Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Shiplap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shiplap is a type of wooden board used commonly as exterior siding in the construction of residences, barns, sheds, and outbuildings.

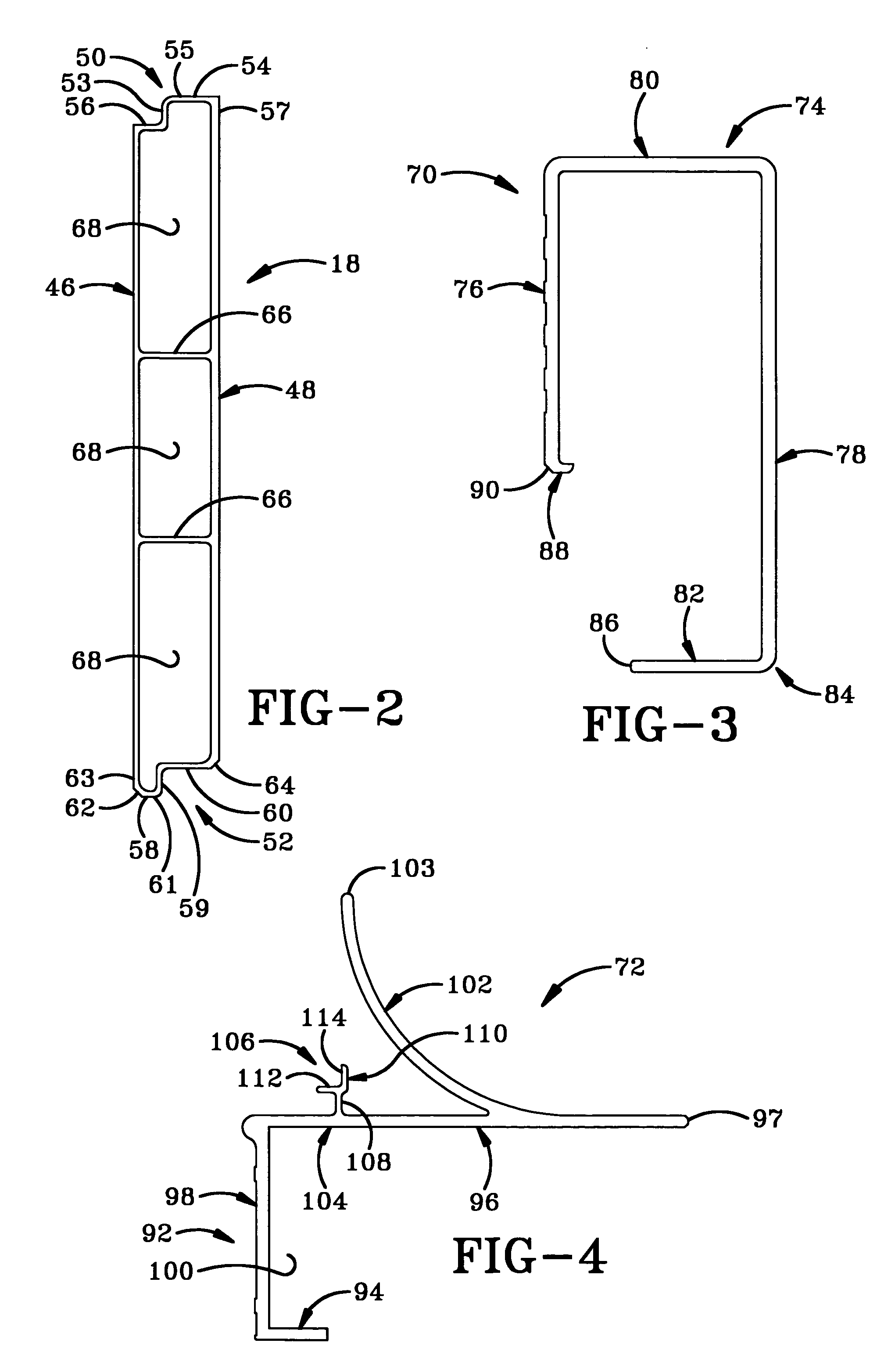

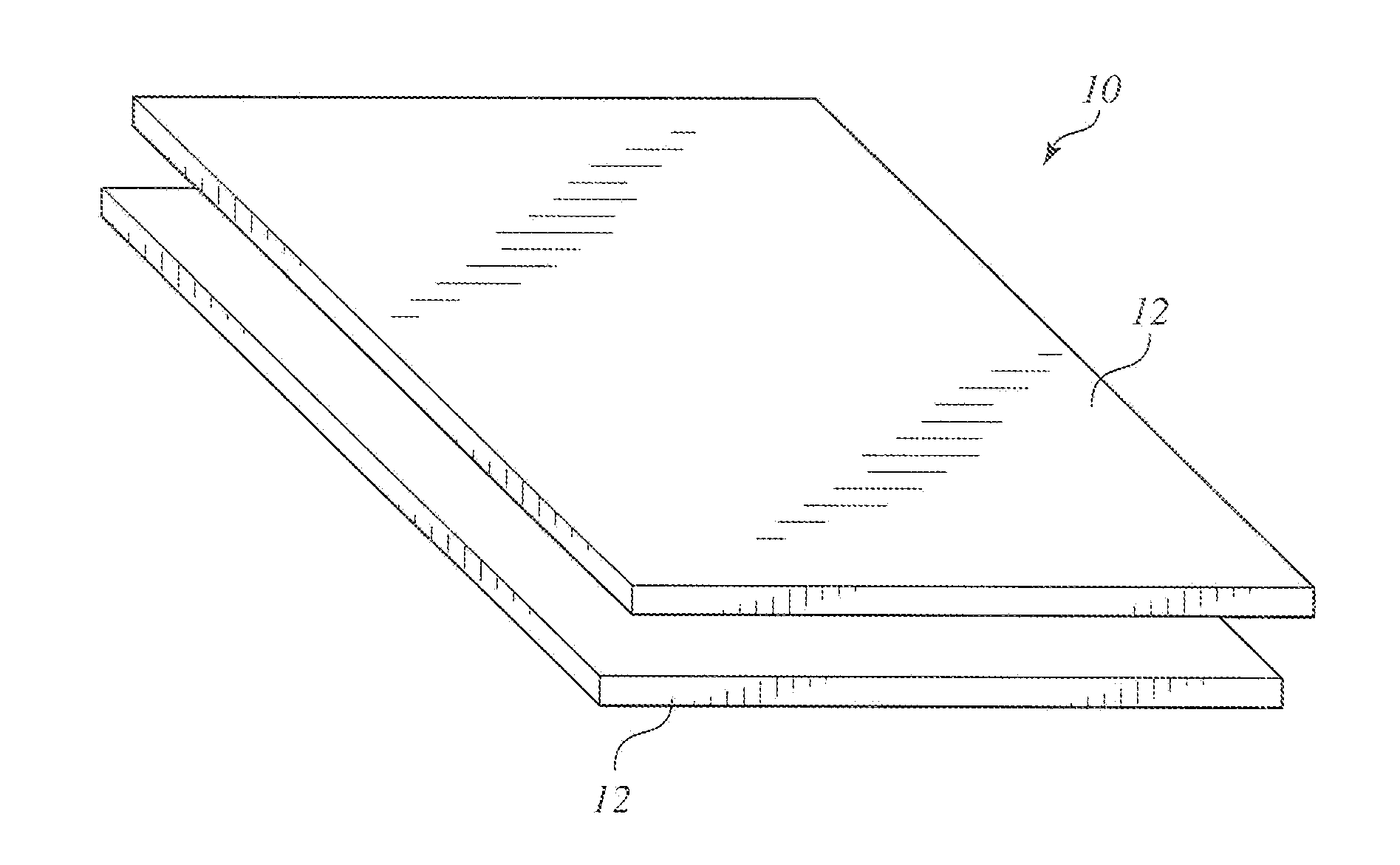

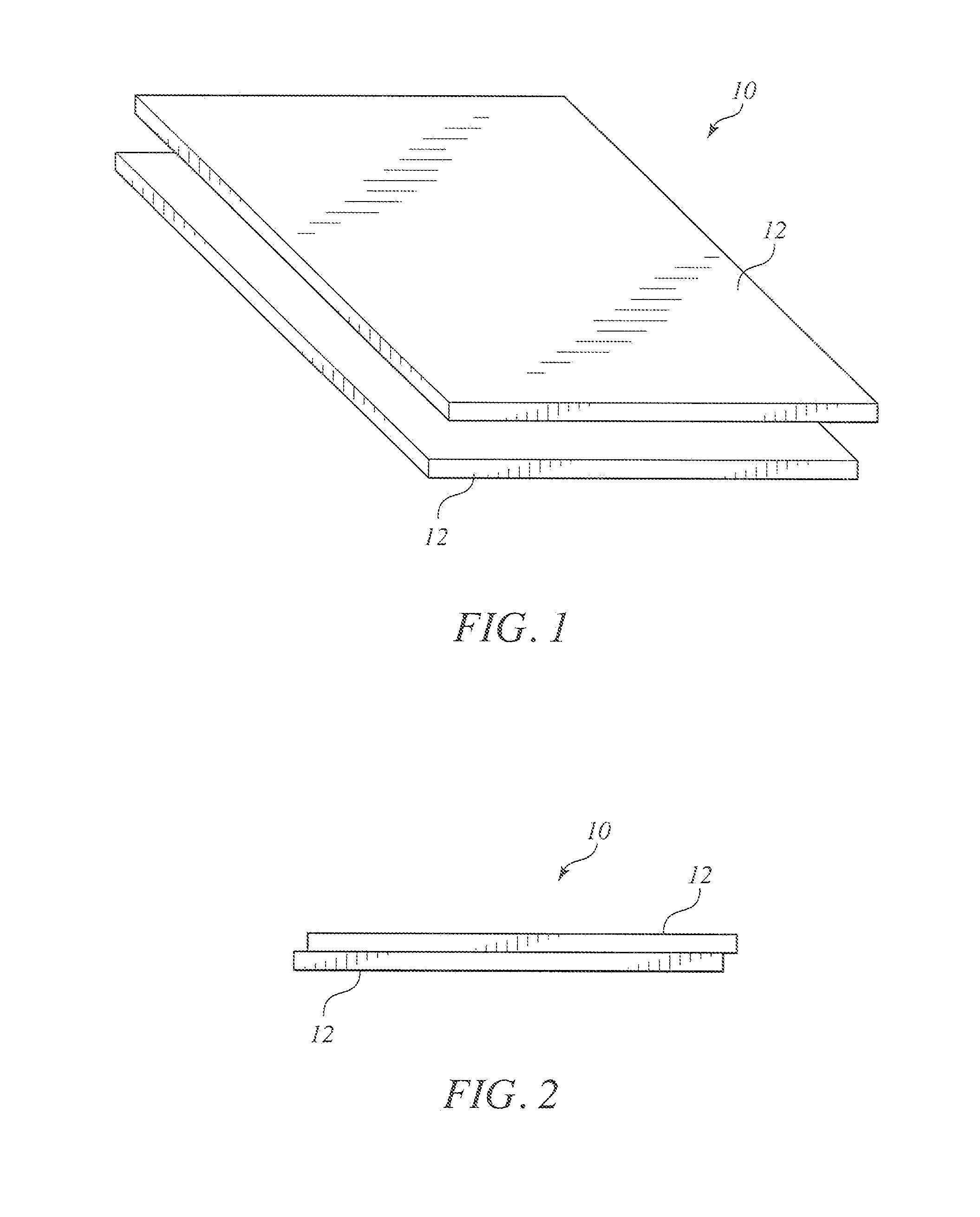

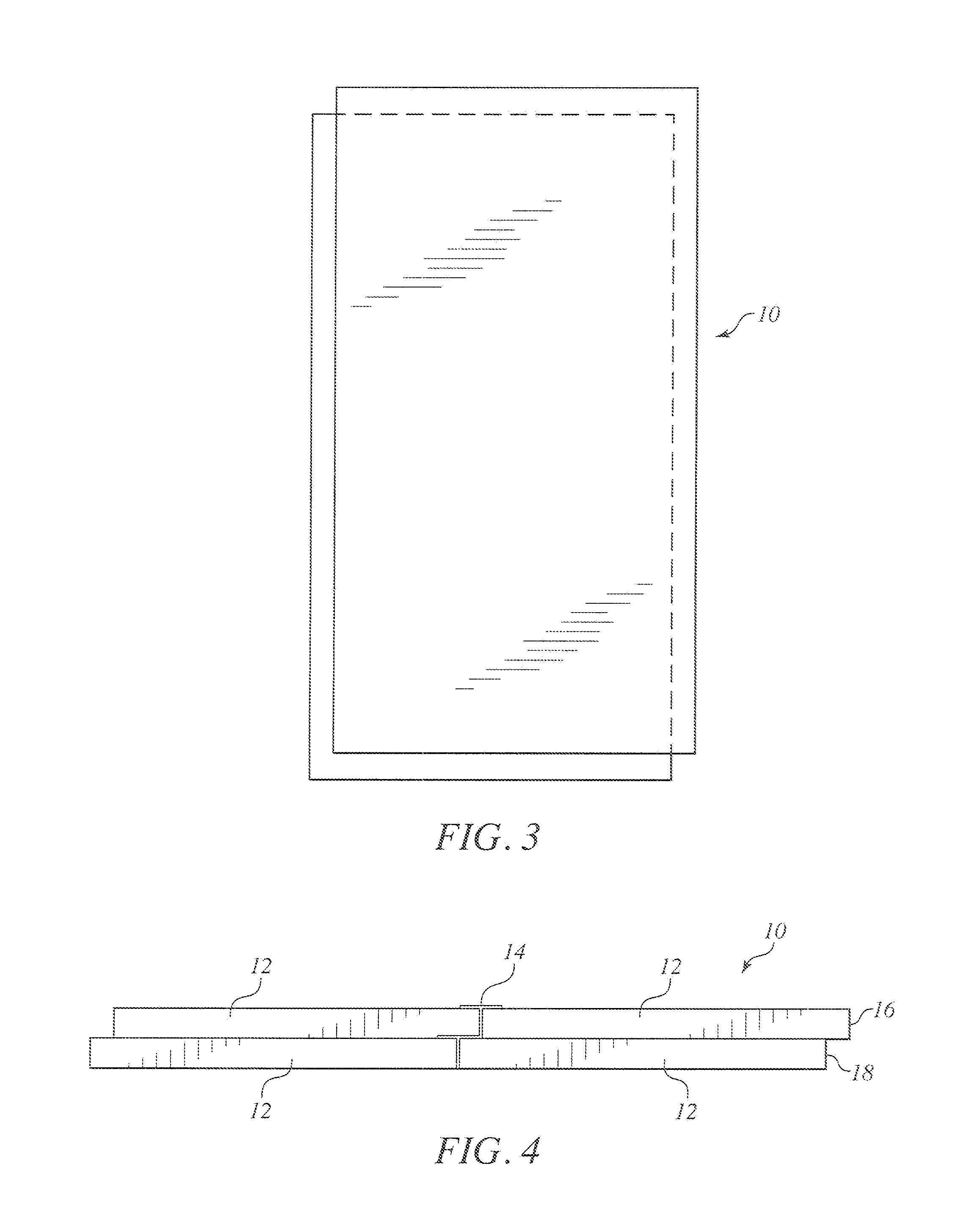

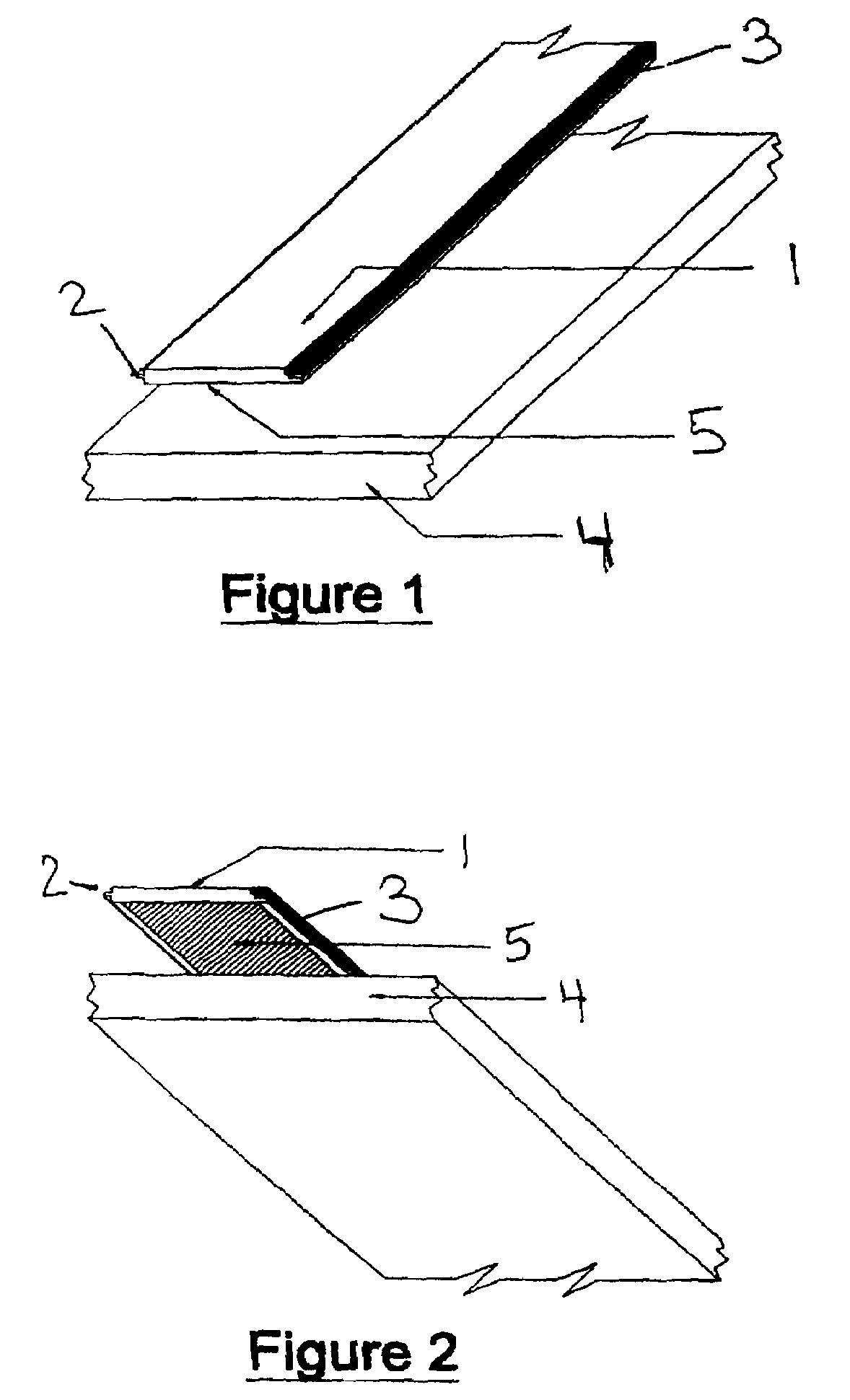

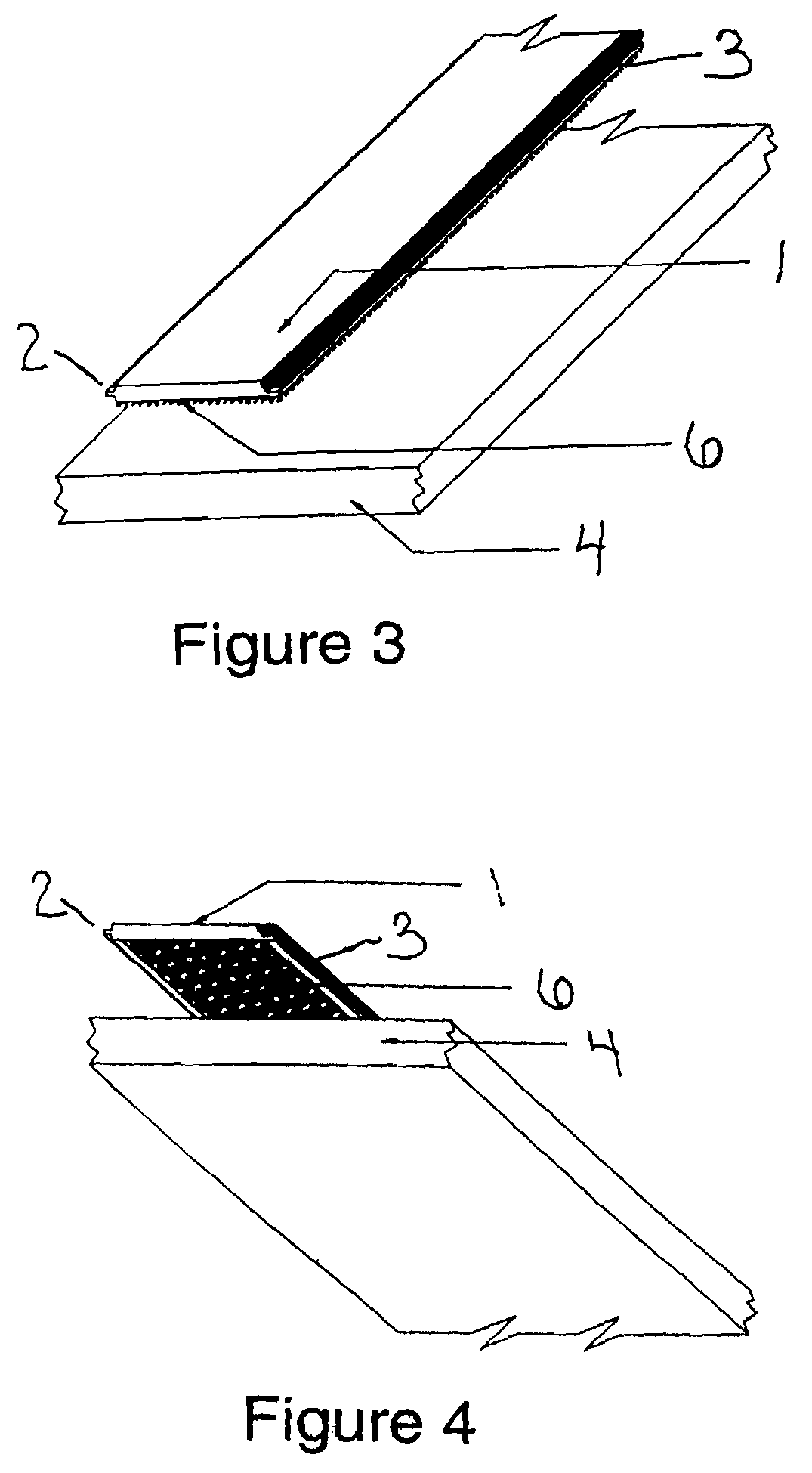

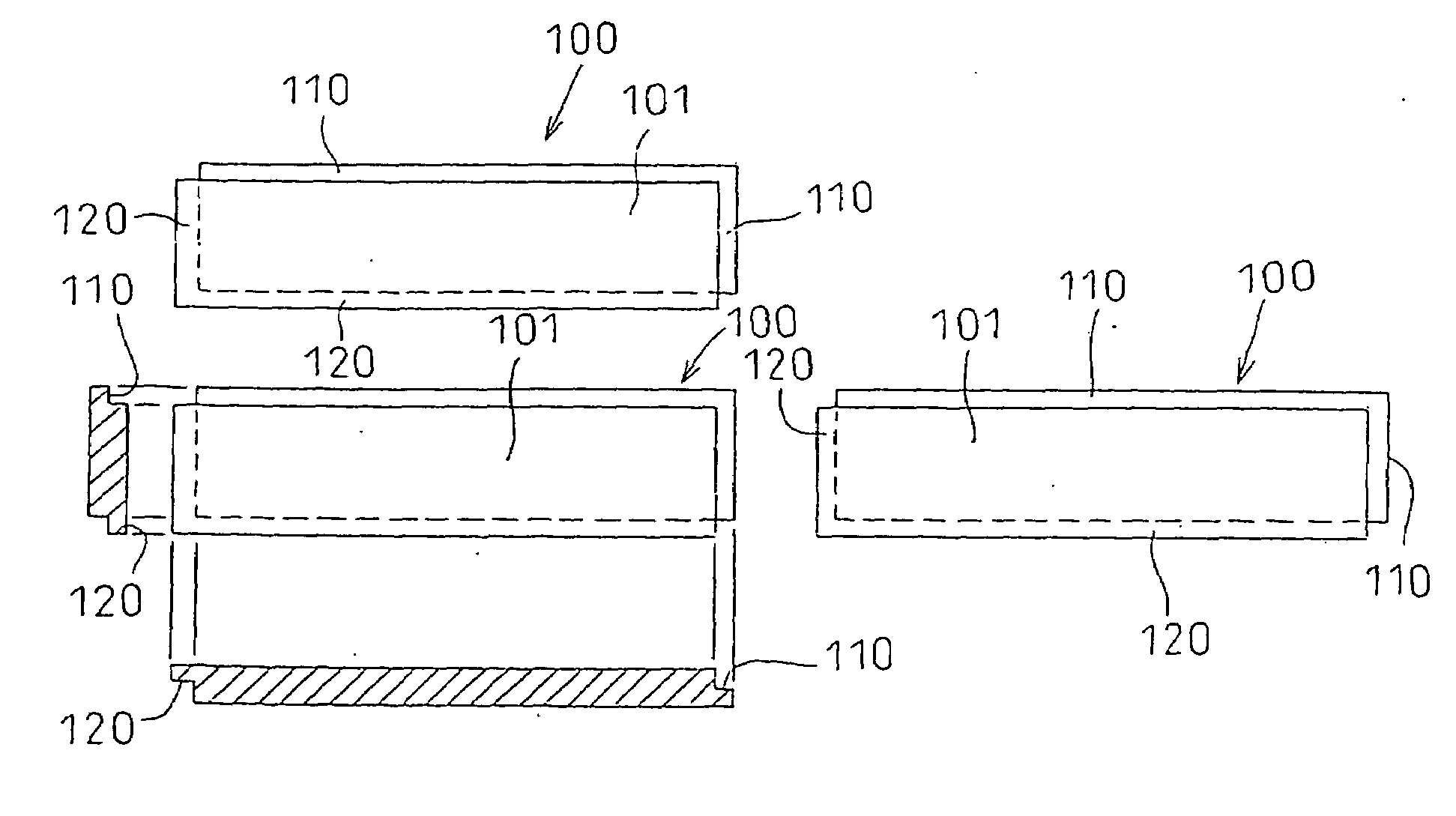

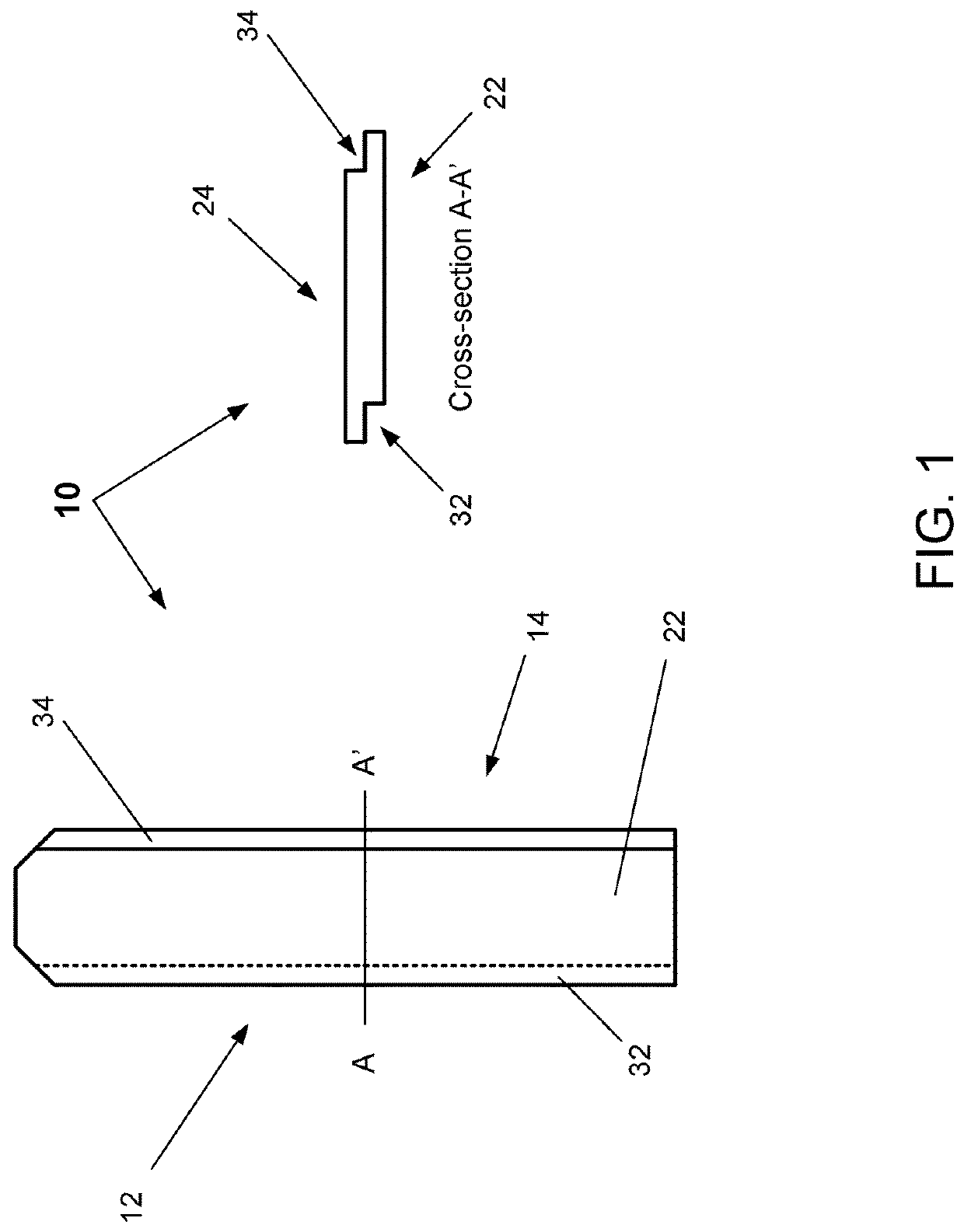

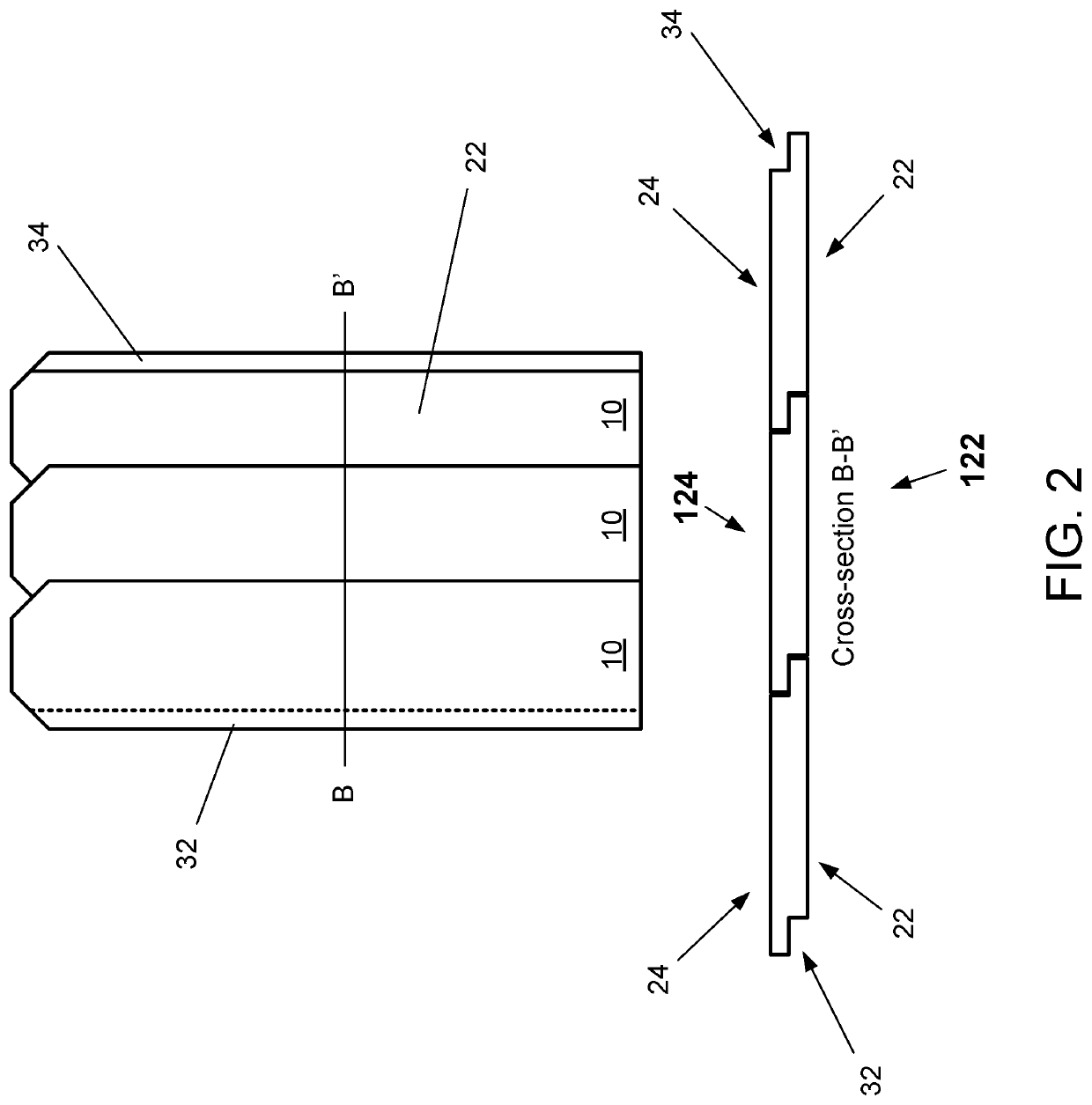

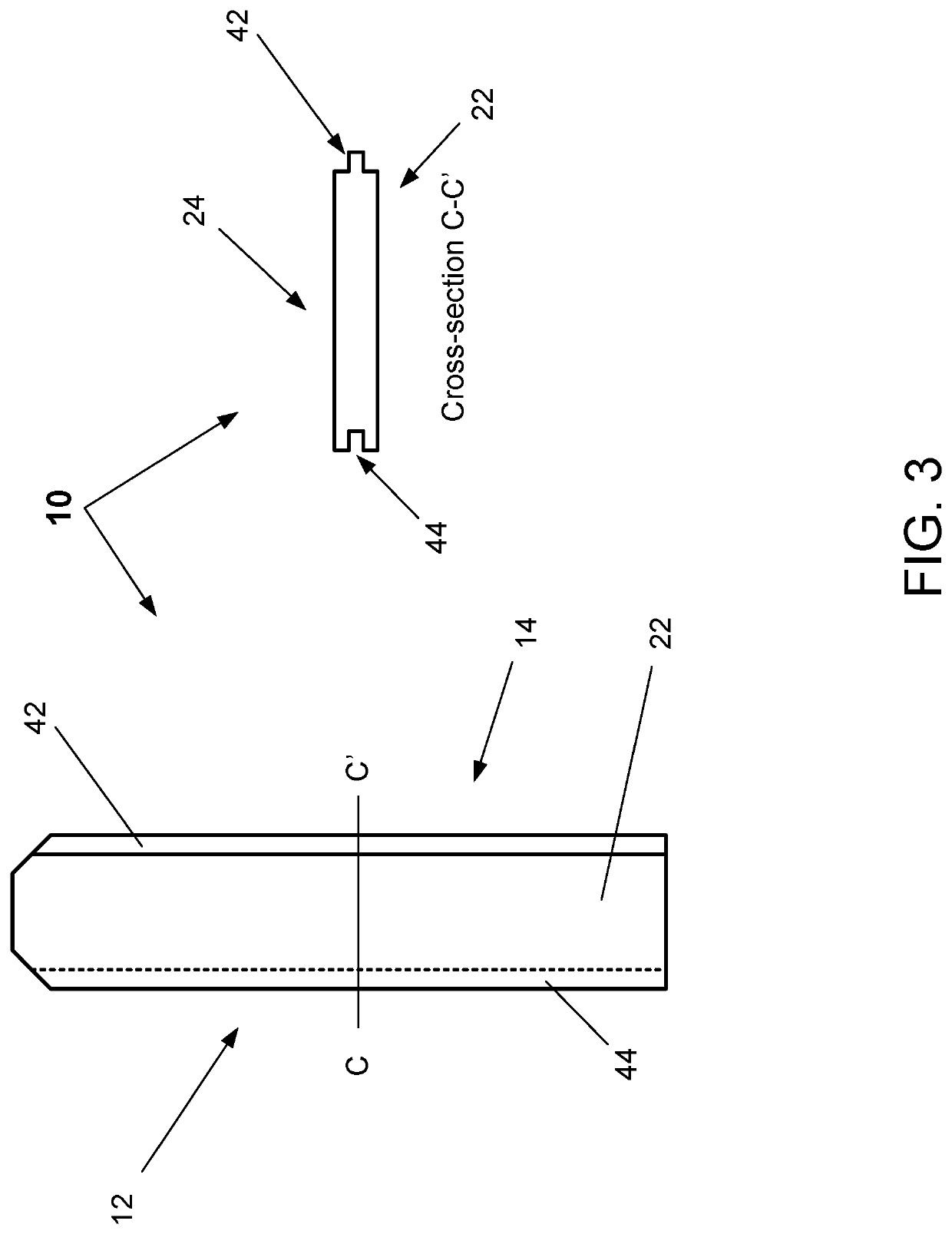

Laminated duct board

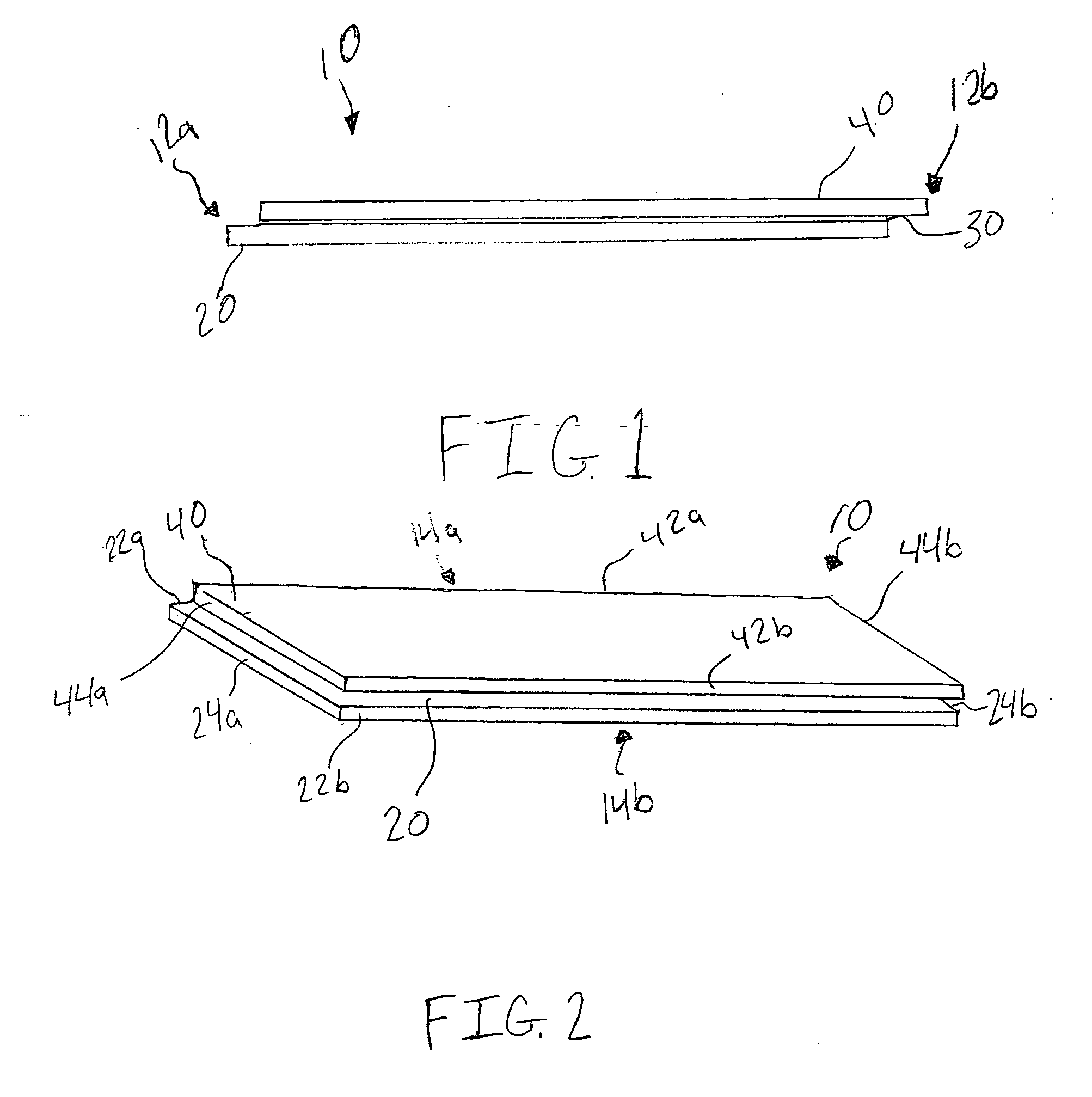

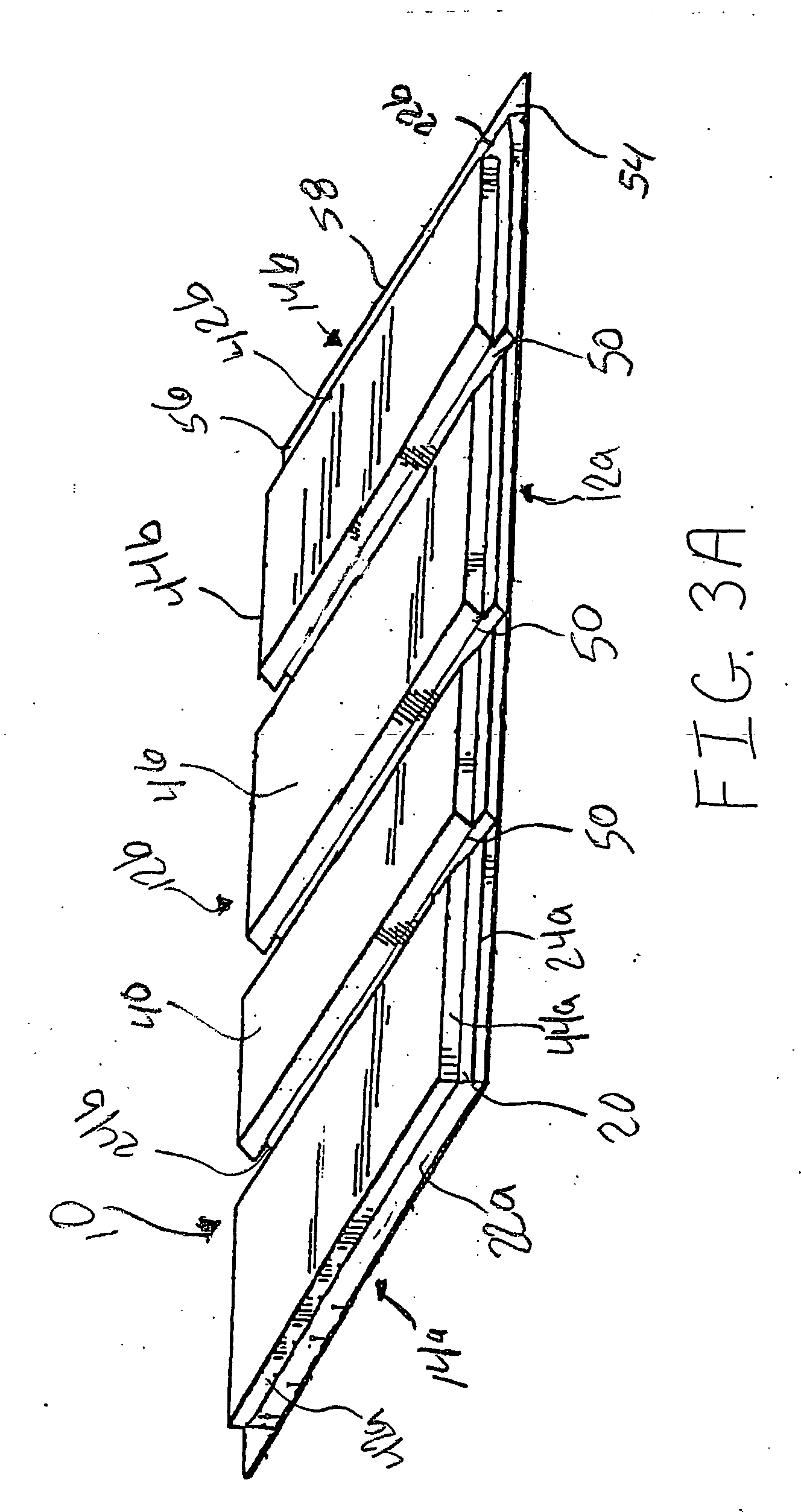

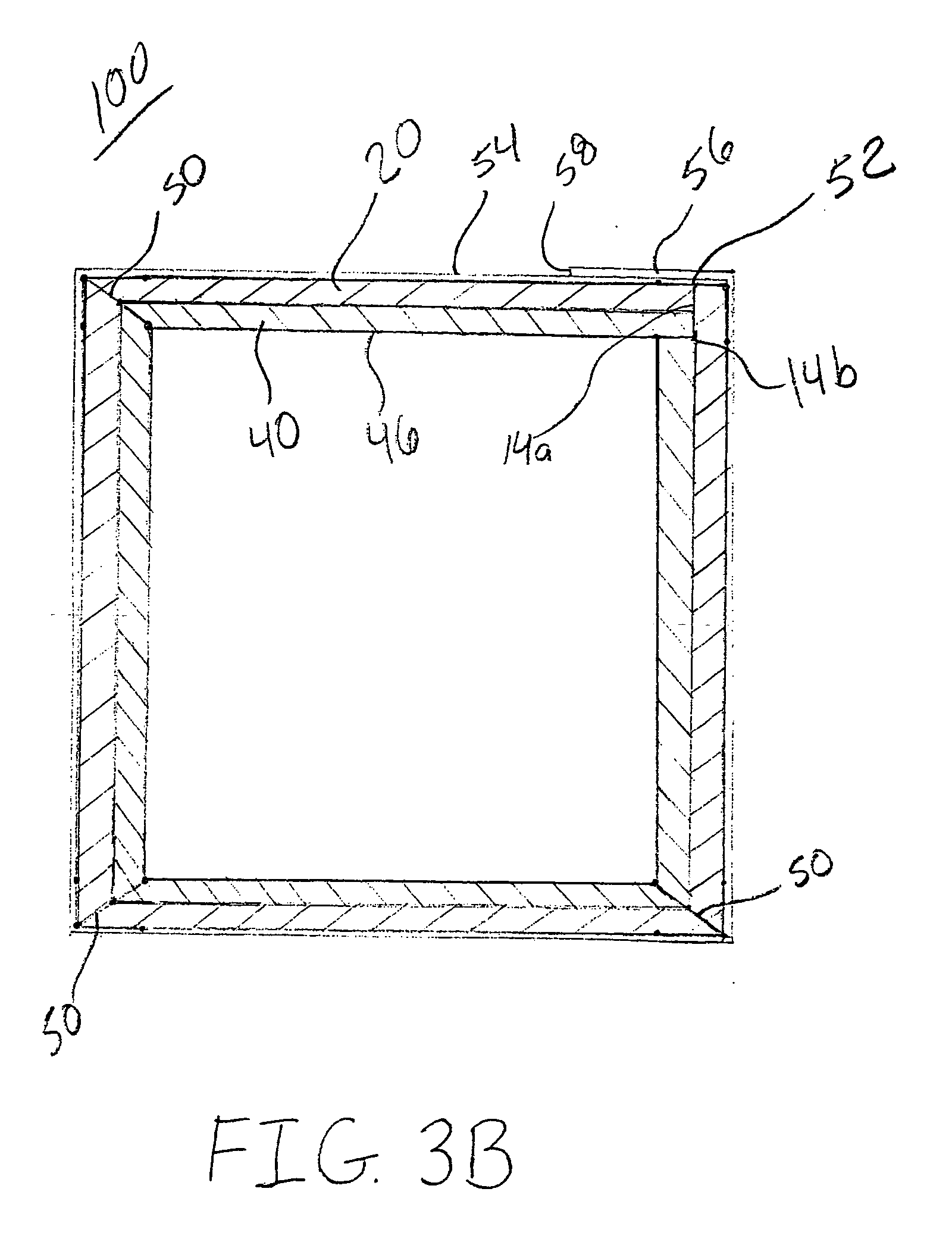

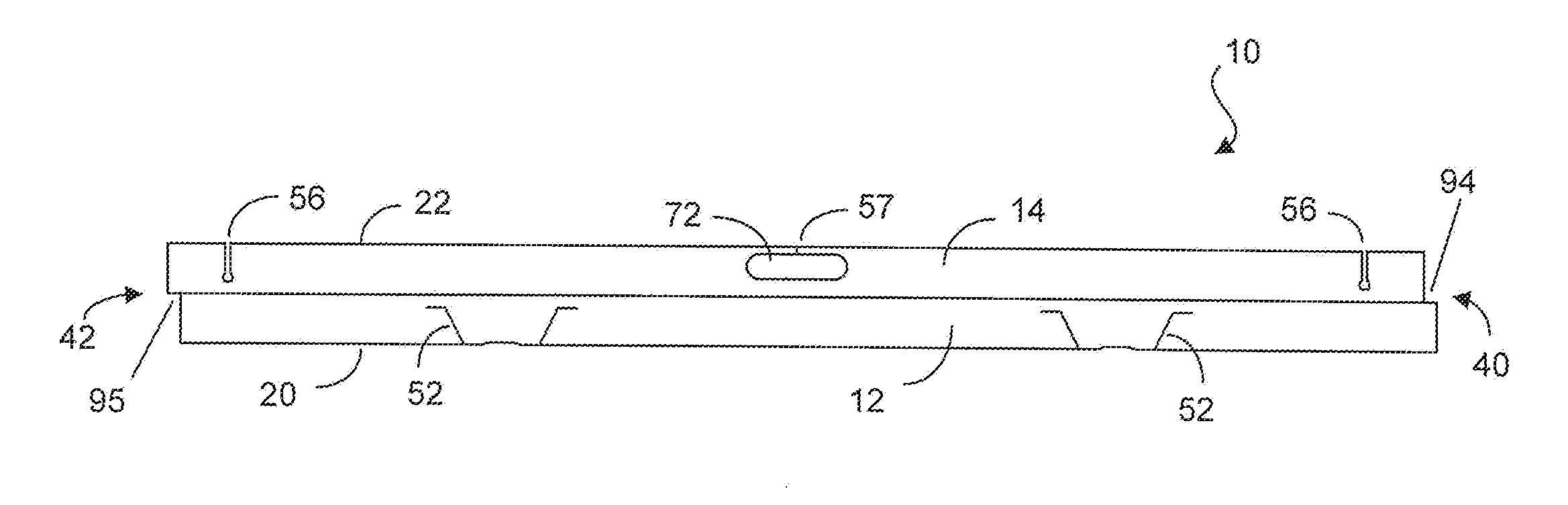

A duct board product includes a fibrous duct board having at least one set of opposing edges, a second board of insulating material having at least one set of opposing edges, and an adhesive material. The fibrous duct board is laminated to the second board of insulating material by the adhesive material. At least one edge of one set of opposing edges of the fibrous duct board is offset from at least one respective edge of one set of opposing edges of the second board of insulating material to form at least one shiplap edge.

