Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105 results about "In-mould labelling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-mould labelling is the use of paper or plastic labels during the manufacturing of containers by blow molding, injection molding, or thermoforming processes. The label serves as the integral part of the final product, which is then delivered as pre-decorated item. Combining the decoration process with the moulding process cuts the total cost, but can increase the manufacturing time. The technology was first developed by Owens-Illinois in cooperation with Procter & Gamble to supply pre-labelled bottles that could be filled on the product filling line. This was first applied to Head & Shoulders shampoo bottles.

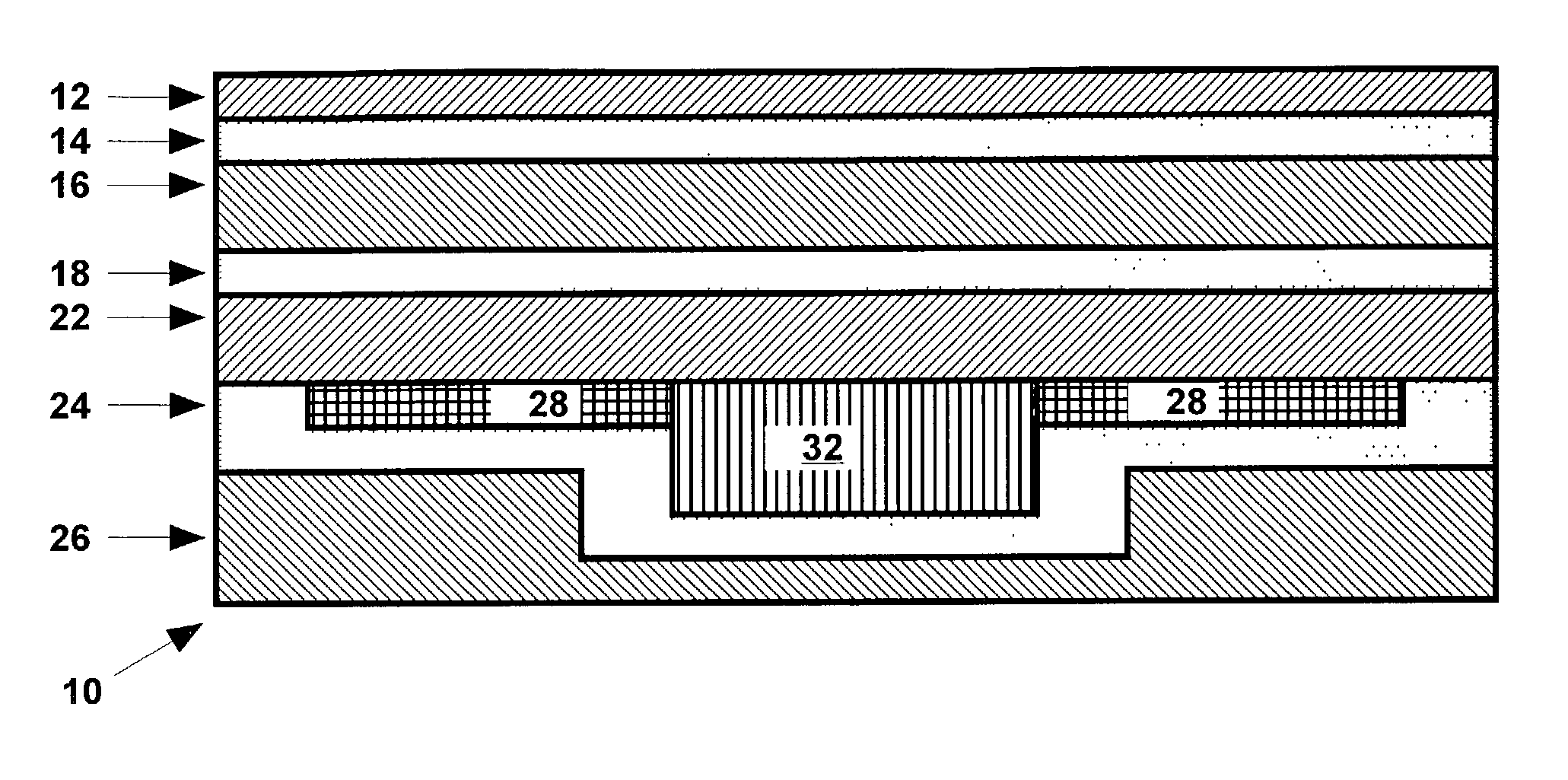

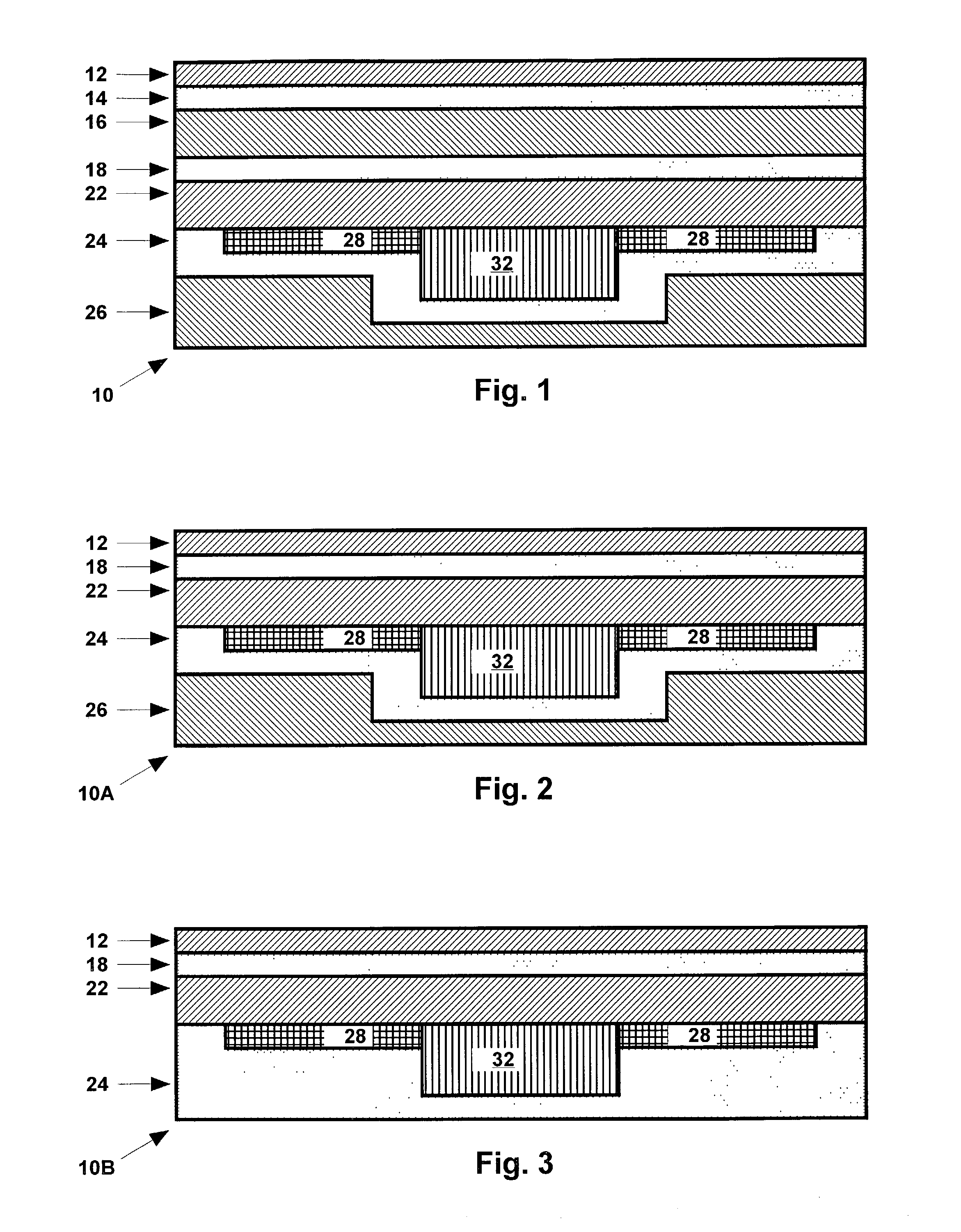

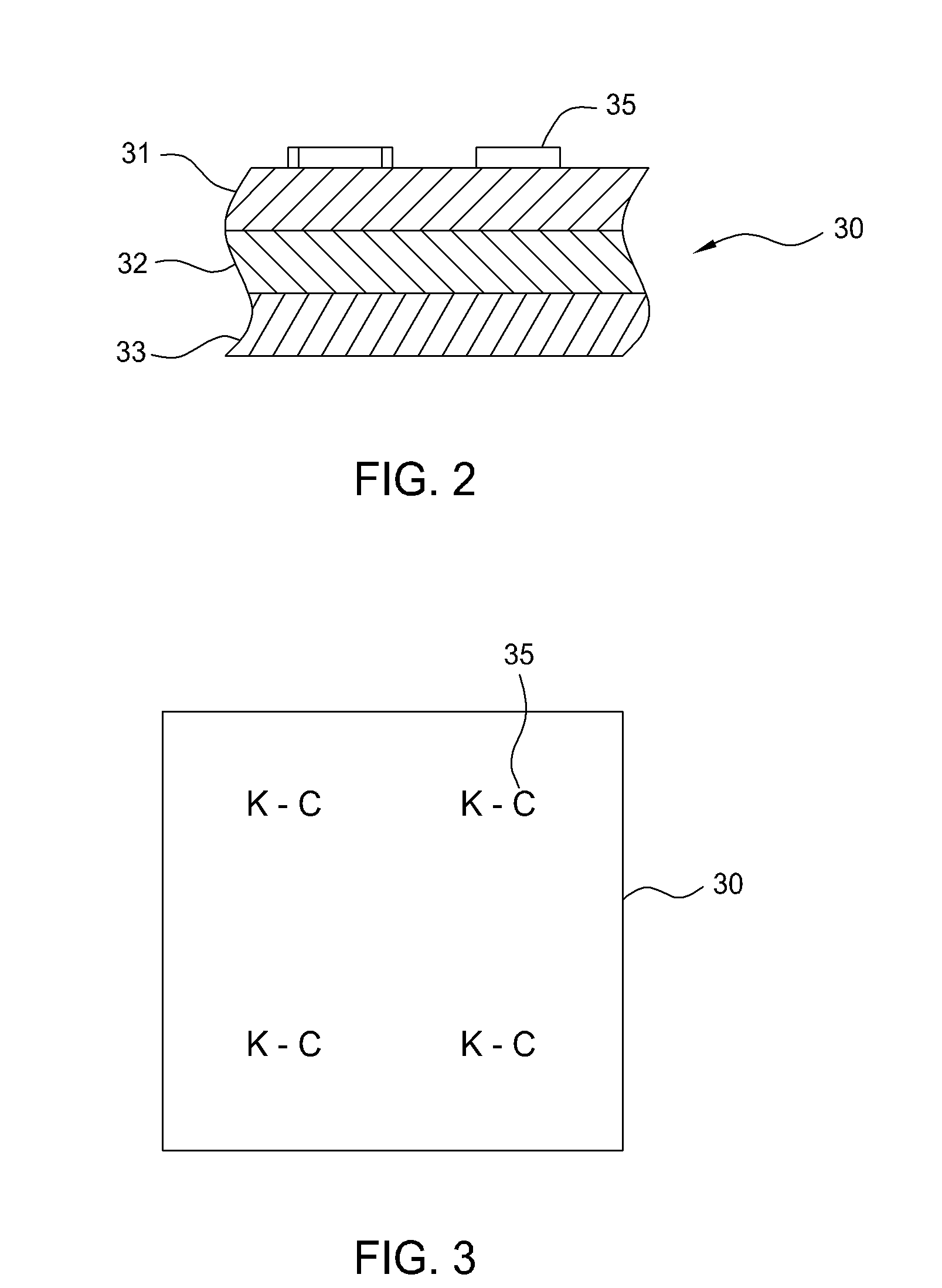

In-mold radio frequency identification device label

InactiveUS7135979B2Improves Structural IntegrityImprove bindingOther printing matterRecord carriers used with machinesSurface layerRadio frequency

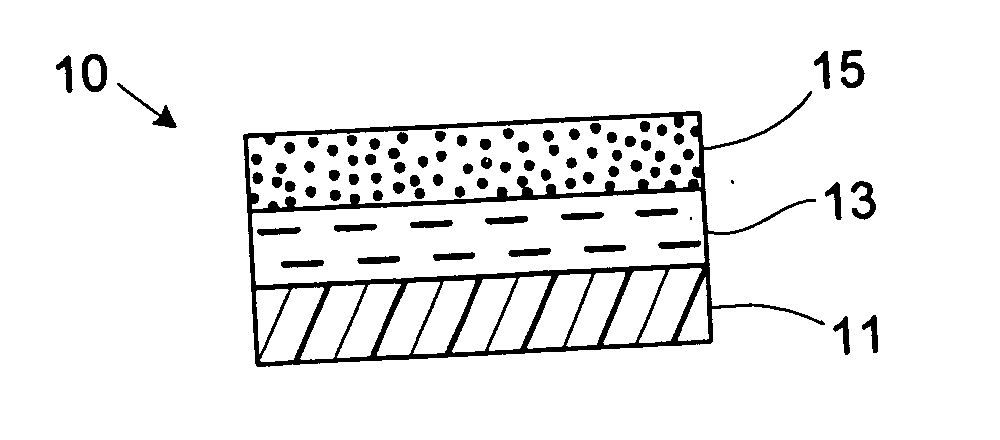

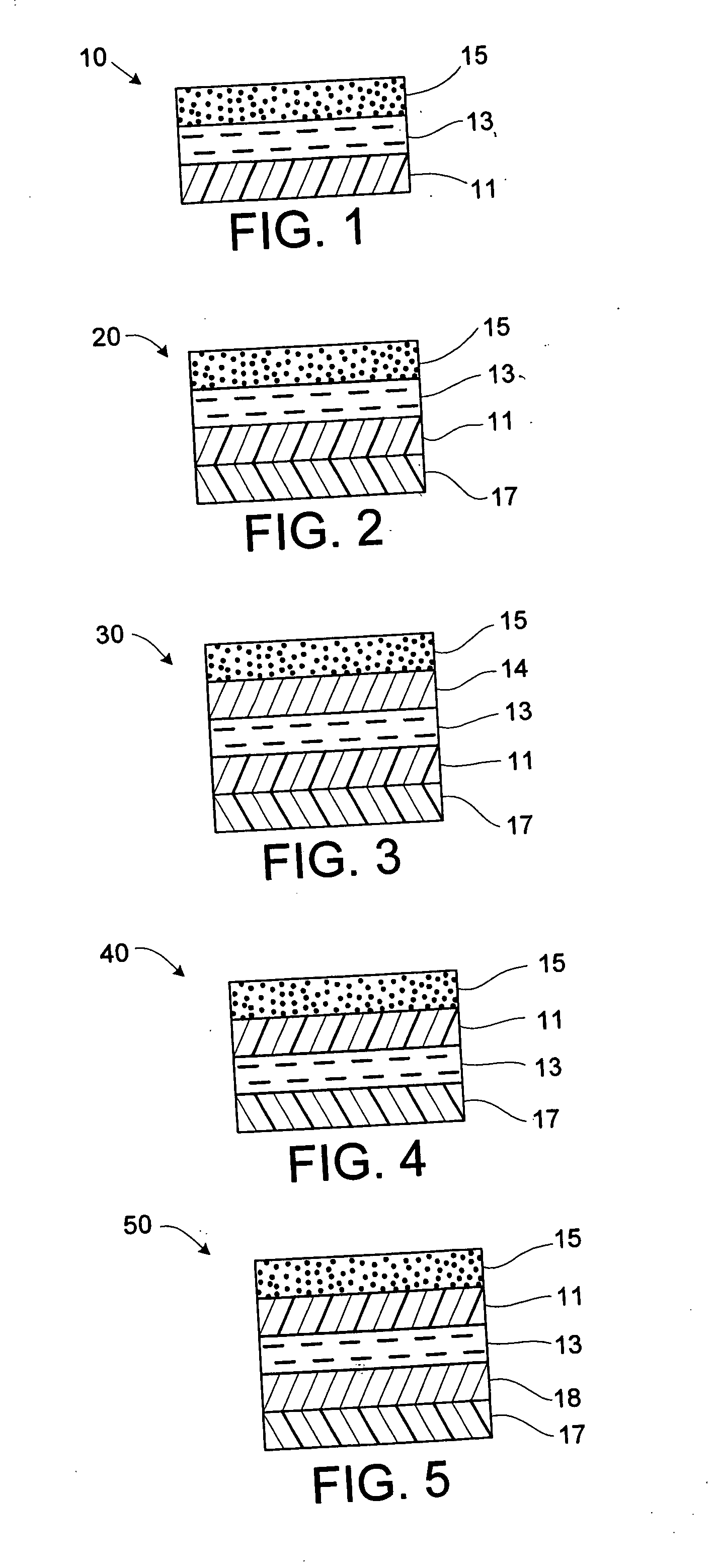

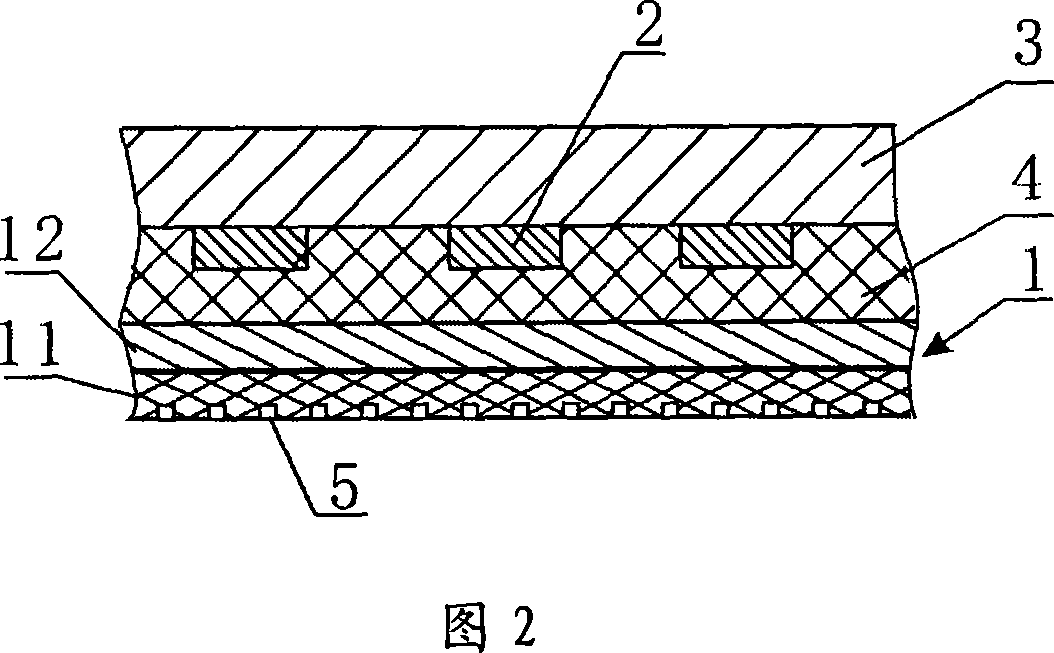

A label for use as an in-mold label and including a radio frequency identification device (RFID) is disclosed. The label includes an RFID having opposed first and second surfaces; a first layer of heat-activated adhesive disposed on the first surface of the RFID; a second layer of heat-activated adhesive disposed on the second surface of the RFID; and a surface layer comprising a polymeric film disposed on a surface of the first layer of heat-activated adhesive opposite the first surface of the RFID. The label is placed in a mold with the surface layer contacting the mold. A polymer is molded in the mold such that the second layer of heat-activated adhesive (or a surface layer over the second layer of heat-activated adhesive) adheres to the polymer thereby producing a labeled article that can be identified using the radio frequency identification device in the label.

Owner:BRADY WORLDWIDE INC

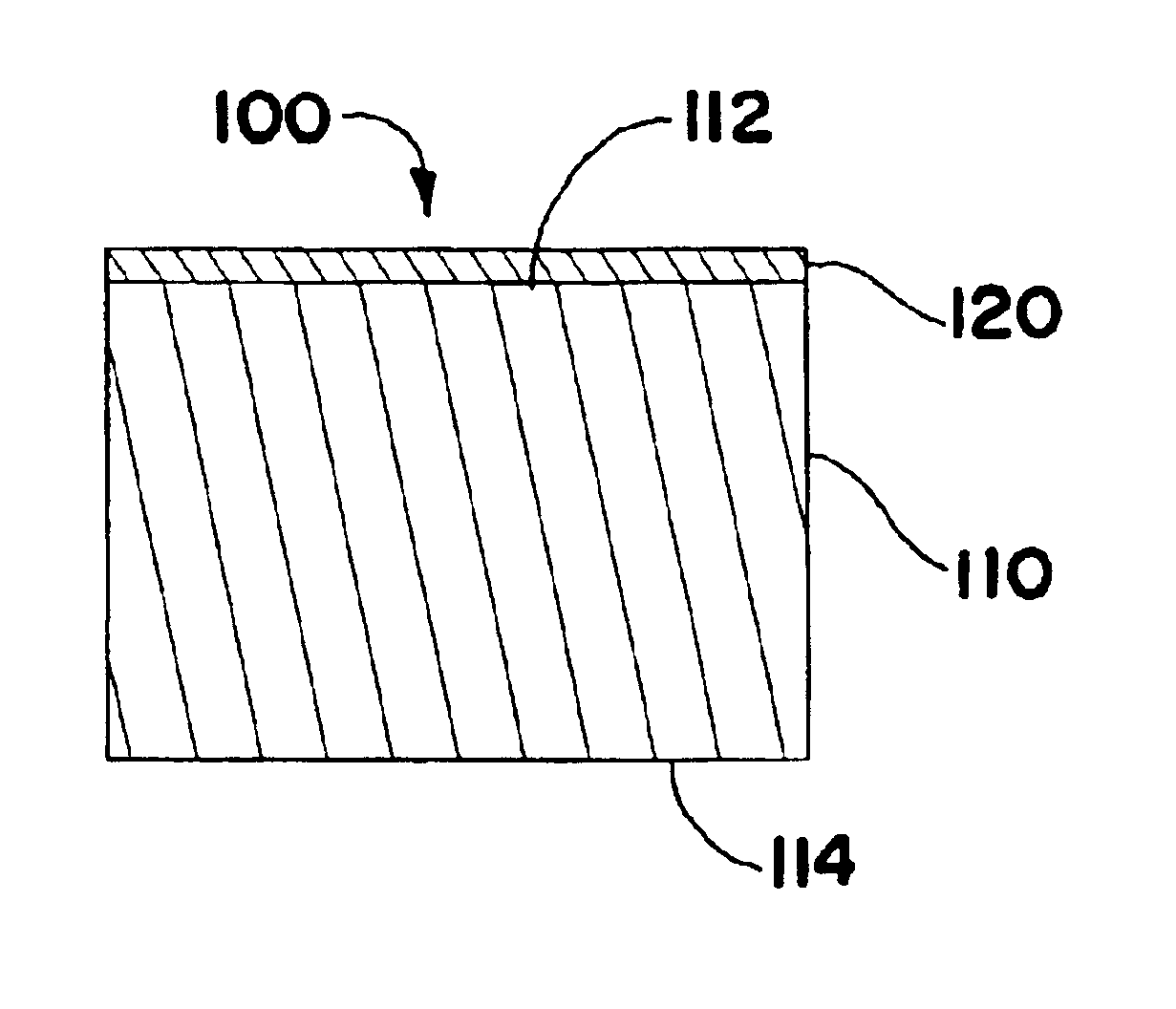

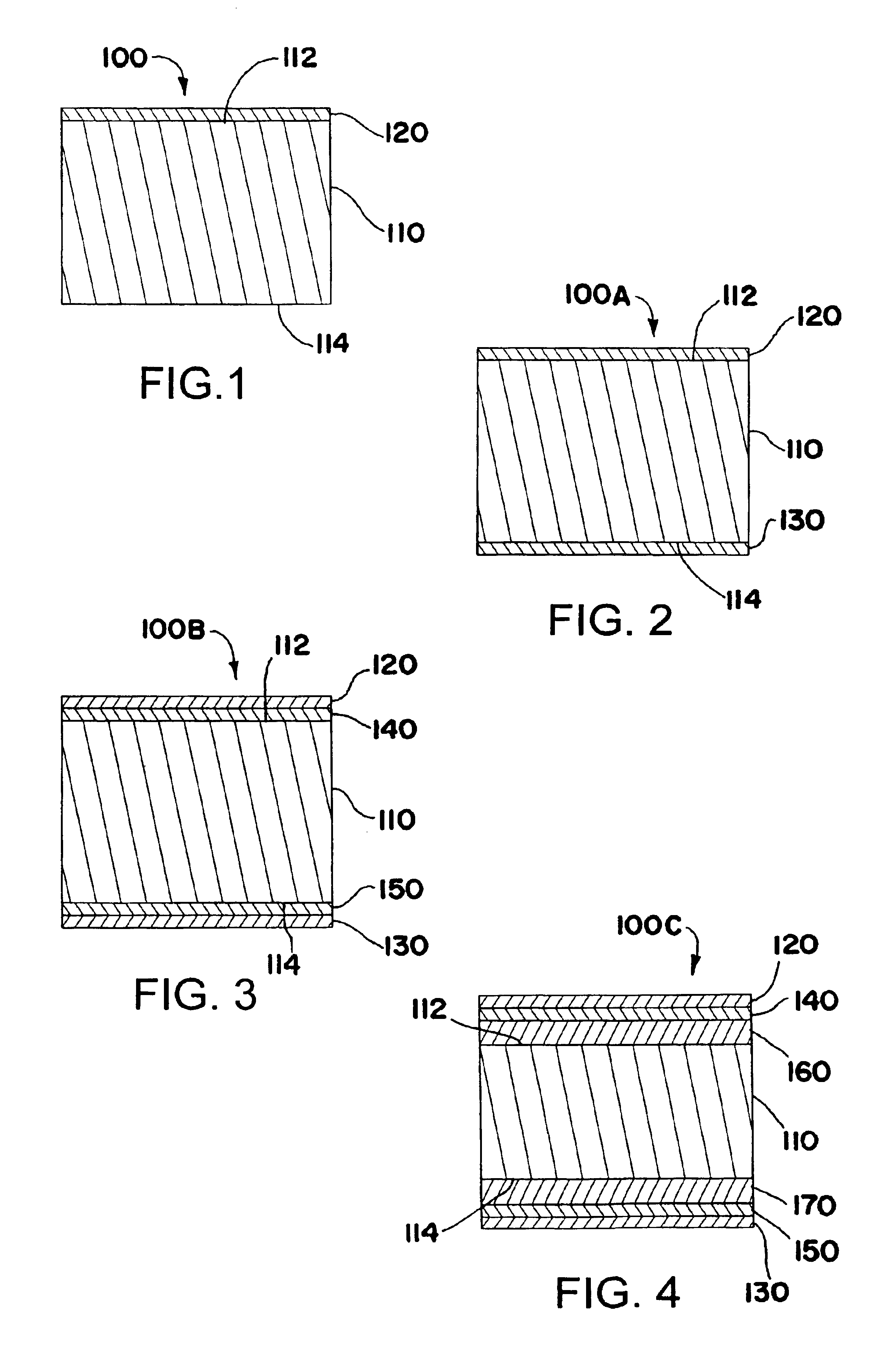

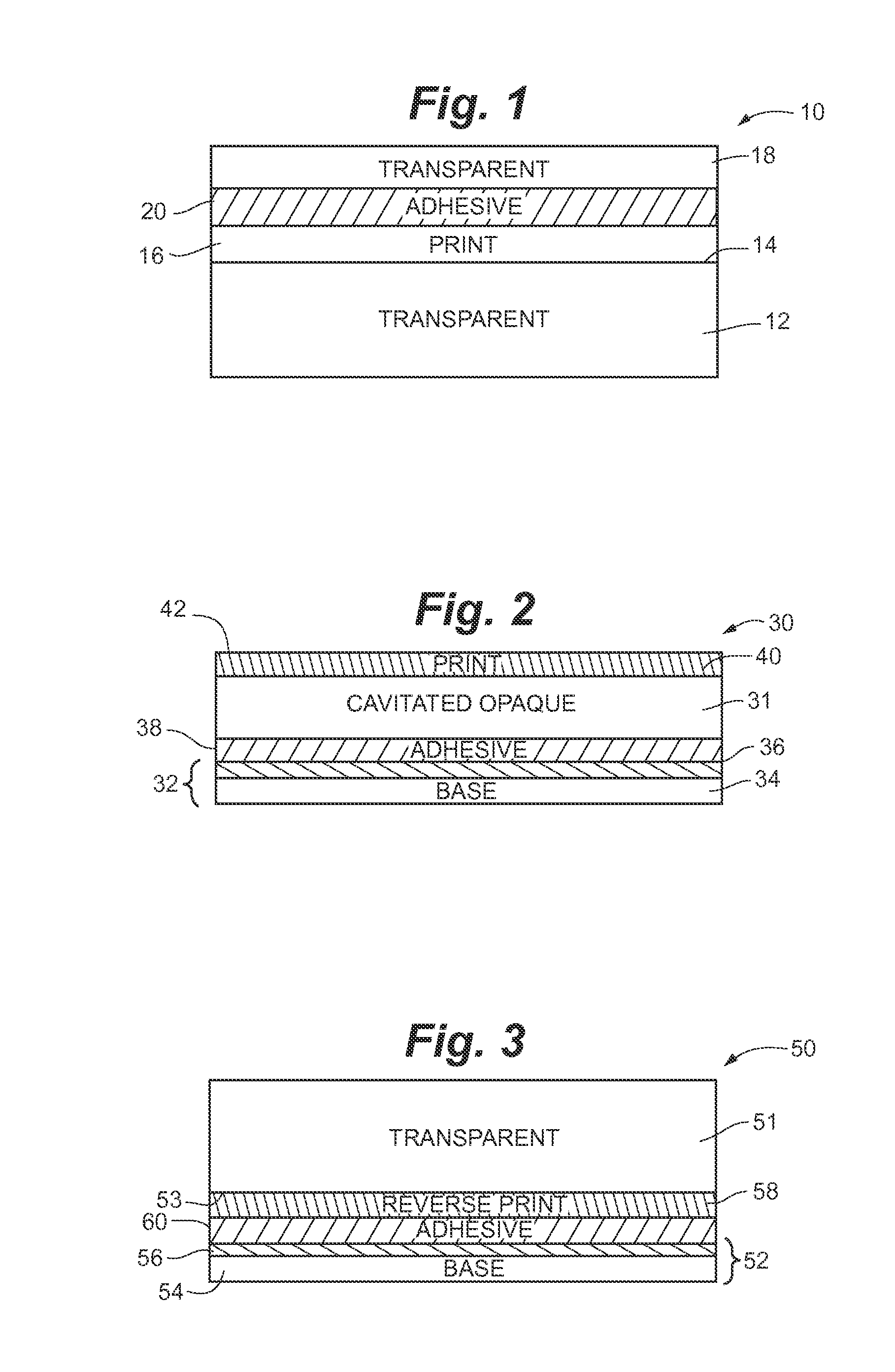

Multilayered film

InactiveUS6919113B2Decorative surface effectsDuplicating/marking methodsVolumetric Mass DensityMaterials science

This invention relates to a multilayered film for use as in-mold label, comprising: a core layer having a first surface and a second surface, the core layer being comprised of a polymeric mixture and particulate solids dispersed in the polymeric mixture; and an ink-printable layer overlying the first surface of the core layer; the film being formed by co-extruding the core layer and ink-printable layer to form the multilayered film, hot-stretching the film at a temperature above the expected service temperature of the label to provide the film with a machine direction orientation, the density of the film being reduced by about 10% to about 25% during hot-stretching, and annealing the film at a temperature above the expected service temperature of the label; the film having a machine direction Gurley stiffness value in the range of about 30 to about 120, a machine direction shrinkage of less than about 3%, and a machine direction shrink tension at 200° F. (93.3° C.) of less than about 100 psi.

