches 10 : Escape wheel 13 : Balance 14 : Rotating cartridge.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

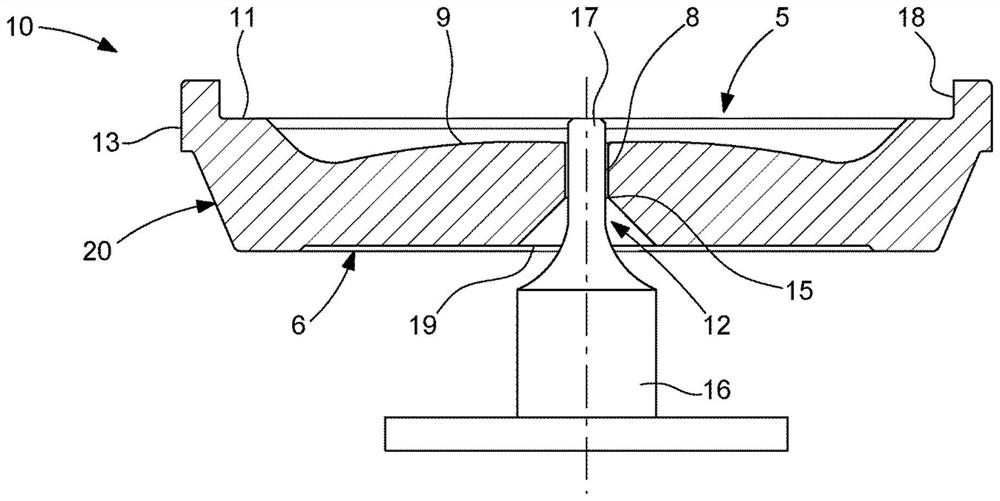

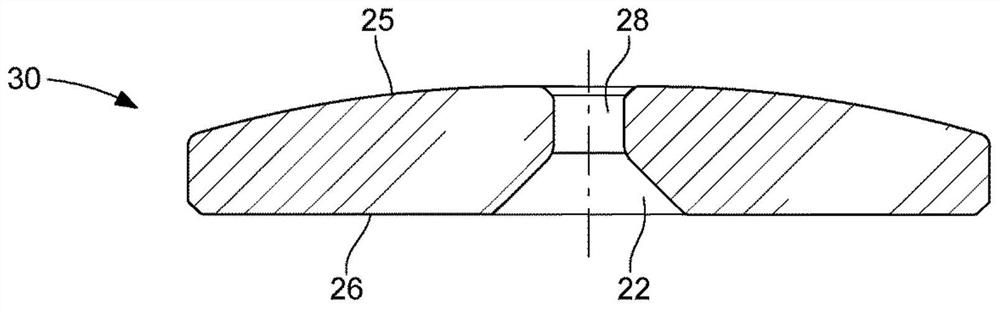

Assembly comprising a rotating wheel made of non-magnetic

The invention relates to an assembly (10), in particular for a timepiece, comprising a rotating wheel provided with at least one pivot (17), said pivot at least partially comprising a non-magnetic material, preferably consisting entirely of a non-magnetic material, and a bearing comprising a surface (6, 26), the invention relates to a bearing (10) comprising a non-magnetic pivot (17) having a surface provided with a hole (8, 28) formed in the body of the bearing, the surface having a functional geometry at the entrance of the hole (8, 28), the functional geometry being in the shape having a tapered portion (12, 22), the non-magnetic material of the pivot (17) comprising an alloy selected from a material comprising copper, a material comprising palladium or a material comprising aluminum. The invention also relates to a timepiece comprising such an assembly (10).

Owner:ETA SA MFG HORLOGERE SUISSE

Oscillator spring composition and method for fabricating an oscillator spring

InactiveUS8888358B2Easy to controlProvide stabilityFrequency stabilisation mechanismDecorative surface effectsCrystalline materialsHost material

An oscillator spring material comprising a mixture of a host material with an additive in proportions which permit the thermal evolution of the material's elastic modulus to be tuned, e.g. to correct or compensate for other thermal changes in an oscillator system. The additive comprises a crystalline material having an abnormal thermal evolution of elastic modulus. The host material has a normal thermal evolution of elastic modulus. The additive is mixed with the host material before the host material undergoes a phase transformation into its final form. The additive has a phase transformation temperature higher than the host material, so that additive remains in the same state while the host material phase transformation takes place.

Owner:CARBONTIME

Component for a timepiece movement

A micromechanical component for a timepiece movement including a metal body formed using a single material. The single material is of high-interstitial austenitic steel type including at least one non-metal as the interstitial atom in a proportion between 0.15% and 1.2% with respect to total mass of the material.

Owner:NIVAROX FAR

Component for a timepiece movement

ActiveUS20180024503A1Reduce sensitivityHigh hardnessGearworksEscapementsEngineeringMechanical engineering

The invention relates to a timepiece component (1) comprising at least one portion (3) machined by chip removal. Said portion (3) is made of a non-magnetic copper alloy in order to limit its sensitivity to magnetic fields, said copper alloy containing between 10 wt % and 20 wt % of Ni, between 6 wt % and 12 wt % of Sn, X wt % of additional elements, wherein X is comprised between 0 and 5, and the remainder is Cu.The invention concerns the field of timepiece movements.

Owner:NIVAROX FAR

Component for a timepiece movement

ActiveUS11131965B2High hardnessReduce sensitivityGearworksEscapementsEngineeringMechanical engineering

Owner:NIVAROX FAR

Part for clock movement

ActiveCN107632510ALimit sensitivityAvoid layeringGearworksEscapementsEngineeringMechanical engineering

The invention relates to a watch component (1) comprising at least one part (3) machined by chip removal. Said part (3) is made of a non-magnetic copper alloy in order to limit its sensitivity to magnetic fields, said copper alloy comprising, by weight, between 10% and 20% of Ni, between 6% and 12% of Sn, X% d additional elements, where X is between 0 and 5, and the remainder of Cu. The inventionrelates to the field of watch movements.

Owner:NIVAROX FAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com