Owner:CERTAINTEED CORP

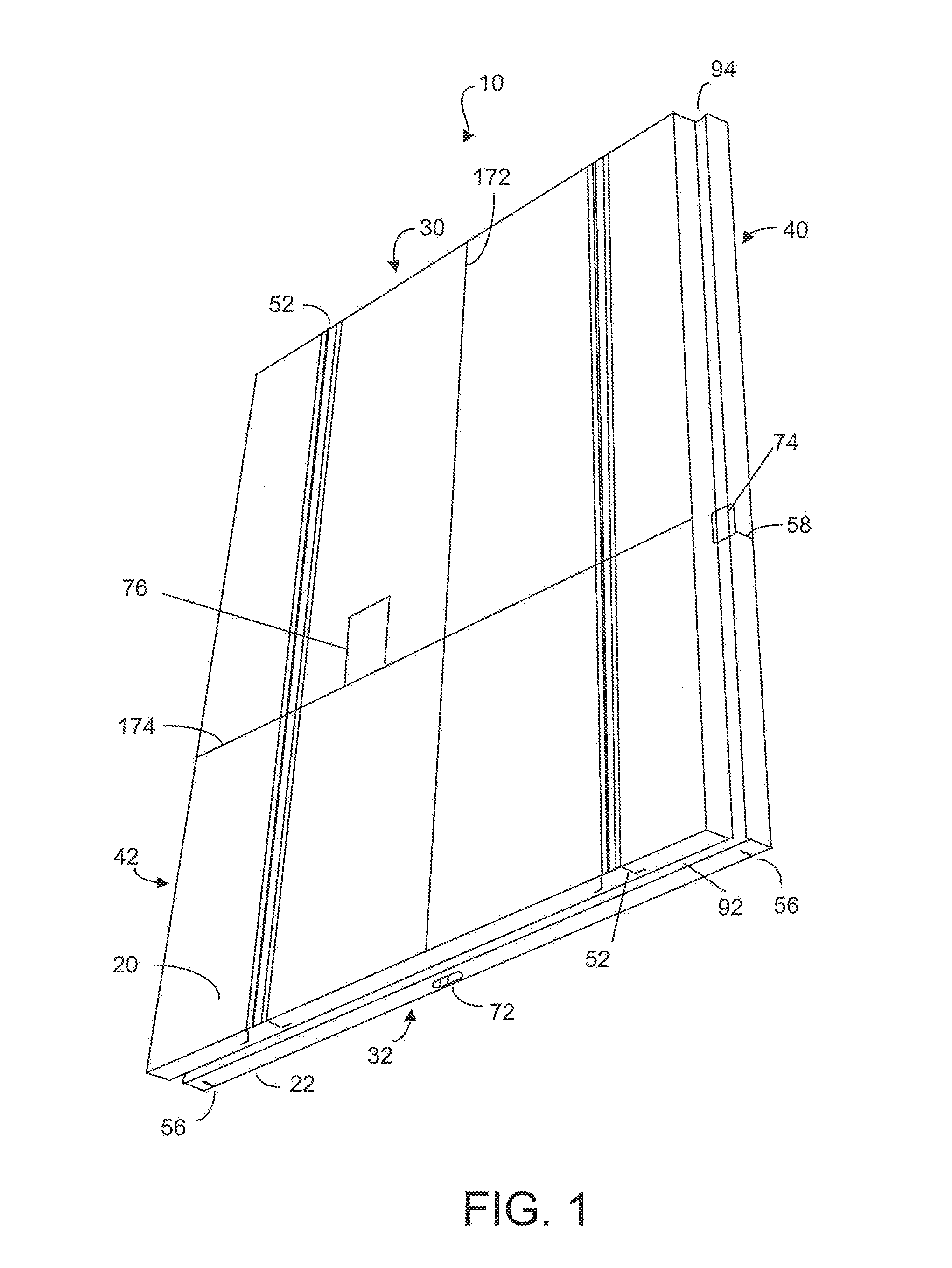

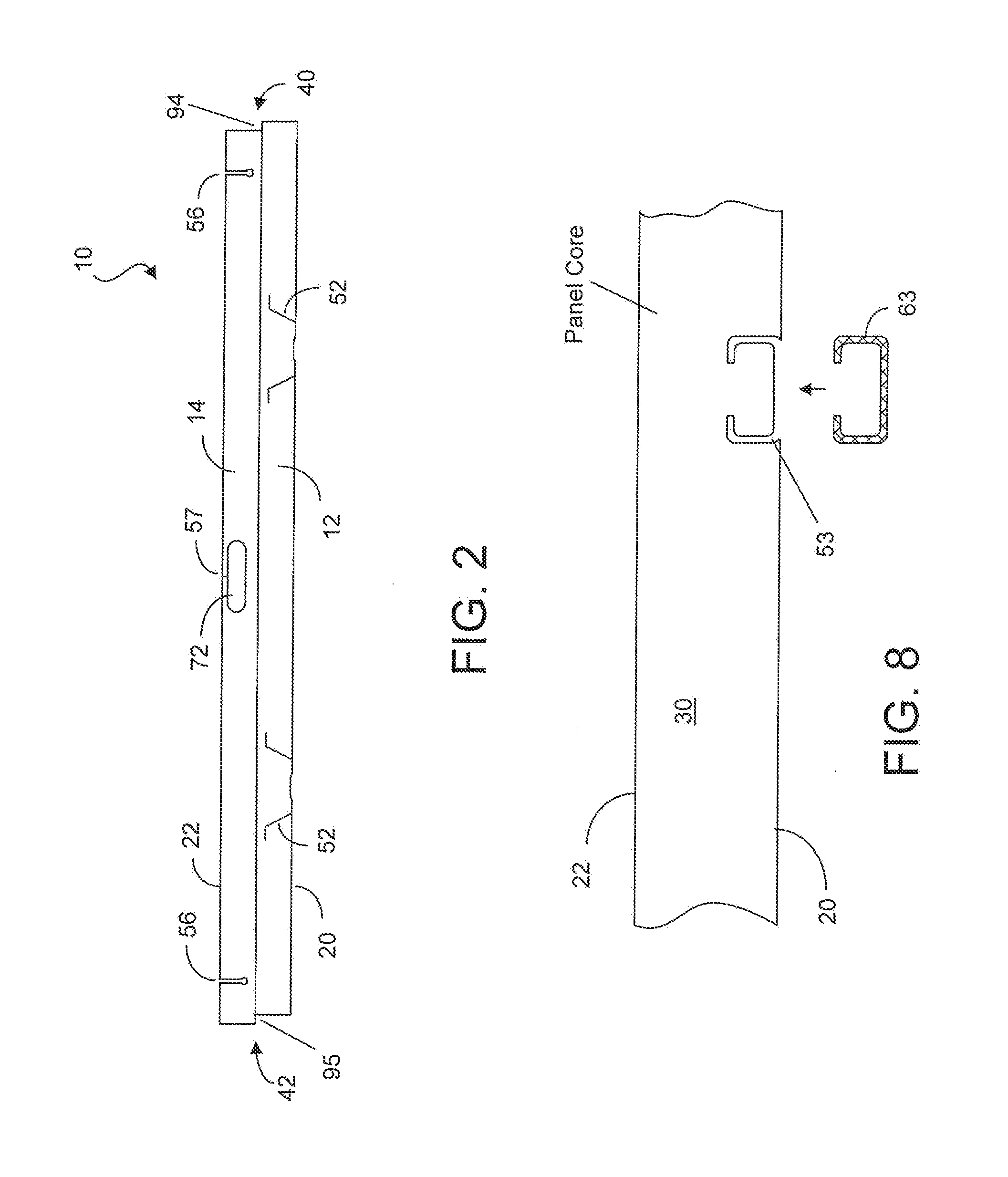

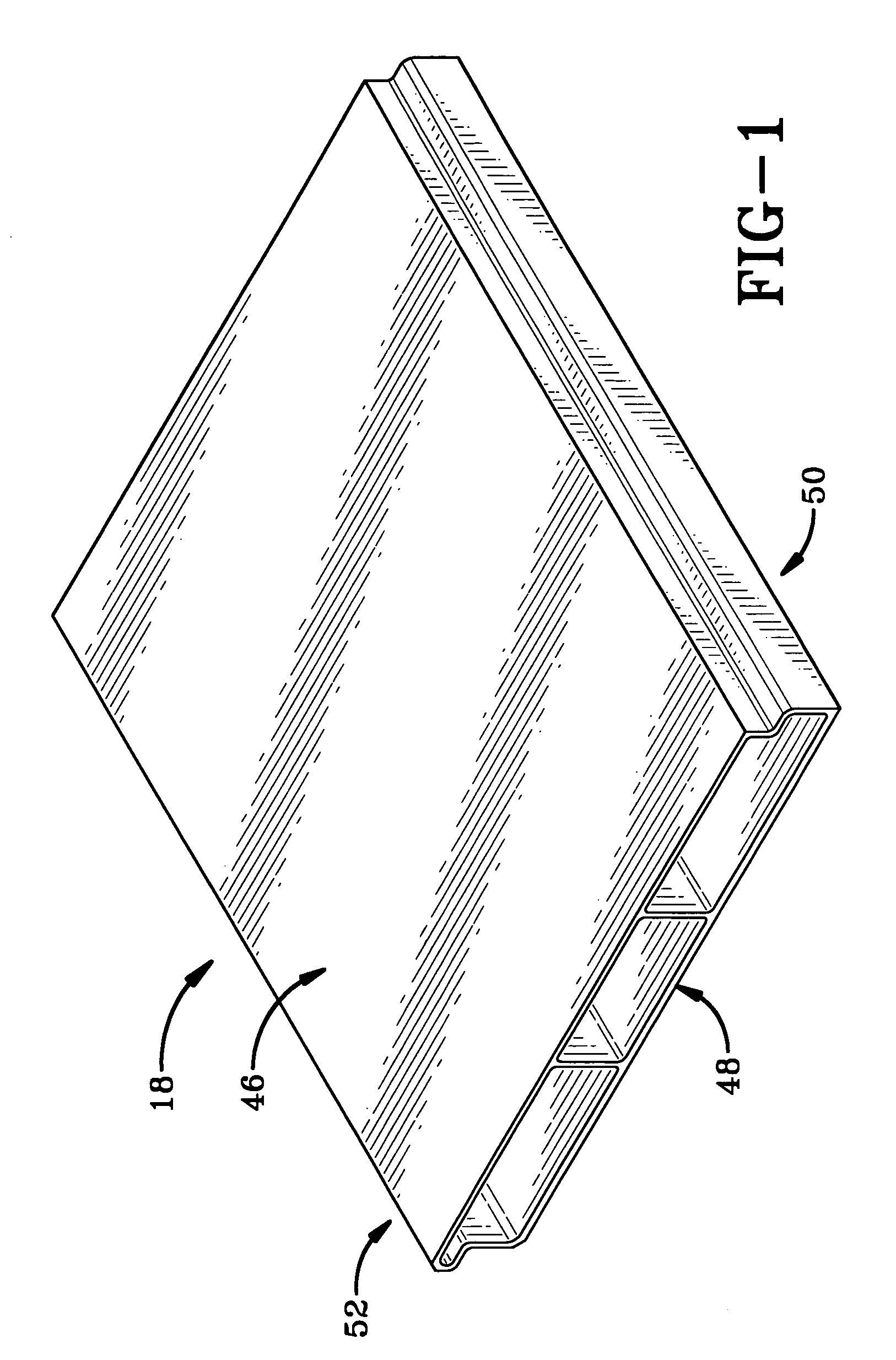

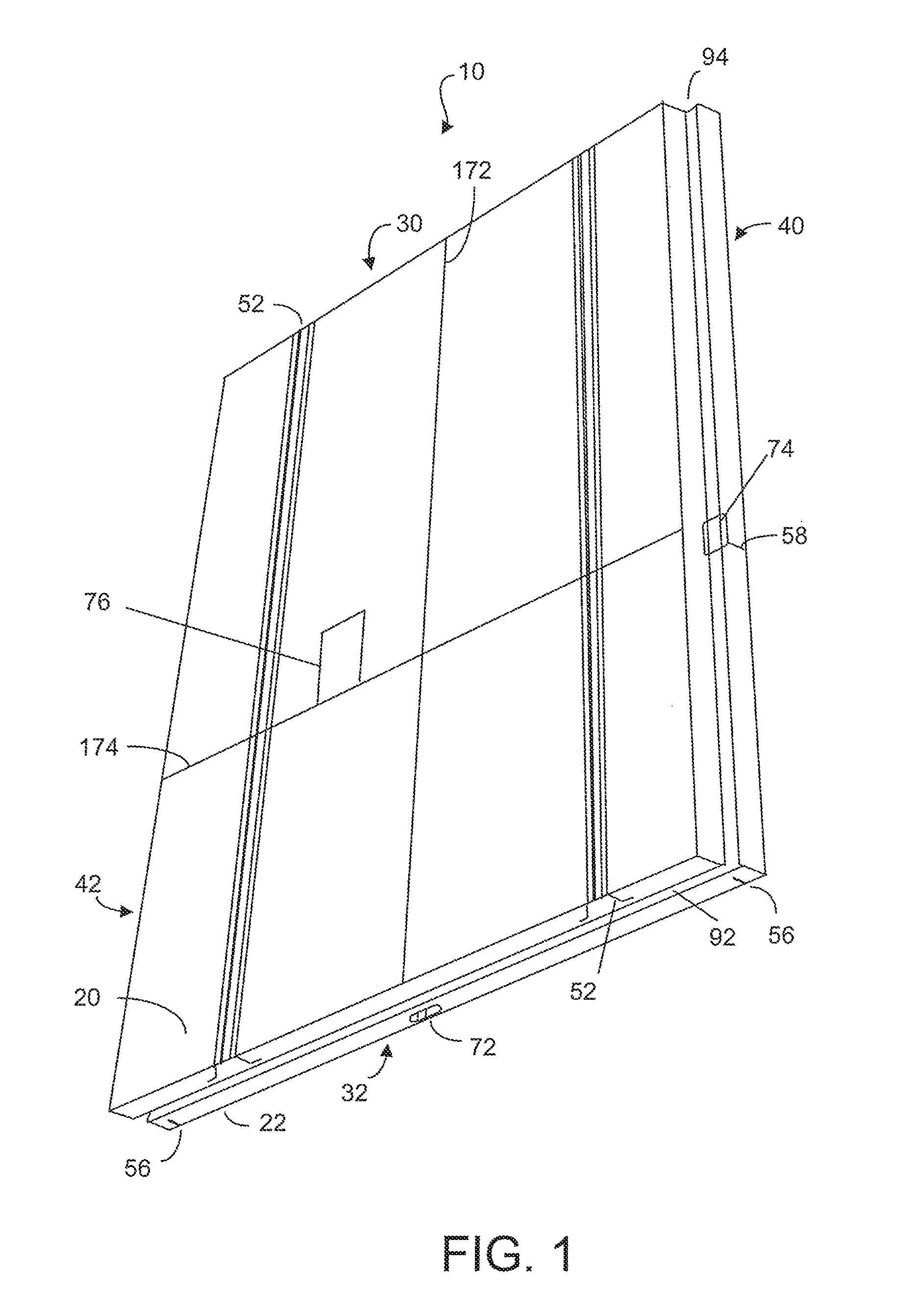

Insulating Wall Panel System

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

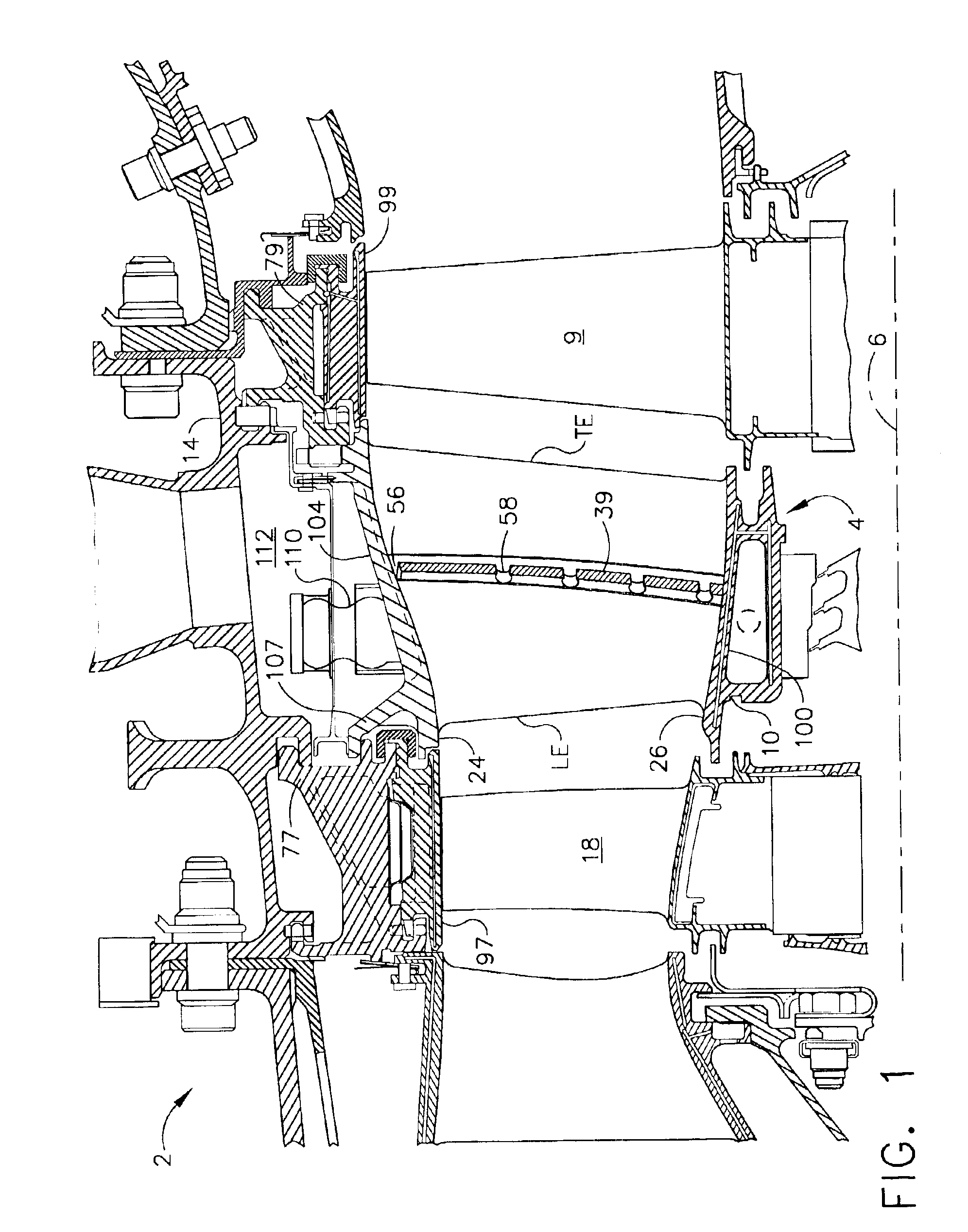

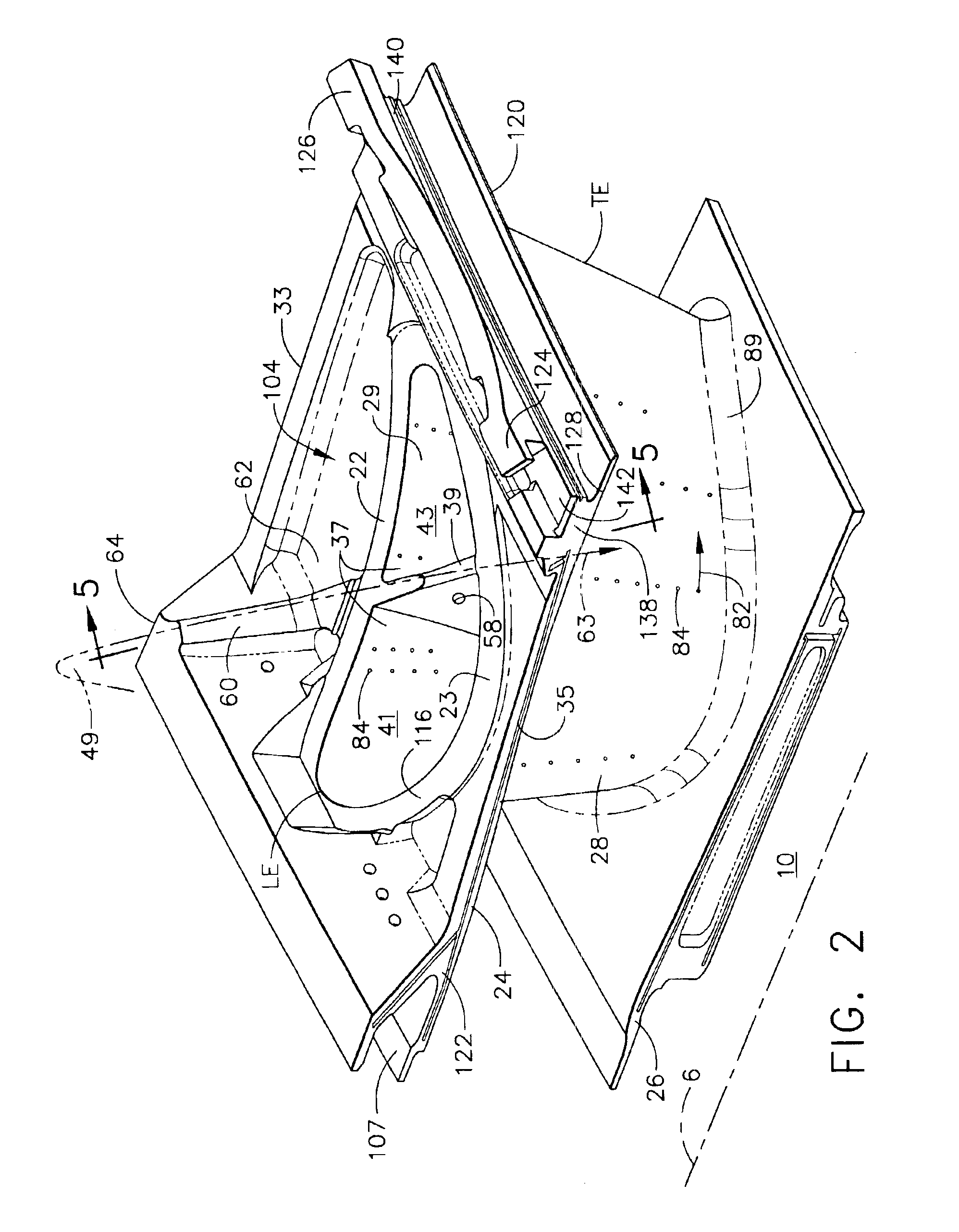

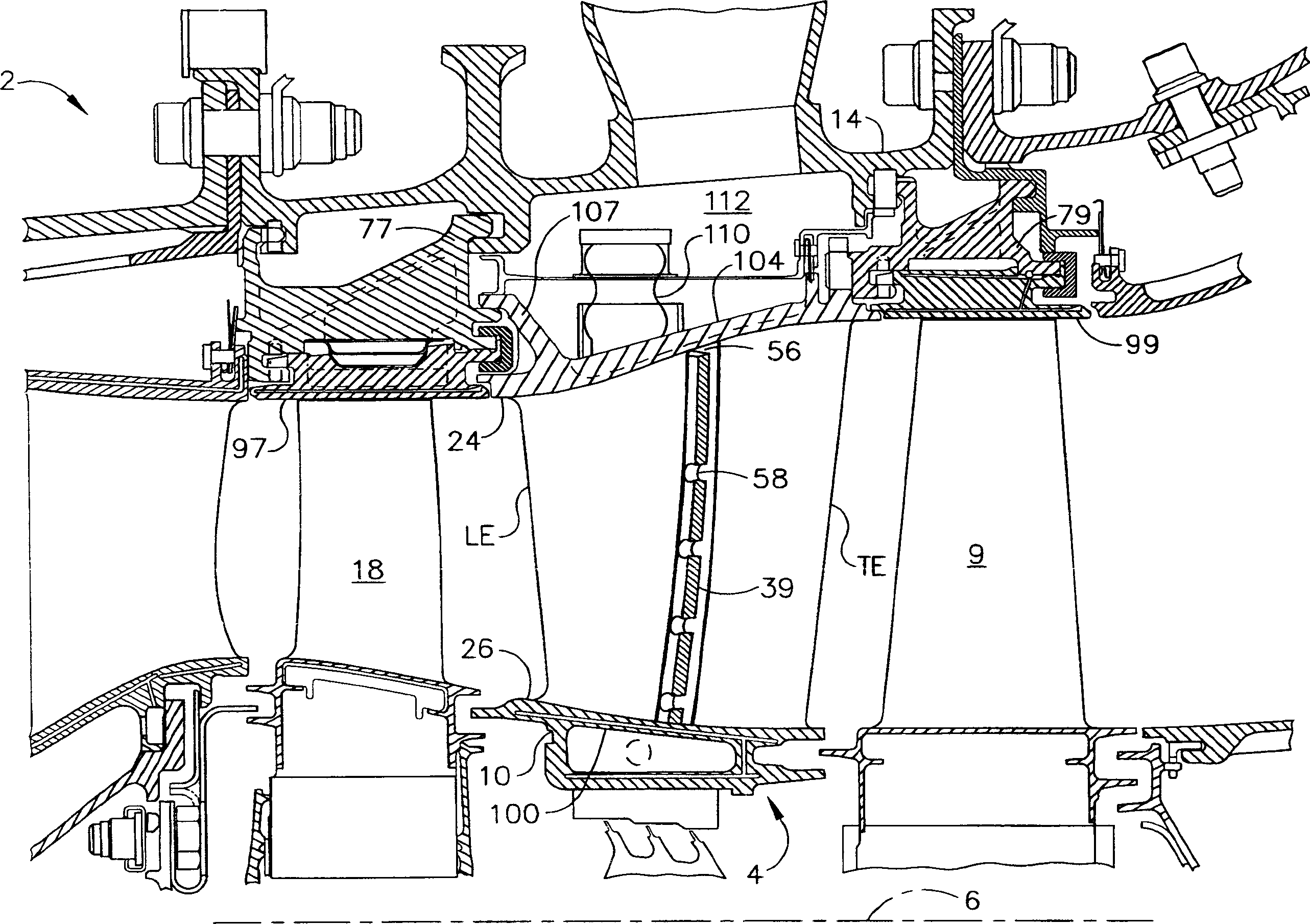

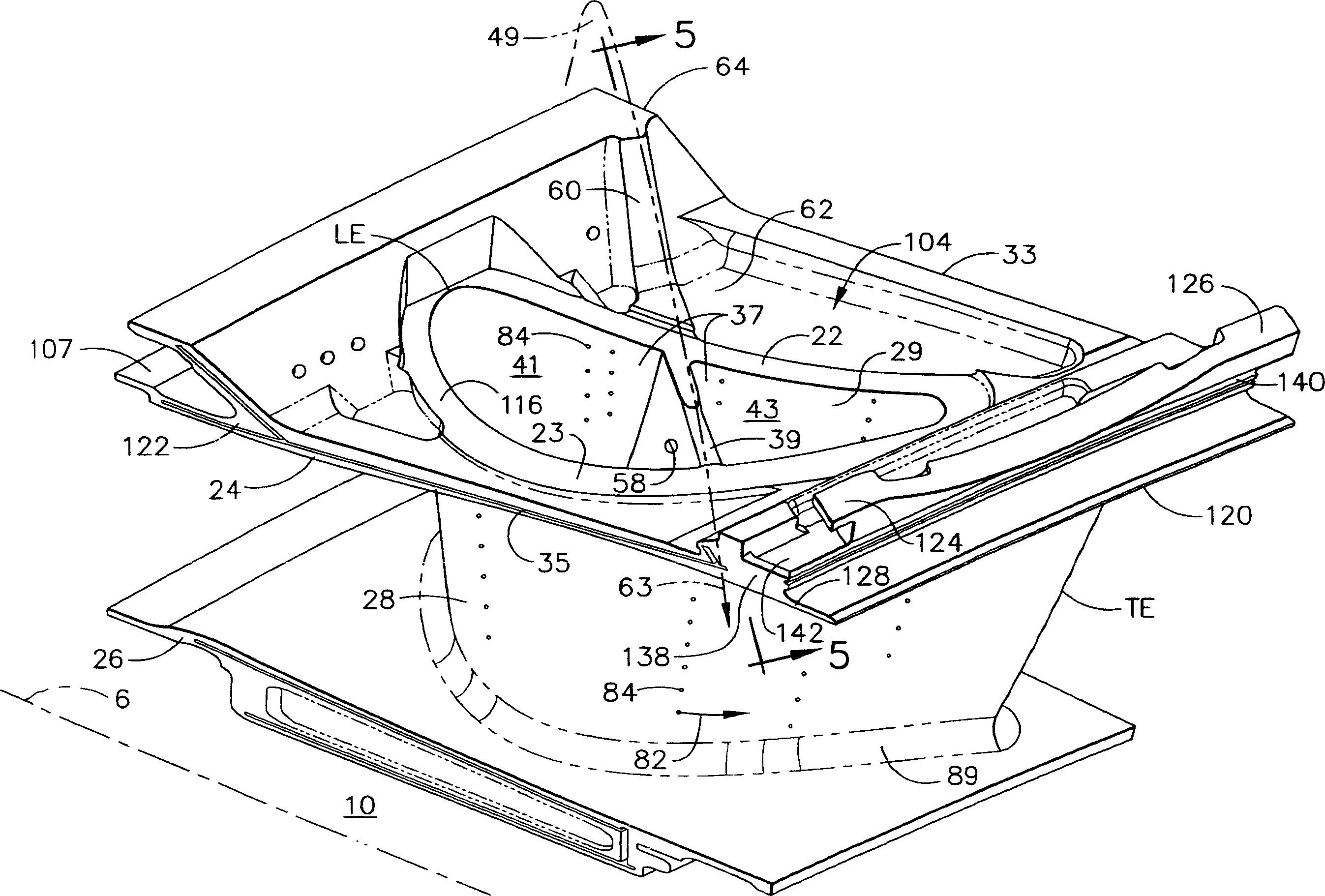

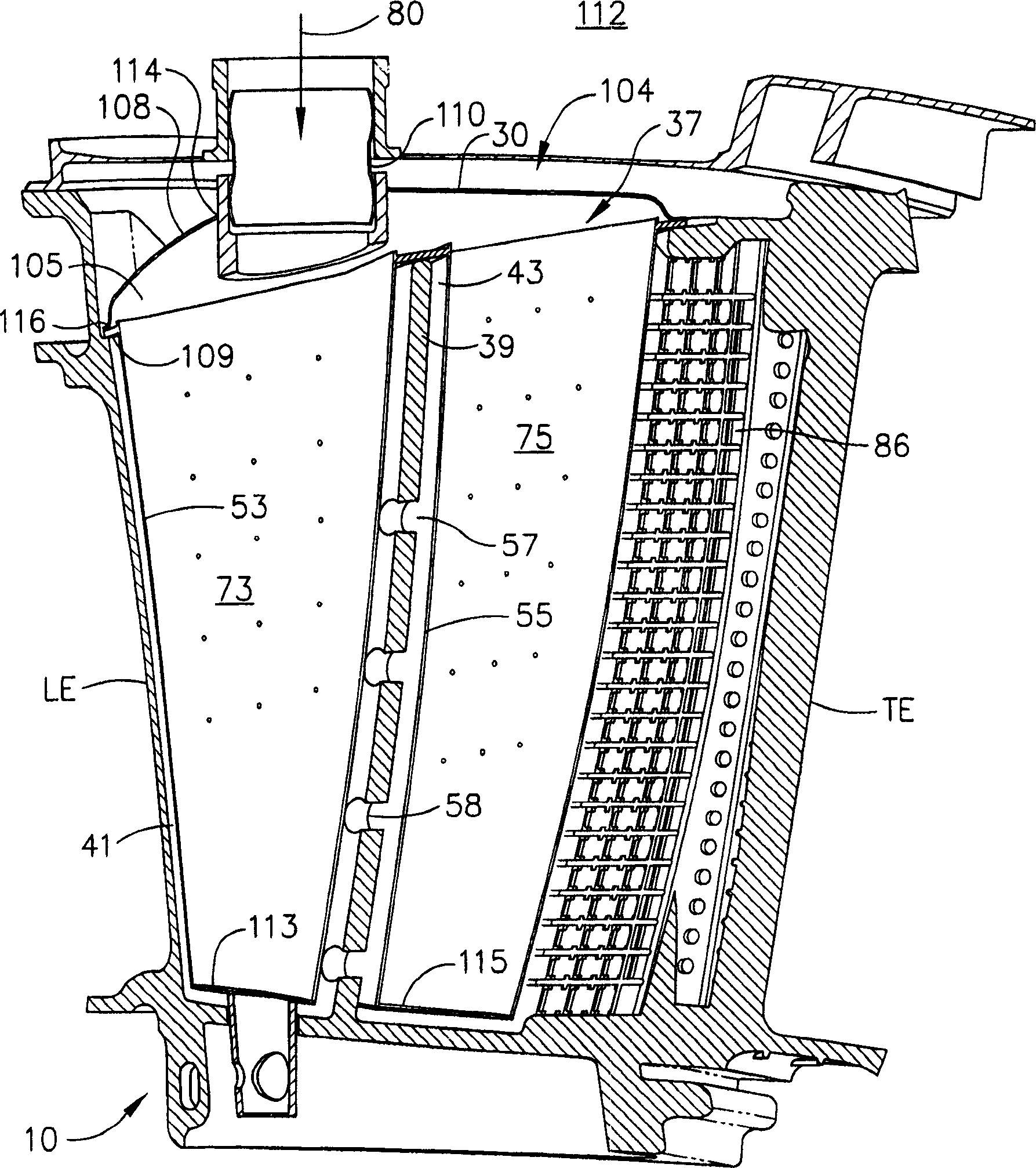

Turbine nozzle segment cantilevered mount

A turbine nozzle segment includes at least one hollow airfoil extending radially between radially outer and inner band segments, a clockwise open hook on a clockwise end at an aft end of the outer band segment, and counter-clockwise open hook on a counter-clockwise end at the aft end of the outer band segments. An exemplary embodiment of the turbine nozzle segment includes a load stop extending radially outwardly from the outer band segment. At least one aftwardly facing load face is at the aft end of the nozzle segment at the outer band segment. The clockwise open hook is C-shaped and the counter-clockwise open hook is a shiplap hook. Another embodiment of the turbine nozzle segment has only one hollow airfoil with an airfoil wall surrounding a bifurcated cavity divided into forward and aft cavities by a bifurcating rib extending between pressure and suction sides of the airfoil wall.

Owner:GENERAL ELECTRIC CO

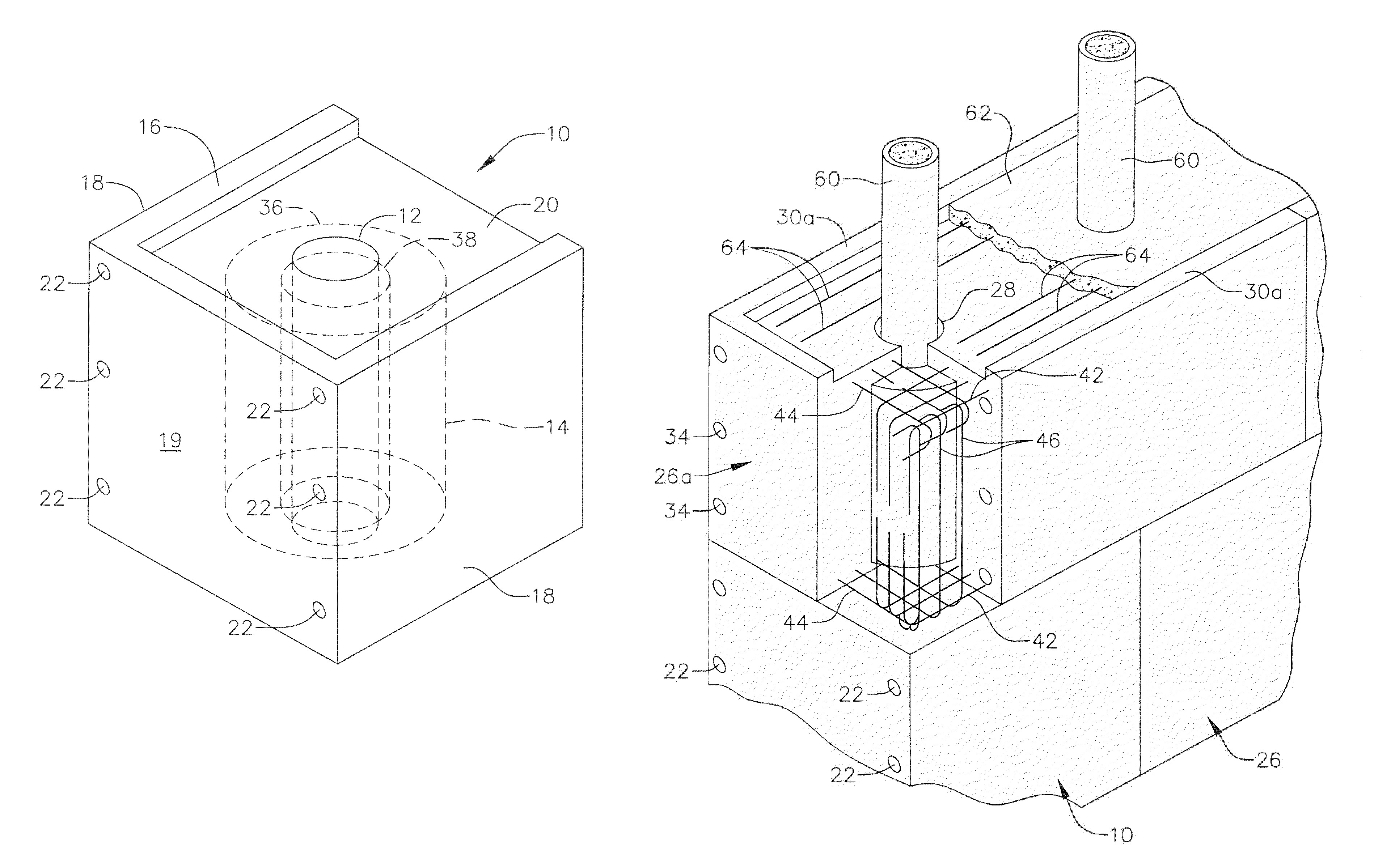

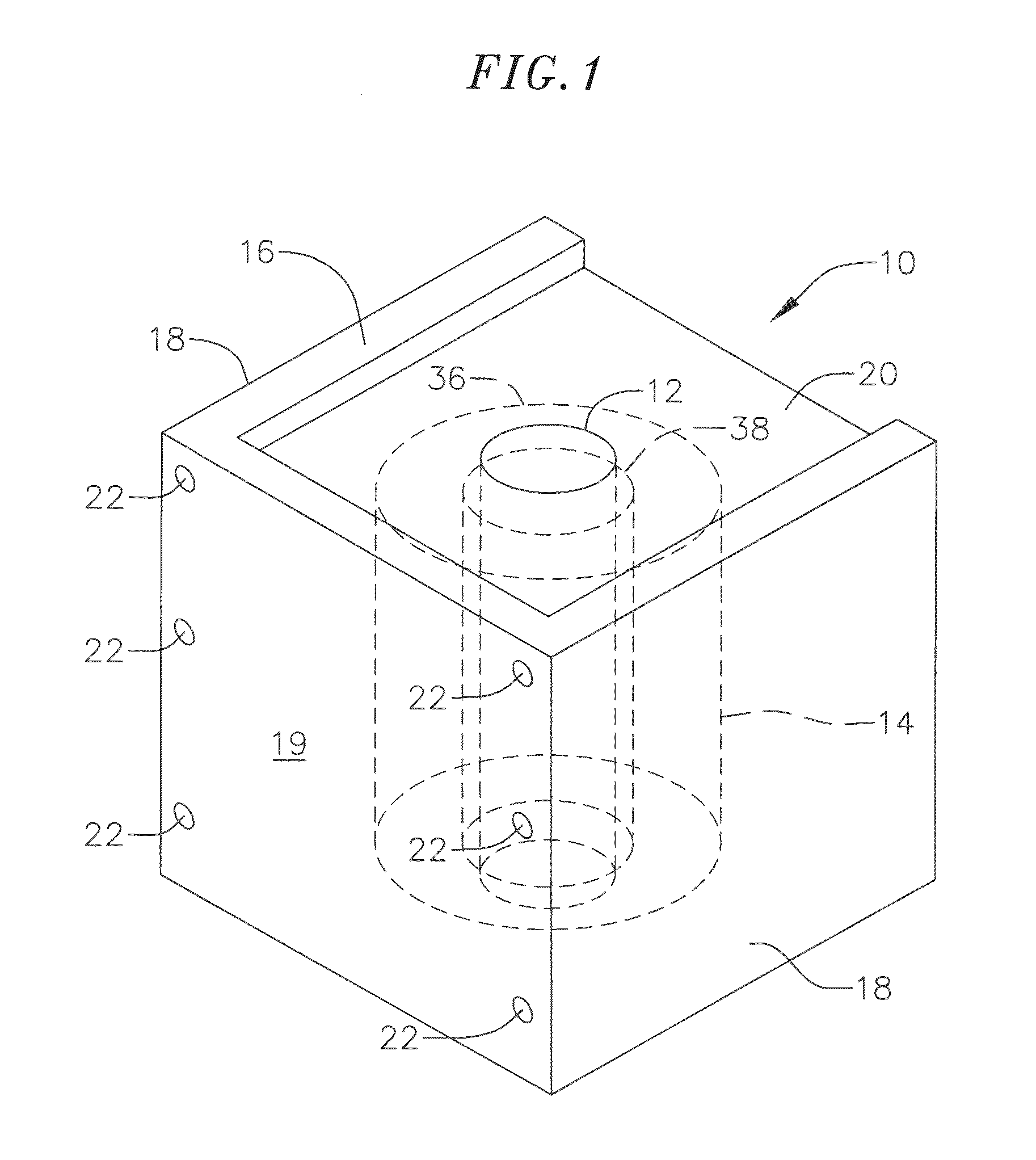

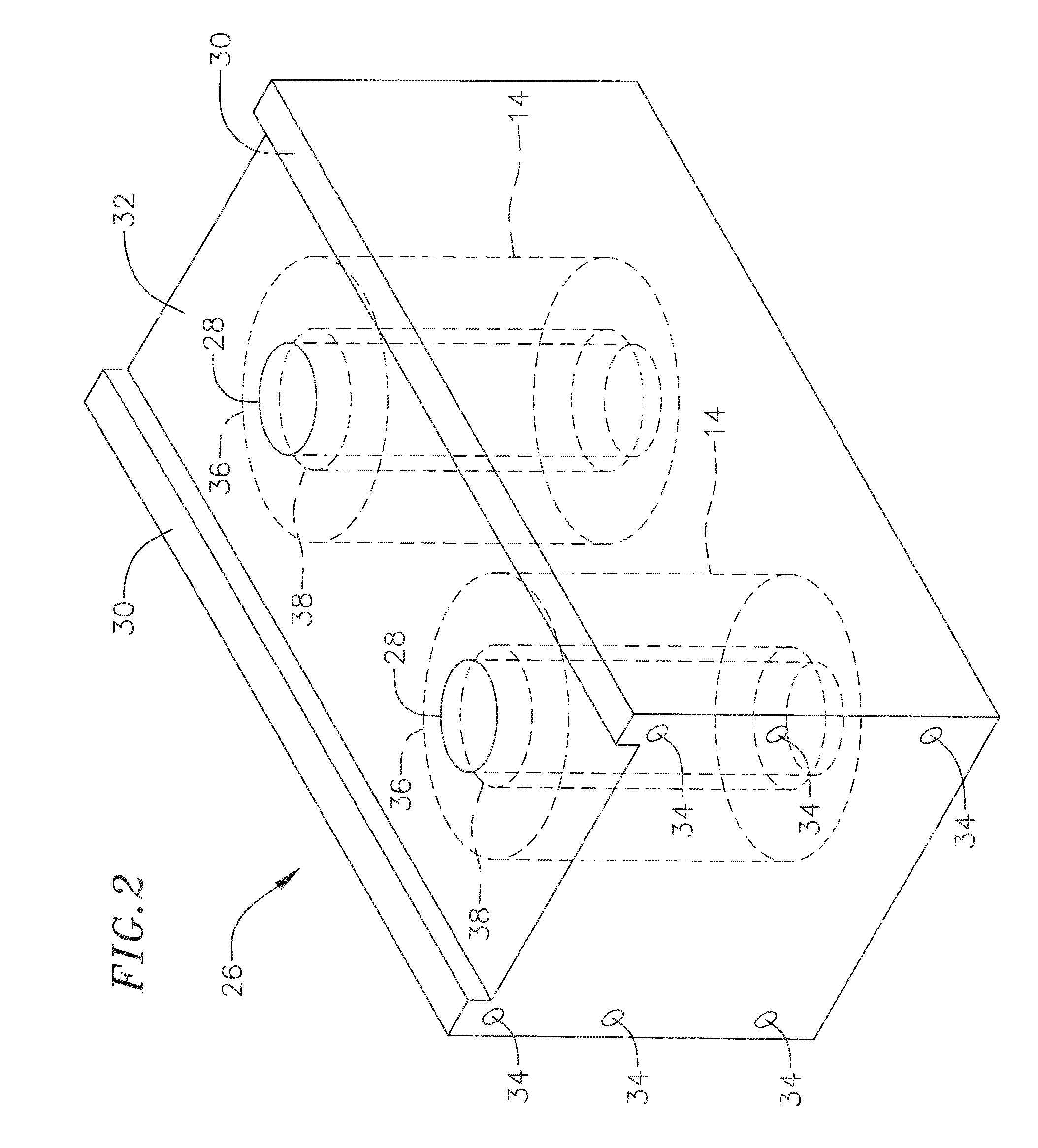

System of stacked concrete blocks, each block having a tire wall stack therewithin surrounding a hollow core through which a vertical reinforcing member extends and reinforcing bars in mortar in void between adjacent blocks

InactiveUS7546712B2Reduce weightPrevent slippingConstruction materialWallsReinforced concretePre stress

An article of manufacture for building concrete structures from precast blocks and the process for making the structural system. The block comprises one or more annular tire wall stack units embedded in reinforced concrete. Prestressing and / or post-tensioning structural reinforcing techniques are used with assembled building blocks. The blocks are made by placing used tire stacks in a form that centralizes the stacks so that reinforced concrete can be placed around them while maintaining a hollow core