Owner:AVERY DENNISON CORP

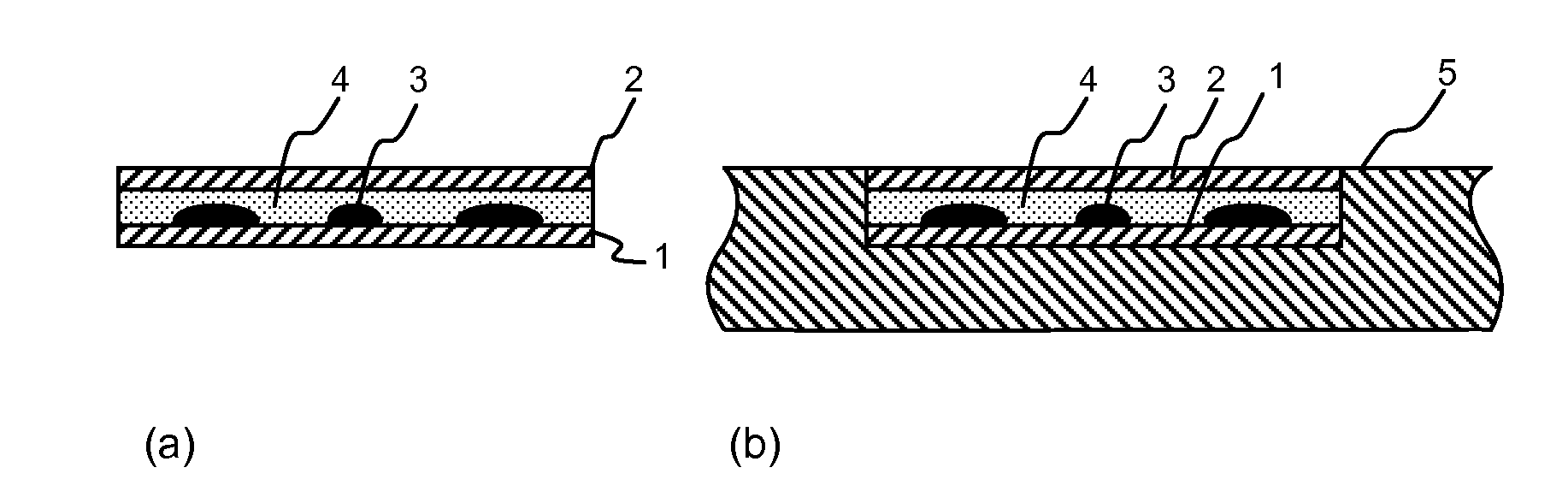

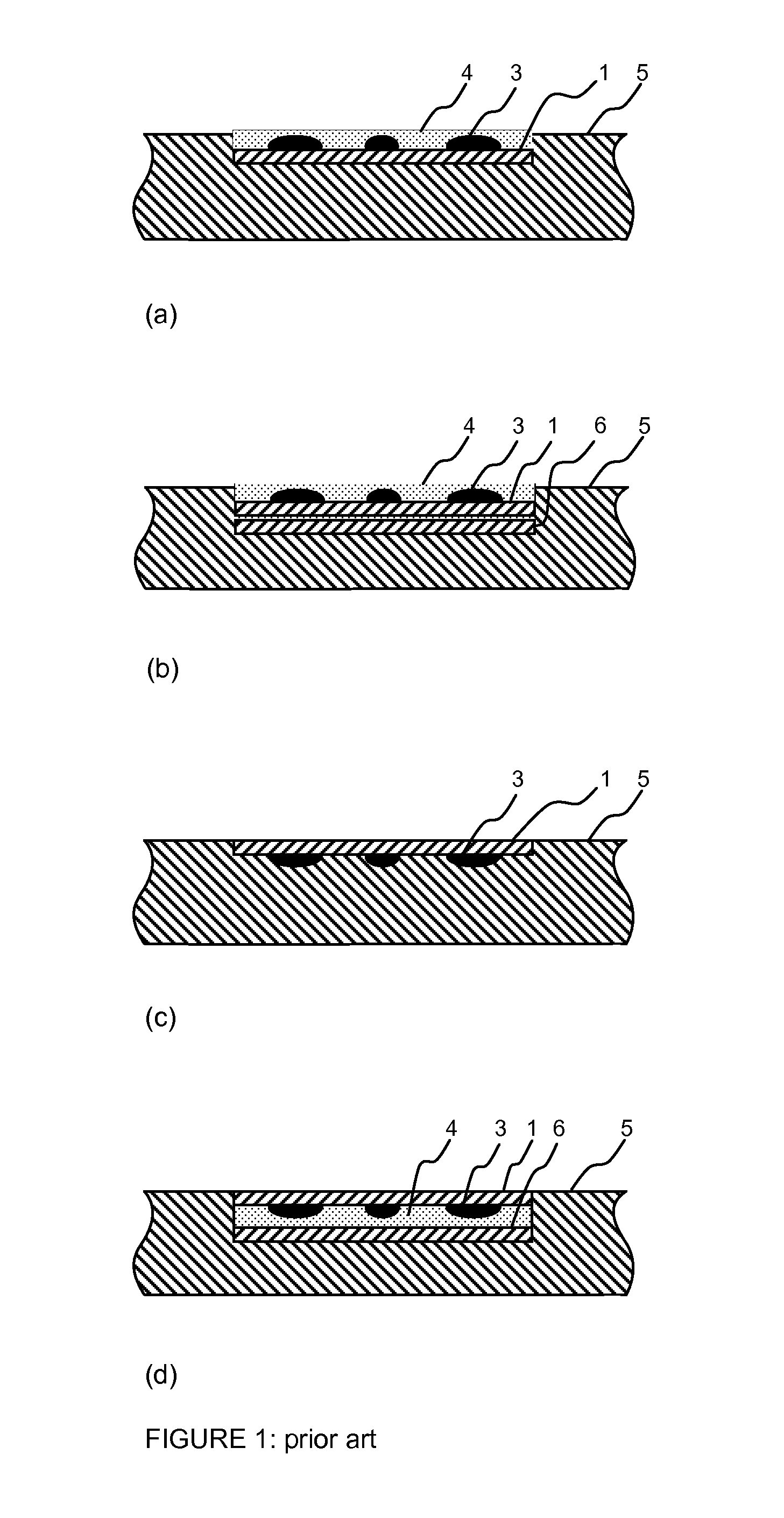

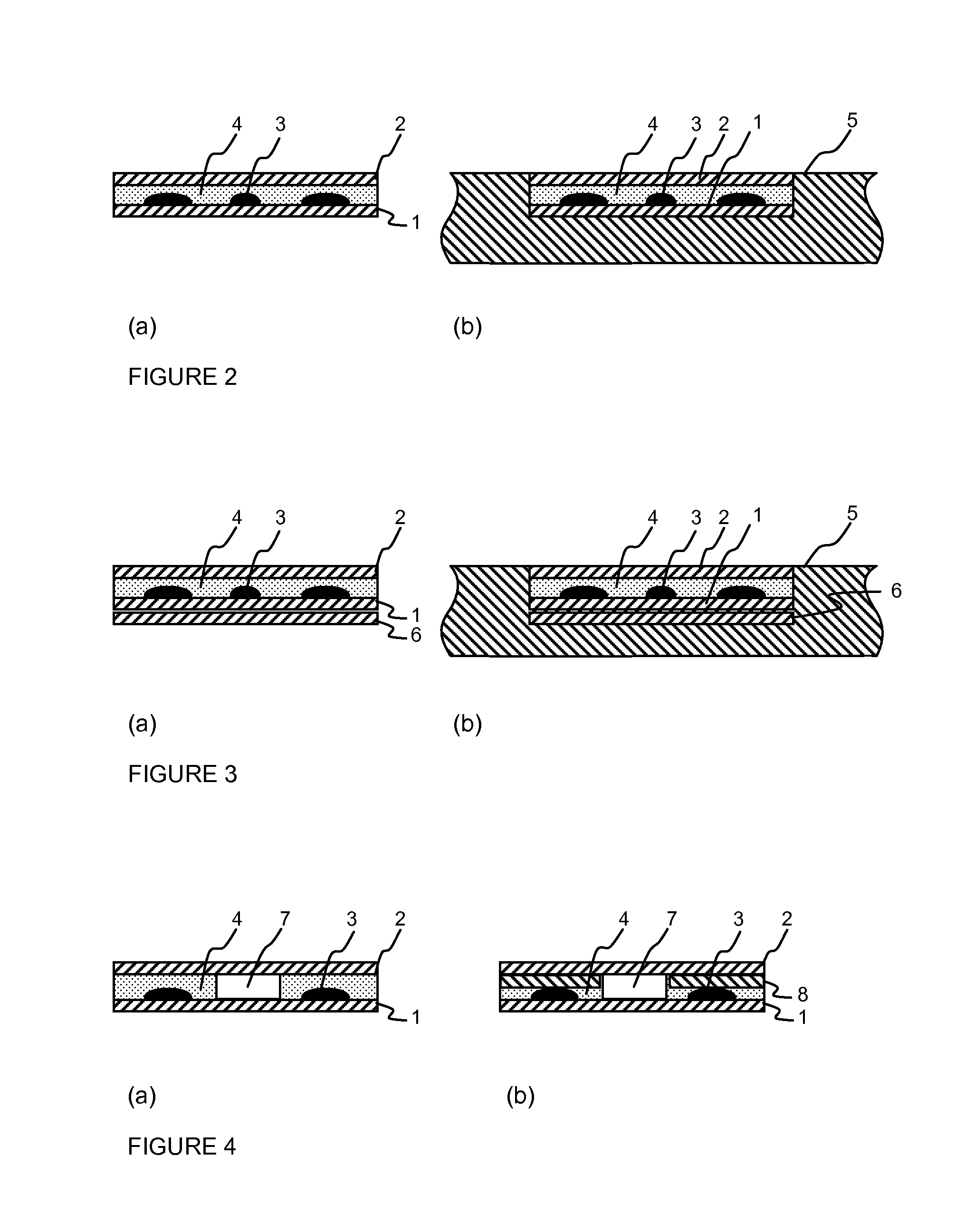

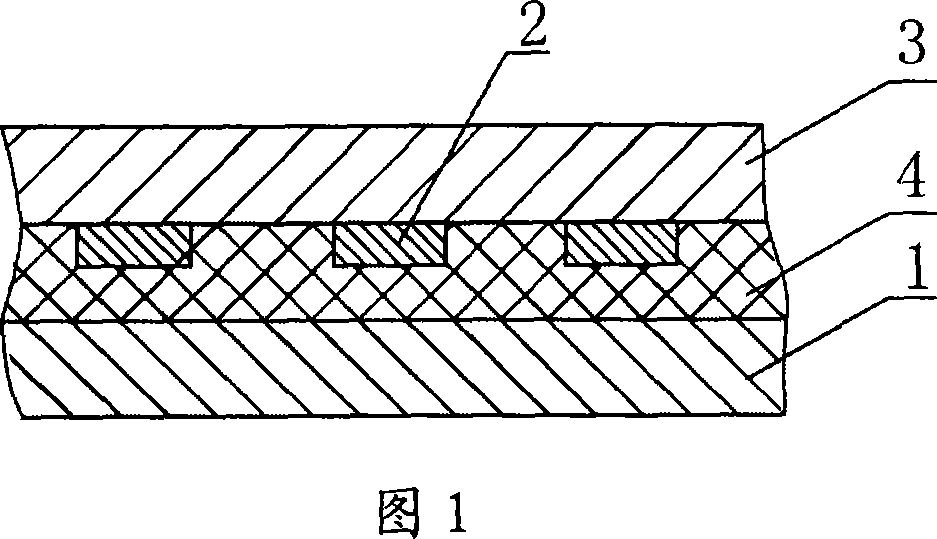

In-mould label and method for manufacturing thereof

InactiveUS20100291329A1Easy to adaptImprove adhesionStampsEnvelopes/bags making machineryAdhesiveEngineering

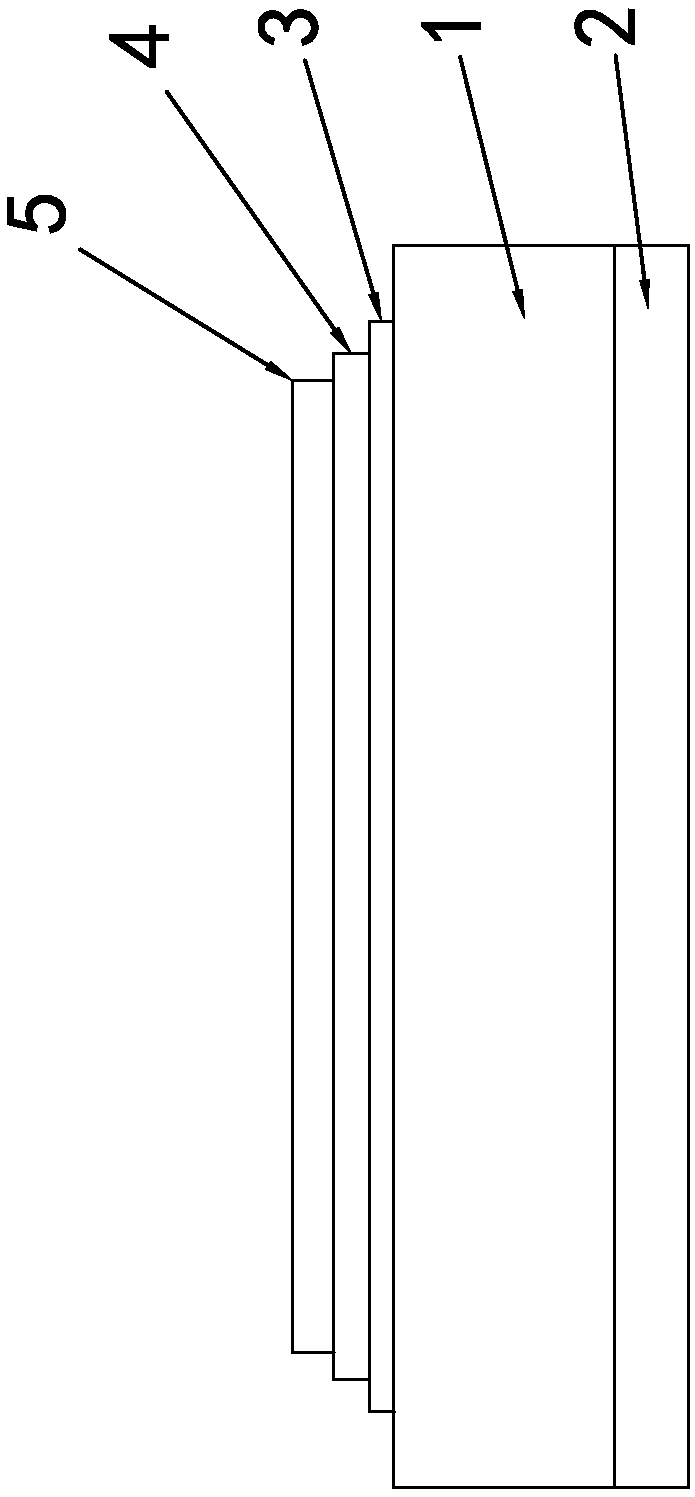

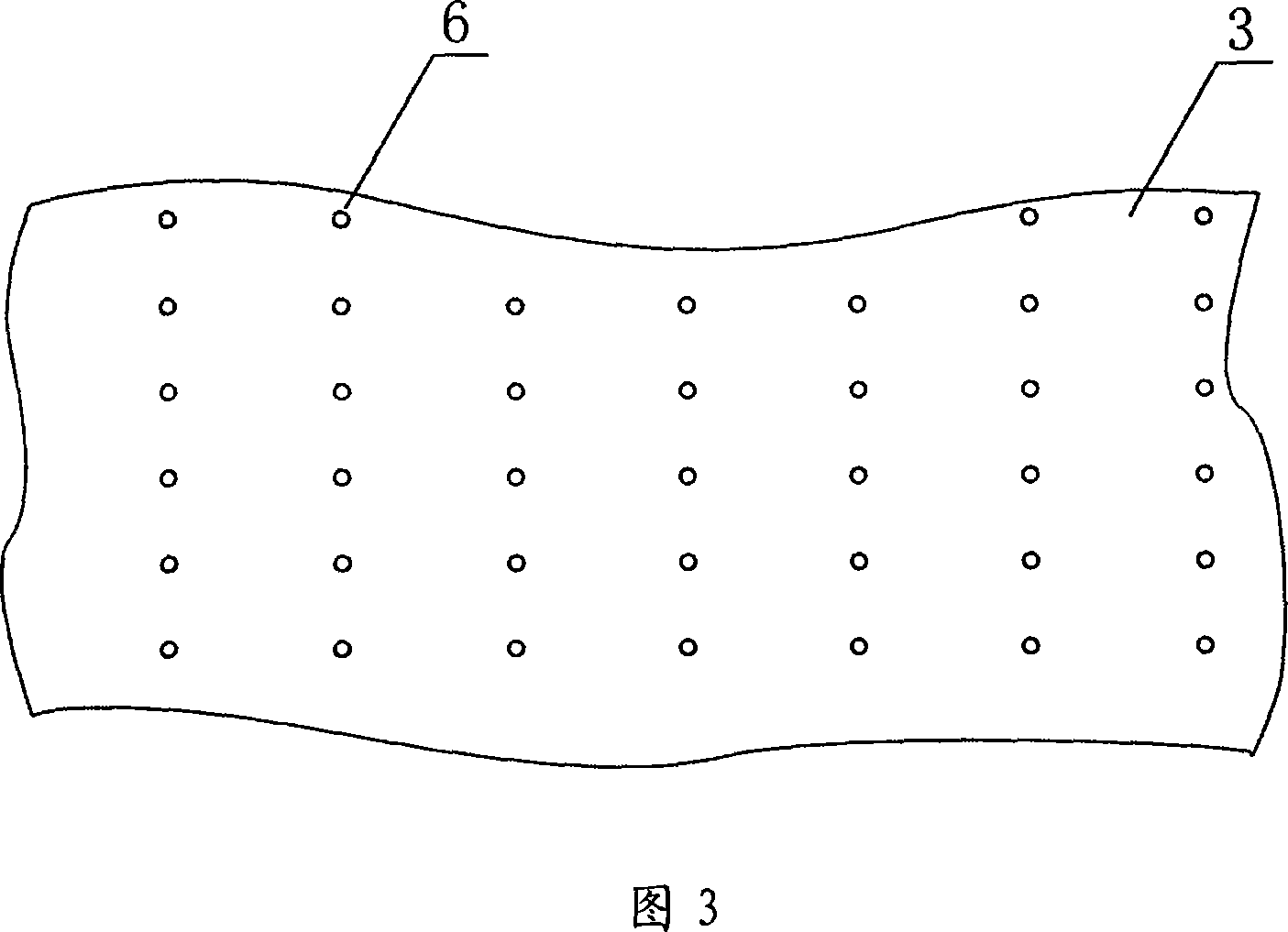

The present invention concerns an in mould label comprising a polymeric or cellulosic carrier base film (1) having a first decorative surface (1a) and a second, backing surface (1b), said label comprising a pattern (3) printed on said first decorative surface (1a) thereof, said printed first surface (1a) being laminated with a transparent protective top film (2), affixed thereto by means of an adhesive (4), the printed pattern (3) being visible through said transparent protective top film (2). It also concerns a method for manufacturing such a label and a method for incorporating it onto the surface of a polymeric article.

Owner:I S D I

In-mold label with separable part

InactiveUS20050191449A1Good lookingEasy to tear offEnvelopes/bags making machineryStampsAdhesion strengthMaterial Perforation

Disclosed is an in-mold label comprising a thermoplastic resin film substrate layer and a heat-seal resin layer, wherein the wettability index of the thermoplastic resin film substrate layer surface and / or the heat-seal resin layer surface is from 34 to 73 mN / m, the label comprises a label body and a separable part, tearable perforations are provided between the label body and the separable part, and, when the label is stuck to a thermoplastic resin container during in-mold production of the container, the adhesion strength between the separable part and the container is from 80 to 270 gf / 10 mm. The in-mold label may be printed on both sides thereof, and the separable part of the label is not loosened from a container during transportation and use of the labeled container. Not broken, the separable part is readily torn off from the container.

Owner:YUPO CORP

Composite film having barrier properties for use as in-mold labels, article with in-mold labels, and methods of making same

Barrier films, in-mold label formed from barrier films, and containers incorporating in-mold labels with barrier properties. Films according to embodiments of the invention include multi-layer or composite films that include one or more layers of a barrier material. The films can be used to form labels in standard in-mold labeling processes such that standard robotics, molds, and materials can be used. Preferably, the film can seal on itself such that an overlap seam can be made. The film has adequate desired barrier properties, i.e. water vapor, oxygen, light, aroma, and / or flavor retention barriers depending on the application, such as packaging of consumable products.

Owner:TAYLOR COMM INC

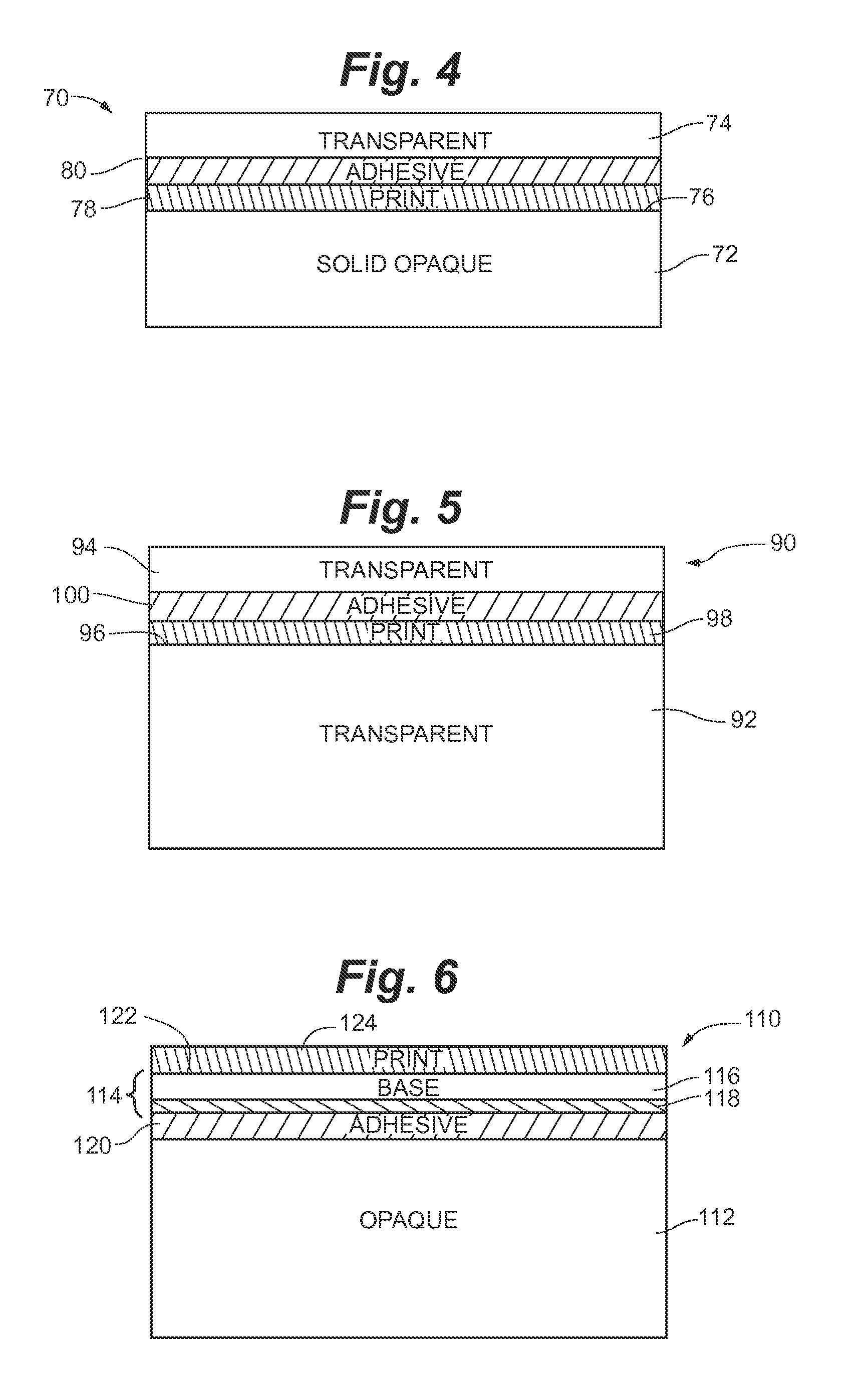

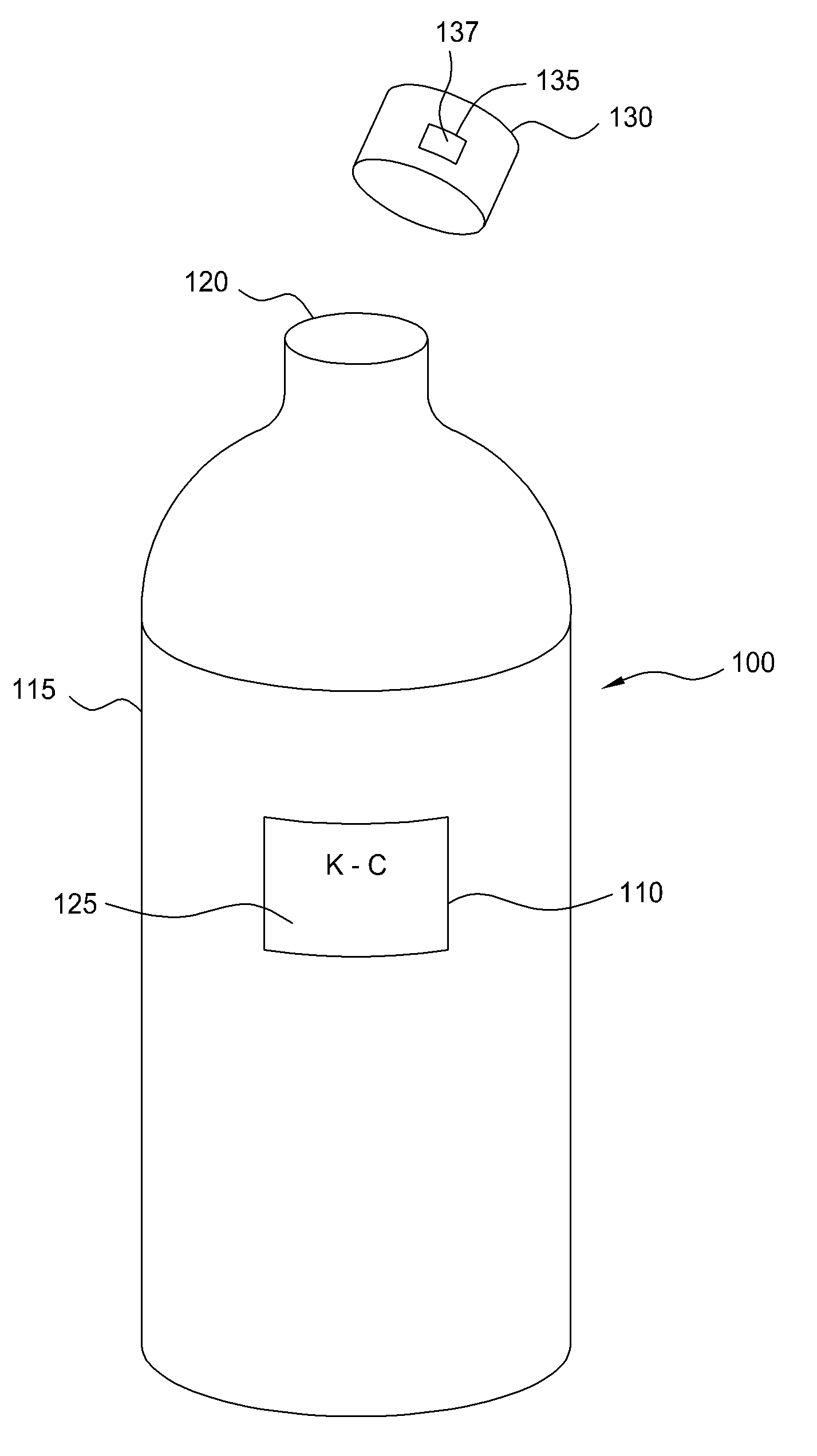

Container with an in-mold label

A container having a scented label attached using an in-mold label process and methods of making the same. A scented material is supplied to the label, and the label is attached to the container using an in-mold label process. In another embodiment, a container comprises an interior cavity for retaining a substance, and a label adapted to dispense a scent, wherein the label is disposed on an exterior surface of the container using an in-mold label process. The scent may be suggestive of the content of the container.

Owner:KIMBERLY-CLARK WORLDWIDE INC

In-mold label and molded article using the same

ActiveUS20070003777A1Easy to eliminateGood lookingSynthetic resin layered productsRecord information storageEngineeringHaze

The invention provides an in-mold label which enables the degree of scumming to be judged during printing and imparts a good appearance to molded articles produced through in-mold molding, and which comprises a base layer (I), a heat-sealable resin layer (II), and a printable layer (III) and has a haze in whole layer of 80-100% and an internal haze of 0-20%. The invention further provides a molded article obtained using the label.

