Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Polymer foil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

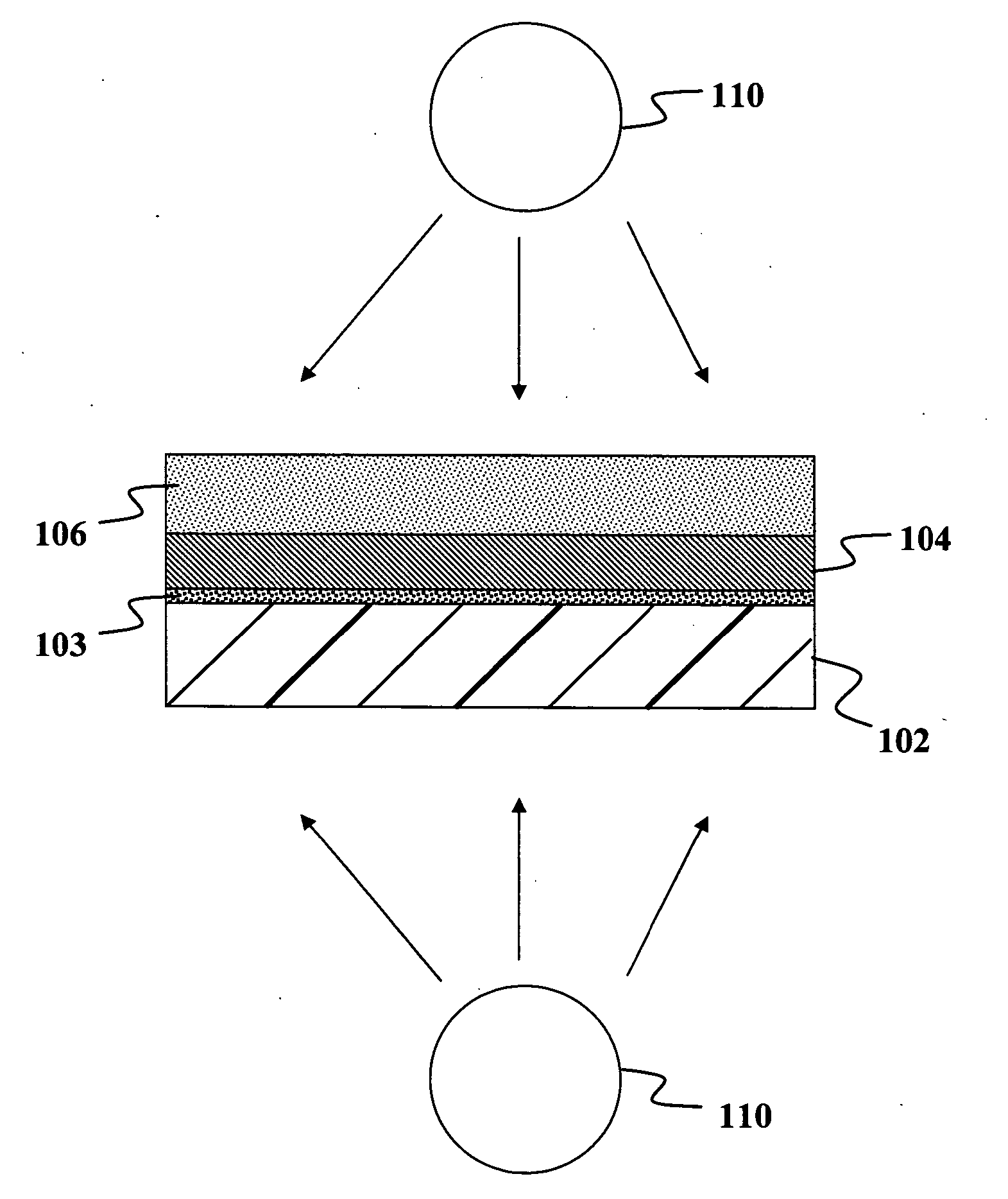

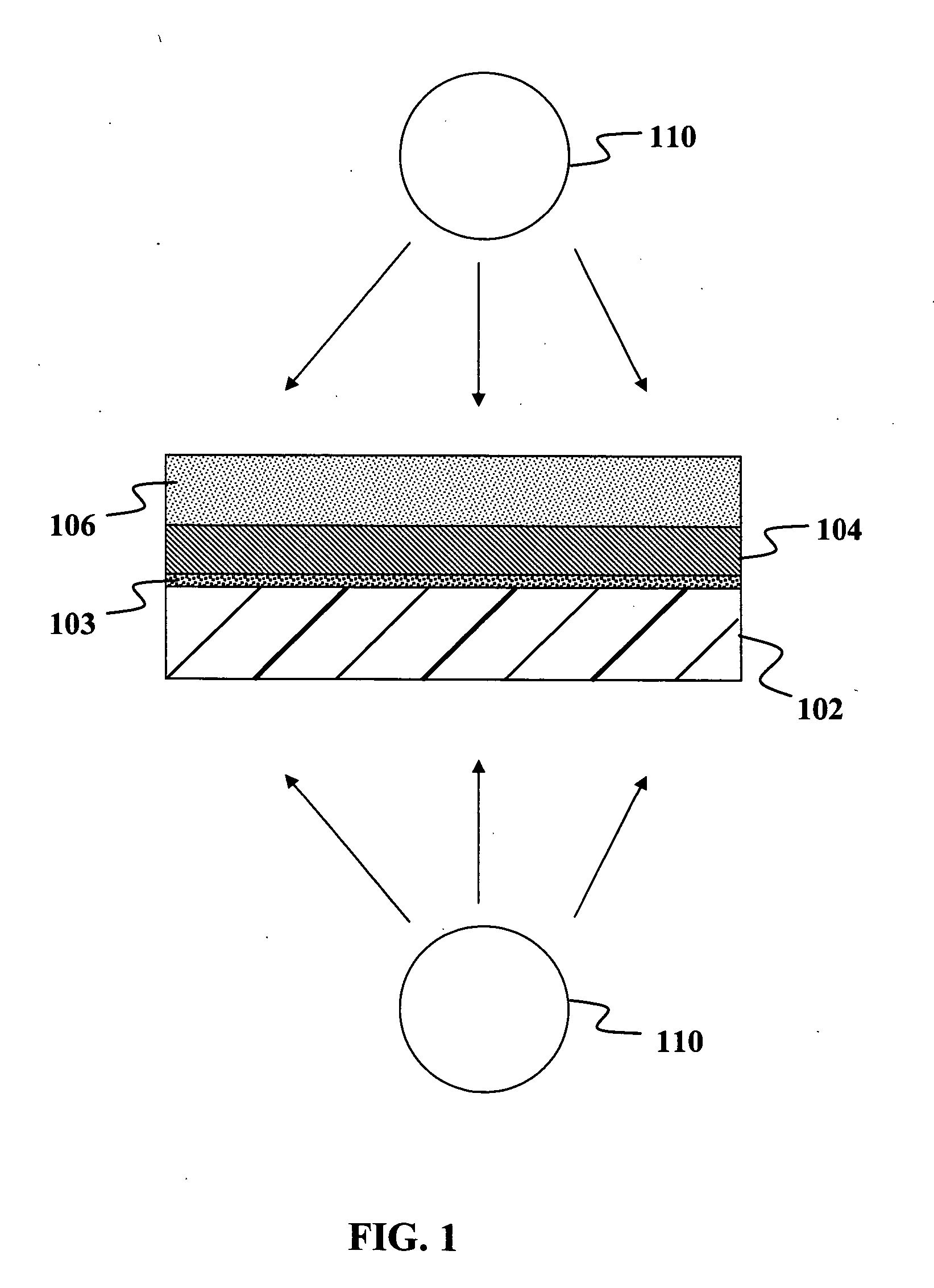

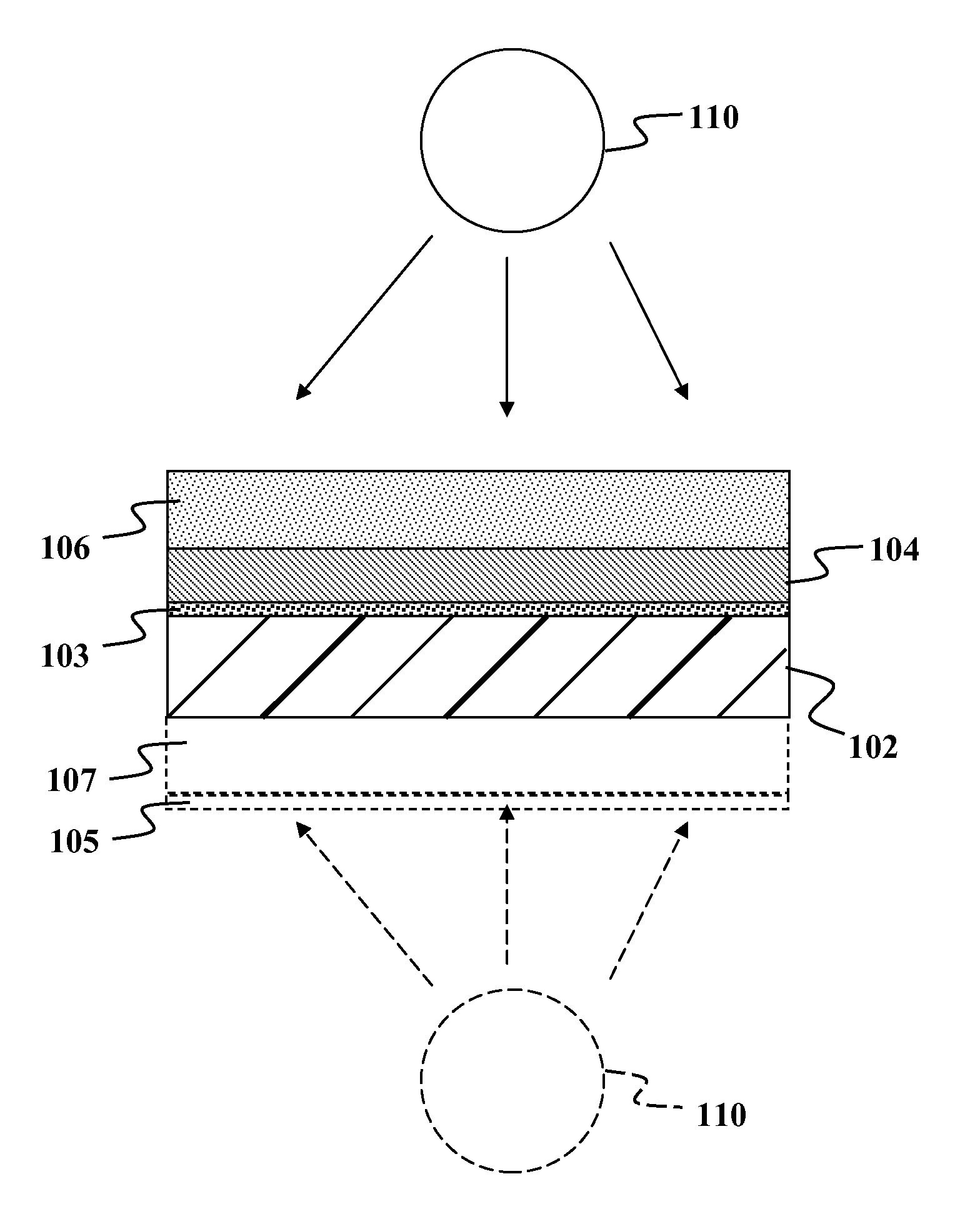

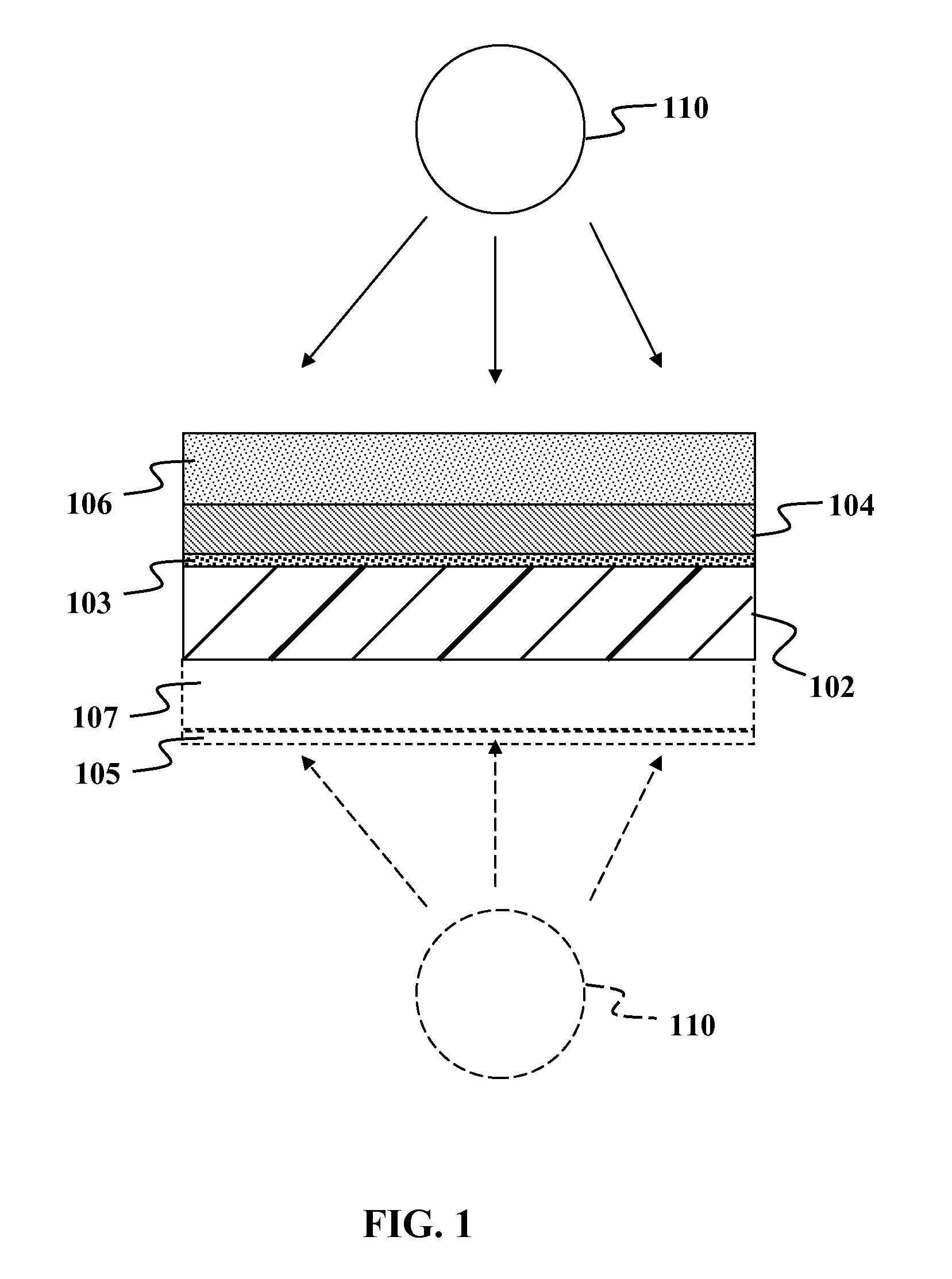

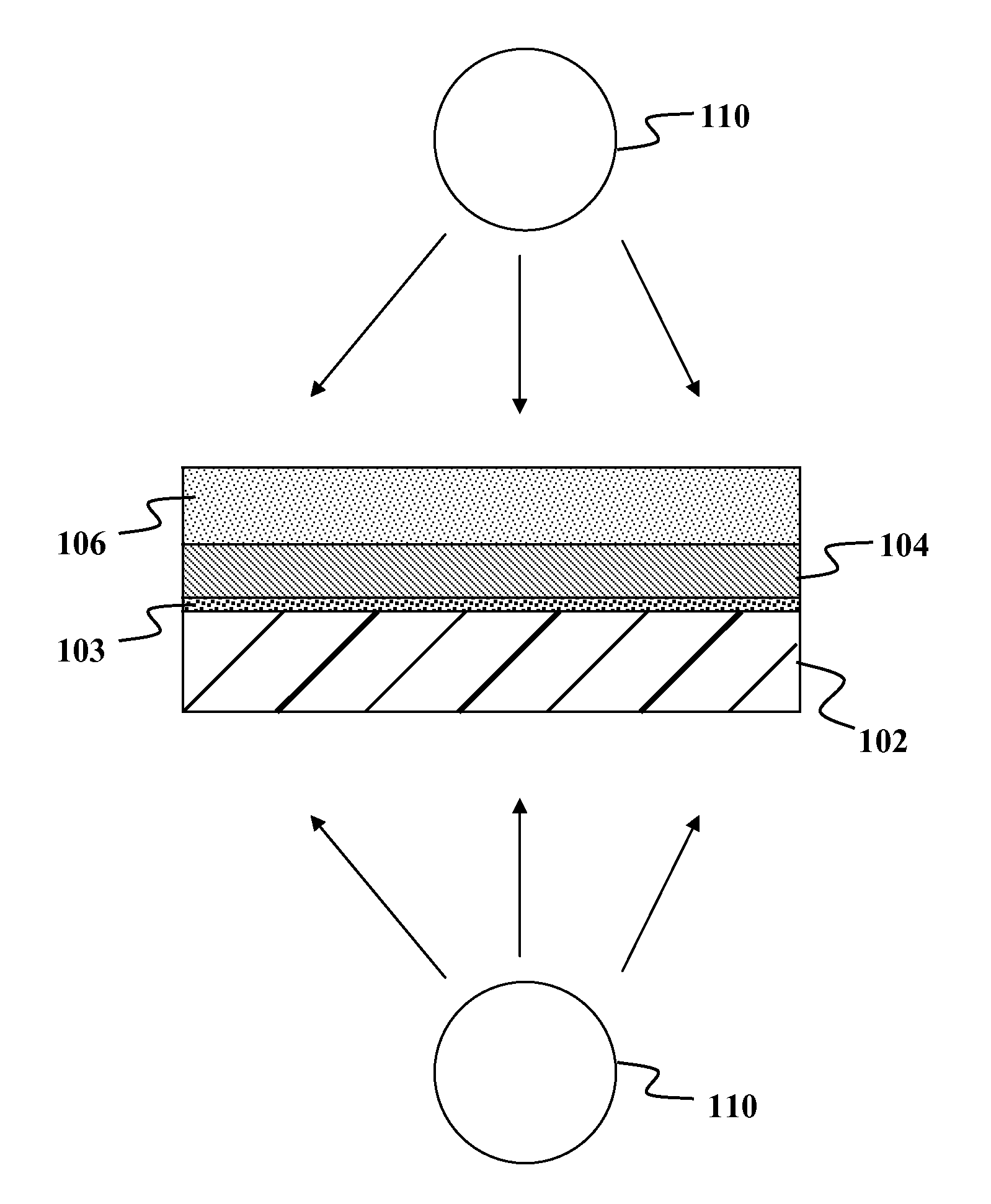

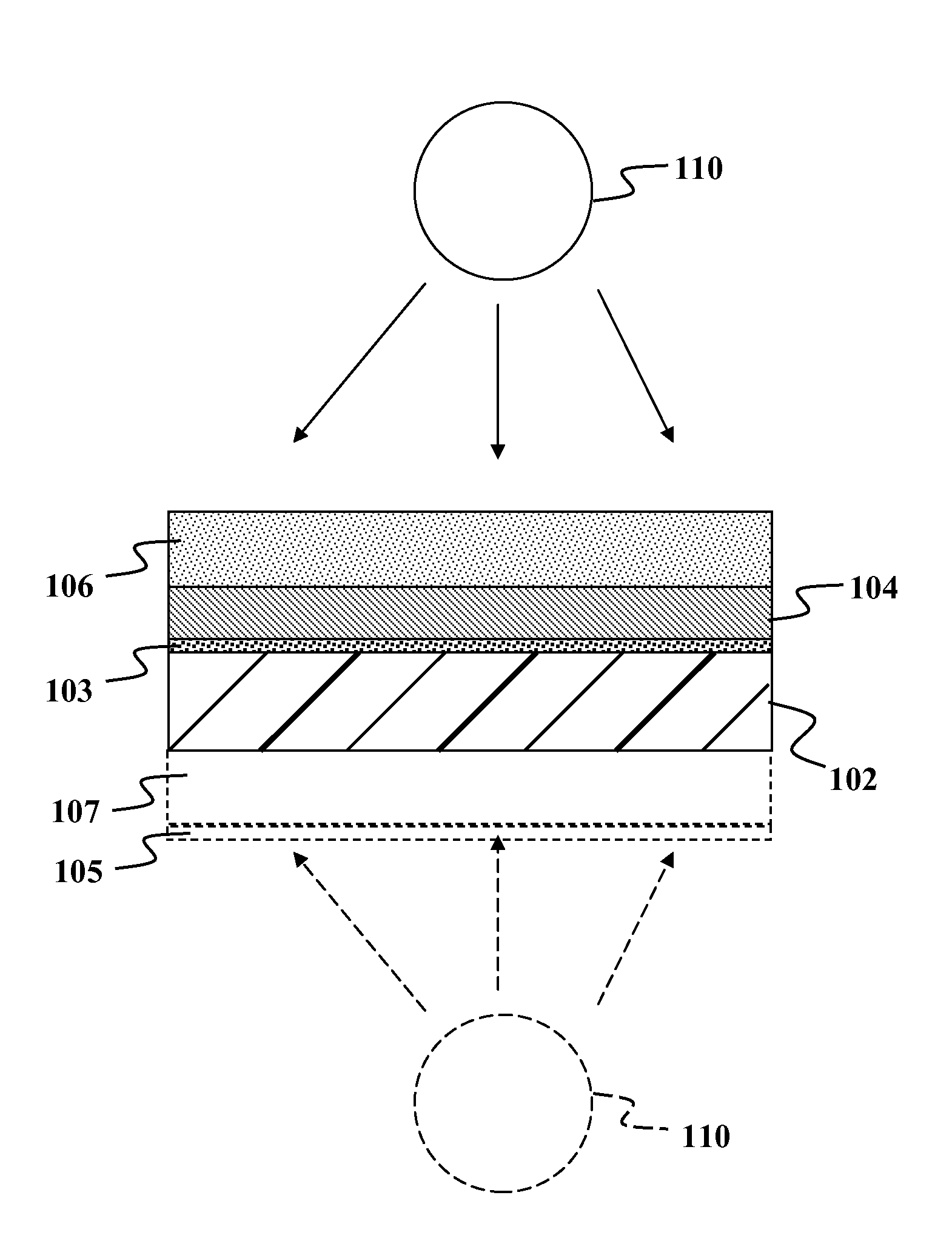

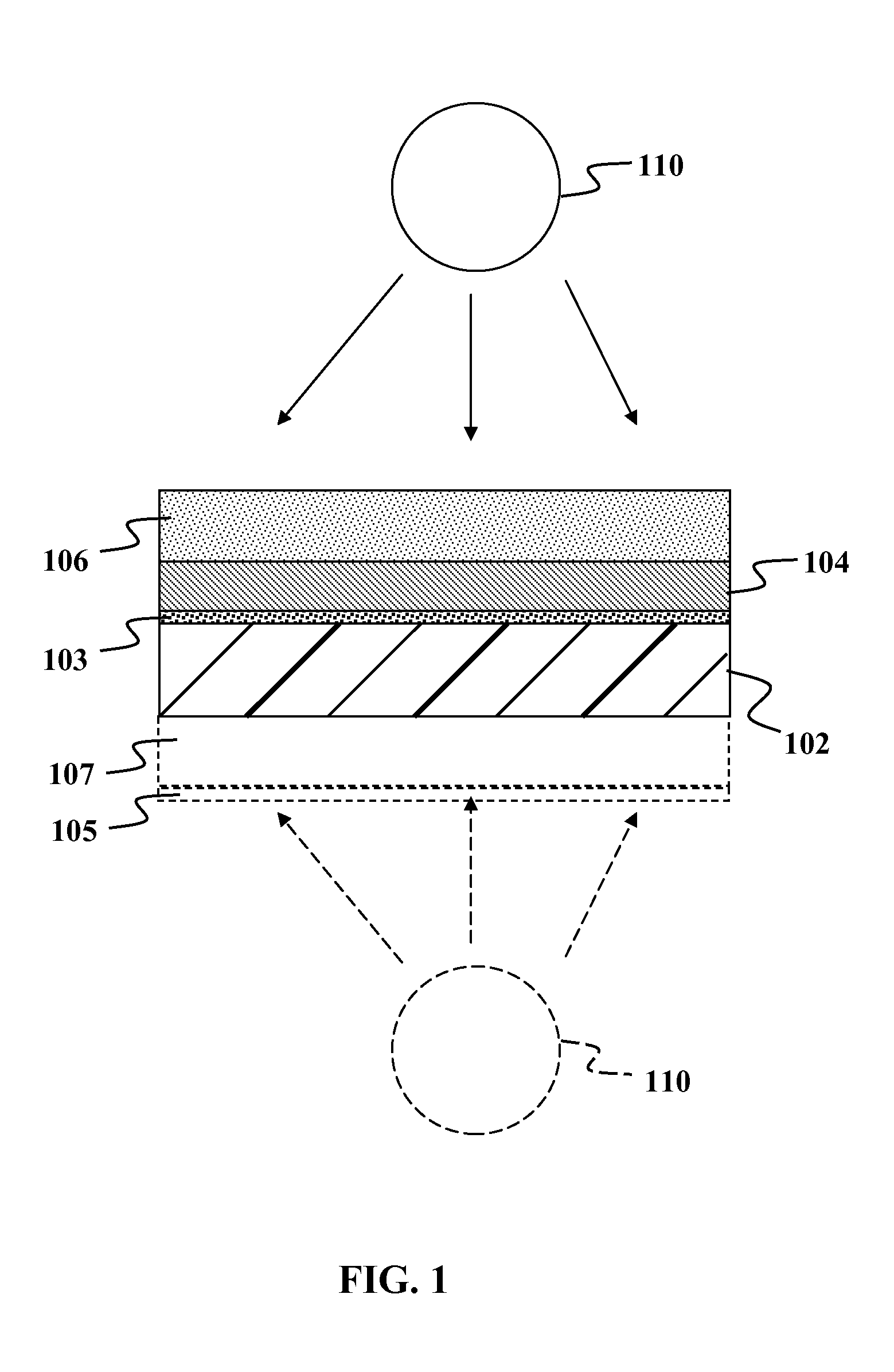

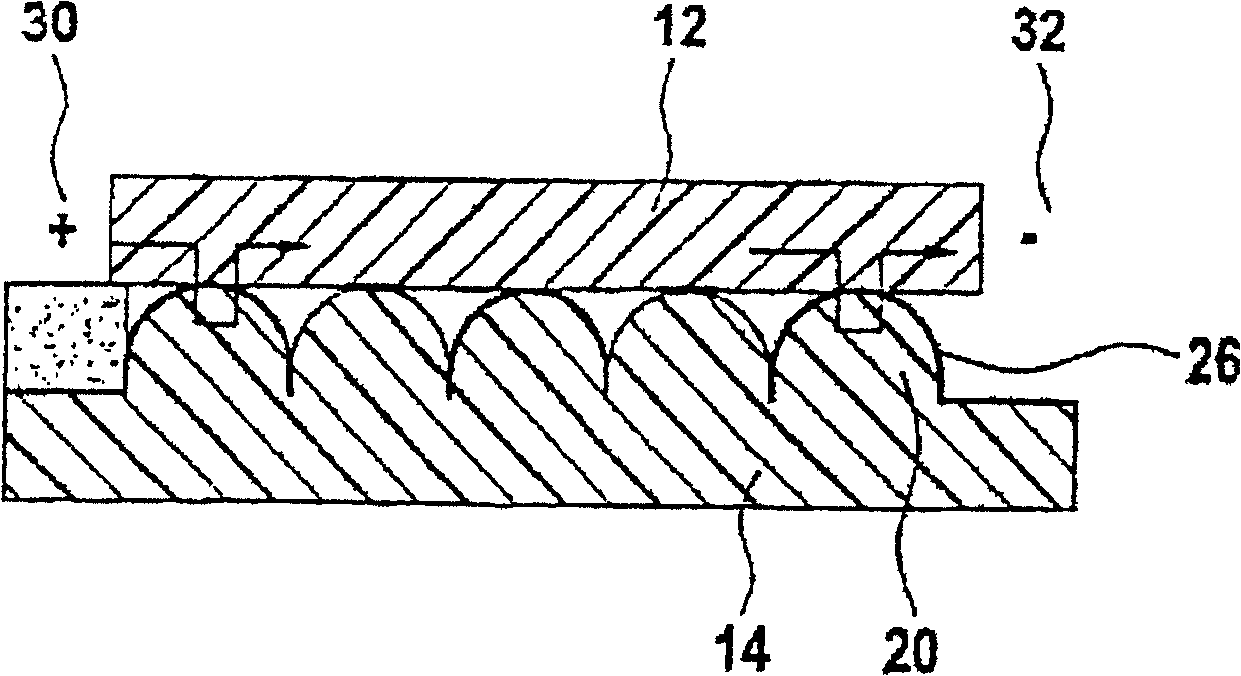

Formation of solar cells on foil substrates

InactiveUS20060060237A1Final product manufactureSemiconductor/solid-state device manufacturingPolymer foilSolar cell

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 2 to 30 minutes after which the temperature is reduced.