through the stacks. Horizontal interlocking between blocks uses reinforcing bars and / or a tongue and groove configuration, and / or post-tension wire strand placed in a recess or post-tension tubes formed in the blocks and mortared in-place during construction. Vertical interlocking between blocks uses a tongue-and-groove interlock, shiplap splicing, and reinforcing bars. Post-tension wire strand, pipe, or H-piles are placed in and through the stacks and mortared in-place during construction.

Owner:SHAW REECE F

Flexible panel

The flexible panel is made of juxtaposed rectangular bars each having holes extending transversely therein and elastic cords threaded through these holes for keeping the bars closely positioned side-by-side. Adjacent bars have a shiplap joint there between comprising a first notch in the top surface and the first side surface of a first bar, and a second notch in the bottom surface and the second side surface of the second bar, wherein these notches have overlapping horizontal surfaces. In another aspect of the present invention, each hole along the shiplap joint is made of two separable cylindrical grooves facing each other and forming a closed cylindrical wall when the shiplap joint is integral and a separable segment when the shiplap joint is pulled apart.

Owner:THORNE MICHAEL B

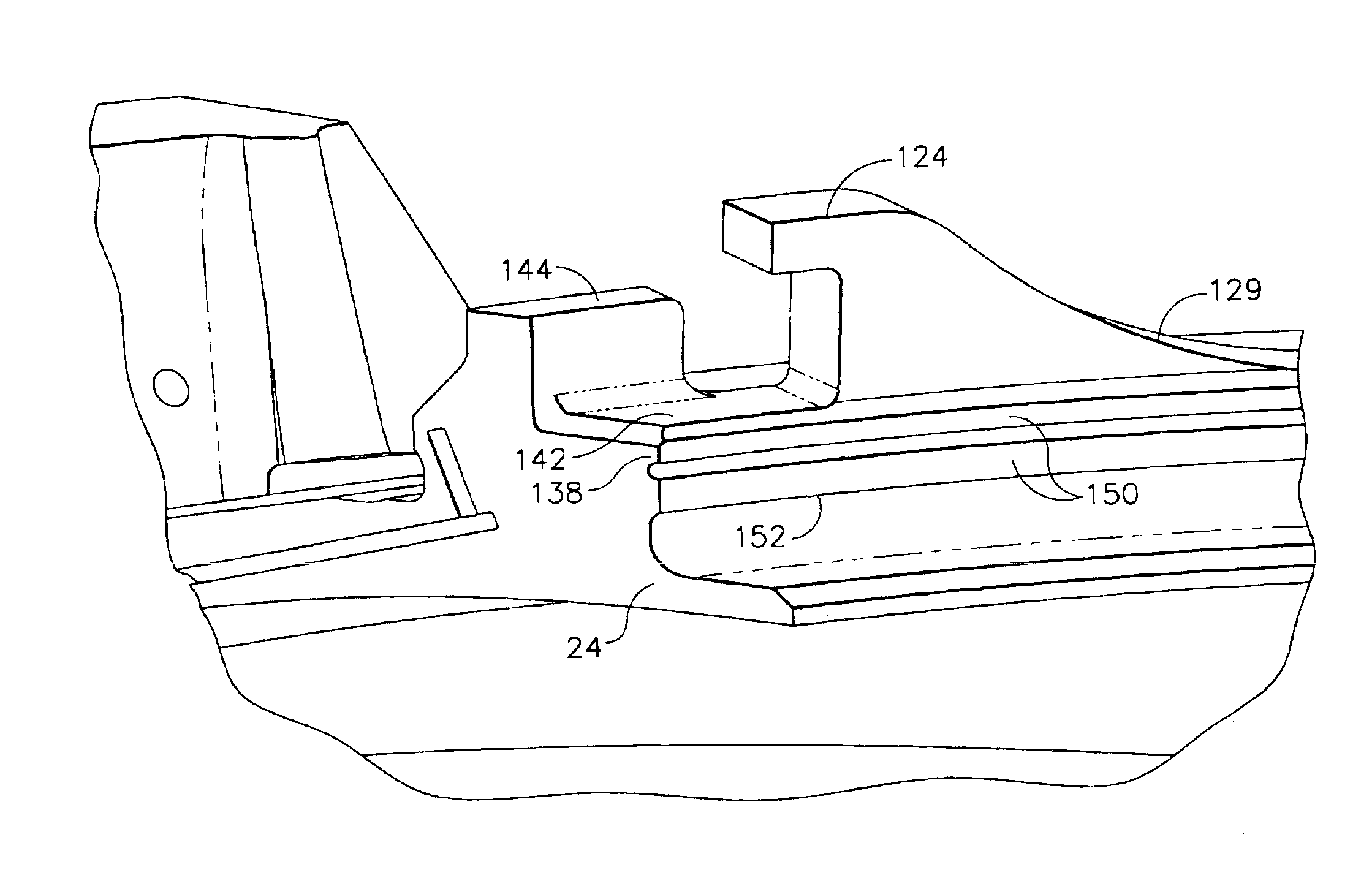

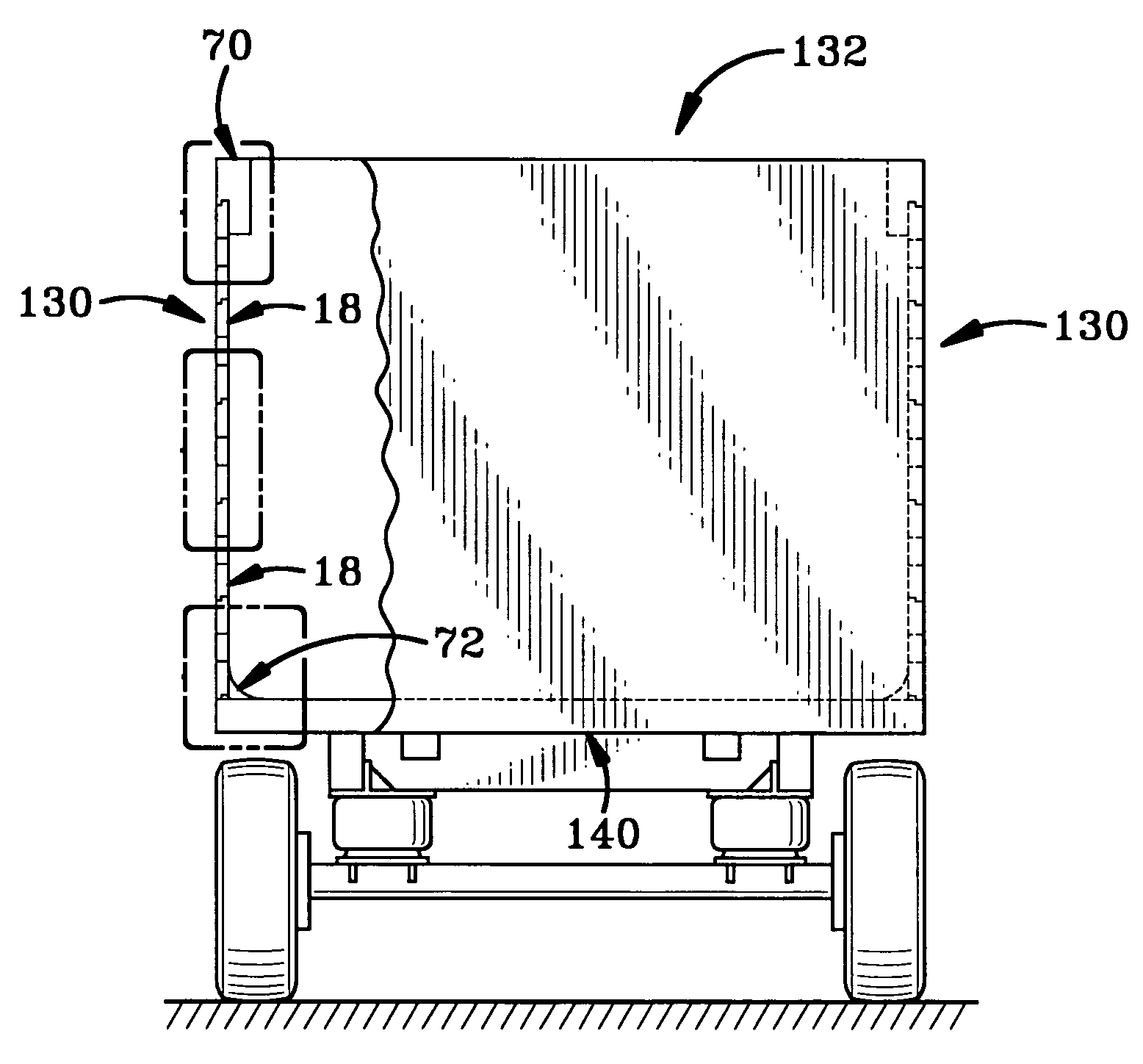

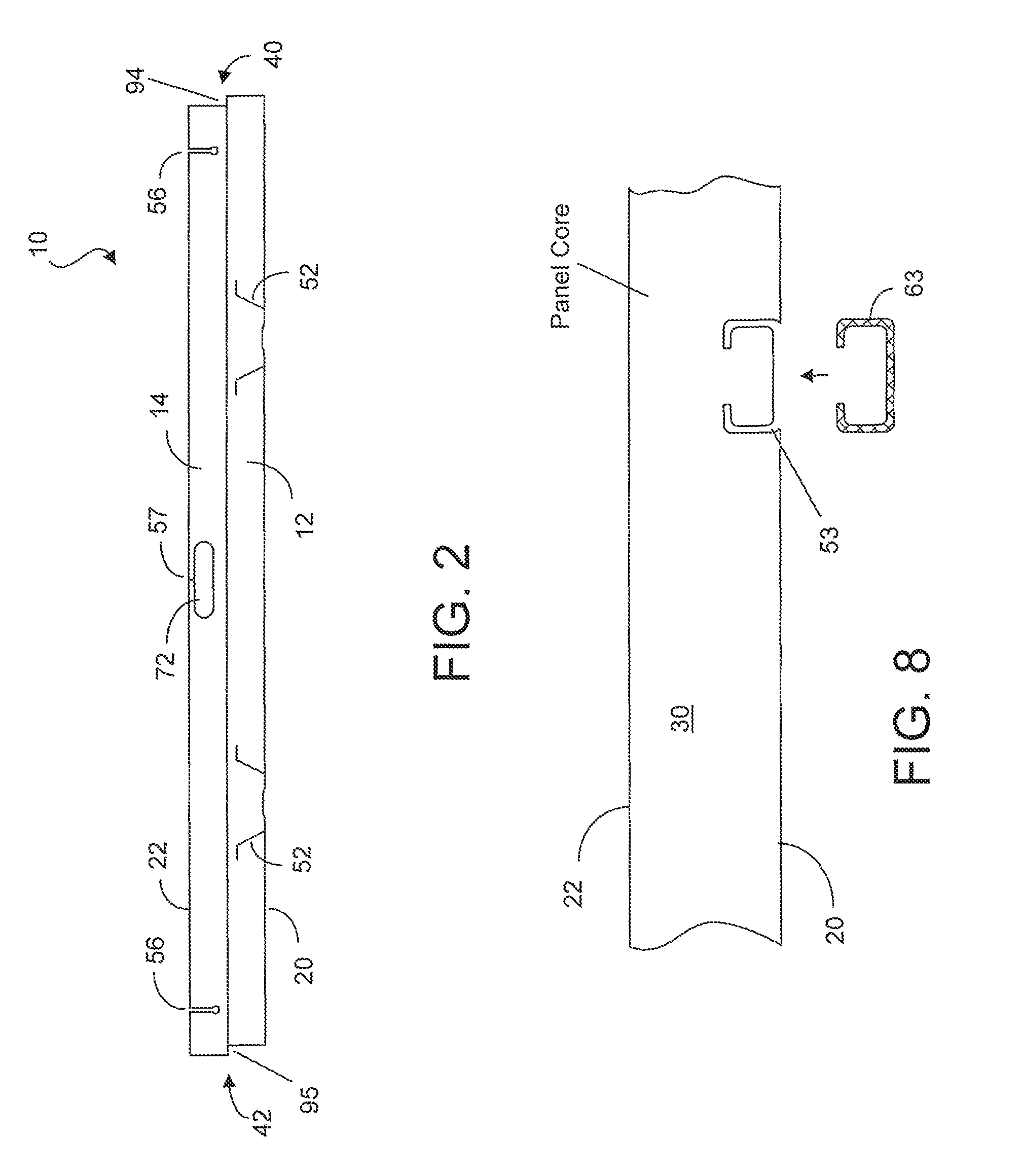

Method and apparatus for manufacturing a trailer wall and wall formed thereby

A method for manufacturing a trailer wall includes welding wall members together on a work surface while pressing the wall members with a rotatable roller toward the work surface and cooling the wall members adjacent points of welding there between to reduce bowing of the wall members related to heat created in the wall members by the welding. A related apparatus includes a movable welding unit having a welding tip for welding a pair of wall members together at a plurality of locations while on a work surface. A rotatable roller is pivotally mounted on the welding unit for applying pressure to the wall members toward the work surface adjacent the welding tip while rolling along the wall members. A cooling unit moves liquid or gas coolant to provide the cooling effect. Preferably, the wall members are hollow shiplap panels and the coolant passes through the hollow panels.