Owner:YUPO CORP

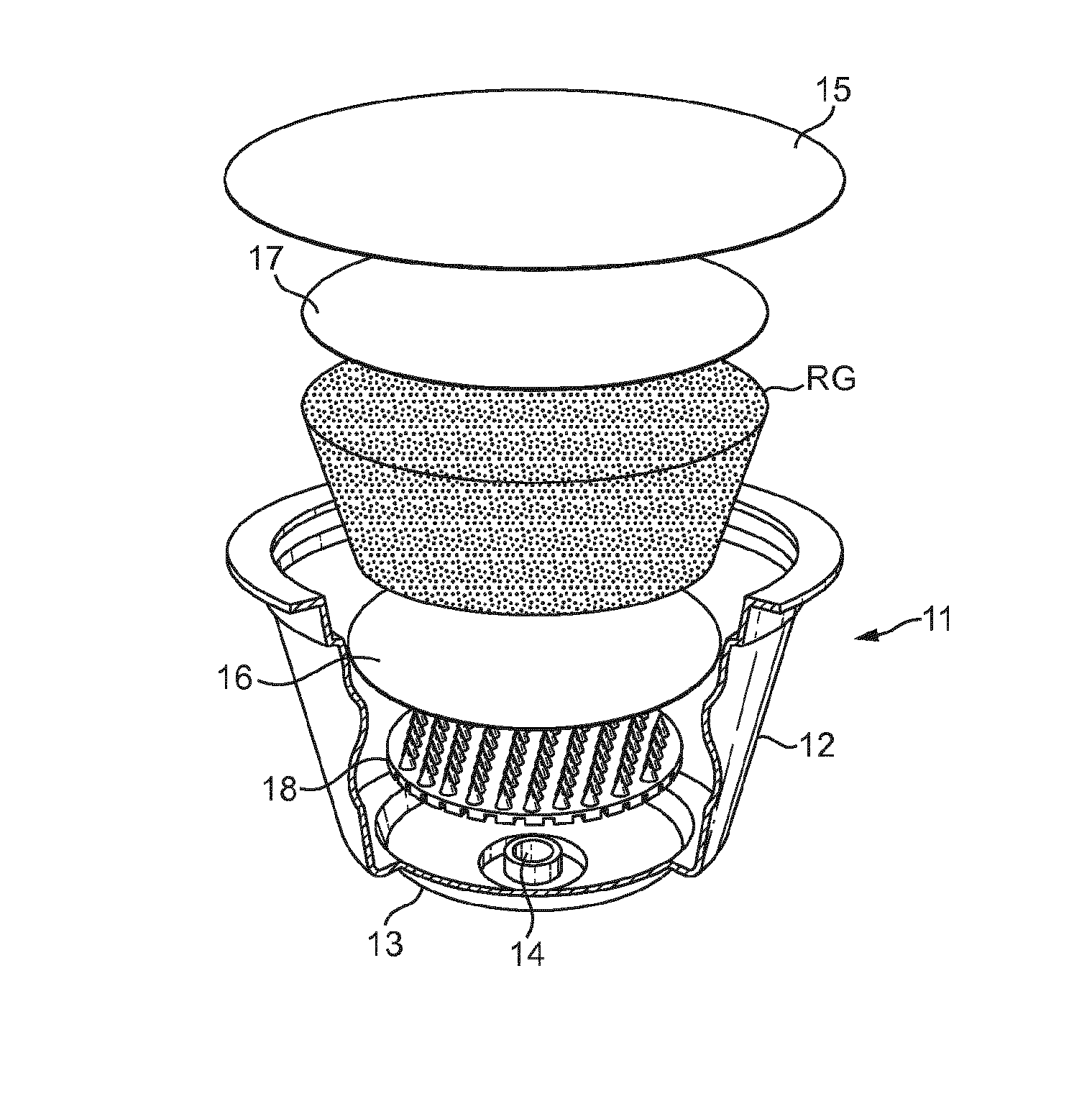

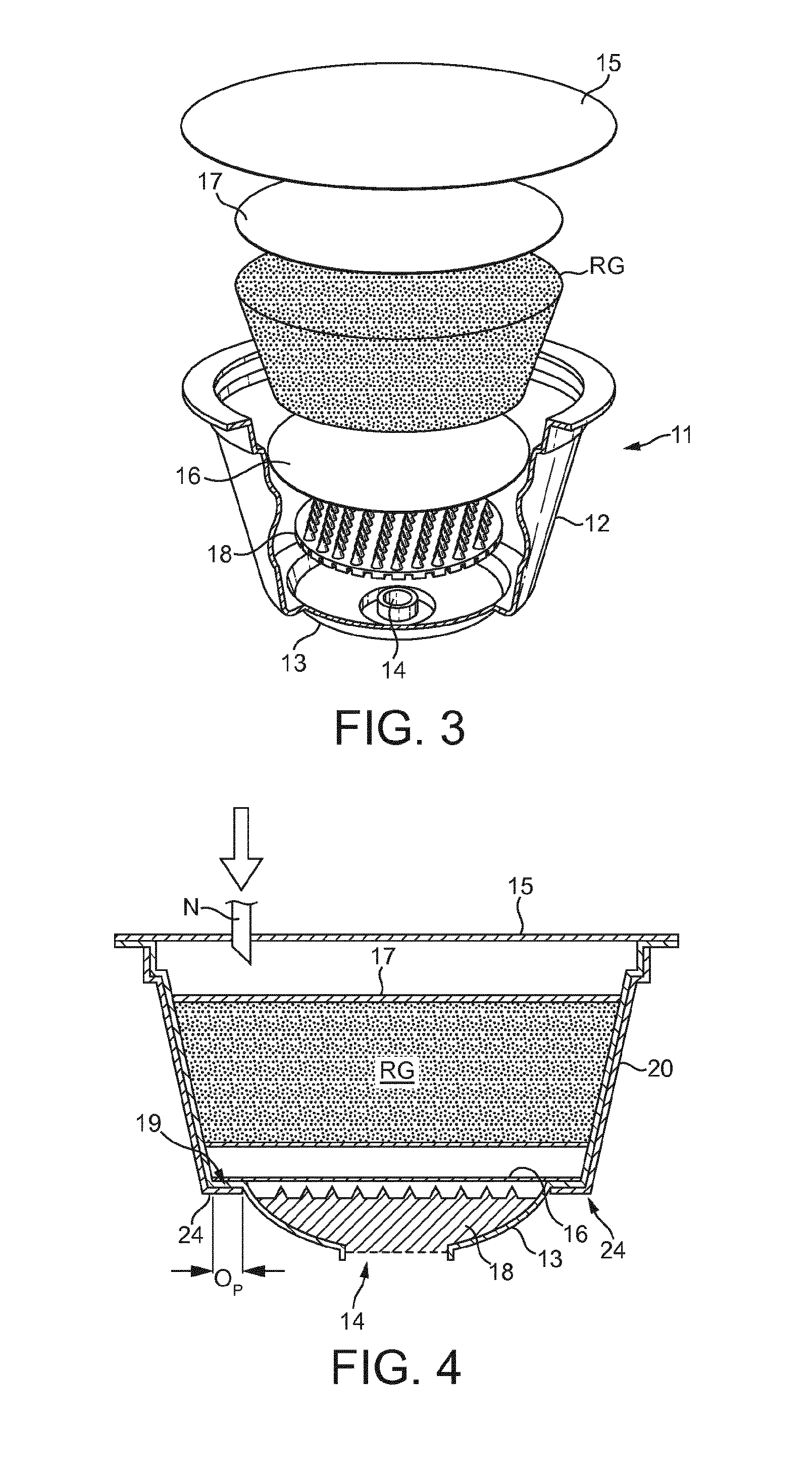

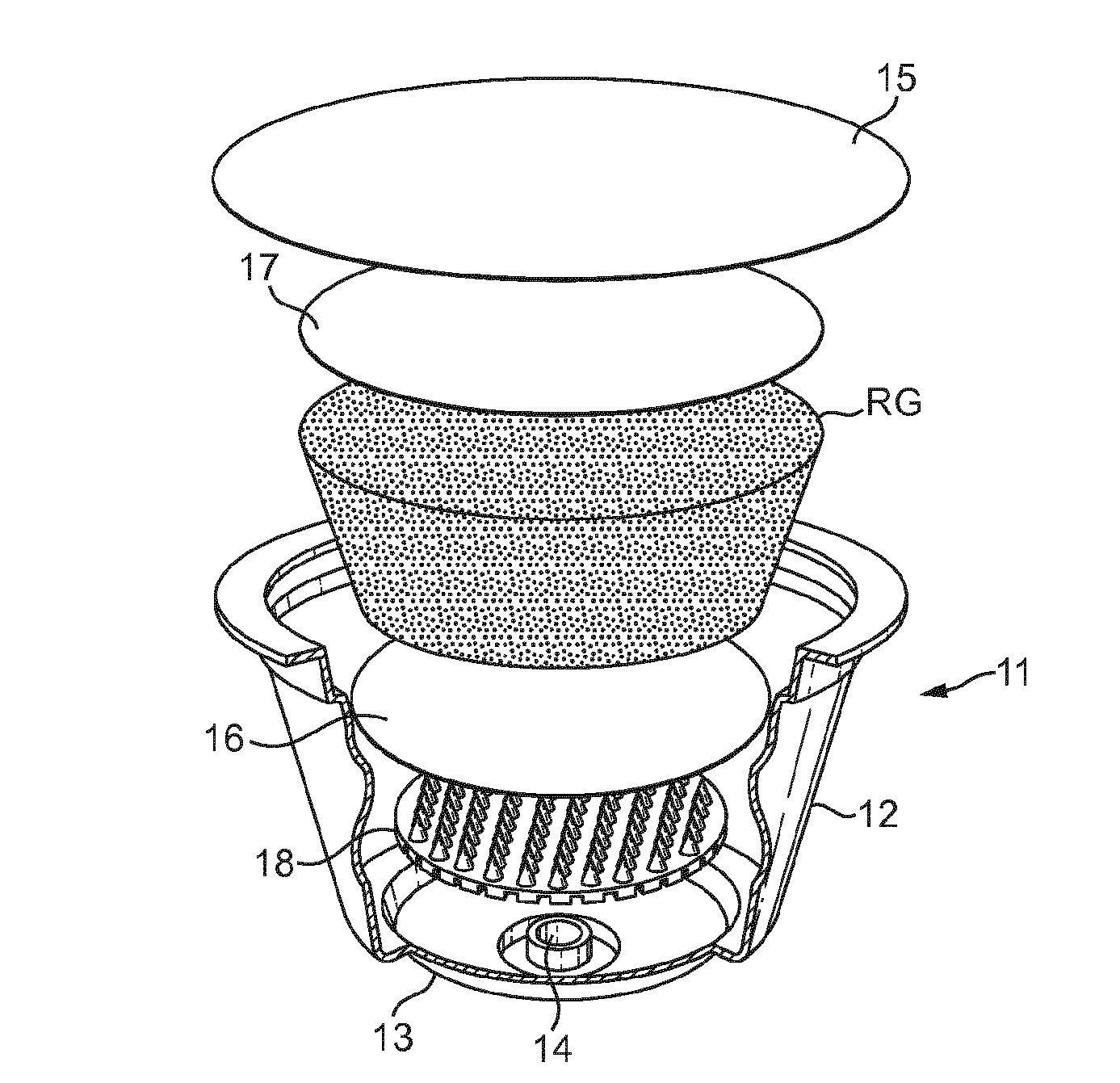

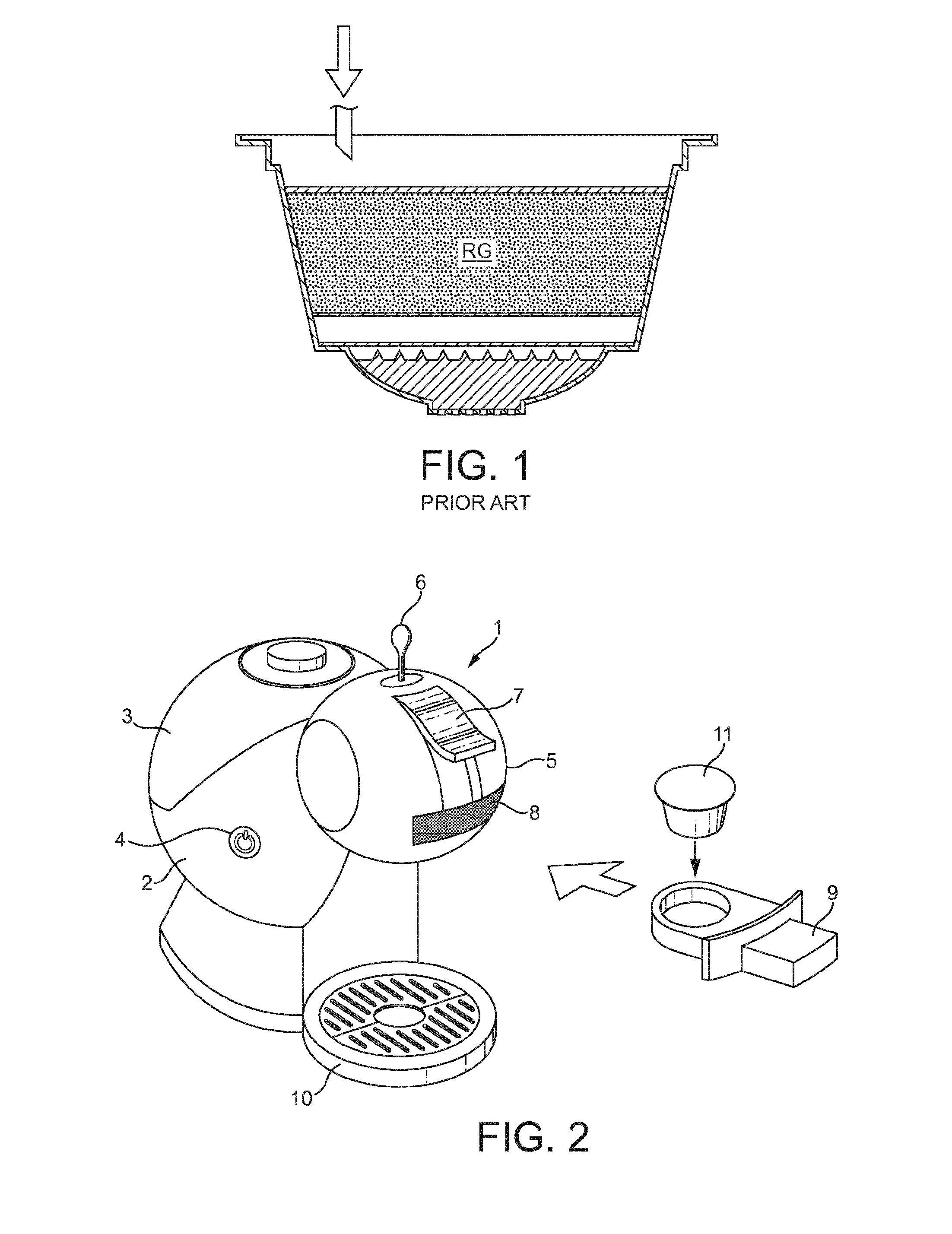

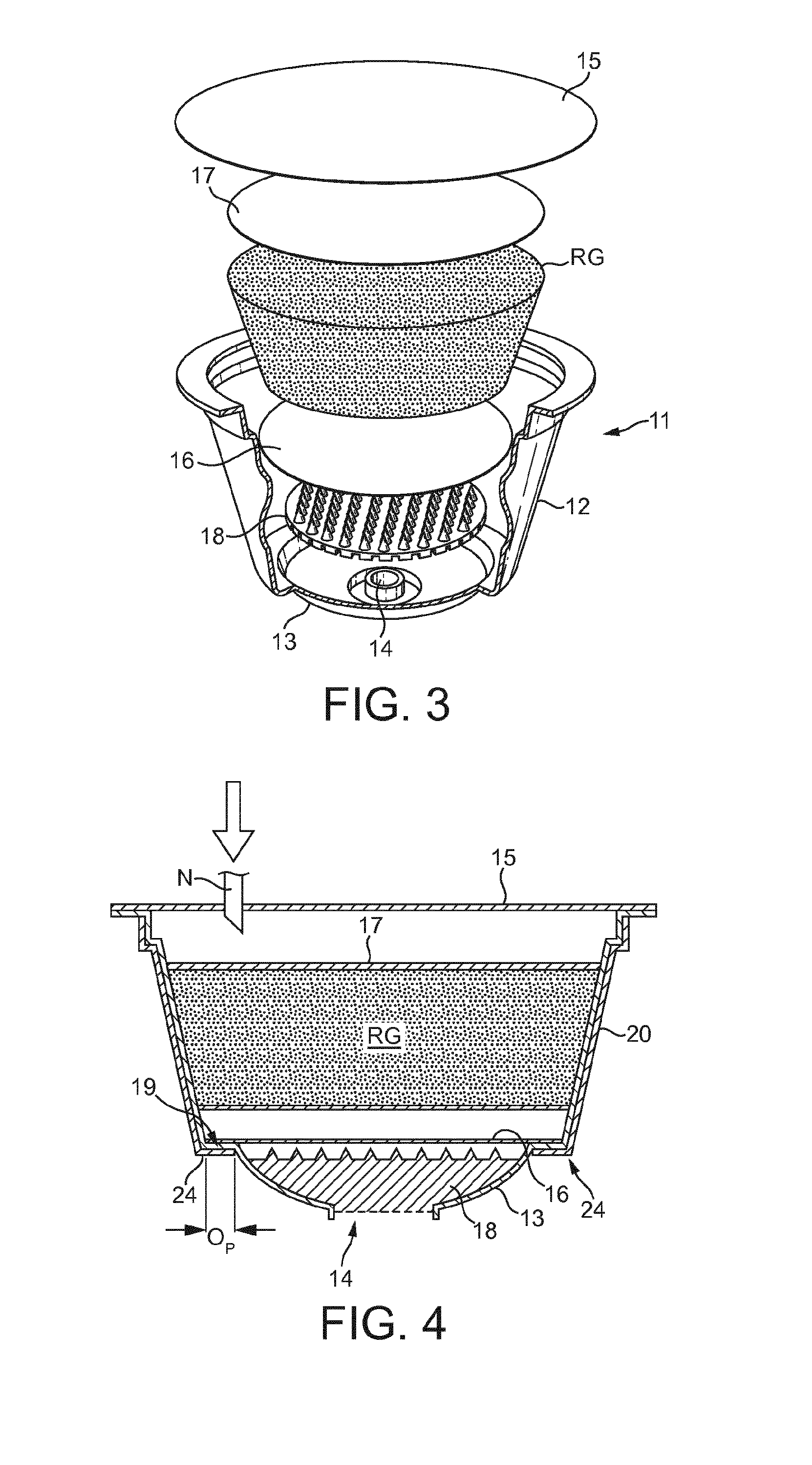

In-mould labelled capsule for beverage preparation

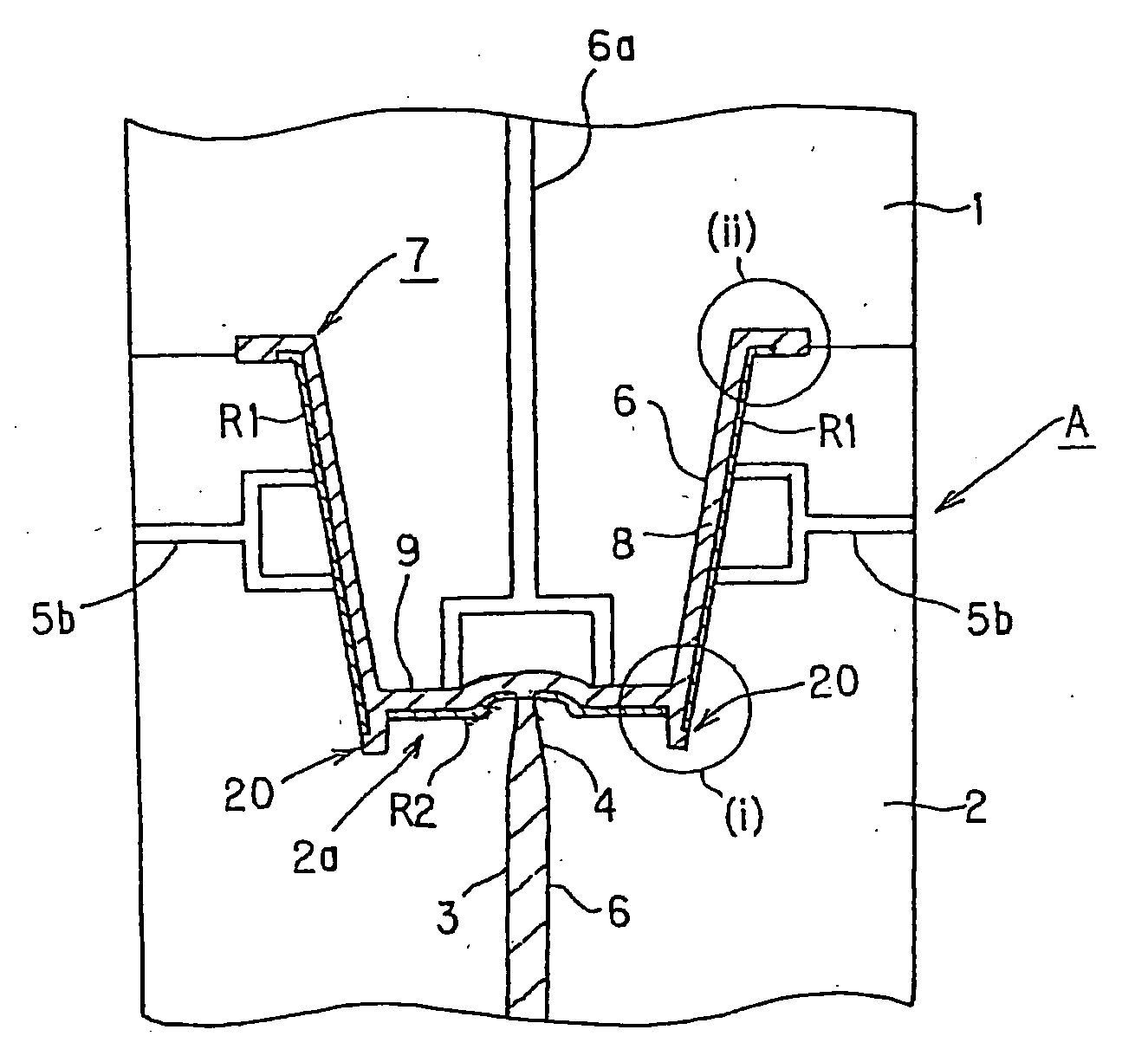

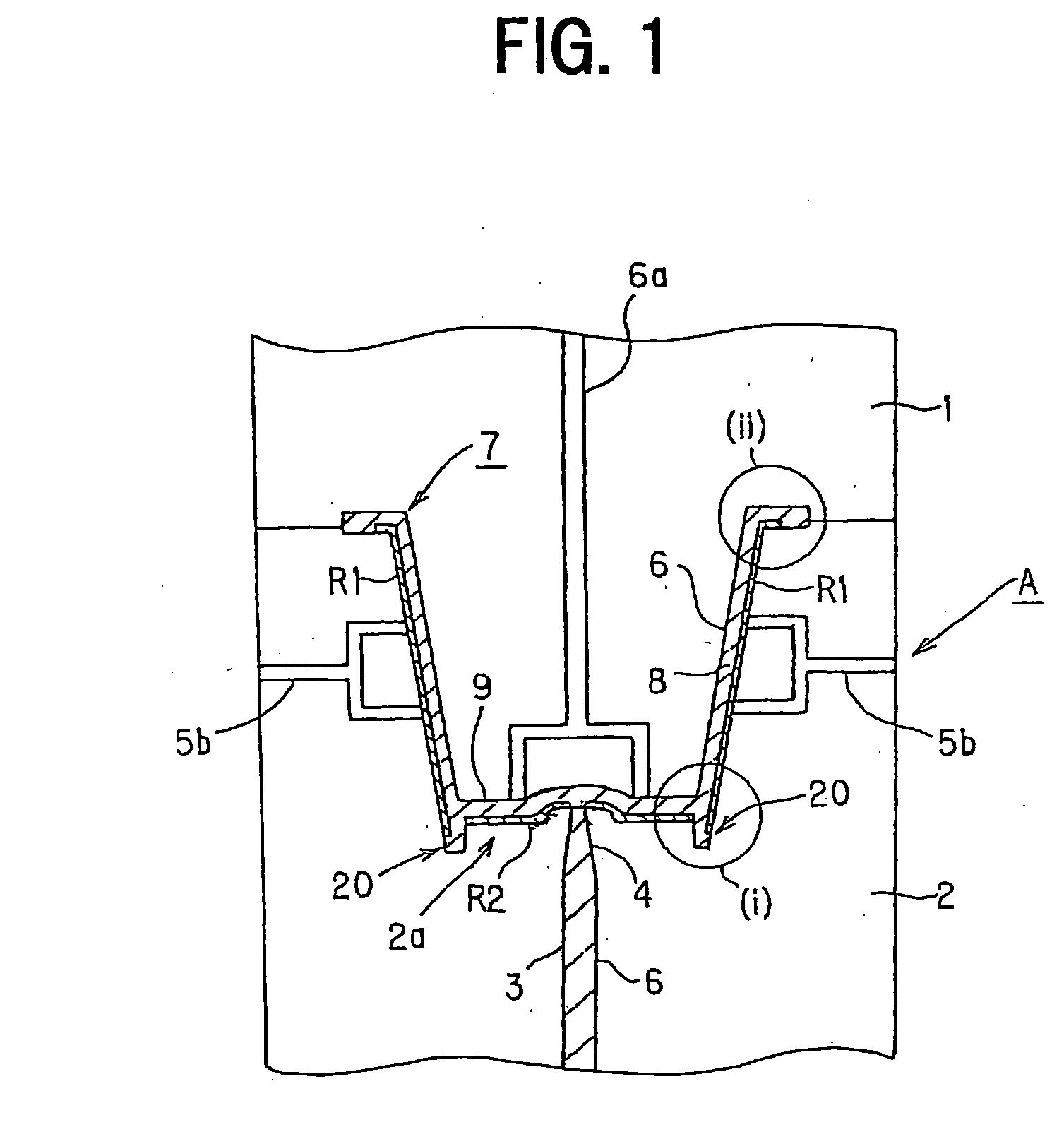

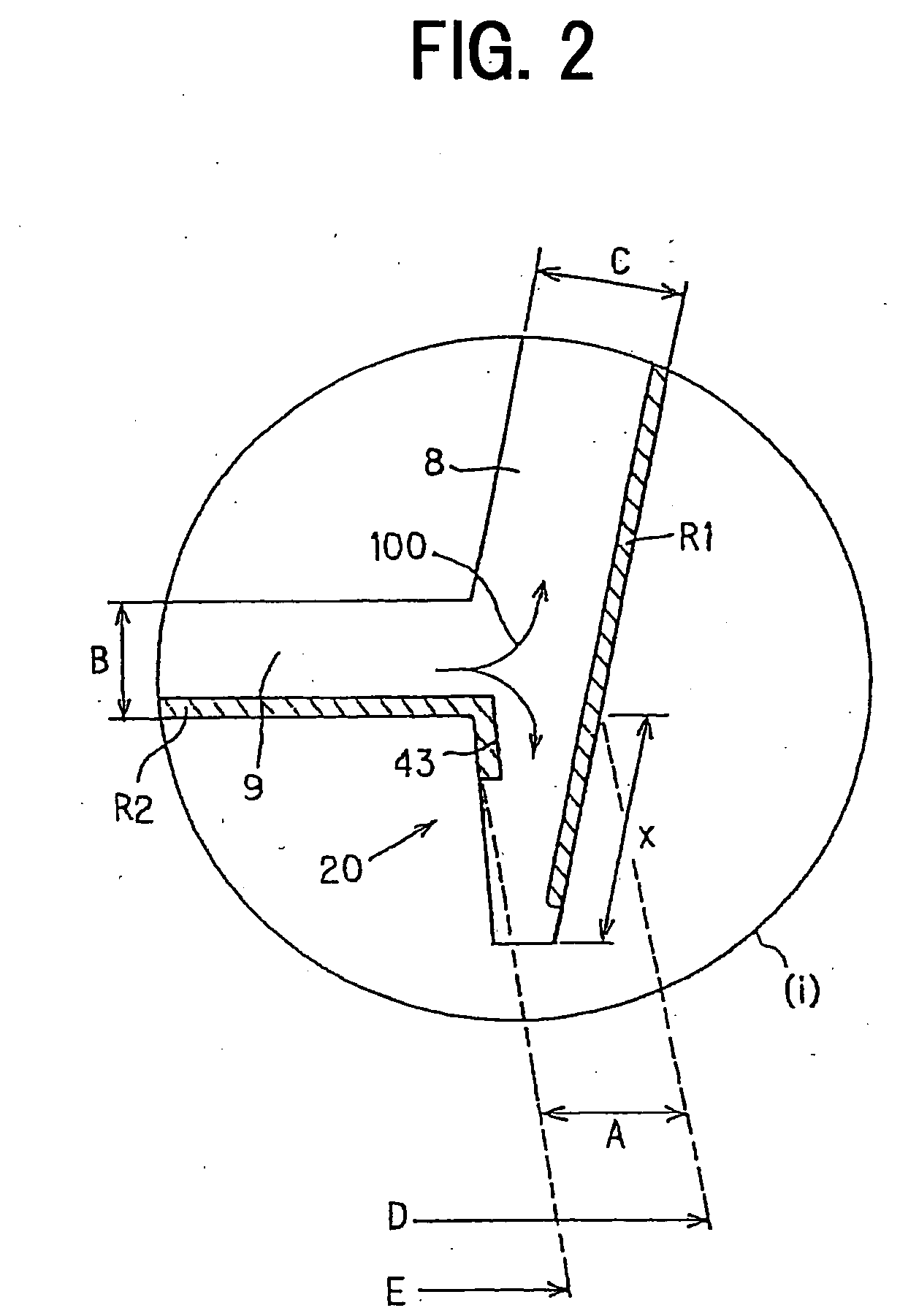

ActiveUS9434525B2The implementation process is simplePromote resultsShock-sensitive articlesPackaging foodstuffsClosed chamberInjection moulding

The present invention concerns a beverage preparation capsule (11) defining a closed chamber for enclosing a mass of soluble and / or extractable food material, for use in a beverage preparation machine, comprising: (i) a capsule body with side walls (12), a bottom wall (13) open with a dispensing opening (14), said capsule body walls comprising an injection-moulded oil-based or biomass-based thermoplastic material, which is not a gas-barrier material, (ii) a gas and moisture impermeable top membrane (15), pierceable by injection means (N) of the machine which are adapted to inject an extraction liquid under pressure inside said chamber, and (iii) a gas and moisture impermeable bottom membrane (16) sealed inside the capsule body near the bottom wall (13), (iv) means (18) adapted to open said chamber by relative engagement with the bottom membrane under the effect of the liquid pressure increase in the chamber during injection of said liquid, characterized in that the inside or outside surface of the capsule body is at least partially covered by a gas-, and optionally moisture-, impermeable label (20) permanently attached by in-mould labelling to said capsule body wall, said label having a tridimensional shape such that the labelled capsule is gas and moisture tight.