Owner:AERIS CAPITAL SUSTAINABLE IP

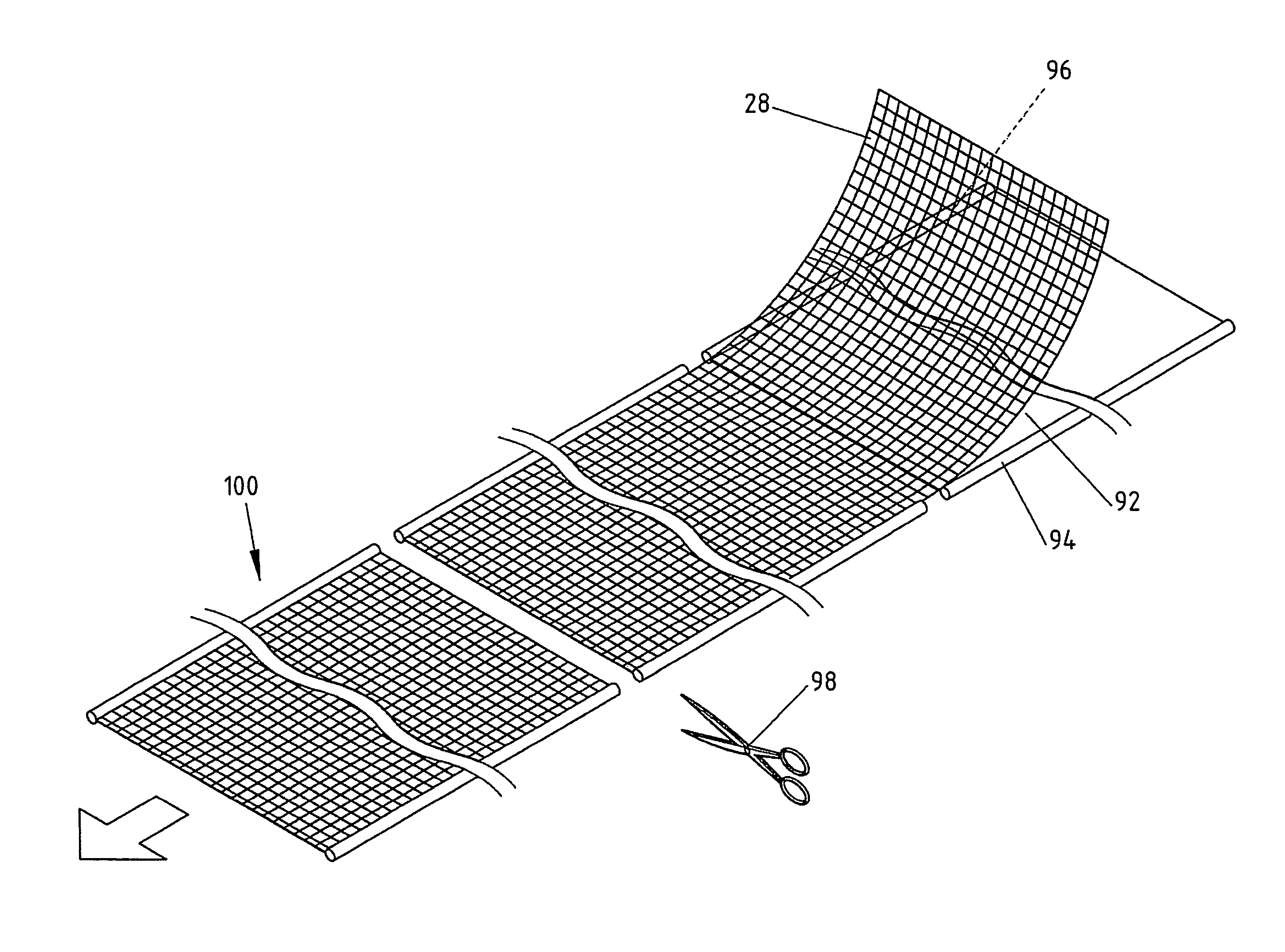

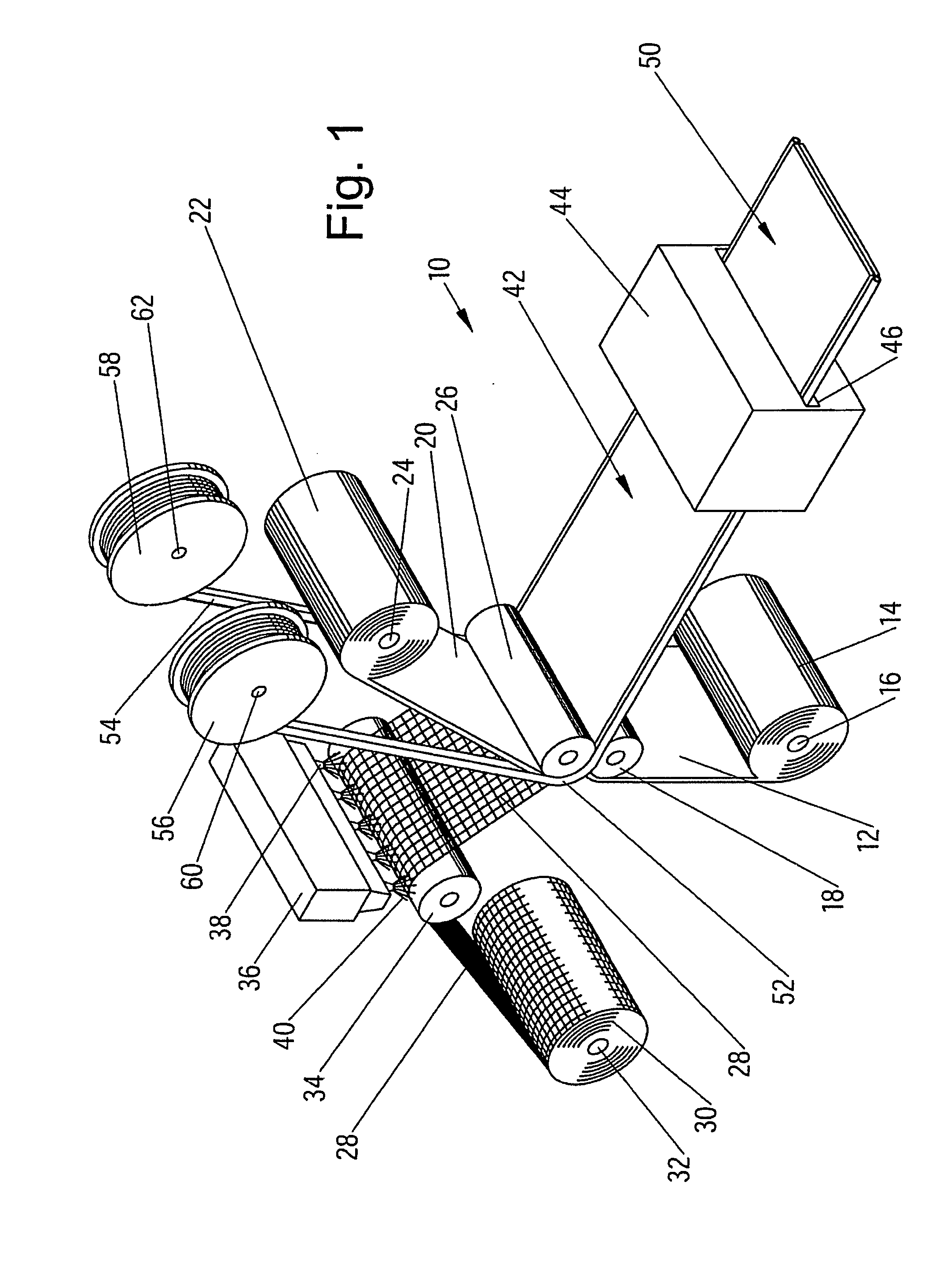

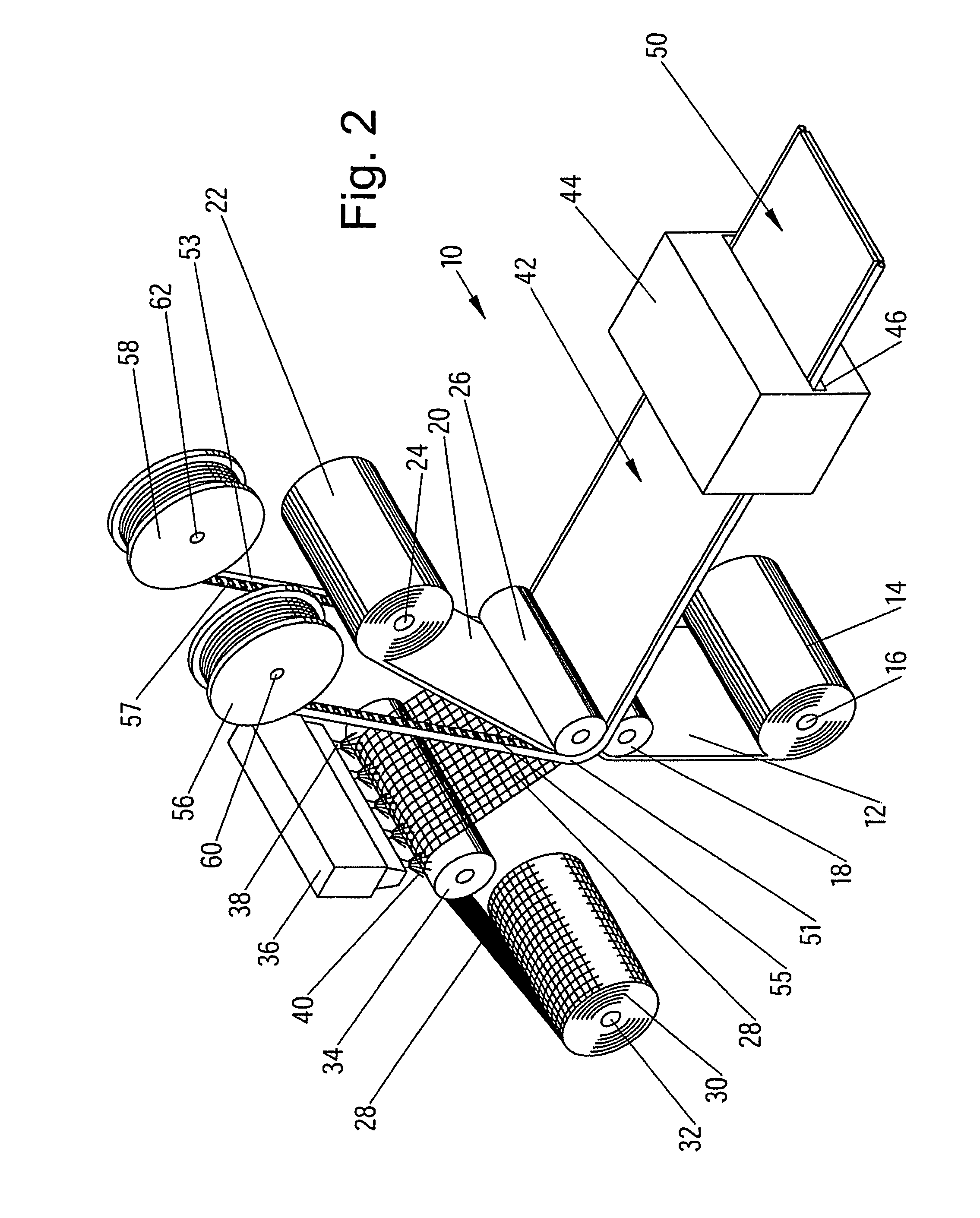

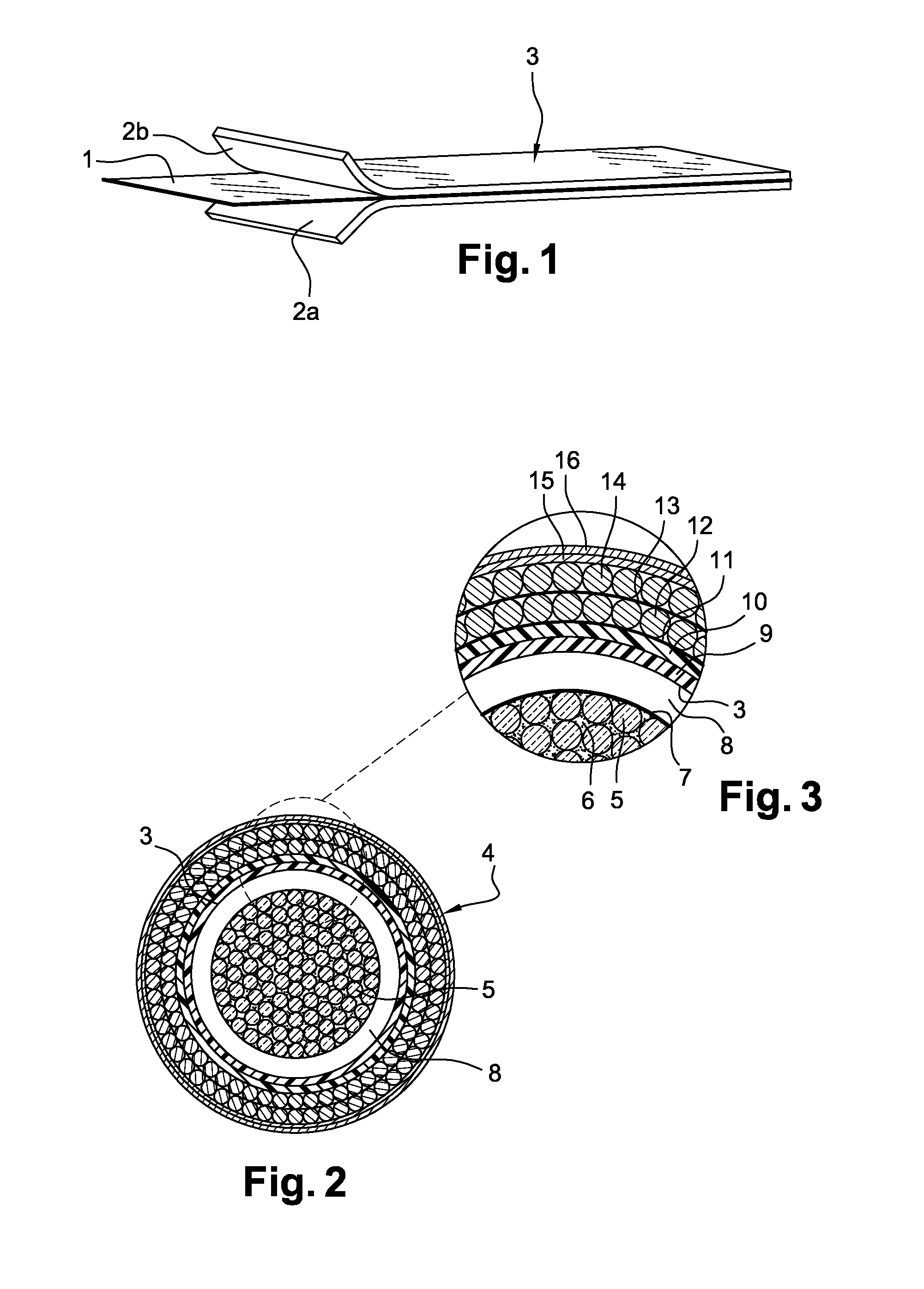

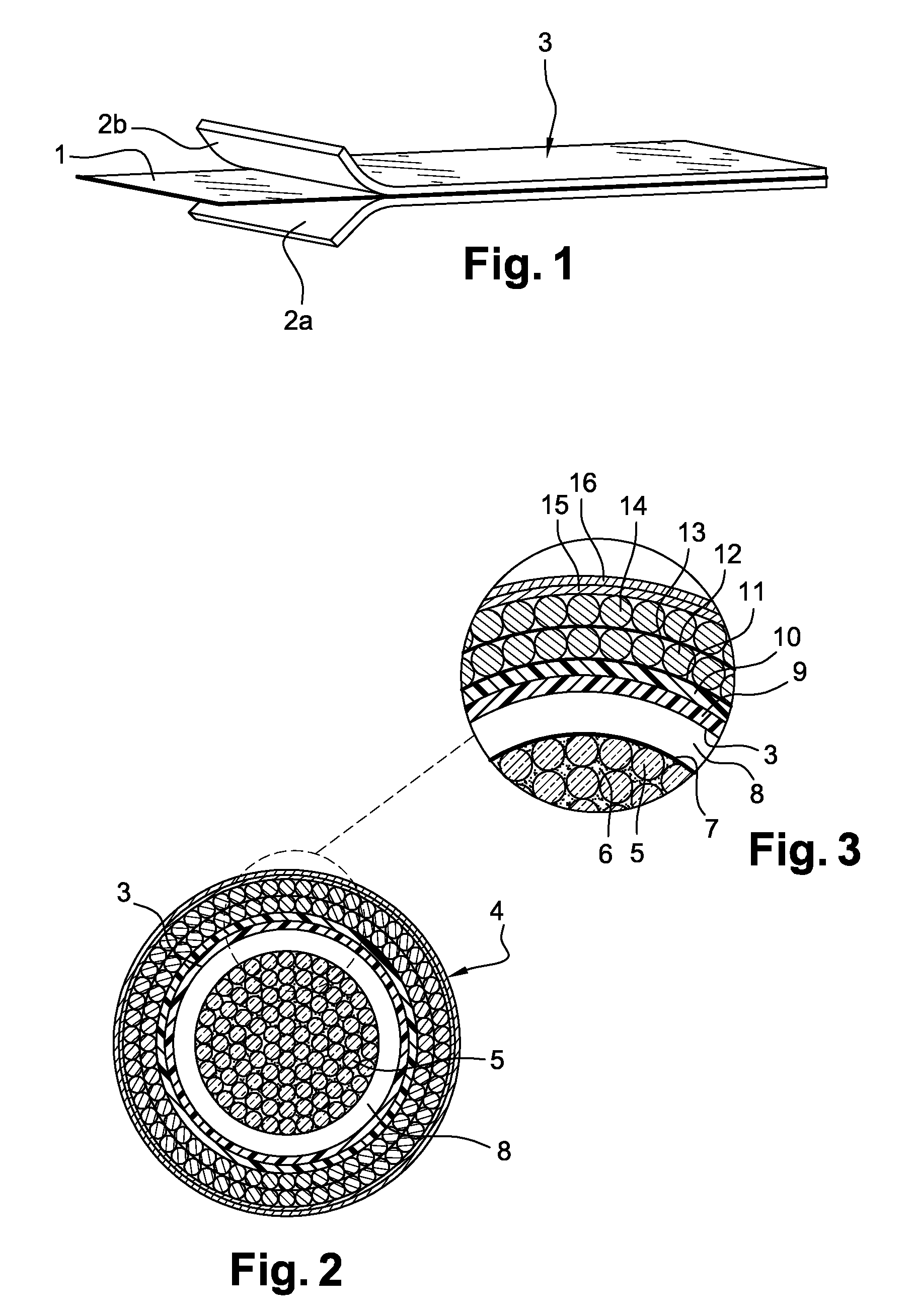

Membrane and a method of producing a membrane

InactiveUS20050170720A1Easy to buildLow in its friction propertyWarp knittingKnotting netsFiberPolymer foil

A membrane, particularly a weather protection membrane, is made from a reinforcing element, such as a regularly laid, woven or non-woven fabric, grid, mesh or scrim having a dimensionally mechanical stable polymer fiber, filament or wire material. First and second polymer foils are provided, preferably of a weather resistant polymer material. Two bands of polymer material are further provided, preferably of a weather resistant polymer material, including a woven or non-woven layer and exhibiting low frictional properties. The reinforcing element is interlaid and sandwiched between the first and second foils, and the bands are positioned edgewise at the first and second foils, and at least partly overlapping the reinforcing element. The first and second foils are laminated together and to the bands for sandwiching the foils for providing an integral structure.