Owner:MAC TRAILER MFG

Rig mat sprayed with polyurea systems

A containment mat generally including matting tiles and a polyuria / polyurethane coating. Matting tiles are preferably formed from composite recycled rubber and are arranged in a first layer and a second layer with overlapping edges forming a shiplap design. The polyuria / polyurethane coating is sprayed on the seams between matting tiles creating a solid containment mat. A rig mat system may include a rig mat and a sealed leak-proof containment berm made from geo-fabric and foam blocks that are encapsulated in the geo-fabric and sprayed with the polyuria / polyurethane coating. The area between the berm and the matting tiles creates a trough for containing liquids.

Owner:HILL JOEY R

Insulating roofing system for flat roofs

InactiveUS20060101777A1Improve drainageEasy and problem-free installationRoof coveringStrutsShiplapLap joint

A roofing system for a substantially flat roof structure is provided, including a central panel with a substantially concave surface provided with a through hole at the centre for engaging a drainage system of the flat roof, and a first row of panels assembled around the central panel. The row of panels includes tapered side panels interlocked to the sides of said the central panel and tapered corner panels interlocked with adjacent side panels. Optionally at least one further row of side and corner panels may be assembled around the first row of panels. The side and corner panels are shaped so as to retain a constant slope to direct water away from their outside edges towards the through hole of the central panel. The panels are interlocked using a system with shiplap joints.

Owner:LES PROD CHIMS DE TOITURE FRANSYL +1

Fluorescent test paper strip capable of simultaneously testing newcastle disease and bird flu virus and application thereof

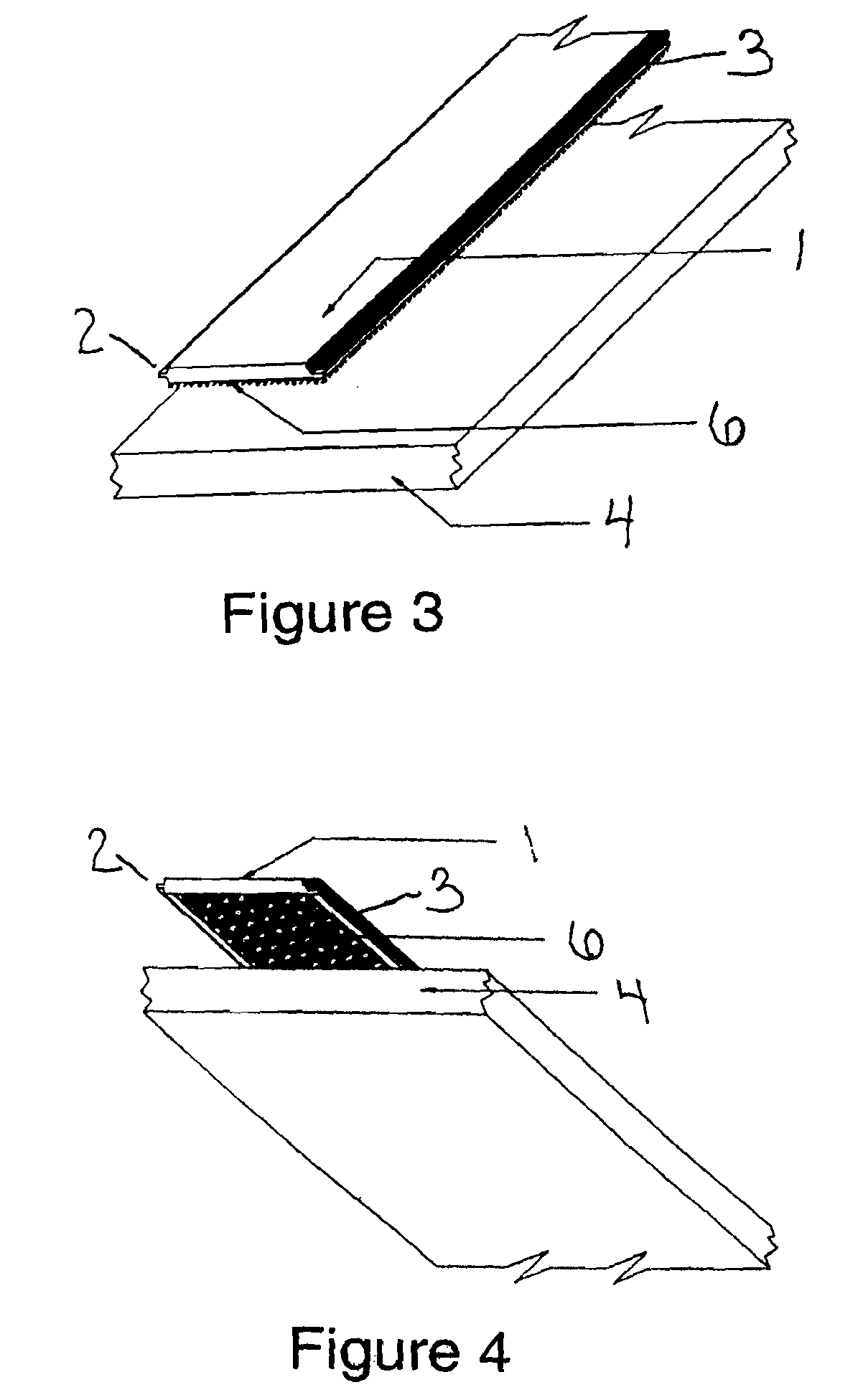

The invention provides a fluorescent test paper strip capable of simultaneously testing newcastle disease and bird flu virus, belonging to the technical field of animal epidemic disease diagnosis and test methods. The fluorescence labeled test paper strip comprises a sample mat, a combination mat, a nitrocellulose membrane, a absorbent mat and a PVC back lining, wherein the sample mat, the combination mat, the nitrocellulose membrane and the absorbent mat successively adhere to the PVC back lining, a shiplap joint is arranged between the combination mat and the nitrocellulose membrane, a shiplap joint is arranged between the nitrocellulose membrane and the absorbent mat; the combination mat is coated with newcastle disease monoclonal antibody-fluorescent label and bird flu virus monoclonal antibody-fluorescent label, and the nitrocellulose membrane is separately coated with two detection lines composed of newcastle disease monoclonal antibody and bird flu virus monoclonal antibody and a quality control line composed of goat anti-rat IgG. The test paper strip of the invention can be used to simultaneously test two viruses so as to realize the test method capable of testing many viruses in one step, and has the advantages of strong specificity, high sensitivity, short test time (20 minutes), simple operation, etc.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Insulating wall panel with electrical wire chase system

ActiveUS8978325B2Reduce sound transmissionConstruction materialElectrical apparatusCement boardShiplap

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

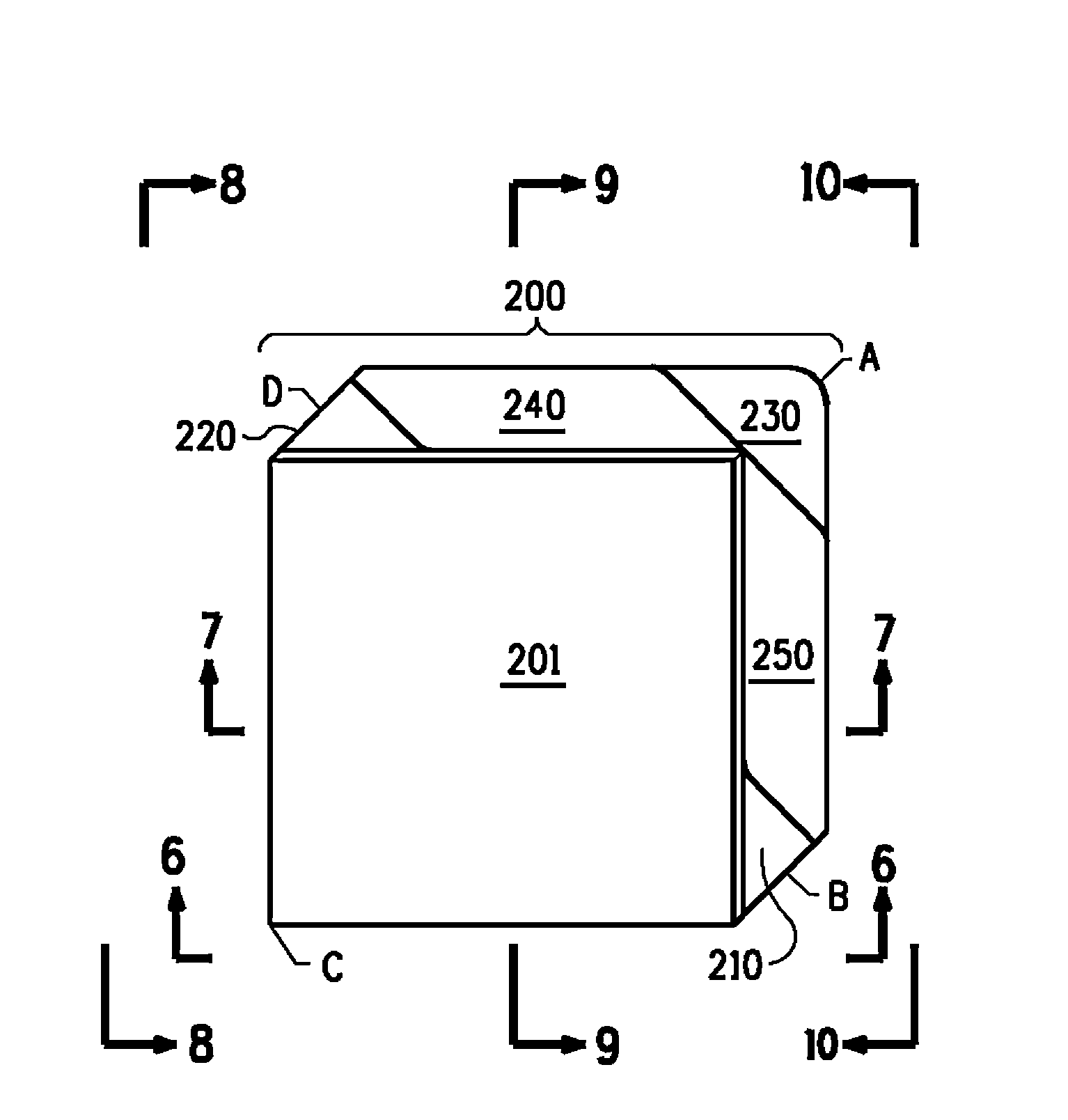

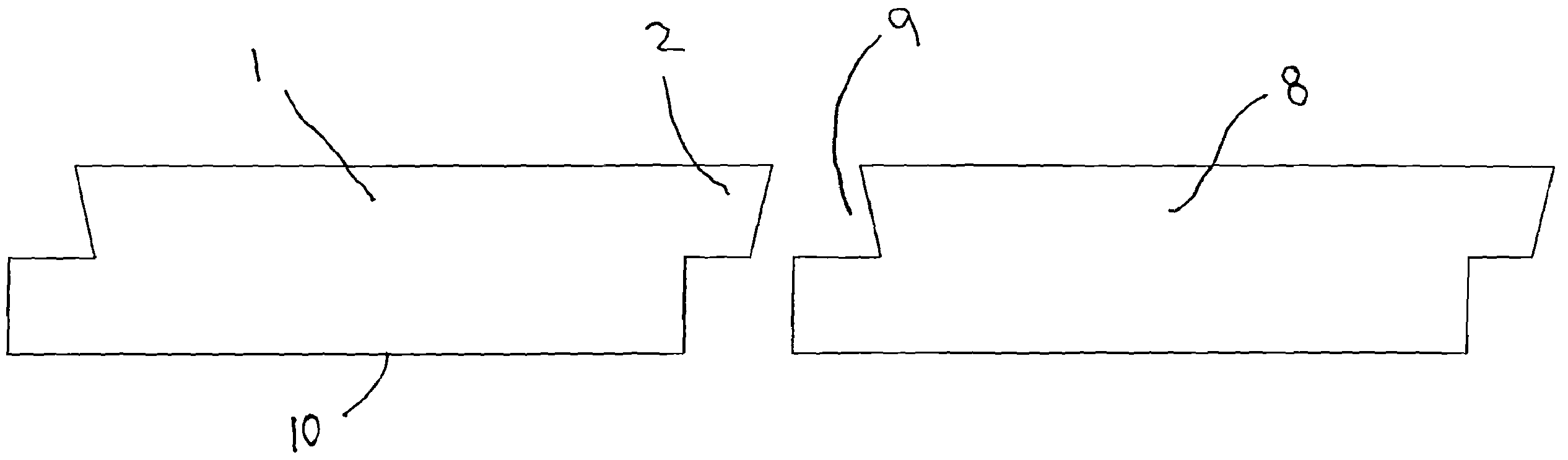

Shiplap joint

A building panel having improved shiplap joints to provide complete coverage with while providing for panel expansion and contraction. The building panel includes an overlap adapted to overlie a back portion of the backface of one or more panels laid up in the next higher course. Alternate corners of the building panels have centerlaps portions formed at a plane central to the thickness of the building panel that fit between the space defined by the front overlap and the backunderlap. The centerlaps mate to fill gaps that would otherwise open when the building panels expand and contract.

Owner:EI DU PONT DE NEMOURS & CO

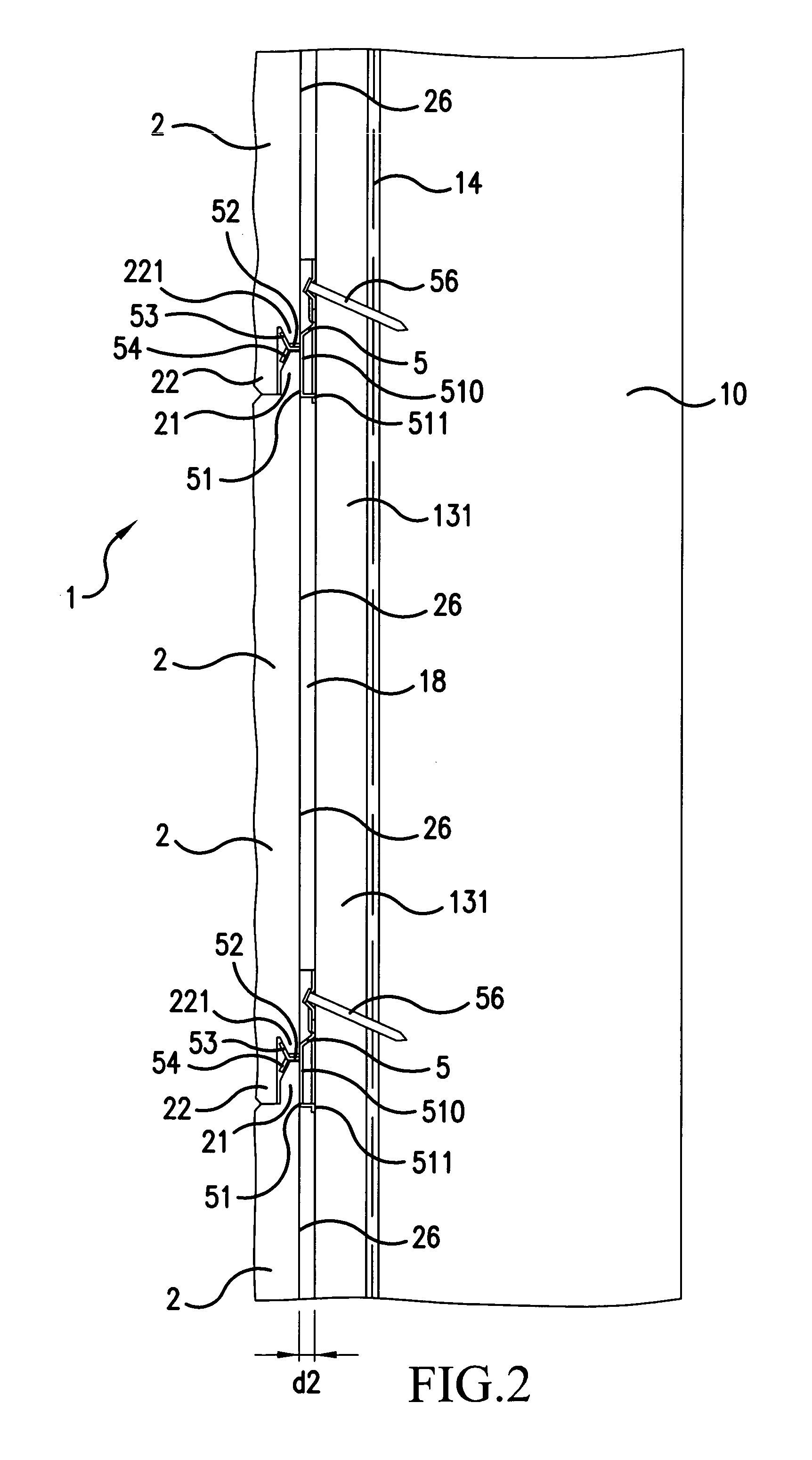

Fastening member and external wall construction structure

A fastening member is formed out of one steel sheet to comprise: a base plate portion constituting amount portion to be fixed to a building frame; a right support portion, a left support portion, a central support portion and a lower support portion that fix stably the exterior wall boards; a central horizontal raised portion and a downwardly bent portion that lock shiplap portions of an exterior wall board disposed below the fastening member; bearing portions and upper-board locking portions that lock the shiplap portions of exterior wall boards that are disposed above the fastening member; upwardly bent portions; and front plate portions. A waterproof material made of bentonite is provided at the left and right ends of the central horizontal raised portion, the top surfaces of the upwardly bent portions and the front surfaces of the front plate portions.

Owner:NICHIHA CORP

Meter cover molding and method

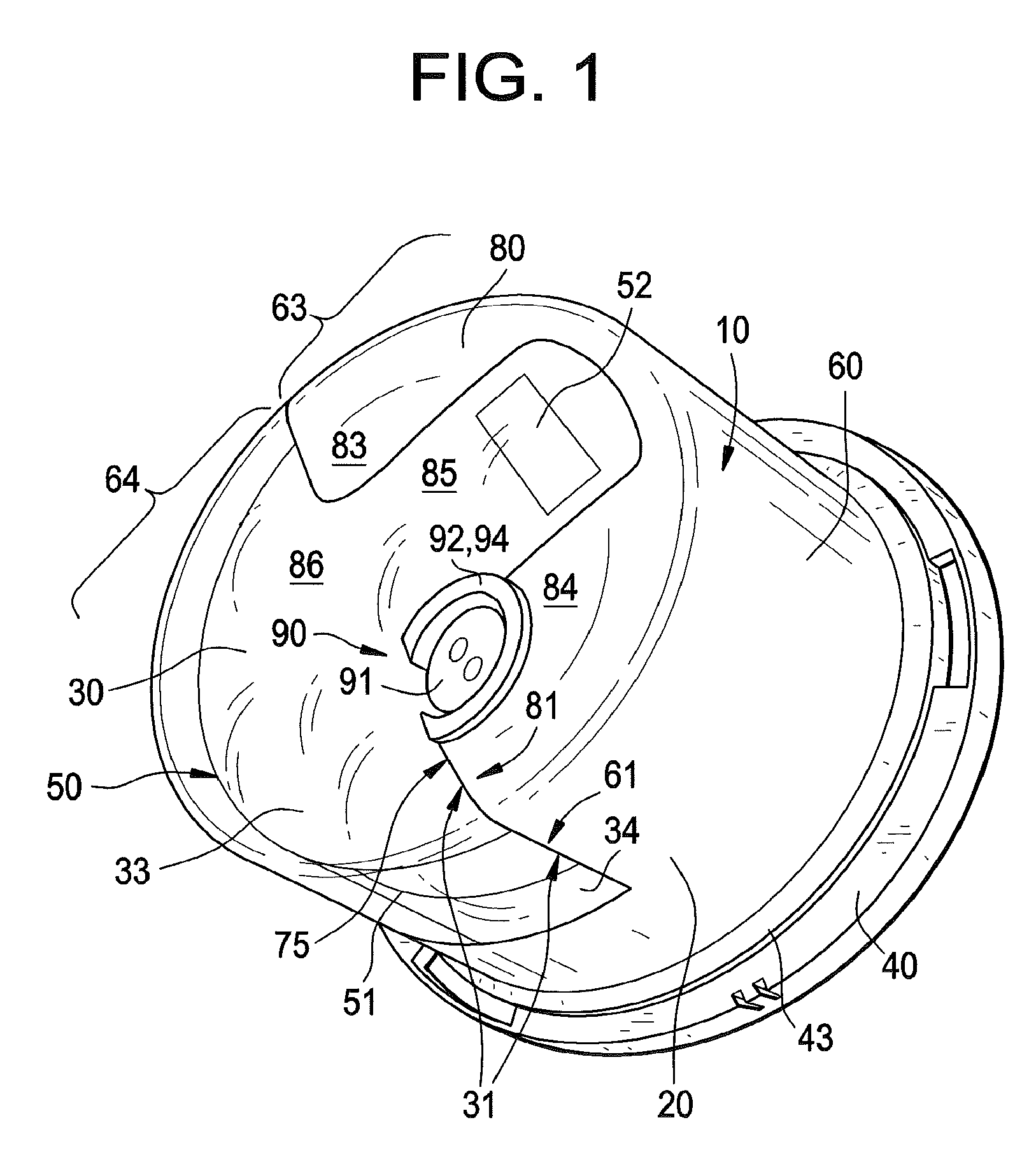

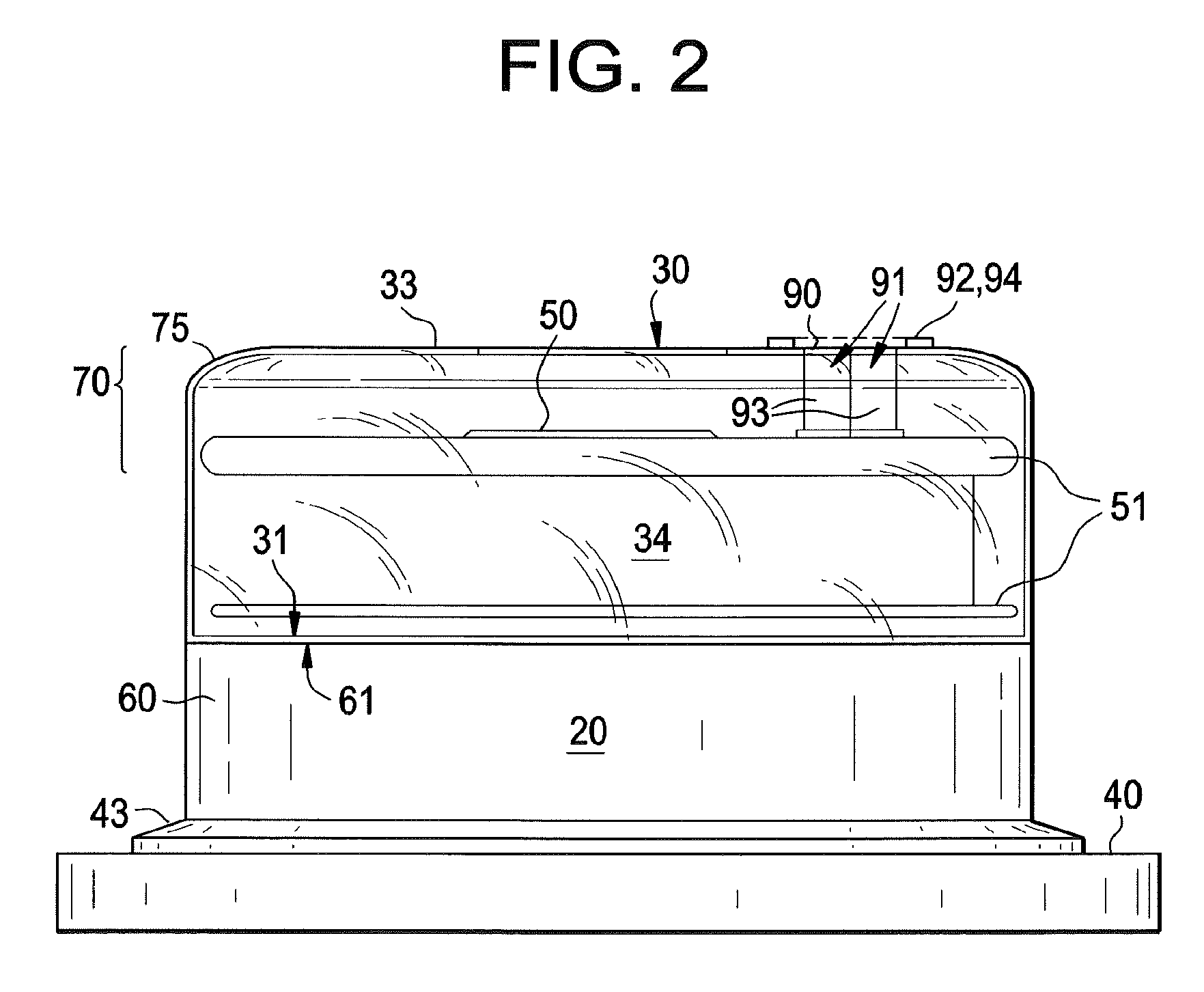

A meter cover is provided and includes an opaque portion, including an outer perimeter section to perimetrically fit around a meter, a sidewall extending axially from the perimeter section toward a frontal region and a shield disposed at a portion of a sidewall edge at the frontal region and a transparent portion having an edge, which is shiplap joint bonded with a remaining portion of the sidewall edge and edges of the shield.

Owner:ACLARA METERS LLC

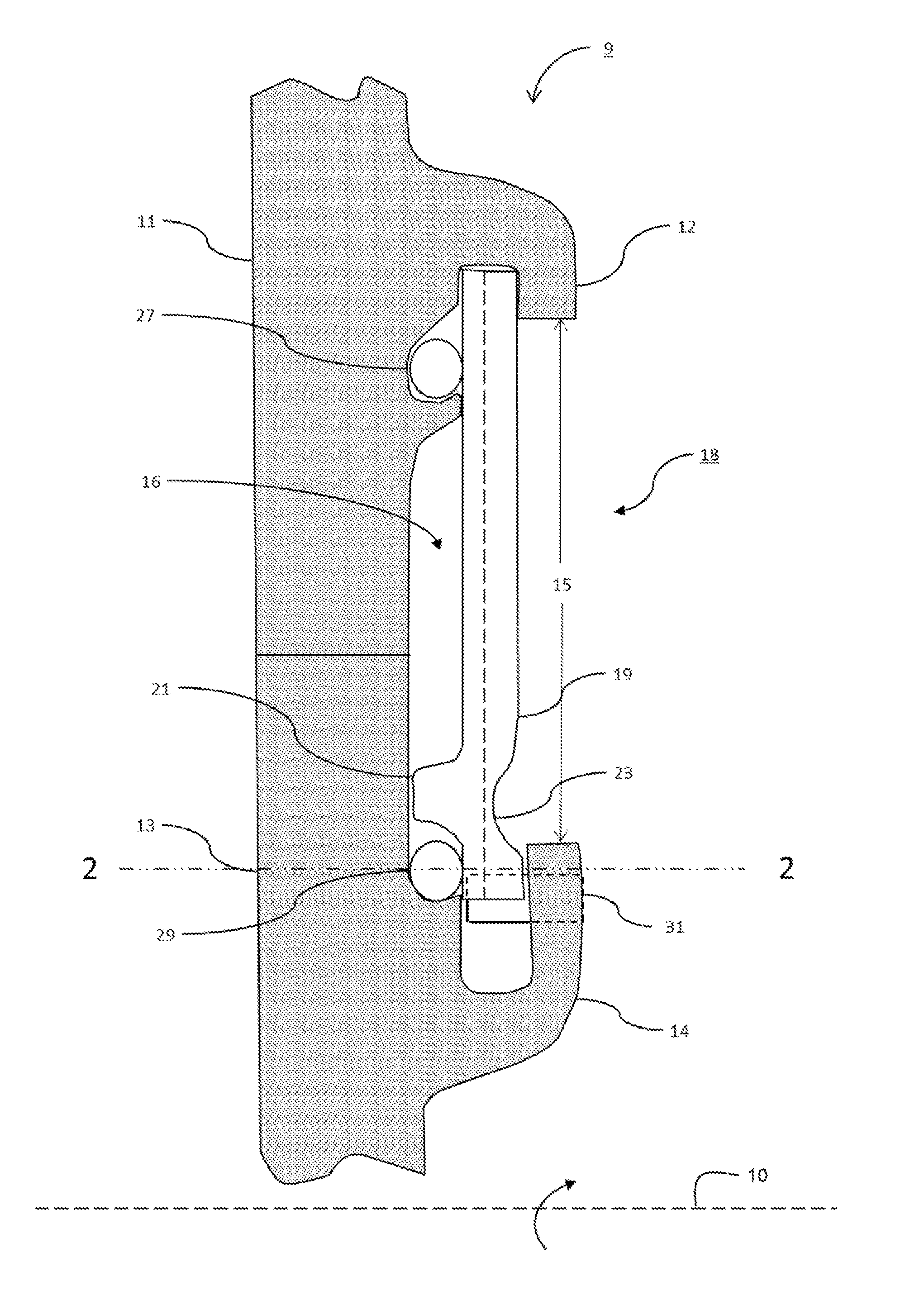

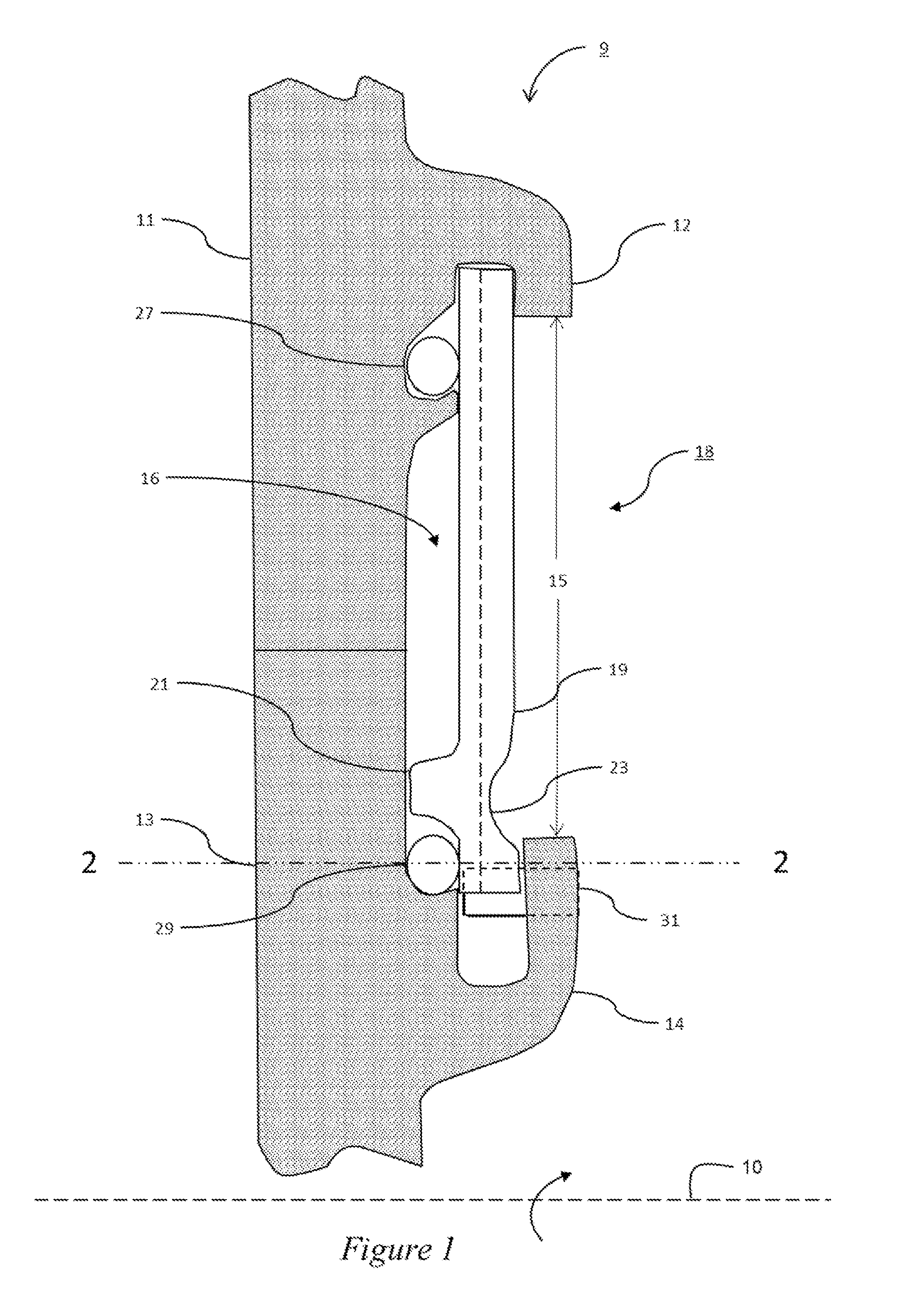

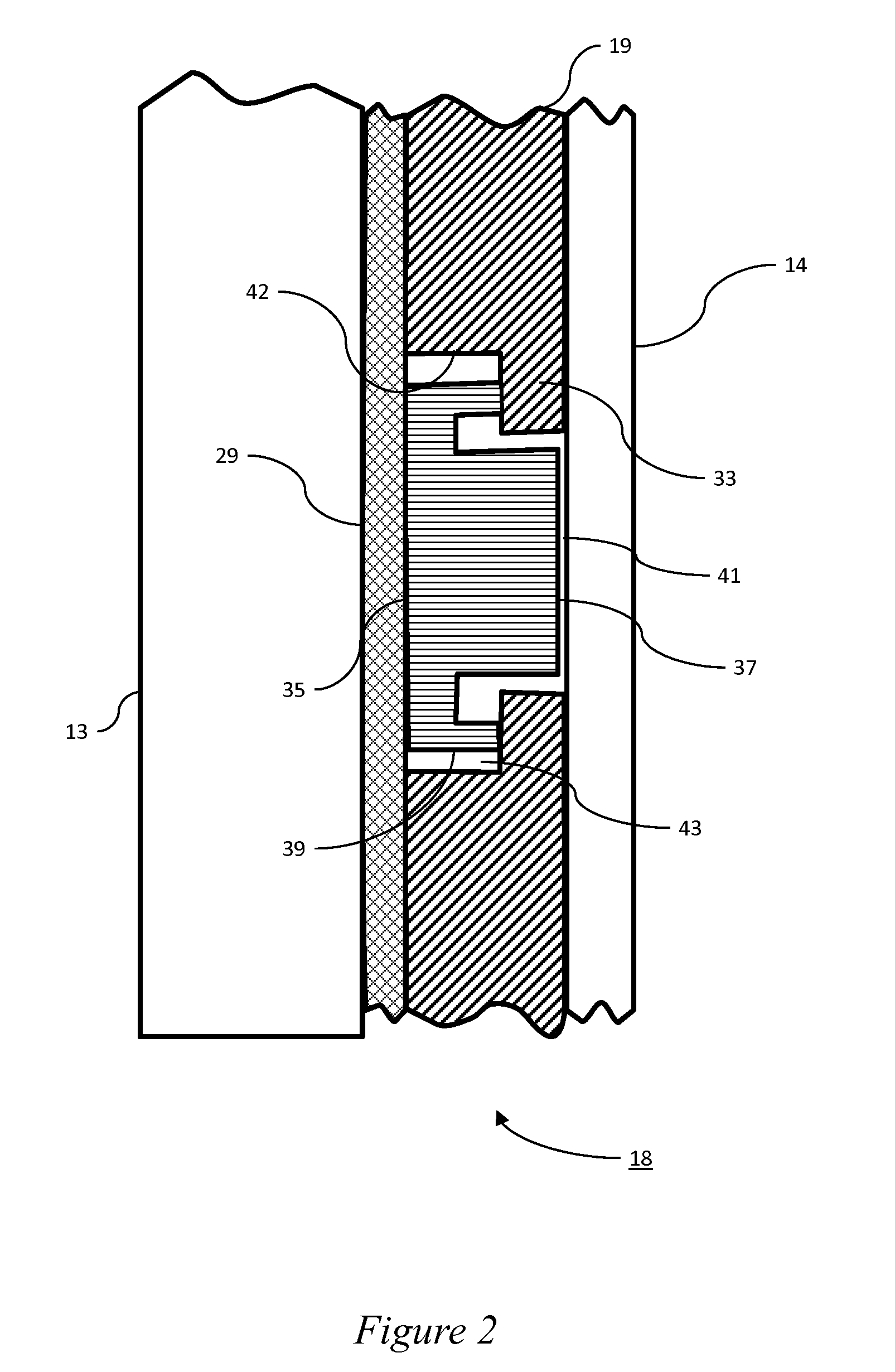

Turbine nozzle segment cantilevered mount

A turbine nozzle segment includes at least one hollow airfoil extending radially between radially outer and inner band segments, a clockwise open hook on a clockwise end at an aft end of the outer band segment, and counter-clockwise open hook on a counter-clockwise end at the aft end of the outer band segments. An exemplary embodiment of the turbine nozzle segment includes a load stop extending radially outwardly from the outer band segment. At least one aftwardly facing load face is at the aft end of the nozzle segment at the outer band segment. The clockwise open hook is C-shaped and the counter-clockwise open hook is a shiplap hook. Another embodiment of the turbine nozzle segment has only one hollow airfoil with an airfoil wall surrounding a bifurcated cavity divided into forward and aft cavities by a bifurcating rib extending between pressure and suction sides of the airfoil wall.