Owner:SOC DES PROD NESTLE SA

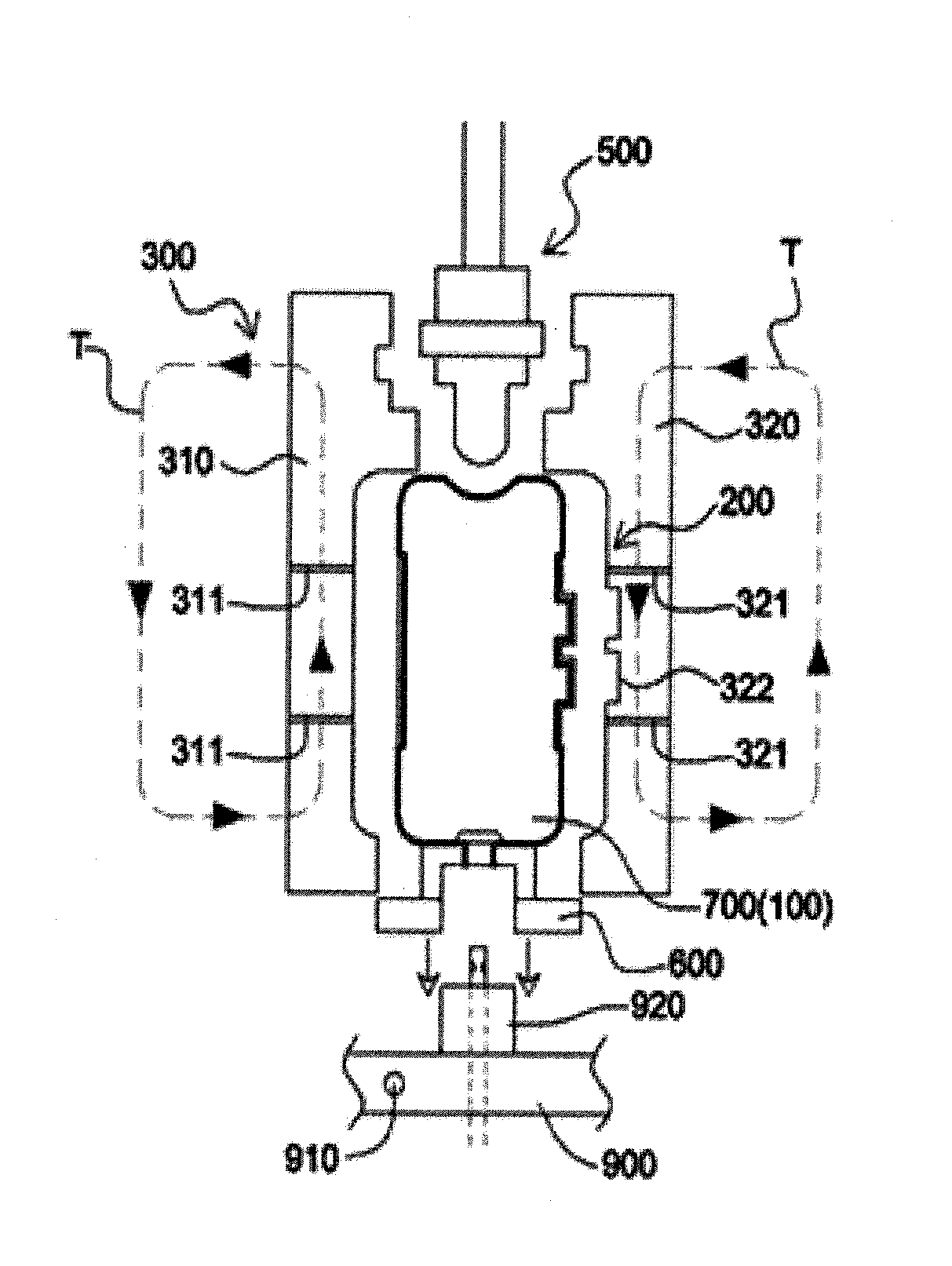

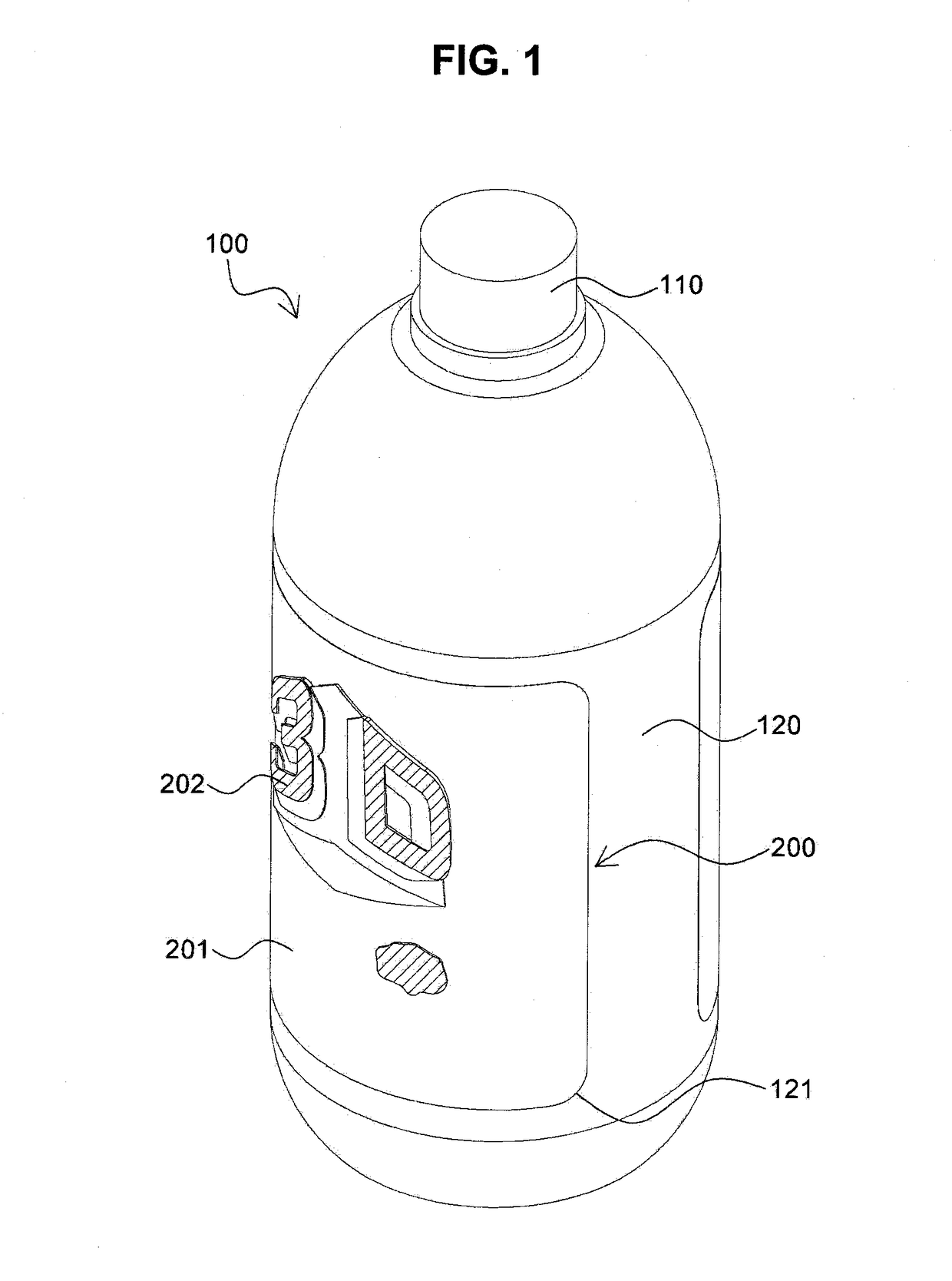

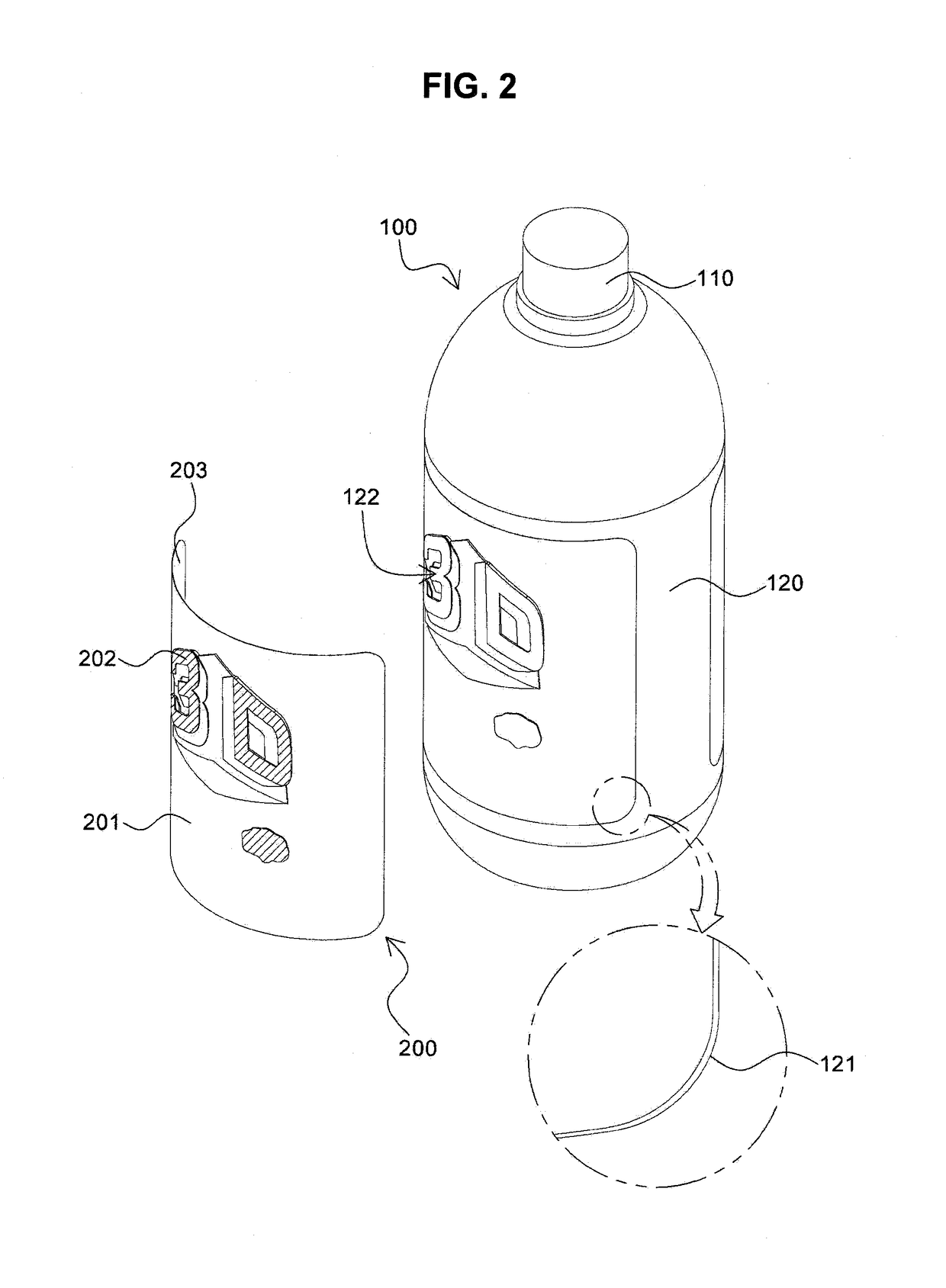

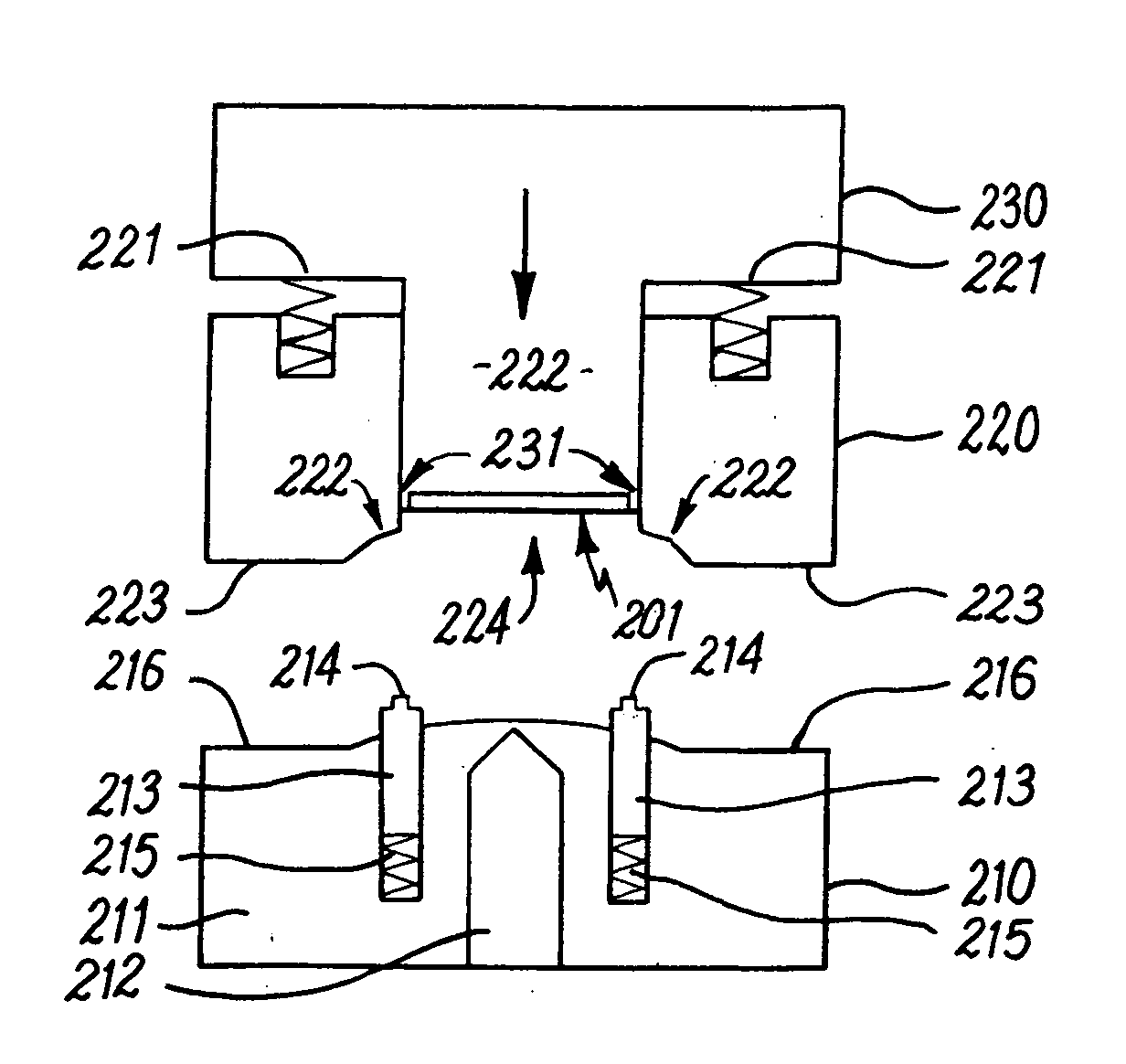

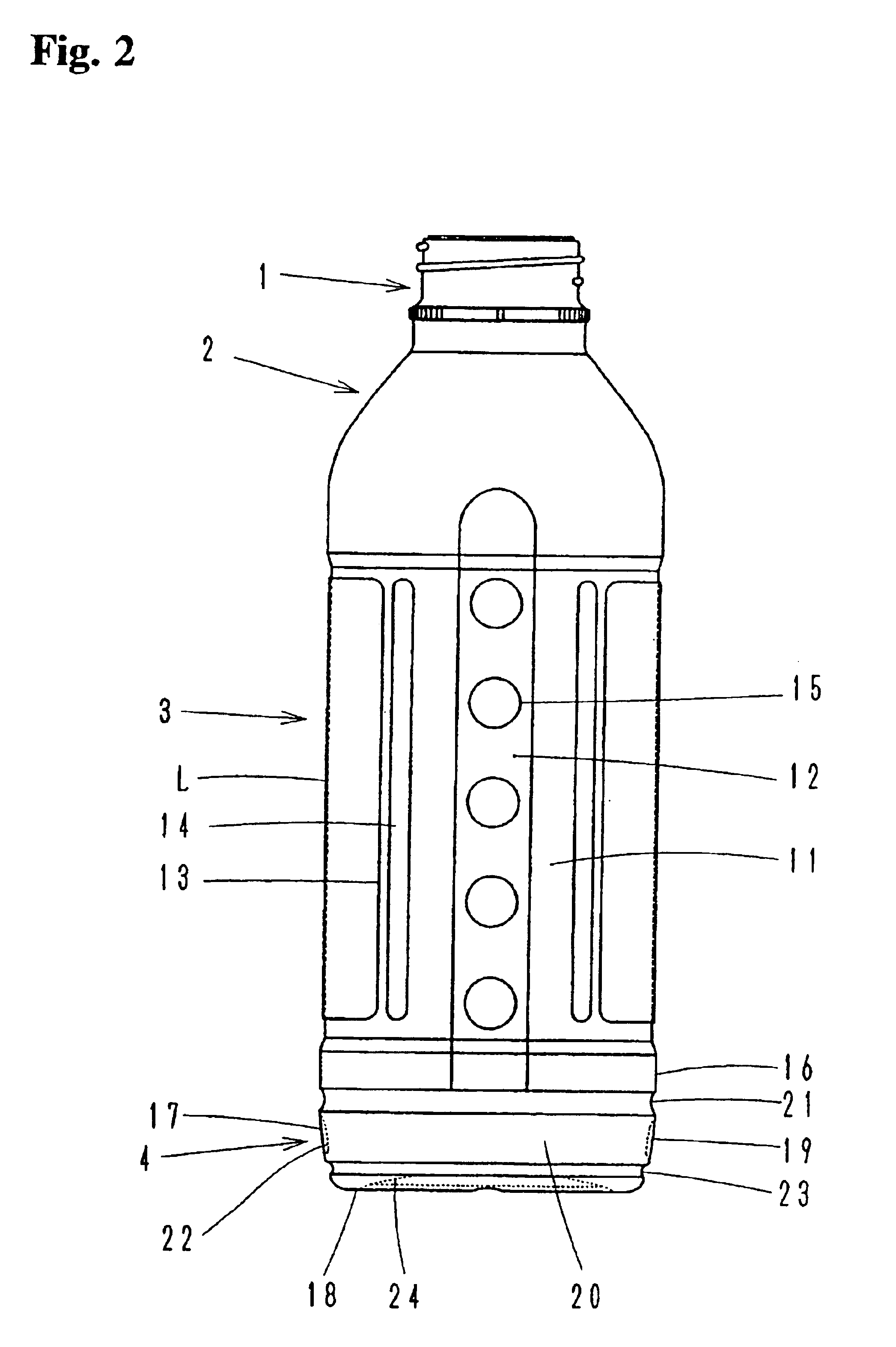

Manufacturing method of pressure container comprising in-mold label and three-dimensional shape

A method of manufacturing a pressure container including an in-mold label and a three-dimensional (3D) portion includes heating molds with a 3D groove formed therein to correspond to a 3D portion to be formed on a surface of the pressure container, separating the molds, attaching a label to an internal surface of the molds to allow at least a portion of the label to cover the 3D groove, positioning a pre-form of the pressure container in a cavity of the molds, closing the molds and injecting air into the pre-form at pressure in a specific range through a first route in a specific pressure range and expanding the pre-form, and three-dimensionally deforming a label attached to a surface of the pre-form to correspond to the 3D groove by air pressure along with the surface of the expanded pre-form while the expanded pre-form and the label are attached.

Owner:BYUN WOO HONG

In-Mould labelling

An In-Mould Labelling process comprising: clamping a label within a mould void of an injection moulding tool; and injecting material into the mould void while the label is clamped. An In-Mould Labelling process comprising: placing a label between a first mould void and a second, separate mould void; and injecting material into the first and second mould voids.

Owner:NOKIA CORP

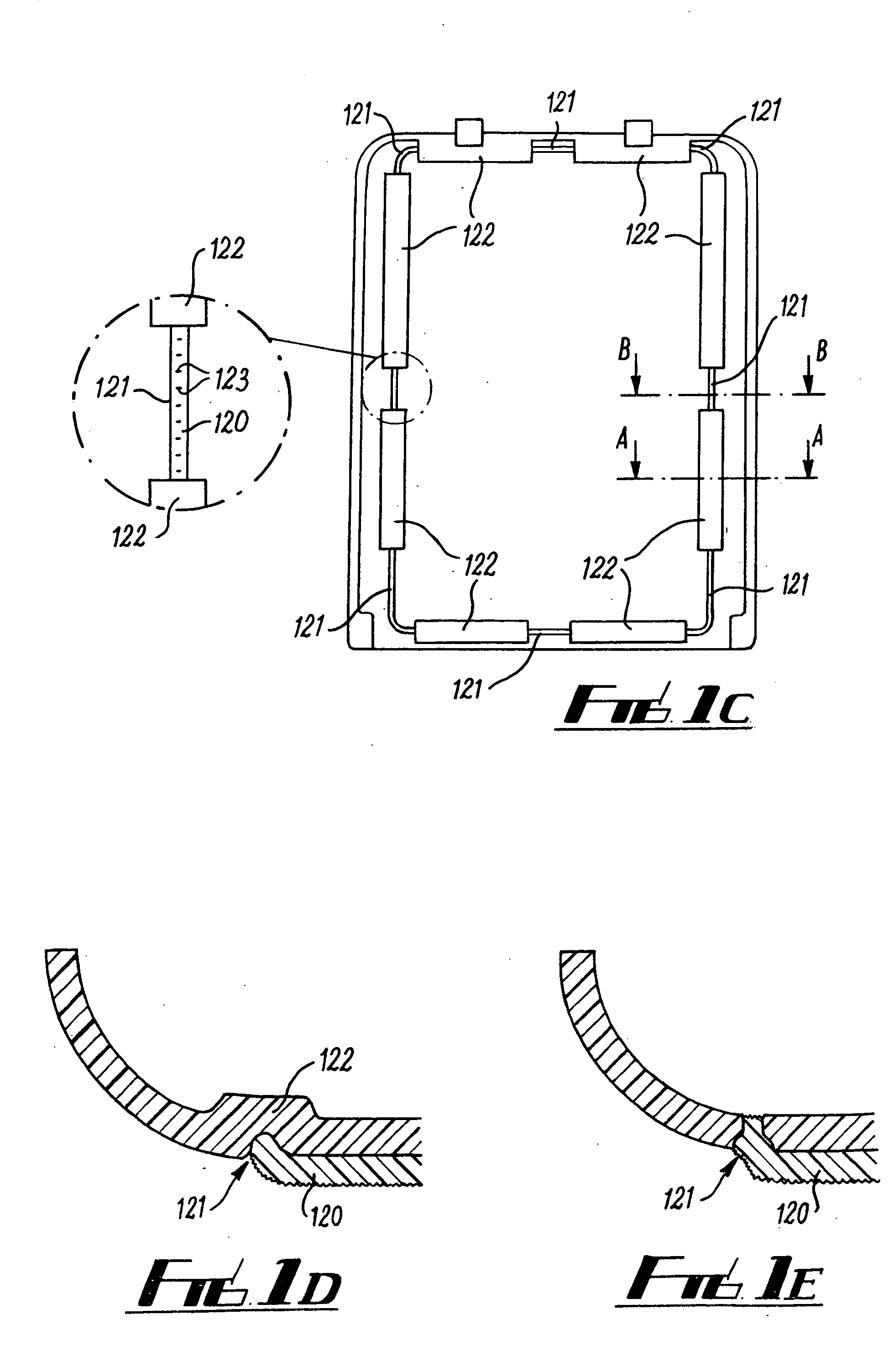

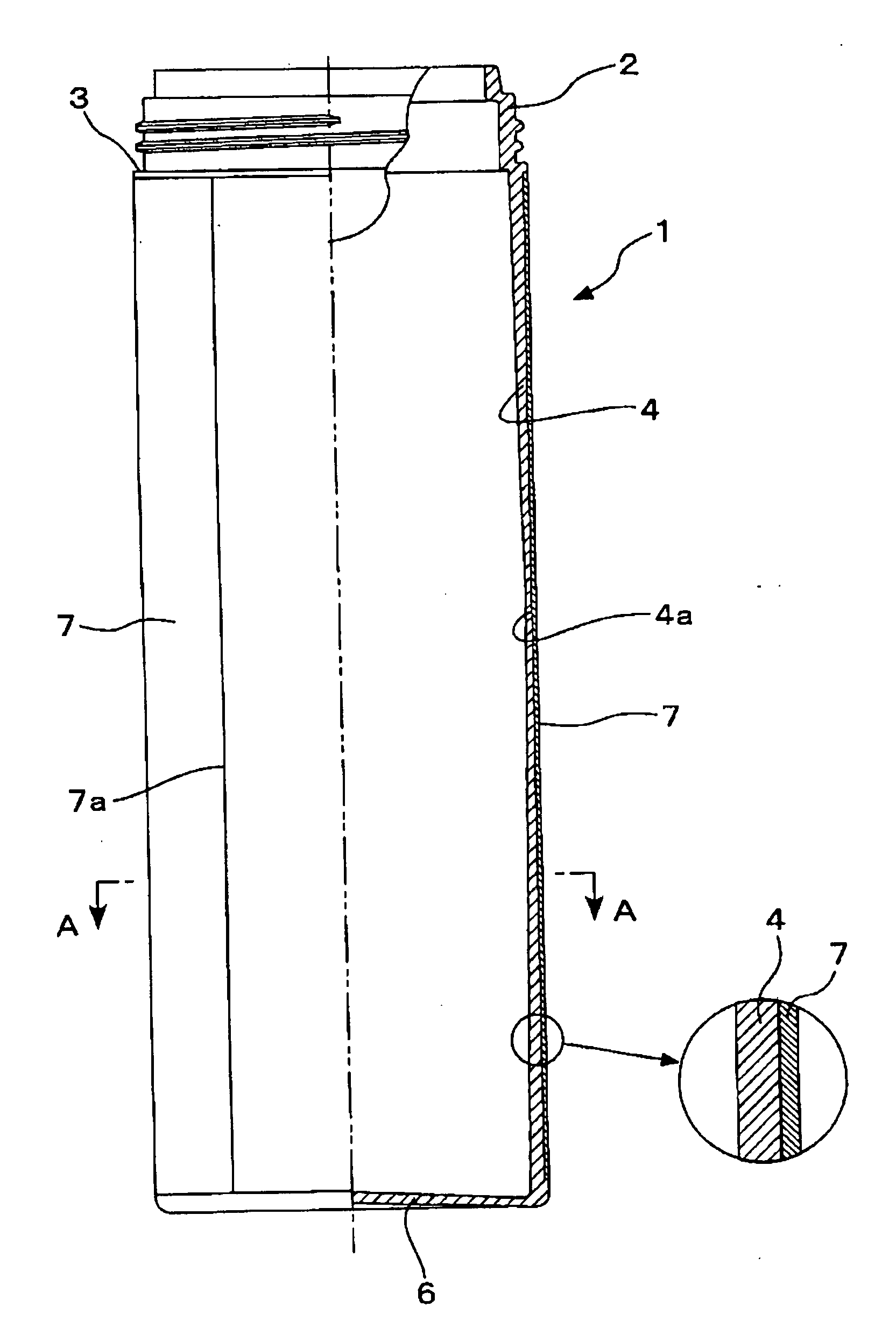

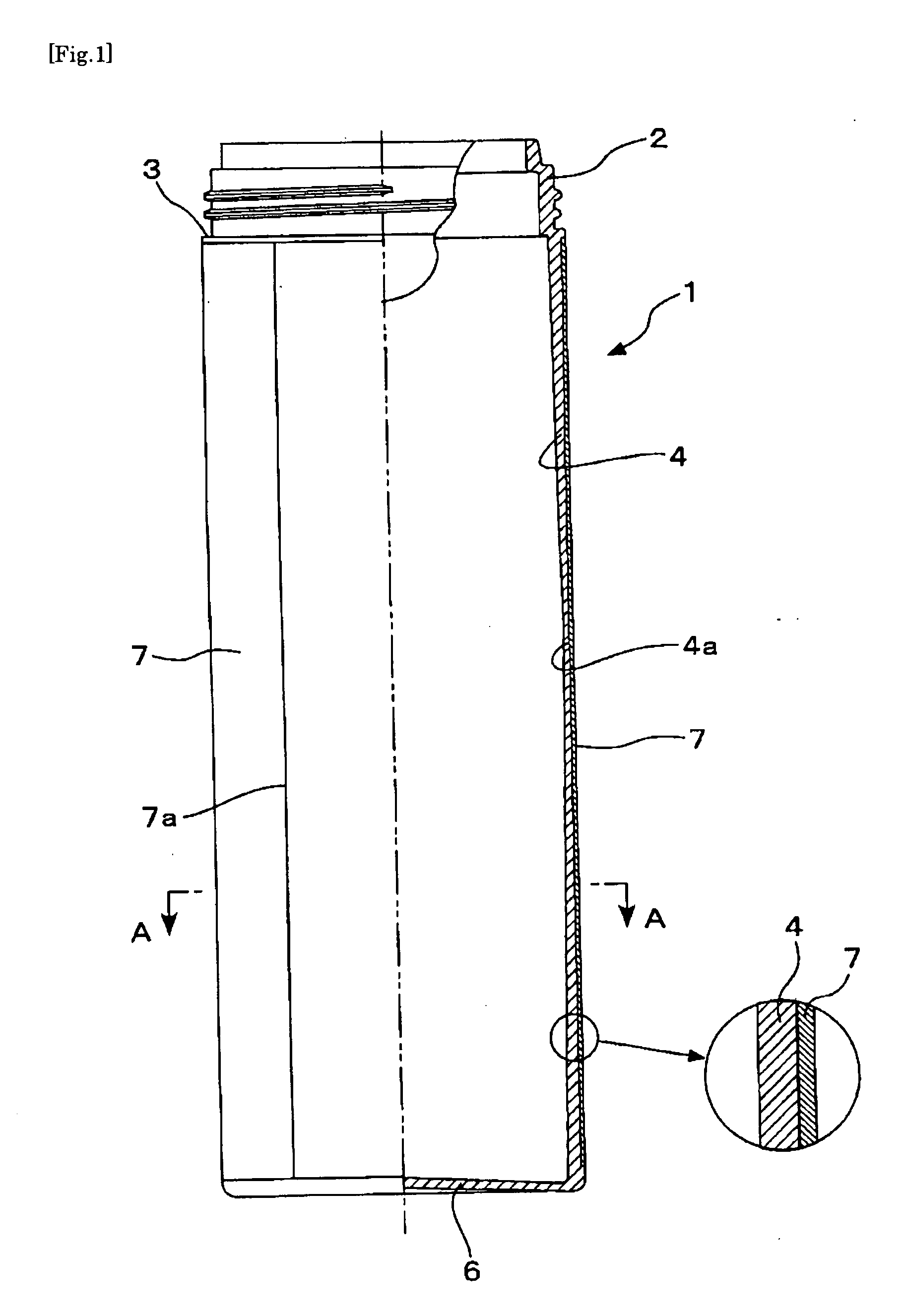

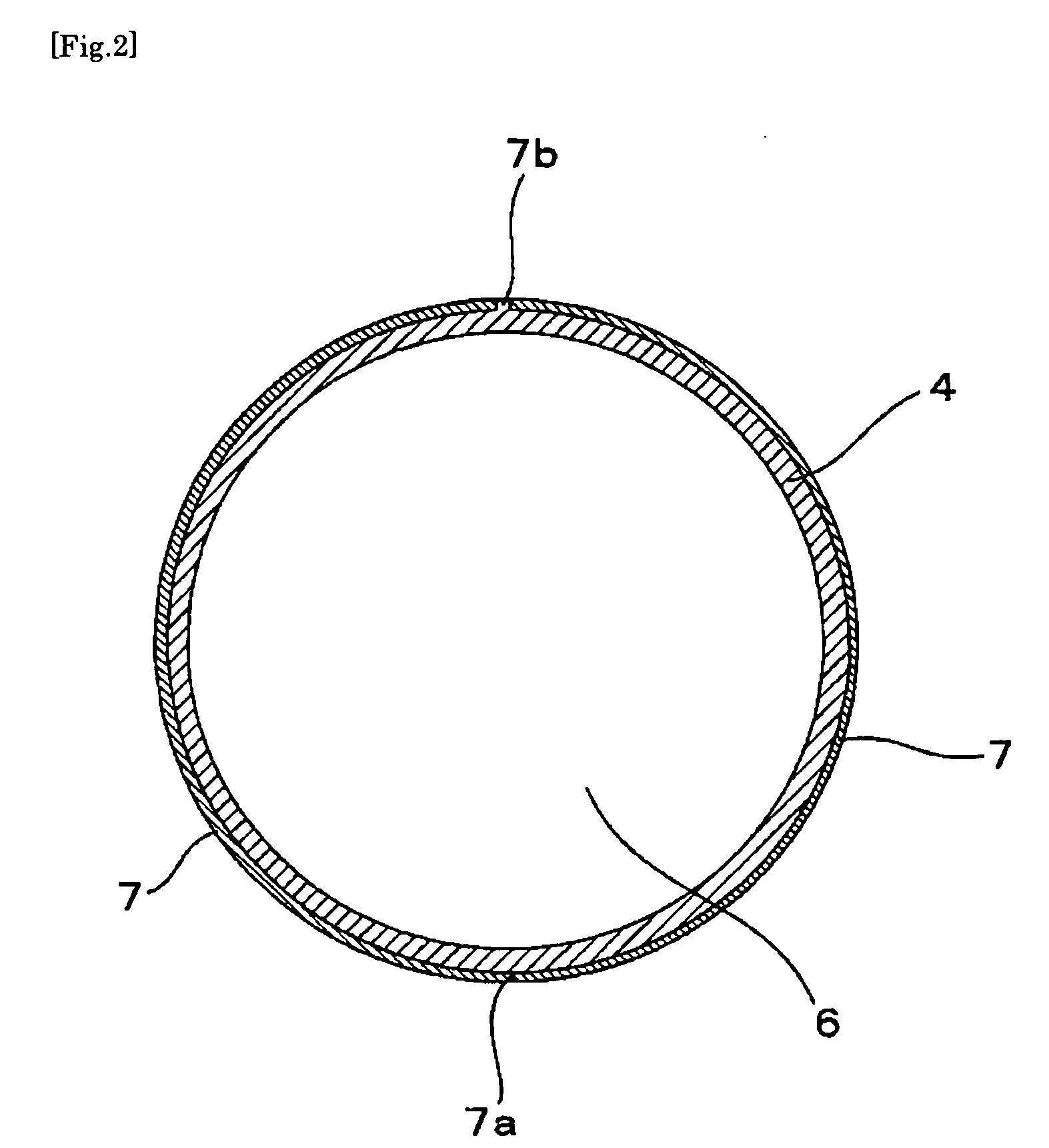

Synthetic resin container bearing label

It is an object of the present invention to prevent the edge of the in-molded label from the crack due to the impact of dropping the container, especially to prevent the occurrence of the crack on the thin synthetic resin container and to provide the synthetic resin container which a reinforce rib is disposed on the wall surface of the container body corresponding to the edge of the in-molded label to surround the label edge or to locate the label edge in said rib.