Owner:ICOPAL PLASTIC MEMBRANES

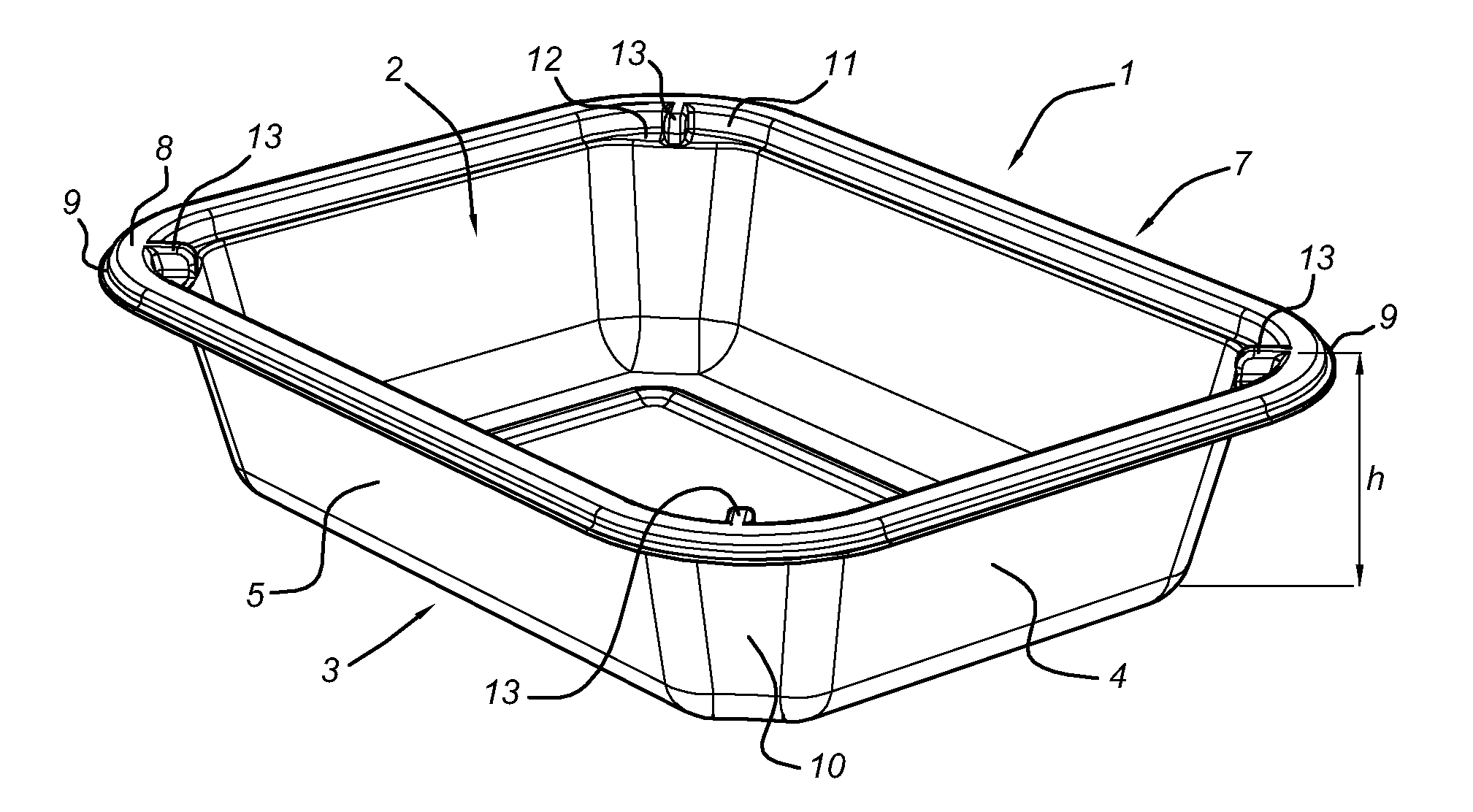

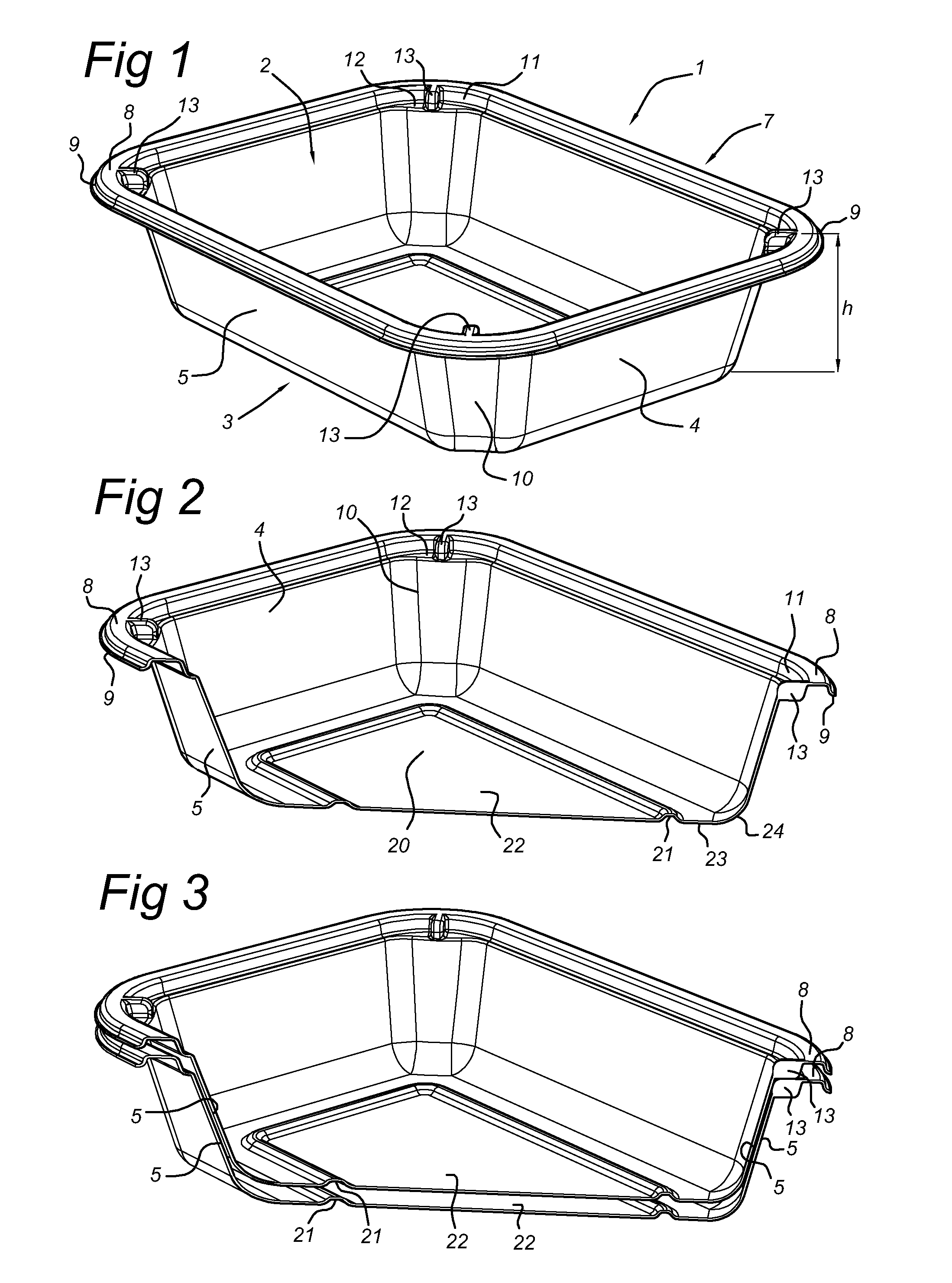

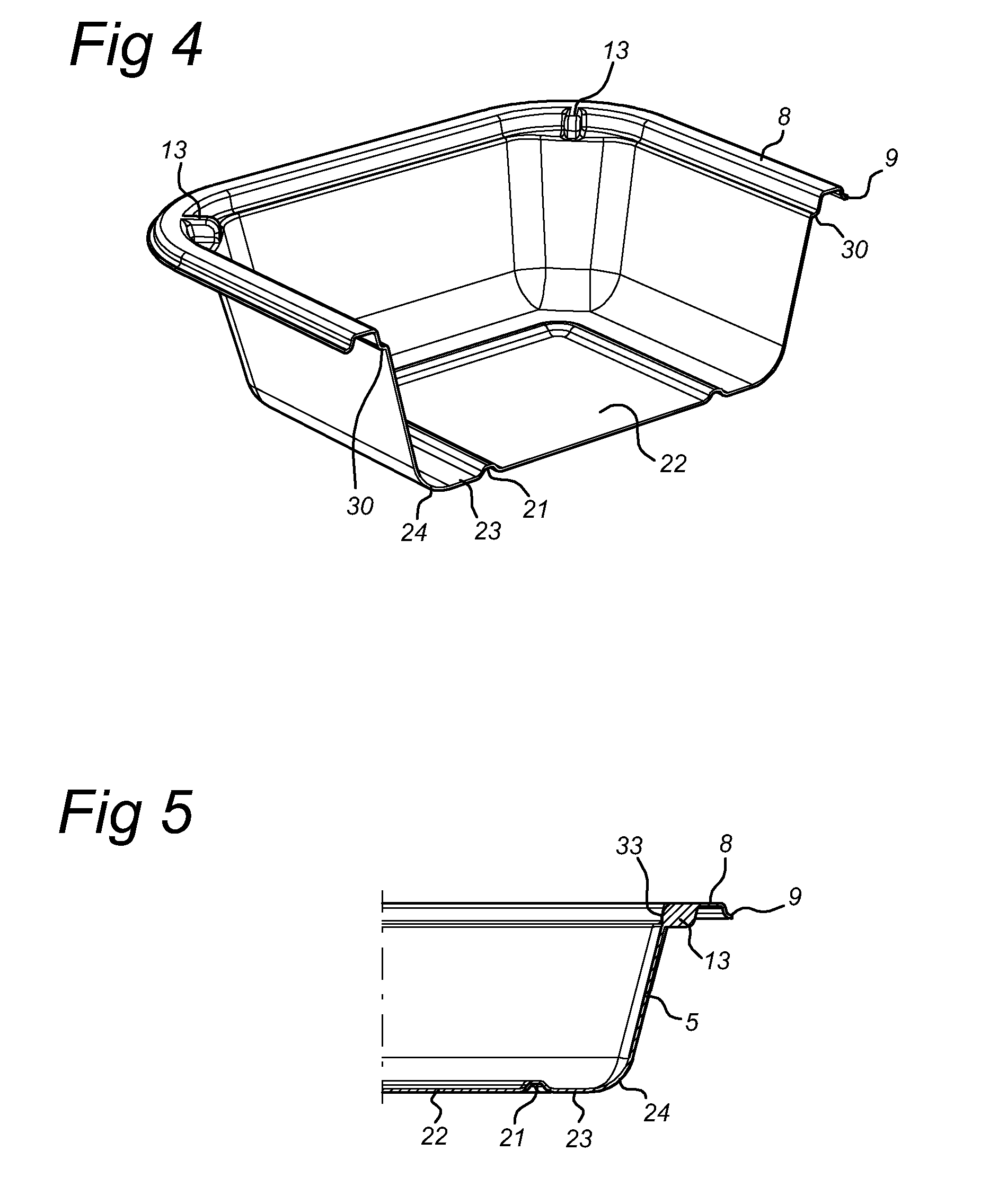

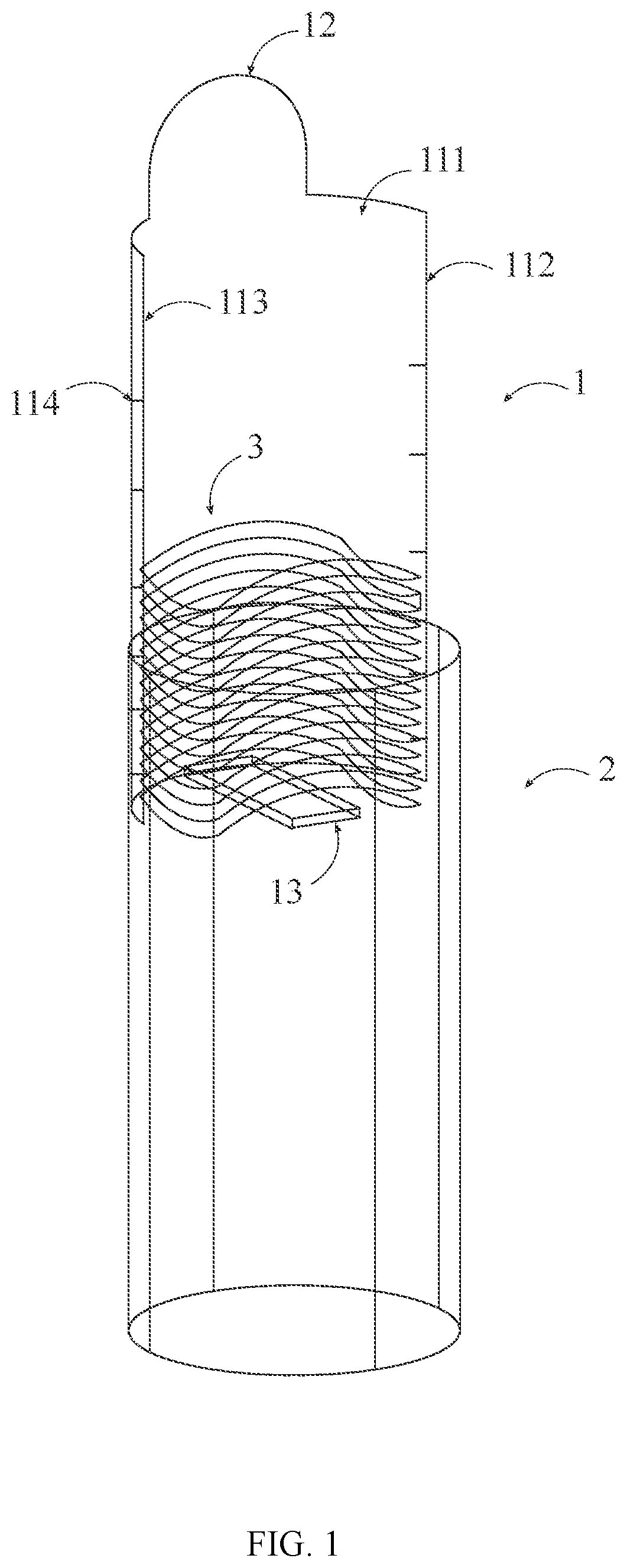

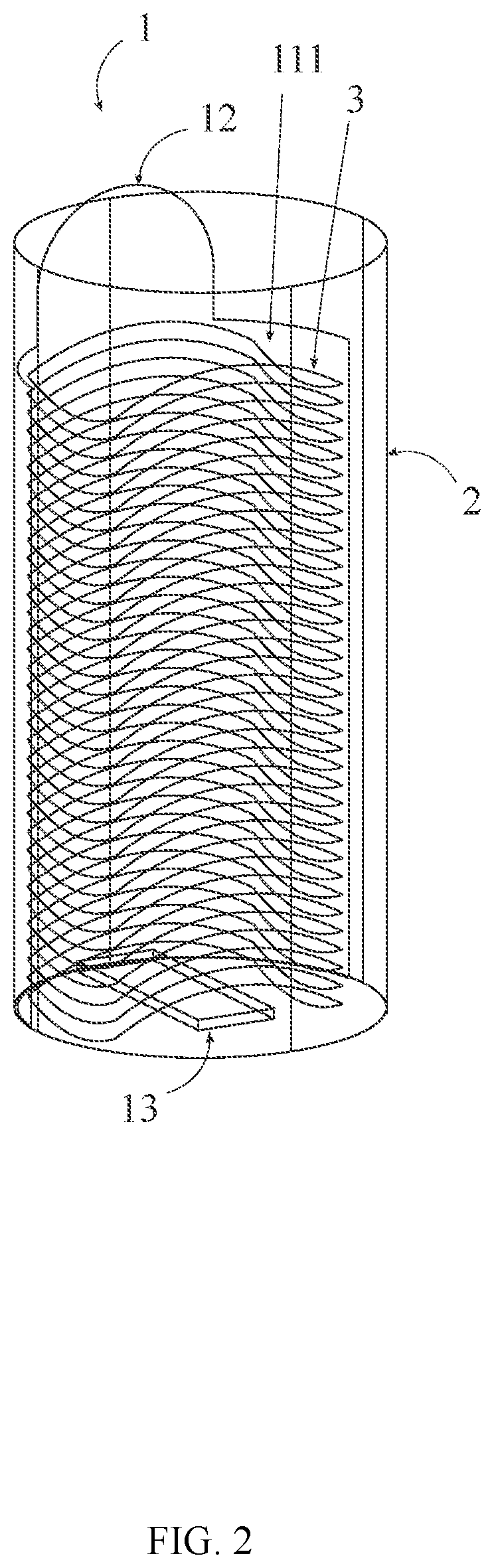

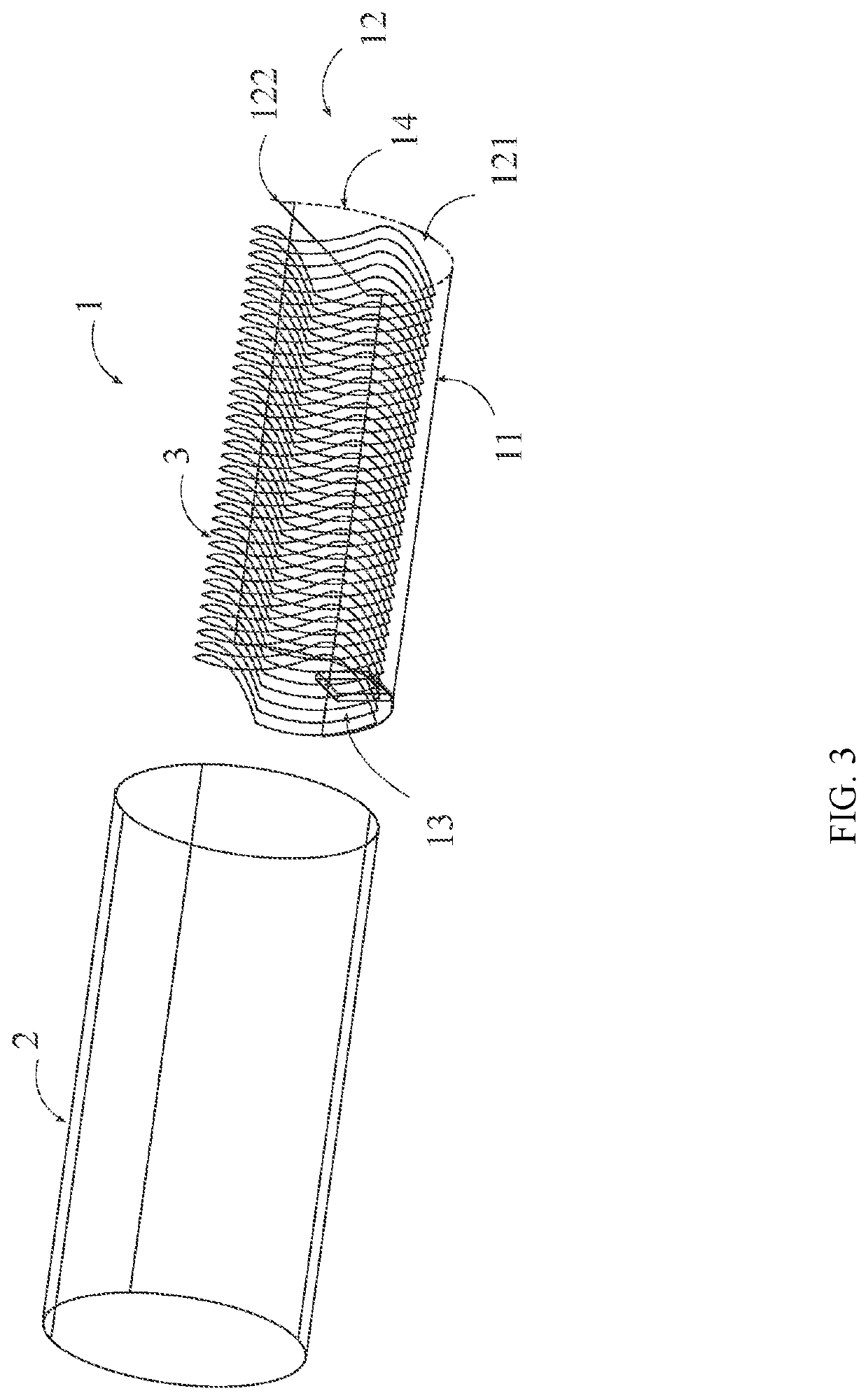

Food Packaging

InactiveUS20110139660A1Improve bindingAvoid crackingOther accessoriesContainer/bottle contructionPolymer foilEngineering

The invention relates to a food packaging (1), for instance a food tray, having a base and side walls (4, 5) from a dimensionally stable moulded fibre layer for providing rigidity to said packaging and enclosing at least one inside volume, a polymer foil layer laminated to said moulded fibre layer, and de-stacking notches (13) within the circumference of and adjacent to, a circumferential rim (7), for preventing the outside of said food packaging touching the inside of another, identical food packaging when it is stacked in the food packaging.

Owner:HUHTAMAKI NEDERLAND

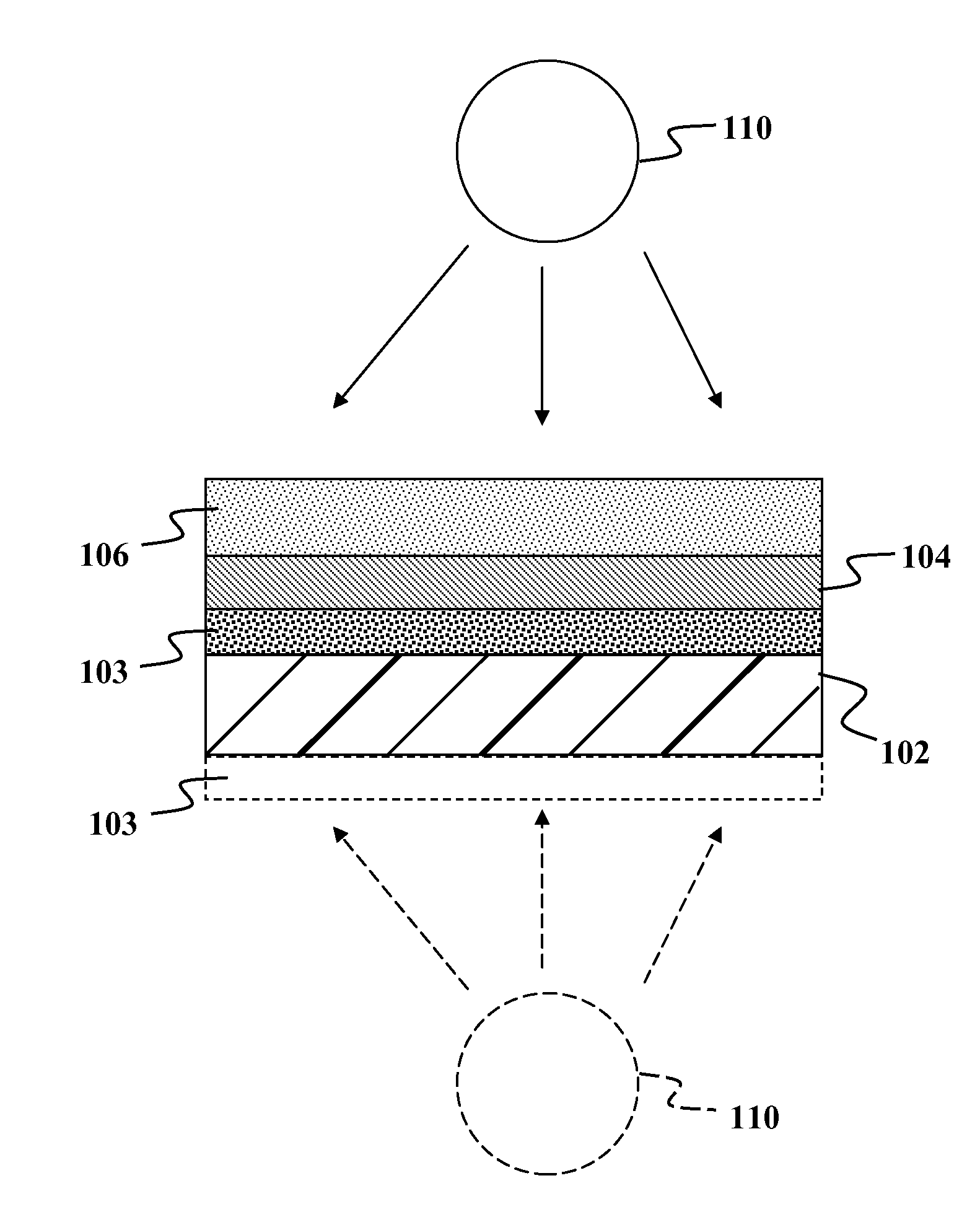

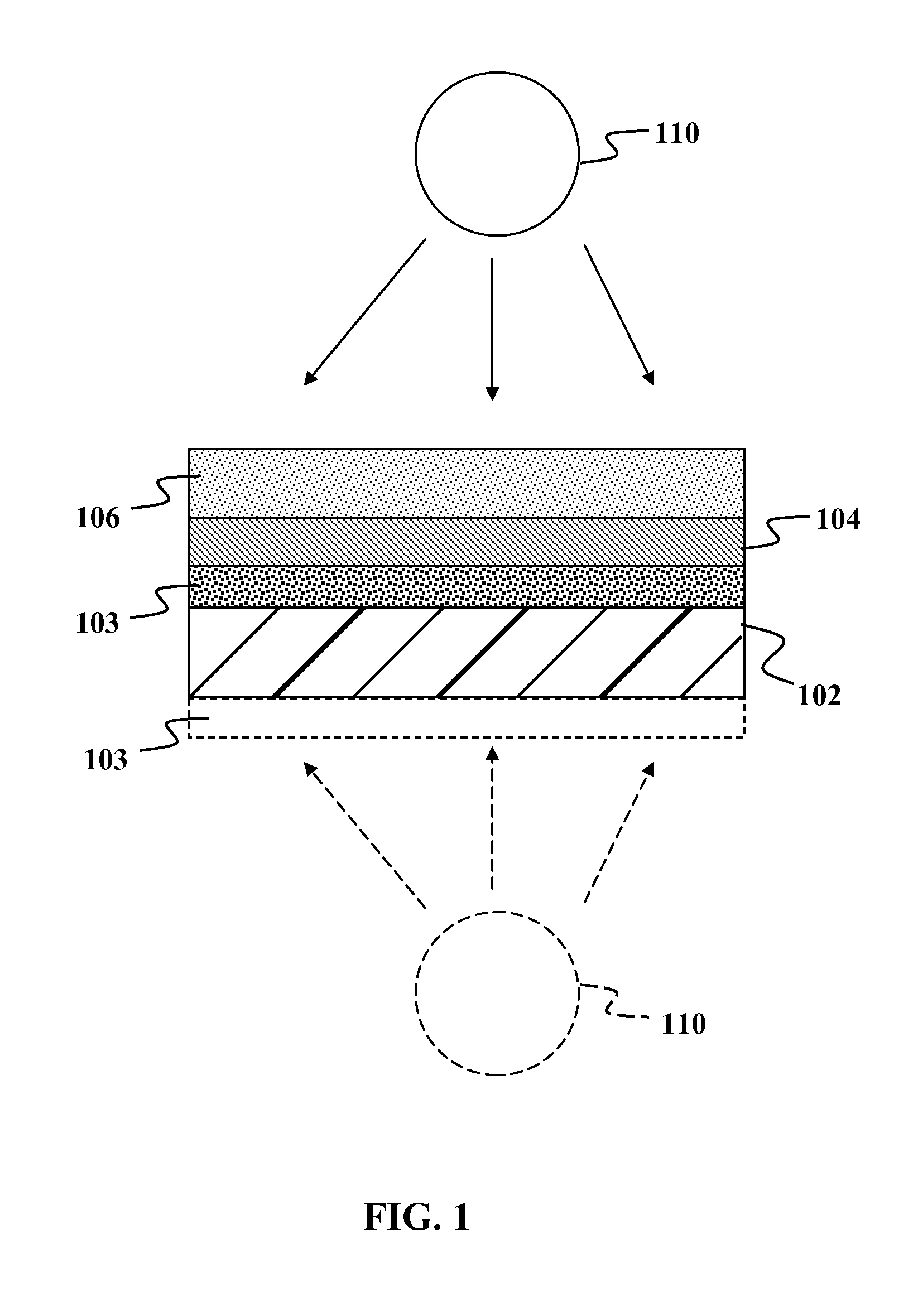

Formation of photovoltaic absorber layers on foil substrates

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 1 to 30 minutes after which the temperature is reduced.

Owner:AERIS CAPITAL SUSTAINABLE IP

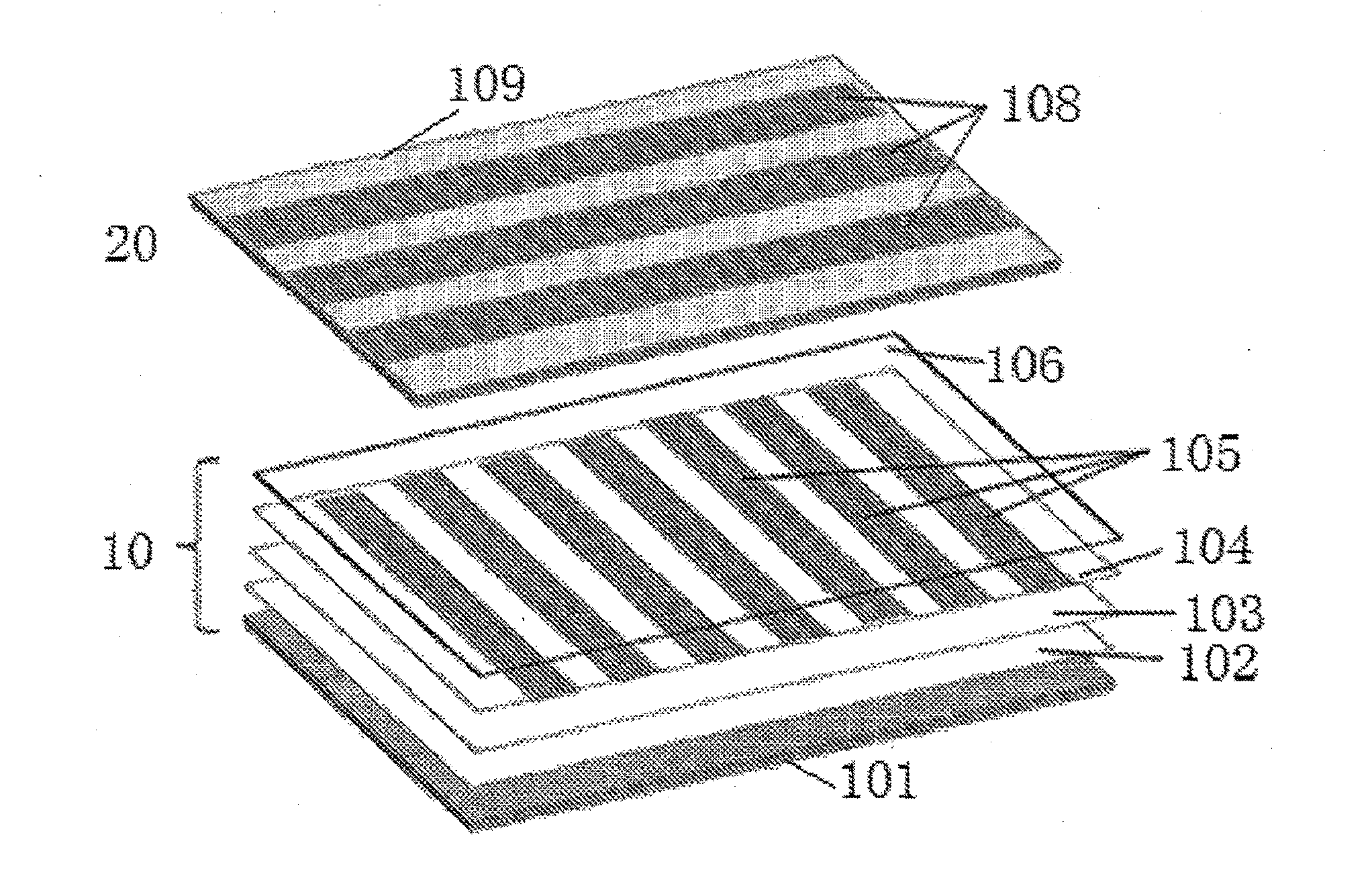

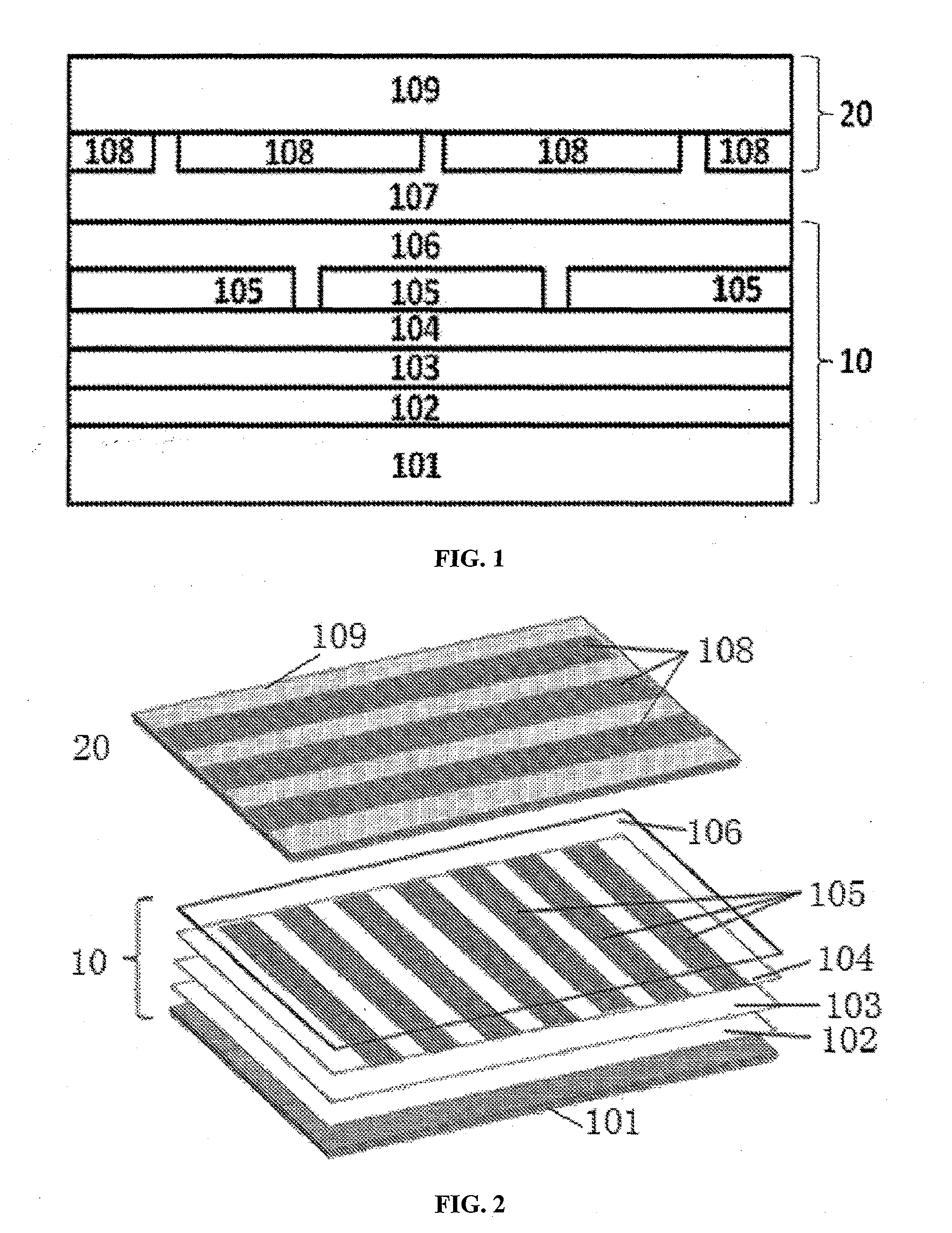

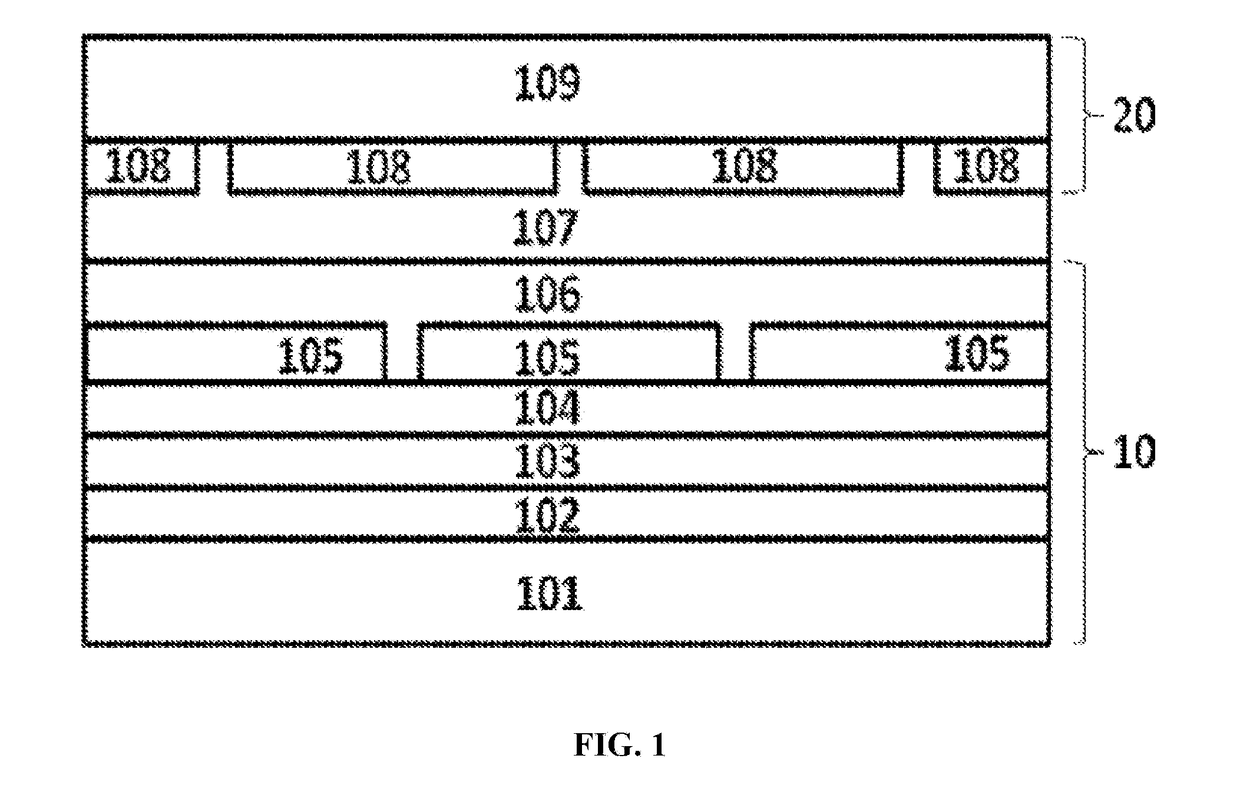

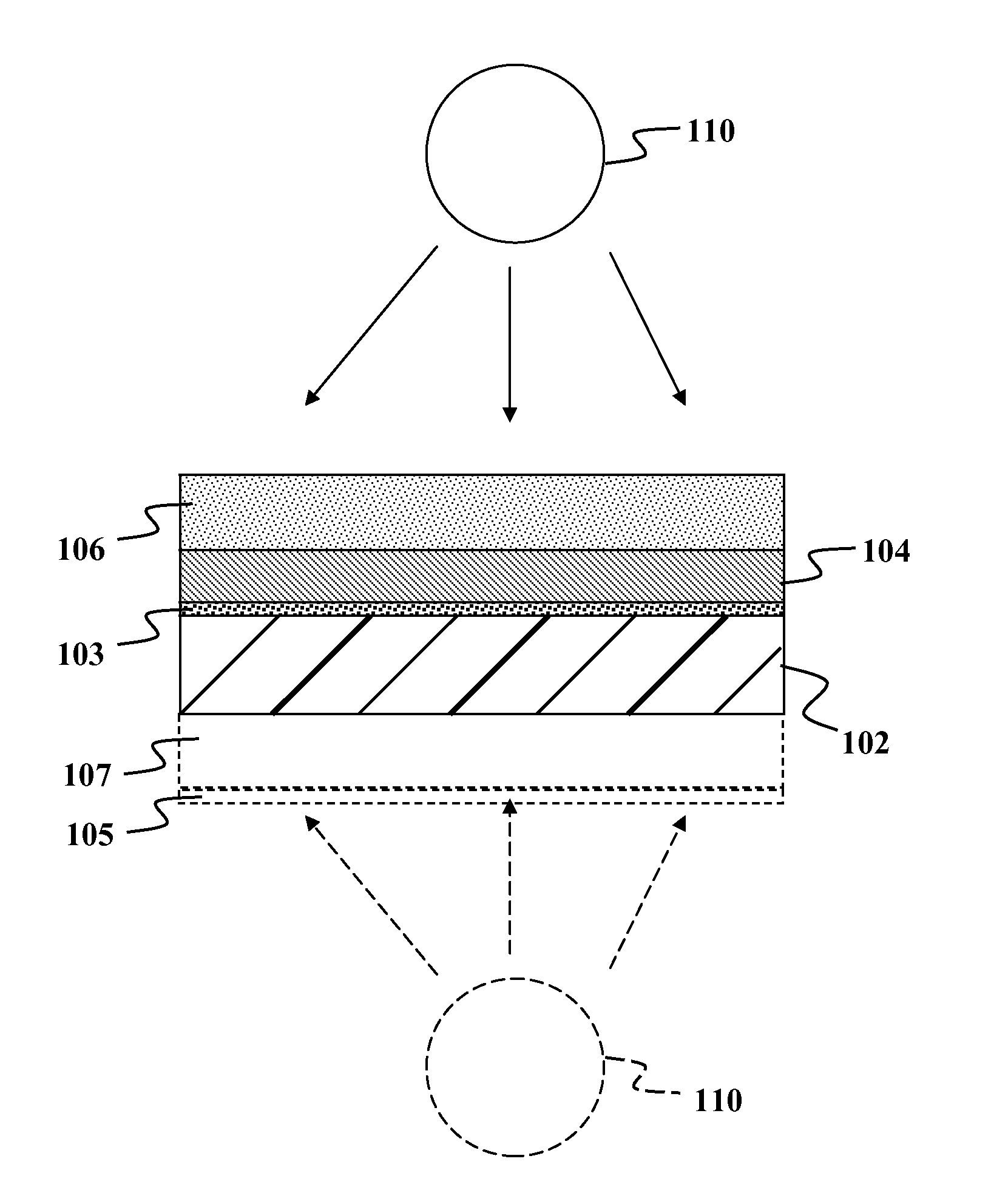

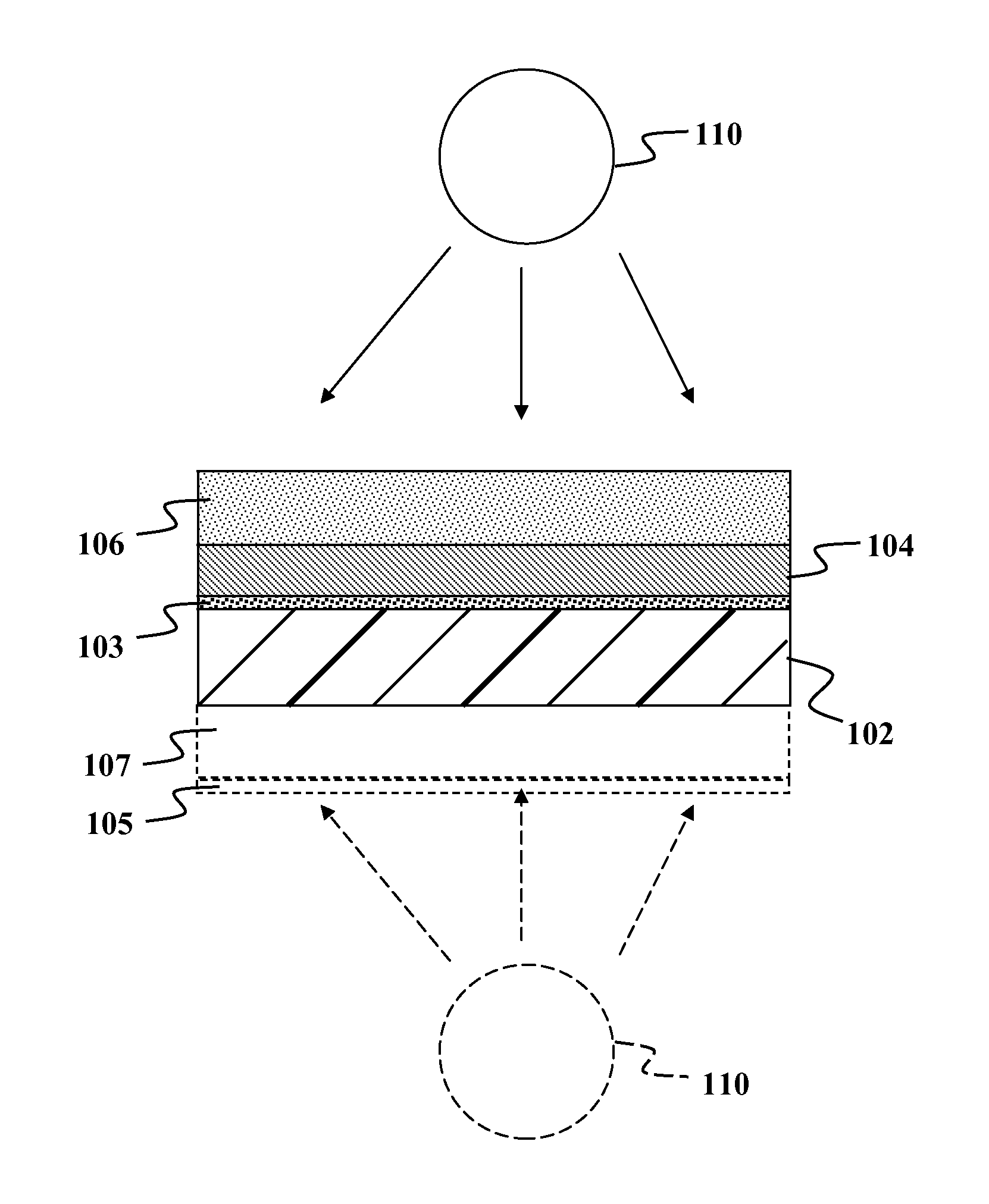

Touch control structure of an amoled display screen

ActiveUS20160306479A1Low costFlexible Touch ControlStatic indicating devicesSolid-state devicesPolymer foilActive matrix

