Inertia separator

A technology of inertial separator and separator, which is applied in the field of coal grinding and can solve problems such as existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

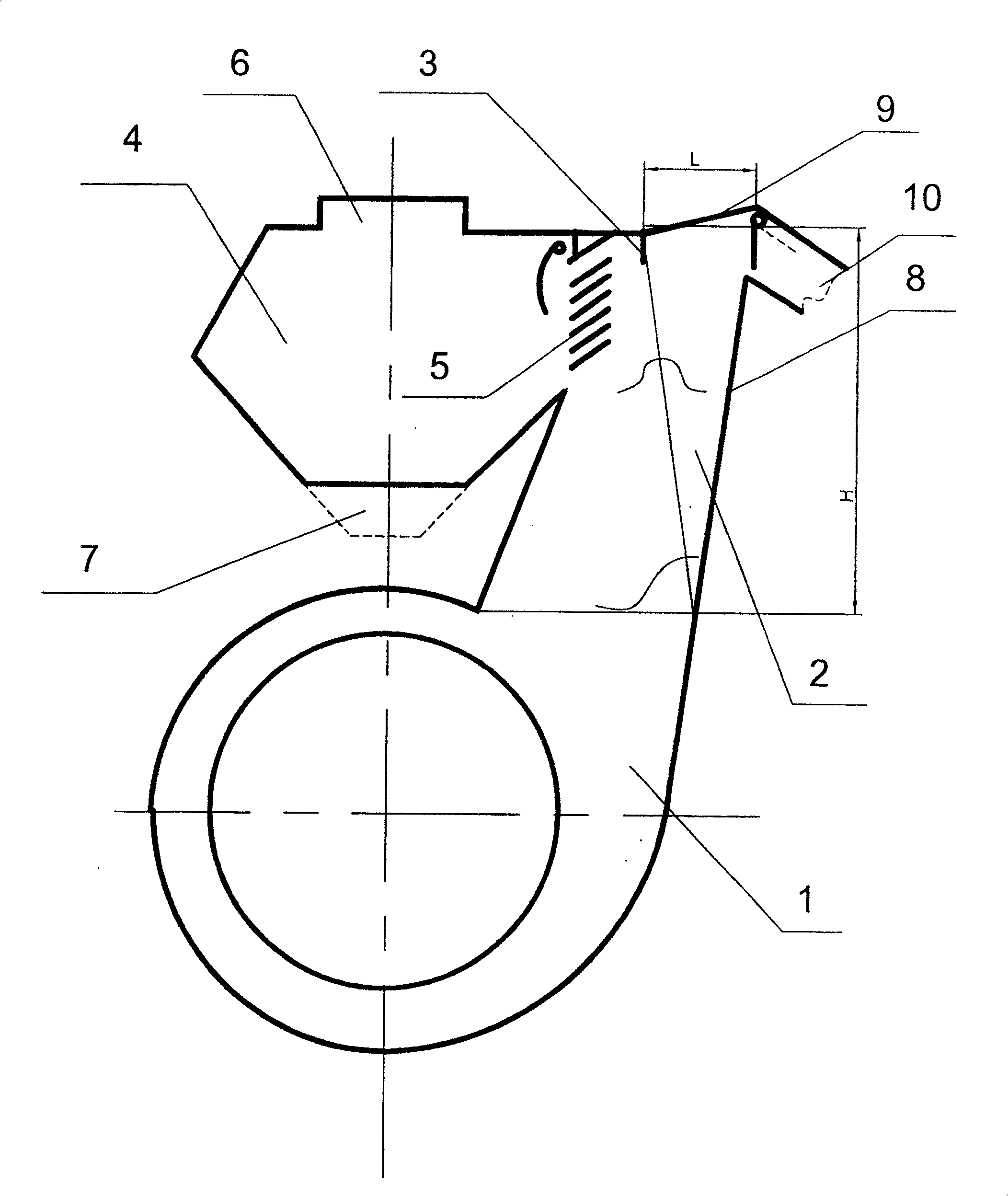

[0013] The inertial separator comprises a grinding chamber 1 , a feed channel 2 connected thereto, and a partition 3 connected to the upper part of the feed channel 2 . The partition plate 3 separates the separation chamber 4 with the fish-scale plate type nozzle grid 5, the product dust outlet pipe 6 and the return leak nozzle 7 from the supply channel 2. The partition plate 3 is installed on the upper part of the supply channel 2, and is set to a distance L to the outer wall 8 of the supply channel 2, satisfying L≥(0.25-0.3)H, where H-the height of the supply channel 2. The upper wall 9 of the supply channel 2 is installed obliquely, gradually rising towards the side of the outer wall 8 of the supply channel 2 . The upper part of the supply channel 2 is provided with an outlet pipe 10 for coarse grain components, which is inclined downward.

[0014] Inertial separators work in the following ways:

[0015] The ground product from the grinding chamber 1 is conveyed to the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com