Owner:YOSHINO KOGYOSHO CO LTD

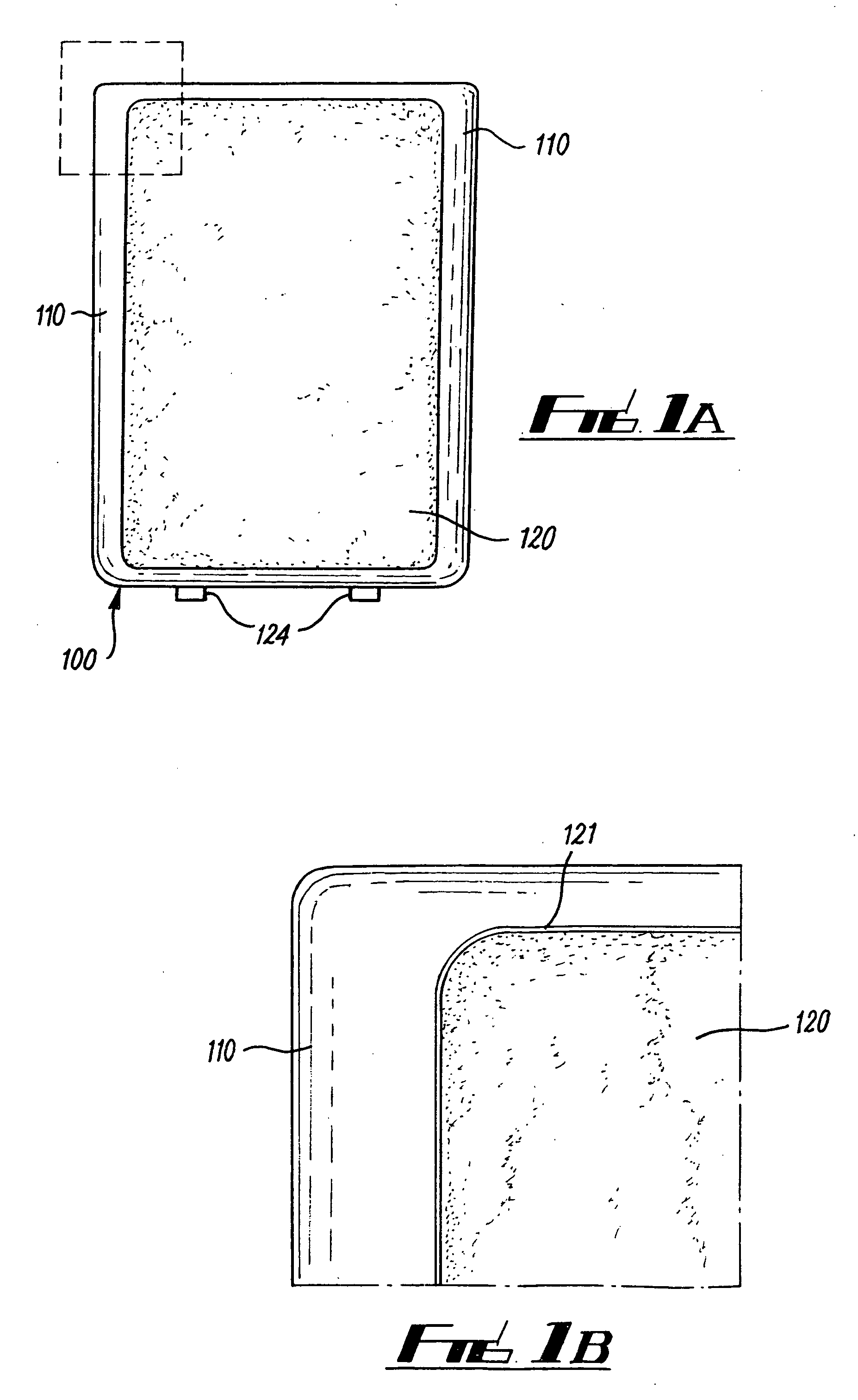

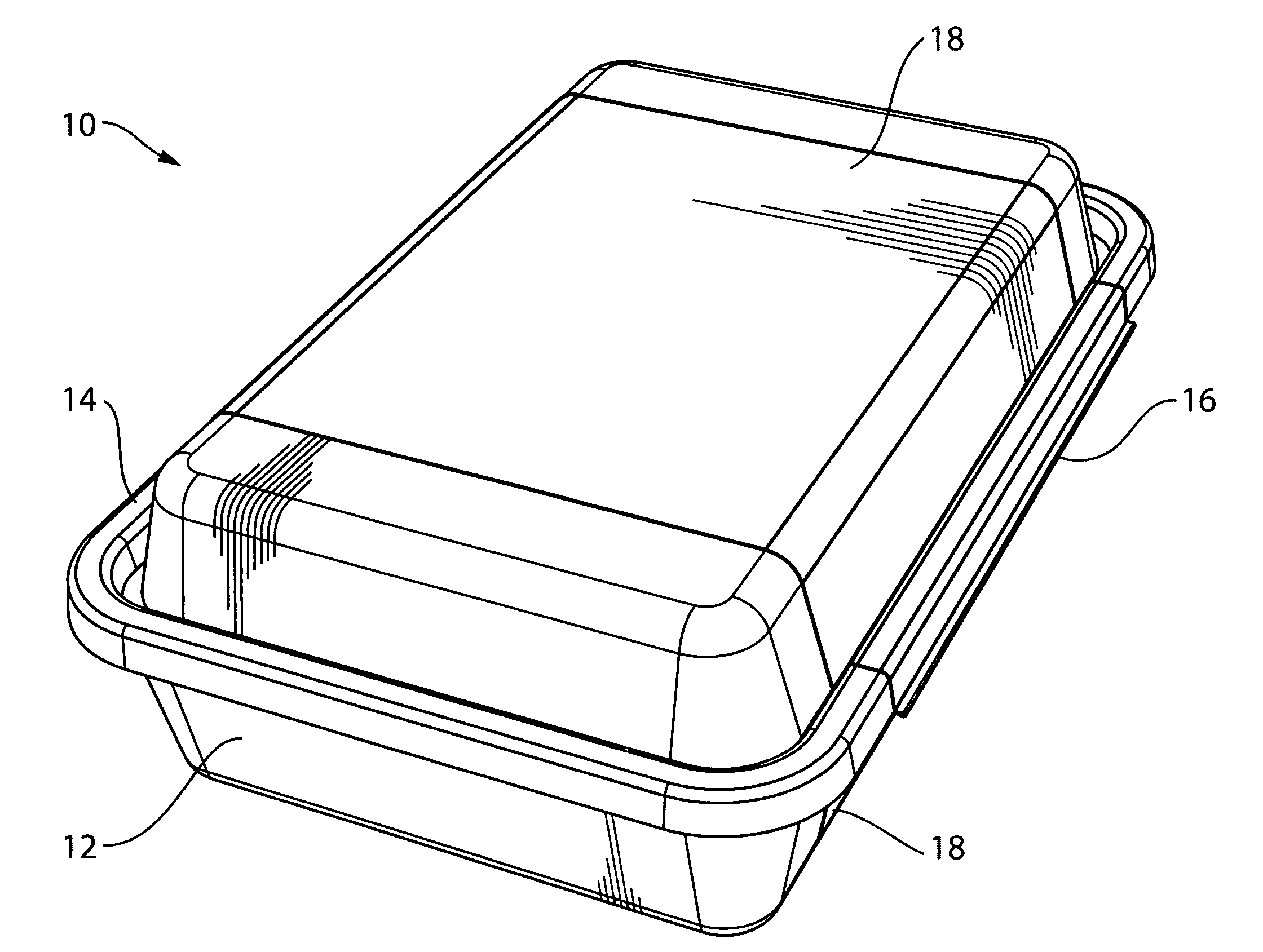

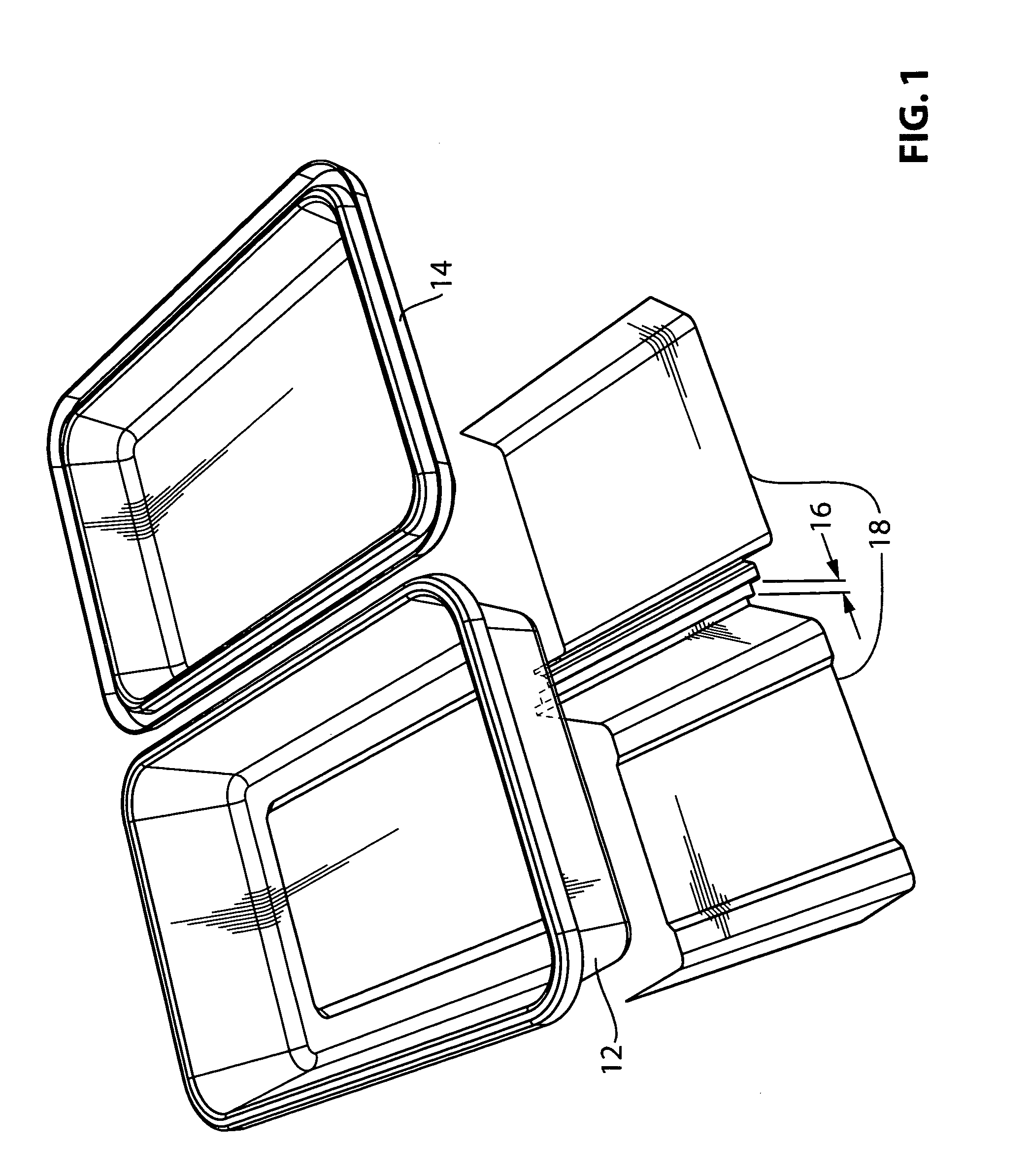

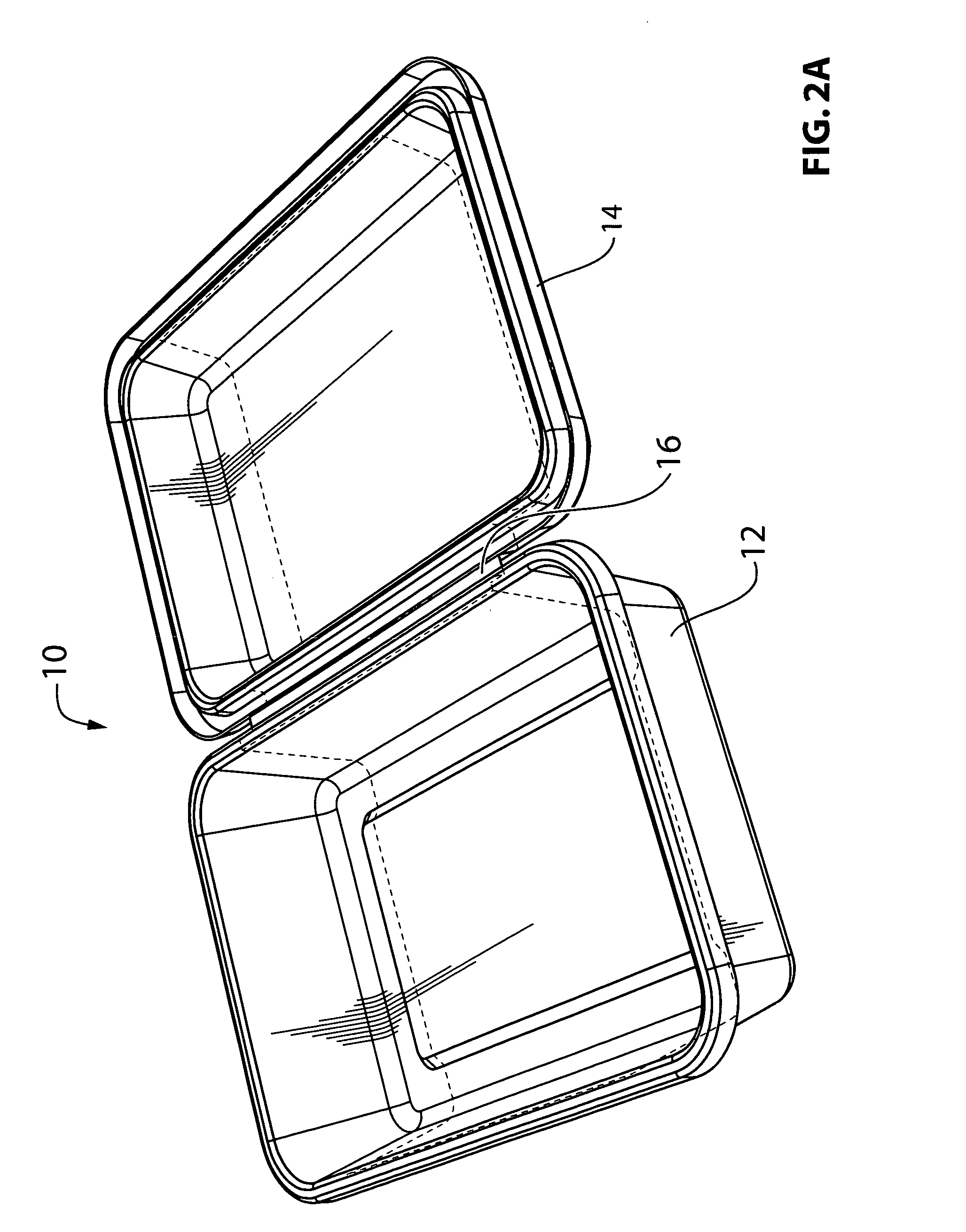

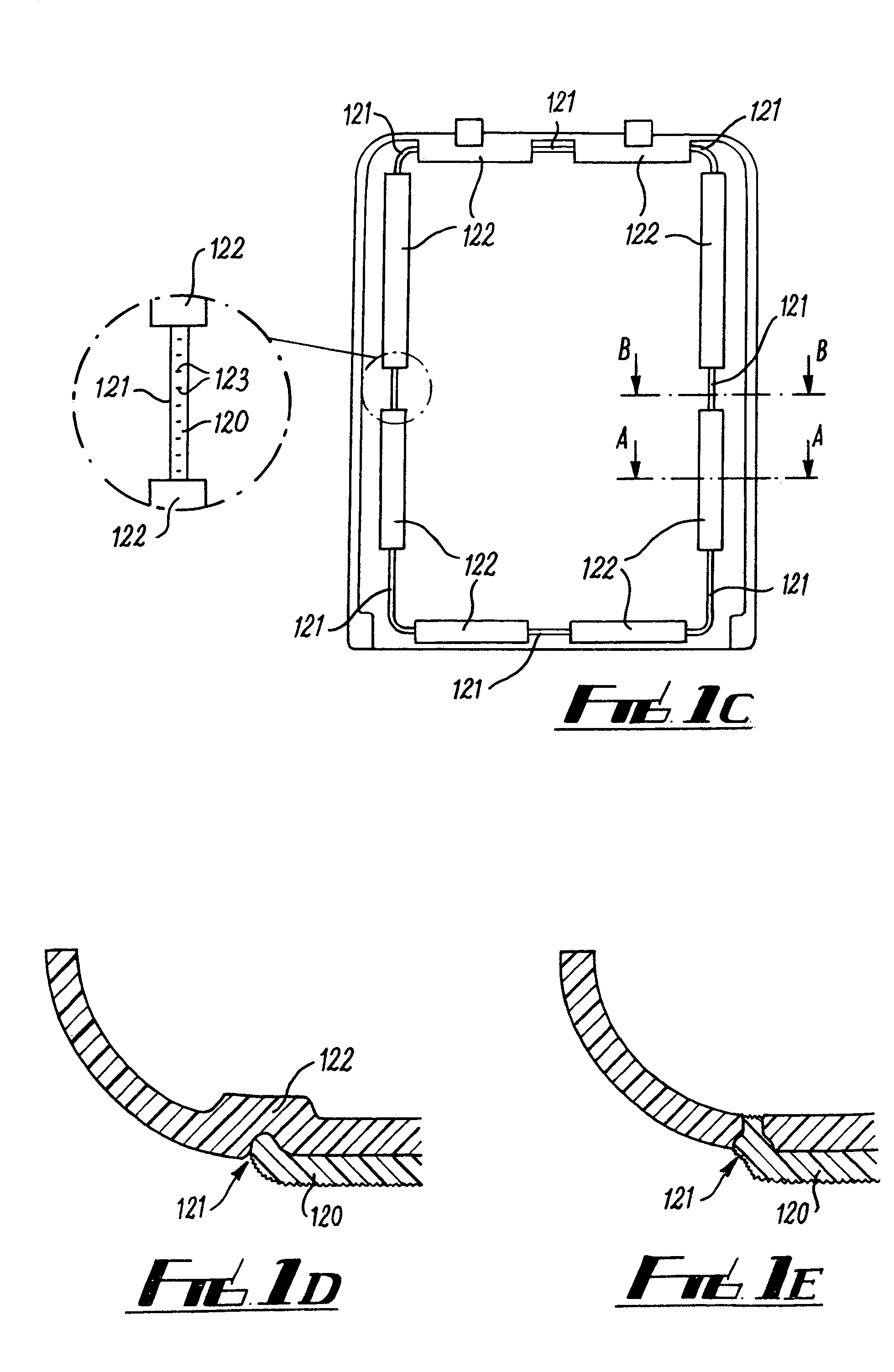

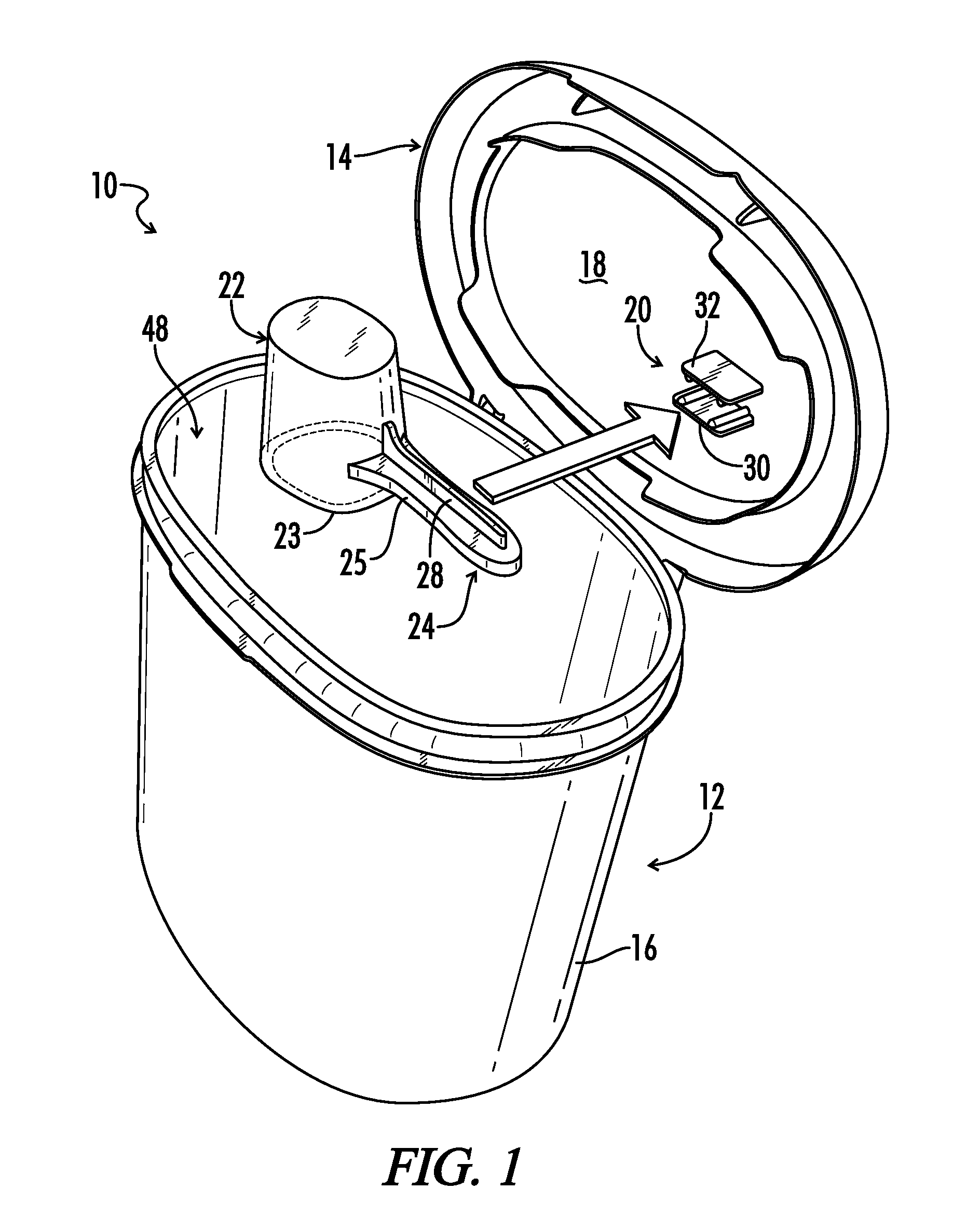

Injection moulded clam shell container utilizing label as hinge element

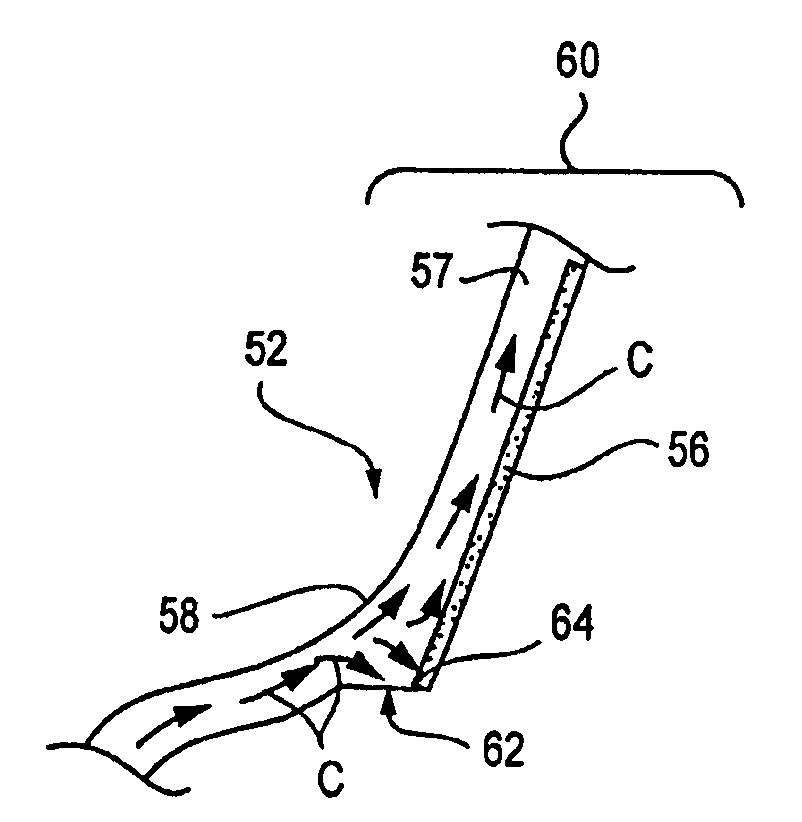

A clam shell type container having an injection moulded base, an injection moulded lid, and a web interconnecting the base and lid, wherein the web is formed from an in-mould label. The in-mould label is preferably deposited into a mould that simultaneously forms the base and lid, with the label being deposited into the mould prior to the injection of molten material. Upon formation, the label extends contiguously into the base and lid and becomes integrally adhered with the walls of the base and lid.

Owner:SEGAL ALEXANDER

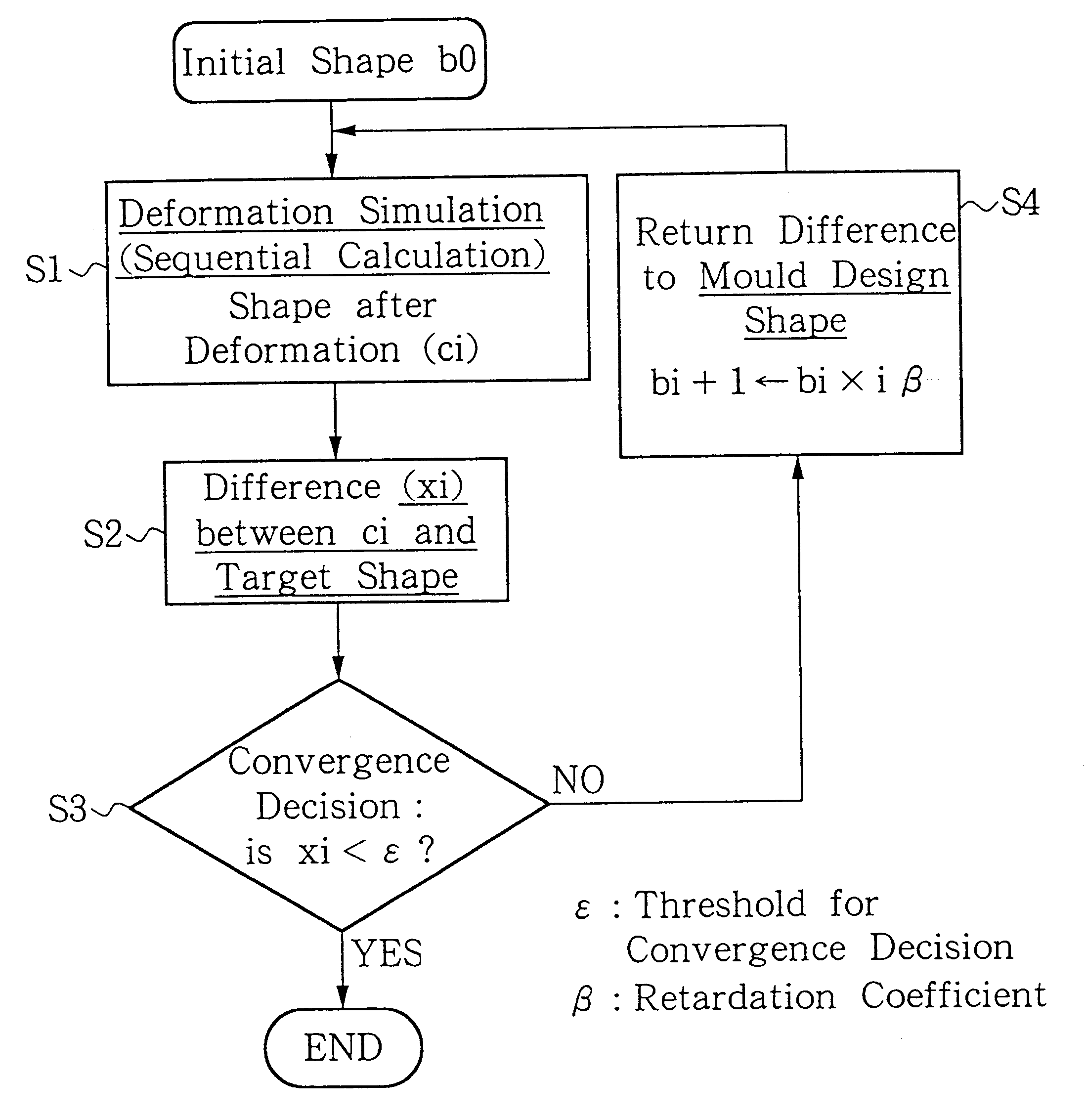

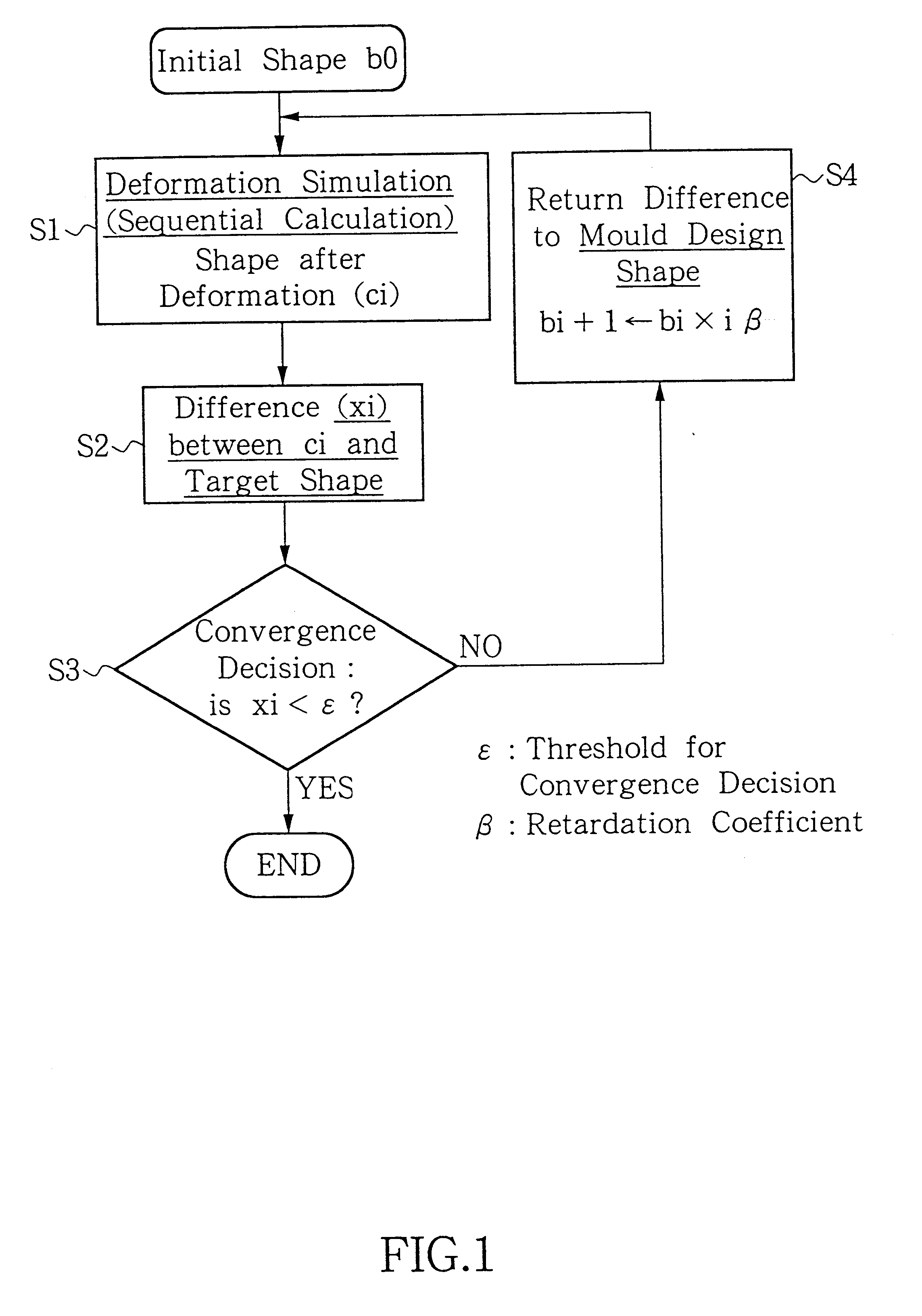

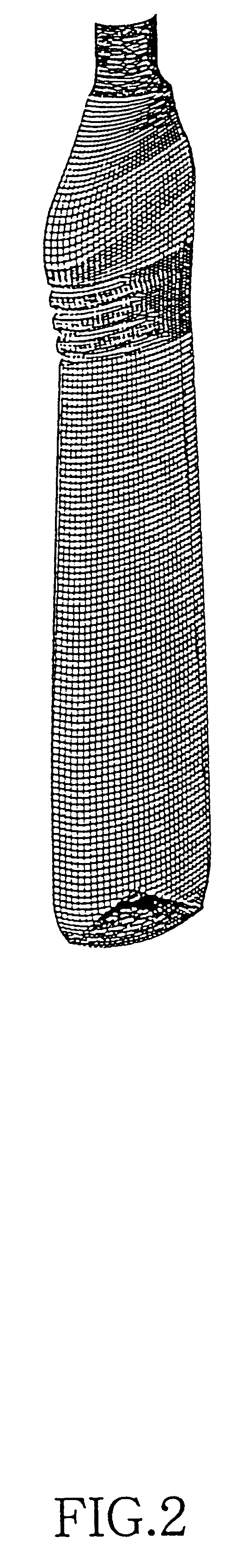

Method for designing a metal mold

InactiveUS6304794B1Reduce in quantityReduce CooldownMoulding machinesAnalogue processes for specific applicationsFinite element methodHydrostatic pressure

When a molten plastic is molded using a metal mold, sufficient cooling time has to elapse before the metal mold is opened, but this cooling time restricts the production per unit time. If a metal mold is opened without sufficient cooling, the plastic undergoes significant deformation by thermal shrink. If this deformation can be estimated and the metal mold designed so as to make allowance for the anticipated deformation, it will be possible to produce a molding with a shape that is equal to the design dimensions, despite shortening the cooling time. The finite element method is used to obtain the deformation. Mold design can also be performed taking account of the deformation due to the hydrostatic pressure that is produced when the molding is filled with its liquid contents. In addition, as for a portion of an in-mold labelled container which include lamination construction, the deformation due to thermal shrink is not estimated as a container which an in-mold label is not being applied. On this case, we have a method which is simulating deformation after adding parameters relating to the material of this label, said parameters including at least its thermal conductivity and coefficient of linear expansion. The thermal conductivity deformation simulation is by the finite element method. Production per unit time can be increased and metal mold design can be carried out independently of experience.

Owner:KAO CORP

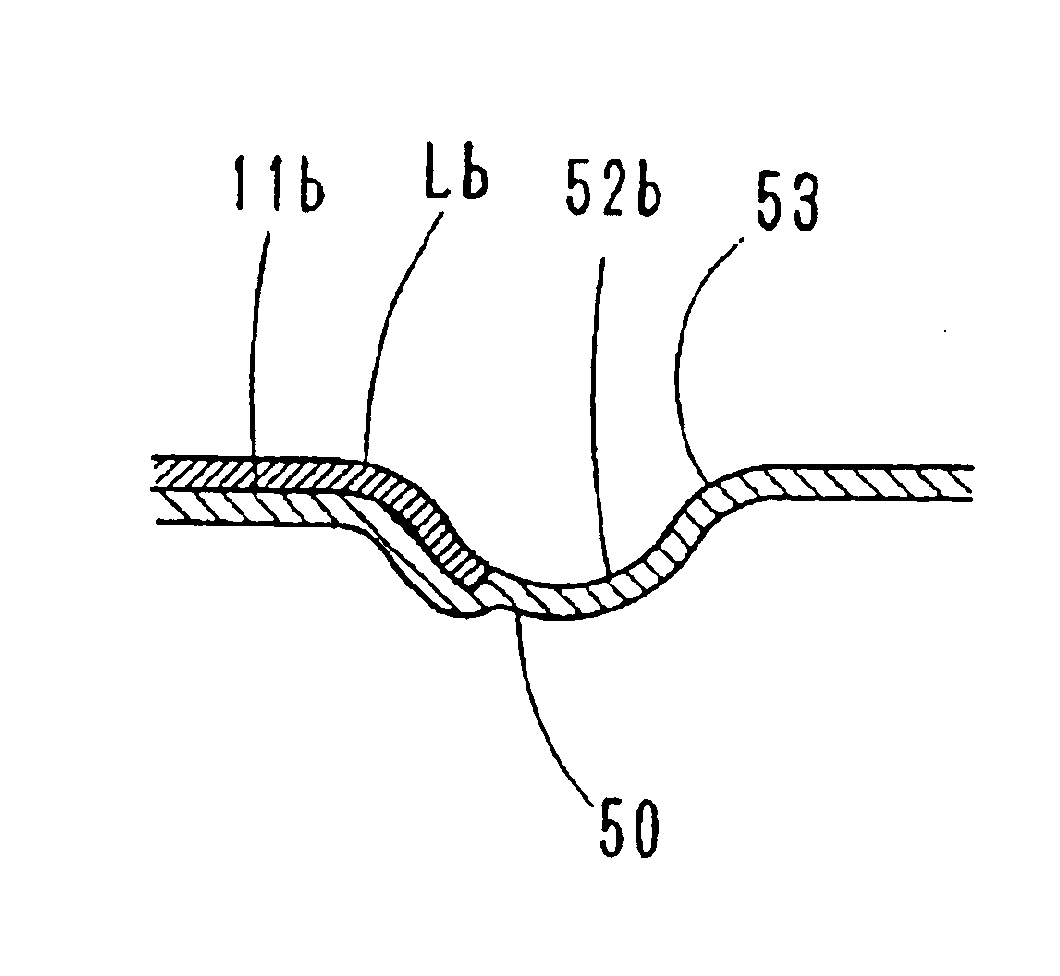

In-mold label system plastic container

The main object is to provide an inmold labeled type plastic container which can be fabricated, even if there are some dimensional errors in the inmold label, with no damage to aesthetic design or no drop in yield is to be provided, and further an inmold labeled type plastic container which allows the consumer to drink or eat the content safely even if he or she brings his or her mouth into direct touch with the opening is to be provided. A bottom rim is disposed in the lower part of the inmold labeled type plastic container, with its dimension being not less than 0.3 mm but not more than 20 mm, and the inmold labeled type plastic container to be provided is labeled on its bottom rim in a similar way to the side part of the container.

