Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

107 results about "D-Lactic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polylactic Acid Resin and Composition and Molded Article of the Same

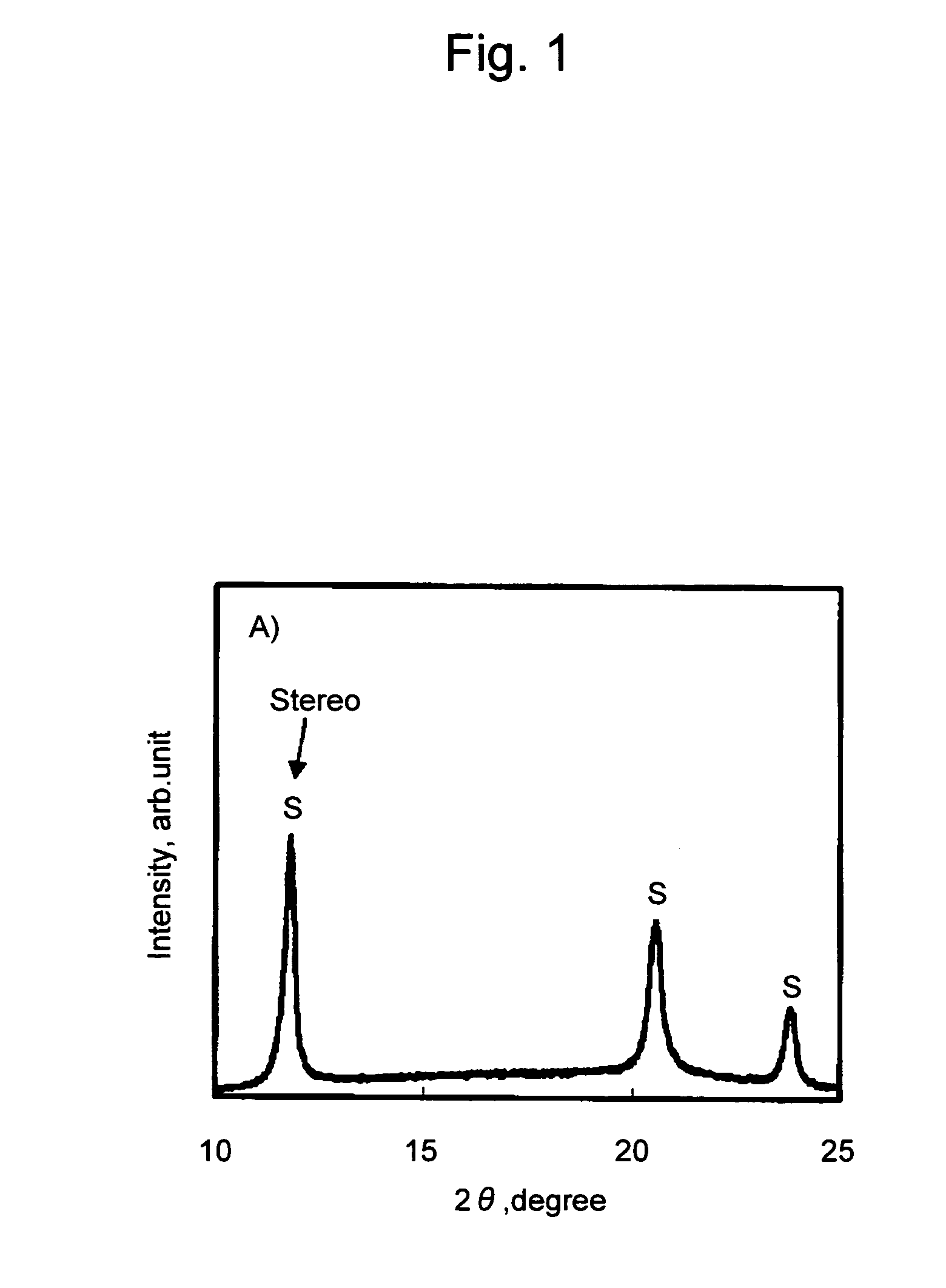

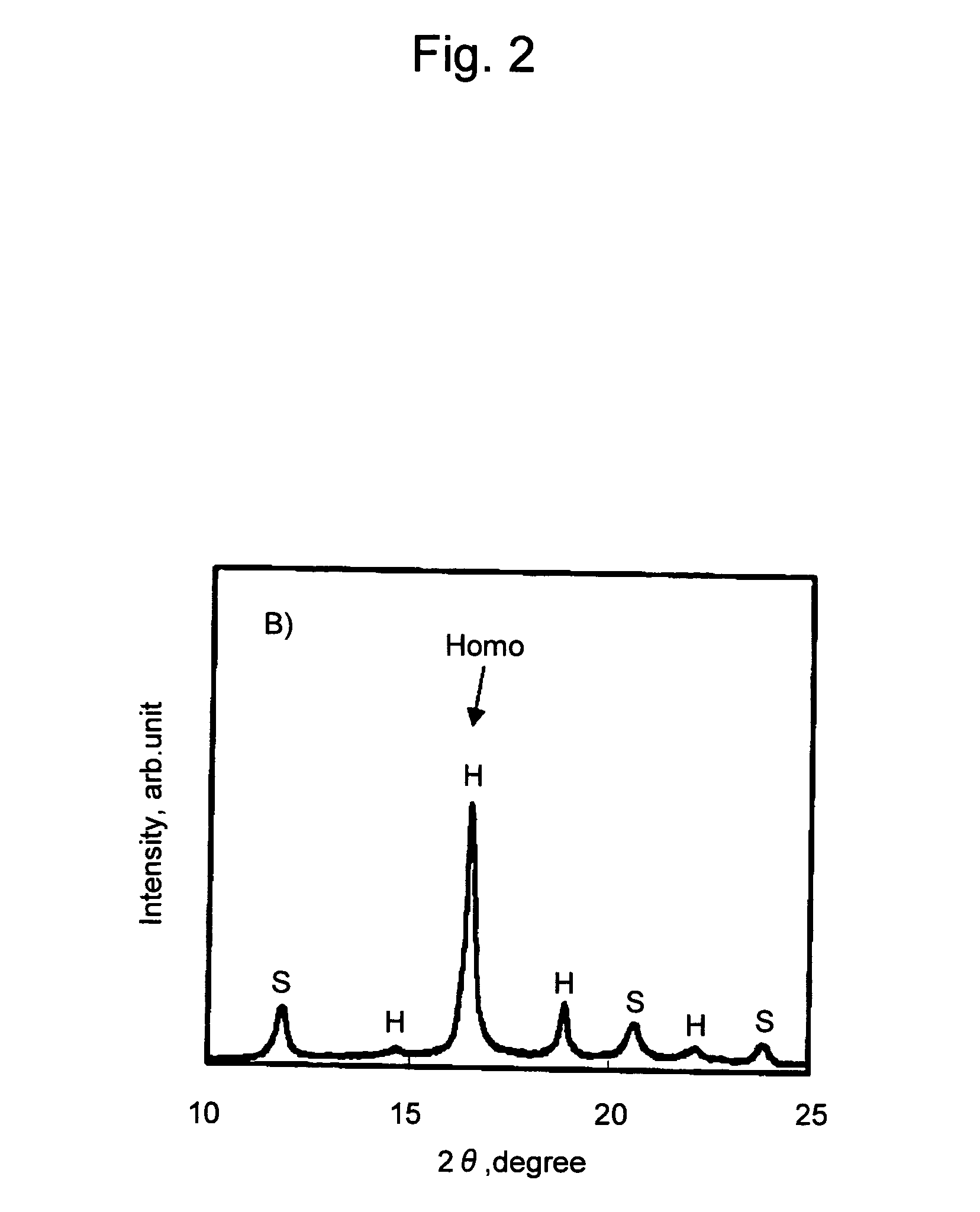

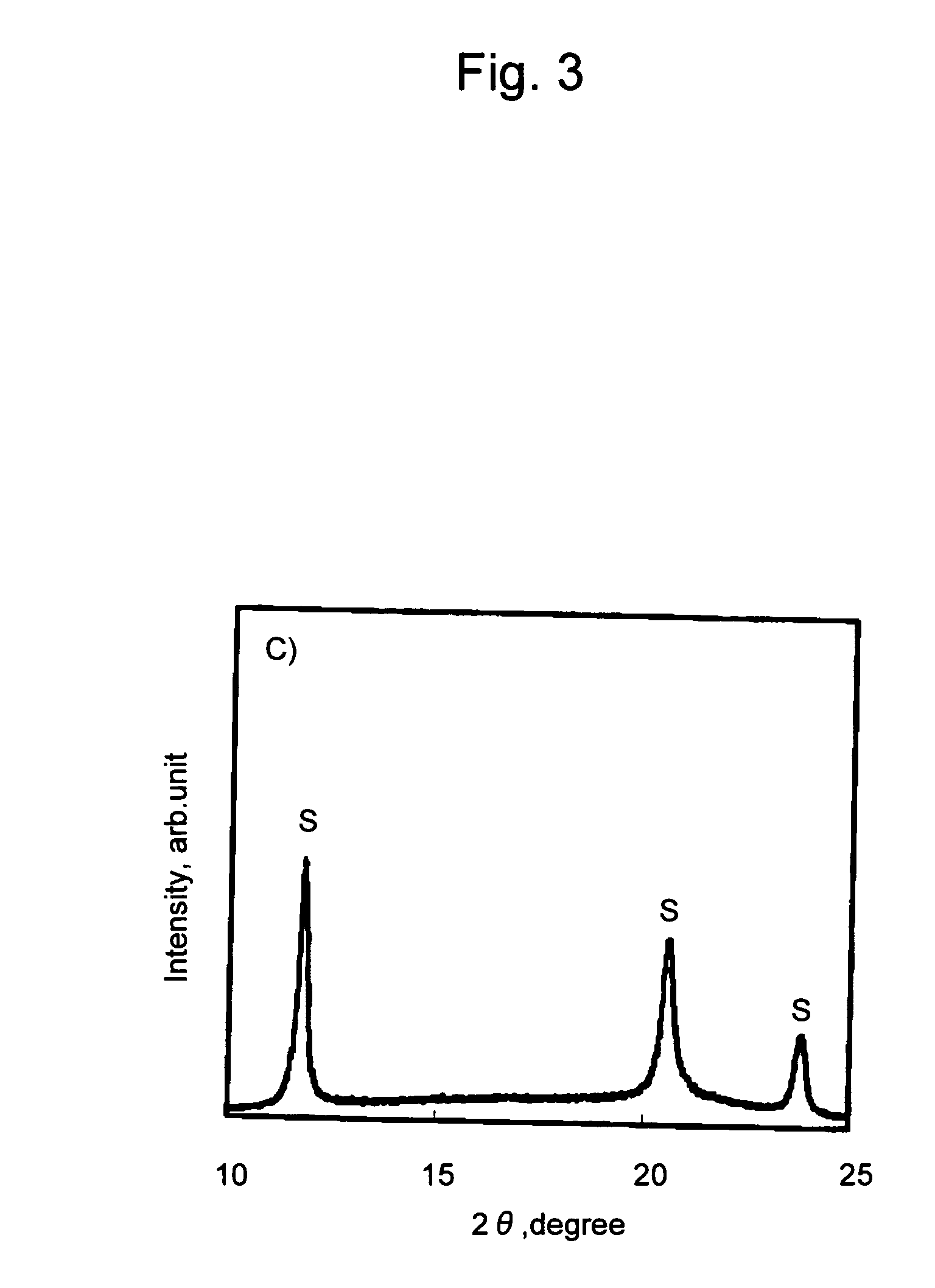

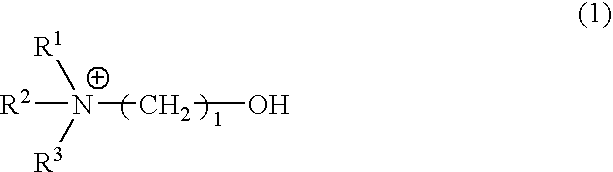

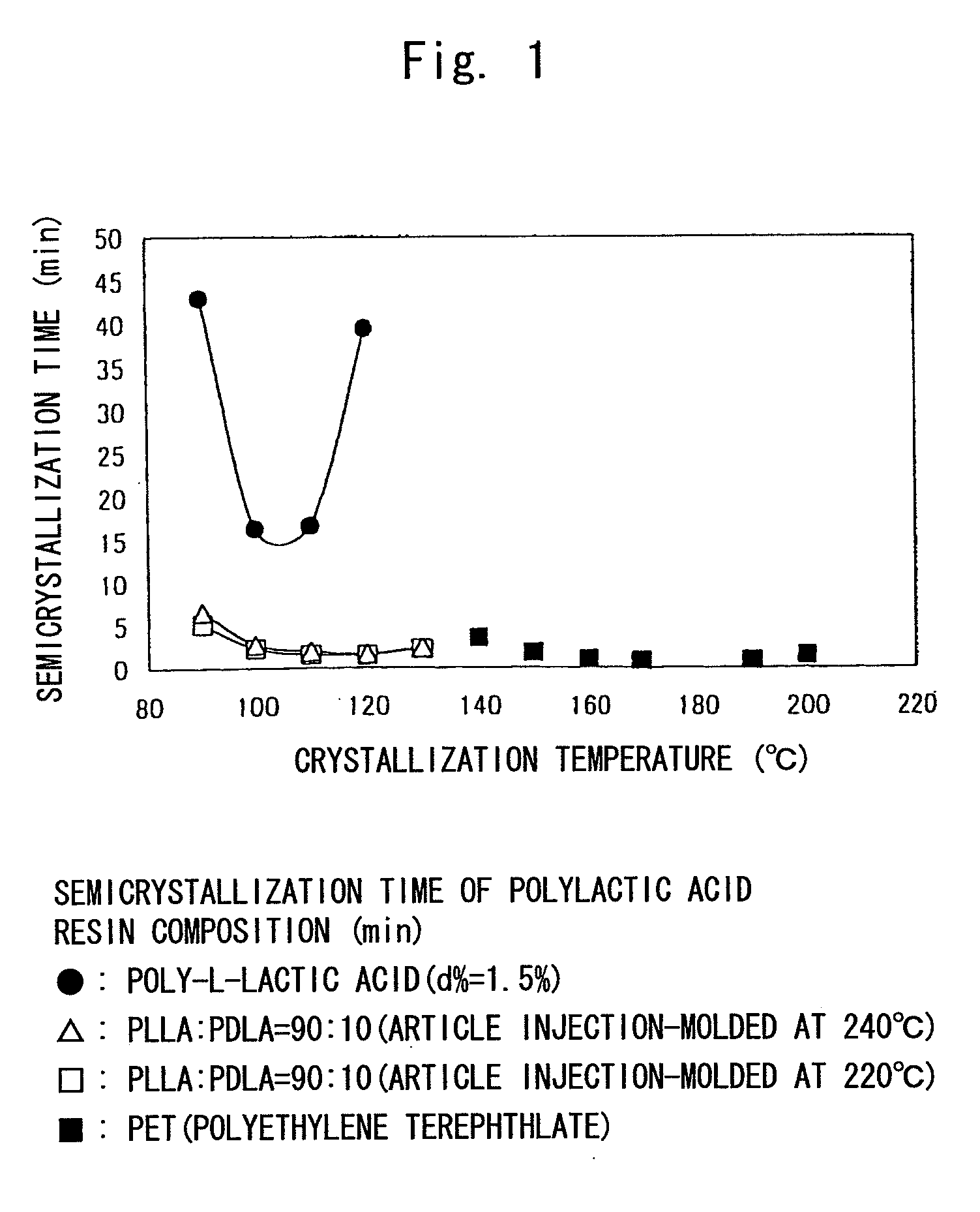

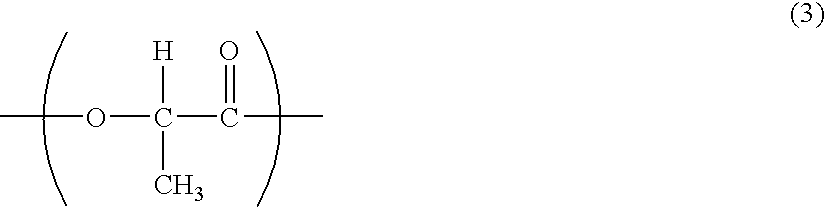