The present invention discloses a touch control structure of an active-matrix organic light-emitting diode display screen which is disposed on a display screen substrate, the touch control structure comprises a transmitting structure and a receiving structure that are mutually inductive, the transmitting structure further comprises a first encapsulation film, a first patterned electrode and a second encapsulation film, wherein the first encapsulation film is formed on an organic light-emitting diode device disposed on the display screen substrate, the first patterned electrode is formed on the first encapsulation film, and the second encapsulation film is formed upon the first patterned electrode; the receiving structure further comprises a flexible polymer foil sheet and a second patterned electrode formed on the flexible polymer foil sheet, wherein the flexible polymer foil sheet is adhered to the second encapsulation film, and the first patterned electrode and the second patterned electrode are oppositely disposed. By configuring the transmitting structure and the receiving structure that are mutually inductive, the present invention significantly simplifies the manufacture process, reduces the cost, and can also achieve flexible touch control.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

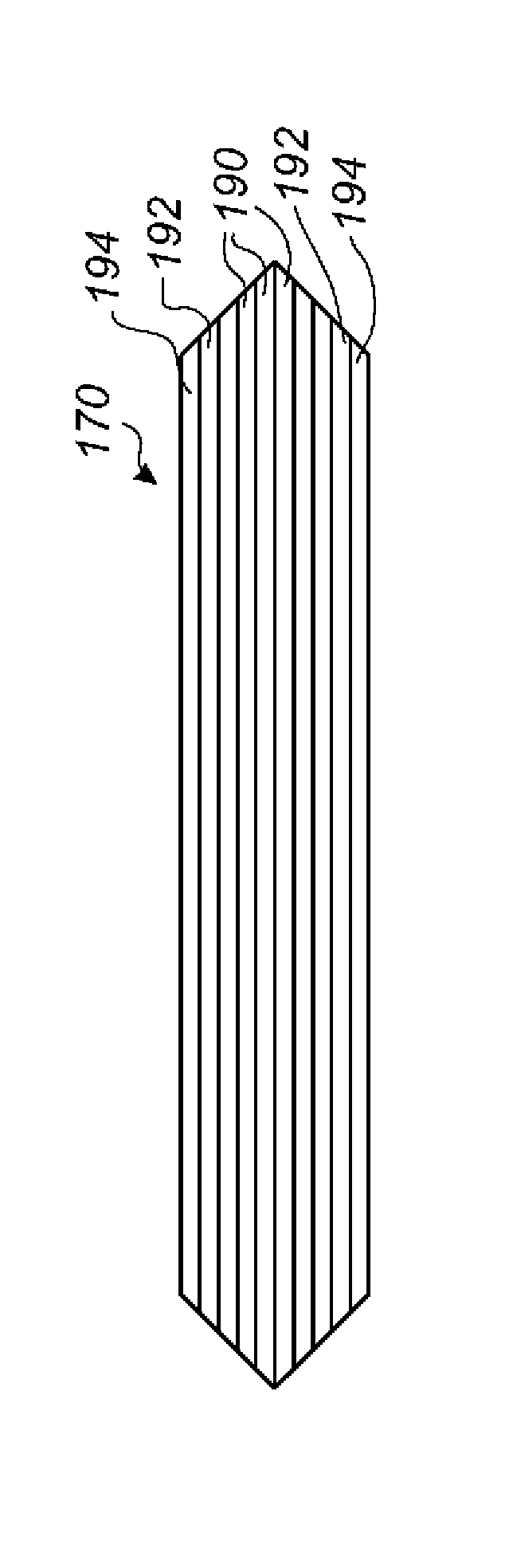

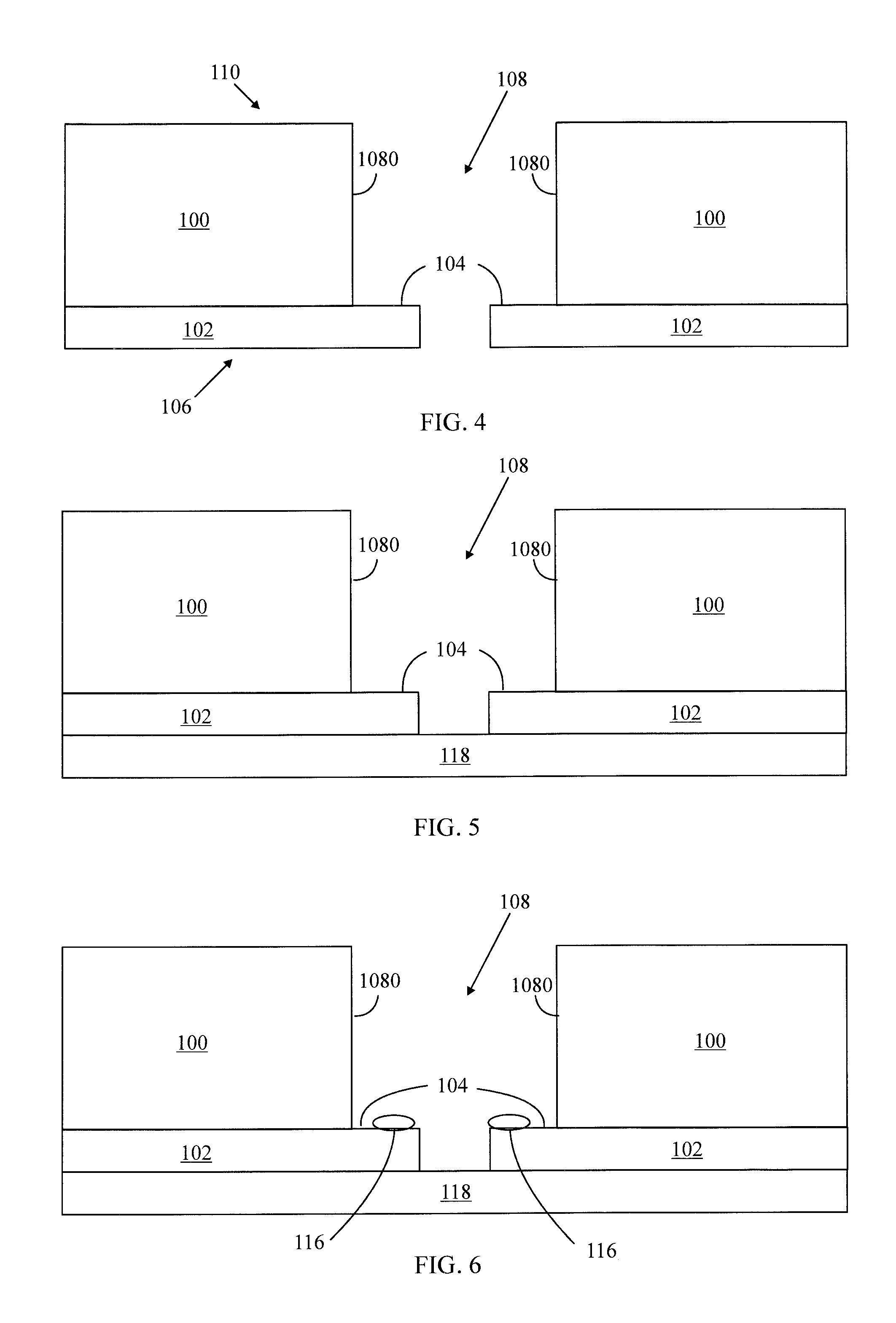

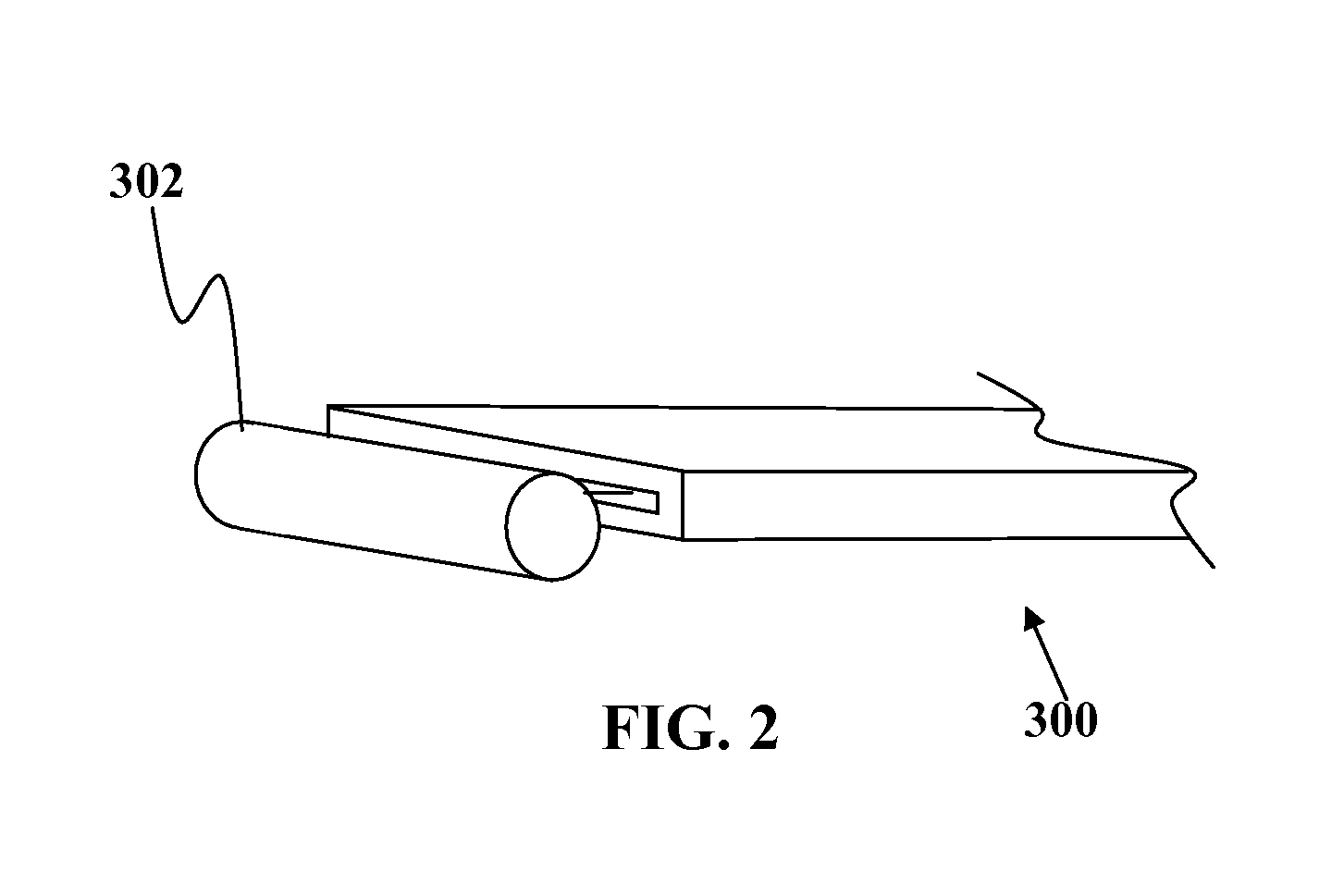

Method of manufacturing a composite structure with prefabricated reinforcement element

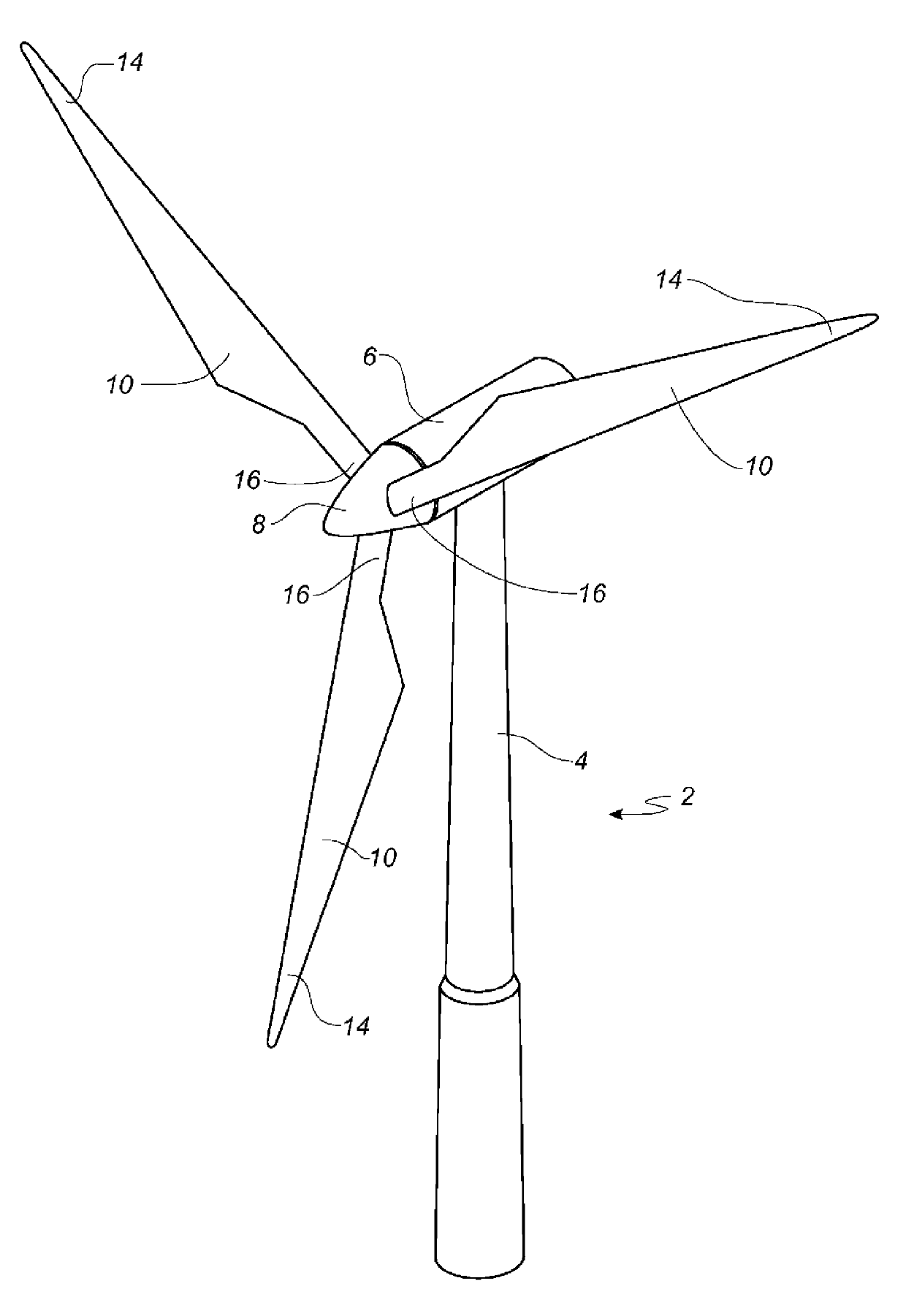

ActiveCN102458805AMake sure not to buckleHigh mechanical strengthFinal product manufactureMachines/enginesPolymer foilFiber

A method of manufacturing a longitudinally extending composite structure including a shell part comprising a fibre reinforced polymer material including a polymer matrix and fibre material embedded in the polymer material is described. The shell part is manufactured in a closed mould comprising at least a first outer mould part (110) having a first forming surface (112) and a second outer mould part (210) having a second forming surface (212). The method comprises the steps of : a) arranging a first fibre material in the first forming surface of the first outer mould part, b) arranging a pre-fabricated longitudinally extending reinforcement element (130), such as a beam or a web, on top of the first fibre material, the reinforcement element having a first side and a second side, and a first bonding surface and a second bonding surface, the reinforcement element being arranged so that the first bonding surface faces towards the first forming surface, c) arranging a second fibre material (252, 253, 270) in the second forming surface of the second outer mould part ( 210), d) sealing a polymer foil (276) above the second fibre material so as to retain the second fibre material against the second forming surface, e) closing the at least first outer mould part and the second outer mould part so as to form the closed mould, and so that the second bonding surface of the reinforcement element faces towards the second forming surface, f) forming a mould cavity by arranging a first vacuum bag (140) between the first outer mould part, the second outer mould part and the first side of the reinforcement element, and arranging a second vacuum bag (142) between the first outer mould part, the second outer mould part and the second side of the reinforcement element, g) evacuating the mould cavity, h) providing a resin in the mould cavity simultaneously with and / or subsequently to steps a) and c), and i) curing the resin in order to form the composite structure.

Owner:LM GLASSFIBER

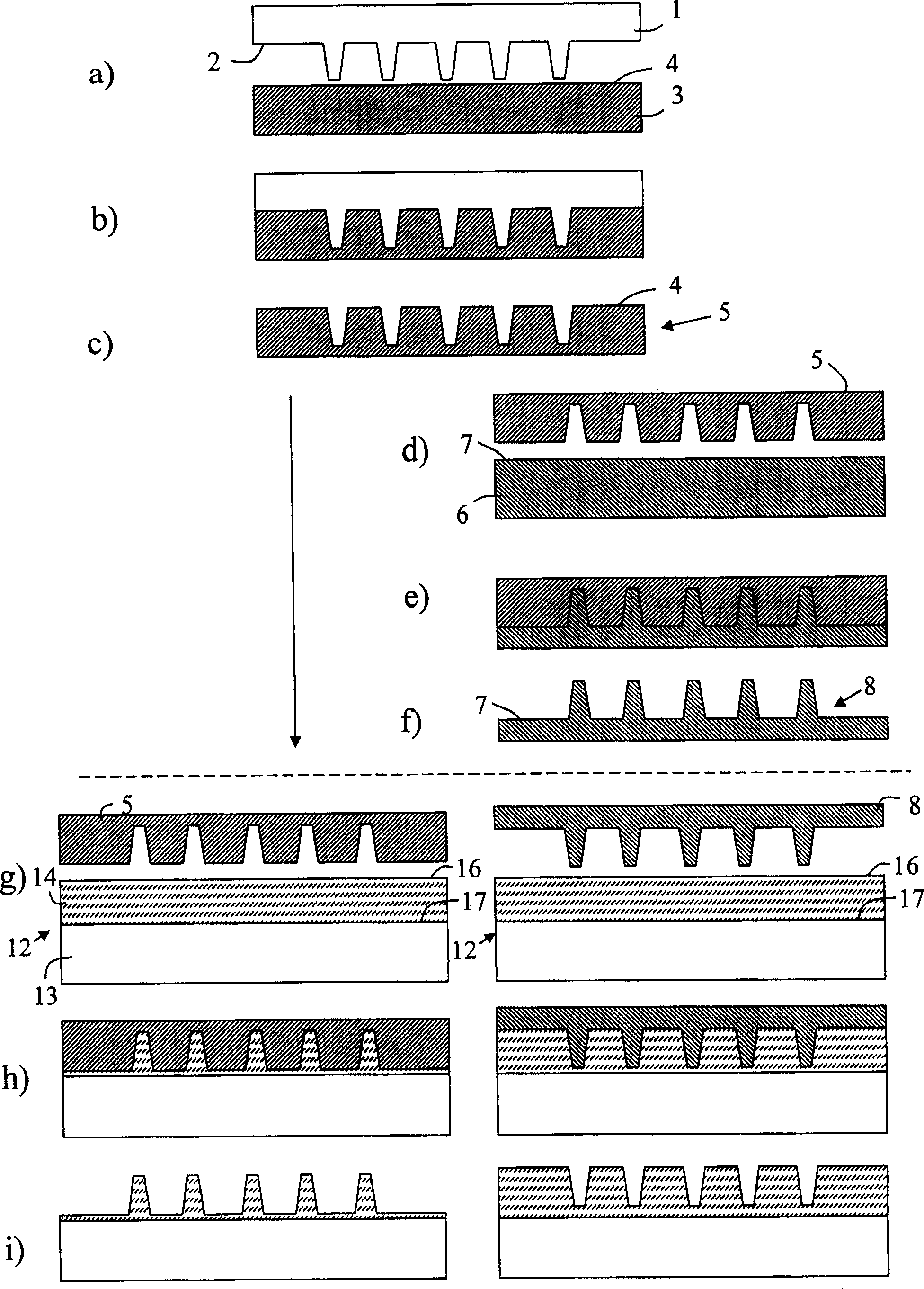

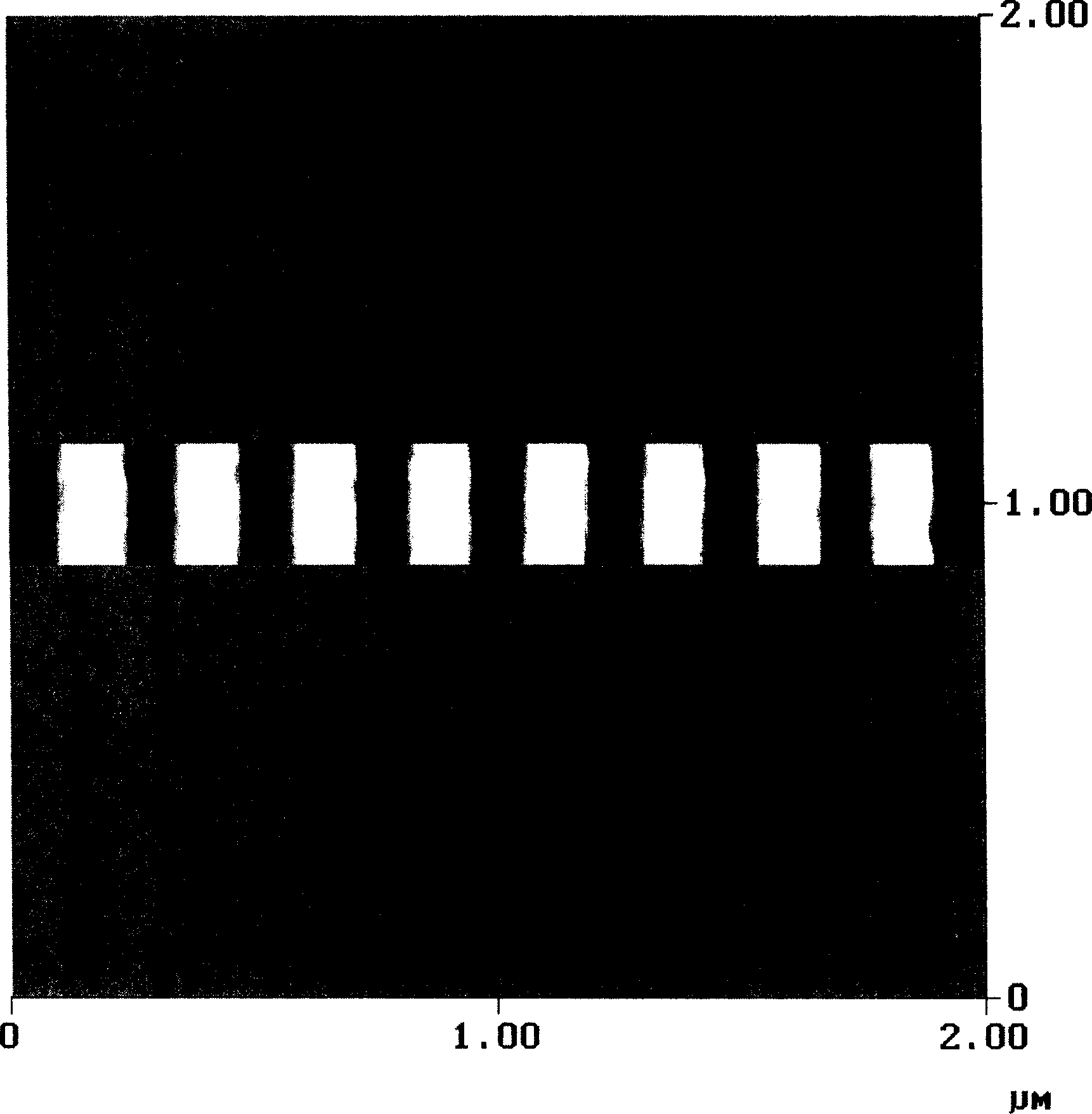

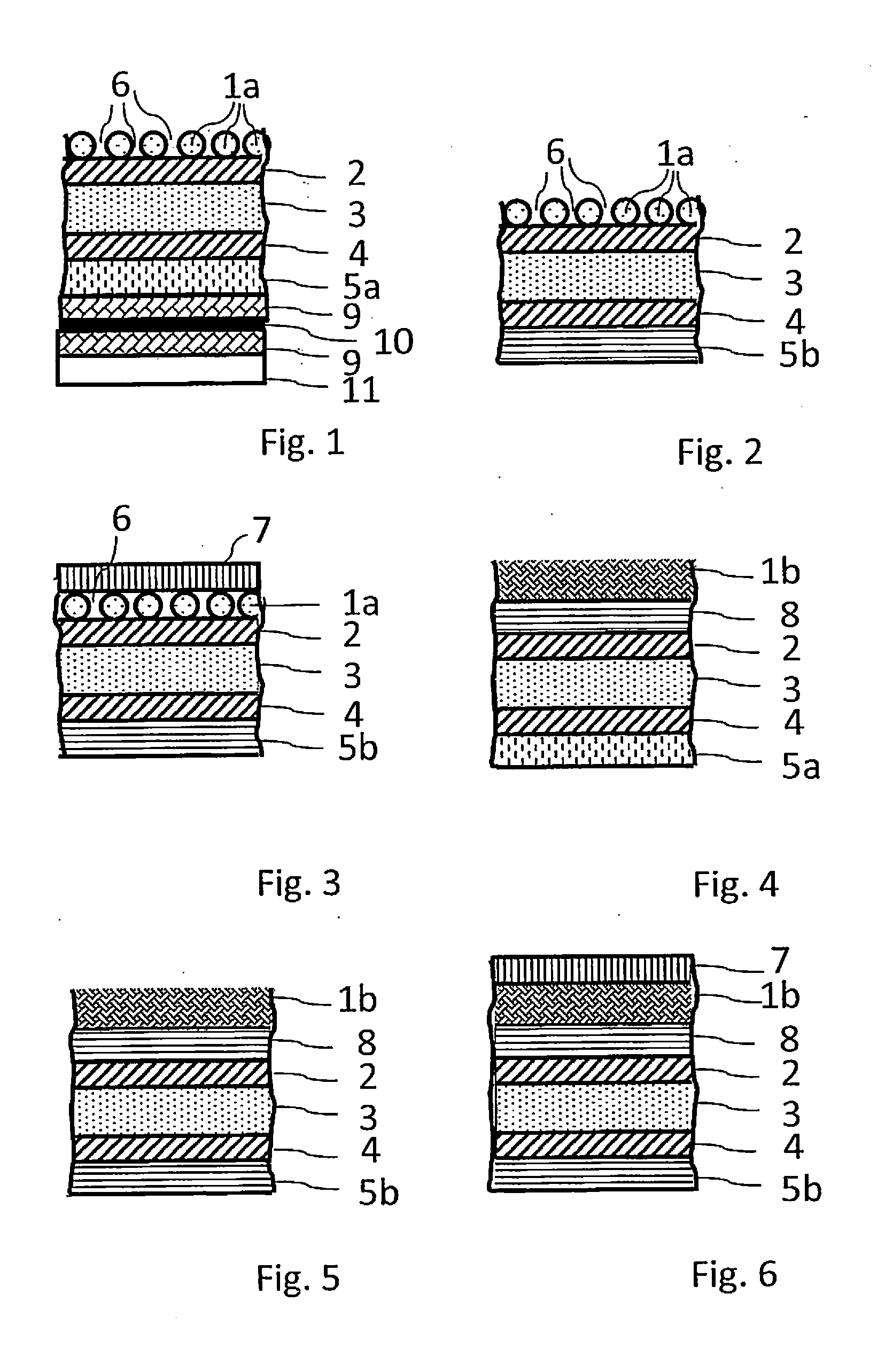

Pattern replication with intermediate stamp

ActiveCN1916759AImproving the embossing processHigh reproduction fidelityNanoinformaticsPhotomechanical apparatusResistSurface pattern

The invention relates to a process method for reproducing a pattern from a template (1) in order to manufacture replicas (5,9) from the template into different materials in a suitable process, whereas in a first step replicas of a template having a patterned surface are formed into flexible polymer foils. In a second step the so-produced replicas can be used as flexible polymer templates to reproduce the pattern into an object surface.