Owner:DAI NIPPON PRINTING CO LTD

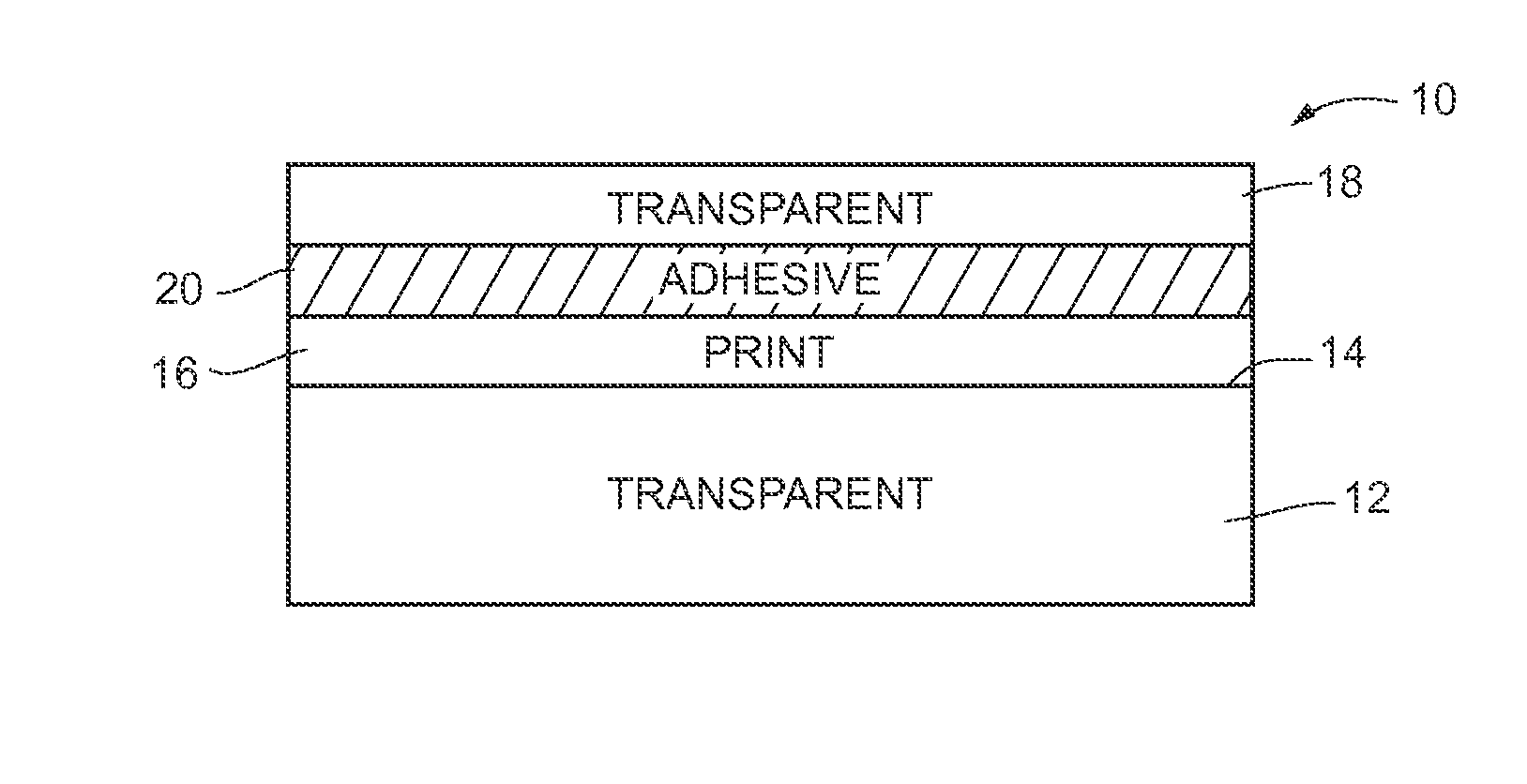

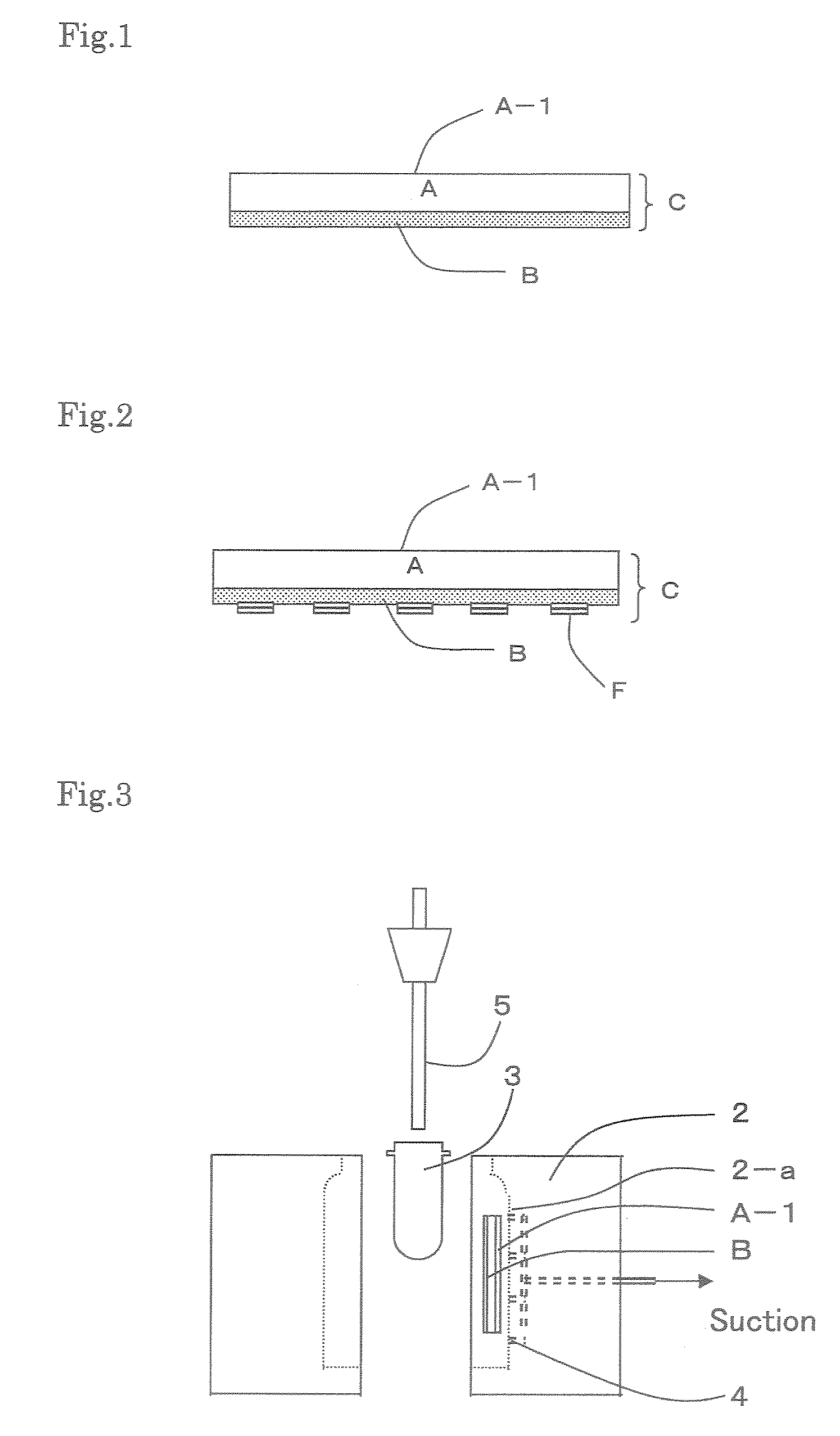

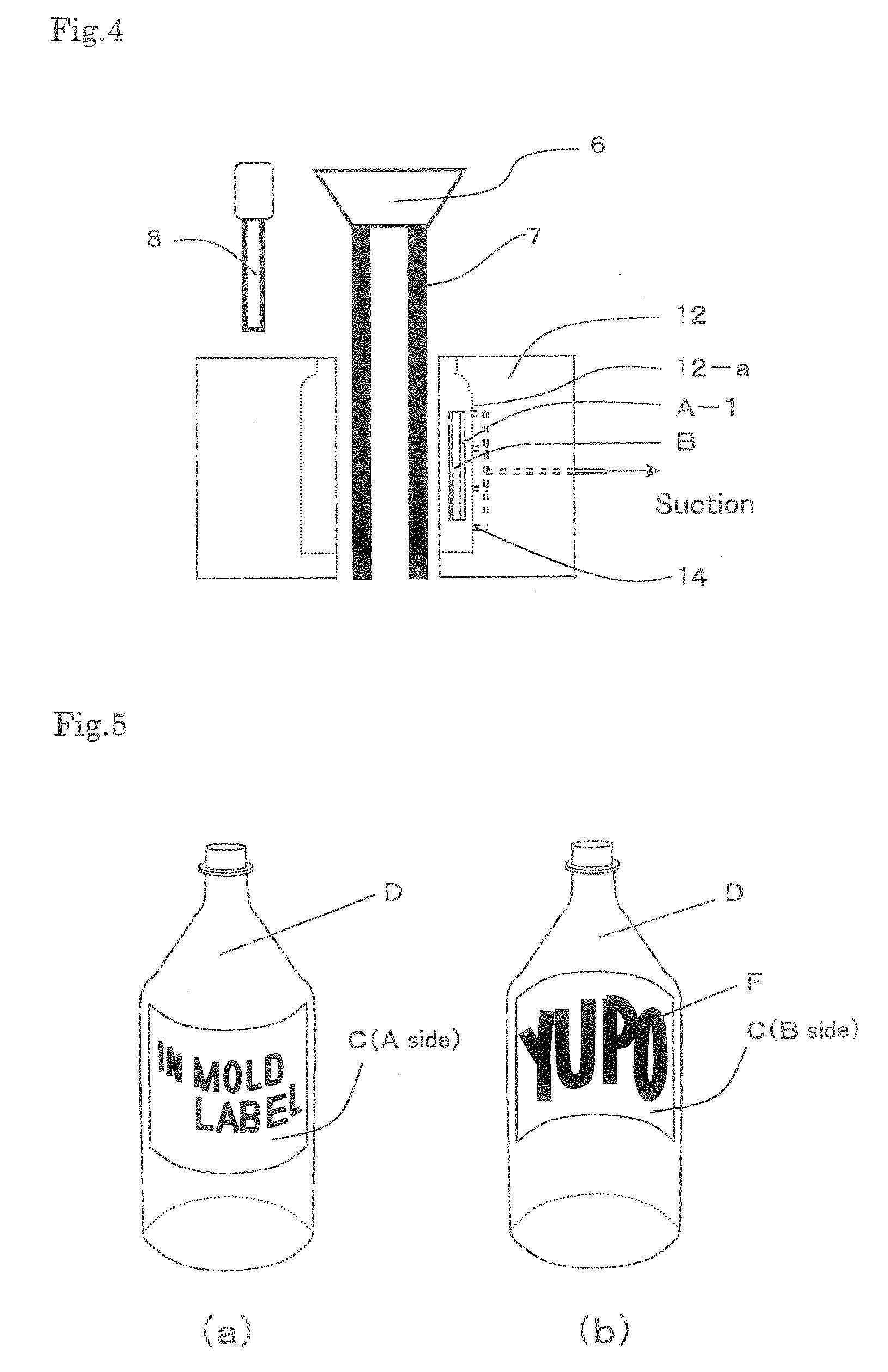

In-mold labeling method and labeled products

The invention relates to an in-mold labeling method, and to molded plastic articles having an in-mold label as described herein. In one embodiment of the invention, the in-mold label film comprises: (A) a polymer facestock having a printable upper surface and a lower surface, (B) a print layer having an upper surface and a lower surface wherein the lower surface of the print layer is in contact with and adhered to the upper surface of the facestock, and (C) an adhesive layer having an upper surface and a lower surface wherein the lower surface is in contact with and adhered to the upper surface of the print layer.

Owner:CCL LABEL INC

Inmold labeled container and molding process thereof

InactiveUS20100001010A1Accurately determineAccurate settingBottlesLarge containersEngineeringMechanical engineering

Owner:YOSHINO KOGYOSHO CO LTD

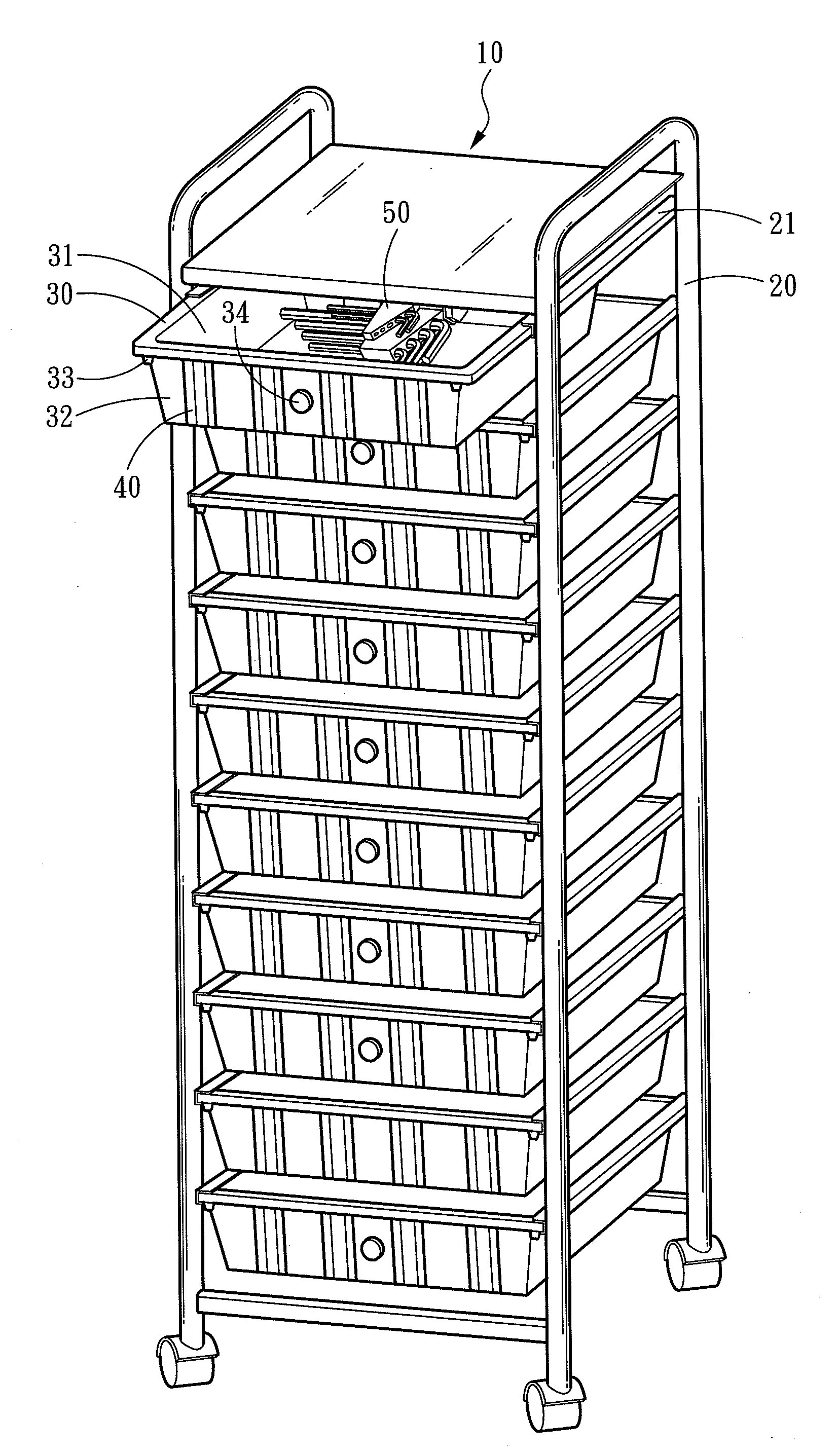

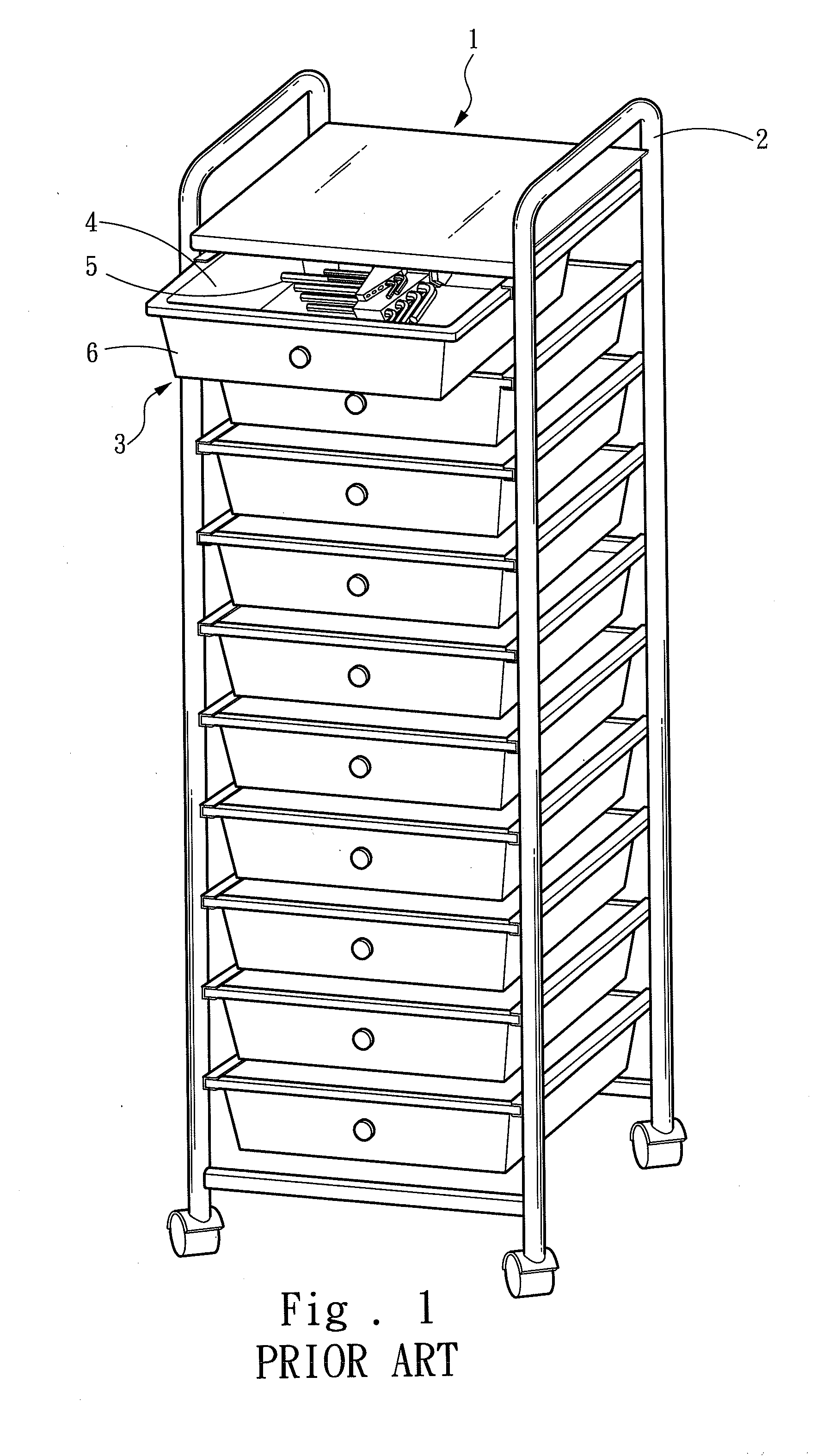

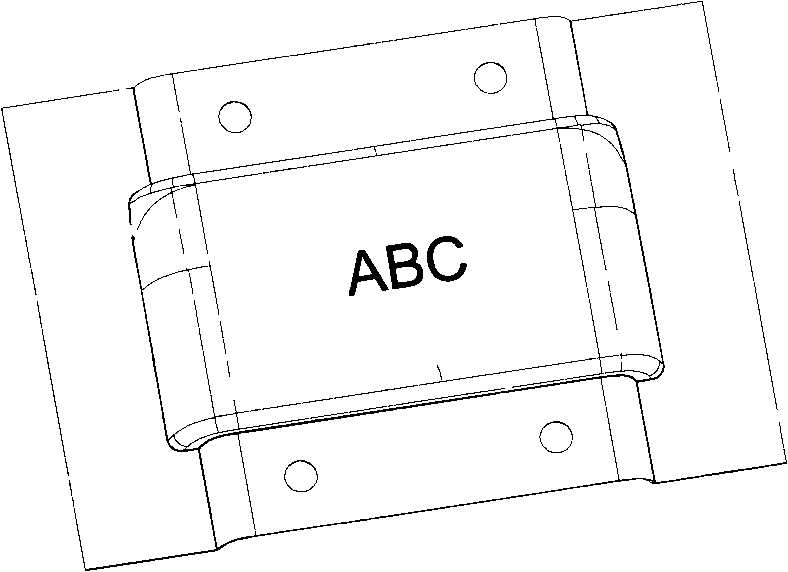

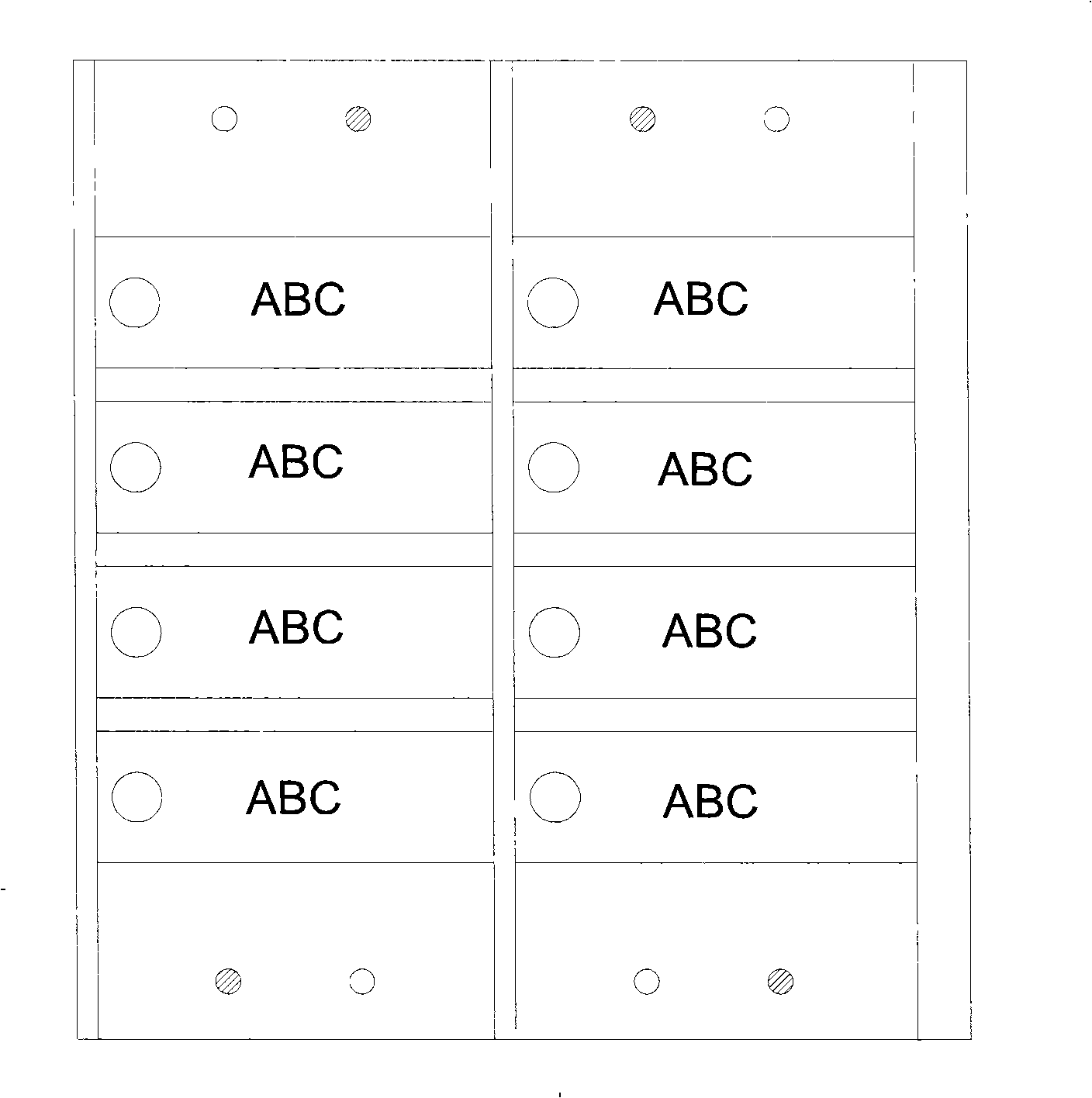

Drawer cart with in-mold labels

InactiveUS20130063012A1Great added-valueImprove usabilityWork tools storageServing tablesBiomedical engineeringIn-mould labelling

A drawer cart with in-mold labels includes a cart and a plurality of drawers made by injection molding. Each drawer has a housing compartment opened upward and a display surface. The drawers are slidably mounted onto the cart with the display surfaces exposed outwards and can be partially drawn away from the cart to expose the housing compartment. The display surface contains an in-mold label formed during the injection molding. The in-mold label has patterns for indication and visual aesthetic, and also facilitating classification of goods held in the drawers. The patterns on the in-mold label can be designed differently in response to varying display surfaces and can be combined to form a whole pattern to enhance total design sense and meet use requirements.

Owner:LU YEN WEN

In-mould labelling

An In-Mould Labelling process comprising: clamping a label within a mould void of an injection moulding tool; and injecting material into the mould void while the label is clamped. An In-Mould Labelling process comprising: placing a label between a first mould void and a second, separate mould void; and injecting material into the first and second mould voids.

Owner:NOKIA CORP

In-mold label composition and process

InactiveUS20050196594A1Low costReduce the amount requiredStampsDecorative surface effectsEngineeringPolymer

An in-mold label composition includes a microporous sheet substrate having first and second faces and a first down coat of a film-forming polymer on the first face of the microporous sheet substrate. A graphic is printed on the first down coat of film-forming polymer after the first down coat has dried. A method of making the label and an article made with the label are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

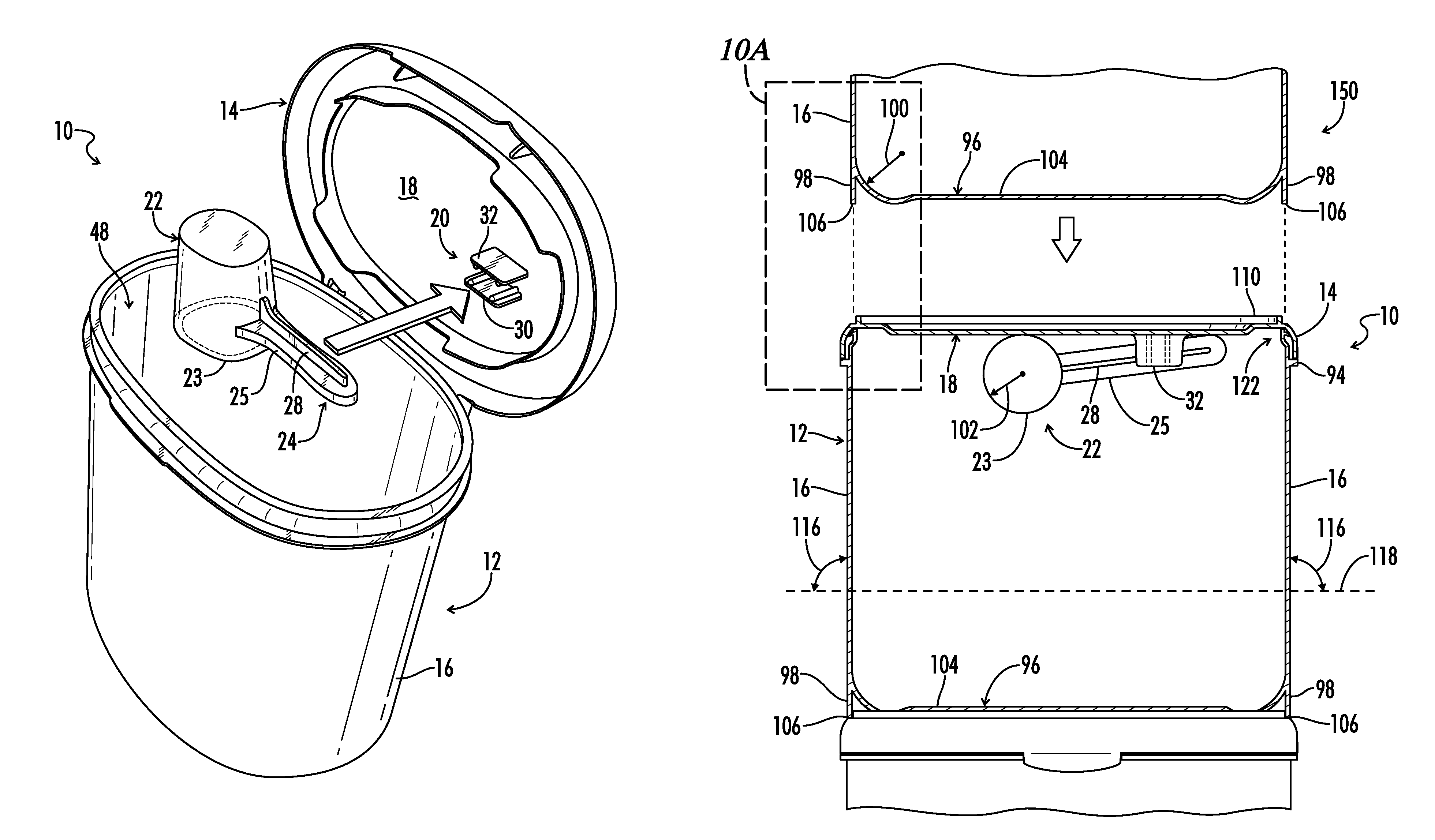

Container and closure

An improved container provides a container body and a closure. In some embodiments, a scooping utensil retainer is disposed on the closure. The scooping utensil retainer includes opposing flanges protruding from the closure surface. A flange rib protrudes from the first flange into the flange gap, extending from the closure surface to the distal end of the flange. A tapered retainer gap is provided between flanges for resiliently clamping the handle of a scooping utensil. In some embodiments, the closure can include an annular ridge shaped for engaging a downwardly extending skirt on a like container when two like containers are vertically stacked. In some embodiments the container body includes an in-mold label affixed to a substantially straight side wall, the in-mold label covering at least about 95% of the exterior surface area of the container body.

Owner:MEAD JOHNSON NUTRITION

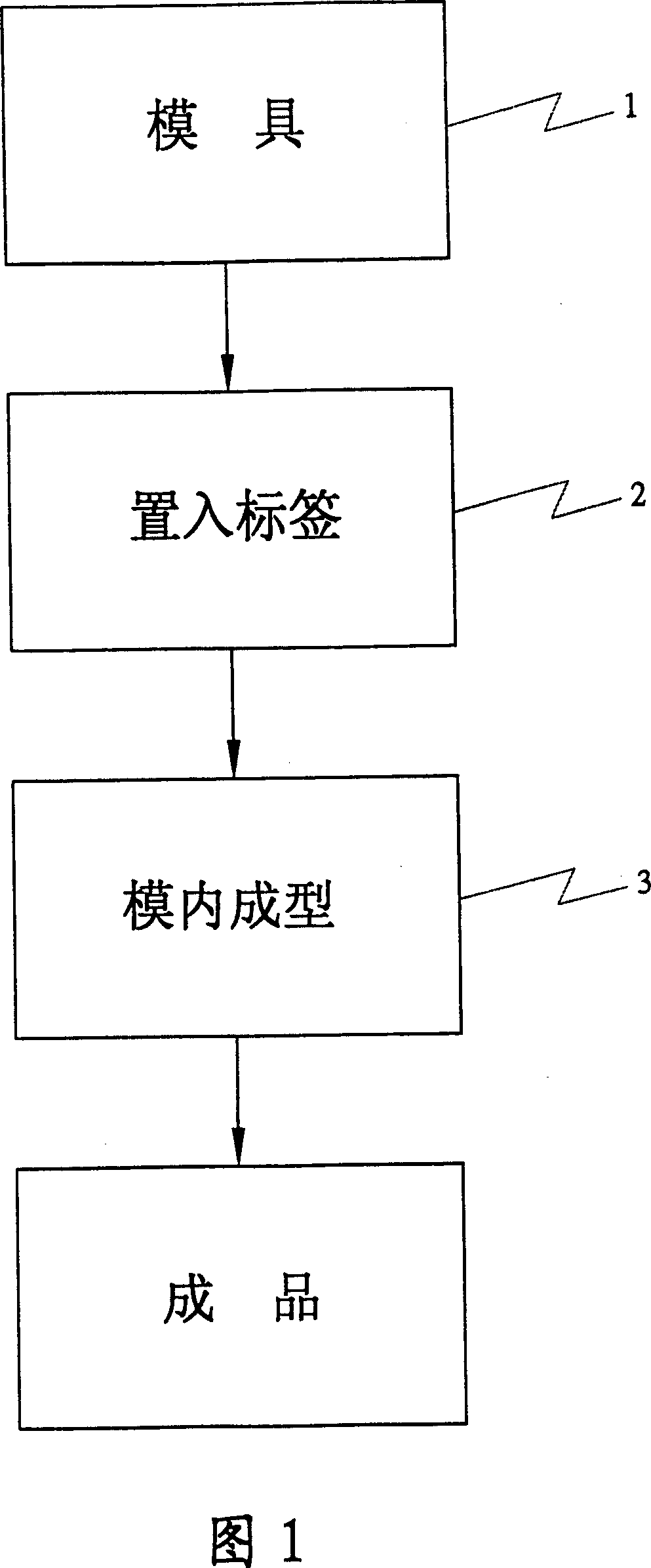

Inner die forming anti-fogery method

InactiveCN1982019AProduce anti-counterfeiting effectPrevent forgeryCoatingsGraphicsForming processes

An antiforge intramould forming method includes such steps as providing a mould with one or more concave parts, convex parts or concave-convex parts in its molding cavity, which may be graphics, characters or totem, putting one or more labels on said parts, and injection (vacuum or press) molding to obtain an antiforge product.

Owner:黄胜昌 +1

Labeled In-Mold Shaped Article, and In-Mold Label

ActiveUS20080118718A1Excellent waterproofness and stabilityImprove adhesionStampsSynthetic resin layered productsPolymer scienceWater soluble

A labeled in-mold shaped article in which an in-mold label having a thermoplastic resin-containing substrate layer and a heat-seal layer that contains a heat-seal resin and a water-soluble binder is stuck to a shaped article and in which the in-mold label does not peel off rom the shaped article even when the labeled in-mold shaped article is dipped in water at 40° C. for 4 days. The labeled in-mold shaped article satisfies both label adhesiveness and delabelability.

Owner:YUPO CORP

In-mould labelled capsule for beverage preparation

ActiveUS20140190863A1Promote resultsPackaging corrosive chemicalsShock-sensitive articlesFood materialInjection moulding

Owner:SOC DES PROD NESTLE SA

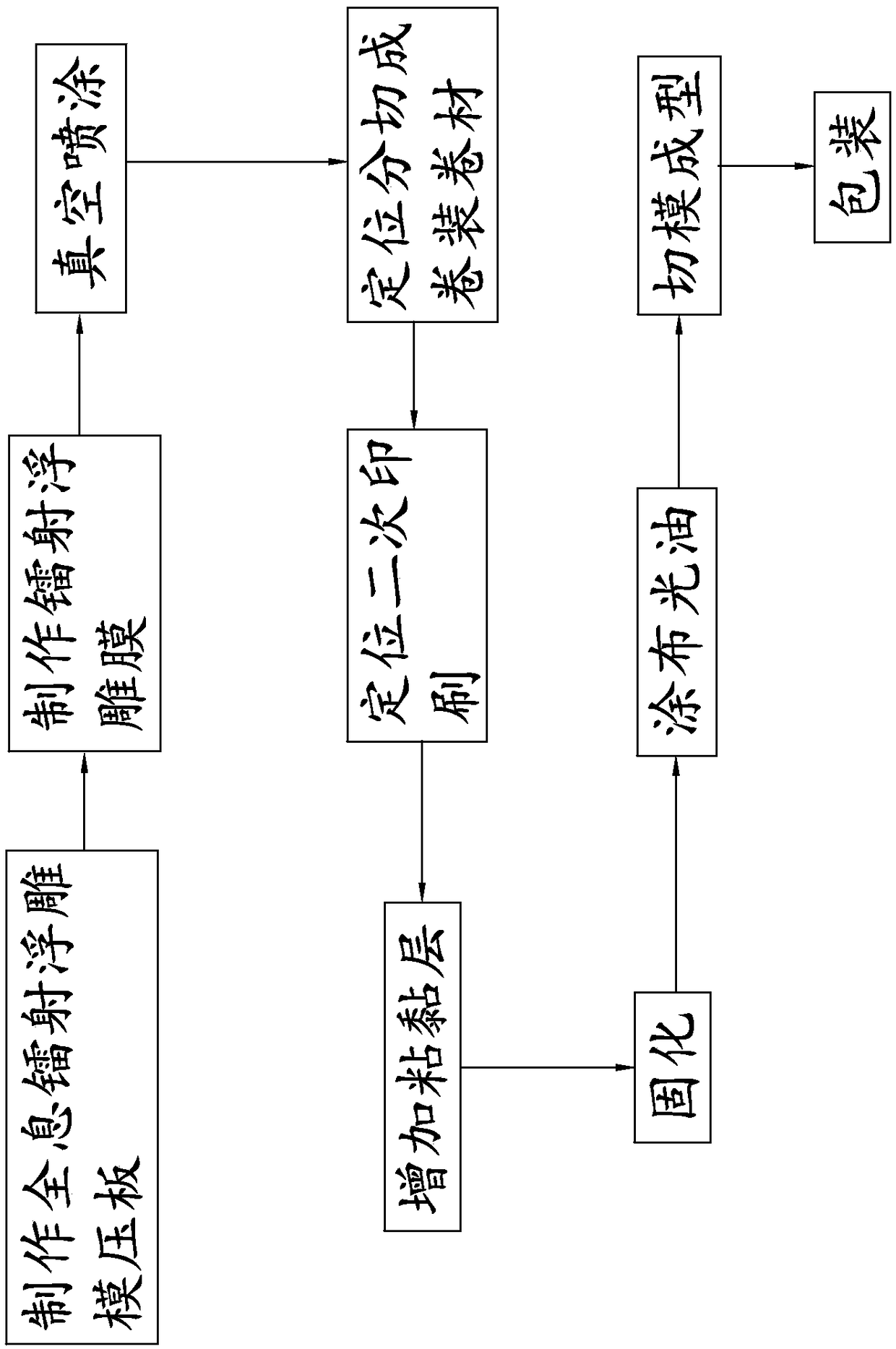

Manufacturing method of in-mould labels

InactiveCN108806485AChange the situation without holographic anti-counterfeiting marksStampsLaser beam welding apparatusPlatinumVarnish

The invention discloses a manufacturing method of in-mould labels. The main steps comprises the following steps of: manufacturing holographic laser embossment moulded board, manufacturing laser embossment film, vacuum spraying, positioning and cutting into rolled coil material, positioning and secondary printing, increasing adhesive layer, curing, applying cloth varnish, mould cutting and mouldingand final packaging. At present, the holographic laser anti-counterfeiting label products are limited to paper boxes, soft packaging, and the like, more visual label products are difficult to achievedue to the complexity of the process, and no label product is used in the in-mould label; through the long-term practice, this scheme creatively combines platinum embossment technology and in-mould label technology, changing the situation that there is no holographic anti-counterfeit label in the industry, and solving the current situation that the in-mould label with holographic anti-counterfeiting label in the industry can not be produced. This manufacturing method of in-mould labels is used in the field of high-end cigarette, wine, cosmetics and gift boxes.