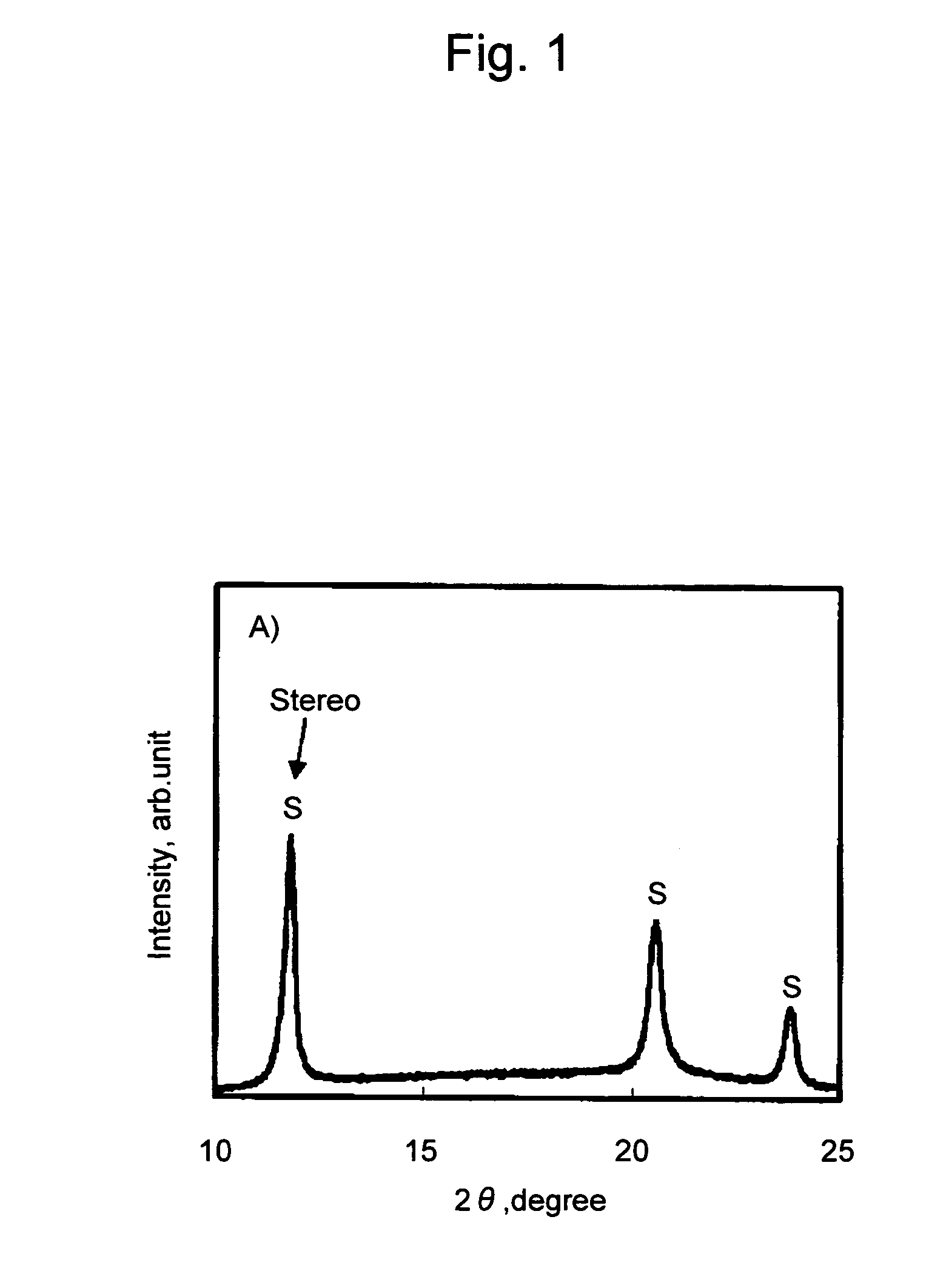

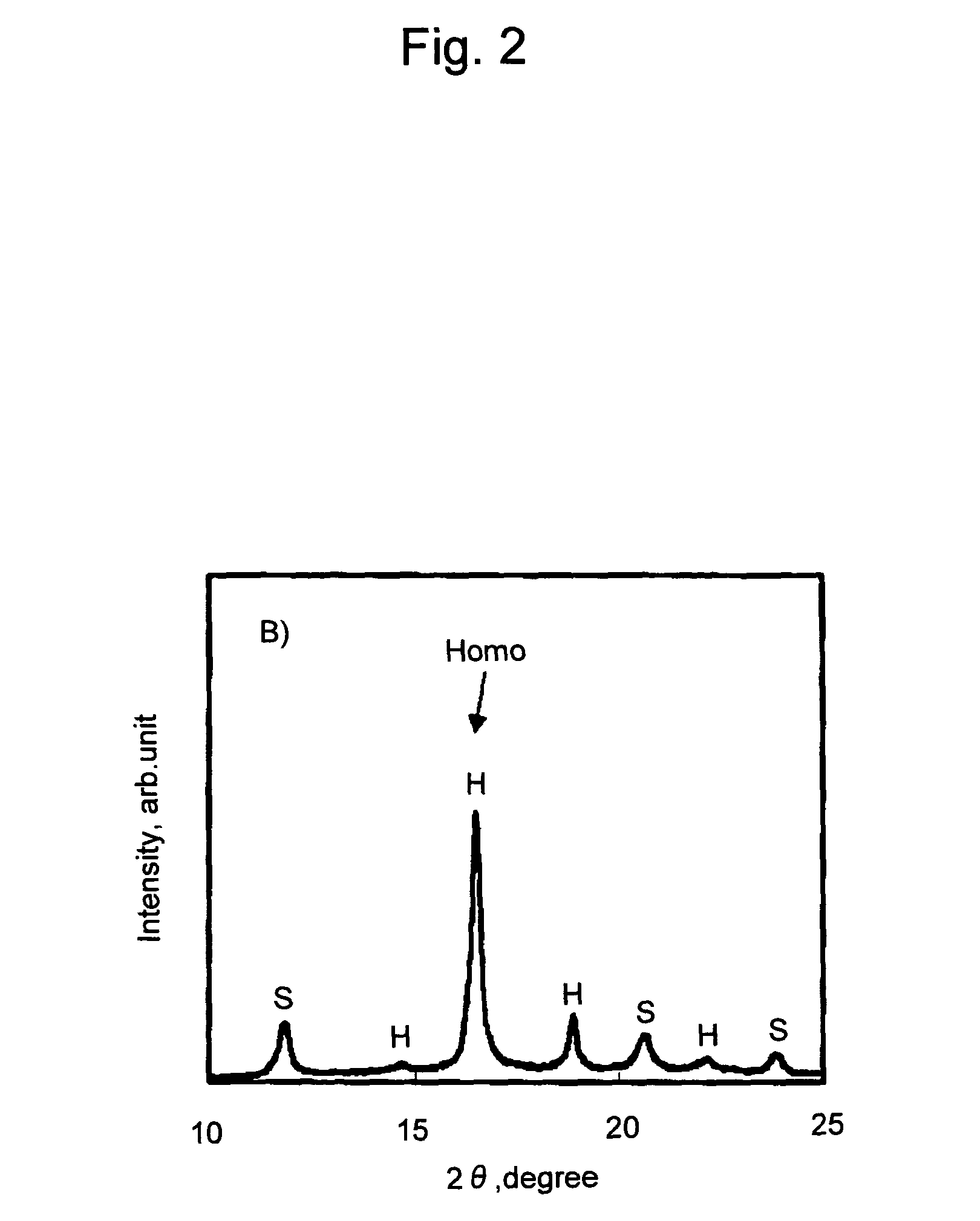

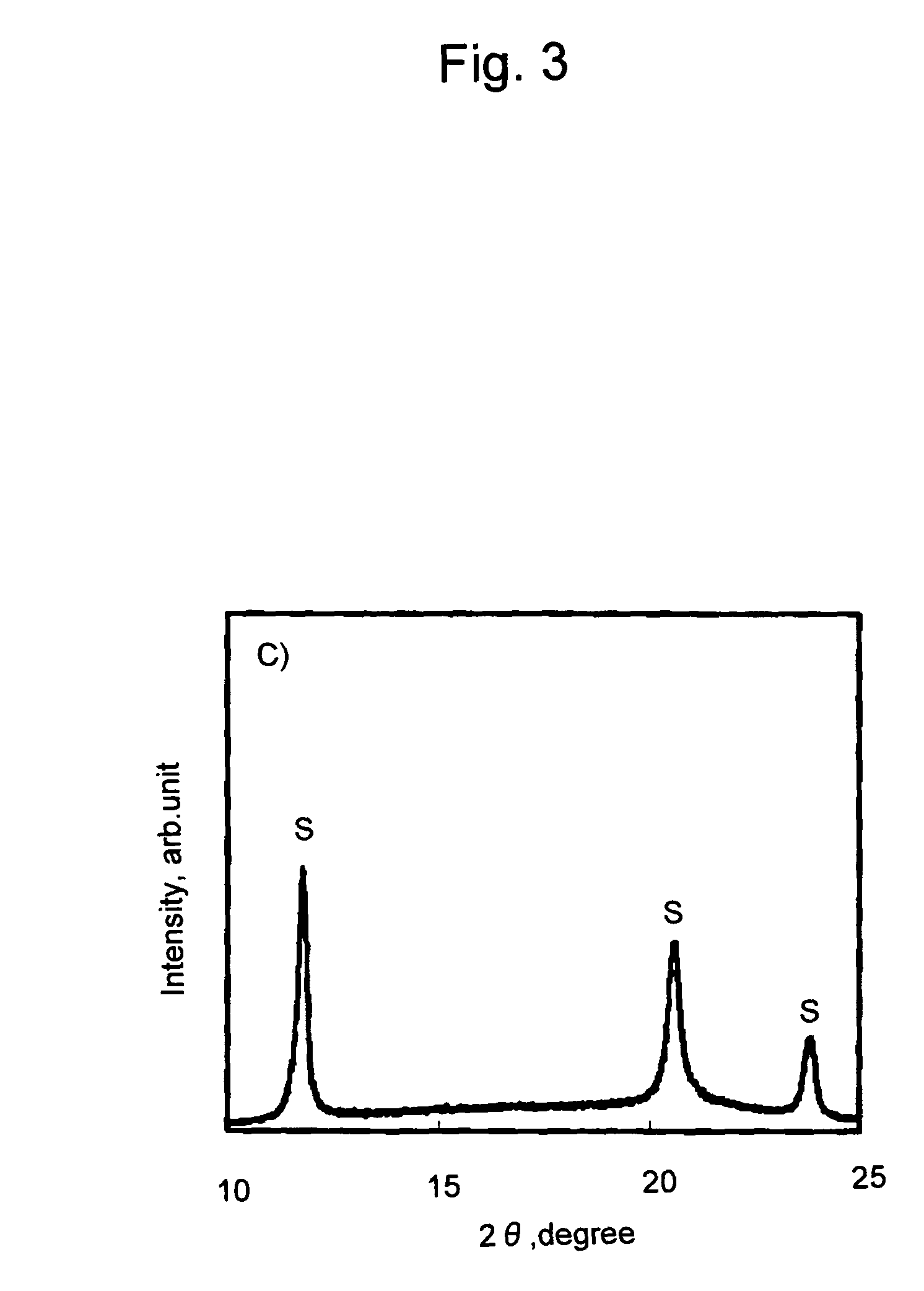

This invention provides a polylactic acid resin composition in which stereocomplex crystals of poly-L-lactic acid and poly-D-lactic acid can be selectively crystallized to obtain polylactic acid having a sufficiently high speed of crystallization and a sufficiently high ratio of stereocomplex crystal and a molded article thereof obtained via melt molding and crystallization of the same. Such polylactic acid resin composition comprises polylactic acid capable of generating stereocomplex crystallization and an aromatic urea compound represented by formula (1):wherein R1 represents an alkylene group having 1 to 10 carbon atoms; R2 represents an alkyl group having 1 to 25 carbon atoms; and m is an integer between 1 to 6.