Owner:OBDUCAT AB SE

Formation of photovoltaic absorber layers on foil substrates

InactiveUS20090032108A1Semiconductor/solid-state device manufacturingSpecial surfacesPolymer foilMetal

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 1 to 30 minutes after which the temperature is reduced.

Owner:AERIS CAPITAL SUSTAINABLE IP

Formation of CIGS Absorber Layers on Foil Substrates

InactiveUS20090305455A1Final product manufactureVacuum evaporation coatingPolymer foilAbsorption layer

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 2 to 30 minutes after which the temperature is reduced.

Owner:LEIDHOLM CRAIG +1

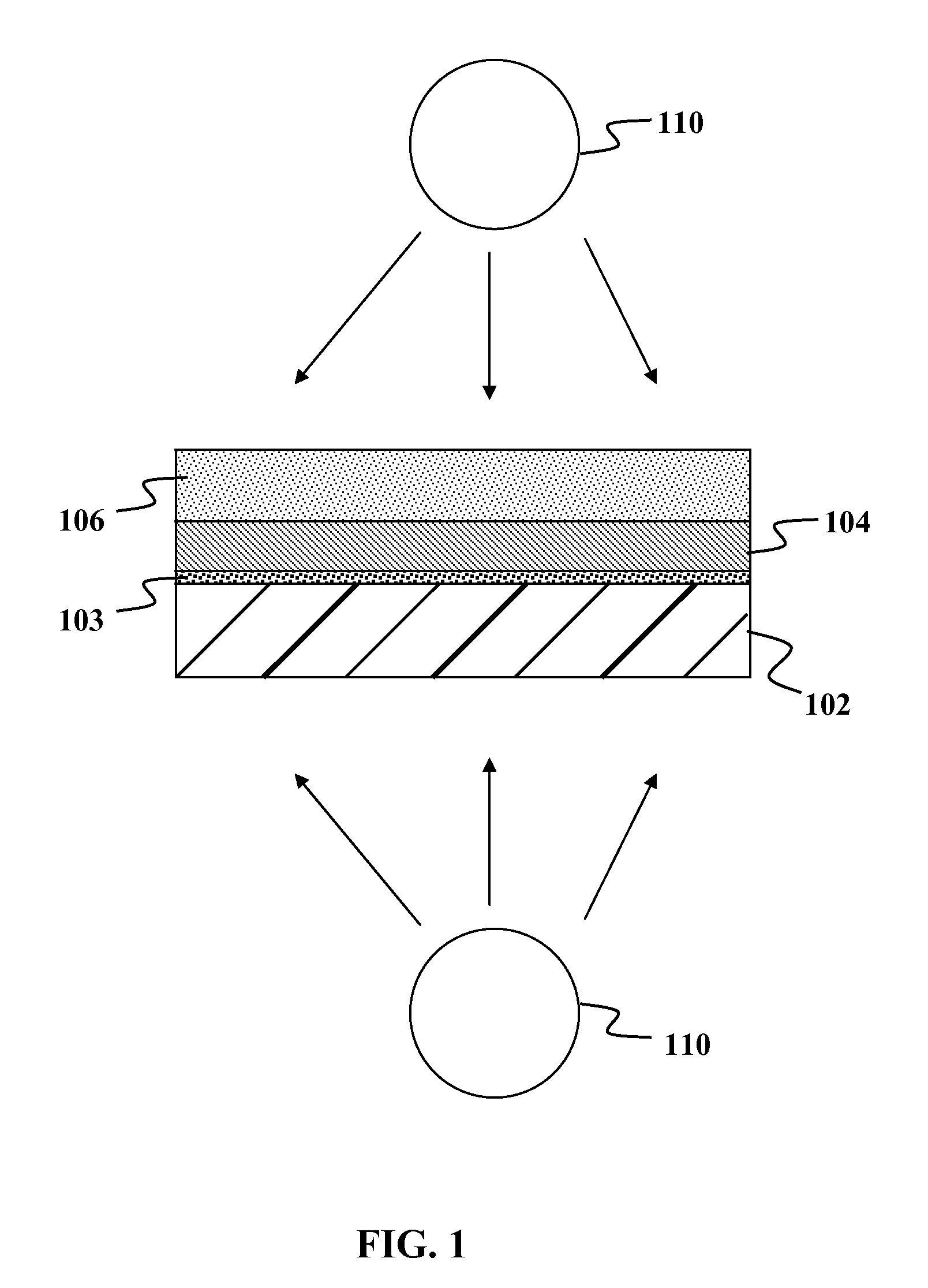

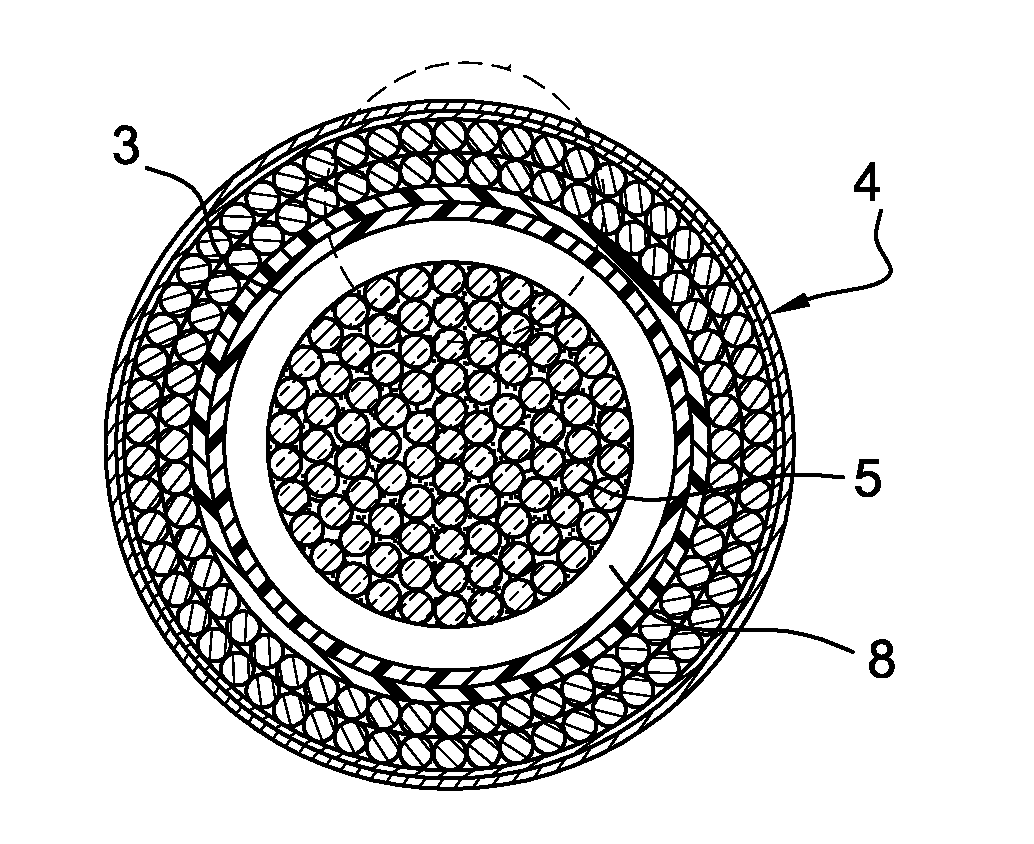

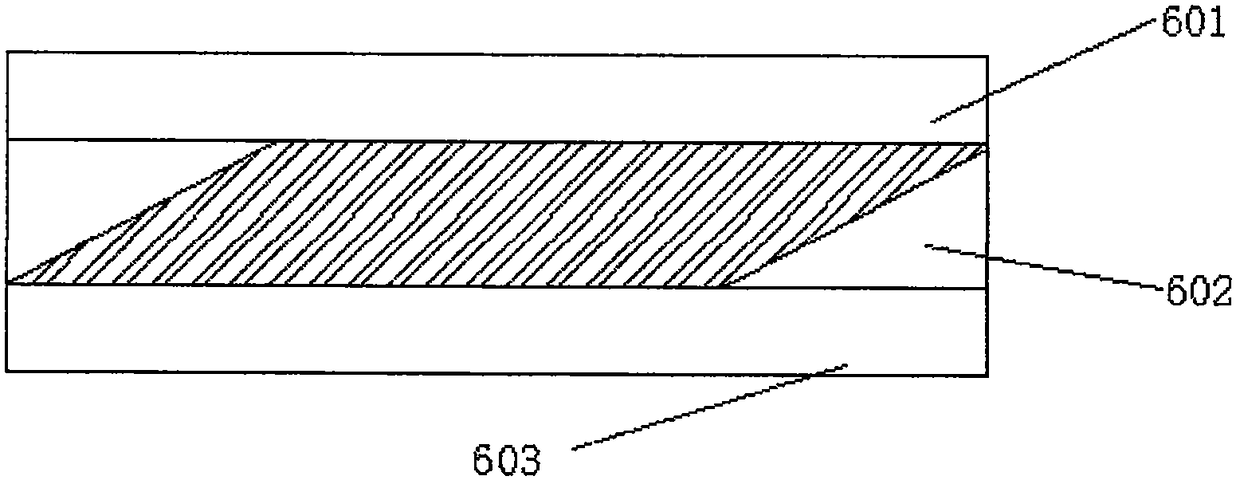

Power cable with a water barrier laminate

InactiveUS20120080213A1Reduce weightClimate change adaptationPower cables with screens/conductive layersPolymer foilPower cable

A power cable having a water barrier laminate where the water barrier laminate has foil made of metal (1) laminated between at least two layers of non insulating polymer foils (2a, 2b) constituting a final laminate (3) that is non insulating.

Owner:NEXANS

Illuminating film structure

InactiveCN105980768AImprove flexibilityIncreasing the thicknessShielding materialsPrinted circuit aspectsPolymer foilEngineering

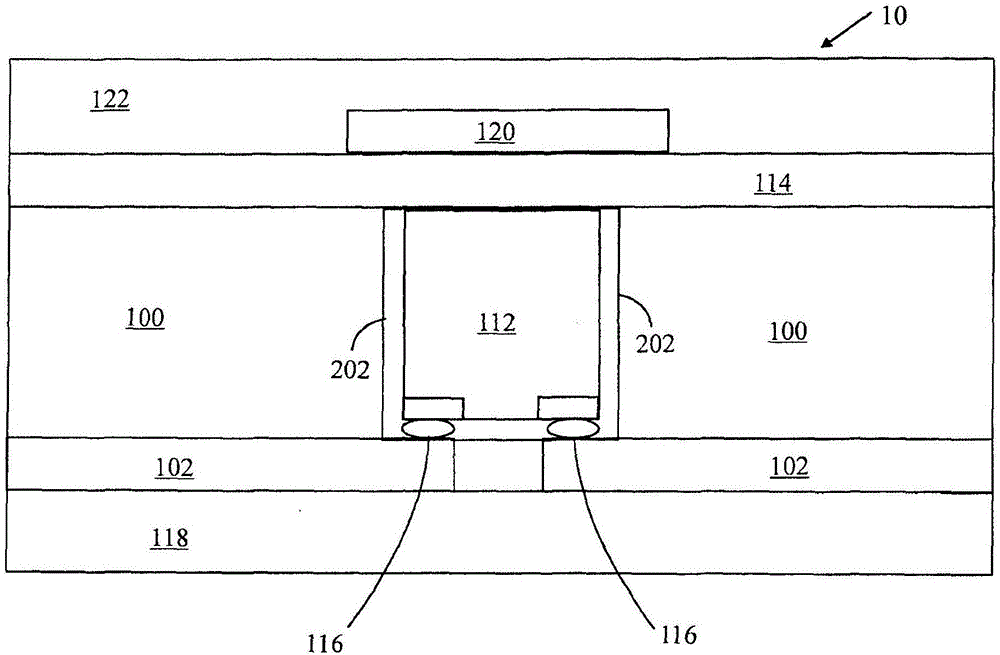

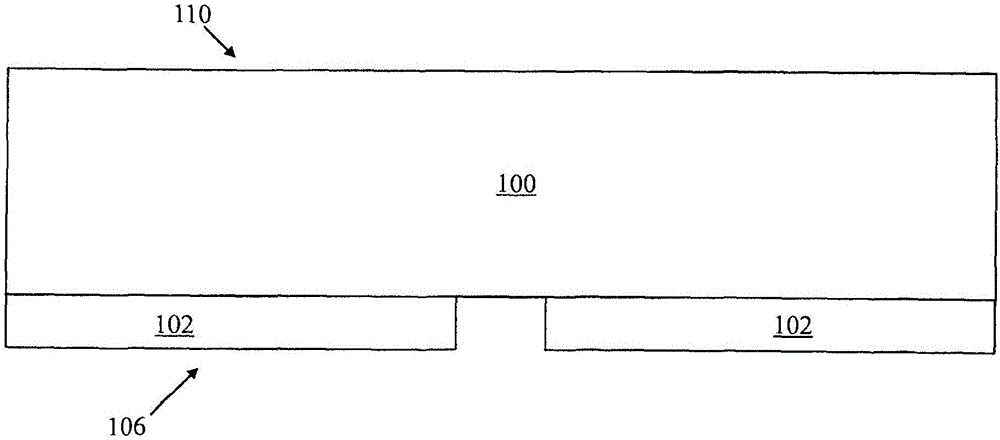

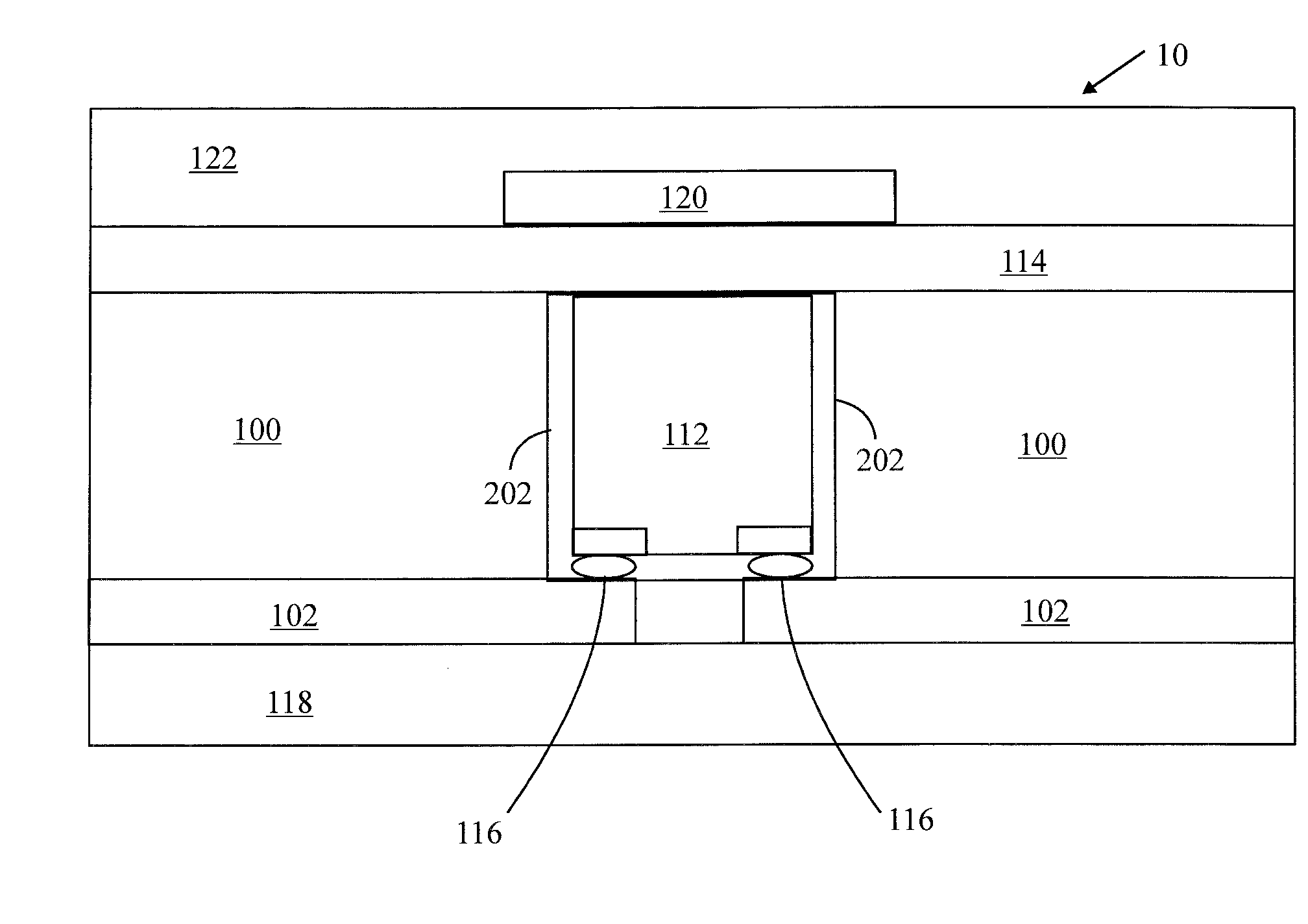

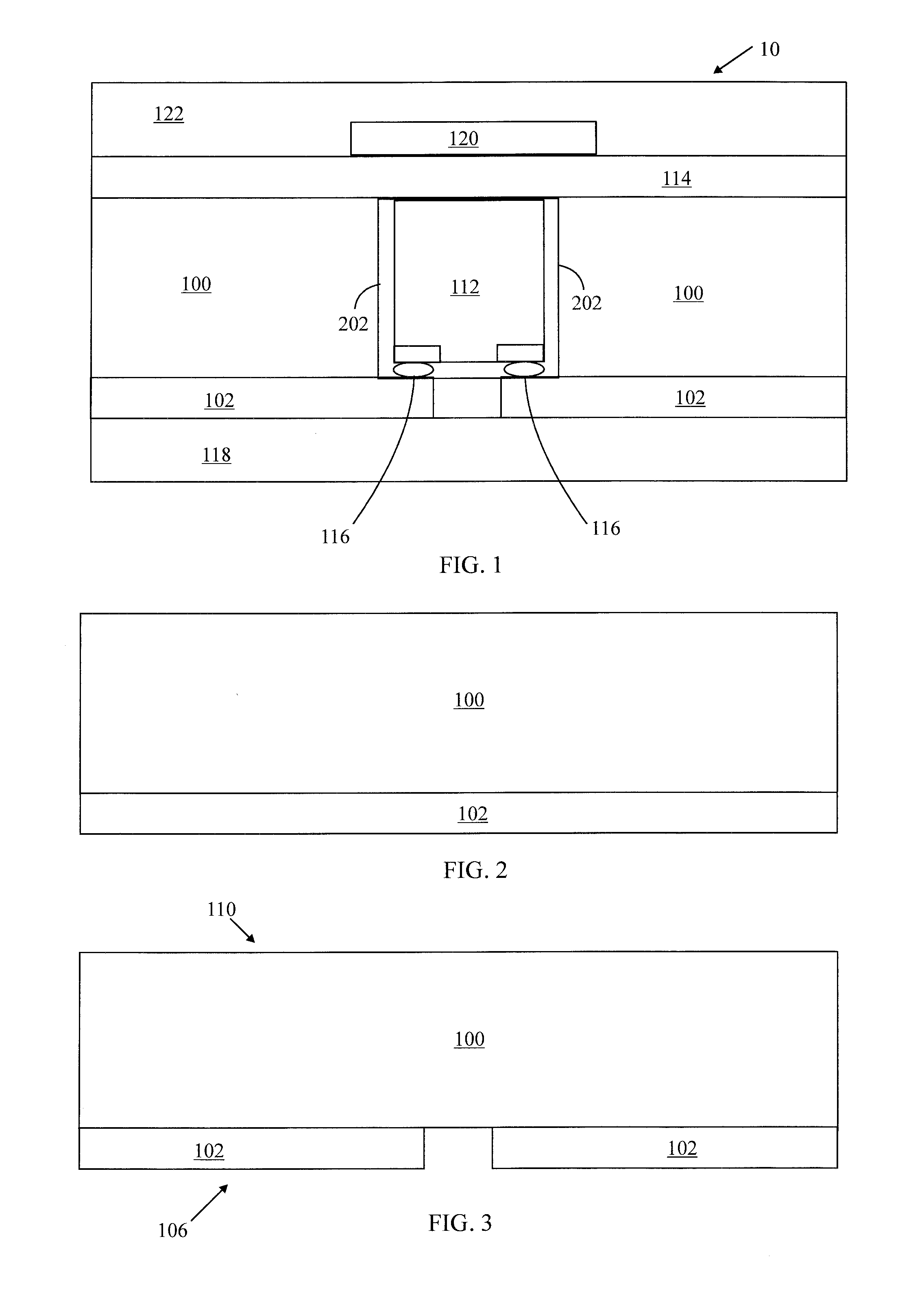

A flexible and illuminating film structure wherein the flexible and illuminating film structure (10) comprises a flexible single polymer foil (100); a flexible electrically conductive pattern layer (102) with contact areas (104) for components on a first side (106) of the polymer foil (100); at least one cavity (108) which extends though the polymer foil (100) from a second side (110) to the contact areas (104) of the conductive pattern layer (102) on the first side (106) and overlaps with at least one contact area (104); at least one non-organic light emitting diode flip-chip (112) in the at least one cavity (108) and electrically coupled with the contact areas (104); and a first flexible shielding foil (114) layered on the second side (110) of the polymer foil (100).

Owner:FLEXBRIGHT

Illuminating film structure

InactiveUS20160315236A1Increase flexibilityIncreasing the thicknessPrinted circuit assemblingShielding materialsPolymer foilEngineering

A flexible and illuminating film structure includes a flexible single polymer foil; a flexible electrically conductive pattern layer with contact areas for components on a first side of the polymer foil; at least one cavity which extends though the polymer foil from a second side to the contact areas of the conductive pattern layer on the first side and overlaps with at least one contact area; at least one non-organic light emitting diode flip-chip in the at least one cavity and electrically coupled with the contact areas; and a first flexible shielding foil layered on the second side of the polymer foil.

Owner:FLEXBRIGHT

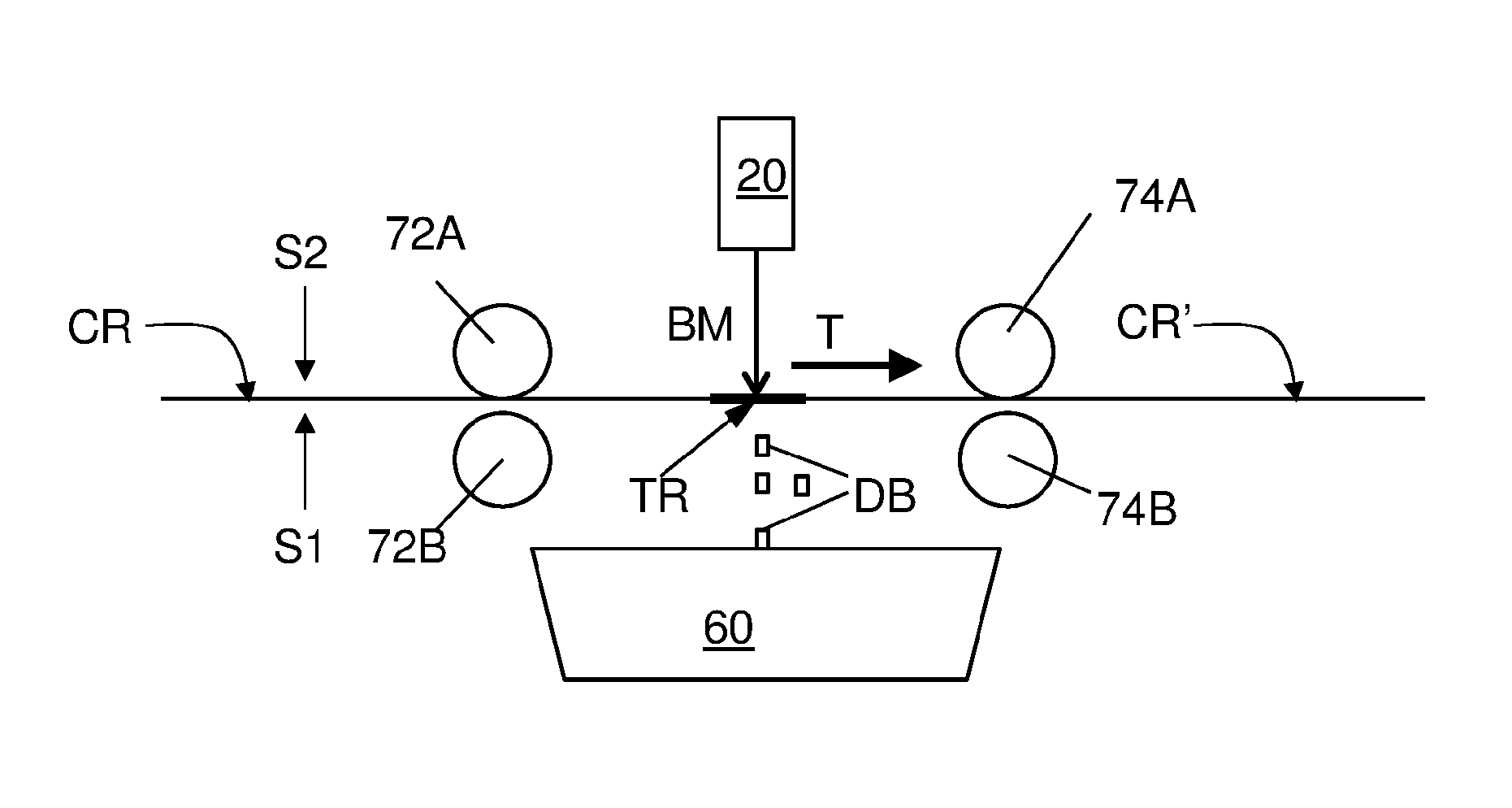

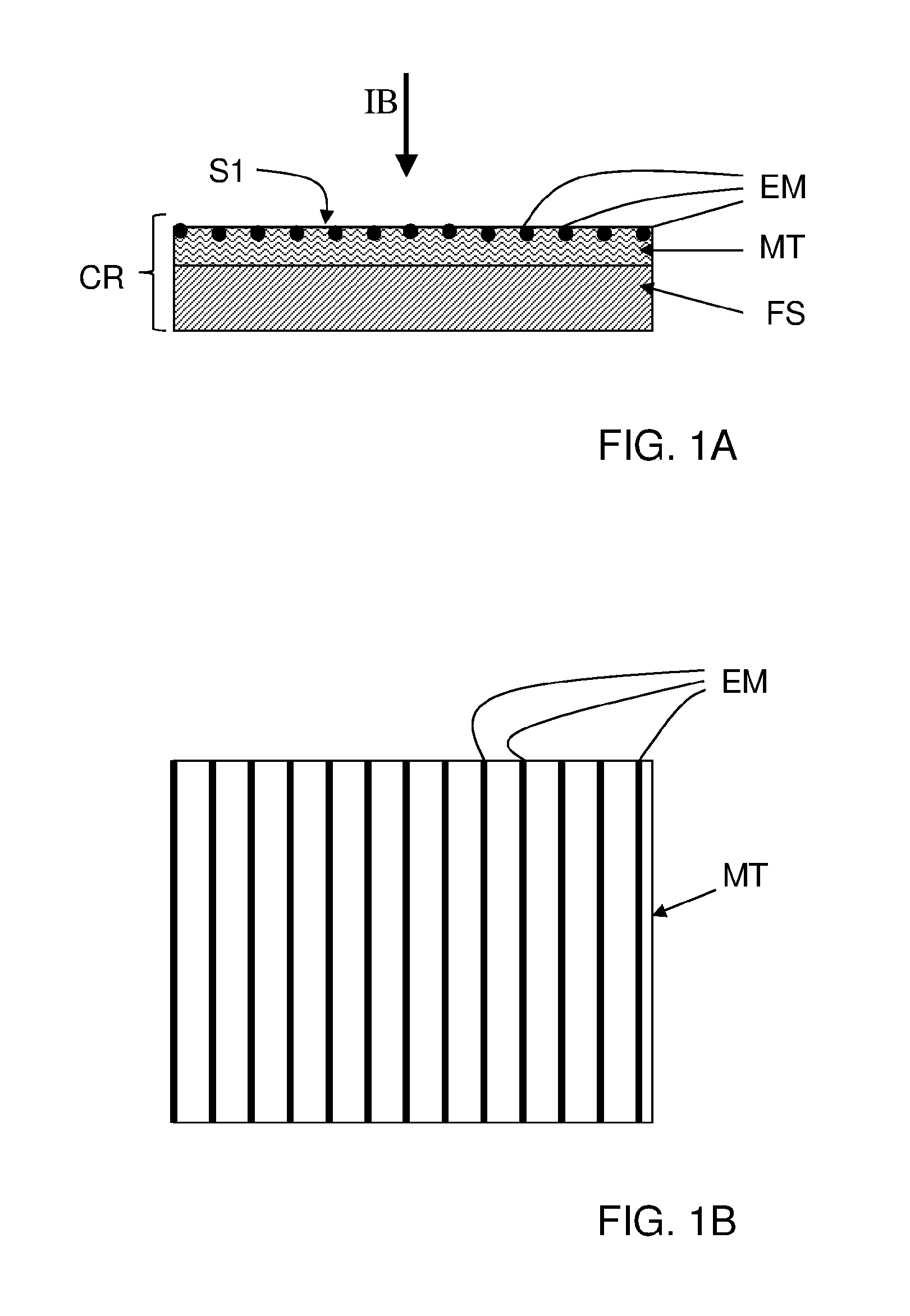

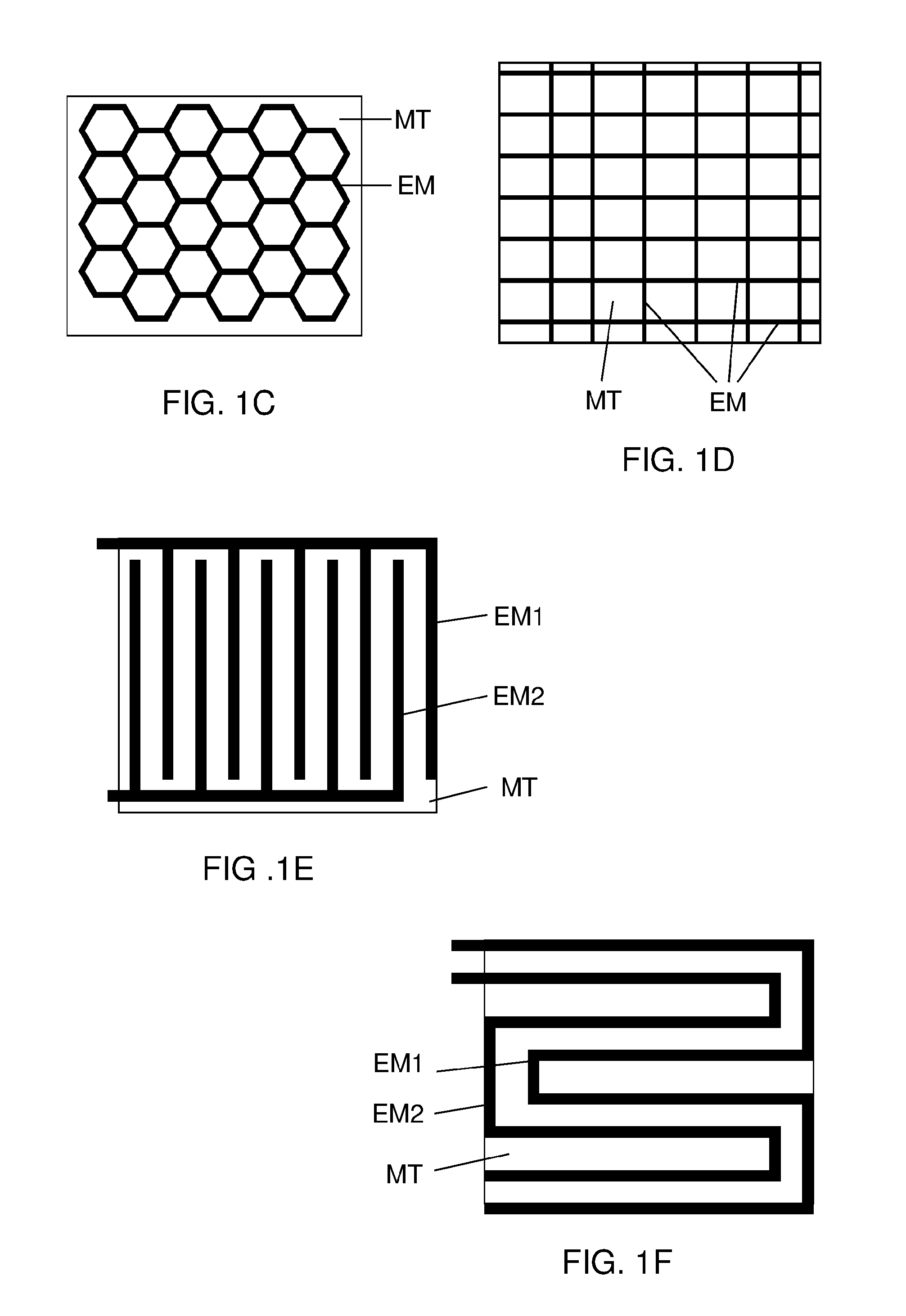

Method and System for Providing a Carrier with an Embedded Patterned Metal Structure