Owner:GENERAL ELECTRIC CO

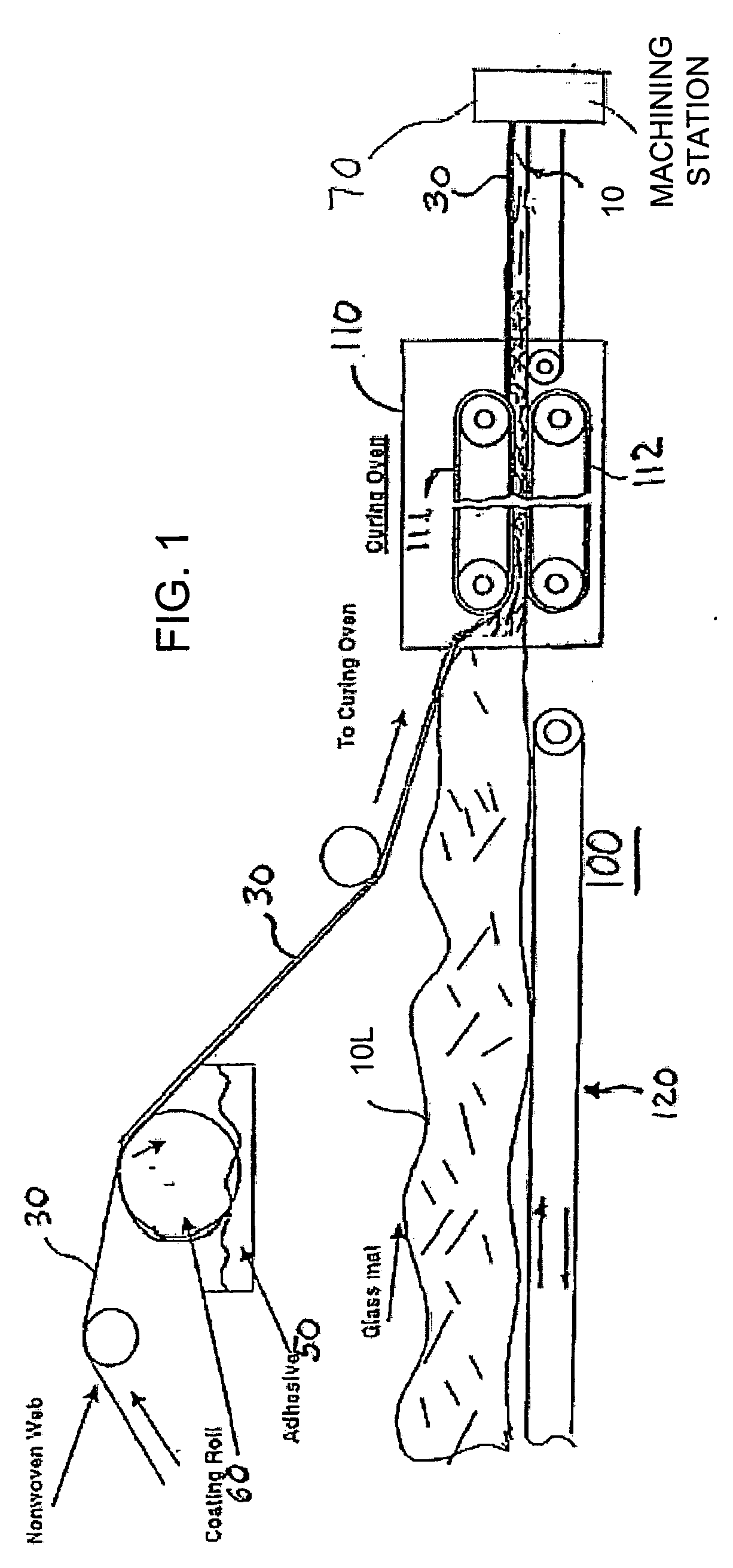

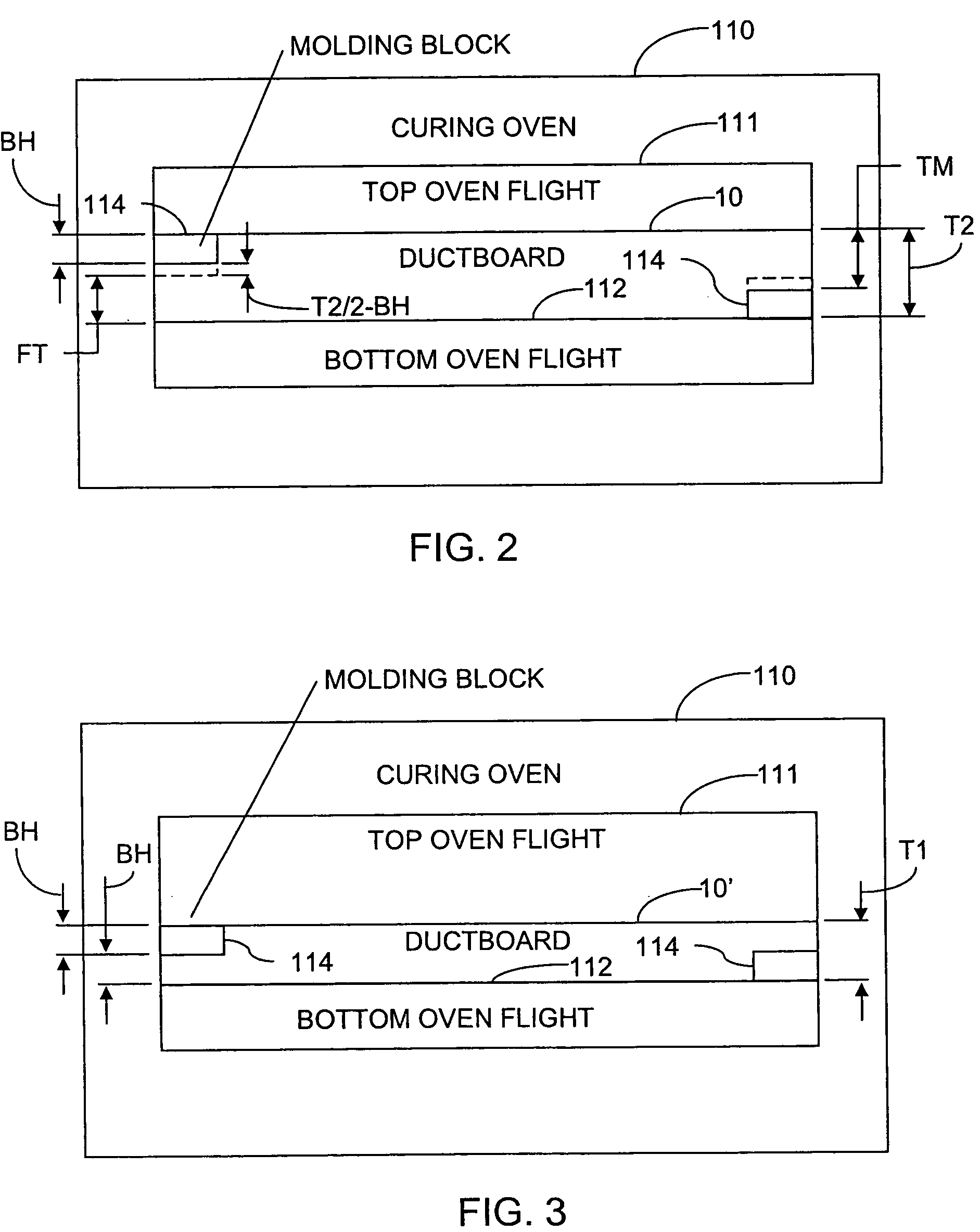

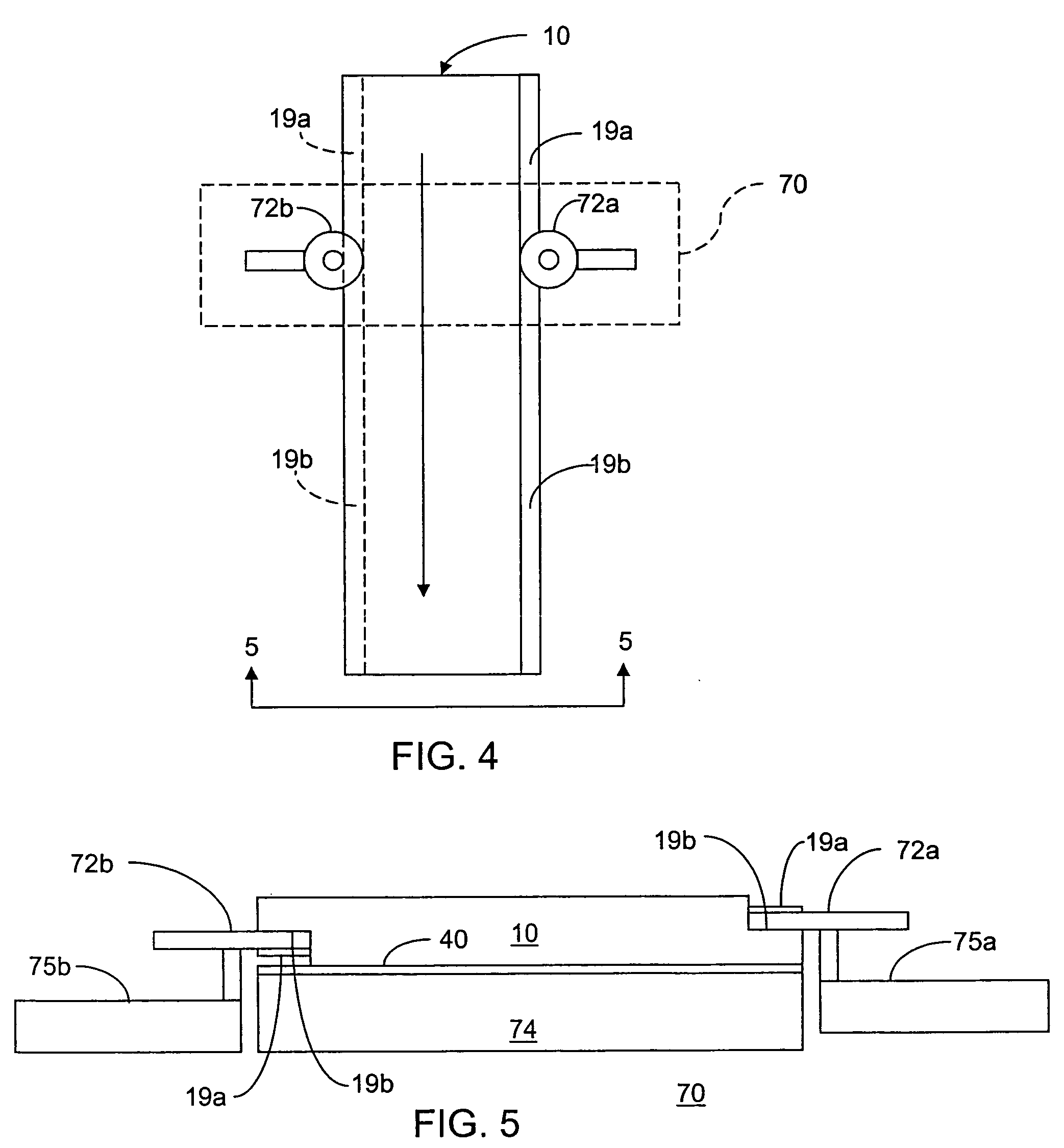

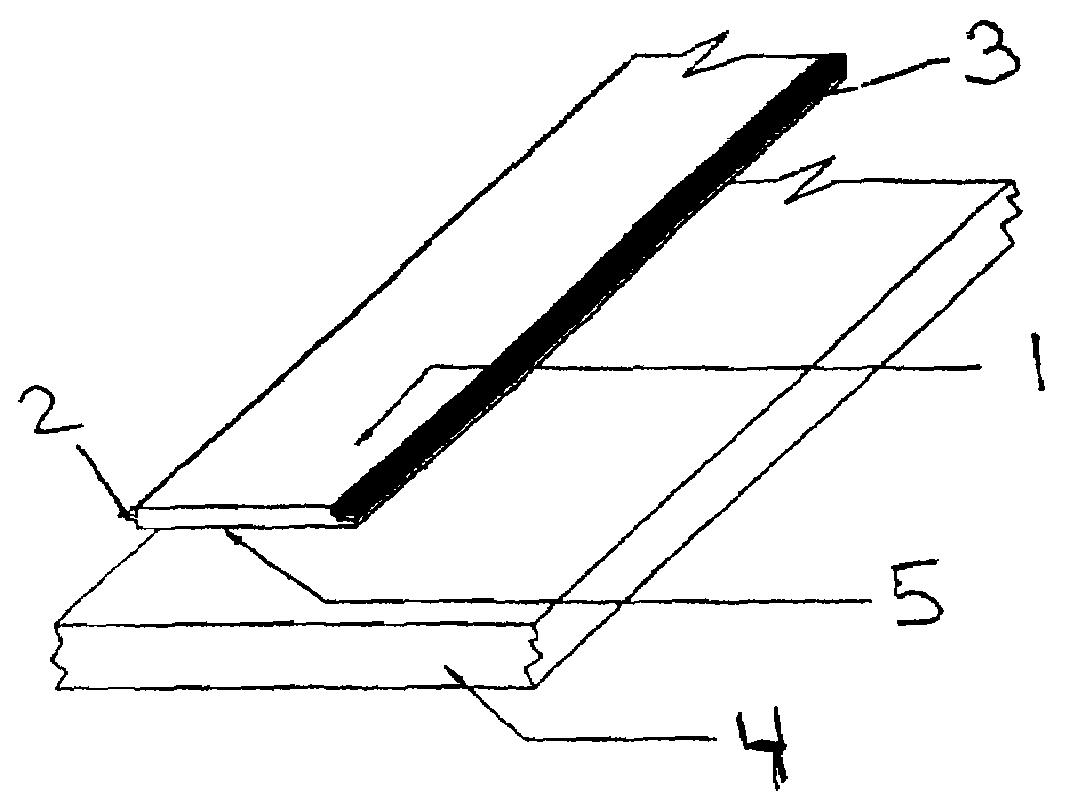

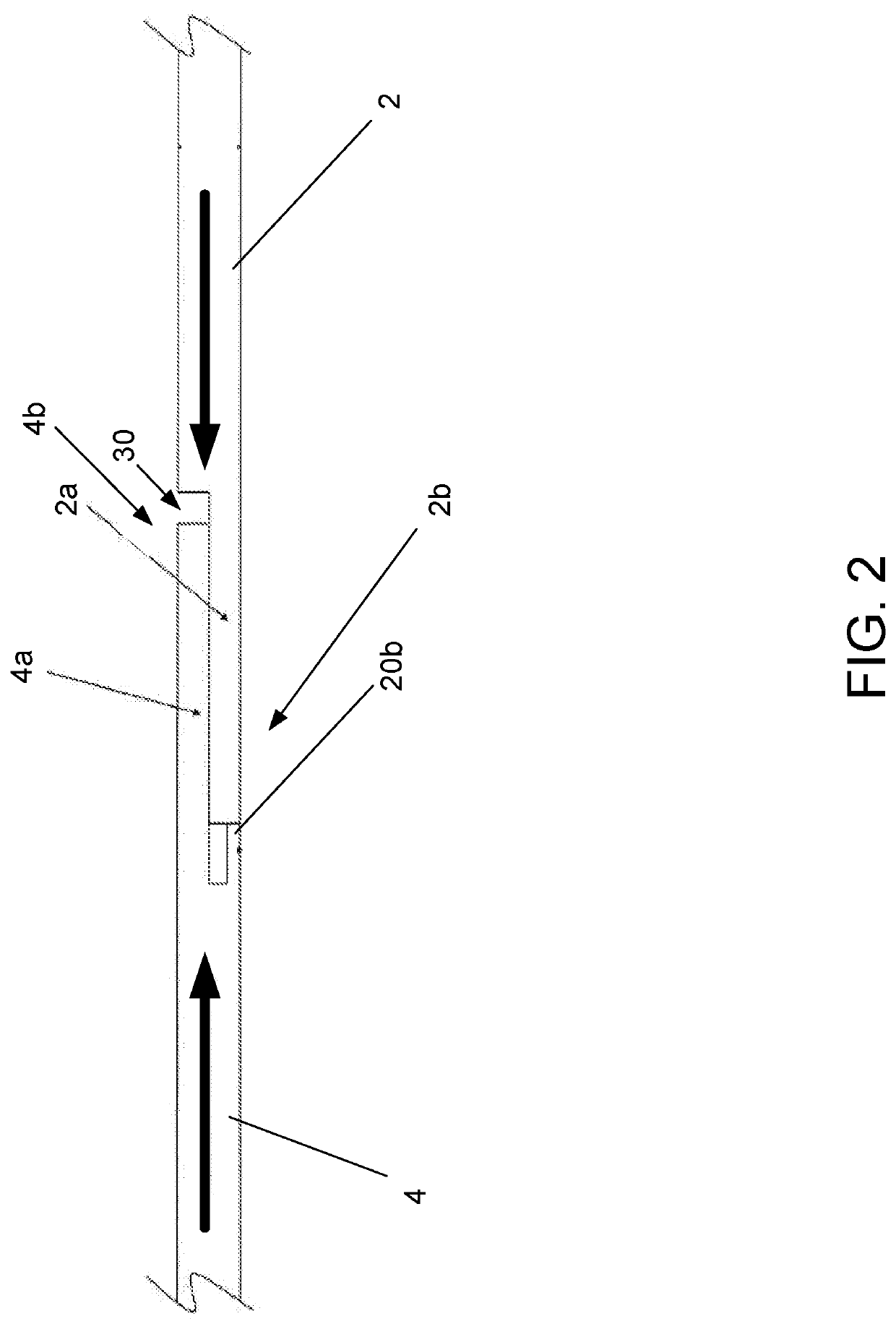

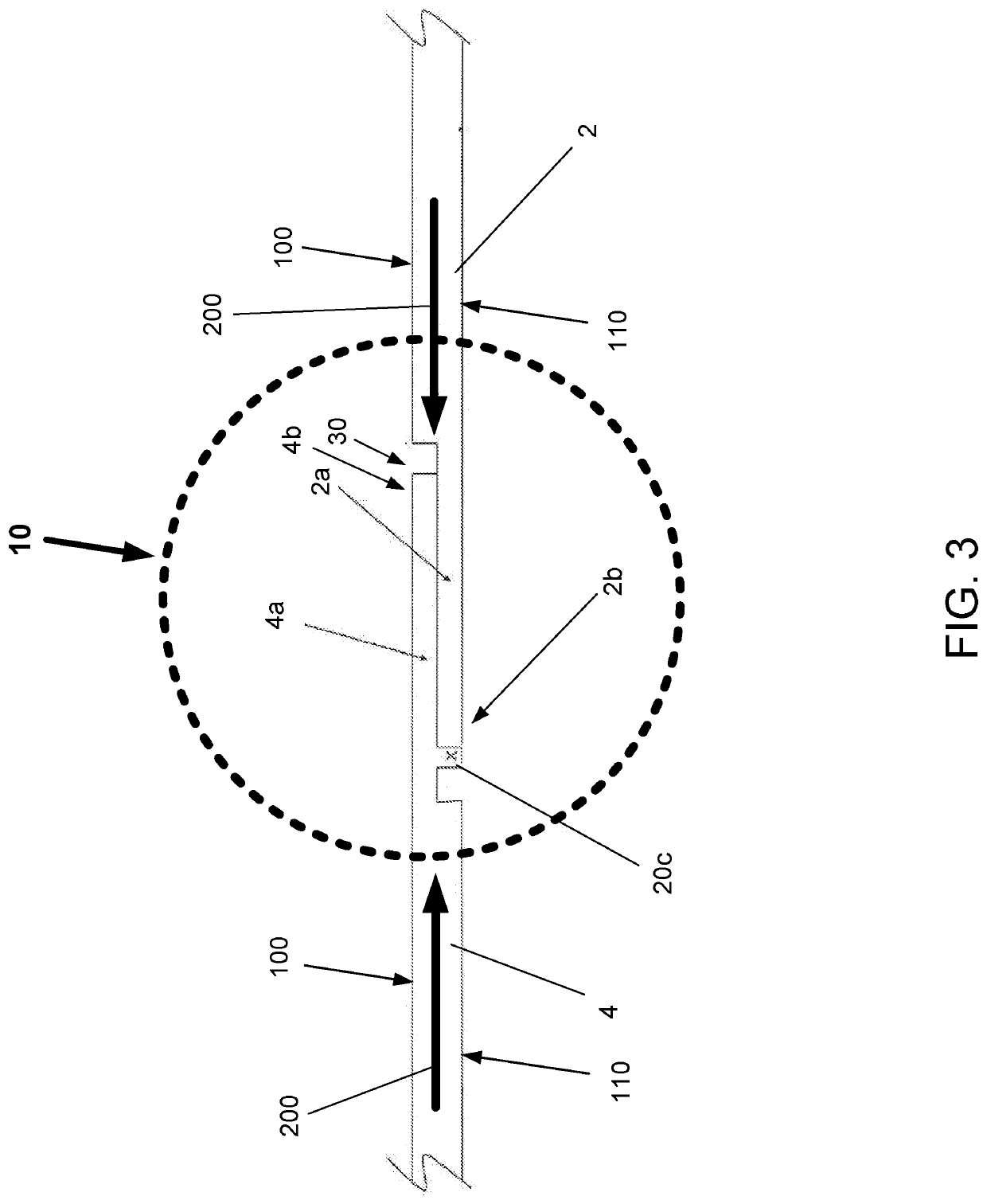

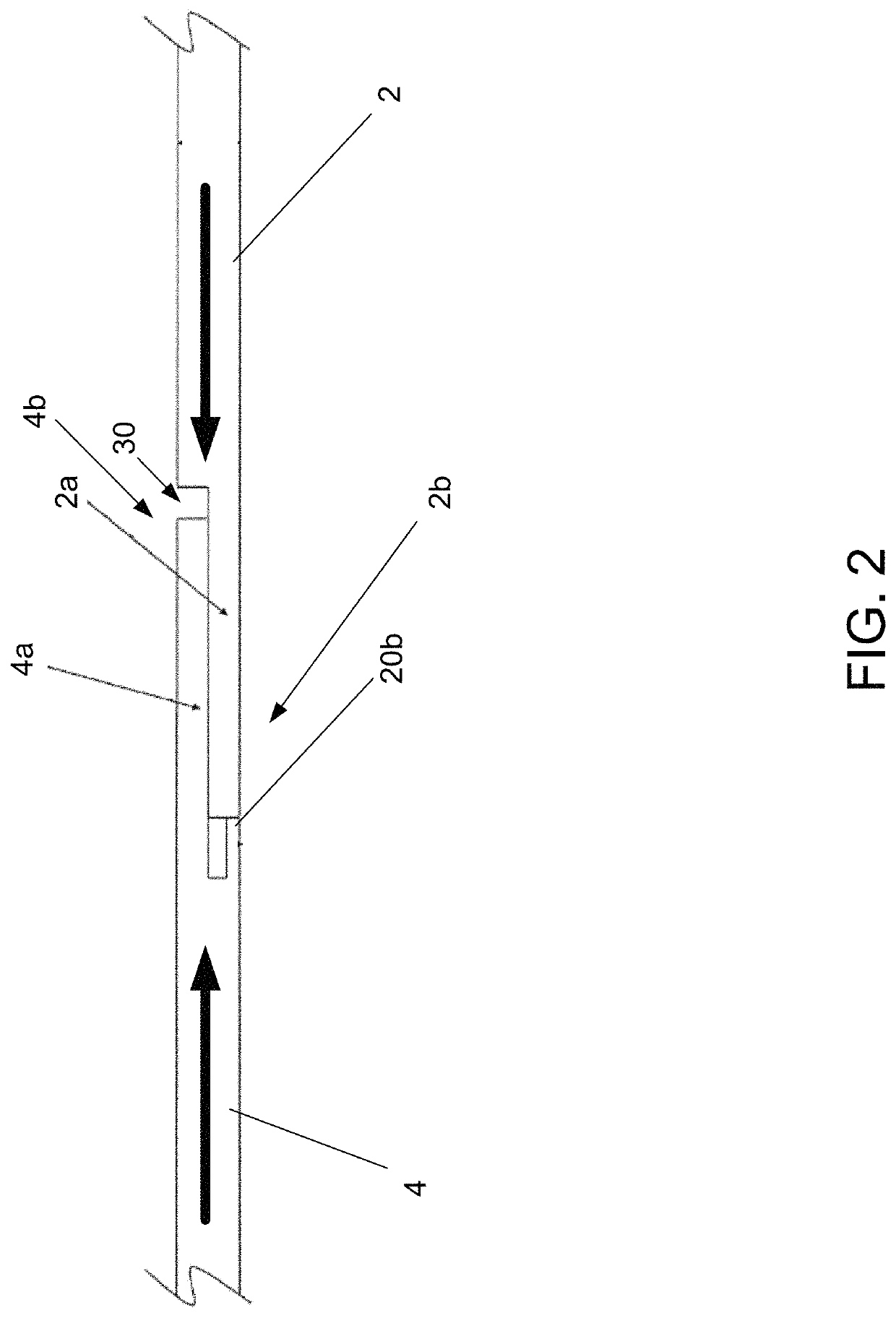

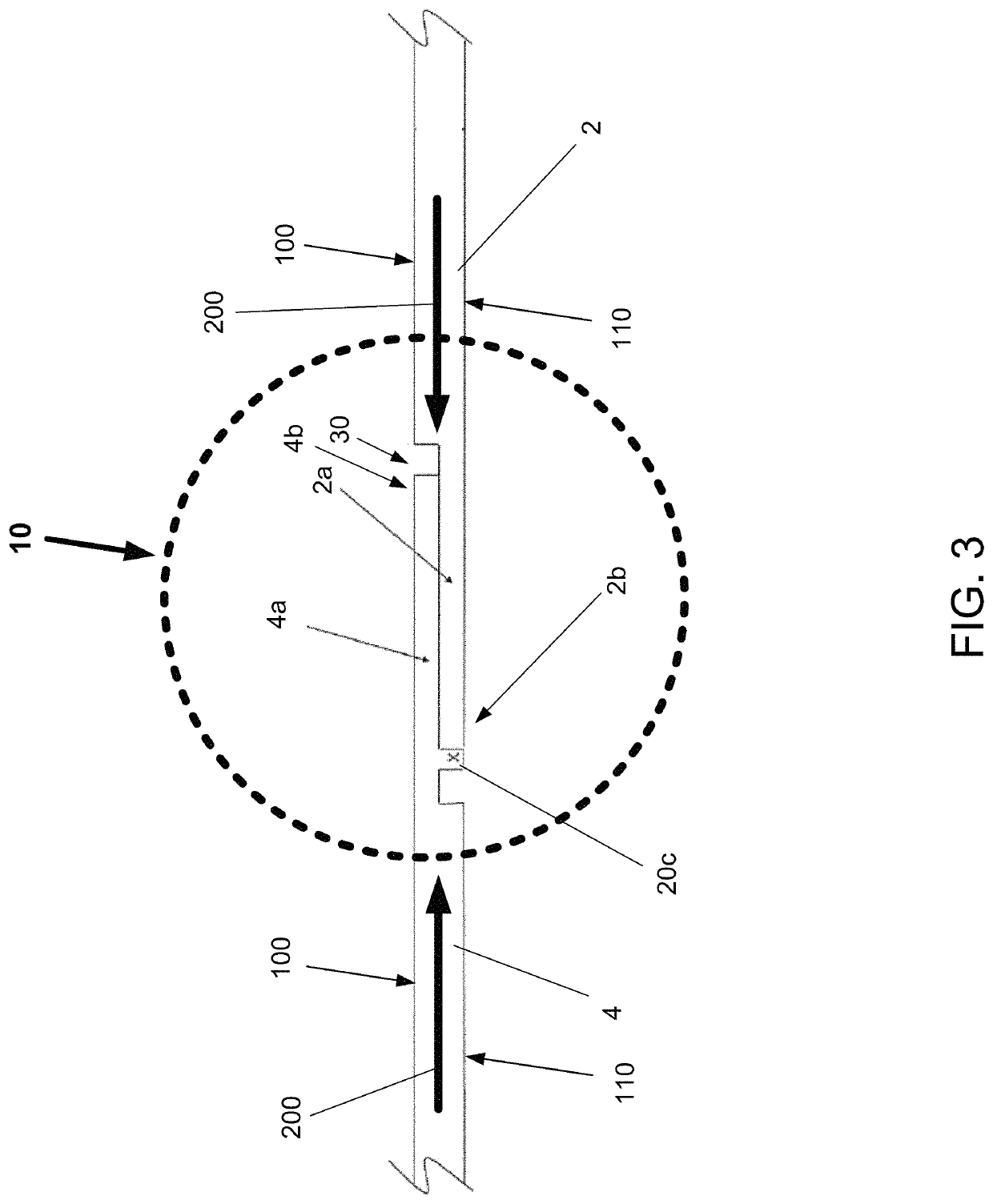

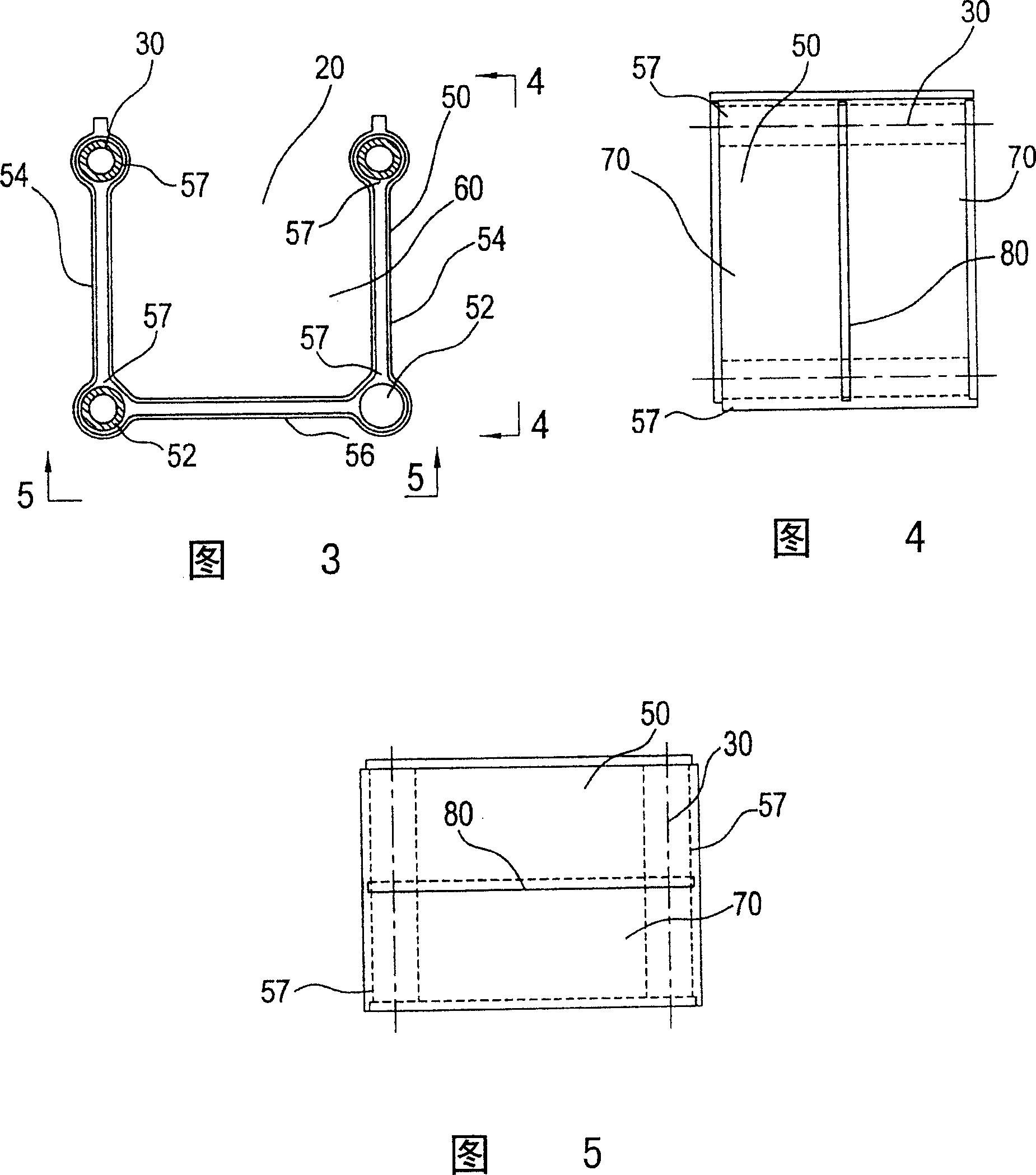

Method and apparatus for forming shiplap edge in air duct board using molding and machining

InactiveUS20050221061A1Lighting and heating apparatusCellulosic plastic layered productsFiberShiplap

A Method for forming a shiplap edge in a duct board comprises the steps of: molding a shiplap edge in a first duct made of mineral fiber or mineral wool, so that the molded shiplap edge has a molded edge thickness, and machining the molded shiplap edge to a desired machined edge thickness that is less than the molded edge thickness.