Owner:TEIJIN LTD

Biodegradable laminated sheet

The biodegradable sheet is a laminated sheet including at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C. and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

Biaxially stretched polylactic acid multilayer film and the use thereof

Disclosed is a biaxially stretched polylactic acid multilayer film and the use thereof as packaging film. The gist of the biaxially stretched polylactic acid multilayer film resides in the construction wherein a substrate layer (1) of the biaxially stretched film comprised of polylactic acid (A) has been laminated on at least one surface thereof with a coating layer (II) of an aliphatic polyester composition (D) comprised of 97˜5% by weight of an aliphatic polyester copolymer (B) having a melting point (Tm) of 80˜120° C., a crystallizing temperature (Tc) of 35˜75° C. and a difference of (Tm)−(Tc) within the range of 35˜55° C. and comprising an aliphatic or alicyclic dicarboxylic acid component (b1), an aliphatic or alicyclic dihydroxyl compound component (b2) and a difunctional aliphatic hydroxycarboxylic acid component (b3) and 3˜95% by weight of a polylactic acid copolymer (C) containing 7˜30% by weight of D-lactic acid, a total of the ingredients (B) and (C) being 100% by weight.

Owner:TOHCELLO CO LTD (JP)

Biaxially stretched polylactic acid multilayer film and the use thereof

Disclosed is a biaxially stretched polylactic acid multilayer film and the use thereof as packaging film. The gist of the biaxially stretched polylactic acid multilayer film resides in the construction wherein a substrate layer (1) of the biaxially stretched film comprised of polylactic acid (A) has been laminated on at least one surface thereof with a coating layer (II) of an aliphatic polyester composition (D) comprised of 97˜5% by weight of an aliphatic polyester copolymer (B) having a melting point (Tm) of 80˜120° C., a crystallizing temperature (Tc) of 35˜75° C. and a difference of (Tm)−(Tc) within the range of 35˜55° C. and comprising an aliphatic or alicyclic dicarboxylic acid component (b1), an aliphatic or alicyclic dihydroxyl compound component (b2) and a difunctional aliphatic hydroxycarboxylic acid component (b3) and 3˜95% by weight of a polylactic acid copolymer (C) containing 7˜30% by weight of D-lactic acid, a total of the ingredients (B) and (C) being 100% by weight.

Owner:TOHCELLO CO LTD (JP)

Biodegradable laminated sheet

ActiveUS20060286373A1Promote crystallizationOvercome lack of heat resistanceSynthetic resin layered productsBoxesVitrificationPolyester resin

The biodegradable sheet is a laminated sheet including at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C. and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

Polylactic acid stretched film

InactiveUS7993745B2Transparency and heat resistanceSynthetic resin layered productsGlass/slag layered productsHeat resistancePolylactic acid

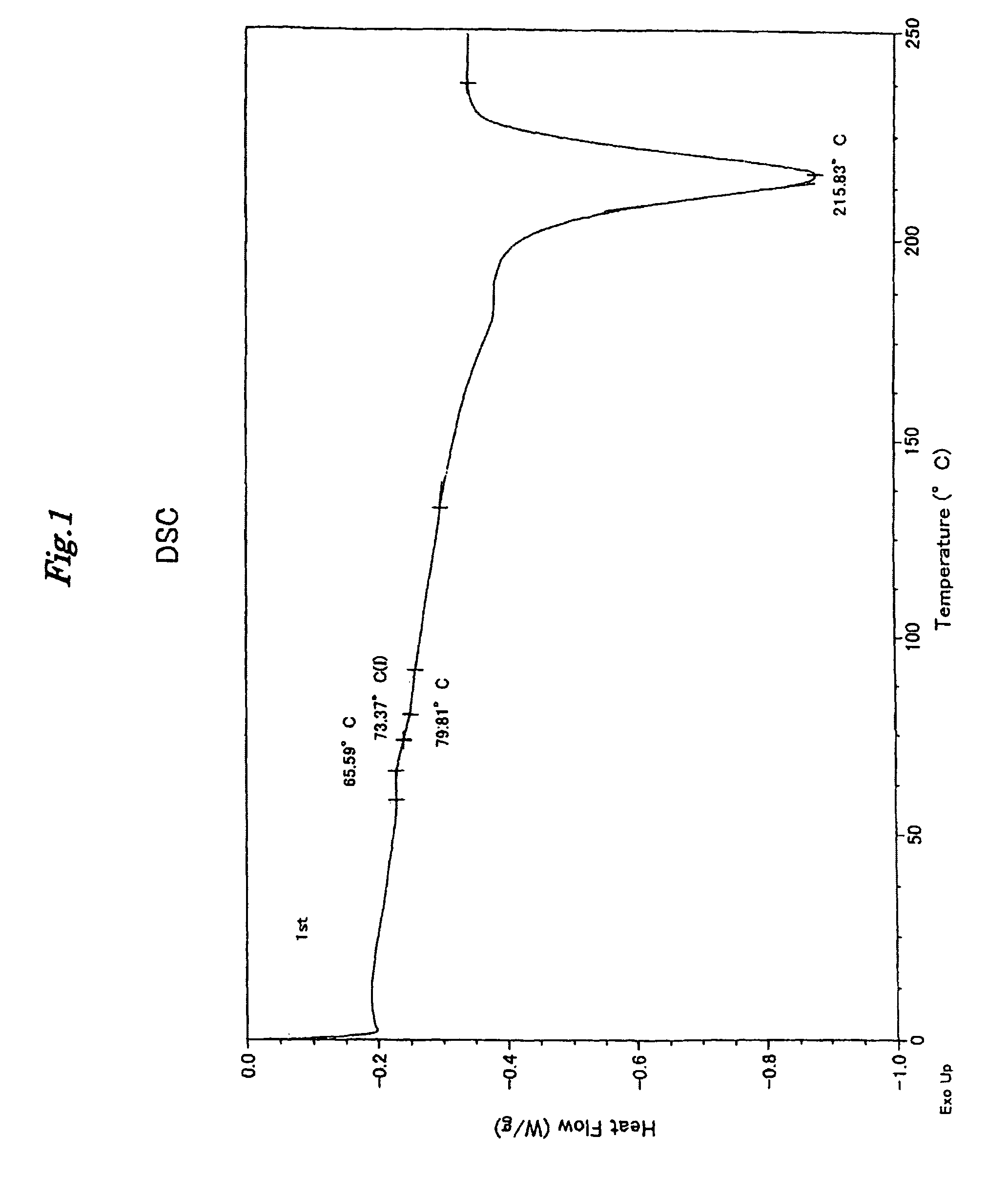

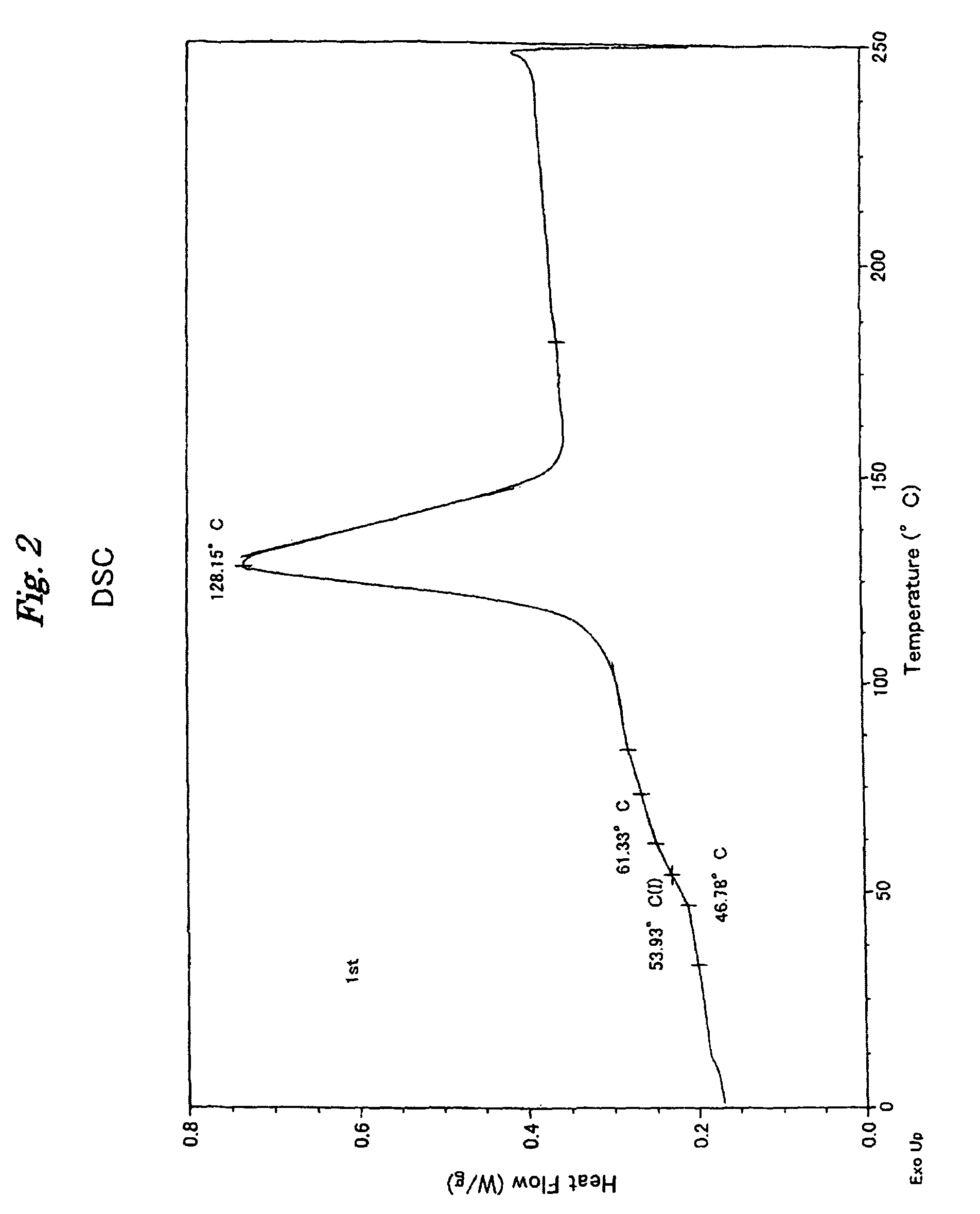

The object of the present invention is to provide a polylactic acid stretched film having biodegradability and excelling in transparency and heat resistance. The main feature is characterized in that a polylactic acid stretched film is composed of a polylactic acid composition containing poly-L-lactic acid and poly-D-lactic acid in which a peak ratio (peak 1 / peak 2) of a peak height (peak 1) of a maximum endothermic peak of endothermic peaks within a range of 150 to 200° C. to a peak height (peak 2) of a maximum endothermic peak of endothermic peaks within a range of 205 to 240° C. in DSC measurements is equal to or less than 0.2.