Owner:广州市丽宝包装有限公司

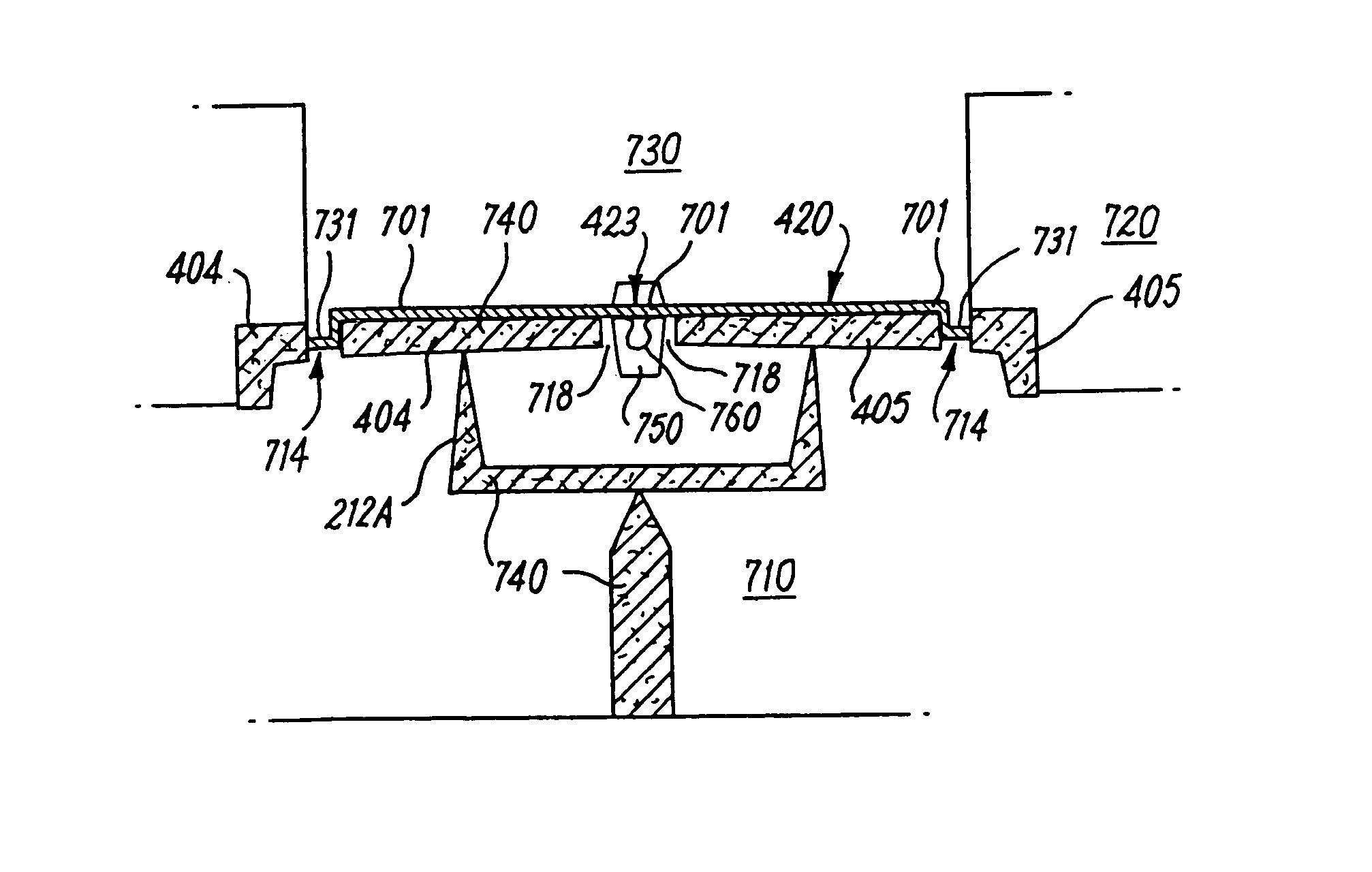

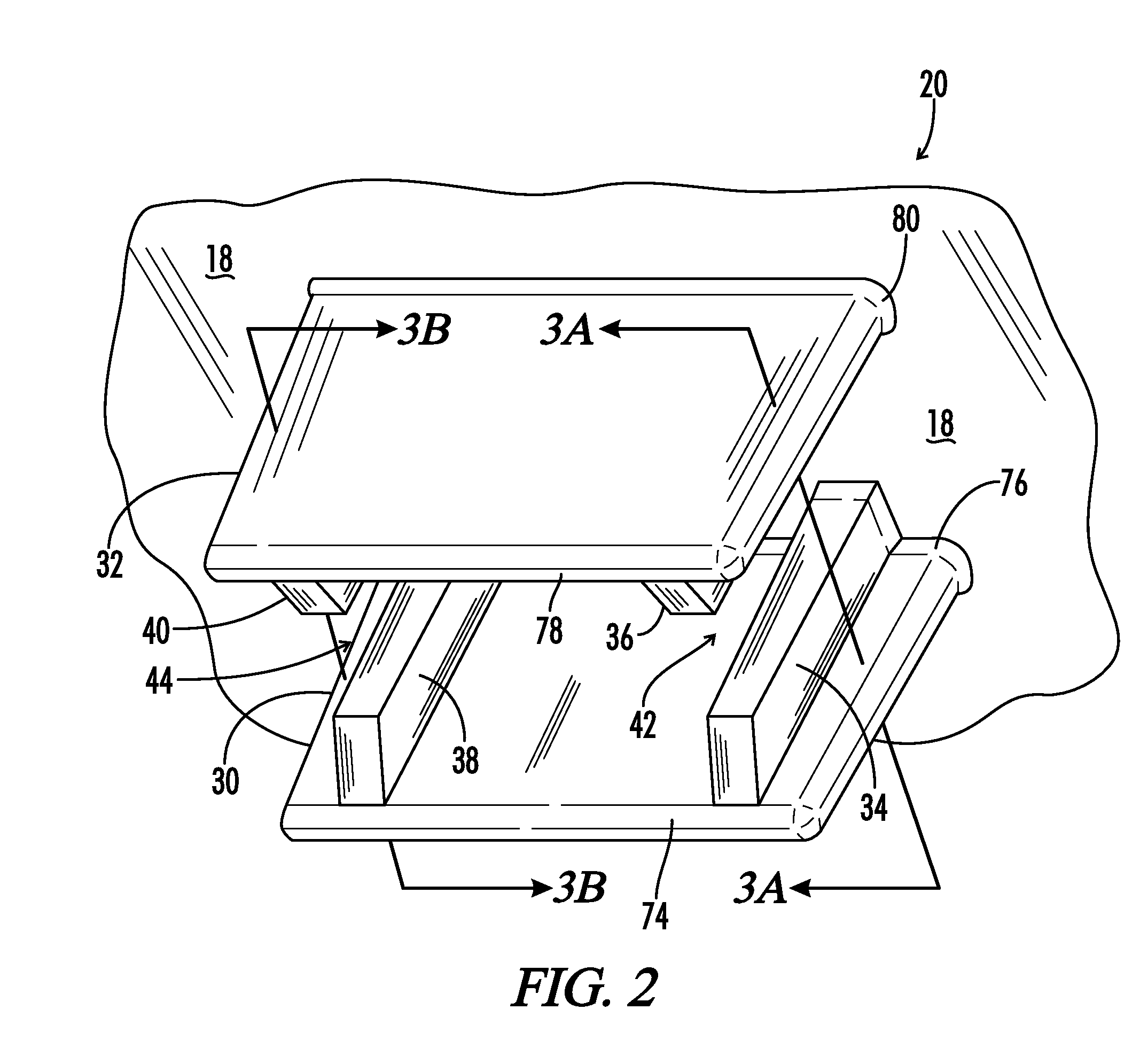

Label ledge for injection molded containers

InactiveUS7140857B2Prevents and minimizes displacementConfectioneryClosure with auxillary devicesLeading edgeShell molding

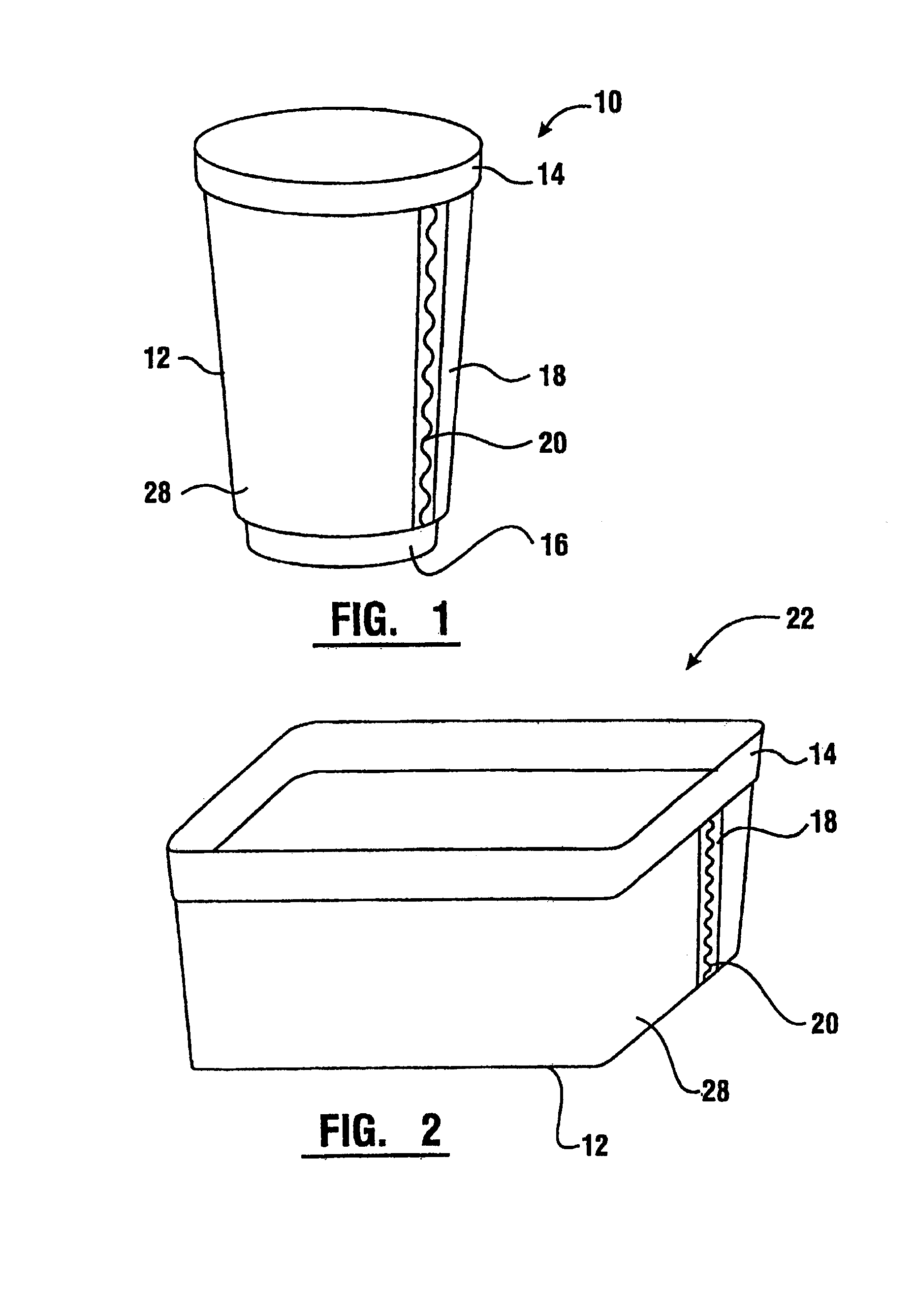

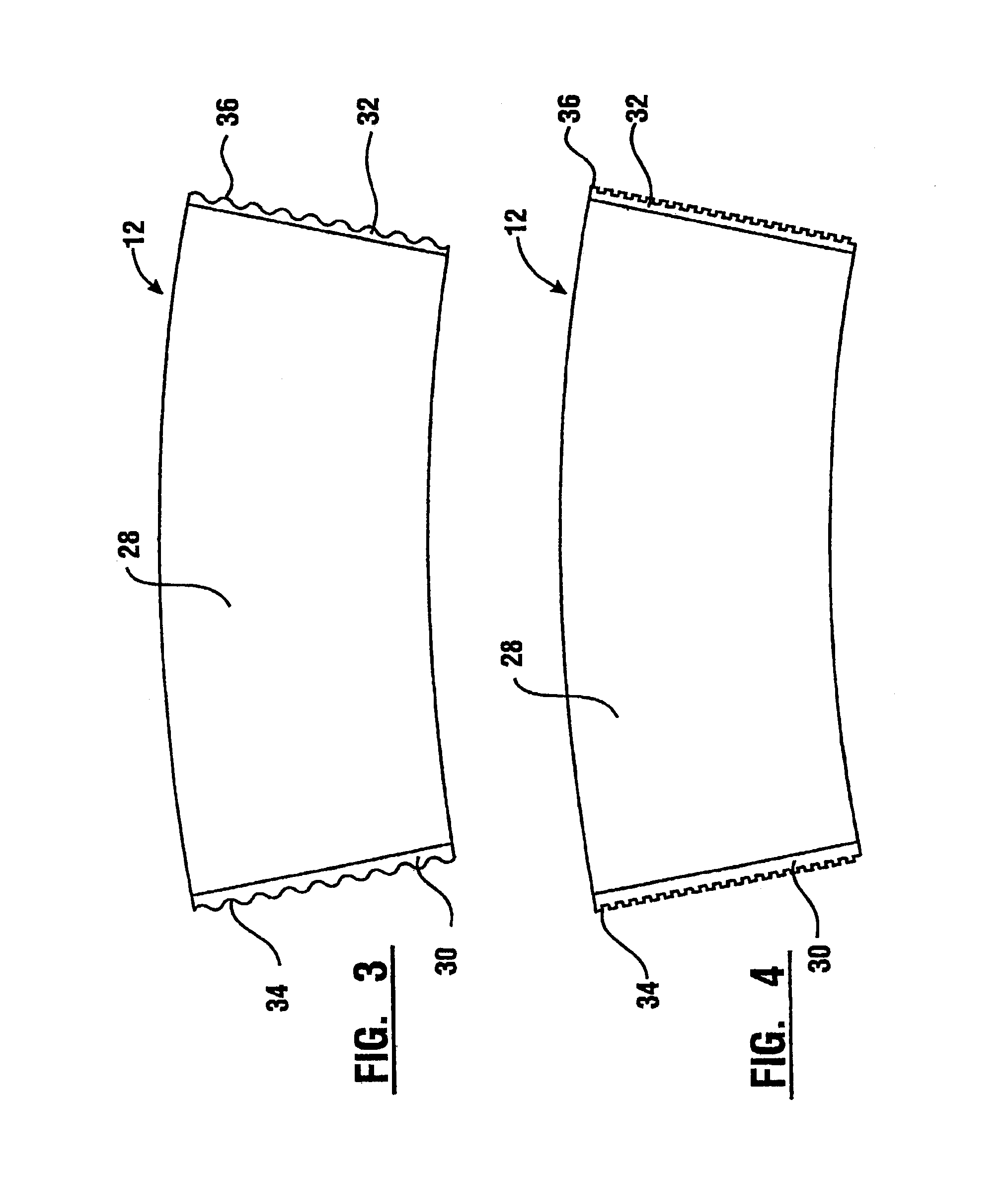

An improved in mold label for use in labeling products made by injection, or other, molding technologies has a zig-zag shaped edge cut contained in a registration area which contains ink that matches the product resin. At least one ledge is formed in a cavity wall of the mold proximate the position intended for receipt of an in mold label. The ledge protects the leading edge of the in mold label from the flow of resin through the cavity walls of the mold. Because the label leading edge is protected, the resin flows over the label and pins the label to the cavity wall of the mold, creating a container with the label formed on the container wall. Alternatively, a container lid is provided with a ledge to facilitate skirting and label placement on the pan area of the lid. These features both enhance the structural integrity and the uniform unblemished appearance of the finished molded container. Because of the enhanced structural integrity, high melt resin may be used to create the container, reducing the cycle time, and thus the cost of the product. The lack of blemishes in the finished container reduces manufacturing waste.

Owner:IML BY IDESIGN

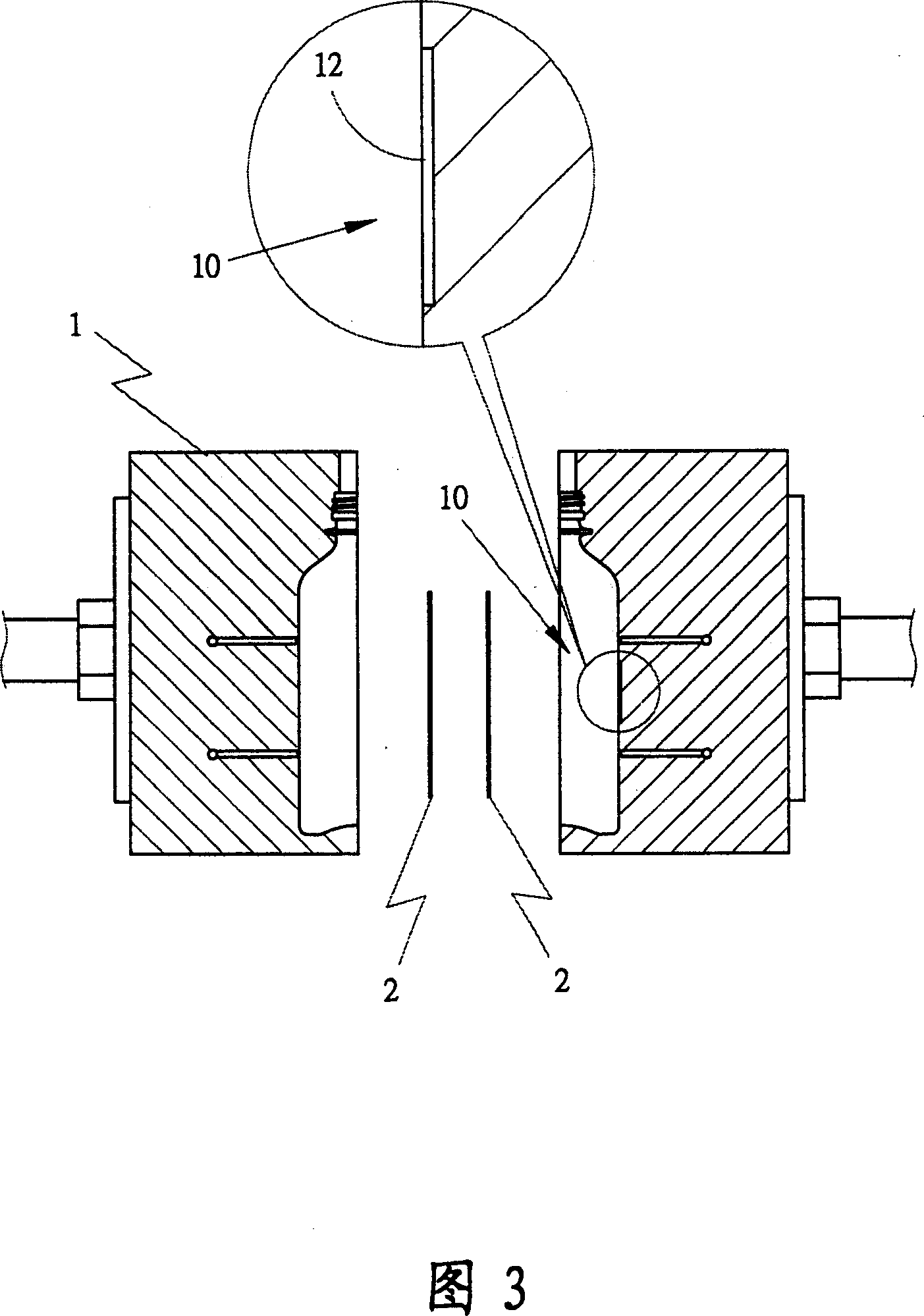

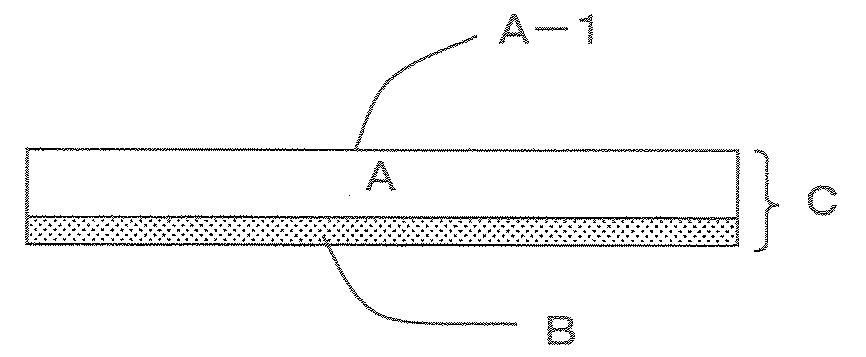

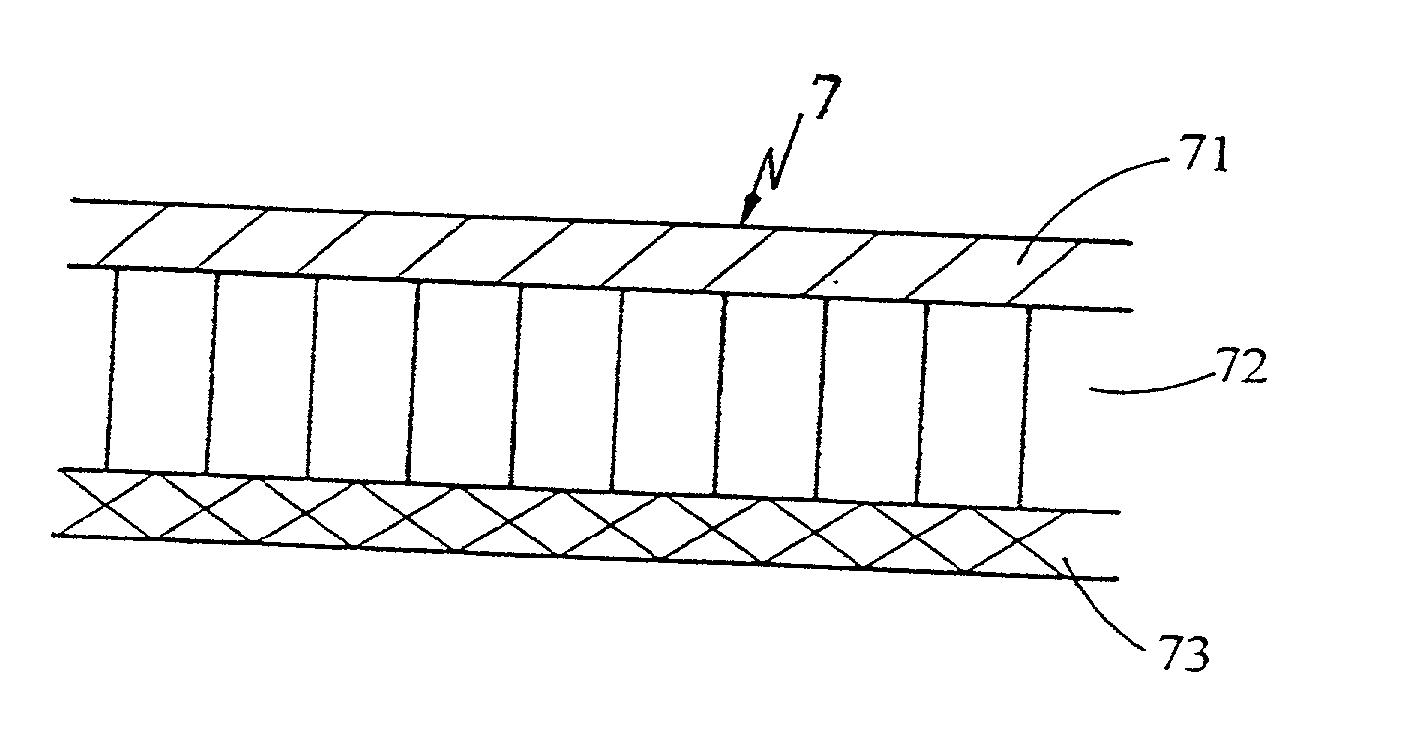

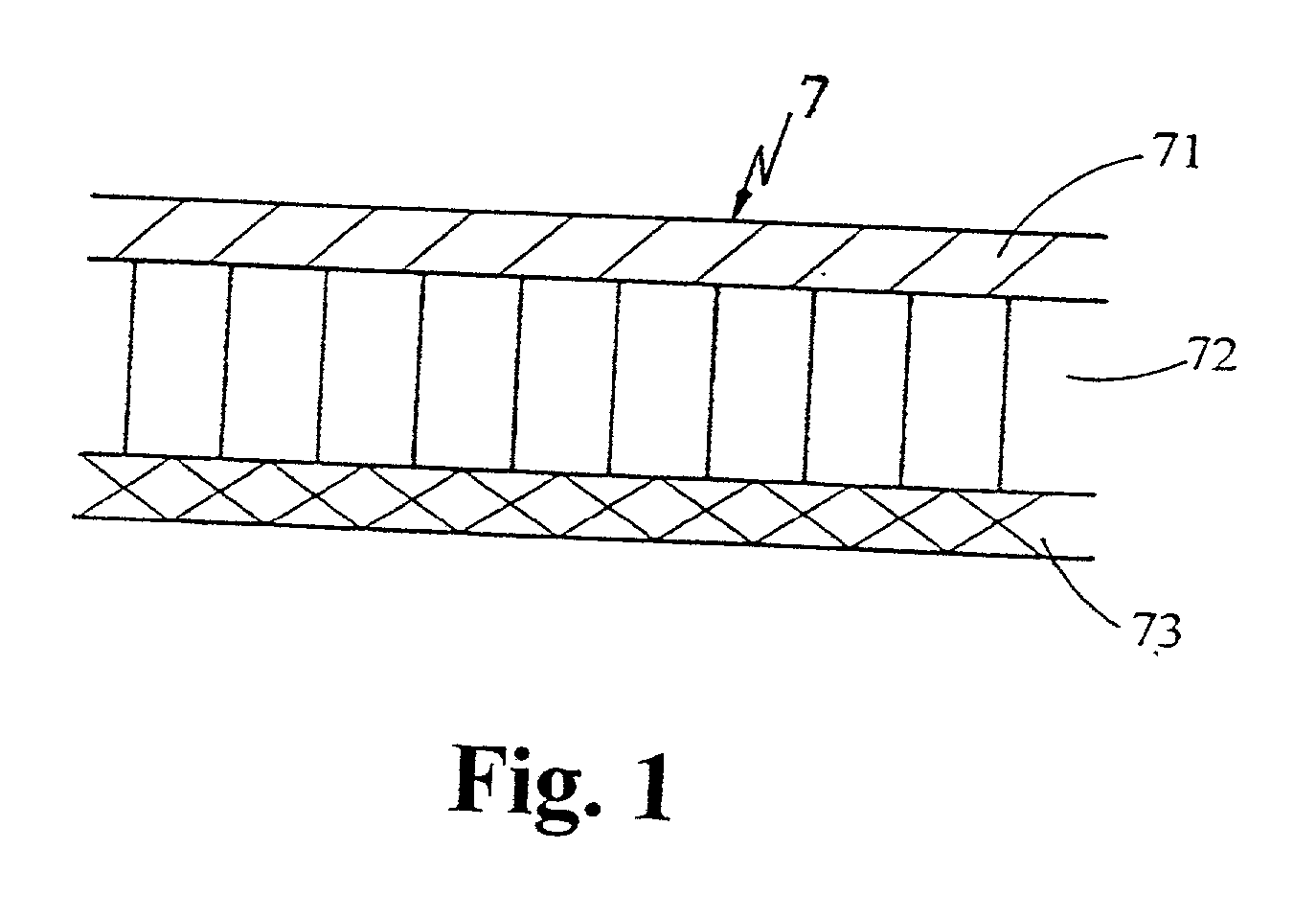

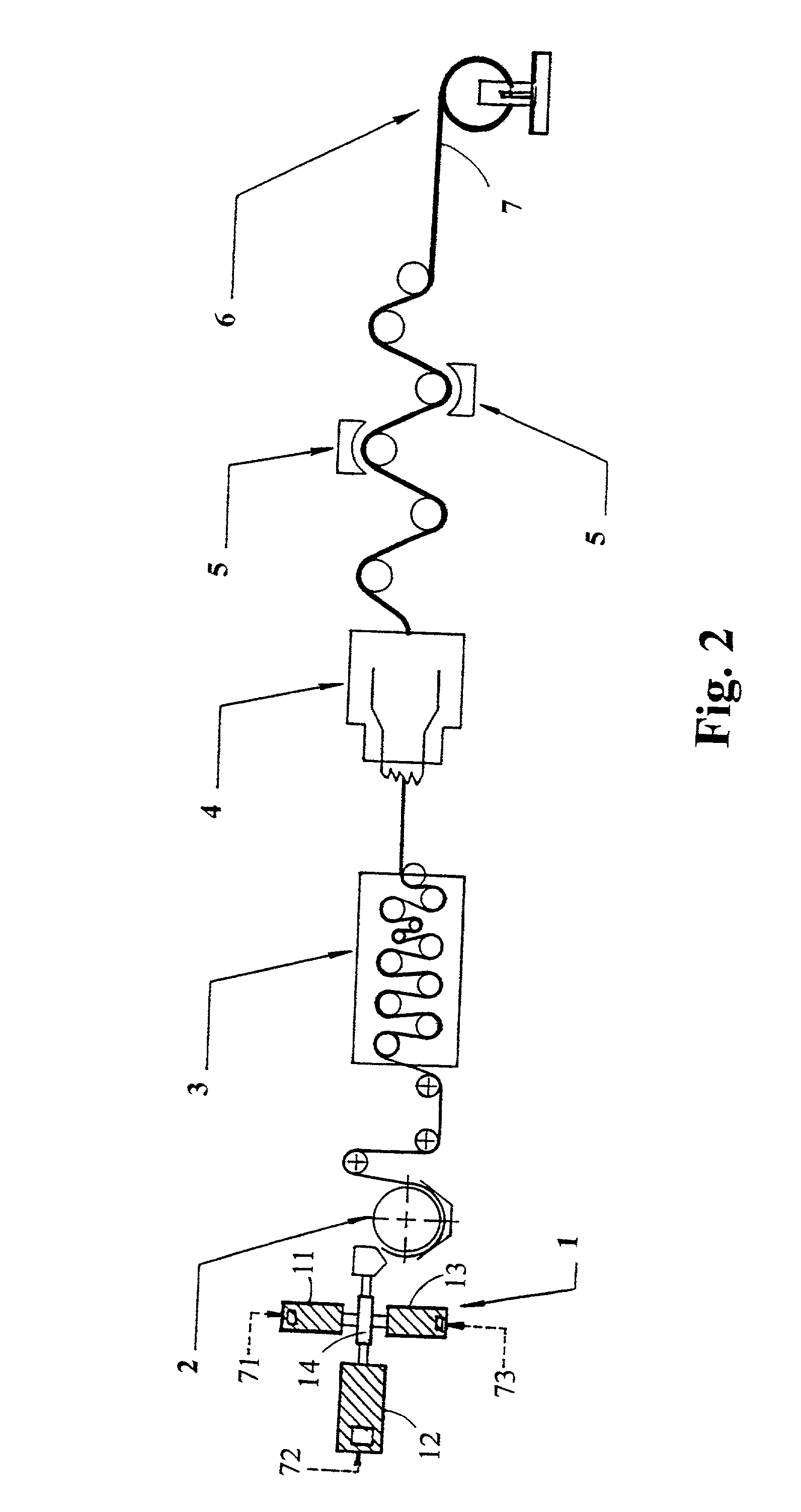

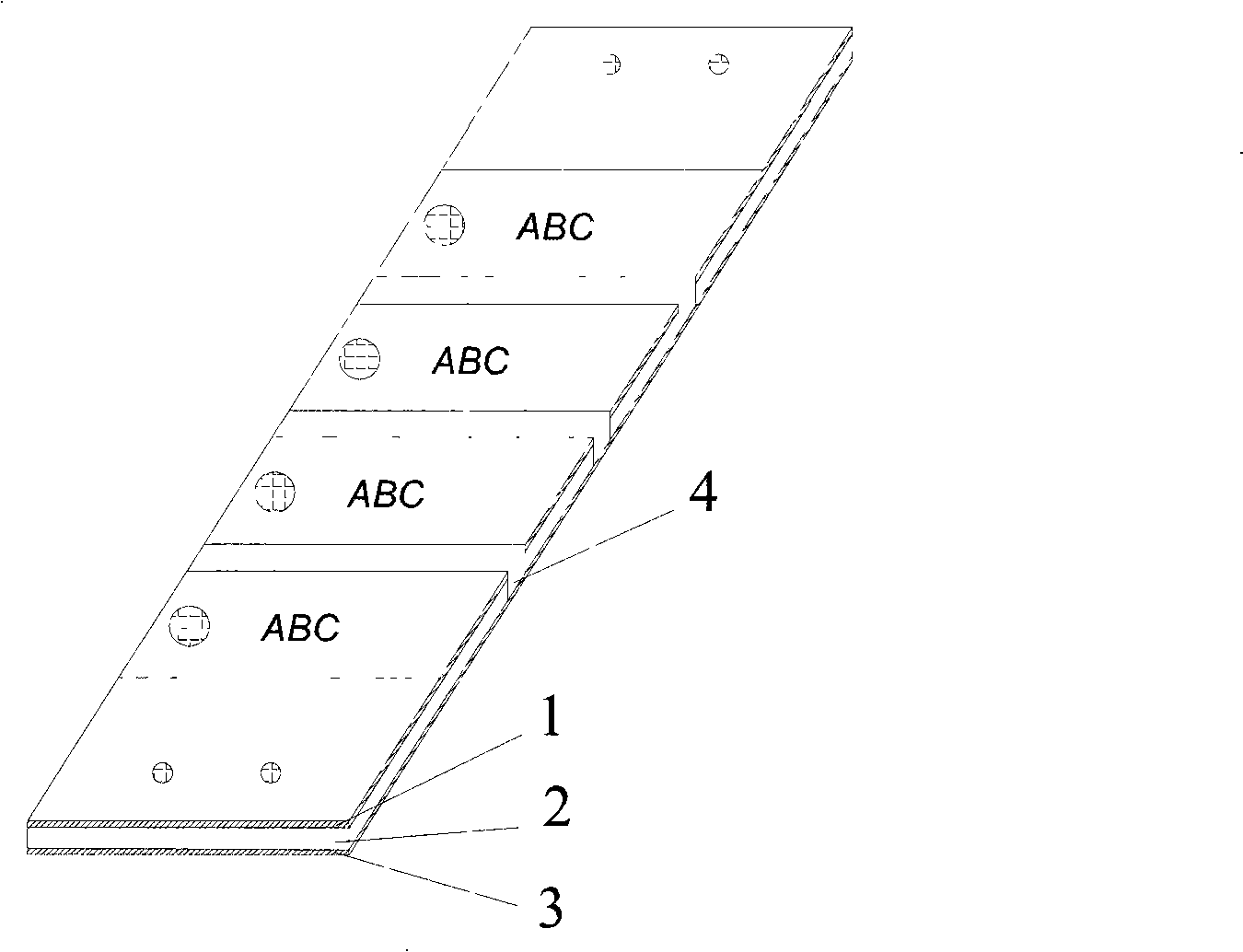

3-Layer co-extruded biaxial-oriented pearly synthetic paper label used for integrally molding with bottle in mold

InactiveUS20030099823A1Increase material costEasy to controlSynthetic resin layered productsThin material handlingPolymer scienceAdhesive

This invention relates to a 3-layer co-extruded biaxial-oriented pearly synthetic paper label used for integrally molding with bottle in mold; more particularly, it relates to a manufacturing equipment and method of said 3-layer co-extruded biaxial-oriented pearly synthetic paper label. The pearly synthetic paper label produced by the manufacturing method of this invention has a 3-layer structure which is layer-laminated with a printing paper surface layer, a foamed intermediate layer, and an in-mold label-adhered layer; the pearly synthetic paper label can be applied in the blow-mold or eject-mold of polypropylene(PP) bottle or of high density poyethylene(HDPE) bottle, in which the pearly synthetic paper label is integrally molded by heat adhesion with the PP bottle or HDPE bottle under being molded in the mold; meanwhile, the abnormal situation like encapsulated air bubbles is prevented from happening so as to make the PP (or HDPE) bottle which is integrally molded with label have an excellent appearance and quality. The main process of the manufacturing method of this invention is: various compositions which represent the printing paper surface layer, the foamed intermediate layer, and the in-mold label-adhered layer respectively are co-extruded, by using two secondary extruders and one primary extruder, through one T-type die to form a 3-layer resin composition; then, through procedures of cooling / forming, biaxial orientation, corona discharge treatment, and laminating / rolling, a 3-layer co-extruded biaxial-oriented pearly synthetic paper label used for integrally molding with bottle in mold is obtained. This invention, of which the manufacturing process is simple and the cost is low, completely breaks through and fully improves the complicated process of conventional methods wherein the plastic film or a synthetic paper is either coated with a heat-melted adhesive or fabricated to be an in-mold label-adhered layer after being embossed; thus, this invention is of industrial applicability to the PP bottle or the HDPE bottle manufacturing industry.