InactiveUS20160311055A1Easy to remove debrisSolid-state devicesSemiconductor/solid-state device manufacturingPolymer foilEngineering

A method is presented for providing a carrier (CR) with an embedded patterned metal structure (EMM). The carrier at least includes a polymer foil (FS). The method comprise the steps of providing a carrier (CR) having a first side (S1) with an initial embedded patterned metal structure (EM). The carrier is then irradiated at a second side (S2) opposite the first side with a radiation beam (BM) that is at least partially transmitted through the carrier (CR) and at least partially absorbed by the initial embedded patterned metal structure (EM), therewith locally heating the initial embedded patterned metal structure and causing a removal of metal (DB) from the initial embedded patterned metal structure.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

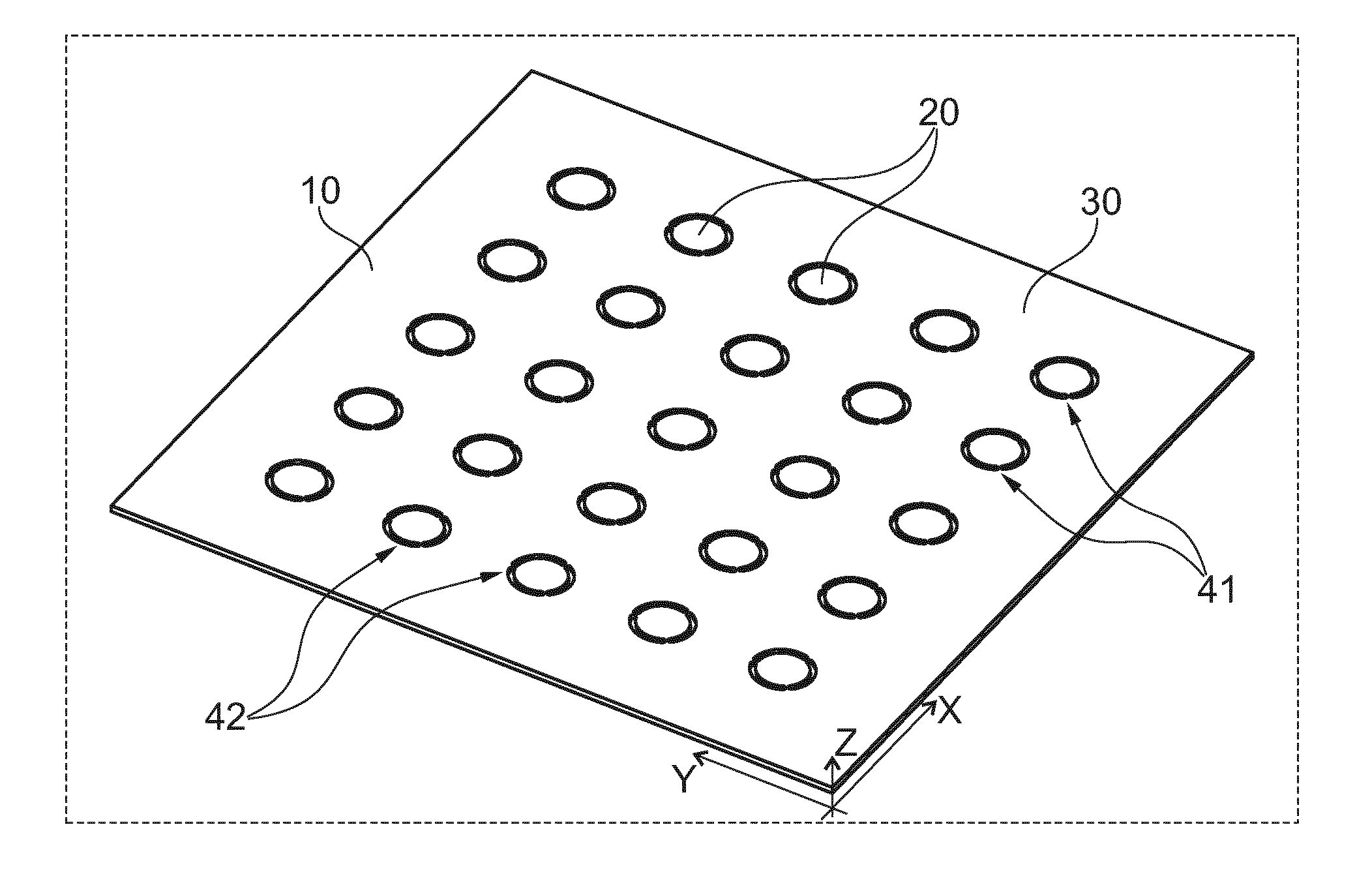

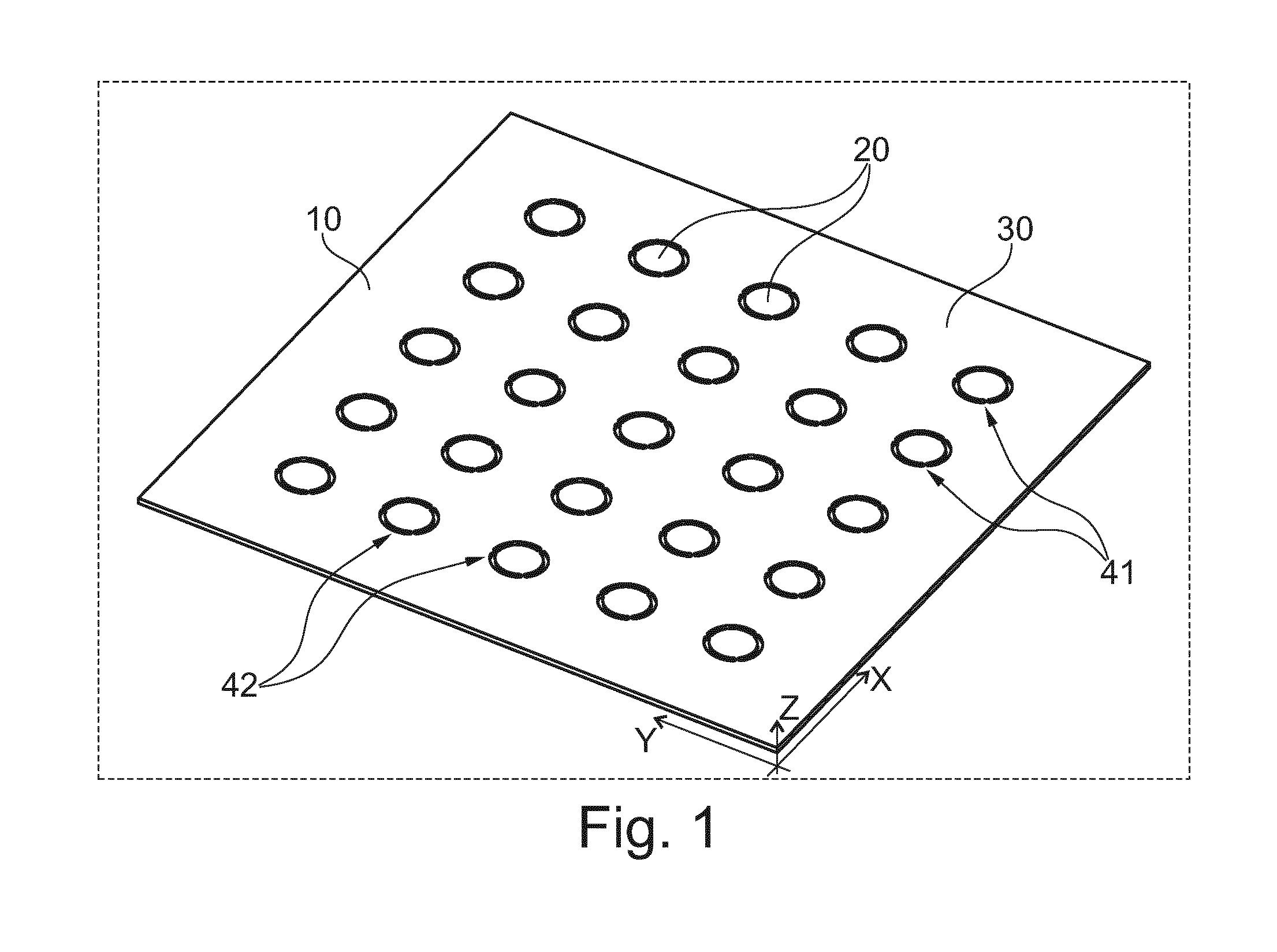

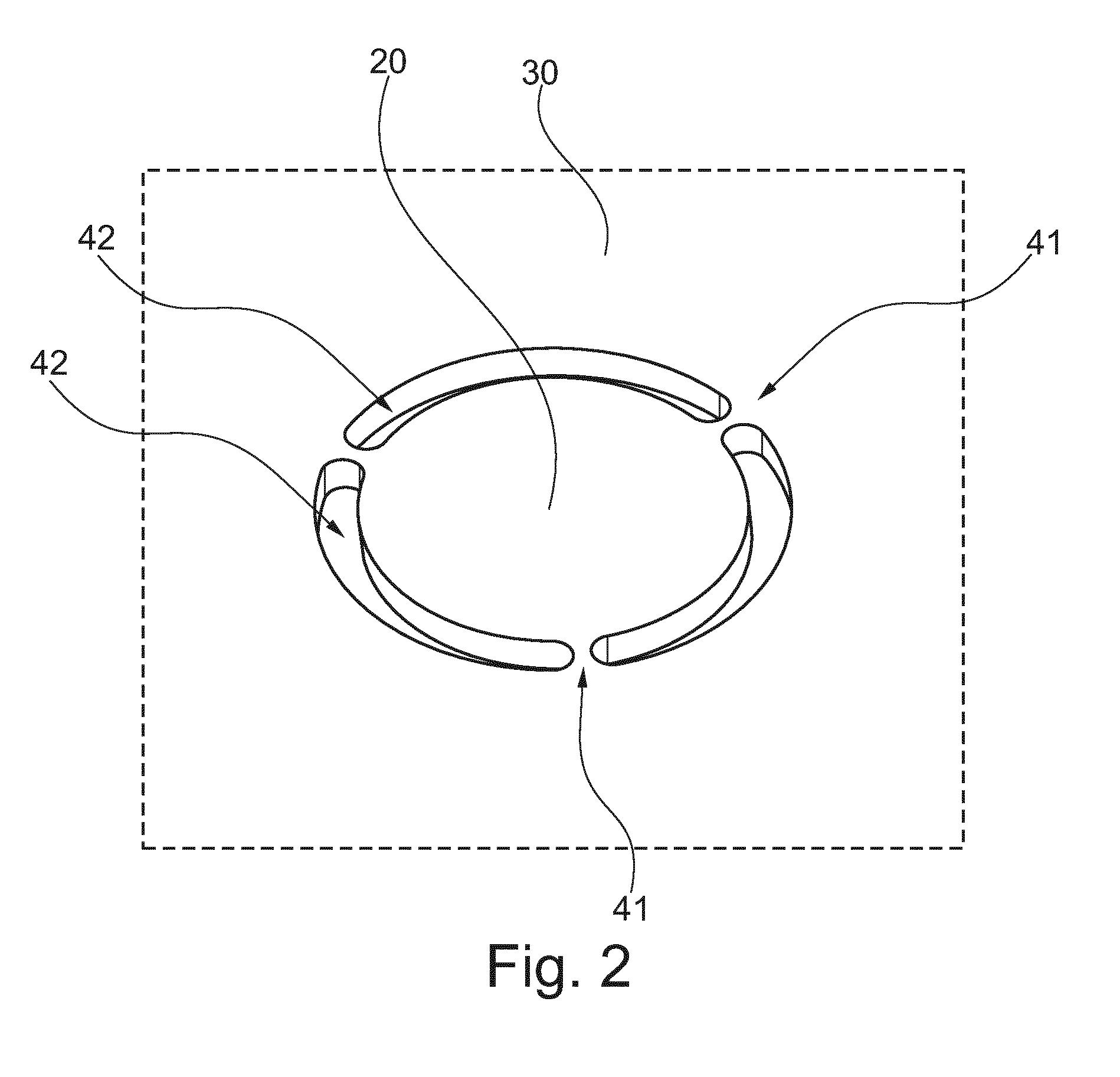

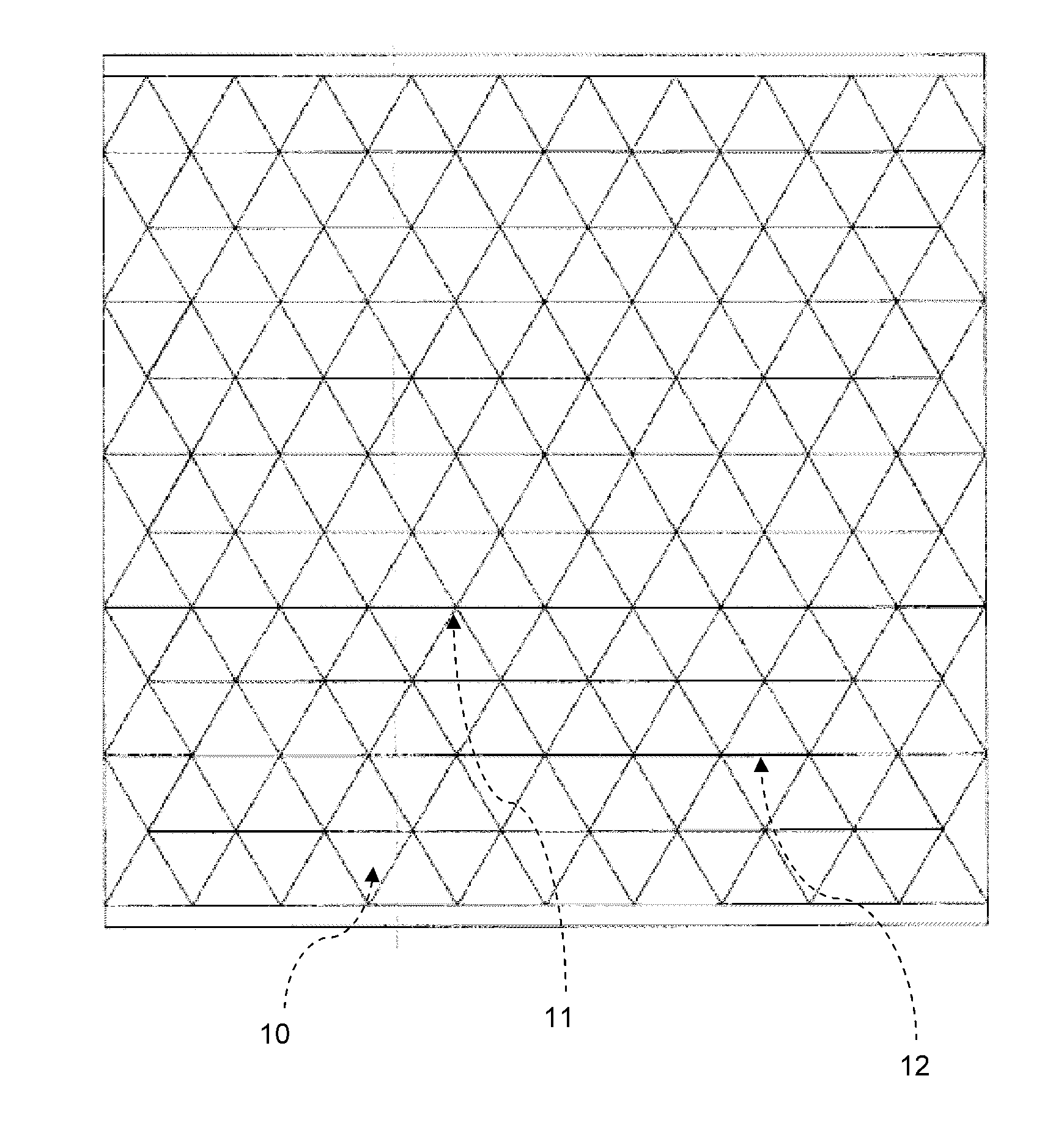

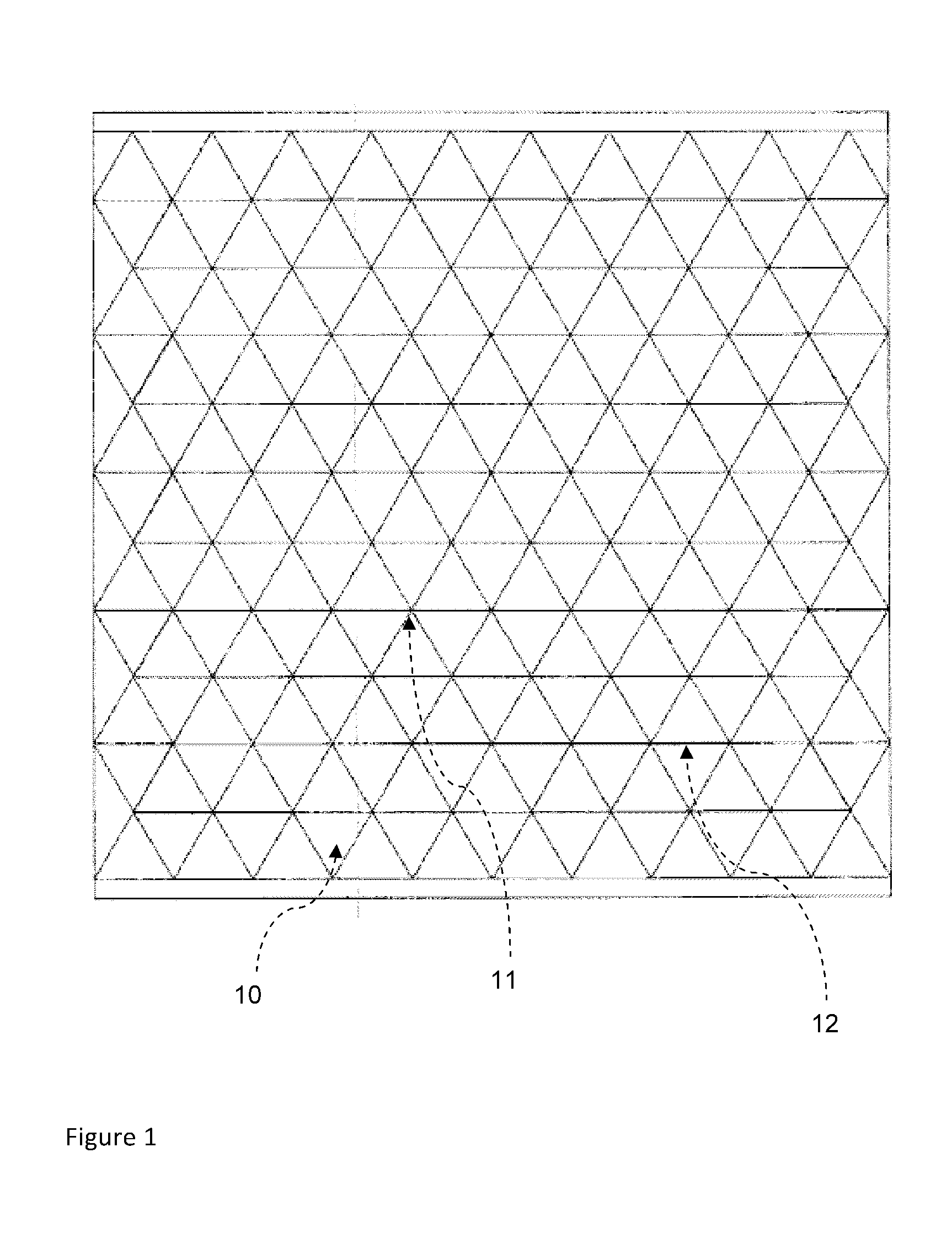

Integrated polymer foil, patch-clamp array and membrane valves

The invention describes a foil of polymeric material comprising a plurality of patch portions and a grid portion arranged between said patches. Each patch portion is connected to the grid portion by means of one or more connecting elements. Each patch portion is separated from the grid portion in the X-Y plane by means of a release portion, said release portion having a tensile strength in the X-Y plane which is lower than the tensile strength of both said patch portions and said grid portion, such that—upon exertion of a tensile force between said patch portions and said grid portion—said foil ruptures preferentially at said release portion. The invention relates to a method for the production of cell-capture chips using said foil, and a cell capture chip produced by said method.