Owner:TOHCELLO CO LTD (JP)

Polylactic acid resin composition, process for producing the same and molding thereof

There are provided a polylactic acid resin composition in which stereocrystals of poly-L-lactic acid and poly-D-lactic acid can be selectively crystallized to obtain polylactic acid having a sufficiently high stereocrystals ratio, a process for producing the same, and a polylactic acid molded article obtained from the same having a sufficiently high stereocrystals ratio. The polylactic acid resin composition is characterized by comprising a polylactic acid-lamellar clay mineral bonded body consisting of a lamellar clay mineral and one of poly-L-lactic acid and poly-D-lactic acid which is bonded to the lamellar clay mineral, and the other of poly-L-lactic acid and poly-D-lactic acid which is not bonded to the lamellar clay mineral.

Owner:TOYOTA JIDOSHA KK

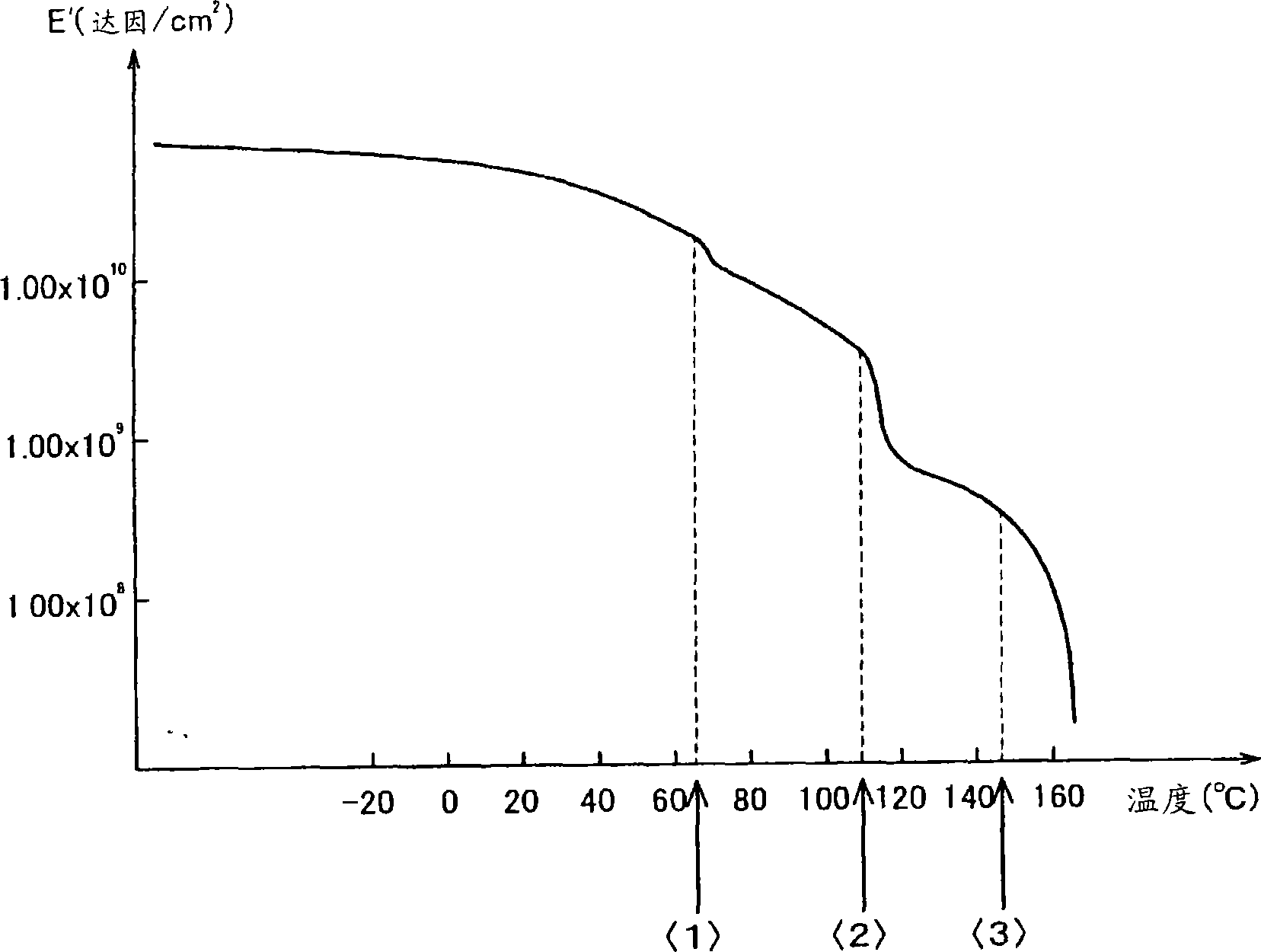

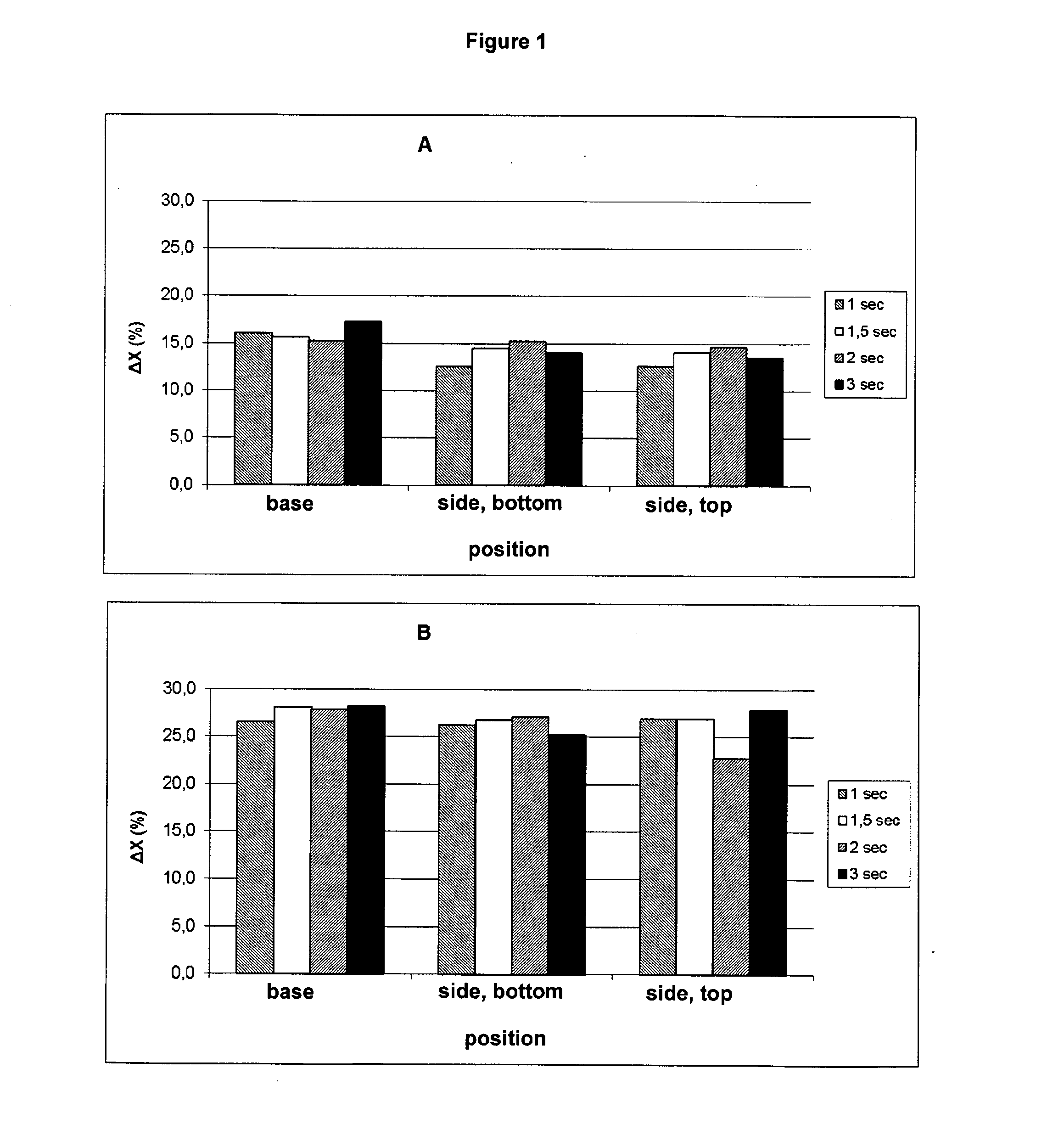

Heat-shrinkable film, molded product and heat-shrinkable label employing the film, and container employing the molded product or having the label fitted thereon