Owner:TOAS MURRAY S +3

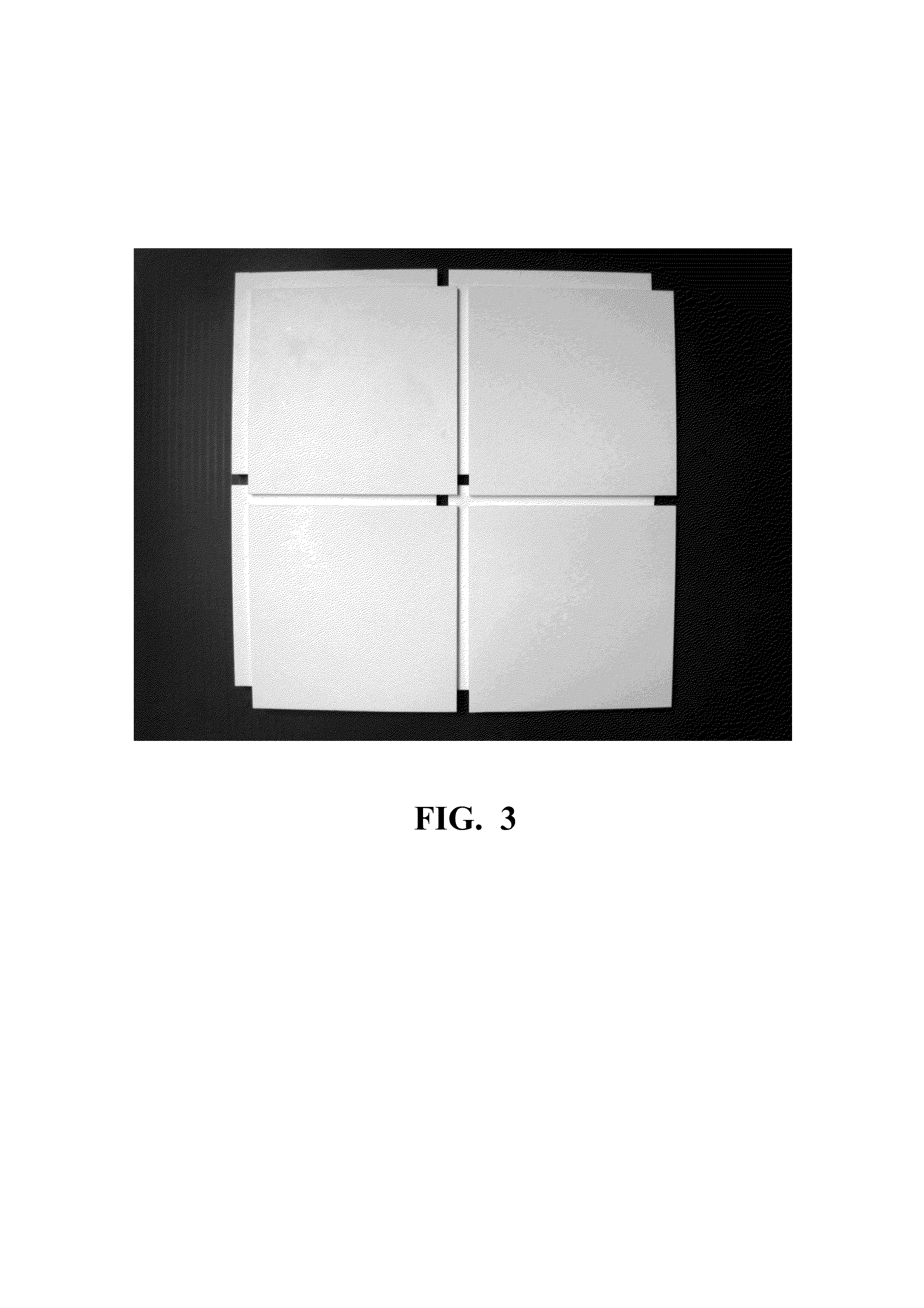

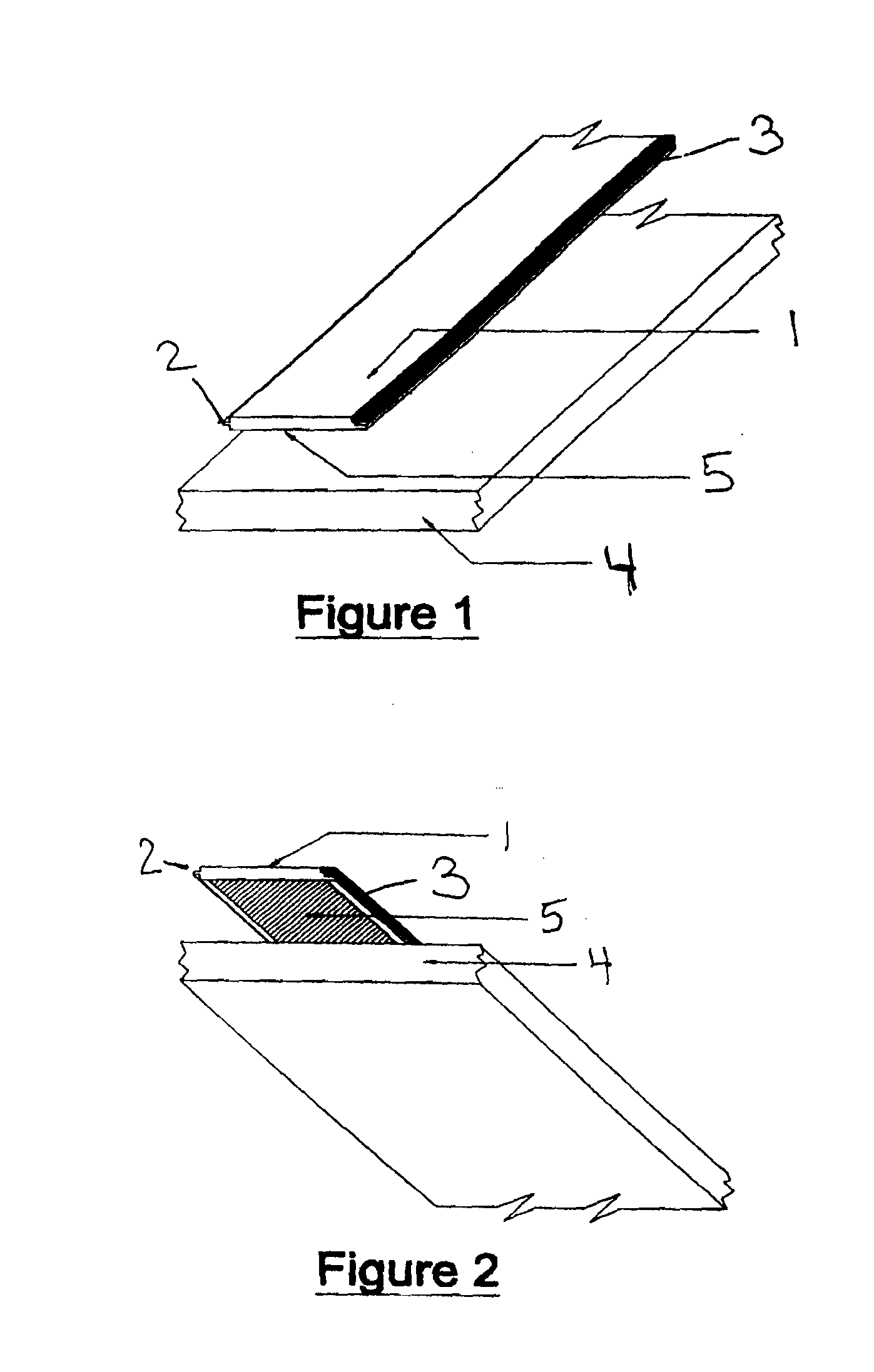

Simulated wood surface covering for decks and floors

ActiveUS7617791B2Easy to cleanImprove waterproof performanceNon-magnetic metal hullsWallsPlasticizerPolyvinyl chloride

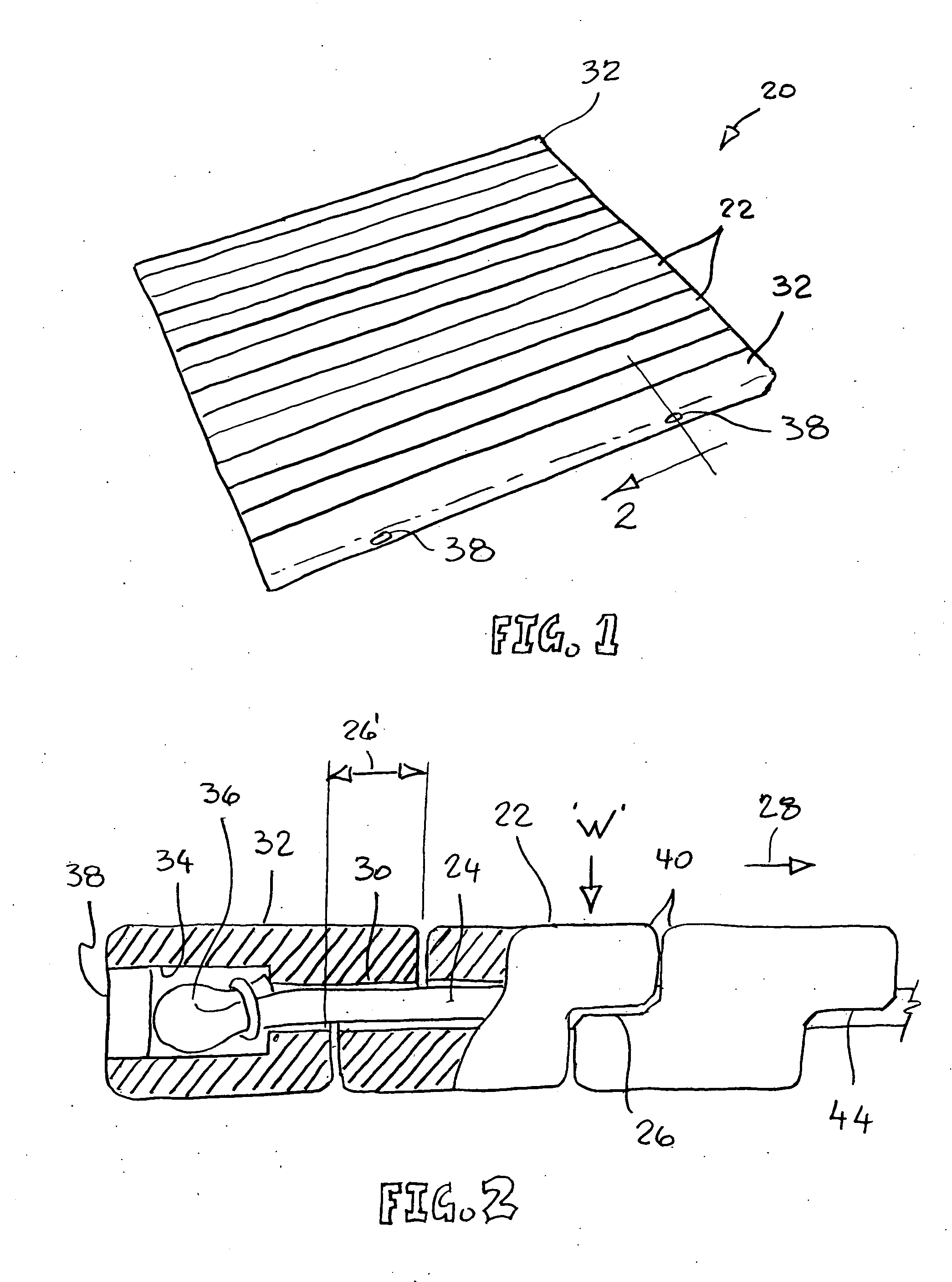

The present invention relates to a simulated wood surface covering which is particularly useful in decking and flooring applications, said simulated wood surface covering being comprised of strips adapted to be interconnected aside of each other thereby forming an assembled simulated wood surface covering of desired dimensions to cover a substrate, wherein the strips are adapted to be interconnected through shiplaps having tongues and rabbets, wherein the rabbets have an included angle which is within the range of 70° to 89°, wherein the strips are comprised of a plastic composition which is comprised of polyvinyl chloride, a non-migrating plasticizer, and a coloring agent, wherein the strips have sufficient flexibility to conform to curved surfaces and to surface irregularities, wherein the upper surface of the strips are roughened to imitate the grain structure of wooden material.

Owner:PLASTEAK

Self-spacing lap siding product

A lap siding product with a unique shiplap joint that spaces abutting pieces of siding correctly from each other without installer measurements. The shiplap joint comprises a bottom element and a top element. A lap siding panel or board has a bottom element shiplap joint at one end, and a top elements shiplap joint at the other end. The corresponding ends of two lap siding panels or boards (i.e., one bottom element and one top element) together form the unique shiplap joint of the present invention. An engineered “stop” on the underside of the top element spaces the pieces of siding correctly, without requiring measurement during installation. This also eliminates the need for caulk, pan flashing or joint covers in the joint between the pieces of siding or cladding. The shape of the joint also reduces the intrusion of water, and re-directs water down and out from behind the siding.