Owner:NANYA PLASTICS CORP

Label inside composite membrane

InactiveCN101049743AEasy dischargeImprove product qualityStampsSynthetic resin layered productsEngineeringElectrical and Electronics engineering

A compound in-mold label is composed of a film substrate with air exhausting veins for exhausting air on moulding, and a transparent covering film with pattern and characters printed on its inner surface.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

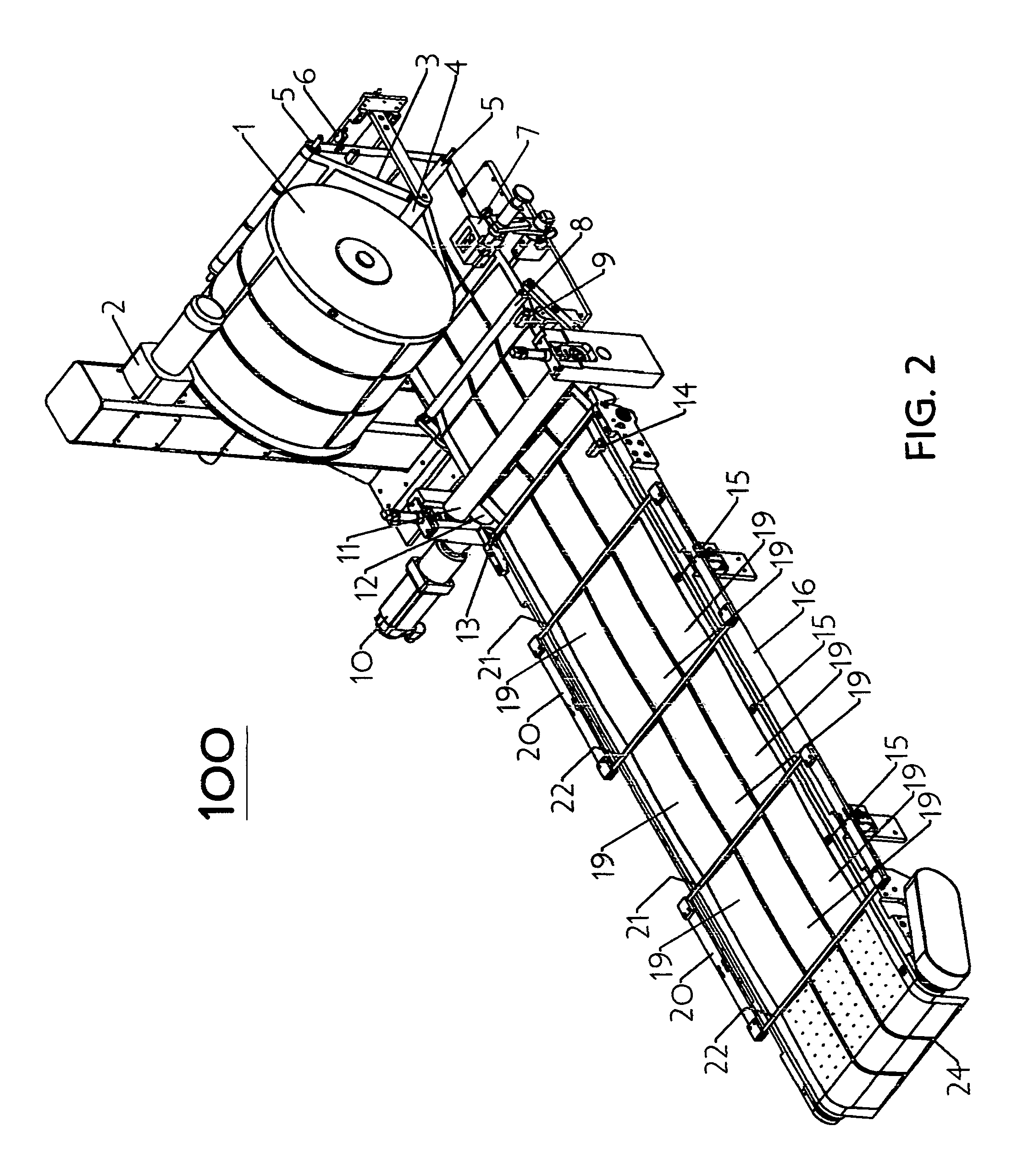

Method and apparatus for handling in-mold labels

InactiveUS20160114501A1Easy to pullEliminate needMetal working apparatusManipulatorEngineeringIn-mould labelling

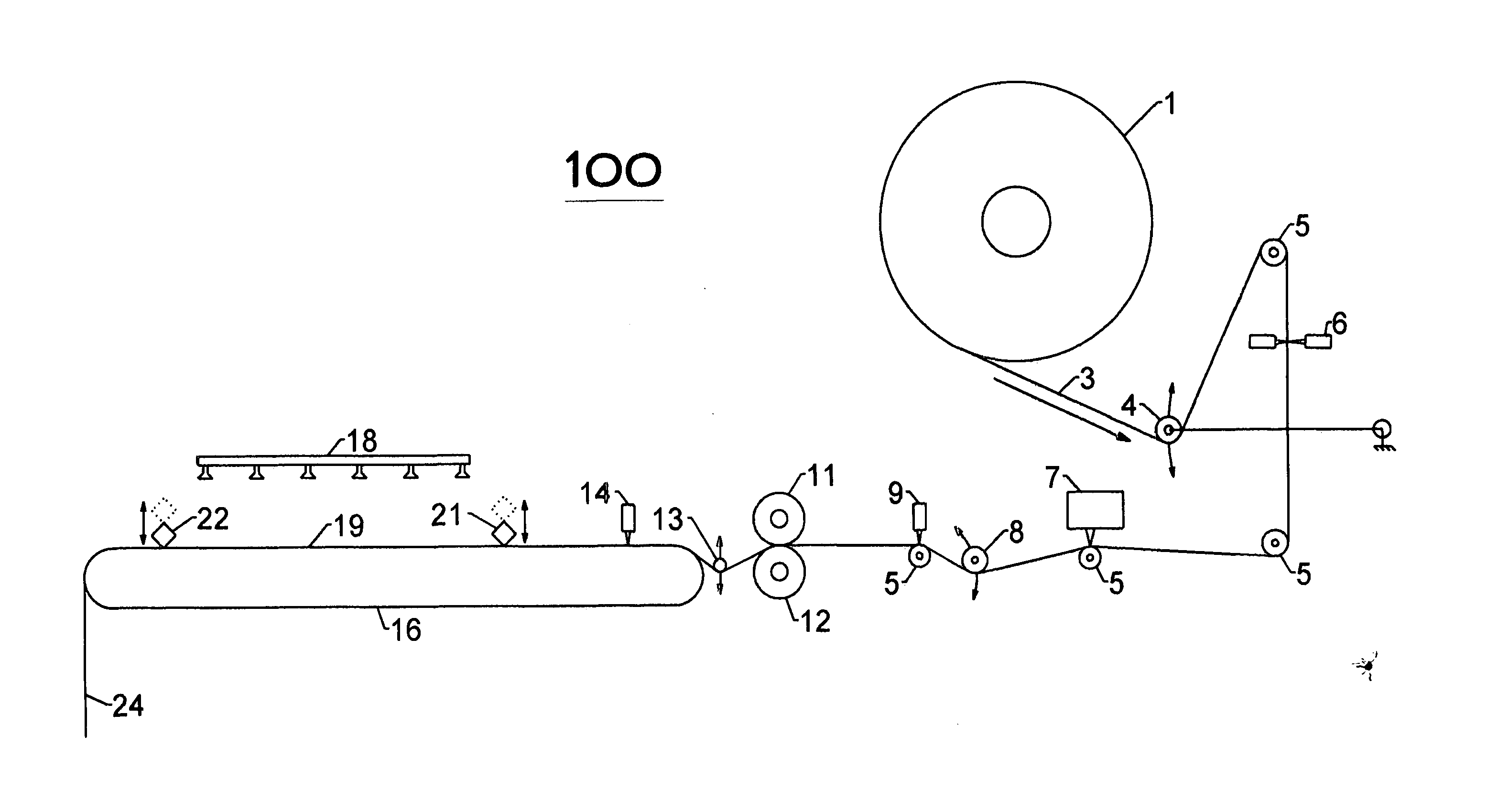

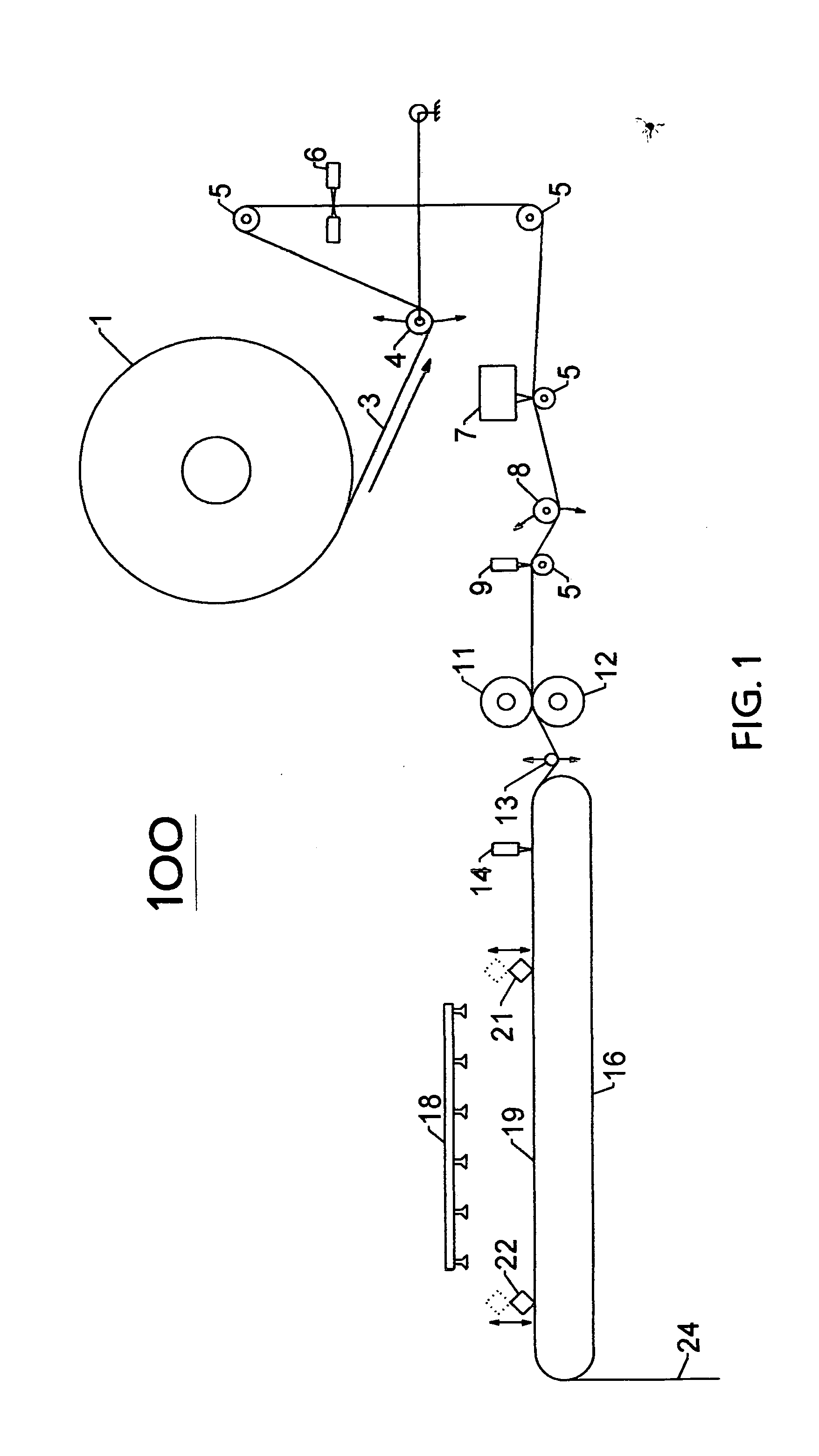

A blank non-adhesive label stock roll containing a continuous blank non-adhesive label sheet is printed as it is being unrolled to provide a multiplicity of pre-printed labels thereon. As the label sheet is being unrolled, each of the printed labels is partially cut along a peripheral edge thereof to leave a plurality of spaced apart uncut ties joining points along the peripheral edge to a scrim area of the label sheet to thereby maintain removable attachment of each of the pre-printed labels to the scrim area. Following printing and partial cutting of the labels, the label sheet is rerolled to form a pre-printed and pre-cut label stock roll, which is then controllably unrolled to permit selective removal of the pre-printed and pre-cut labels by an apparatus that conveys them for use in an external molding process.

Owner:CBW AUTOMATION

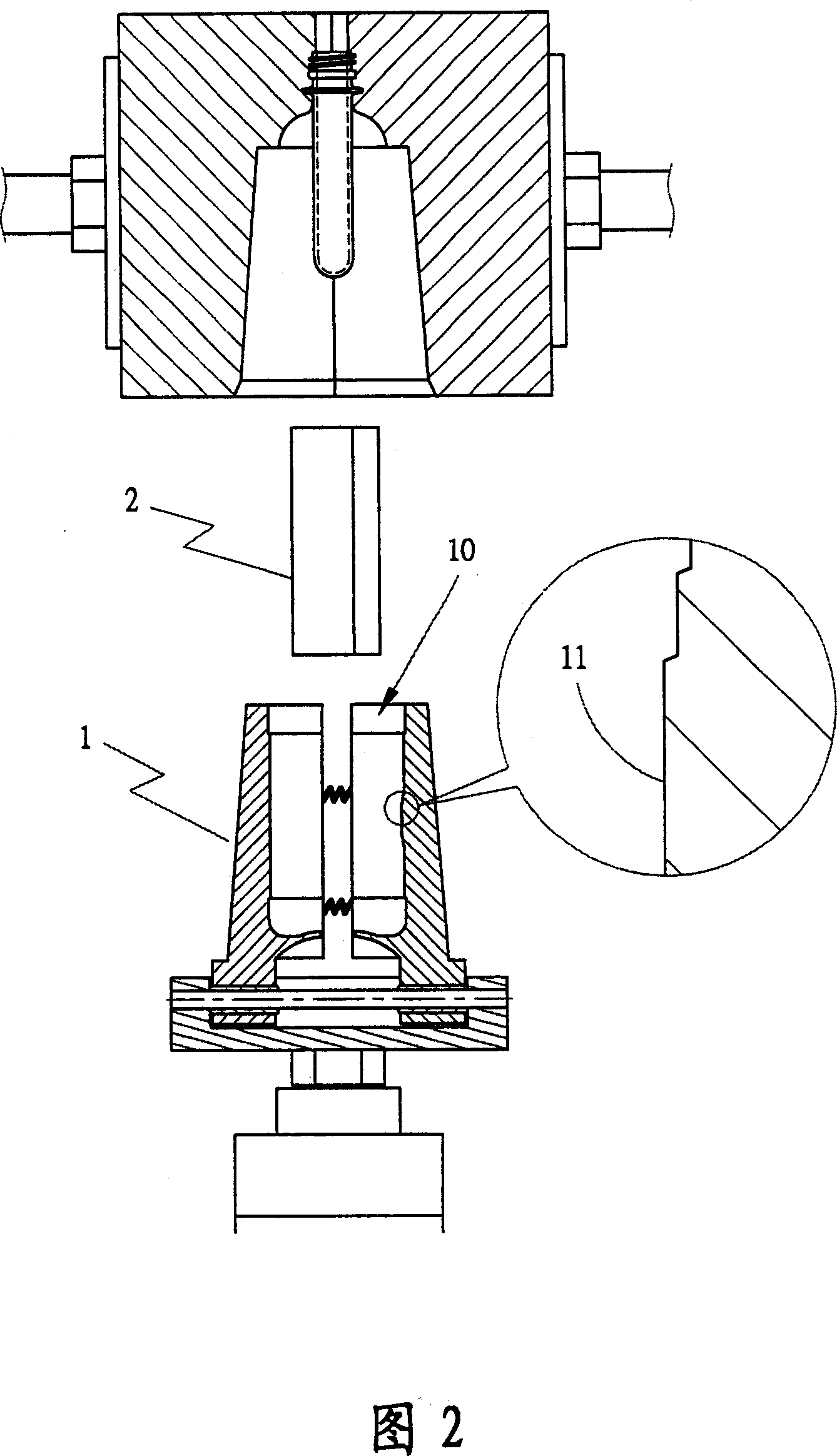

Manufacturing technique of label in mold

ActiveCN101332641AStretch smoothlyWon't wrinkleMetal working apparatusState of artThree dimensional shape

The invention discloses a manufacture process for labels in dies, comprising the steps as follows: a) printing the justification sheets such as patterns of products, justification positioning hole and a unit positioning hole; b) punching corresponding justification positioning hole on the sheets; c) die-cutting the unit positioning hole and the label shape required to be formed by a die cutter; d) forming a label with a certain three-dimensional shapes on a forming die; e) processing the final product by the injection molding. The manufacture process of the invention has the beneficial effects of overcoming the defects in the prior art such as large consumption of leftover material, easily appeared pressing marks on the edges, rupture and colour difference appearing on the curved surface, low efficiency, and the like, changes the type of the prior art that a label is singly positioned, realizes the effects that a plurality of labels commonly use the positioning hole and a plurality of labels are formed once, improves the performance of the product and reduces the production cost.

Owner:BYD CO LTD

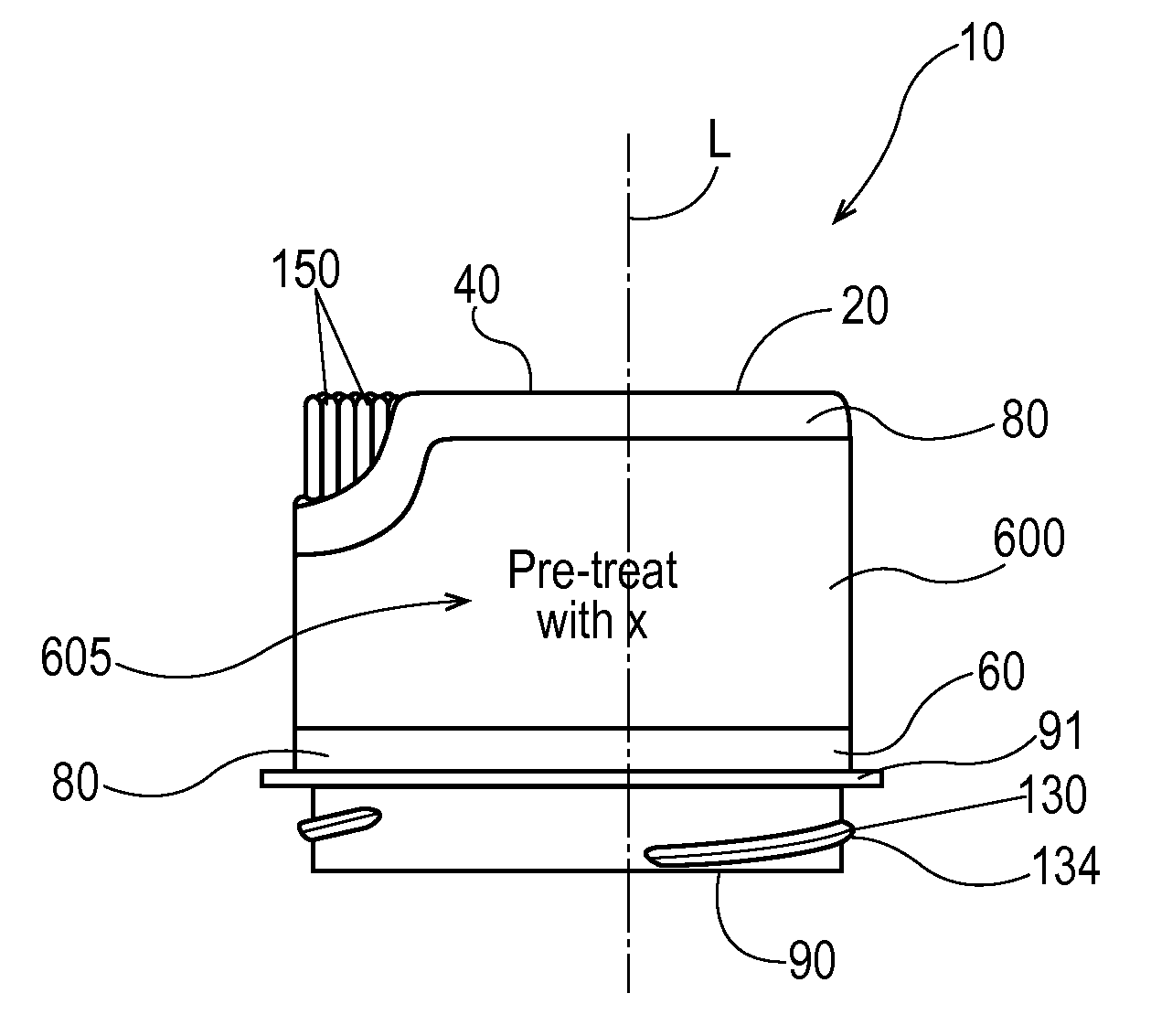

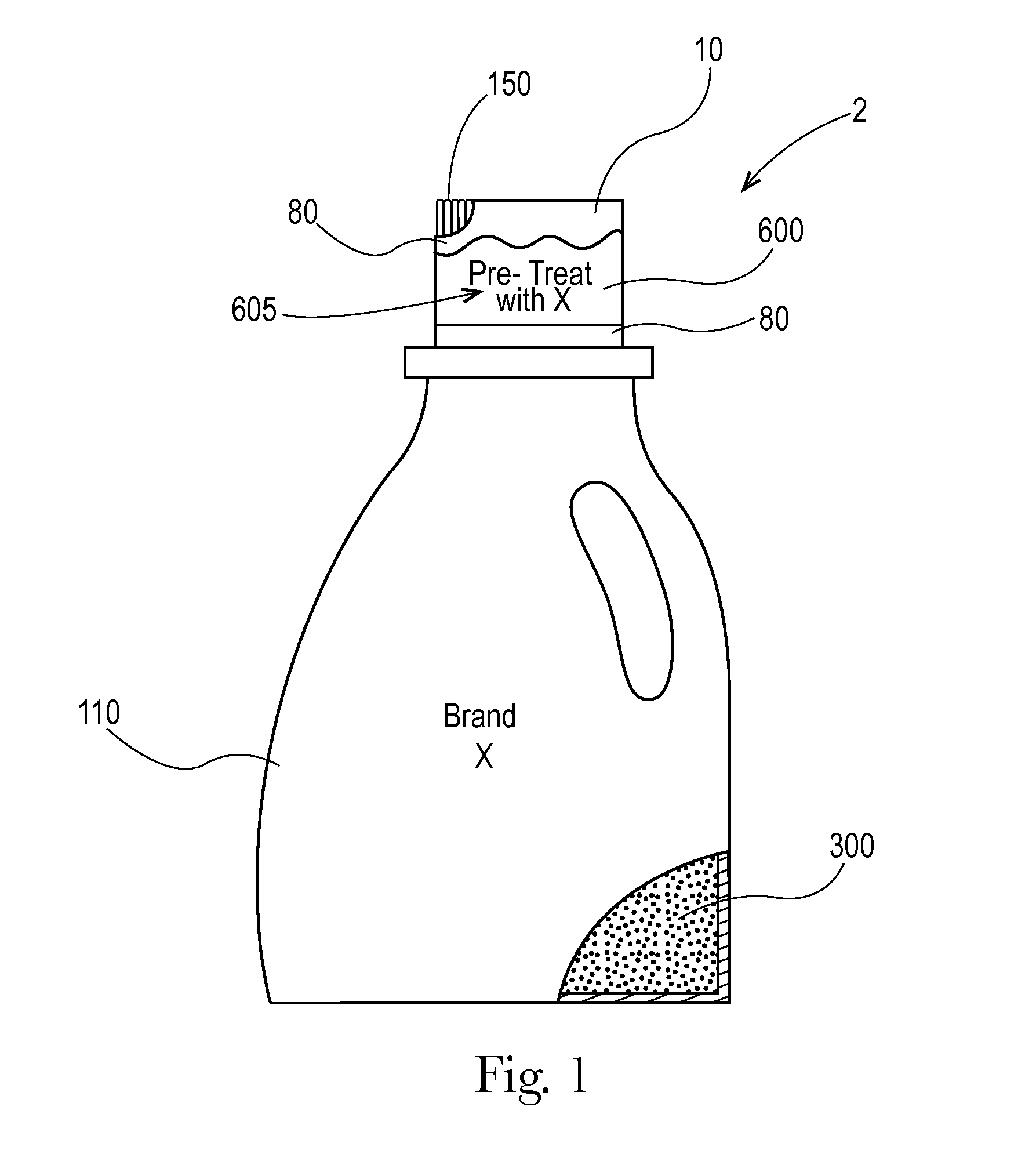

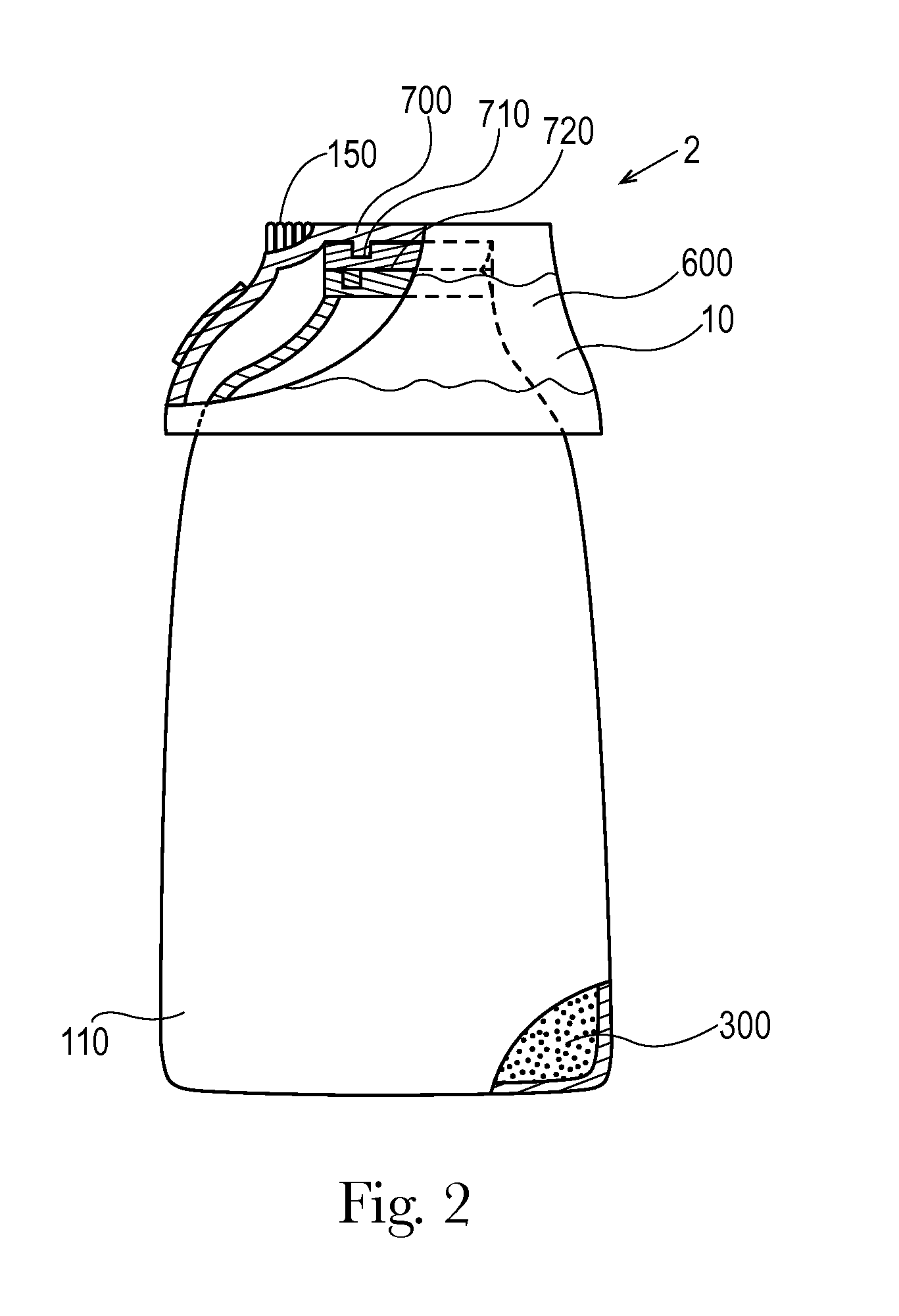

Package for a liquid laundry detergent

A package for a liquid laundry detergent composition. The package includes a container; a liquid laundry detergent composition contained in the container; and a cap removably attached to the container. The cap has a base having a base interior and a base exterior opposing the base interior, the base interior having a periphery. The cap has a vessel wall having an interior surface and an exterior surface opposing the interior surface, the vessel wall extending from the periphery to a rim and the interior surface and the base interior defining a pour volume. The base interior forms a closed end of the pour volume. The cap has an in-mold label affixed to at least a portion of the exterior surface.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com