ActiveUS20100143623A1Excellent heat-shrinkable property propertyImprove impact resistanceWrappers shrinkageSynthetic resin layered productsPolyolefinPolymer science

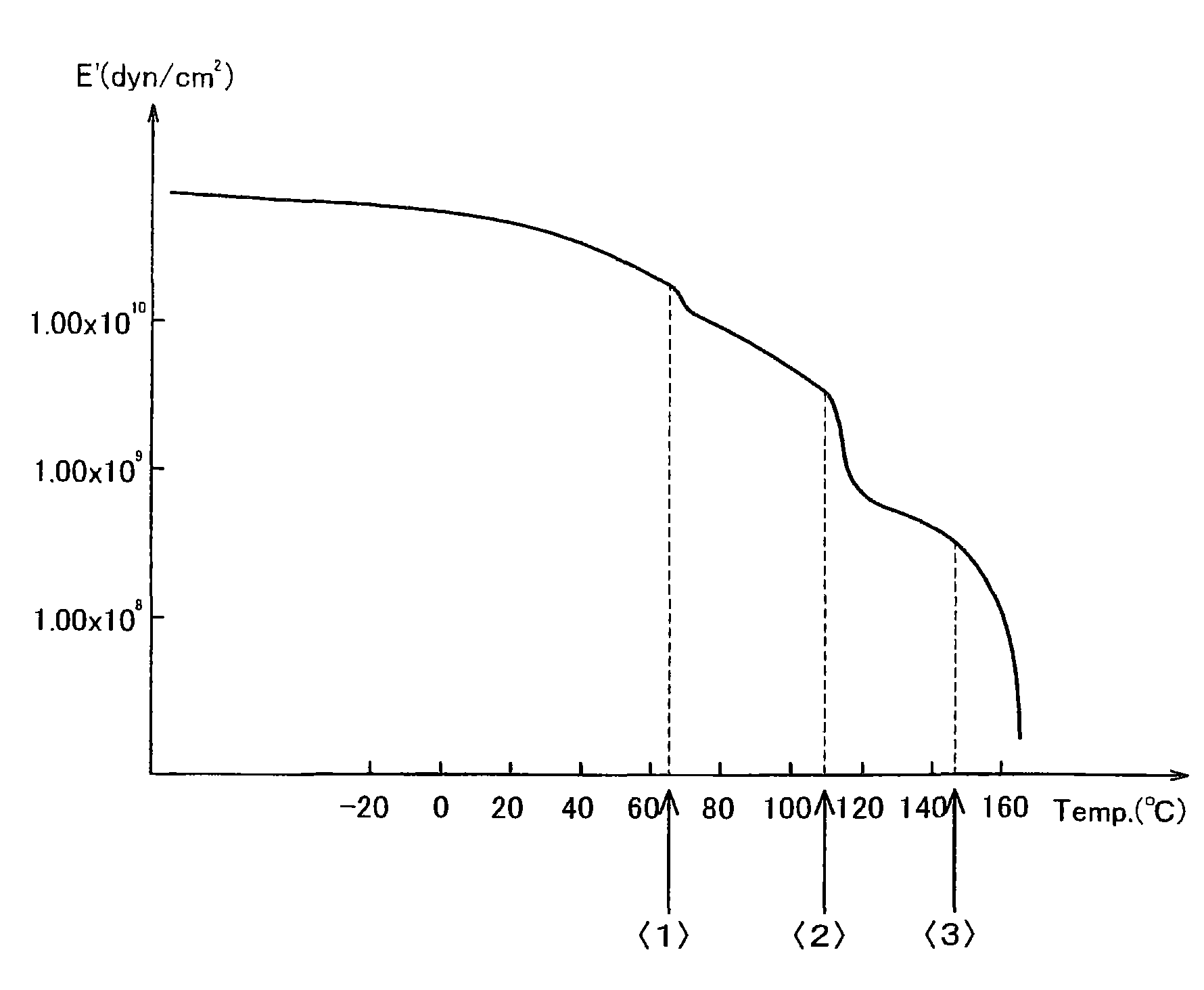

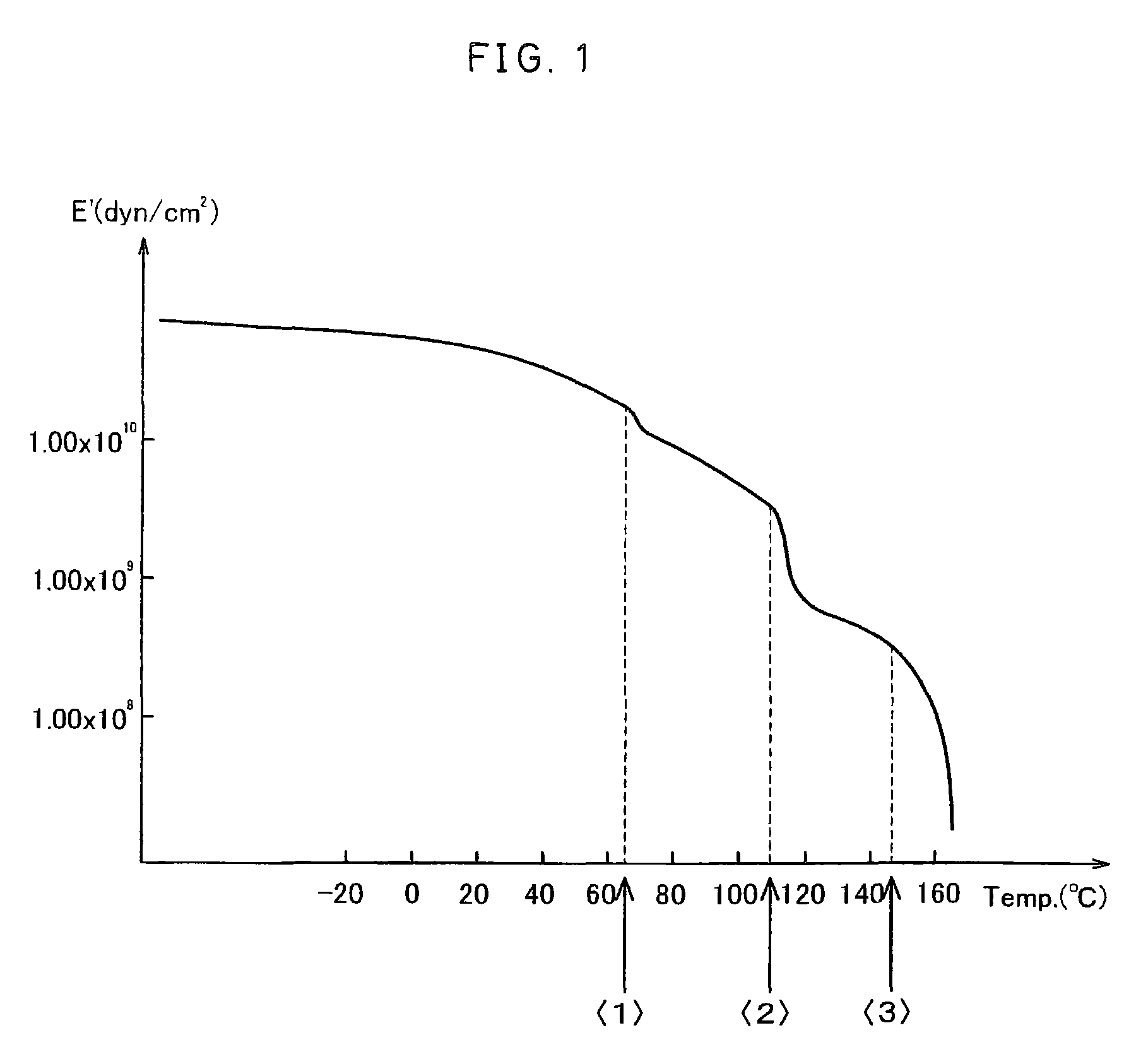

The present invention provide a heat-shrinkable film consisting of a layer or comprising at least one layer, wherein the layer is made of a mixed resin containing a polylactic acid resin and a polyolefin resin as the main components, wherein mass ratio of the polylactic acid resin and the polyolefin resin is 95 / 5 to 50 / 50 by mass, the polylactic acid resin being a copolymer of D-lactic acid and L-lactic acid or a mixed resin of the copolymer, wherein D / L ratio of D-lactic acid and L-lactic acid is 3 / 97 to 15 / 85 or 85 / 15 to 97 / 3, the storage elastic modulus (E′) of the polyolefin resin or the soft acrylic resin at 20 degree C. being 100 MPa or less as measured at an oscillation frequency of 10 Hz and a strain of 0.1%, the film being stretched in at least one direction, and the heat shrinkage ratio of the film in the main shrinking direction being 20% or more as measured after the film is immersed in hot water of 80 degree C. for 10 seconds.The heat-shrinkable film exhibits excellent heat-shrinkable property, impact resistance, transparency, mechanical property, and shrink finishing quality; it is applicable to shrinkable packing, shrinkable bond-packing, shrinkable label and the like.