Owner:SOPHION BIOSCI

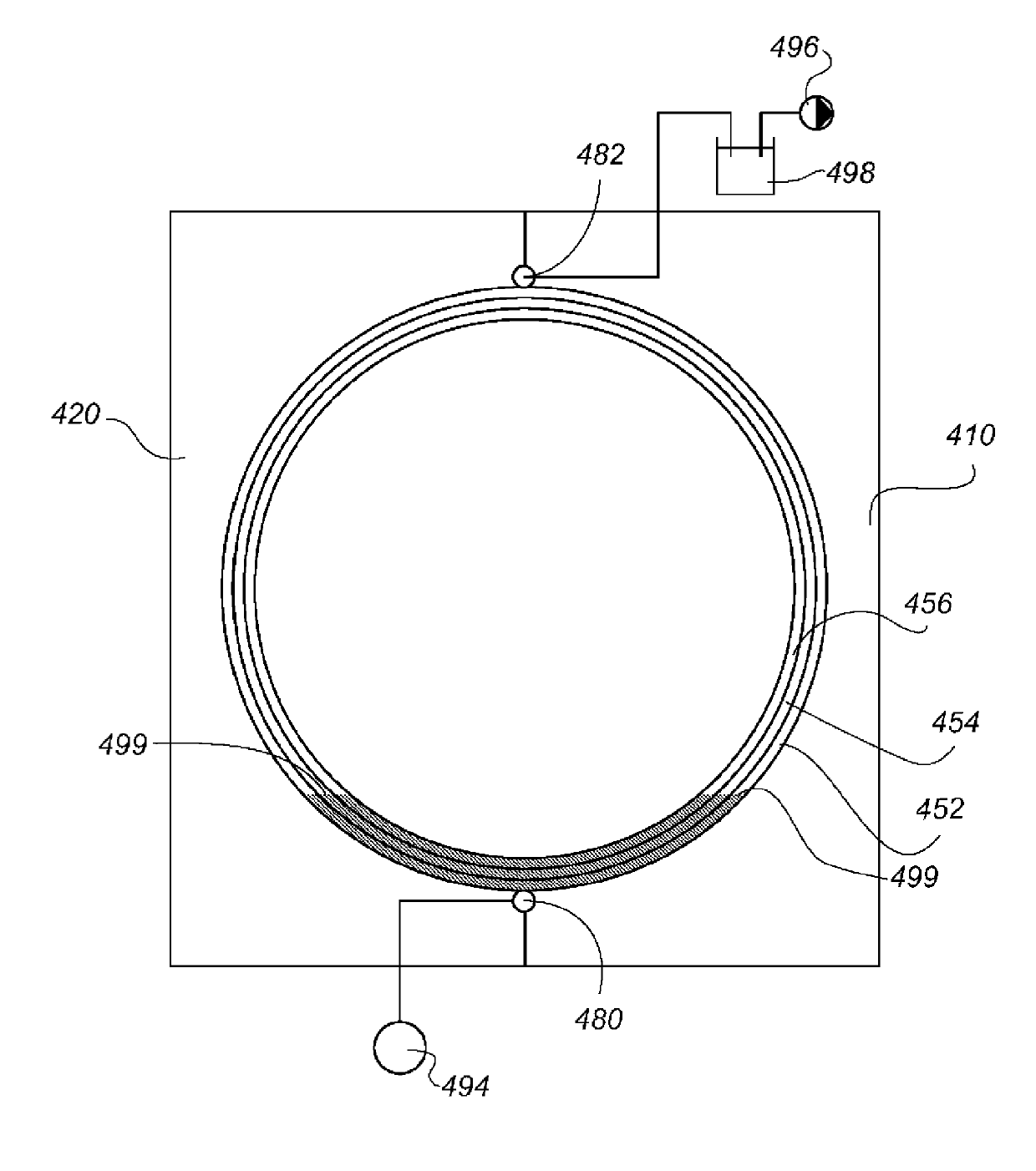

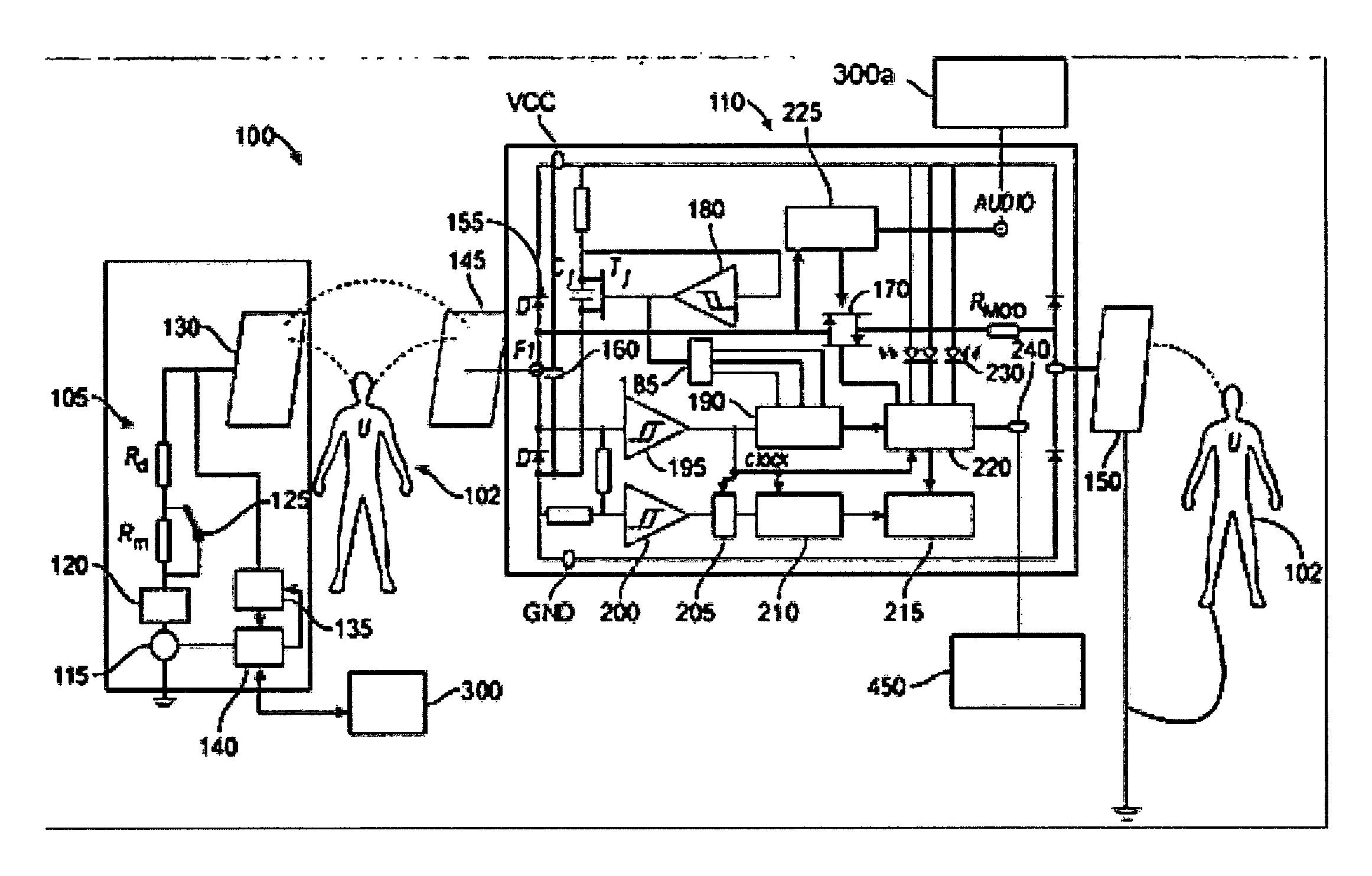

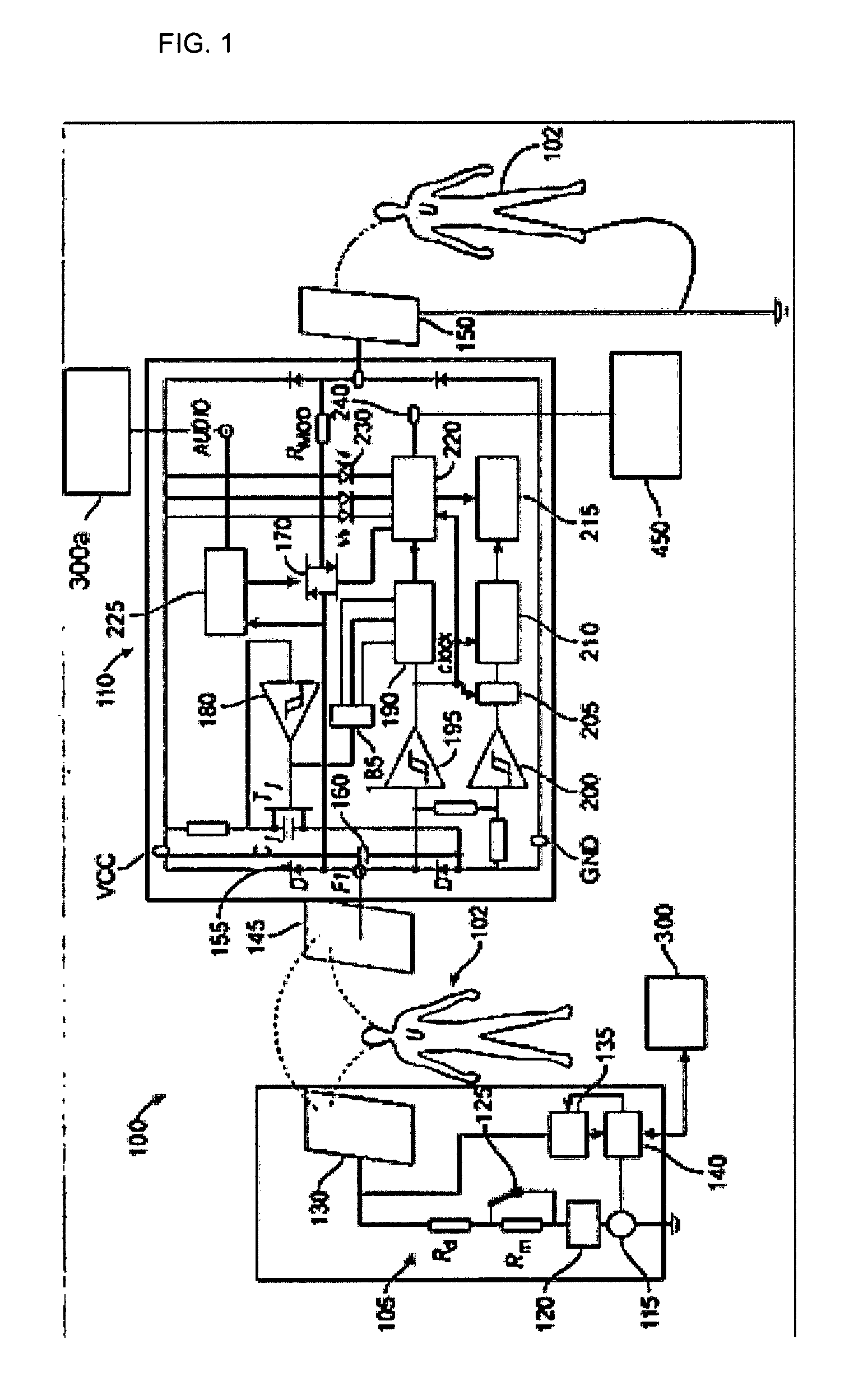

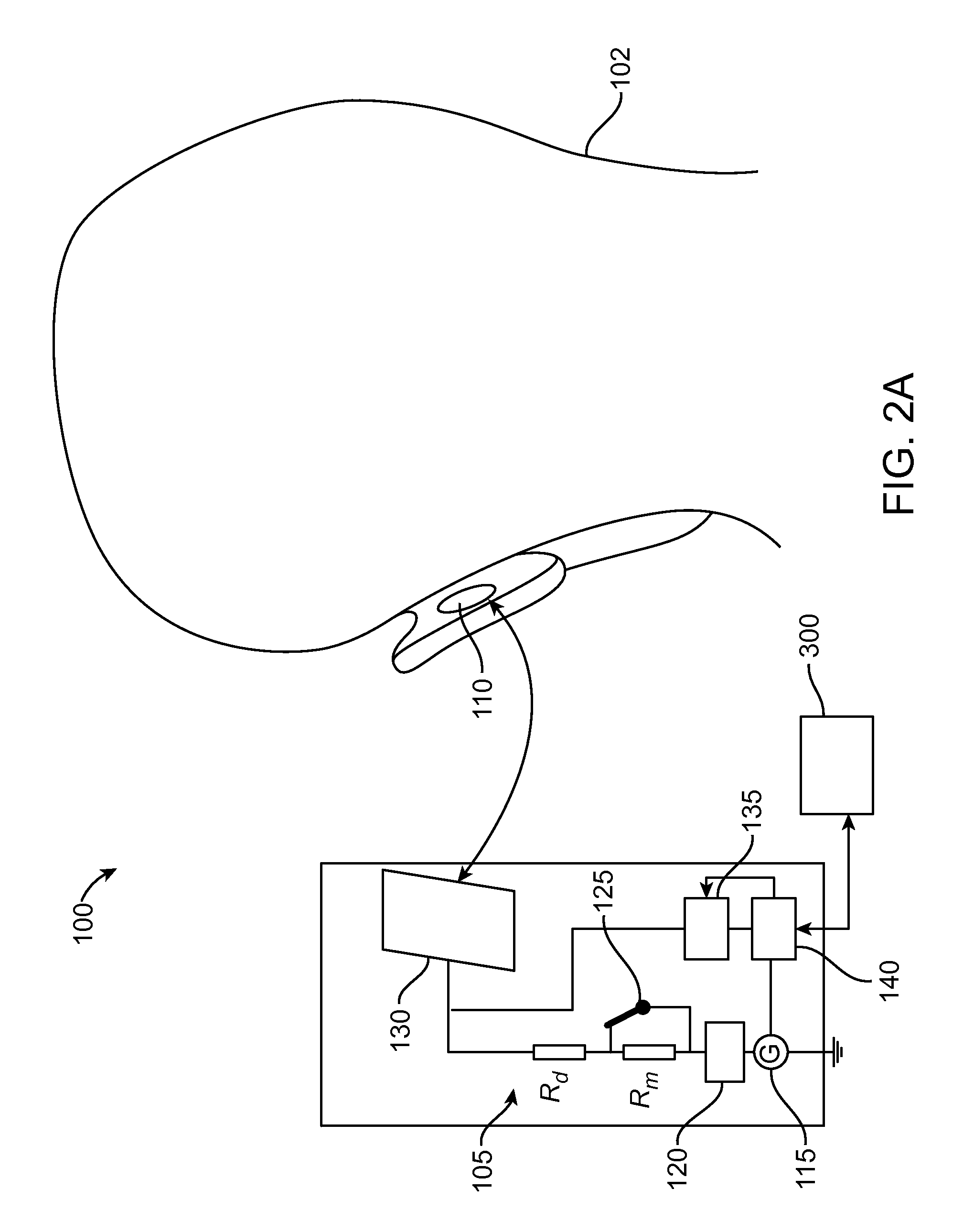

System and a method for communicating user interaction data to one or more communication devices

ActiveUS9509178B2Near-field transmissionInformation technology support systemPolymer foilComputer hardware

Owner:R2Z INNOVATIONS

Formation of photovoltaic absorber layers on foil substrates

InactiveUS20130025532A1Liquid surface applicatorsVacuum evaporation coatingPolymer foilMaterials science

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 1 to 30 minutes after which the temperature is reduced.

Owner:NANOSOLAR

Method for the production of a protection device

InactiveUS20120096703A1Produced cost-effectivelyArmourLamination ancillary operationsPolymer foilBrick

A method for the production of protection devices is provided. The method includes the step of providing a tile package. The provision of the tile package includes the steps of: laminating at least one board of a tile material onto a polymer foil; scoring the board on the side which is opposite to the polymer foil; and fracturing the board along the scoring lines for achieving a plurality of tiles which are fixed on the polymer foil.

Owner:SCHOTT AG

Touch Control Structure of an Active-Matrix Organic Light-Emitting Diode Display Screen

ActiveUS20190018531A1Minimizing adverse influenceReduce difficultyStatic indicating devicesSolid-state devicesPolymer foilActive matrix

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

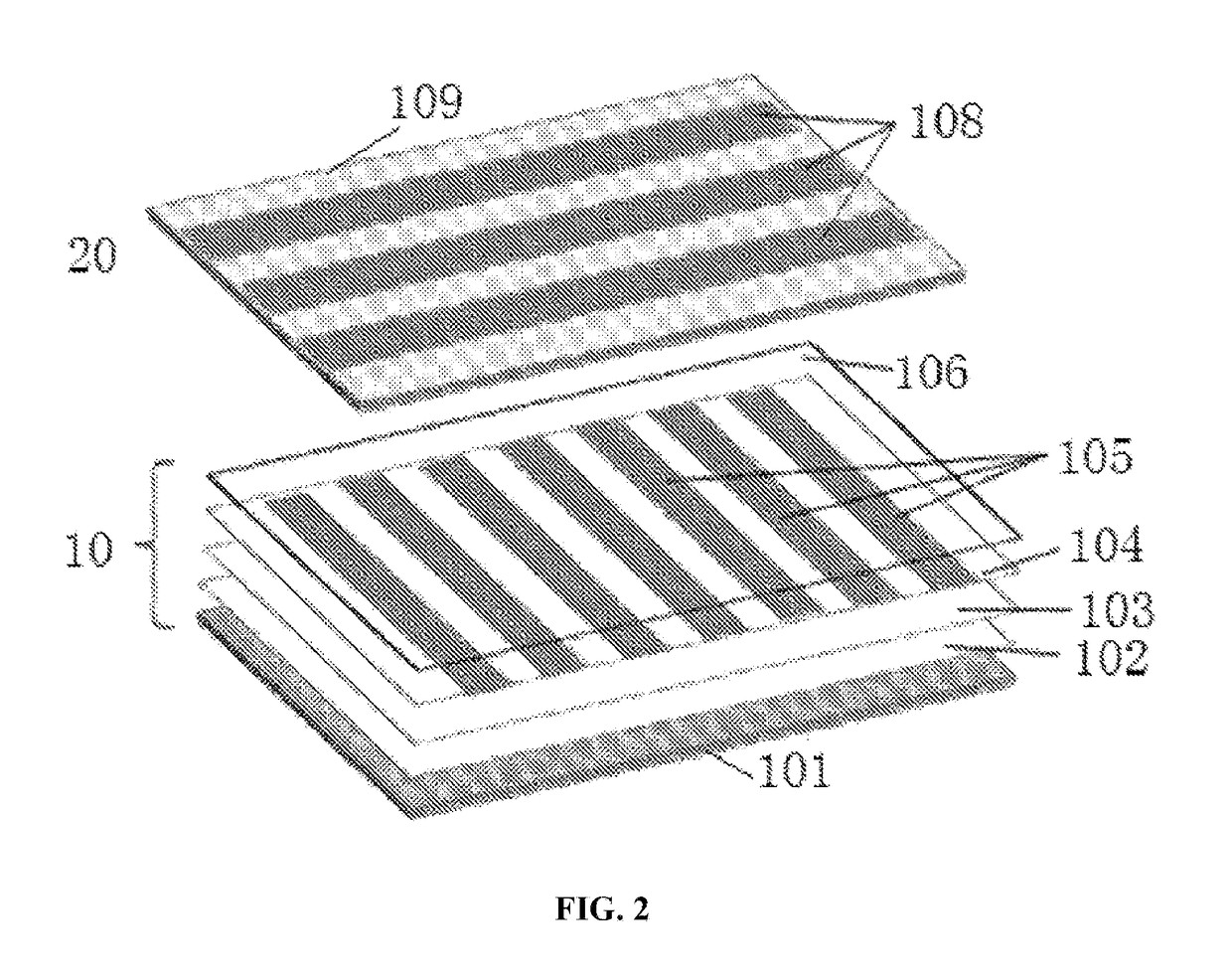

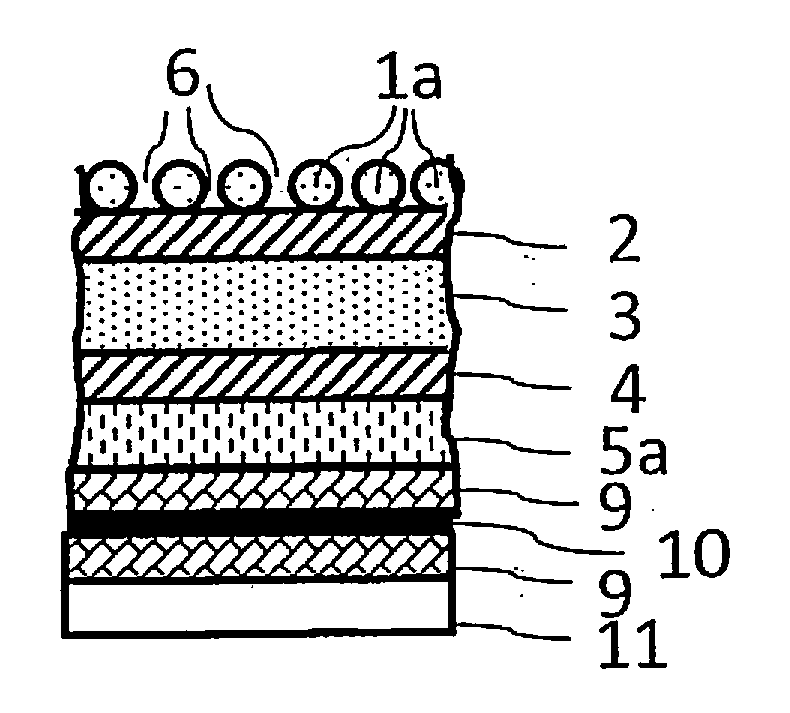

Solar module rear side encapsulation element and solar module

A solar module rear side encapsulation element having a laminate-type layer construction having at least one polymer plate or polymer foil (2,3,4,5a,5b,8) having a laminate surface is provided. The laminate-type layer construction has at least one protective layer having layer openings (6). The protective layer (1a, 1b) covers at least 70% of the laminate surface by a covering area, and due to the layer openings (6) at least 15% and maximum 99.9% of the regions of the solar module rear side encapsulation element lying under the protective layer (1a,1b) are covered in the covering area, and the protective layer is formed as a structure made of threads, thus being open to diffusion.

Owner:HANWHA Q CELLS

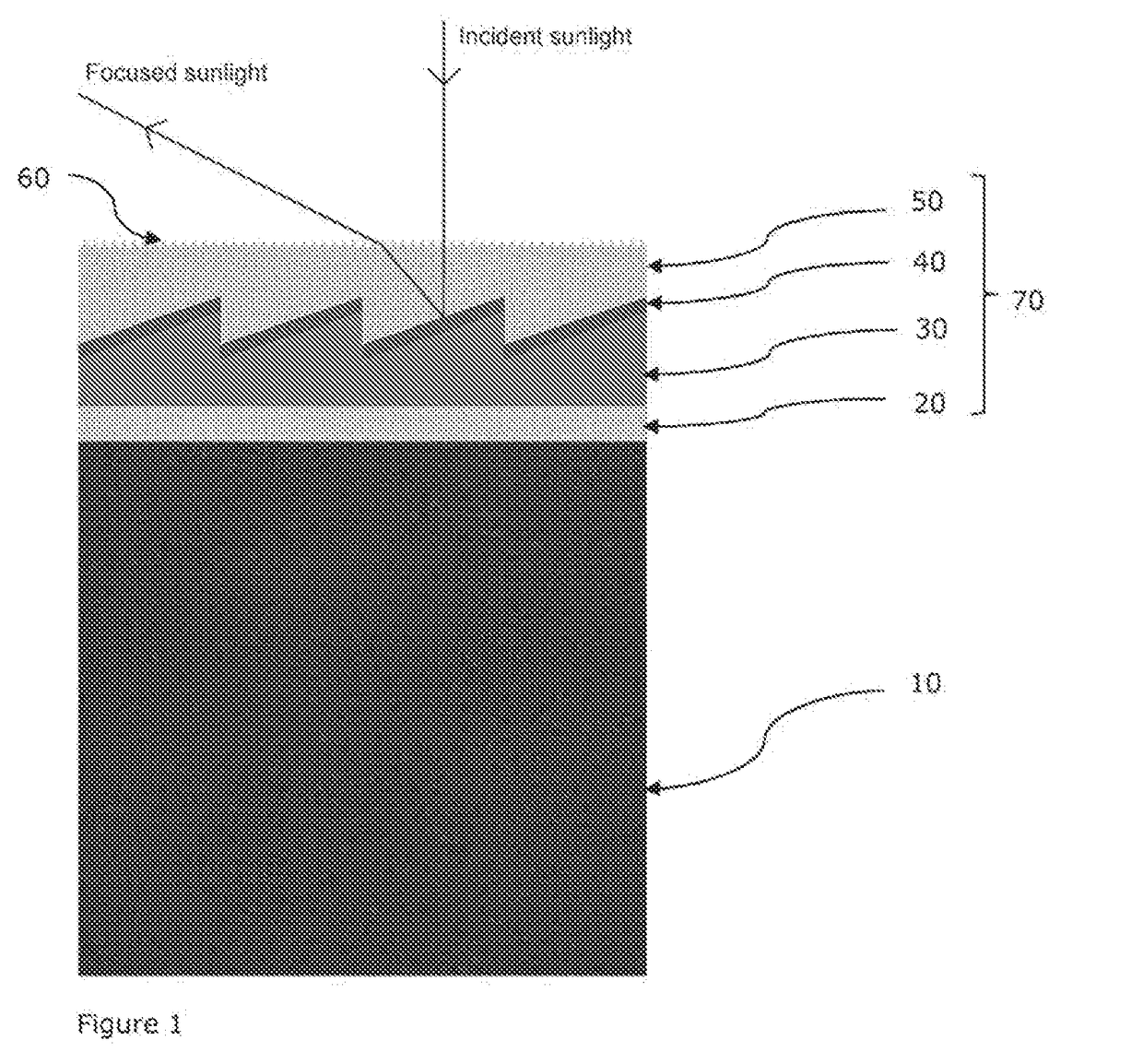

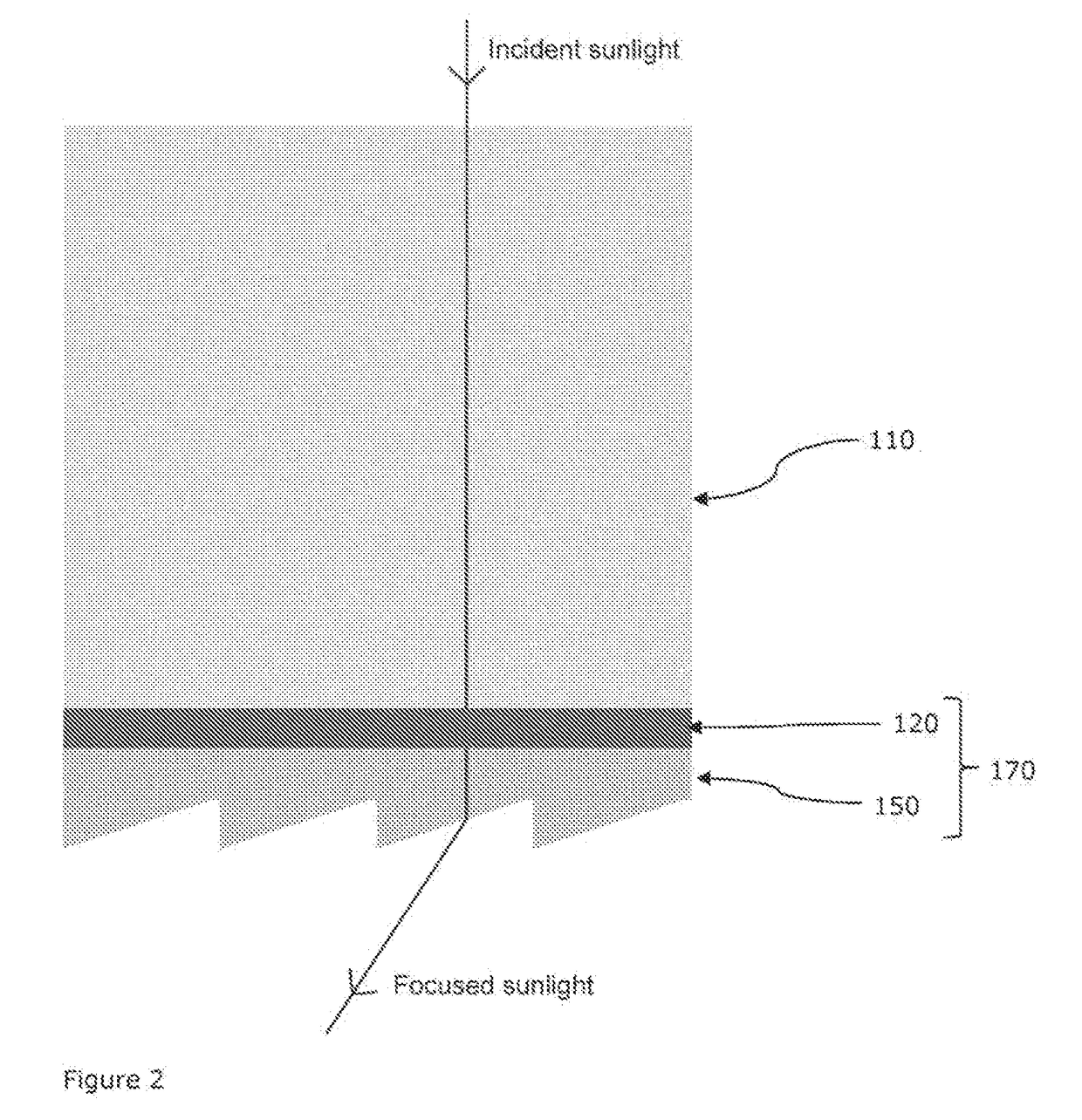

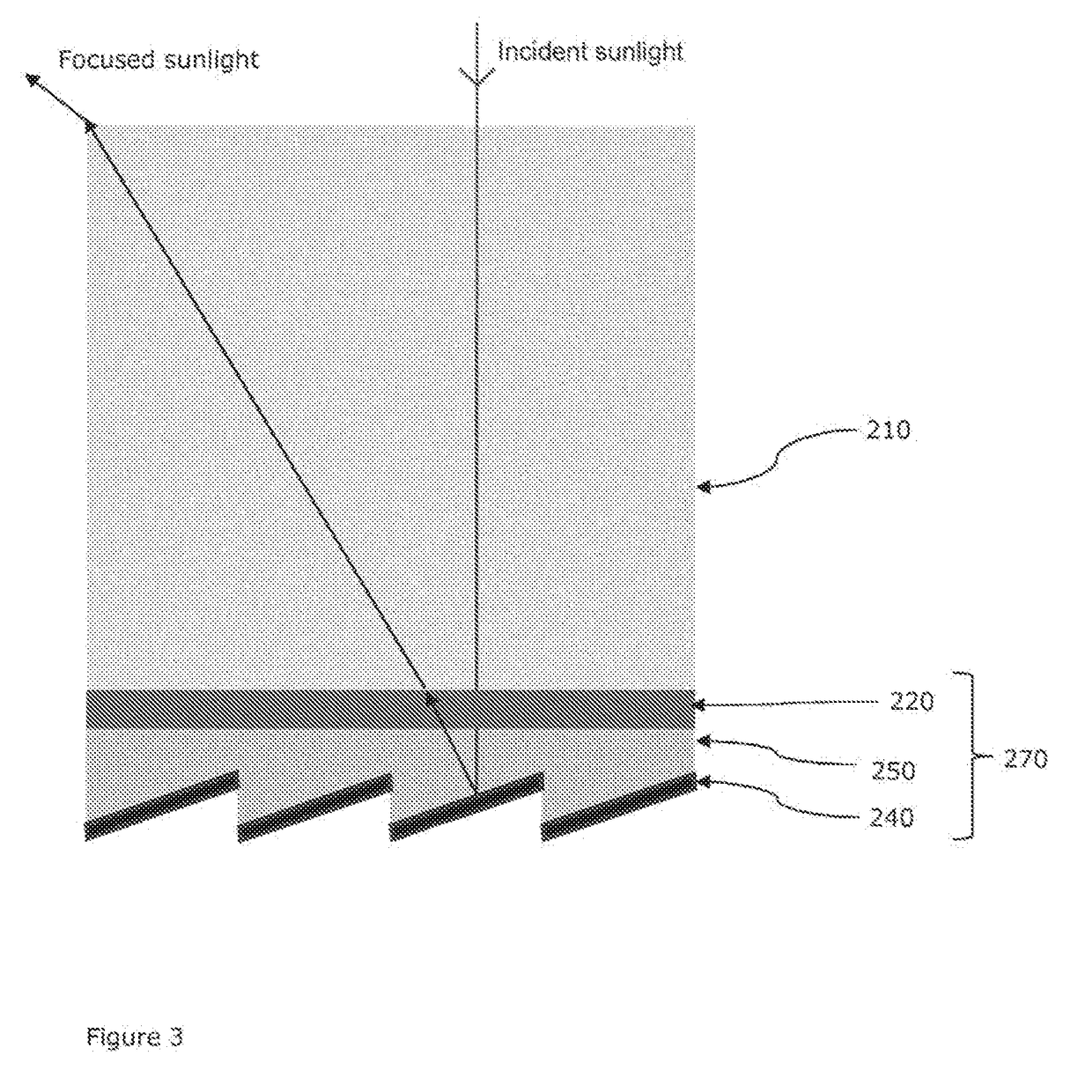

Laminate Solar Concentrator

InactiveUS20190081195A1Increased durabilityEasy maintenanceSolar heating energyMirrorsPolymer foilEngineering

A focusing polymer foil for use in forming an optical element for use in a solar concentrator, and an optical element for use in a solar concentrator, arranged such that the focusing polymer foil is removable in order to renew the function of the optical element following damage and / or wear to the focusing polymer foil due to environmental conditions. A method of repair of such a damaged optical element, and methods of making the focusing polymer foil and optical element.

Owner:HELIAC APS

Electric heating mat

PendingUS20210207815A1Avoid flowWeakening rangeLighting and heating apparatusOhmic-resistance electrodesPolymer foilPolymer science

The invention relates to an electric surface heater, or heating mat, based on an electrically conductive polymer foil or a conductive polymer foam that only heats locally where persons, animals or objects are positioned on the mat. Energy can thereby be saved in comparison with a full-area heater. Ideally, this local heat generation functions without any external electronic control or regulation.

Owner:THURINGISCHES INST FUR TEXTIL & KUNST FORSCHUNG EV RUDOLSTADT

Method of Producing a Gas Barrier Polymer Foil and a Gas Barrier Polymer Foil

InactiveUS20080292895A1Improve adhesionEasy adhesionPretreated surfacesLaminationPolymer foilPolymer science

The invention relates to polymer foil comprising at least one polymer layer coated with a barrier glass coating of an oxide composition, wherein said oxide composition comprises the element Si in the form of an oxide network, the oxide composition preferably comprises Si and at least one other element X in an oxide network. The oxide network may preferably be applied using plasma. The foil may be a multi-layered foil comprising a plurality of layers, at least one of the layers being a barrier glass coating. The foil has good barrier properties.

Owner:NANO

Formation of photovoltaic absorber layers on foil substrates

An absorber layer of a photovoltaic device may be formed on an aluminum or metallized polymer foil substrate. A nascent absorber layer containing one or more elements of group IB and one or more elements of group IIIA is formed on the substrate. The nascent absorber layer and / or substrate is then rapidly heated from an ambient temperature to an average plateau temperature range of between about 200° C. and about 600° C. and maintained in the average plateau temperature range 1 to 30 minutes after which the temperature is reduced.

Owner:AERIS CAPITAL SUSTAINABLE IP

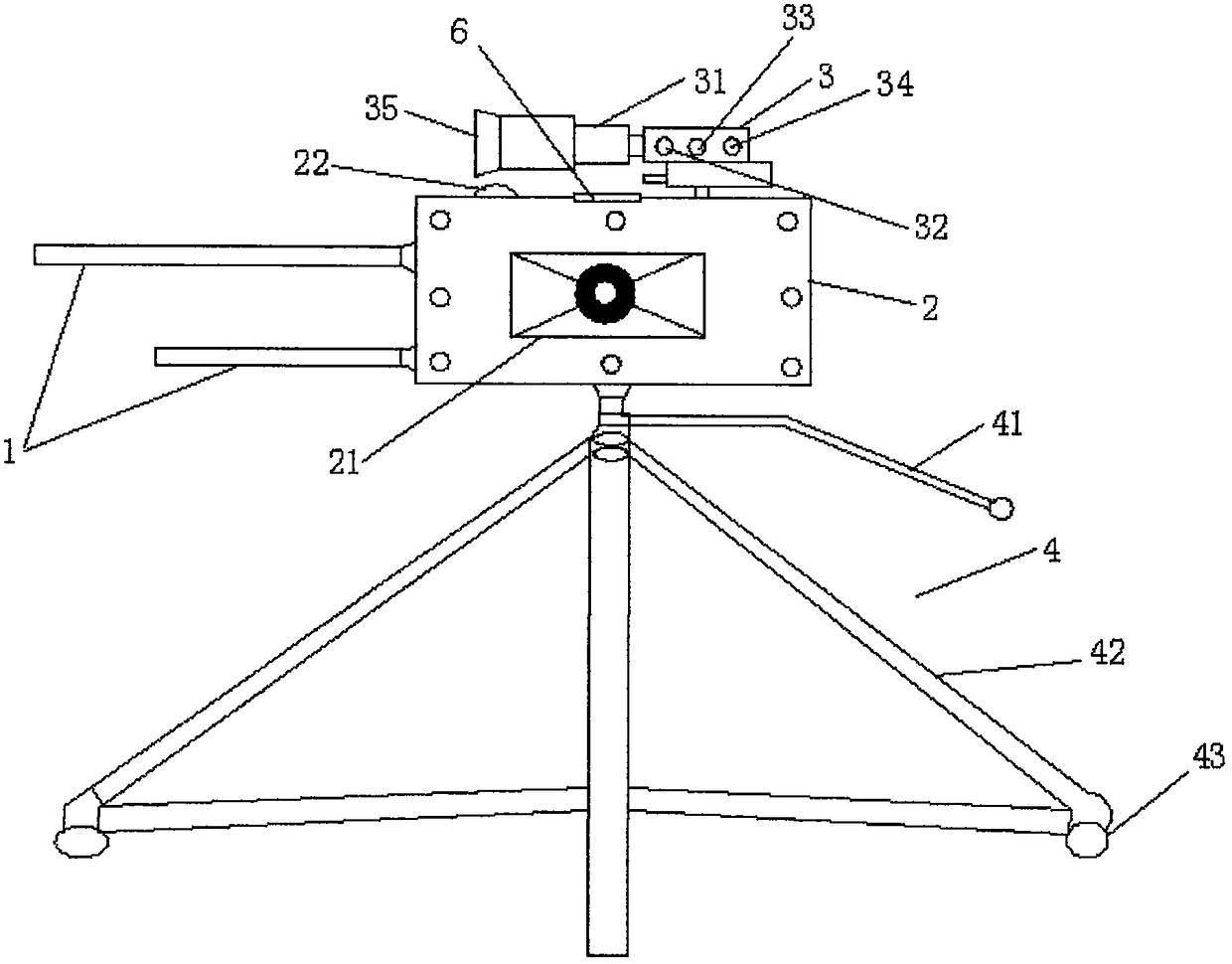

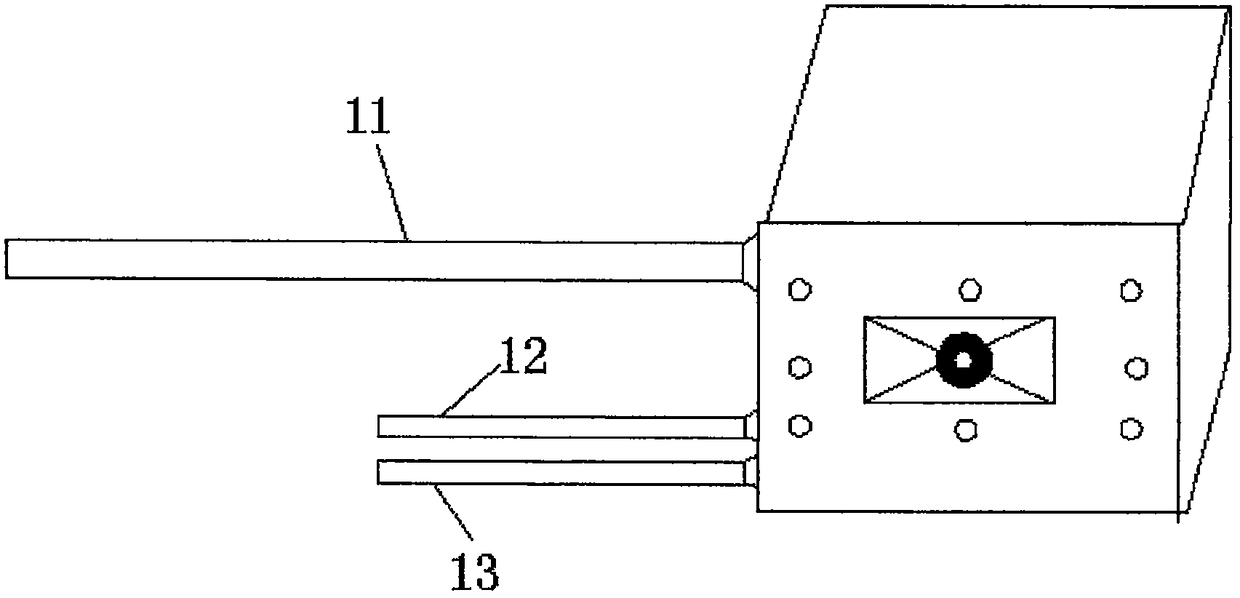

Mobile unmanned aerial vehicle (UAV) interference device

PendingCN108923881ALarge effective interference distanceEffective shieldingCommunication jammingPolymer foilMetal foil

The invention discloses a mobile unmanned aerial vehicle (UAV) interference device, comprising an interference antenna, a main box, an electronic telescope, a tripod and a battery box, wherein the interference antenna is composed of a positioning interference antenna disposed at the upper part of the front end of the main box and a 2.4G interference antenna and a 5.8G interference antenna disposedon both sides of the lower part; an anti-interference layer is further arranged on the inner wall on the top of the main box, and the anti-interference layer contains a magnetic metal foil, a non-magnetic metal foil and a polymer foil; a heat dissipation hole for the cooling fan is mounted on the side of the main box, a radio frequency work indicator is mounted on the top end, the rear end is inlaid with a telescope screen display, the electronic telescope is connected at the upper end of the main box, and the tripod includes an operation handle for controlling the direction at the upper endand three tilting brackets for supporting. The invention has the advantages of large effective interference distance and wide application range, and the anti-interference layer provided on the inner wall on the top of the main box may effectively shield high and low frequency electromagnetic signals and improve the signal transmission efficiency.

