Rig mat sprayed with polyurea systems

a technology of polyurea and rig mats, applied in the direction of single unit pavings, wellbore/well accessories, ways, etc., can solve the problems of hdpe systems being often breached, the integrity of plastic liner is threatened, and the environment is exposed to harmful contaminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]It is to be understood that at least some of the figures and descriptions of the invention have been simplified to illustrate elements that are relevant for a clear understanding of the invention, while eliminating, for purposes of clarity, other elements that those of ordinary skill in the art will appreciate may also comprise a portion of the invention. However, because such elements are well known in the art, and because they do not facilitate a better understanding of the invention, a description of such elements is not provided herein.

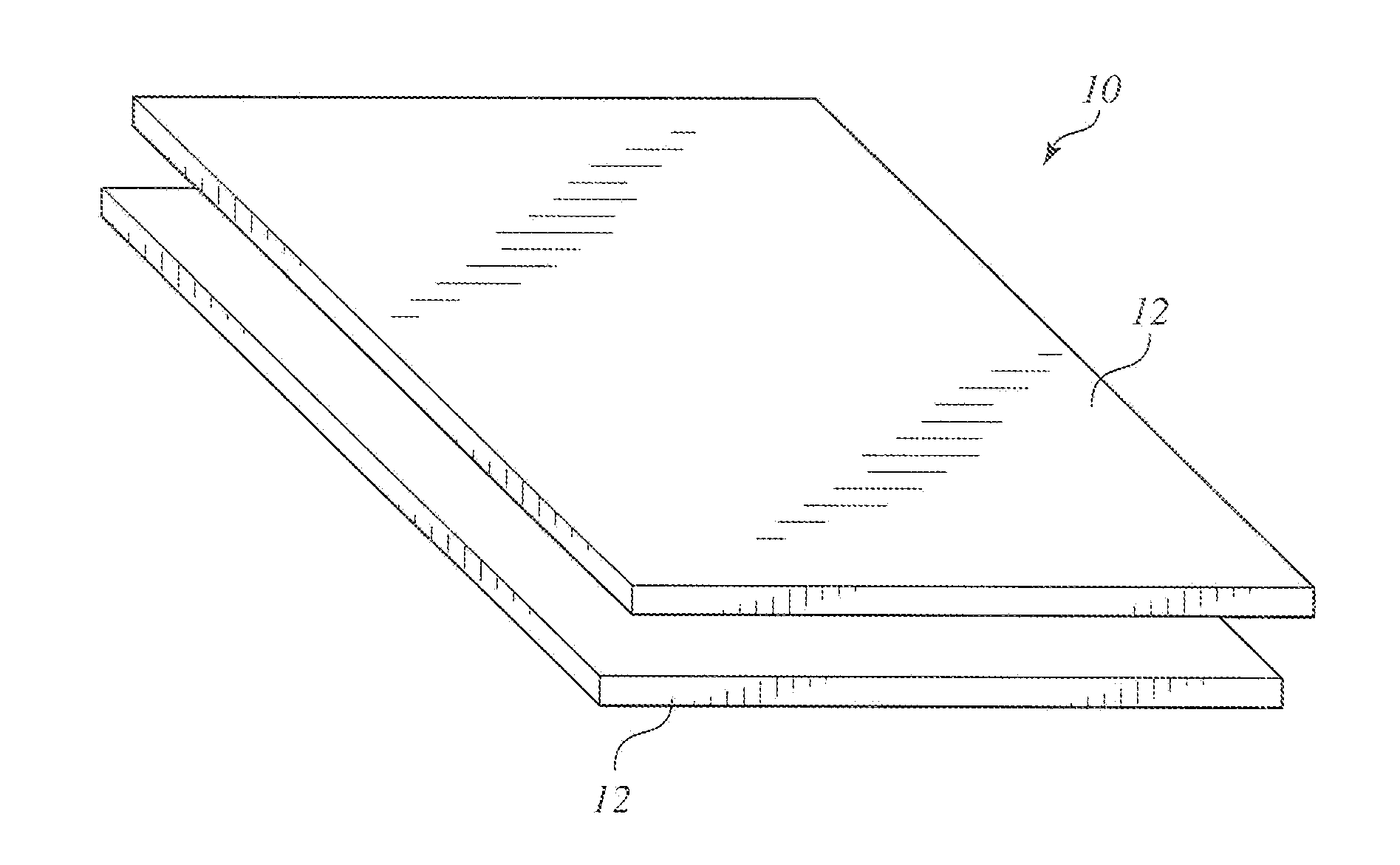

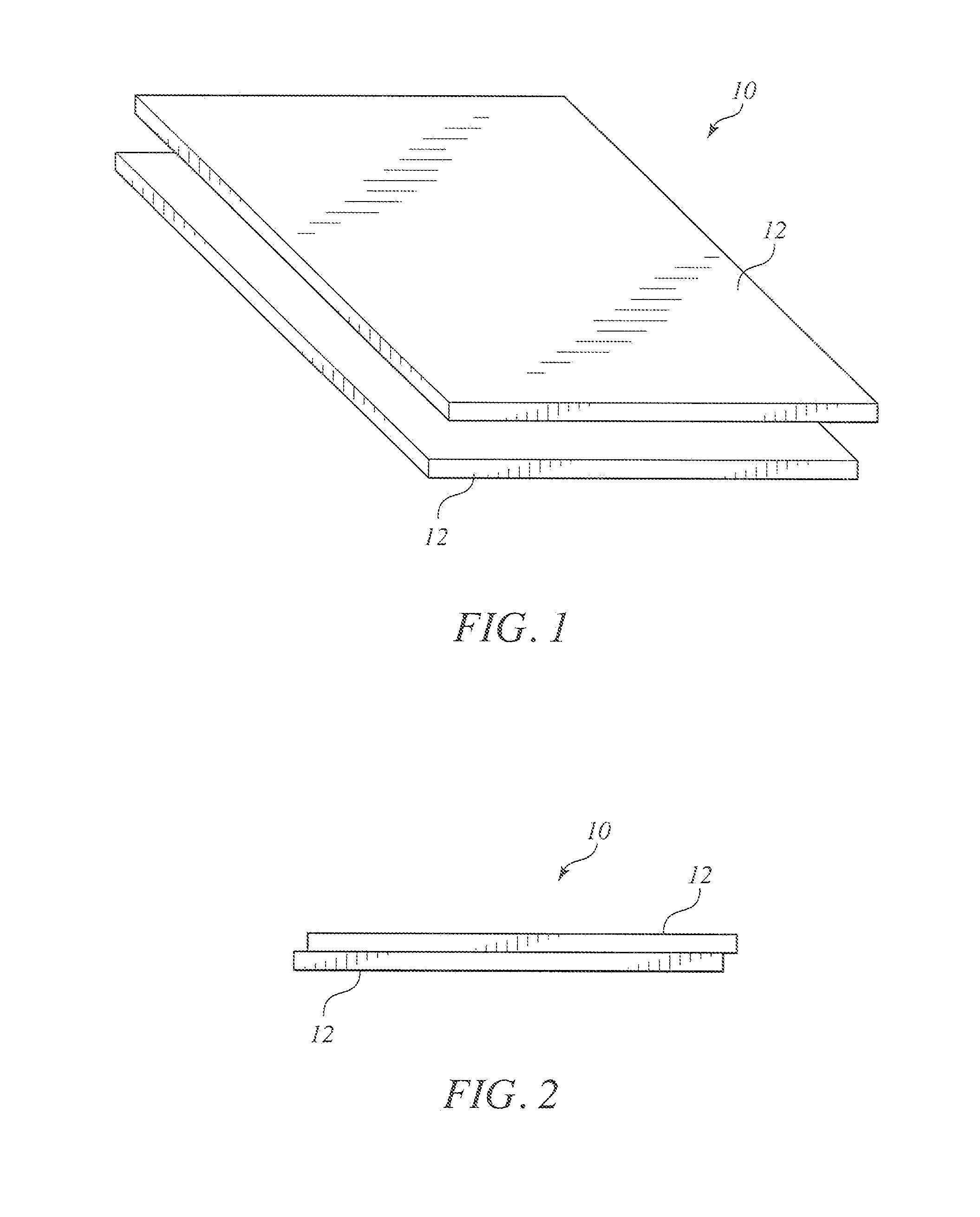

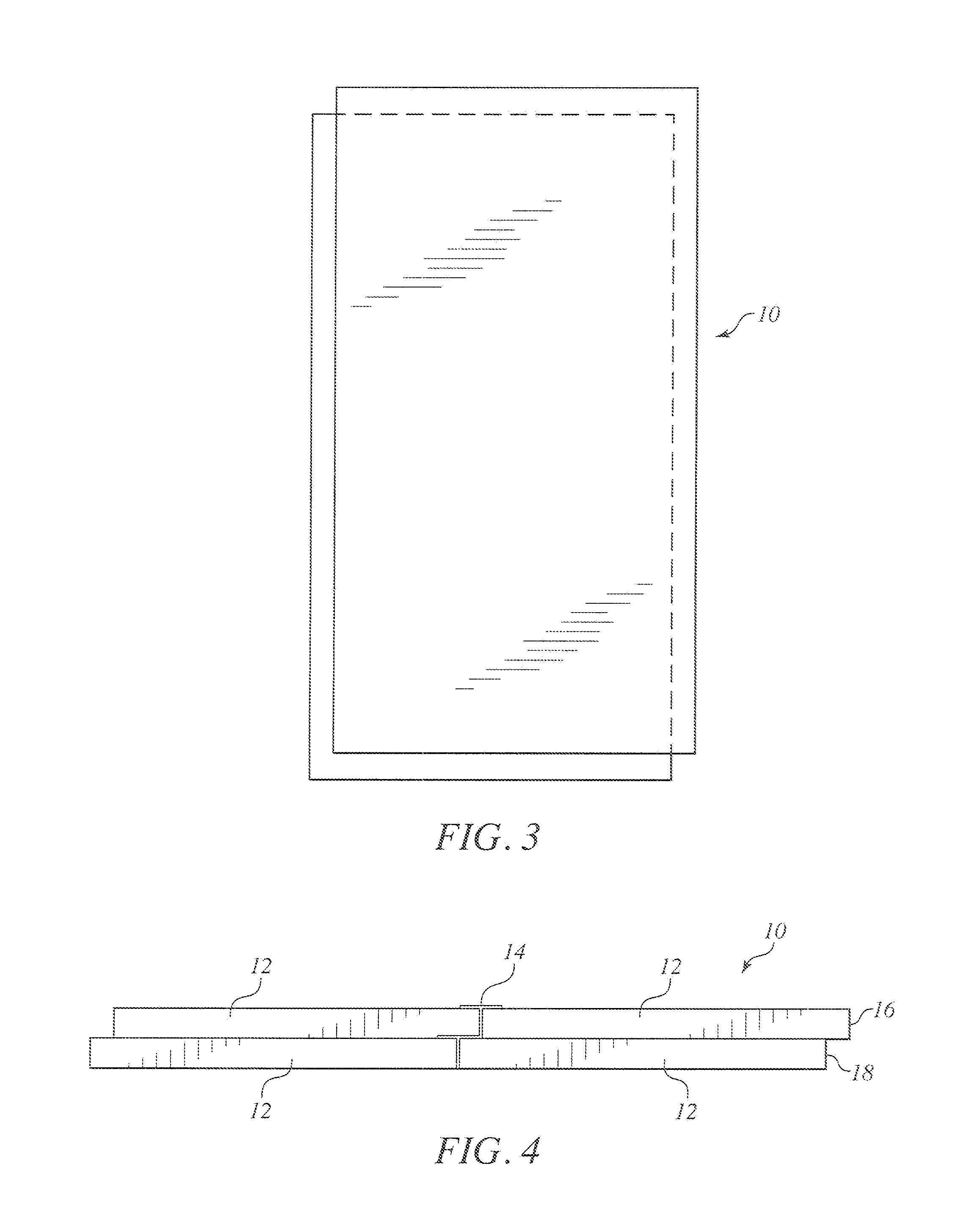

[0014]The Figures illustrate various embodiments of a system for a rig mat sprayed with polyuria system; common parts will be represented by the same reference numeral. The rig mat according to embodiments of the invention creates a flooring for the drilling rig and is a non-breachable sealed system for containing liquids that may be harmful to the environment produced by the drilling and hydraulic fracking process.

[0015]The rig mat of vario...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com