Owner:MITSUBISHI CHEM CORP

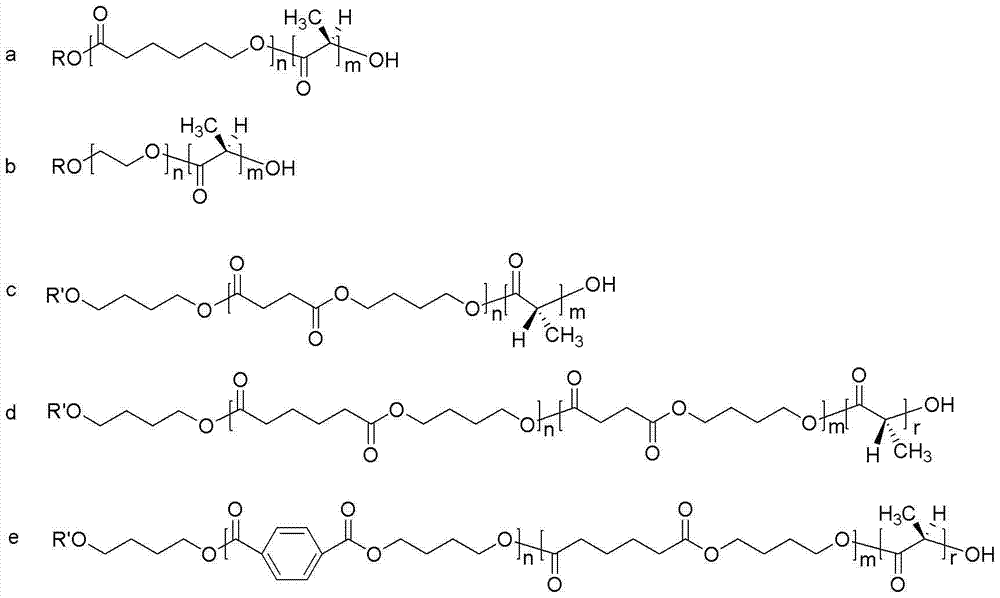

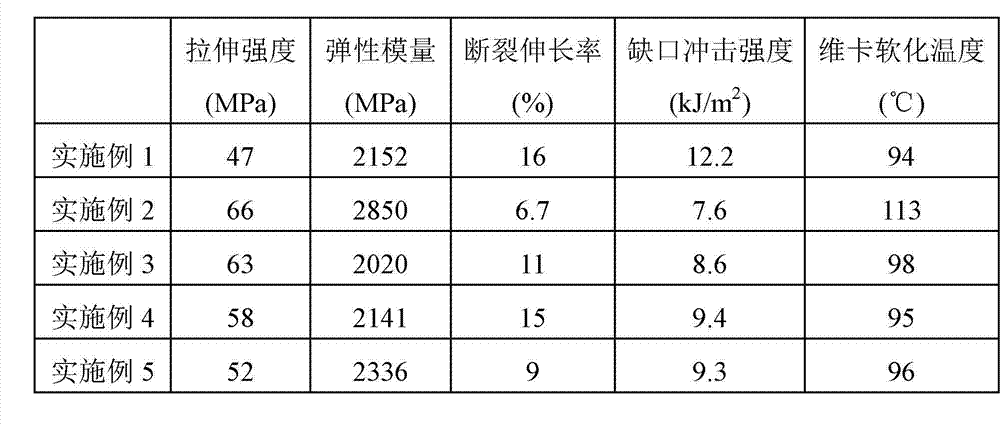

Polylactic resin composition with high heat resistance and high flexibility and preparation method of composition

InactiveCN102924892AHigh heat resistance and high toughnessImprove toughnessPolymer scienceHeat resistance

The invention discloses a polylactic resin composition with high heat resistance and high flexibility and a preparation method of the composition, solving the problem that polylactic resin with high heat resistance and high flexibility does not exist in the prior art. The polylactic resin composition consists of the following components in parts by weight: 50 to 99.5 weight parts of poly-L-lactic acid homopolymer and 0.5 to 50 weight parts of poly-D-lactic acid copolymer, wherein the poly-D-lactic acid copolymer is prepared from poly-D-lactic acid and a polymer with a flexible chain structure. The invention also provides the preparation method of the polylactic resin composition with high heat resistance and high flexibility. The preparation method is simple and suitable for industrialized production; and the prepared polylactic resin composition has high flexibility and heat resistance, the elongation at break reaches 16 percent, the notch impact strength reaches 12.2kJ / m<2>, and the vicat softening temperature reaches 113 DEG C.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

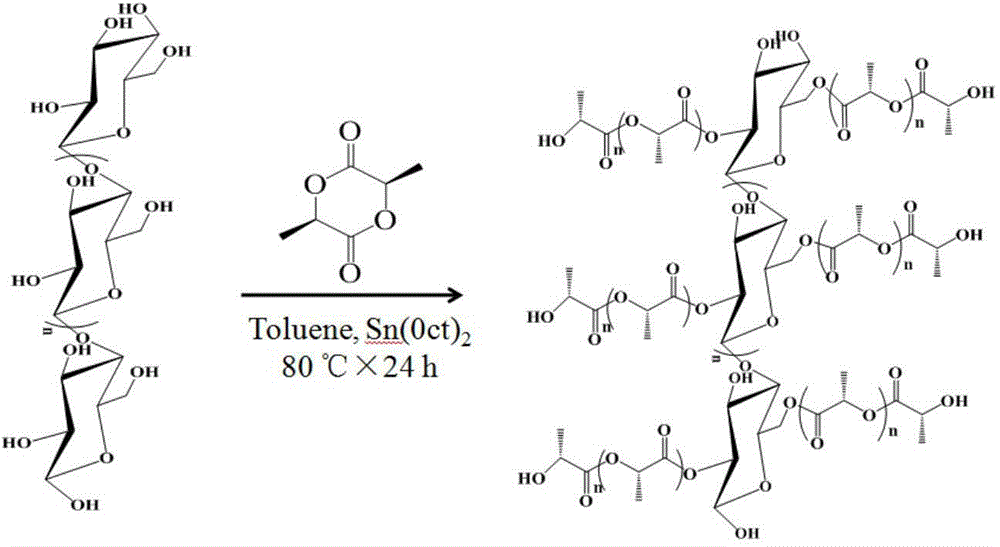

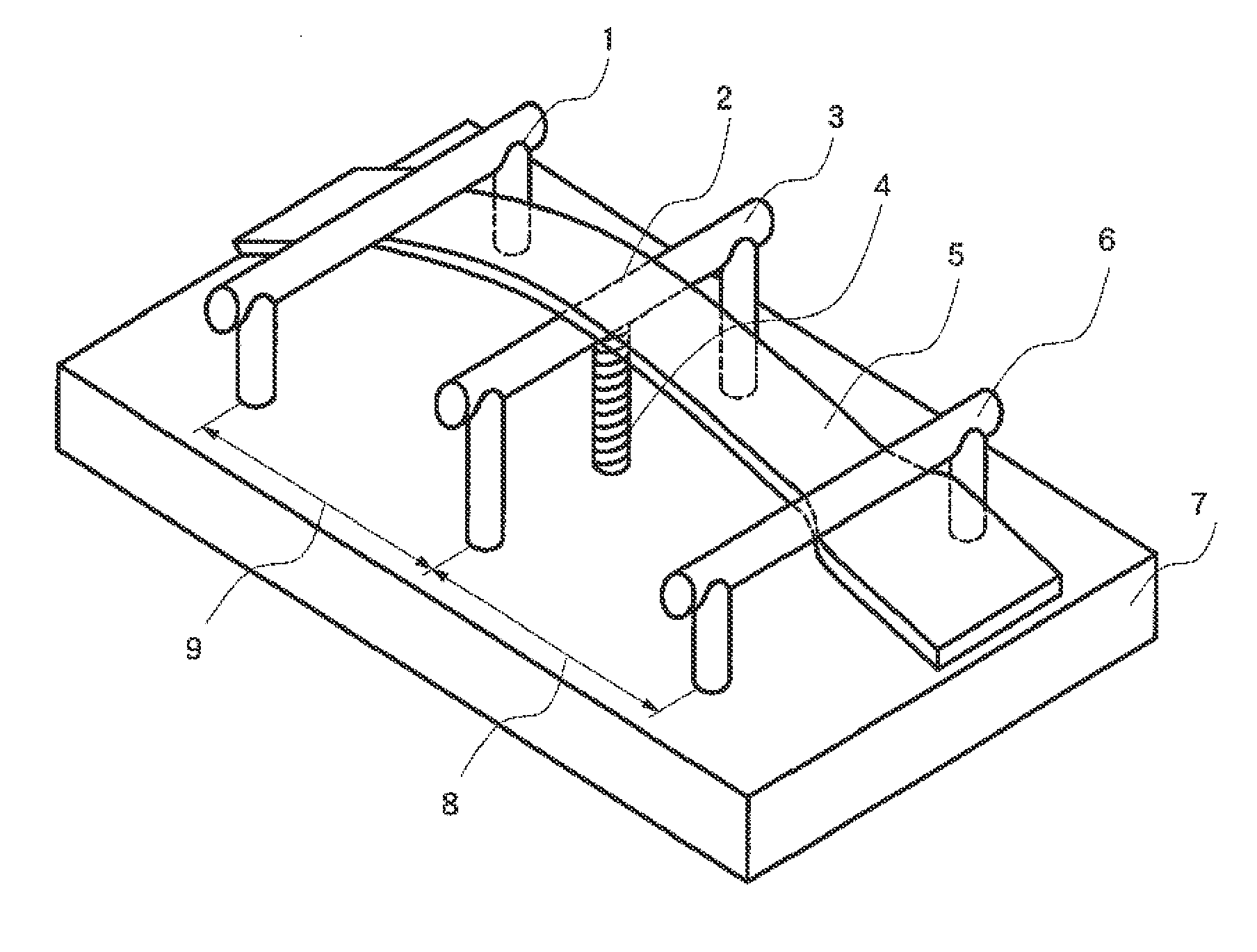

Method for rapidly forming polylactic acid stereocomplex

The invention discloses a method for rapidly forming a polylactic acid stereocomplex. The method comprises the following steps of performing solution mixing on poly-D-lactic acid and nanocellulose-grafted poly-L-lactic acid with a comb structure or on poly-L-lactic acid and poly-D-lactic acid with a comb structure in parts by weight, and removing a solvent to prepare the polylactic acid stereocomplex. A high-content polylactic acid stereocomplex can be rapidly formed at 130 to 200 DEG C after the stereocomplex is molten at 230 to 260 DEG C, the components of the polylactic acid stereocomplex are renewable resources, and the method is simple in process and easy to industrialize.