Owner:GANG NAIL SYST

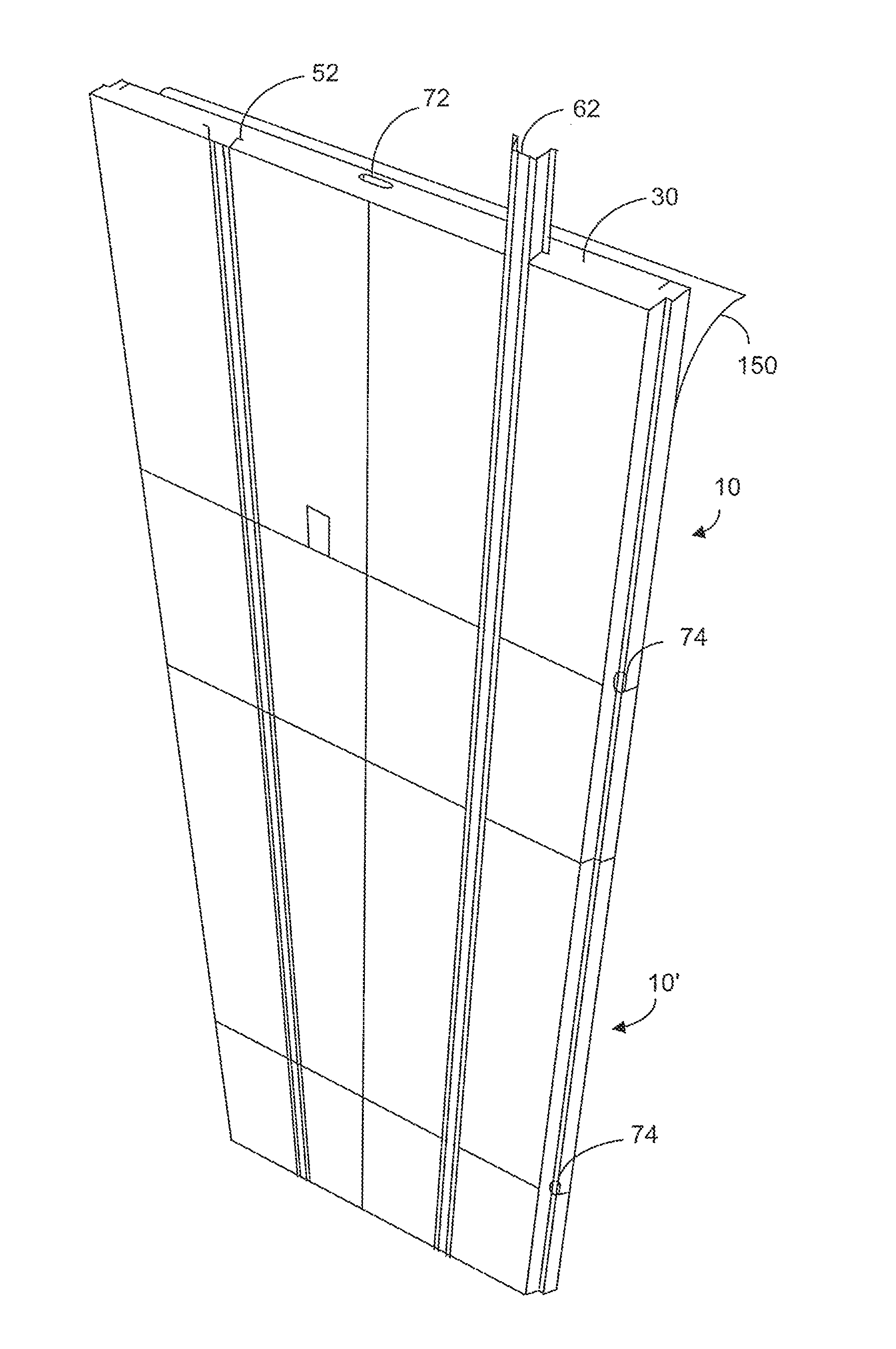

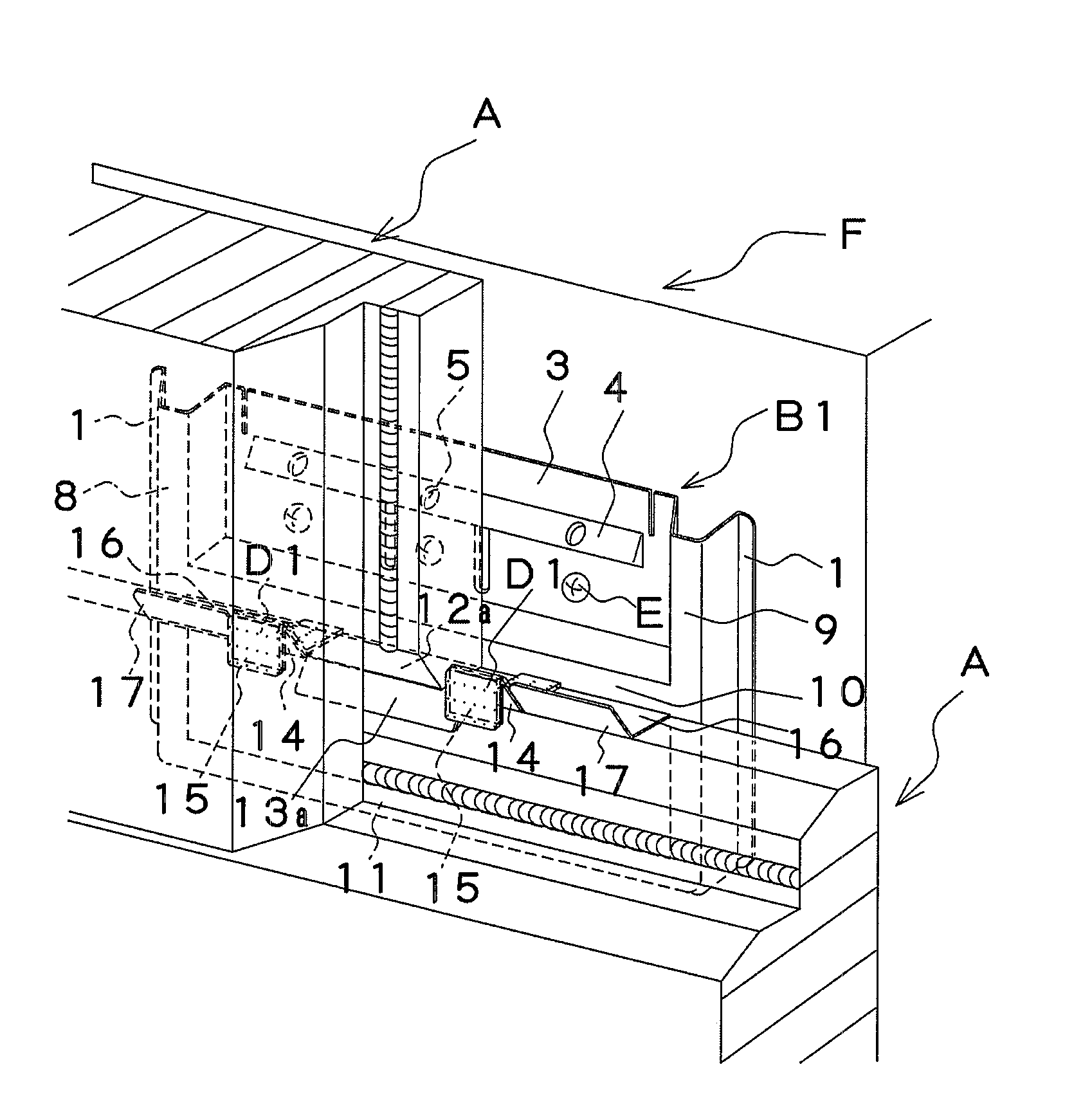

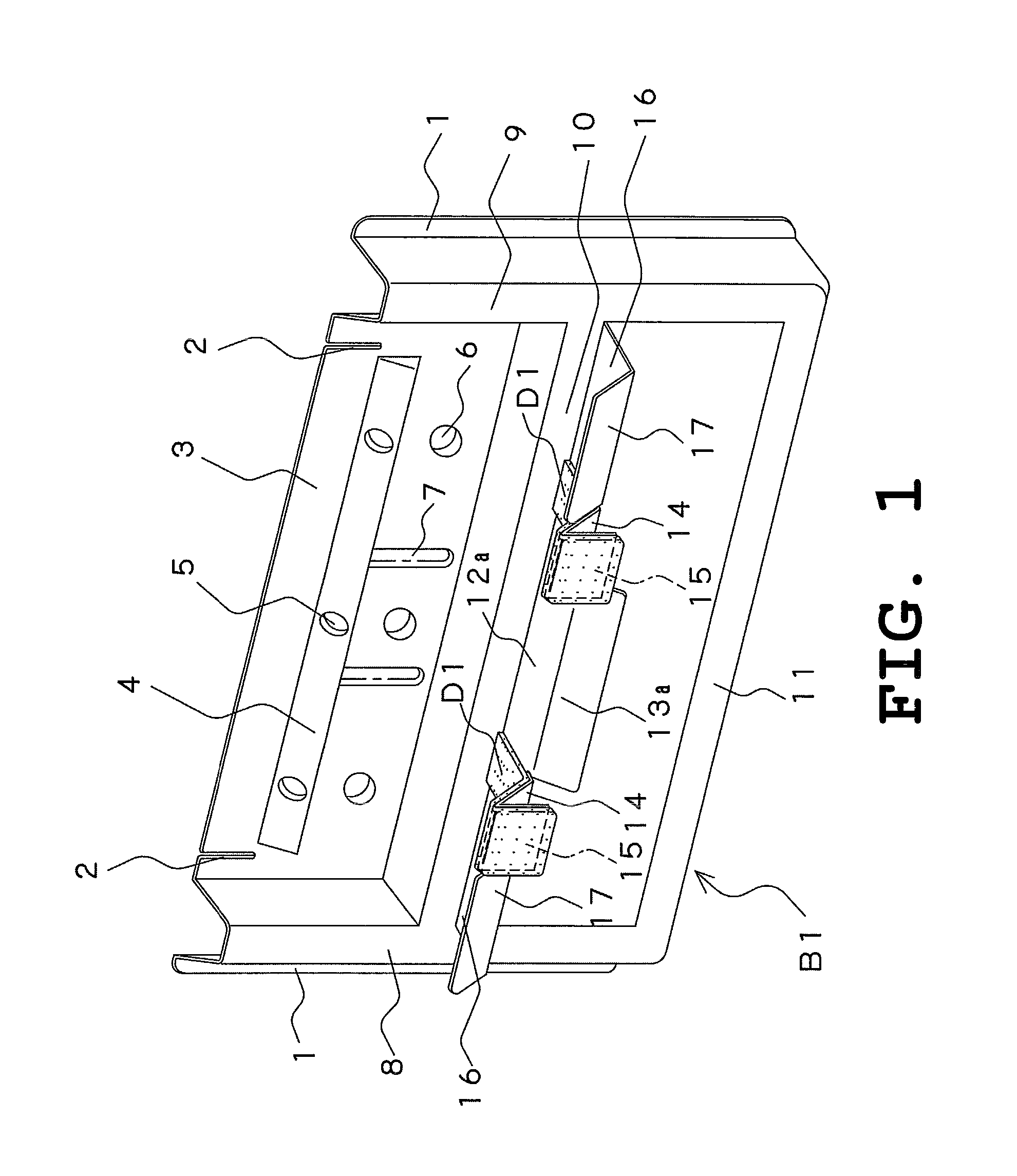

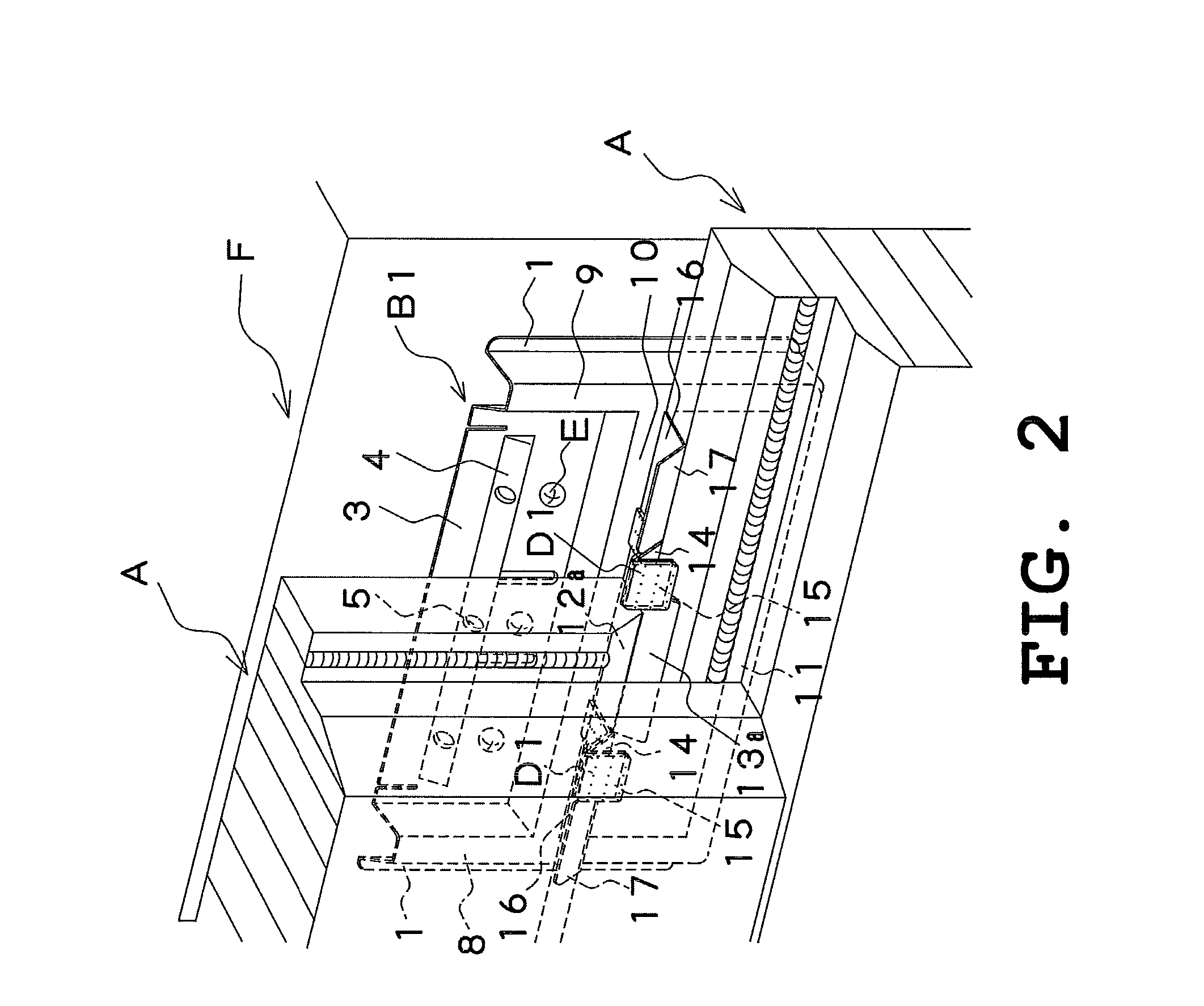

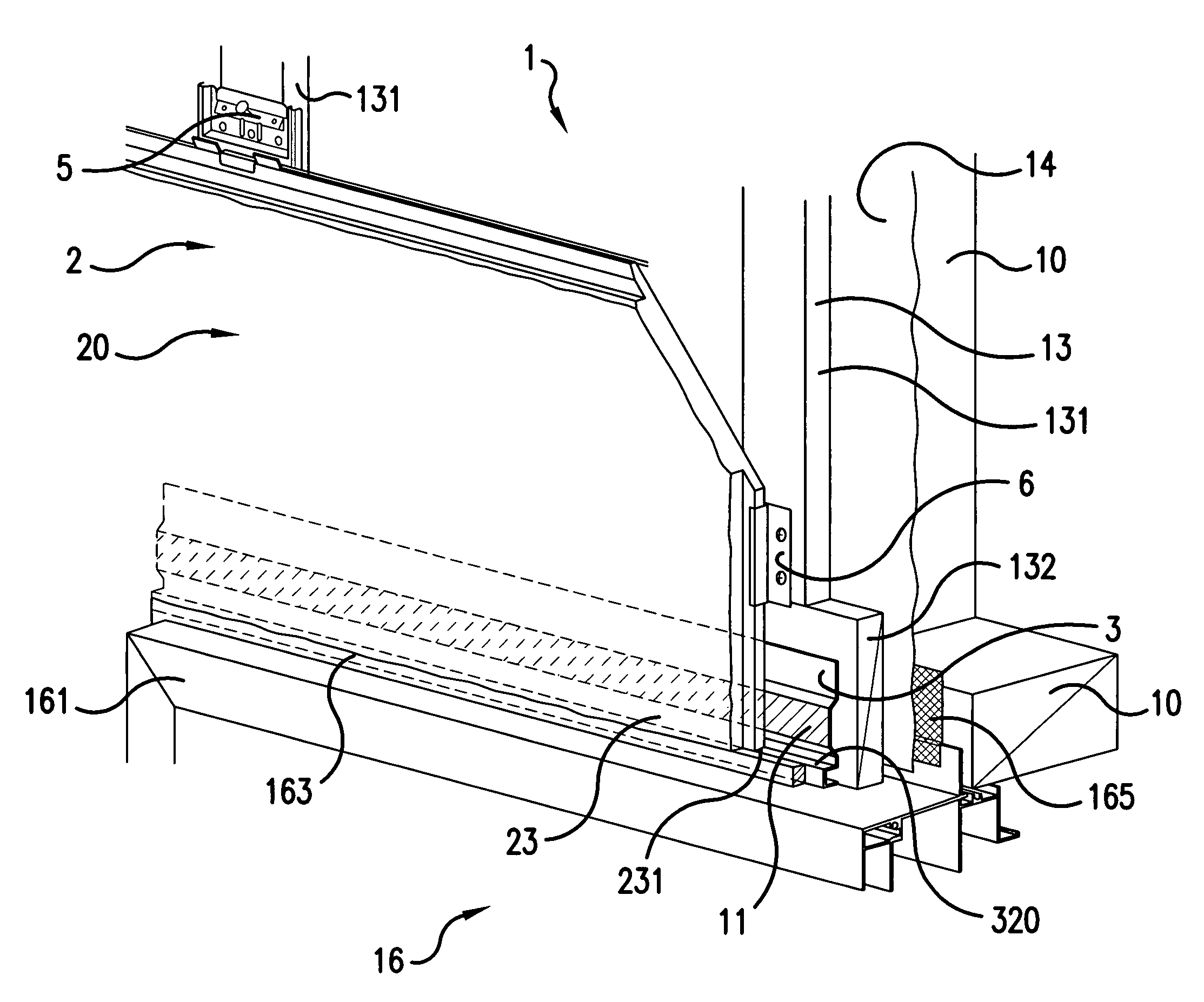

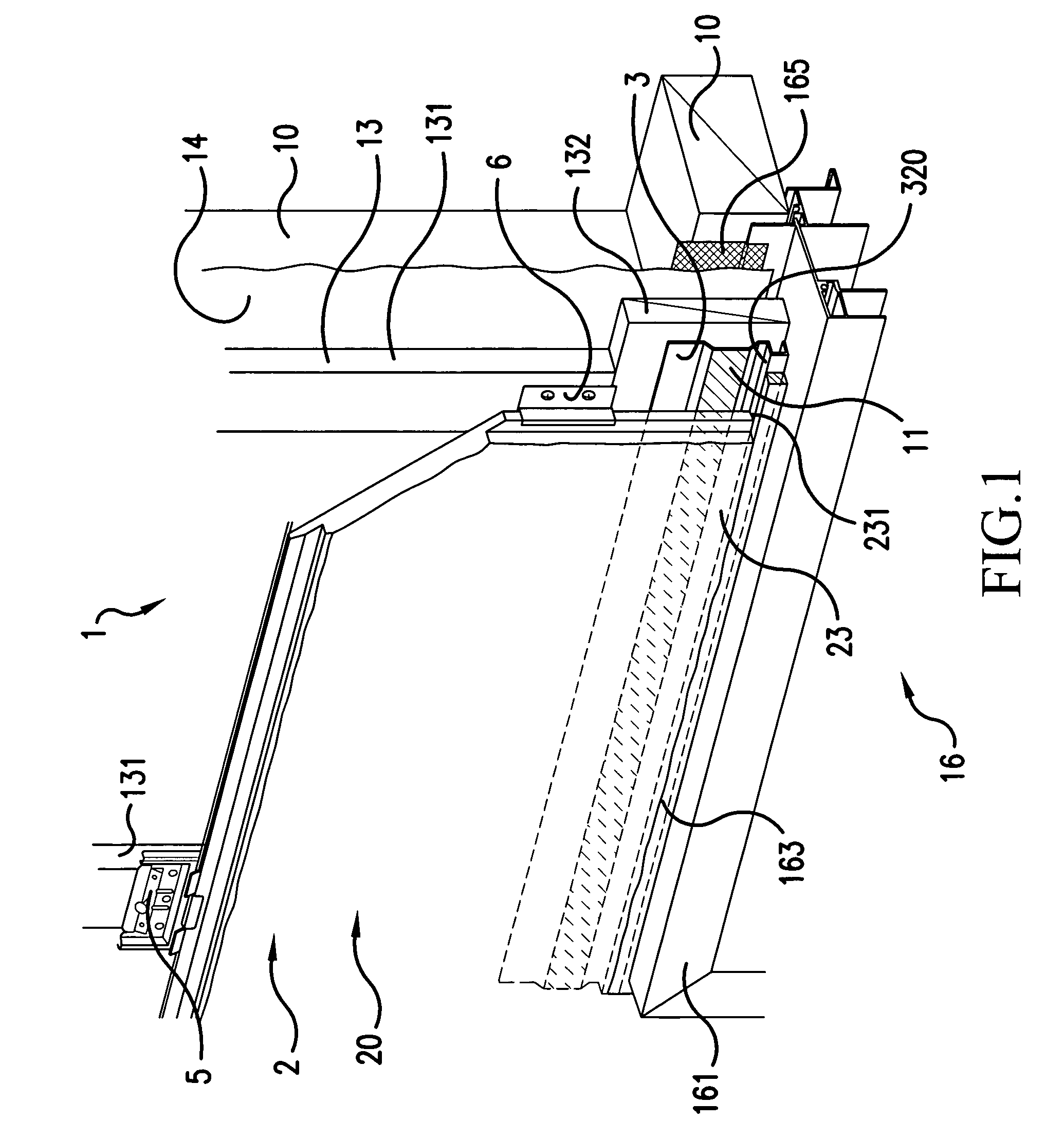

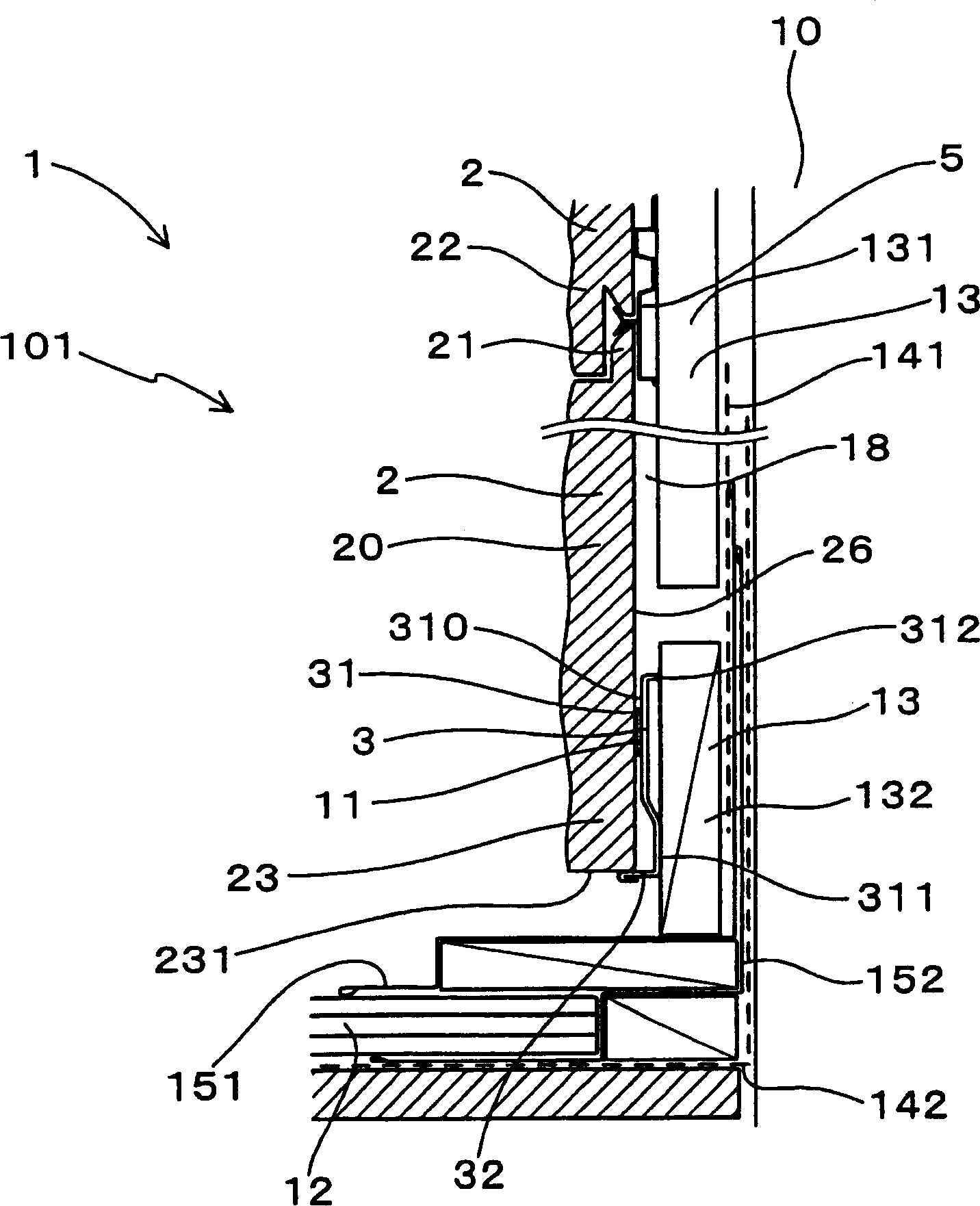

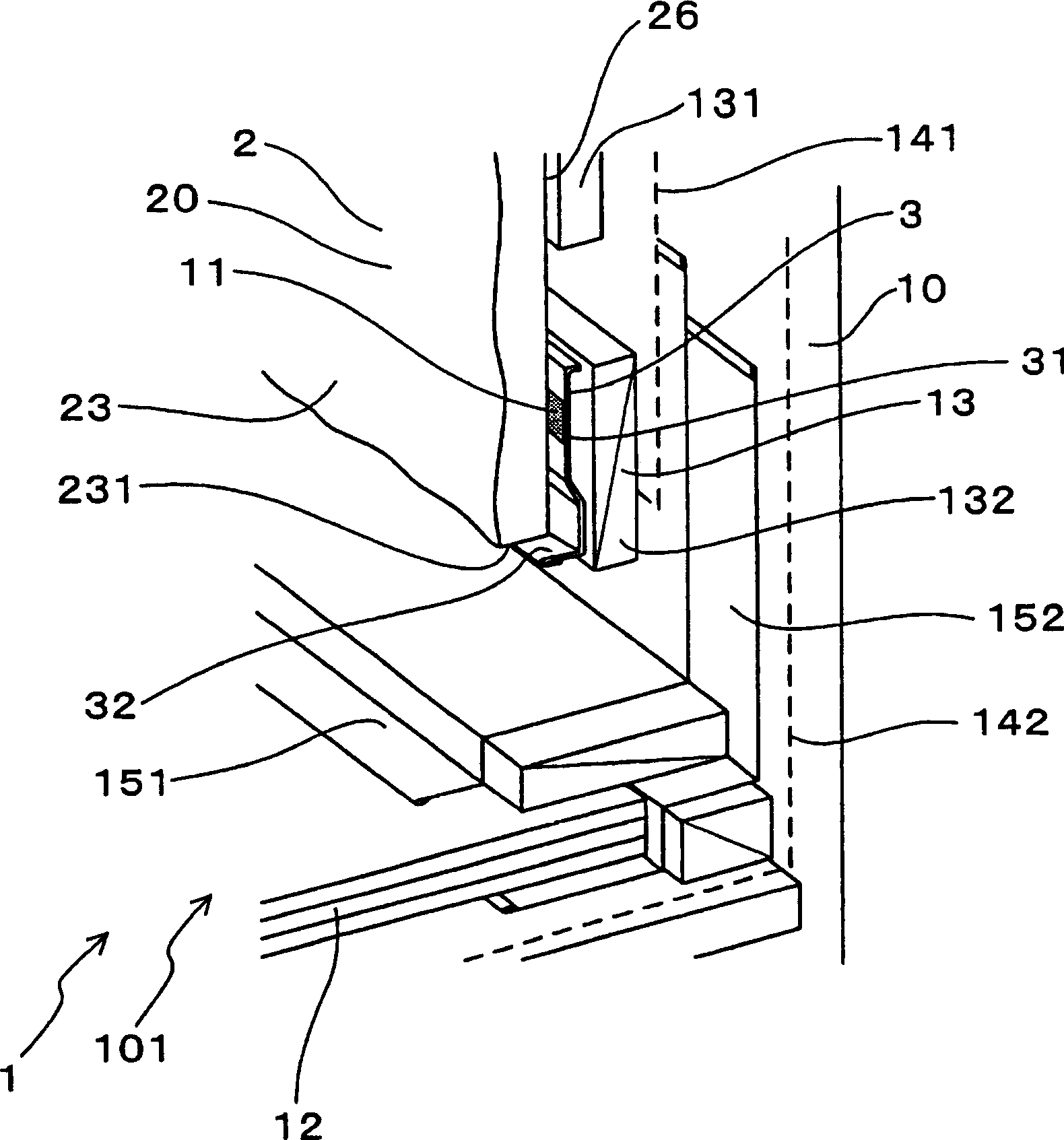

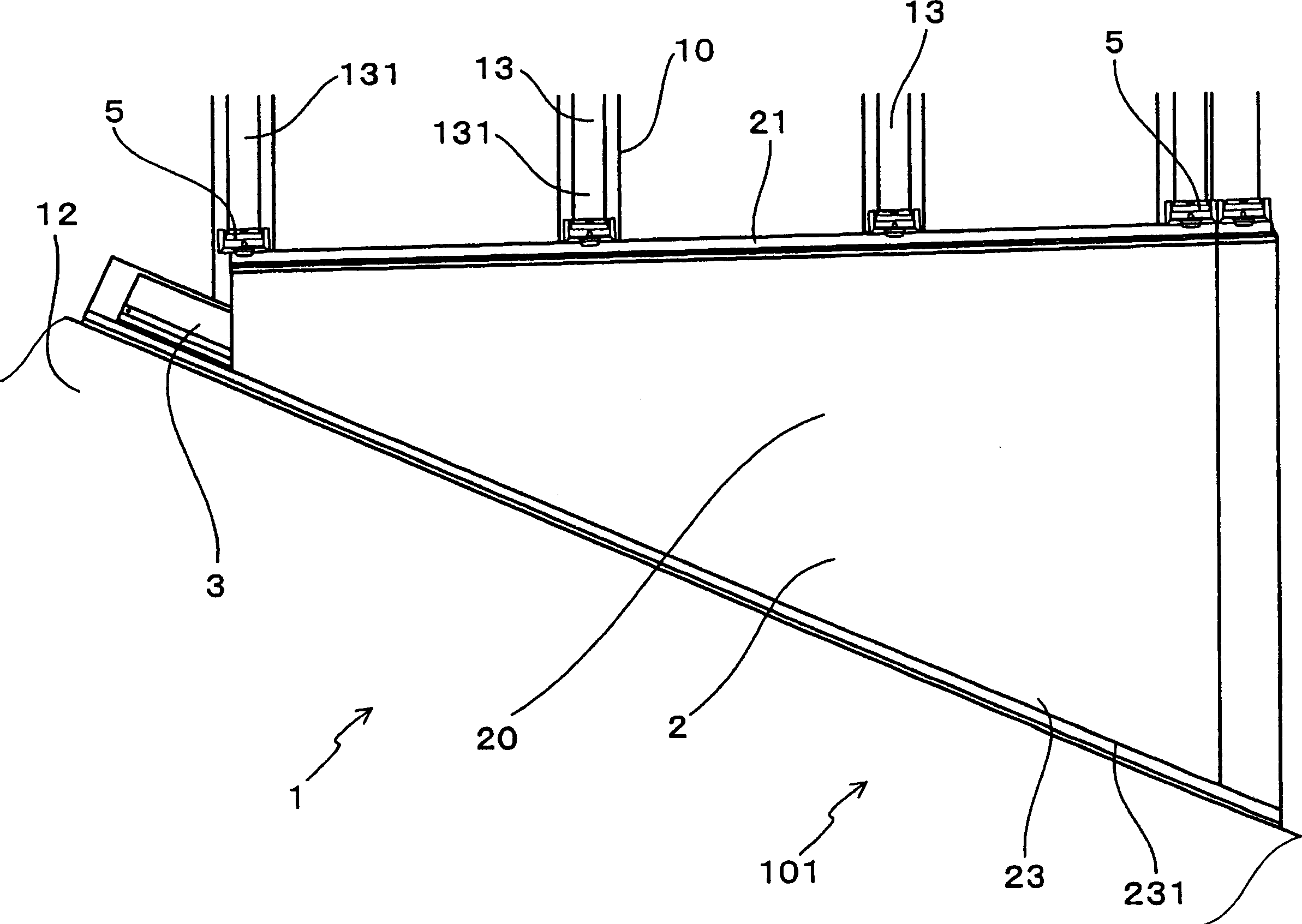

External wall constructing structure

ActiveUS8099920B2Nice appearanceImprove constructabilityBuilding roofsCovering/liningsWeather resistanceShiplap

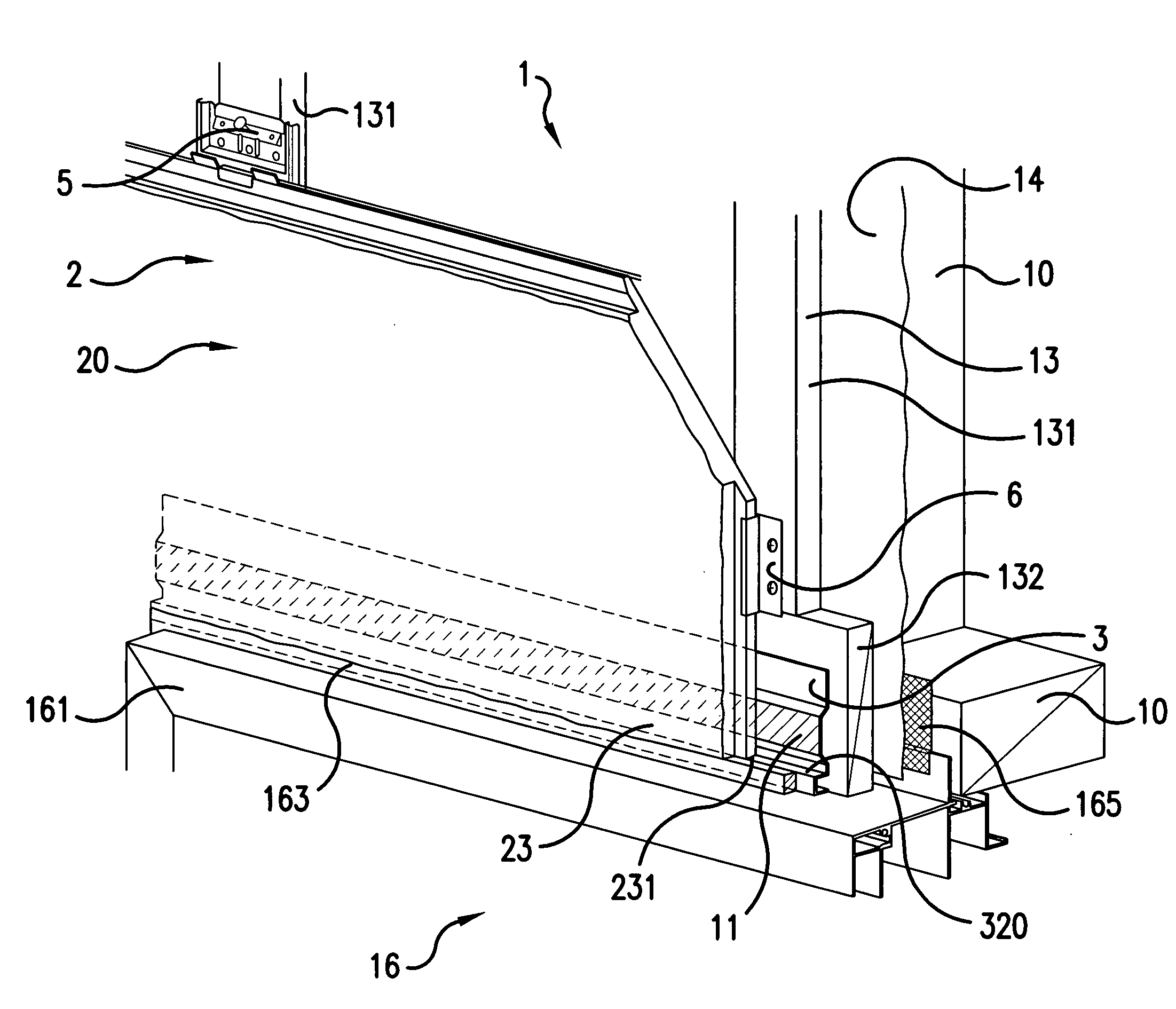

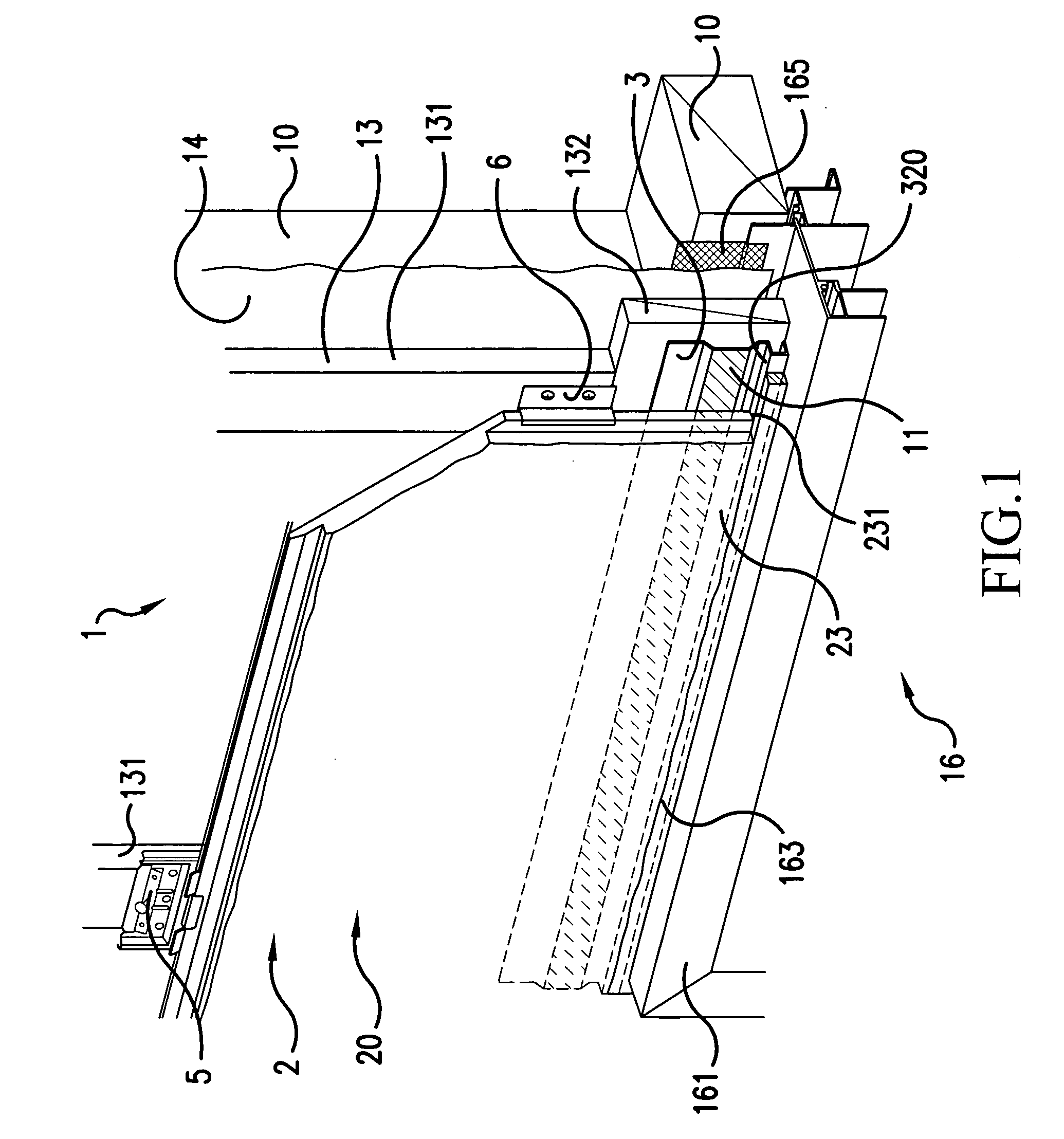

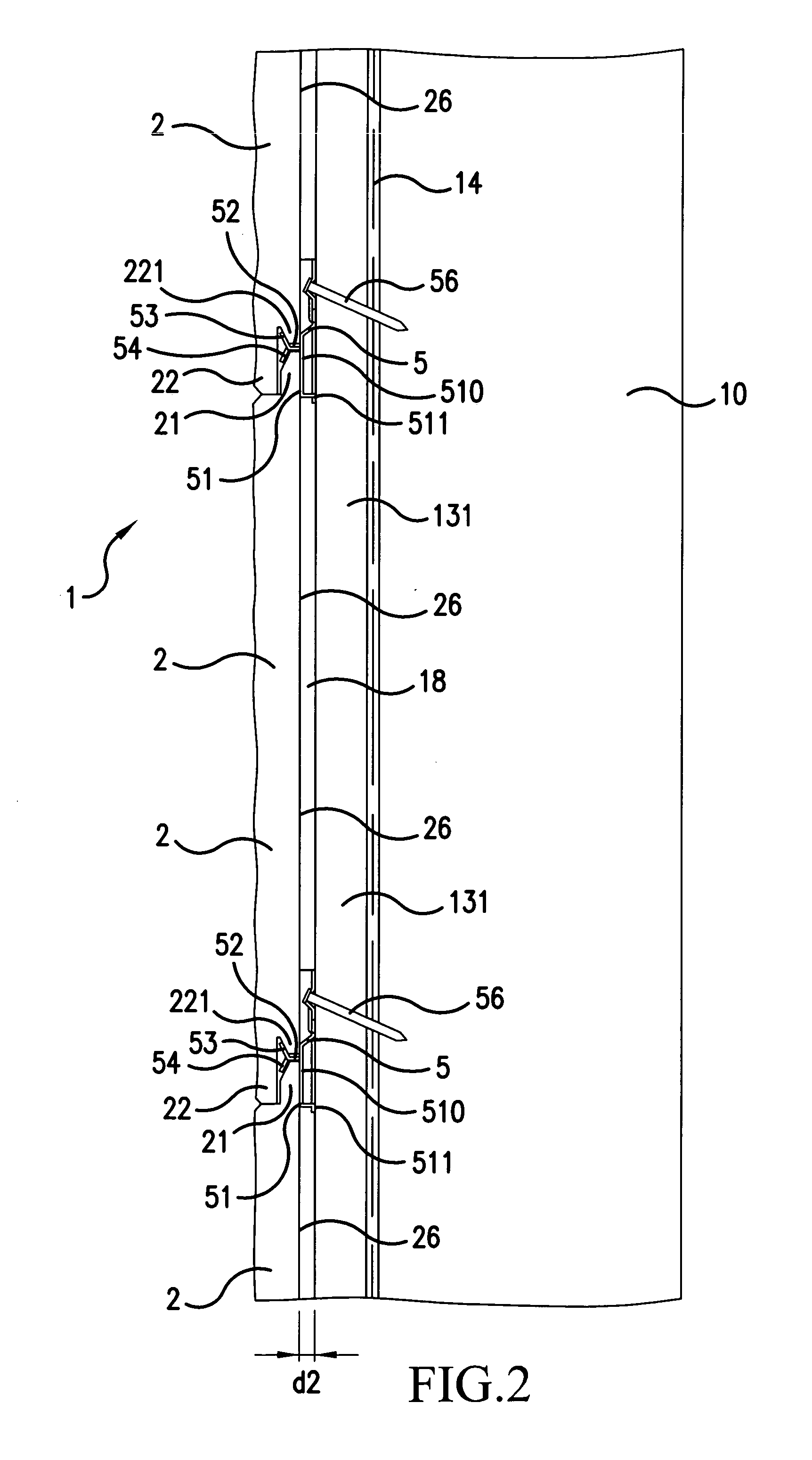

An external wall constructing structure excellent in ornamental appearance, weather resistance, contractibility, and safety is provided. An external wall constructing structure 1 comprising external wall panels that are joined to each other by vertical and horizontal shiplap joints and secured to a skeleton of a building by securing a metal fitting 5. A cut-off end portion 23 of a dimension-adjusted external wall panel 20 among the plurality of external wall panels is fixed to a skeleton 10 of the building via end constructing bracket 3. Left and right joint end portions of the dimension-adjusted external wall panel 20 are fixed to the skeleton 10 via lateral end securing metal fittings 6. In the end constructing bracket 3, a rear plate portion 31 is abutted on rear surface 26 of the dimension-adjusted external wall panel 20 and forward-bending portion 32 is abutted on cut-off end surface 231 of the dimension-adjusted external wall panel 20. The rear plate portion 31 and the rear surface 26 of the dimension-adjusted external wall panel 20 are adhered by adhesive agent 11. The forward-bending portion 32 of the end constructing bracket 3 has horizontal section 320, front section 321 and third abutting section 322 and sealing material 163 is placed in front of the front section 321.

Owner:NICHIHA CORP

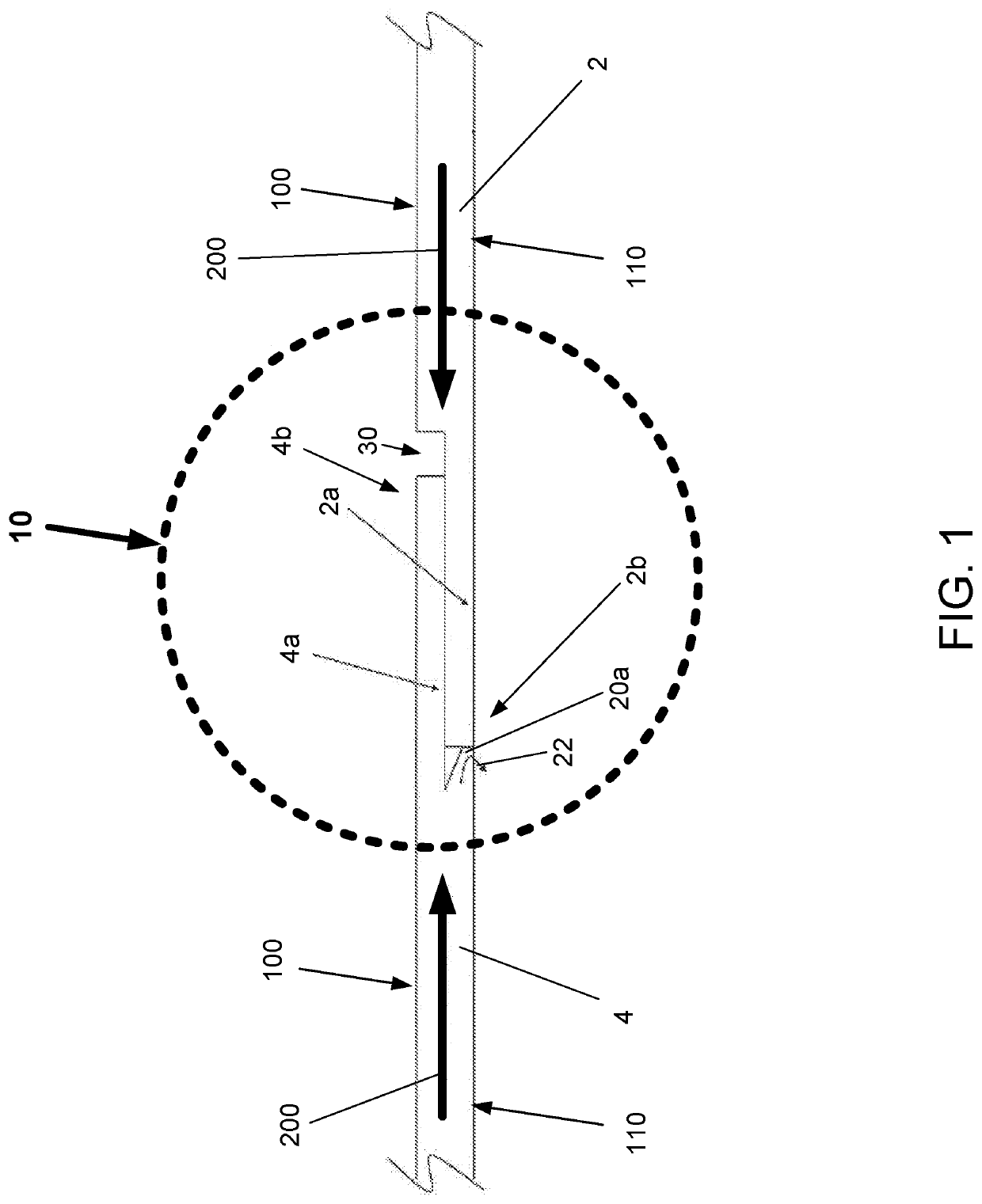

Siding boards attachment structure

The exterior wall construction structure 1 is formed by stopping an exterior wallboard 2 to a structure skeleton 10 with a stopping metal fitting 5 while making vertical shiplap connection. The stopping metal fitting 5 interlocks an upper part lower tongue 21 of the exterior wallboard 2 placed on the lower side with a lower part upper tongue 22 placed on the upper side. The cutting end 23 of a dimension adjusting exterior wallboard 20 among a plurality of exterior wallboards 2 is fixed to the structure skeleton 10 through an end construction metal fitting 3. The end construction metal fitting 3 has a back board 31 fixed to the structure skeleton 10 and a forward bending section 32 bent forward from one end thereof. The end construction metal fitting 3 is made to abut on the back board 31 on the back side 26 of the dimension adjusting exterior wallboard 20, and the forward bending section 32 is made to abut on the cutting end face 231 of the dimension adjusting exterior wallboard 20. The back board 31 and the back side 26 of the dimension adjusting exterior wallboard 20 are adhered to each other with an adhesive 11.

Owner:NICHIHA CORP

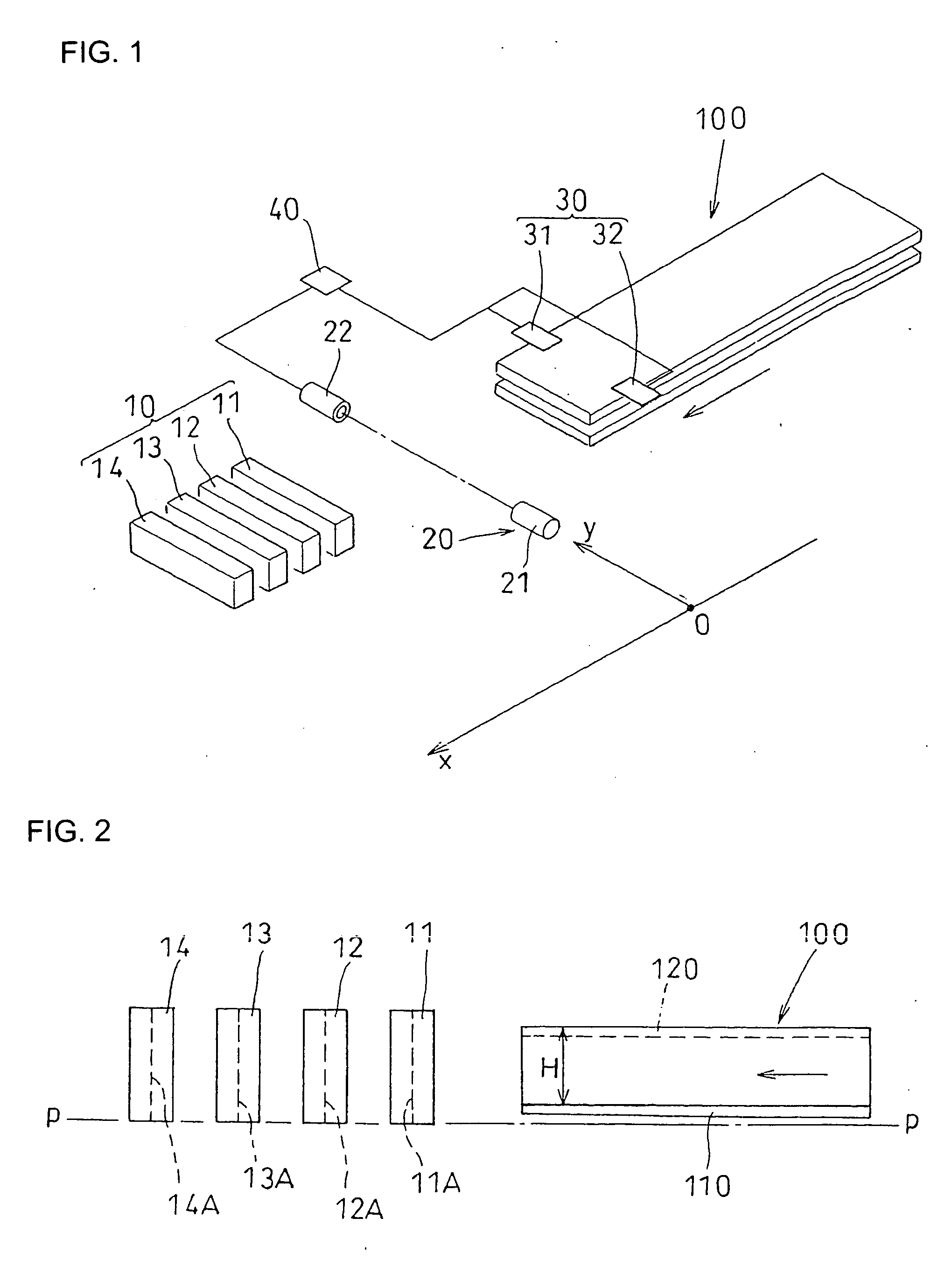

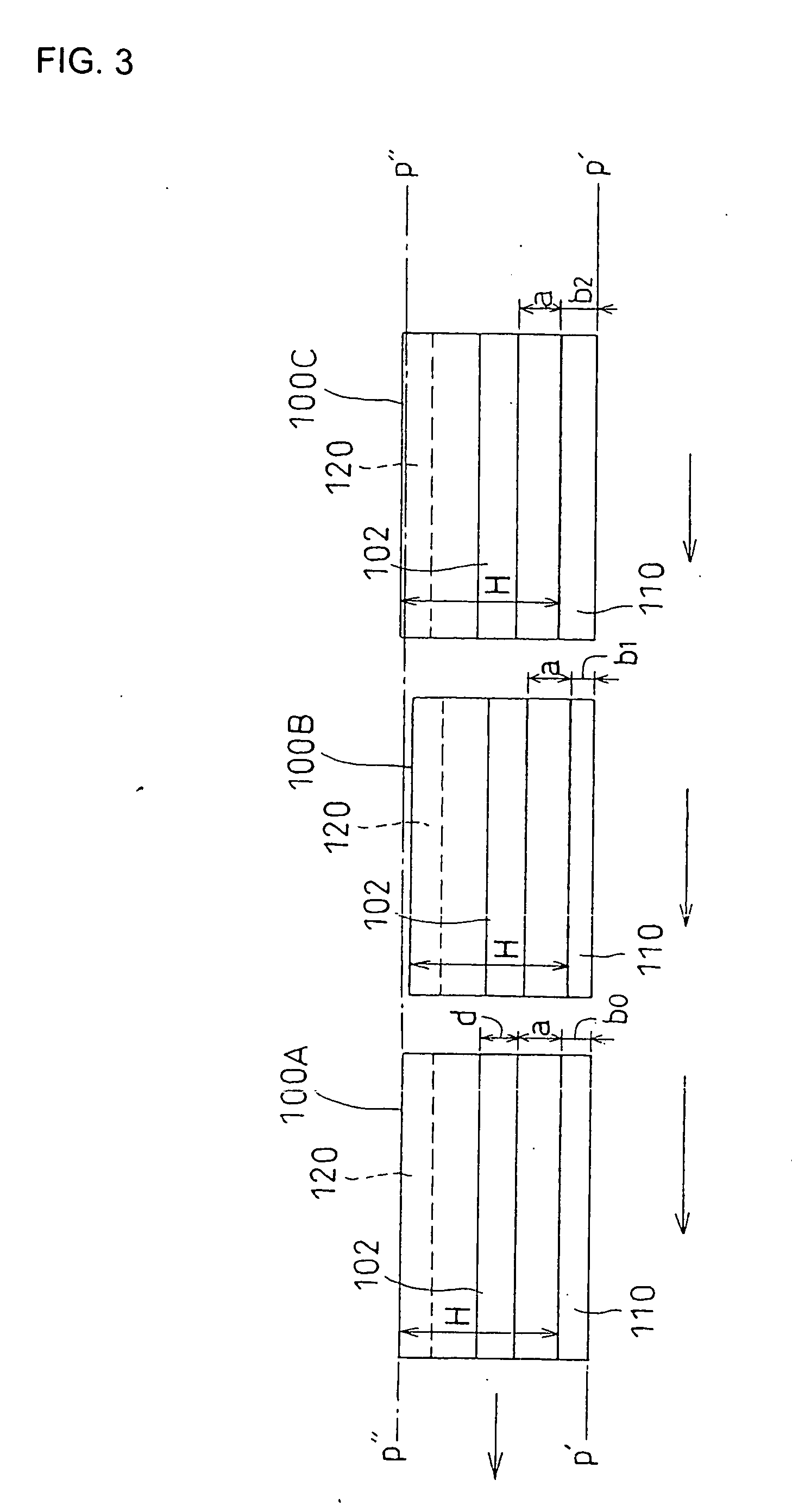

Printing apparatus and printing method for the same

InactiveUS20080011168A1Good external wall designTypewritersRotary pressesShiplapElectrical and Electronics engineering

Horizontal joint portions of abutting building boards are constructed in a manner to look straight-line in an external appearance when constructed even in a case that the building board has a dimension error. A printing apparatus for printing a building board of a shiplap joint system composed of a design surface having a horizontal joint portion formed along a longitudinal direction of the building board and an upper and lower shiplap portions formed at an end portion of the building board includes a fixed printing head having a plurality of nozzles for performing printing operation by means of emitting a jet of ink toward the design surface of the building board, in which the printing head performs printing operation along a printing line spaced apart from an edge of the upper shiplap portion or the lower shiplap portion at a constant distance when performing the printing operation for the horizontal joint portion.

