Pivot mandrel of adjustment member

A technology of adjusting parts and pivoting, applied in mechanically driven clocks, usage of anti-magnetic alloys, repair tools, etc., can solve problems such as tarnishing and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In this specification, the term "non-magnetic" alloy refers to a paramagnetic or diamagnetic or antiferromagnetic alloy having a magnetic permeability less than or equal to 1.01.

[0043] The term "chip machining" refers to any shaping / shape forming operation performed by a desired material removal process to bring the dimensions and surface finish of a component within given tolerances. Such operations are for example profiling, milling or any other technique known to those skilled in the art.

[0044] The present invention relates to a component for a timepiece movement, and more particularly to a non-magnetic timepiece component, such as a pivoting arbor, for a mechanical timepiece movement.

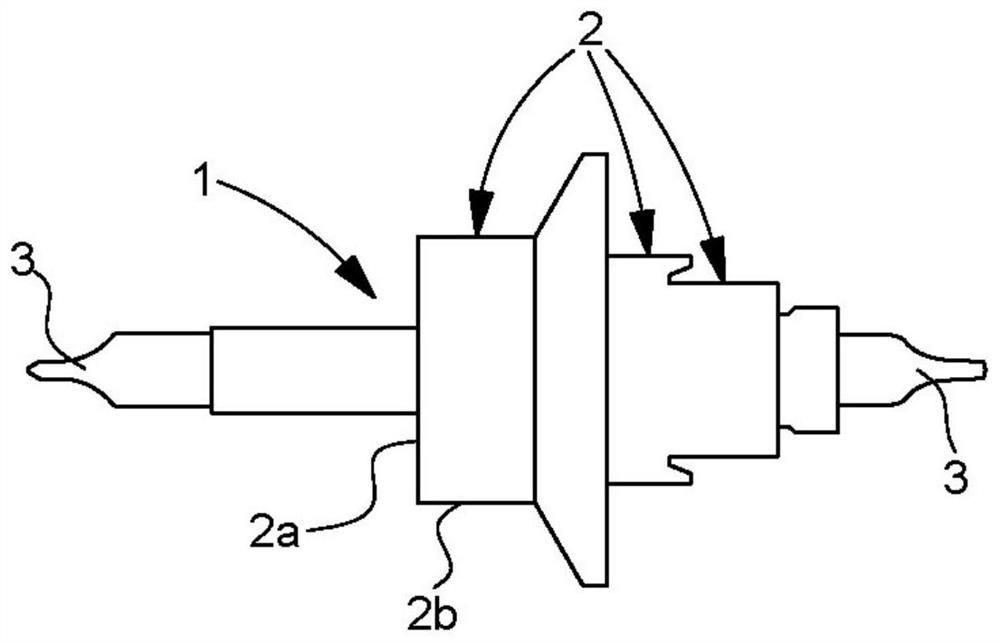

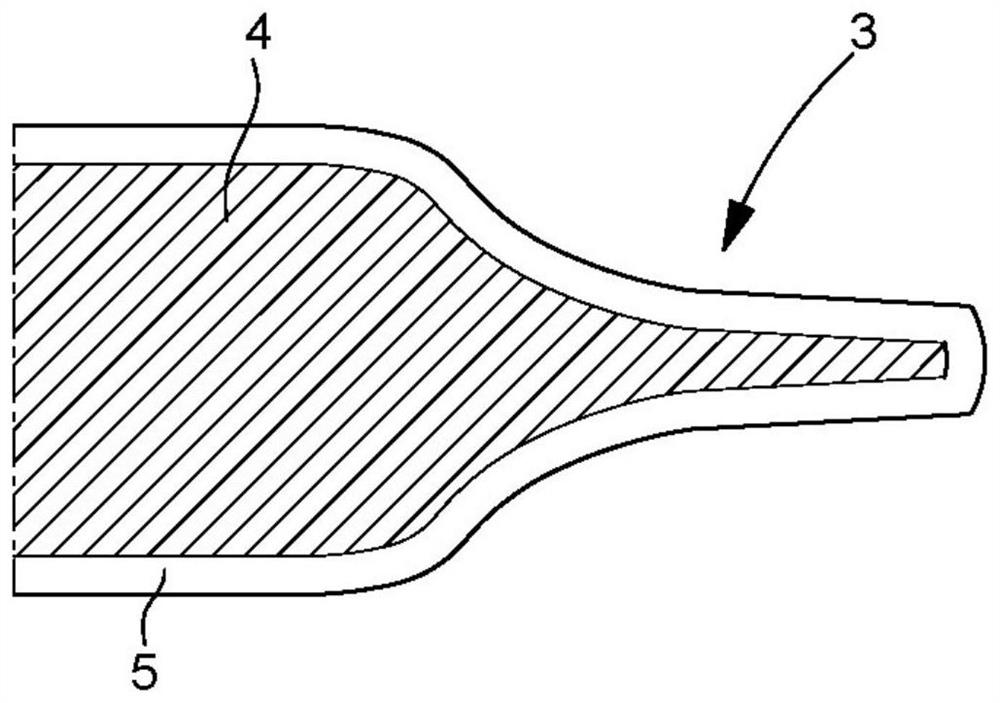

[0045] Below will be in figure 1The invention is described in the application of the non-magnetic balance shaft 1 shown. Of course, other types of timepiece pivot arbors are conceivable, such as a clock wheel arbor, typically an escape pinion, or a pallet arbor. Members of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com