Owner:智飞智能装备科技东台有限公司

Power cable with a water barrier laminate

InactiveUS9029705B2Reduce weightClimate change adaptationPower cables with screens/conductive layersPolymer foilPower cable

A power cable having a water barrier laminate where the water barrier laminate has foil made of metal (1) laminated between at least two layers of non insulating polymer foils (2a, 2b) constituting a final laminate (3) that is non insulating.

Owner:NEXANS

Chip Container Helper

A snack dispensing insert positioned within a container, such that the snack dispensing insert holds and dispenses snack media housed within the container is presented. The snack dispensing insert contains an insert body, a handle, and a base. The handle is connected terminally opposite to the base, along the insert body. The base is connected perpendicular to the insert body. The snack dispensing insert is made out of a sheet-like material that is flexible and food-safe. This sheet-like material may take the form of biodegradable polymers, foils, papers, cardboard or any other suitable material. The snack dispensing insert allows a user to pull the snack dispensing insert out of the container, partially or entirely, such that the snack media is easily accessible by the user. Additionally, the snack dispensing insert also serves as a standalone snack tray, allowing the user to place the snack dispensing insert along a flat surface.

Owner:LOUDON JOHN MICHAEL

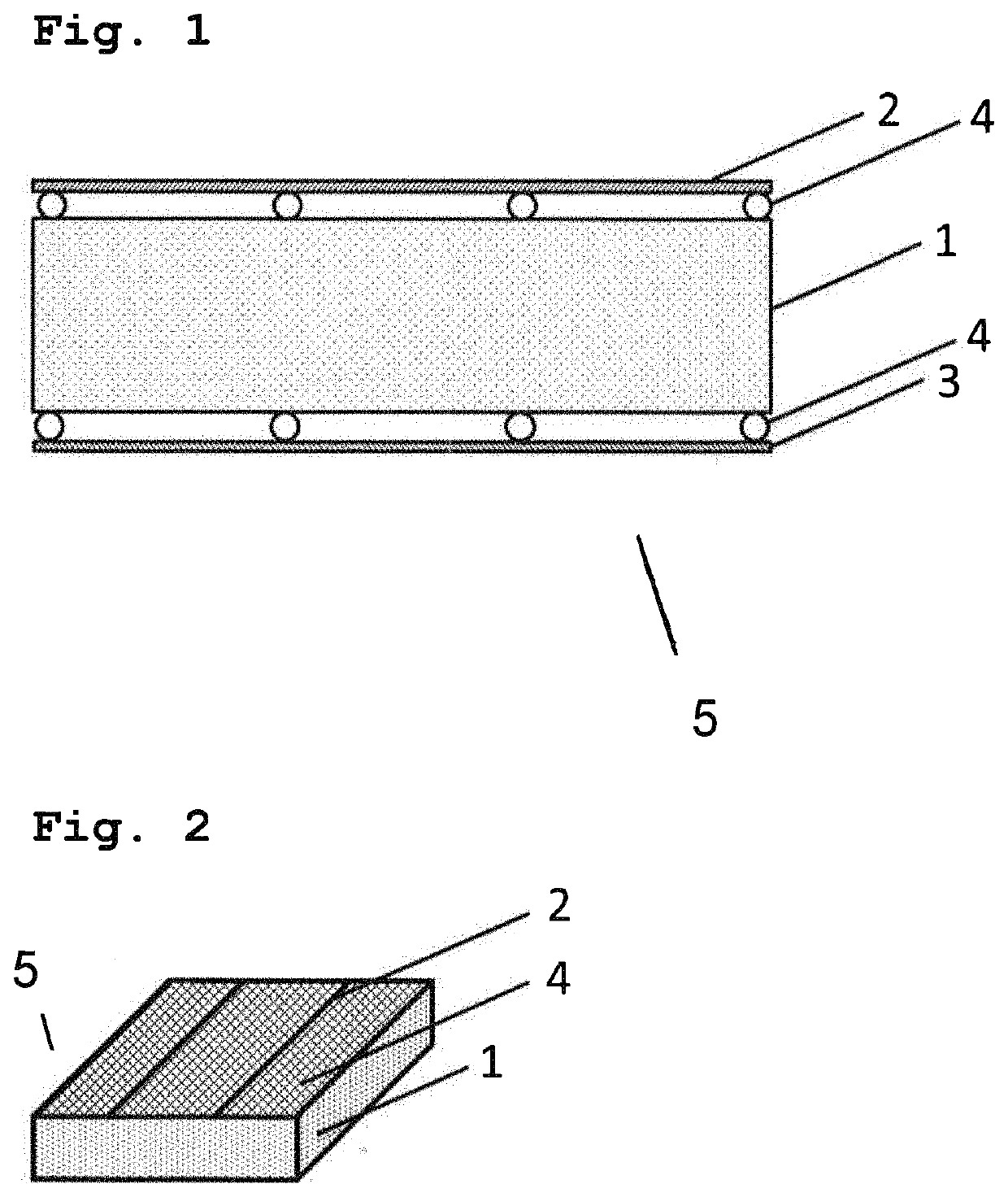

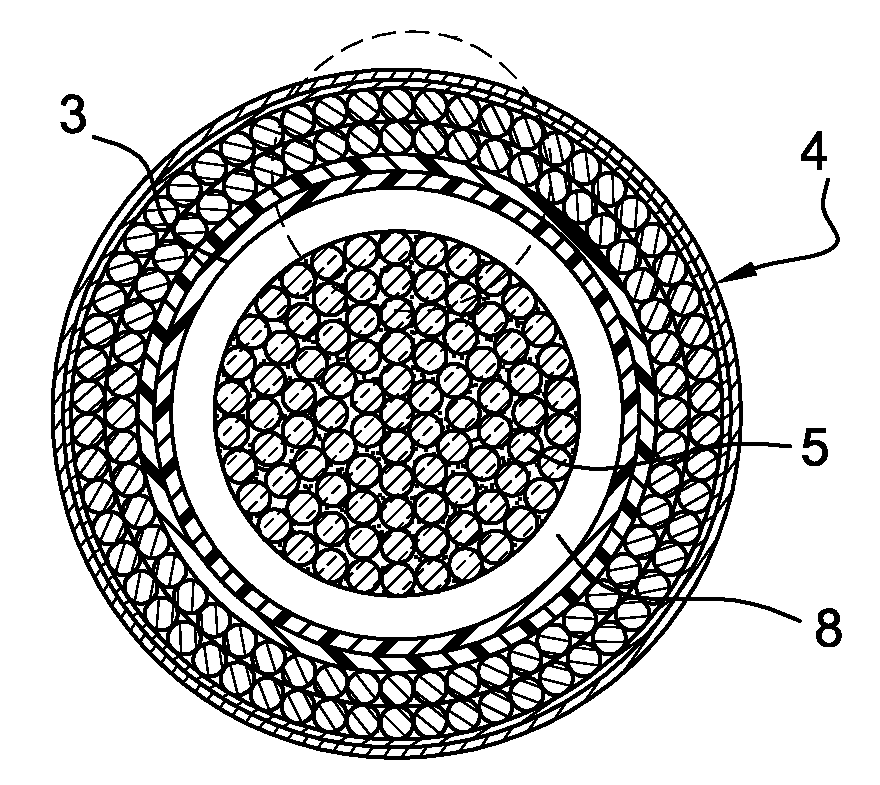

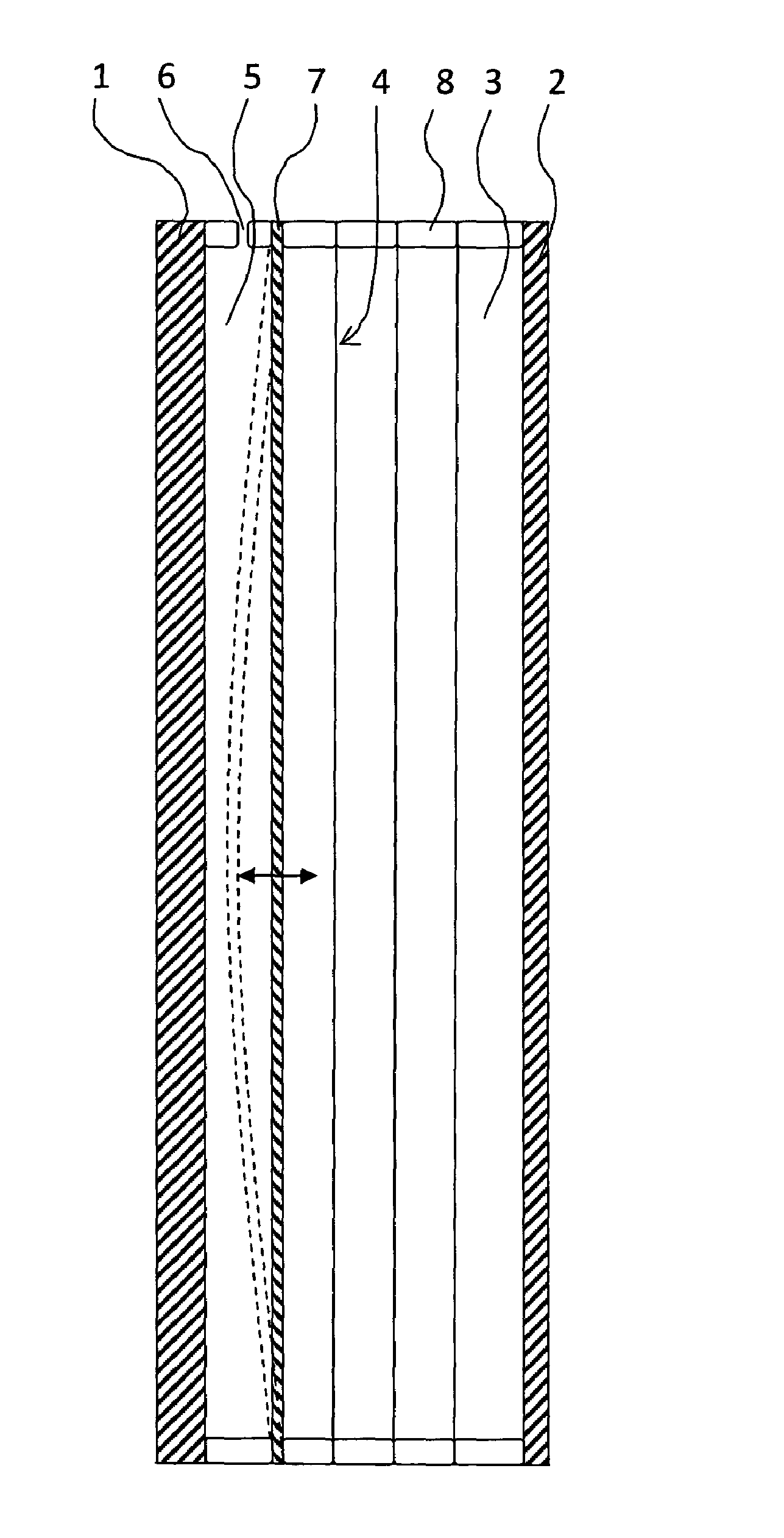

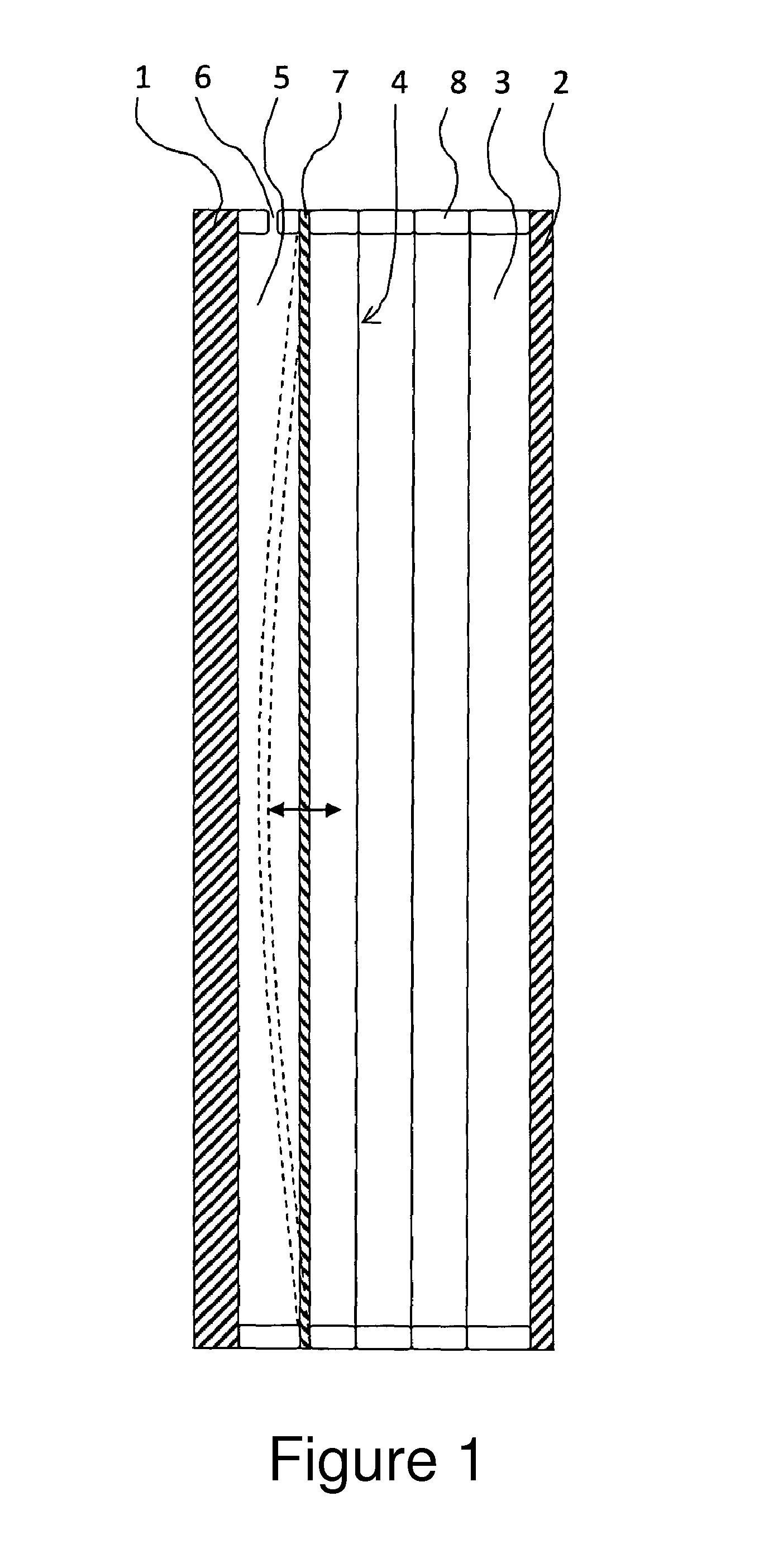

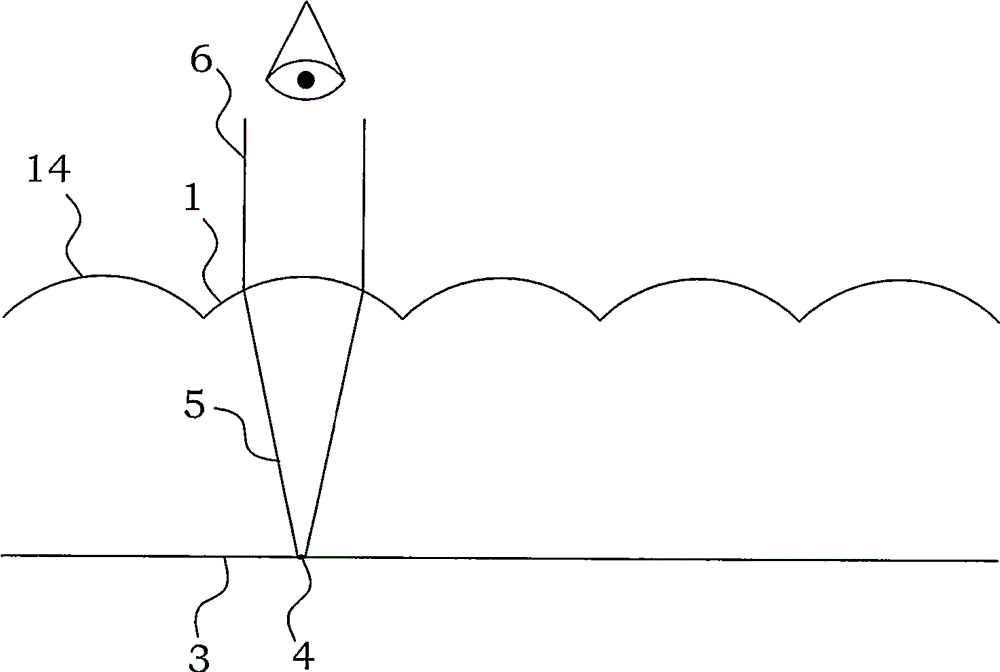

Multi chamber filled construction panel

A Multi Chamber gas filled building panel is structured of essentially planar parallel inner (1) and outer (2) plates. Between the inner (1) and outer (2) plates, preferably of glass, there is at least one chamber (3) filled with insulation gas, the chambers (in case of plurality thereof) divided between themselves using dividers (4) usually manufactured of transparent polymer foils. The building panel according to this invention in addition features at least one air-filled chamber (5) which is connected to surrounding air via opening (6) enabling inner volumetric expansion and contraction of insulation gas.

Owner:CBS INST CELOVITE GRADBENE RESITVE D O O +1

Solar module rear side encapsulation element and solar module

InactiveUS20160064584A1More cost-efficientCost efficientPV power plantsSynthetic resin layered productsPolymer foilEngineering

A solar module rear side encapsulation element having a laminate-type layer construction having at least one polymer plate or polymer foil having a laminate surface. The laminate-type layer construction has at least one protective layer having layer openings. The protective layer covers at least 70% of the laminate surface by a covering area, and due to the layer openings at least 15% and maximum 99.9% of the regions of the solar module rear side encapsulation element lying under the protective layer are covered in the covering area, and the protective layer is formed as a structure made of threads, thus being open to diffusion.

Owner:HANWHA Q CELLS

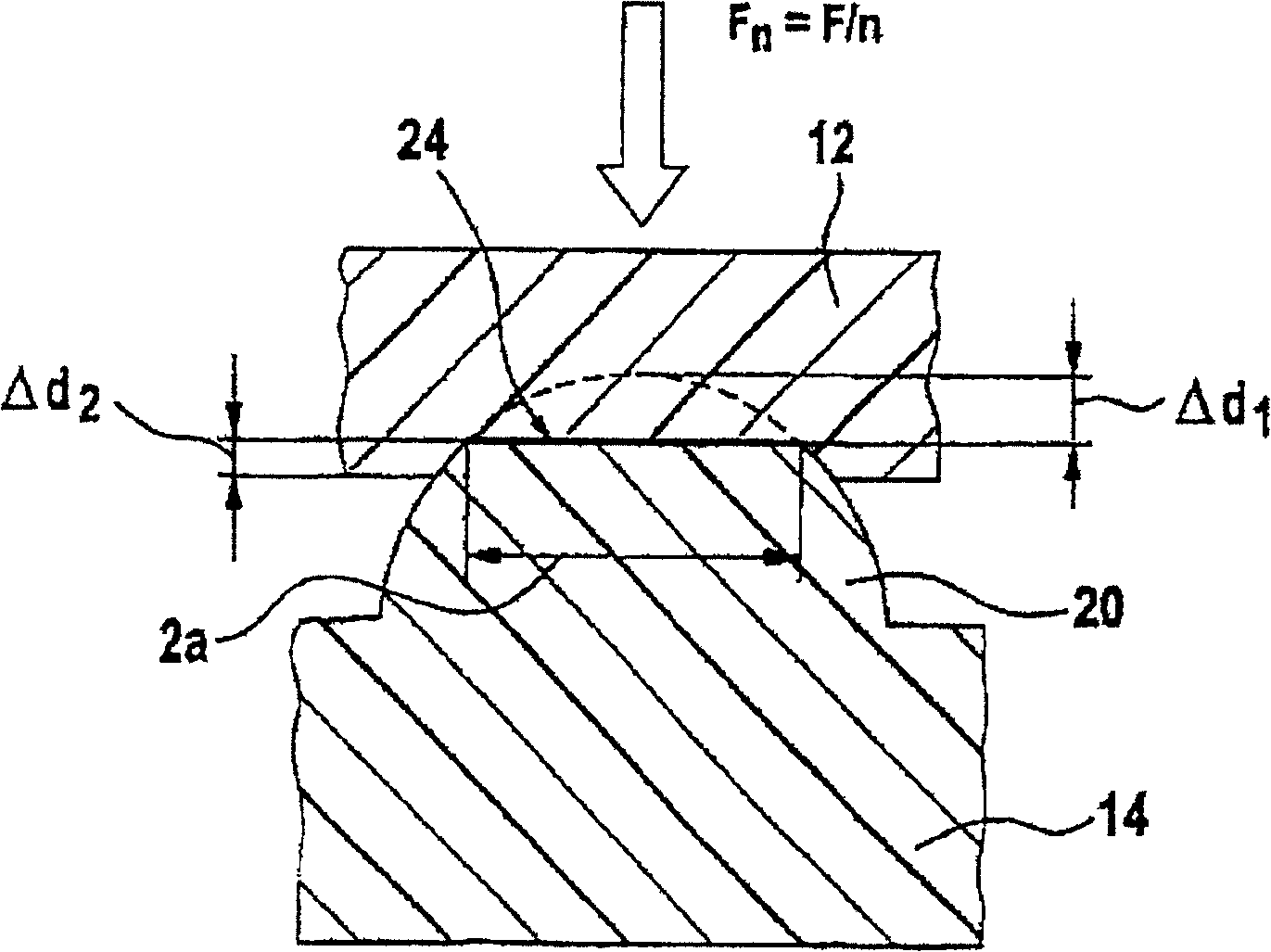

Pressure sensor comprising an elastic sensor layer with a microstructured surface

A pressure sensor has first (12) and second (14) sensor layers that are made from flexible, resistive material and are each applied to a polymer foil. A spacer (22) is coated with an adhesive. The second sensor layer has a micro-structured surface with spherical structures (20) in an active zone (16). The radius (R) of the spherical structures is 50 mum and the compression path 10 mum.

Owner:IEE INT ELECTRONICS & ENG SA

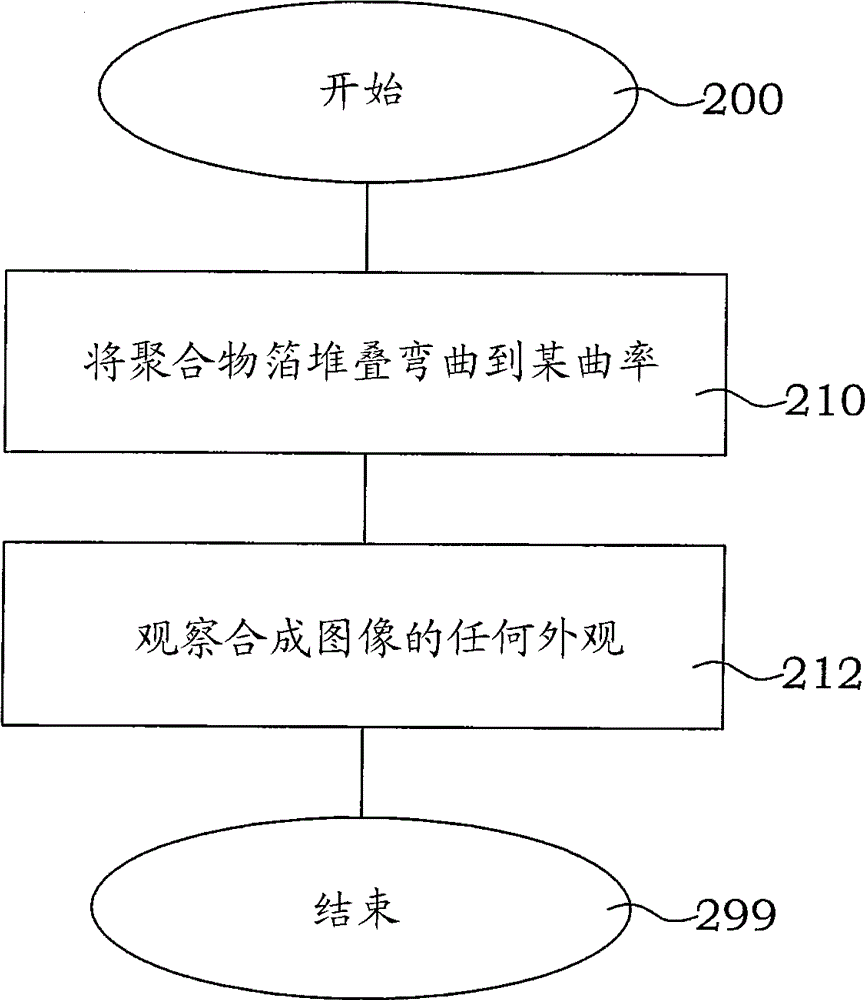

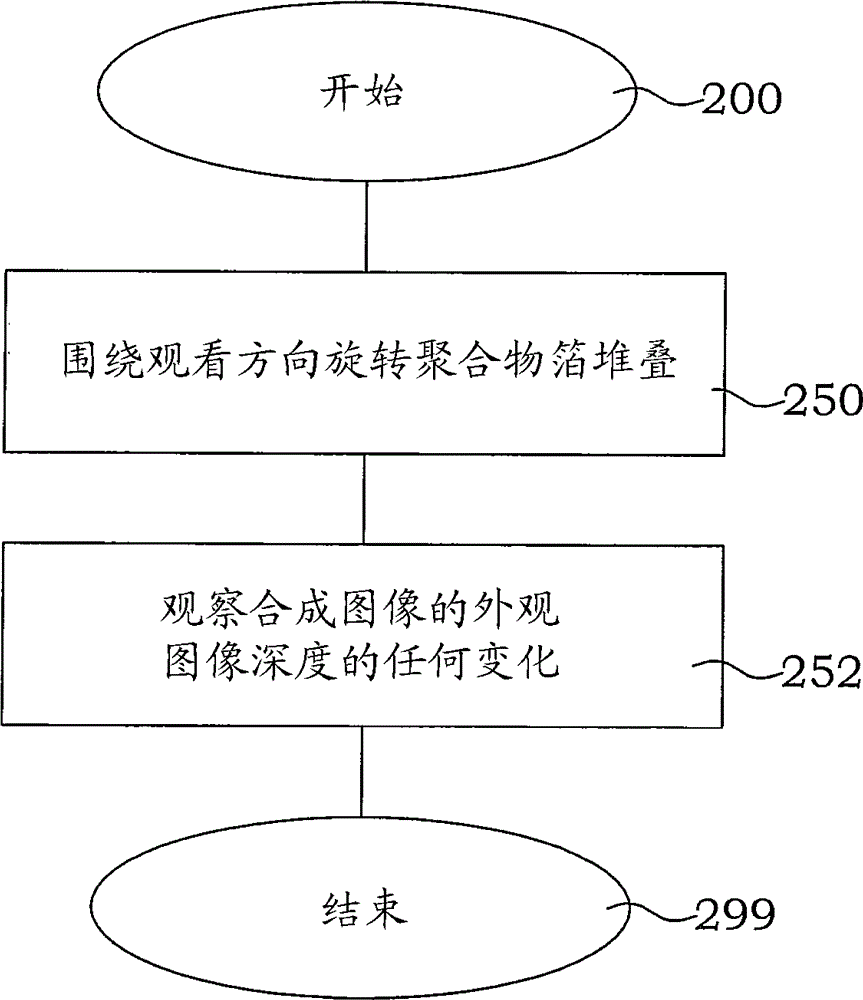

Optical device for providing synthetic integral image and method for identifying objects

ActiveCN102282025BQuality improvementDistinguishabilityStampsOther printing matterPolymer foilShortest distance

Owner:罗灵光学创新有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com