Owner:NICHIHA CORP

Self-spacing lap siding product

Owner:GANG NAIL SYST INC

Simulated Wood Surface Covering for Decks and Floors

ActiveUS20090186192A1Improve water resistanceEasy to cleanNon-magnetic metal hullsWallsPlasticizerPolyvinyl chloride

The present invention relates to a simulated wood surface covering which is particularly useful in decking and flooring applications, said simulated wood surface covering being comprised of strips adapted to be interconnected aside of each other thereby forming an assembled simulated wood surface covering of desired dimensions to cover a substrate, wherein the strips are adapted to be interconnected through shiplaps having tongues and rabbets, wherein the rabbets have an included angle which is within the range of 70° to 89°, wherein the strips are comprised of a plastic composition which is comprised of polyvinyl chloride, a non-migrating plasticizer, and a coloring agent, wherein the strips have sufficient flexibility to conform to curved surfaces and to surface irregularities, wherein the upper surface of the strips are roughened to imitate the grain structure of wooden material.

Owner:PLASTEAK

External wall constructing structure

ActiveUS20090084052A1Improve constructabilityExcellent in ornamental appearanceBuilding roofsCovering/liningsWeather resistanceArchitectural engineering

An external wall constructing structure excellent in ornamental appearance, weather resistance, contractibility, and safety is provided. An external wail constructing structure 1 comprising external wall panels that are joined to each other by vertical and horizontal shiplap joints and secured to a skeleton of a building by securing a metal fitting 5. A cut-off end portion 23 of a dimension-adjusted external wall panel 20 among the plurality of external wall panels is fixed to a skeleton 10 of the building via end constructing bracket 3. Left and right joint end portions of the dimension-adjusted external wall panel 20 are fixed to the skeleton 10 via lateral end securing metal fittings 6. In the end constructing bracket 3, a rear plate portion 31 is abutted on rear surface 26 of the dimension-adjusted external wall panel 20 and forward-bending portion 32 is abutted on cut-off end surface 231 of the dimension-adjusted external wall panel 20. The rear plate portion 31 and the rear surface 26 of the dimension-adjusted external wall panel 20 are adhered by adhesive agent 11. The forward-bending portion 32 of the end constructing bracket 3 has horizontal section 320, front section 321 and third abutting section 322 and sealing material 163 is placed in front of the front section 321.

Owner:NICHIHA CORP

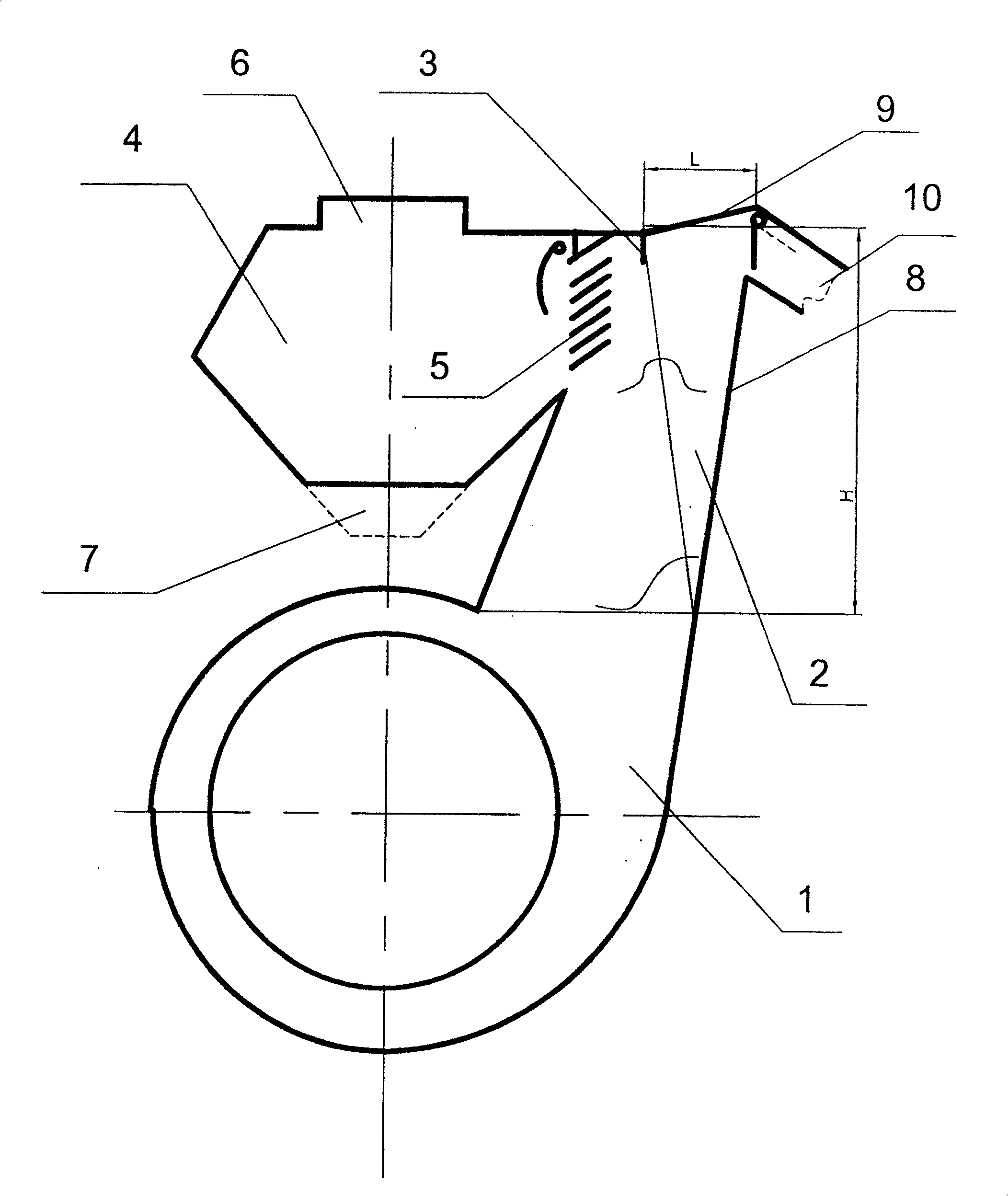

Inertia separator

The invention relates to a milling machine in the energy industry. The invention can be used in building, chemistry and other industry. A separator is set on the upper wall of the supply passage of an inertia separator. The inertia separator has a passage providing the milling product and an inertia vapor head comprising a shiplap-spout grid and a transfer pipe of the finished goods dust. The separator is set at the distance L which is equal or greater than 0.25-0.3H wherein the H is the height of the passage to the passage's outer wall, and the length of the separator is not less than the height of the upper spout of the shiplap-spout grid. The upper wall of the supply passage is made as incline and hoisted gradually toward the outer wall, the upside of the passage has a decline transfer pipe which is used to clear the coarse component.

Owner:泰亚兹马斯股份公司

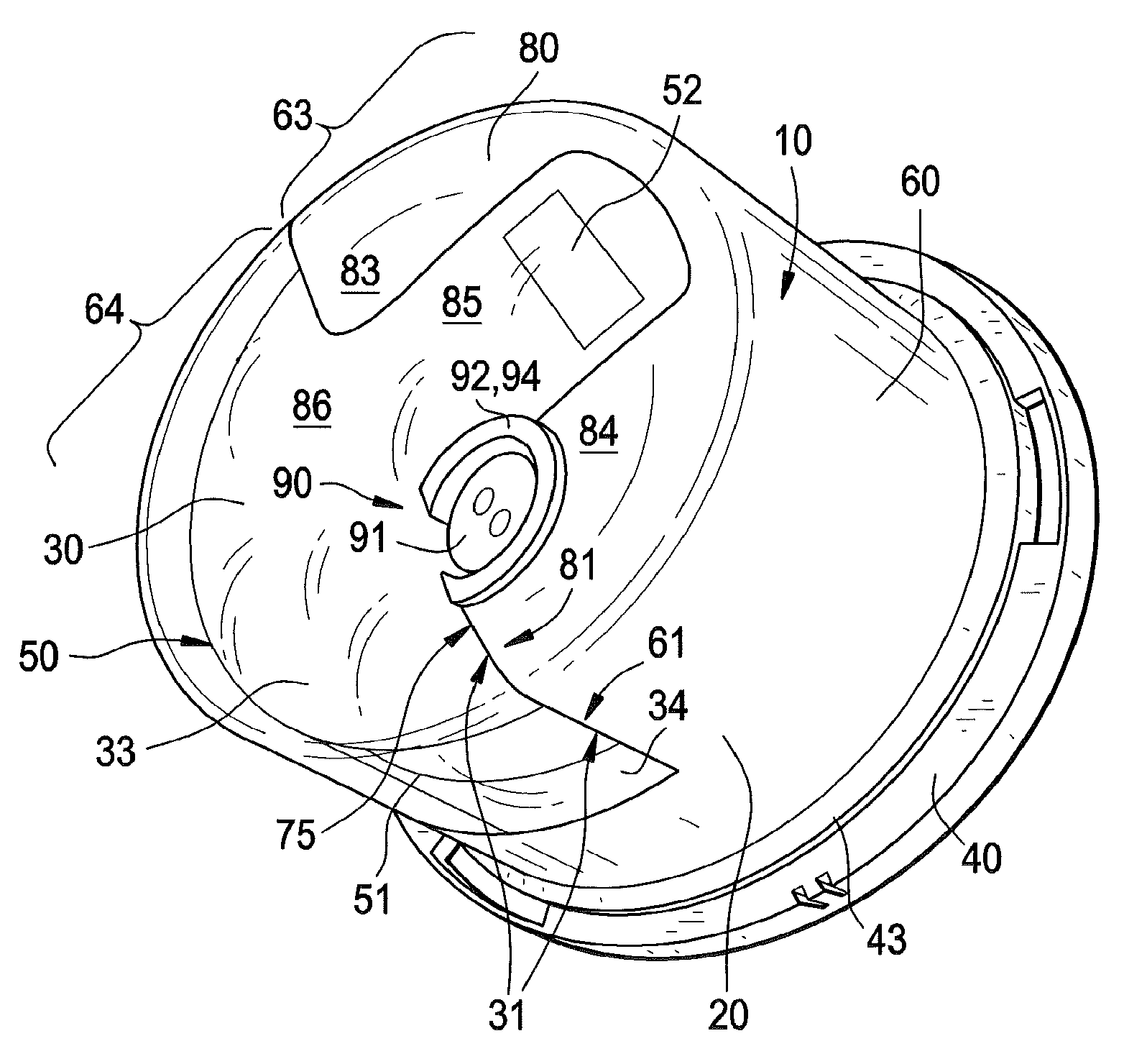

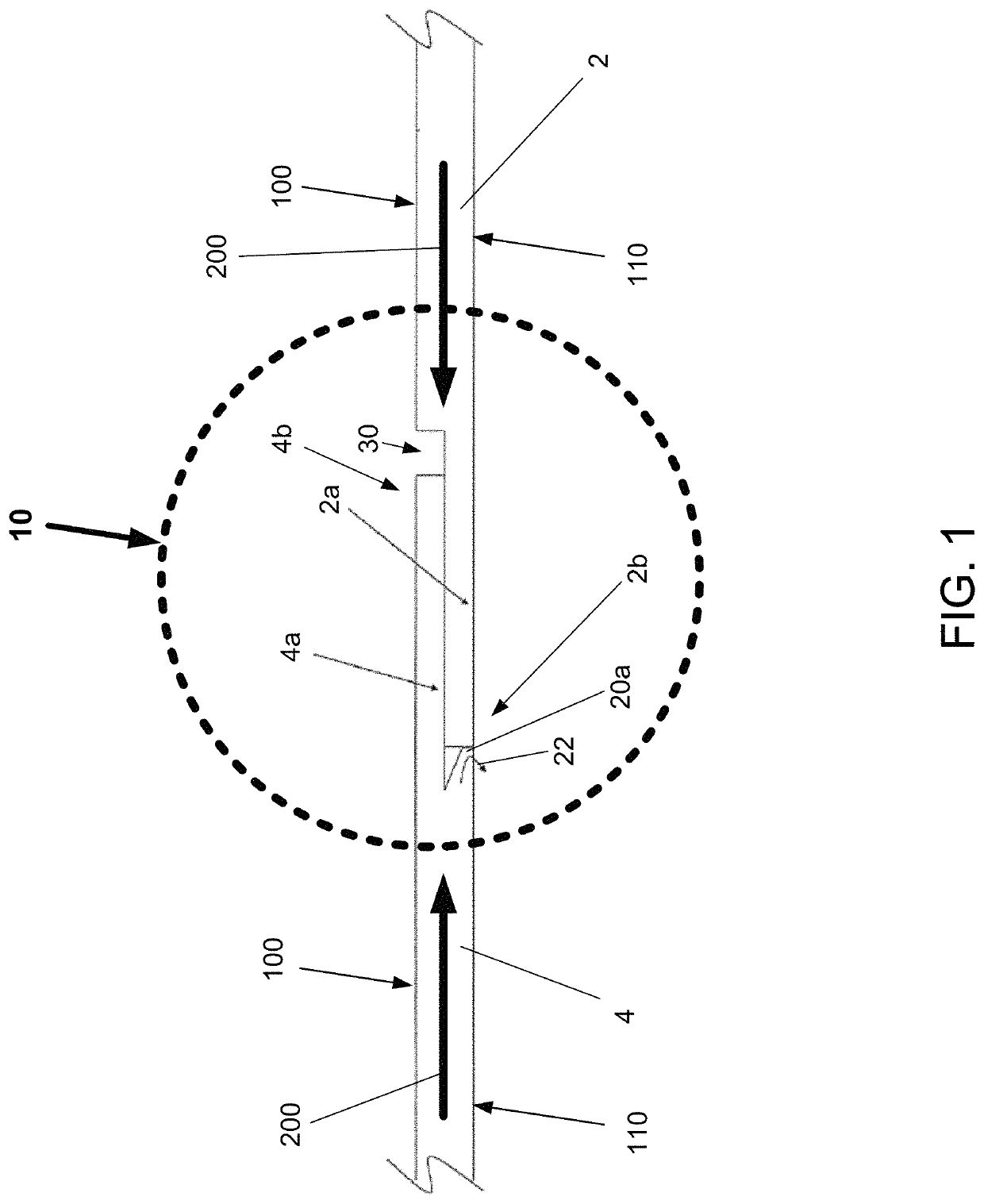

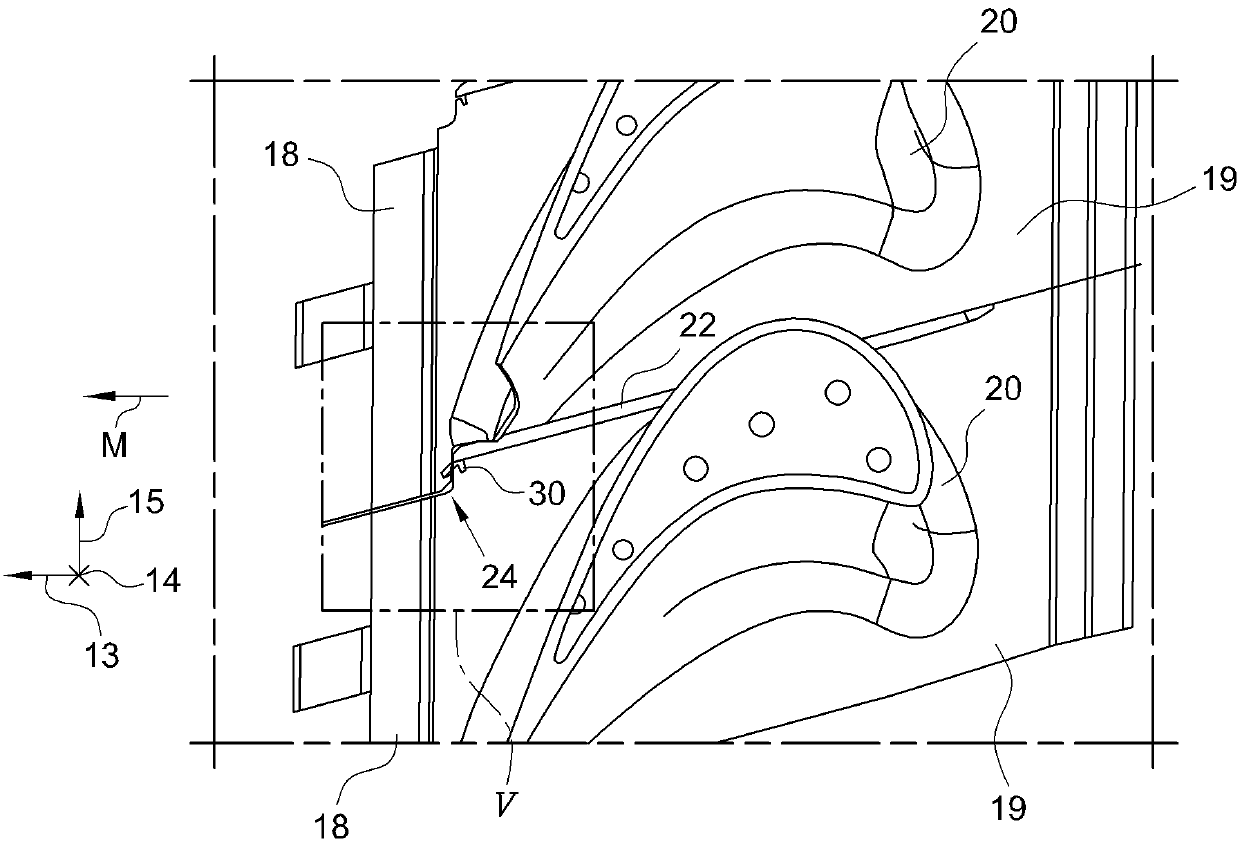

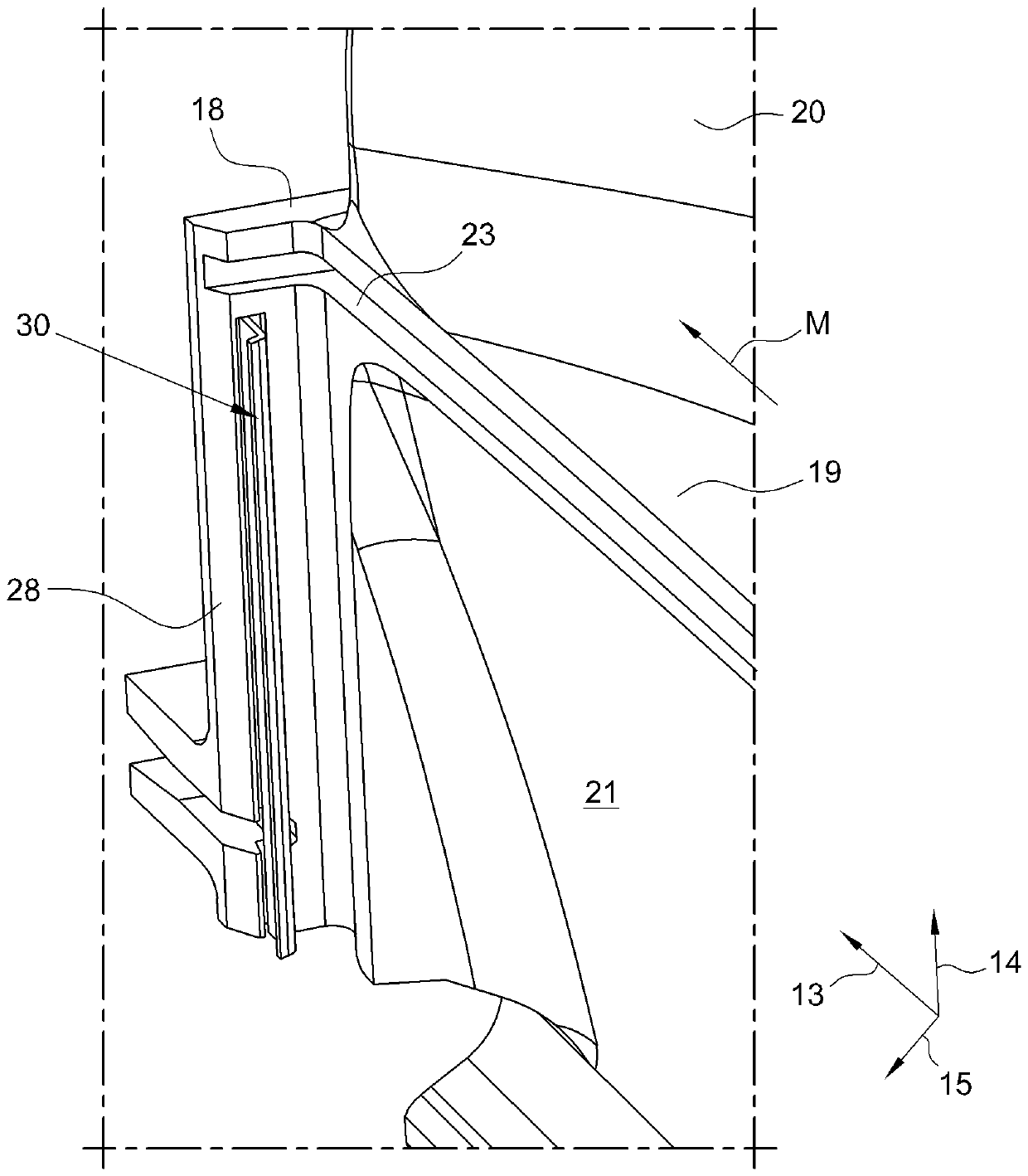

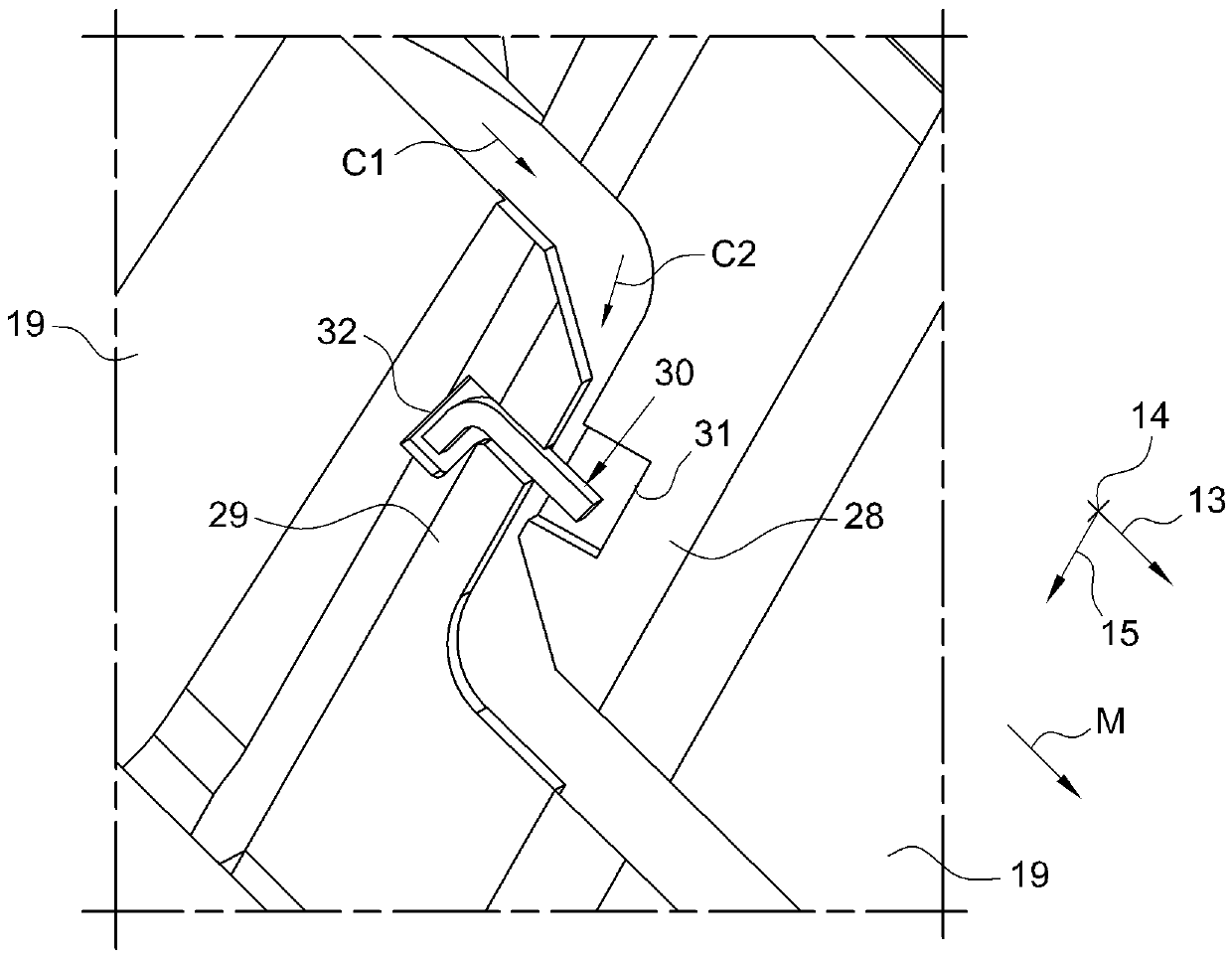

Shiplap seal arrangement

A shiplap arrangement for a gas turbine having an axis A; the shiplap arrangement comprising: a first and a second blade adjacent arranged along a circumferential direction centered in the gas turbineaxis A; each blade along a radial direction comprising a foot configured for coupling the blade to a rotor, a shank portion provided with a downstream closing wall, a platform and an airfoil; betweenthe adjacent blades in the shank portion a cooling air cavity is provided that is outwardly sealed by an axial seal arranged along the gap between the adjacent platforms and downstream sealed by a shiplap coupling between the adjacent shank closing walls; the shiplap coupling comprising a circumferential projecting portion of the shank closing wall of the first blade and a corresponding receivingrecess portion in the adjacent shank closing wall; a radial seal arranged along the gap between the projecting portion and the recess portion of the shiplap coupling and housed at one side in a firstradial groove realized in the projecting portion and at the other side in a second radial groove realized in the recess portion to provide a barrier against leakage flow passing through the shiplap coupling.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Shiplap plate seal

A seal plate assembly for a turbine rotor includes at least one inner shiplap seal plate disposed on the rotor; and at least one outer seal plate adapted to engage the at least one inner shiplap plate. The thickness of the at least one outer seal plate is different than the thickness of the at least one inner shiplap plate causing either the at least one inner shiplap plate or the at least one outer seal plate to come into contact first under centrifugal load.

Owner:GENERAL ELECTRIC CO

Engineered fence pickets with ship lapped edges

An engineered wood fence picket and system for manufacturing fence pickets using engineered wood products, including, but not limited to, oriented-strand board (OSB), laminated veneer lumber (LVL), fiber strand, and / or laminated strand lumber (LSL). The opposing right and left edges of each picket has corresponding elements of a joint, such as, but not limited to, a shiplap joint or tongue-and-groove joint. A fence or fence segment may be constructed by aligning a plurality of said fence pickets vertically or horizontally so that the edges of adjacent pickets mate or meet to form a joint. The fence can be assembled more quickly and cheaply than with any prior art materials, and the fence will be higher quality, with longer life, thinner and lighter, and minimal maintenance.

Owner:GANG NAIL SYST

Building material and method for producing the same

A building material having a caulking on a shiplap portion. The caulking is covered with a caulking-coating film. The building material demonstrates superior cuttability and adhesion with the shiplap portion and demonstrates almost free of staining caused by bleeding of the oil and the like. The caulking preferably contains either a styrene-based block copolymer resin, or a mixture of an olefin-based resin and an adhesive resin. A method for producing the building material includes a step of heating a caulking material to a temperature equal to or higher than a softening point of the caulking material, a step of forming a bead-like caulking by applying the heated caulking material onto a shiplap portion formed in a base material, and a step of coating the caulking with a caulking-coating material.

Owner:NICHIHA CORP

Building material and method for producing the same

A building material having a caulking on a shiplap portion. The caulking is covered with a caulking-coating film. The building material demonstrates superior cuttability and adhesion with the shiplap portion and demonstrates almost free of staining caused by bleeding of the oil and the like. The caulking preferably contains either a styrene-based block copolymer resin, or a mixture of an olefin-based resin and an adhesive resin. A method for producing the building material includes a step of heating a caulking material to a temperature equal to or higher than a softening point of the caulking material, a step of forming a bead-like caulking by applying the heated caulking material onto a shiplap portion formed in a base material, and a step of coating the caulking with a caulking-coating material.

Owner:NICHIHA CORP

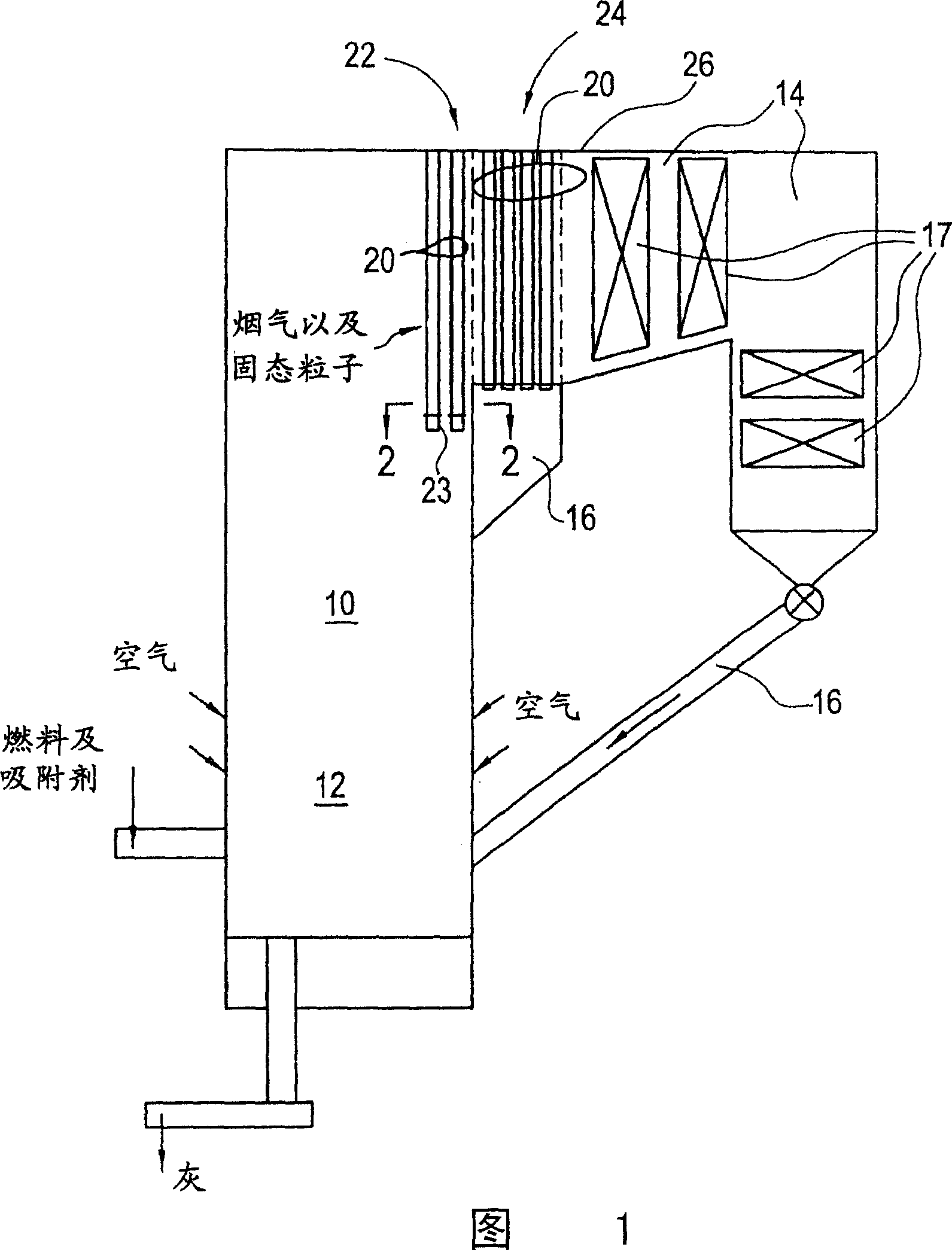

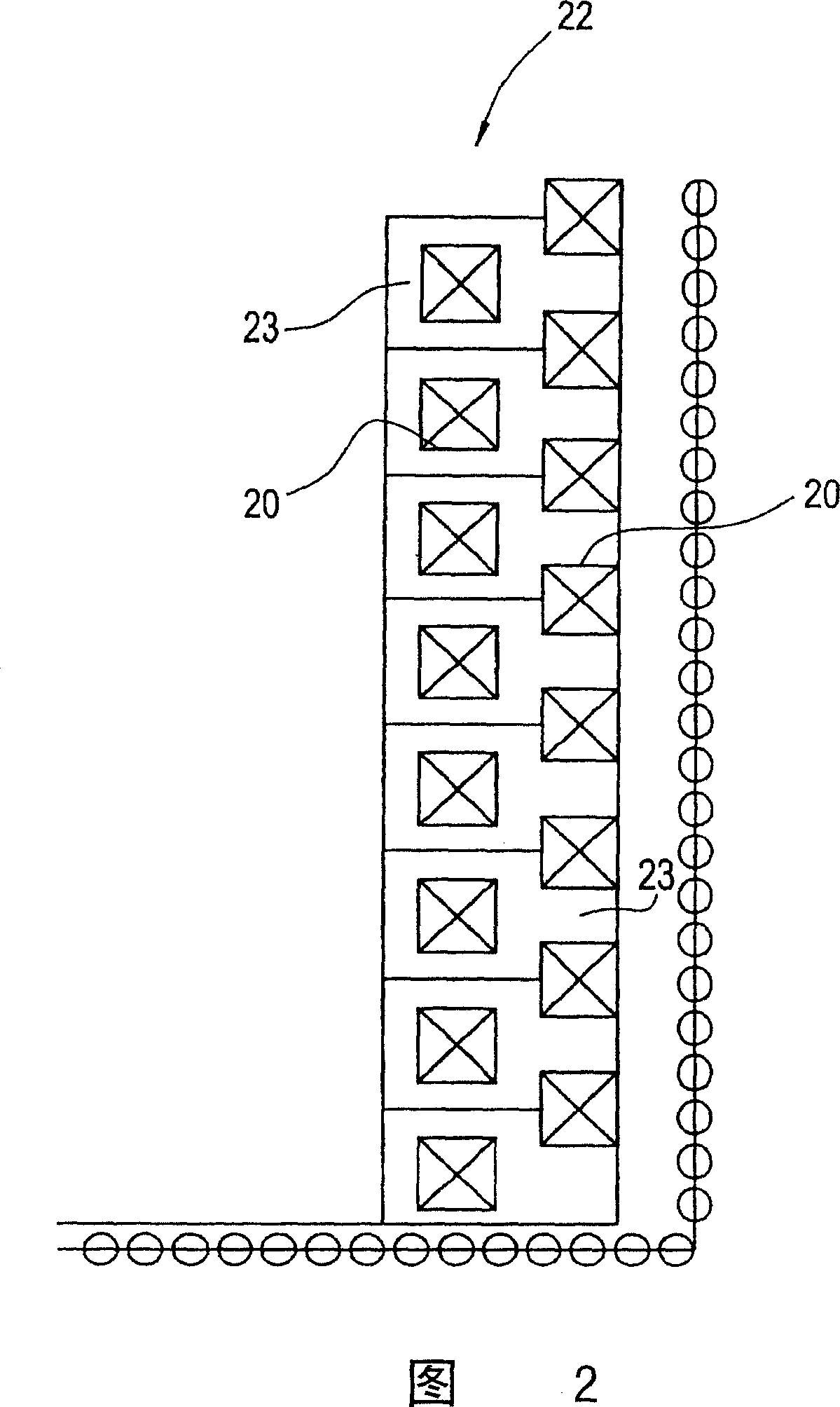

Cooled tubes arranged to form impact type particle separators

Apparatus for separating solids from flue gas in a circulating fluidized bed (CFB) boiler comprises plural vertical, impact type particle separators made of cooling tubes located within the CFB in a plurality of staggered rows. One embodiment employs a plurality of stacked, slip fit elements having apertures which accept the cooling tubes. The slip fit elements cooperate with one another to form a collecting channel, typically U-shaped, which separates particles from flue gases conveyed across the particle separators. Shiplap joints in betwee n the individual slip fit elements prevent gas and solids from leaking therebetween and allow for thermal expansion. Alternatively, the impact type particle separators comprise cooling tubes connected to one another to form a unitary structure. Pin studs welded to the cooling tubes a nd covered with a coating of refractory; ceramic tiles; metal or ceramic spray coatings; metal or ceramic castings; weld overlay; and / or shields provide erosion resistance.

Owner:THE BABCOCK & WILCOX CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com