Owner:JIANGNAN UNIV

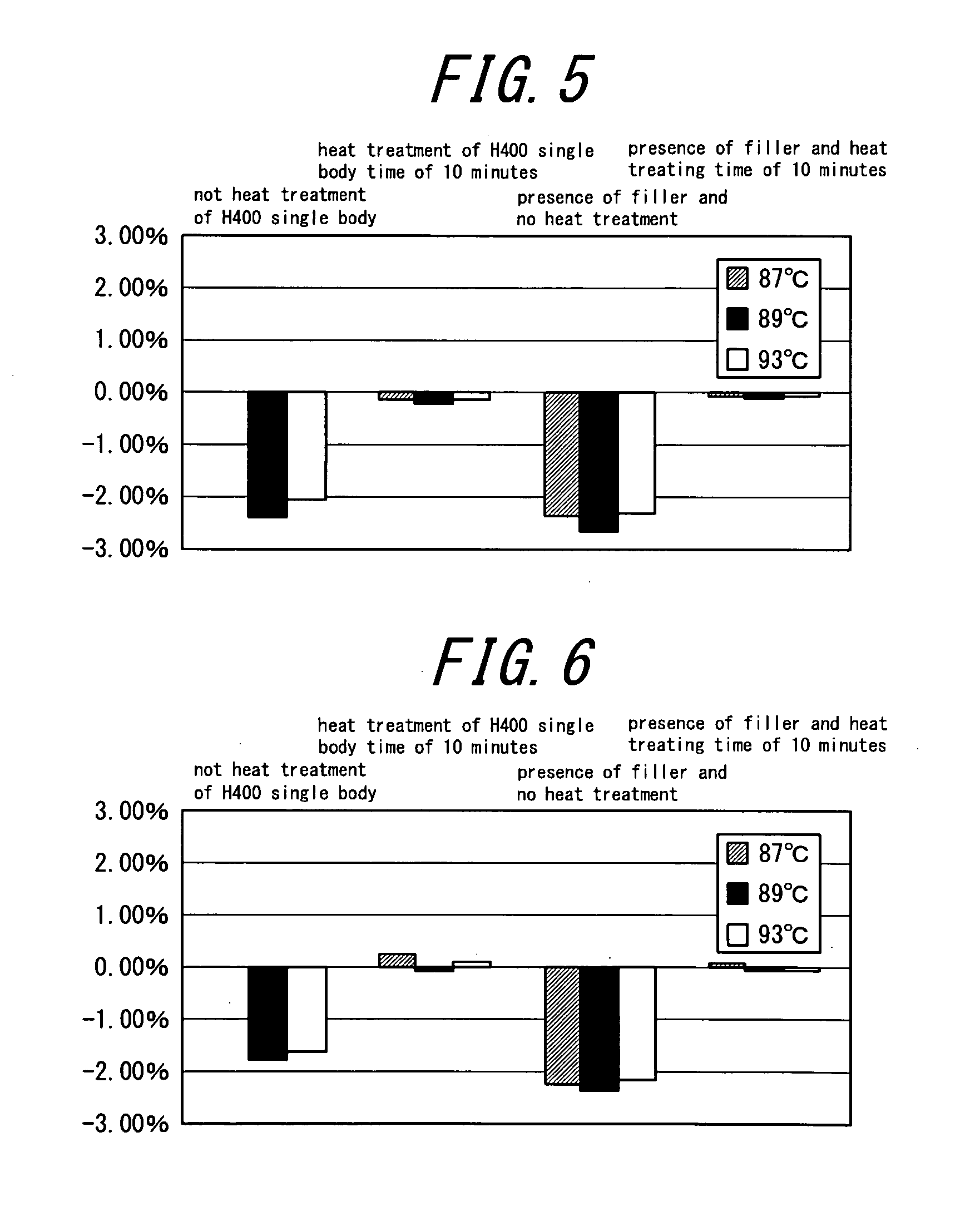

Biodegradable stretch mold container having excellent heat resistance

ActiveUS20090186178A1Improve heat resistanceFast heat-crystallization timeSynthetic resin layered productsThin material handlingPolymer scienceHeat resistance

A stretch mold container of the present invention is obtained by draw-forming a resin composition containing a poly-L-lactic acid (A) and a poly-D-lactic acid (B) at a molar ratio A:B in a range of 95:5 to 60:40, and has an amount of heat shrinkage of 5.0% or less under heat treatment conditions of 65° C.×24 hours. Despite of being made from the polylactic acids, the stretch mold container exhibits excellent heat resistance.

Owner:TOYO SEIKAN KAISHA LTD

Polylactic acid stretched film

InactiveUS20090318631A1Excels in heat resistanceExcels in transparencySynthetic resin layered productsGlass/slag layered productsHeat resistancePolylactic acid

The object of the present invention is to provide a polylactic acid stretched film having biodegradability and excelling in transparency and heat resistance. The main feature is characterized in that a polylactic acid stretched film is composed of a polylactic acid composition containing poly-L-lactic acid and poly-D-lactic acid in which a peak ratio (peak 1 / peak 2) of a peak height (peak 1) of a maximum endothermic peak of endothermic peaks within a range of 150 to 200° C. to a peak height (peak 2) of a maximum endothermic peak of endothermic peaks within a range of 205 to 240° C. in DSC measurements is equal to or less than 0.2.

Owner:TOHCELLO CO LTD (JP)

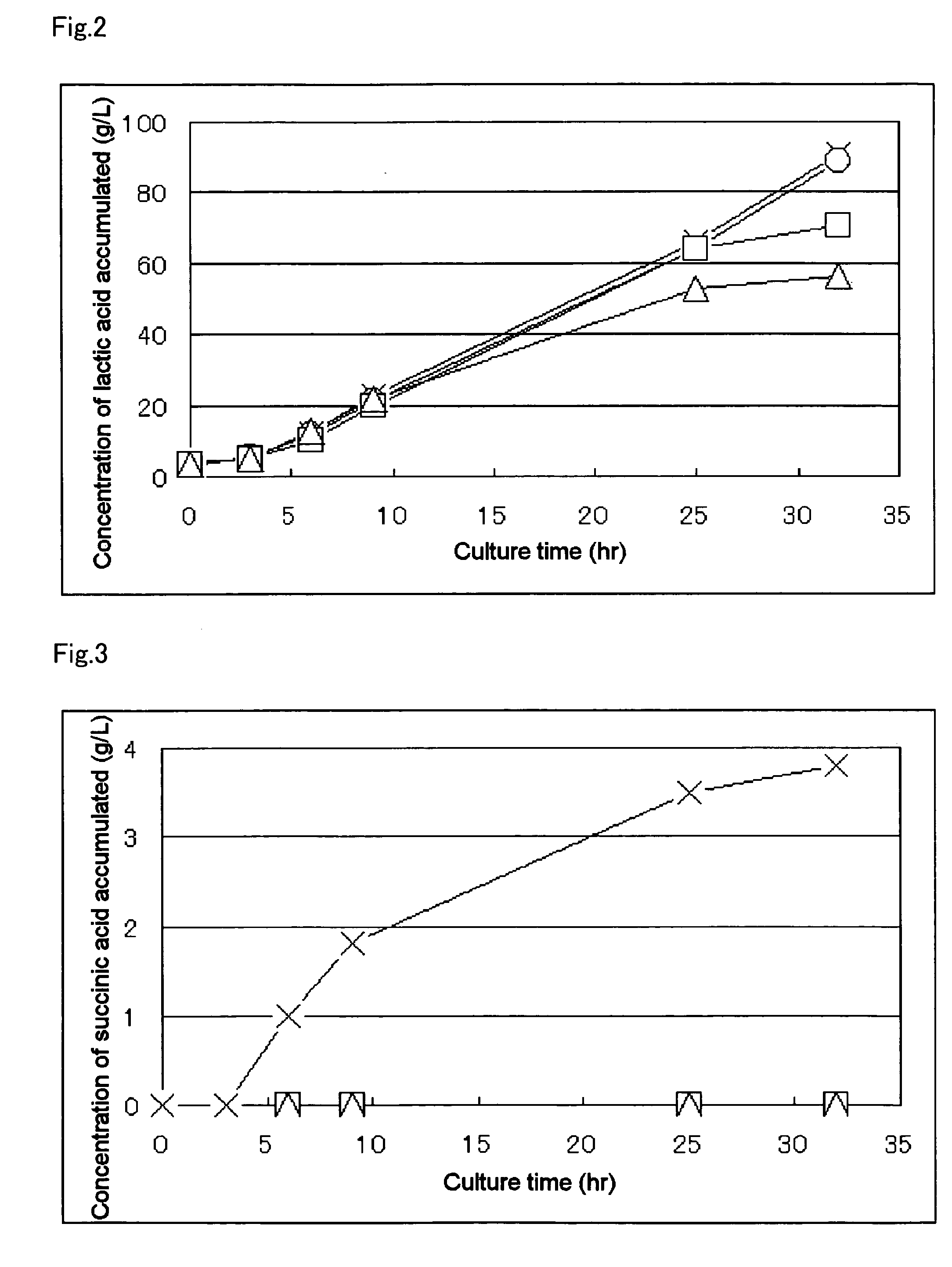

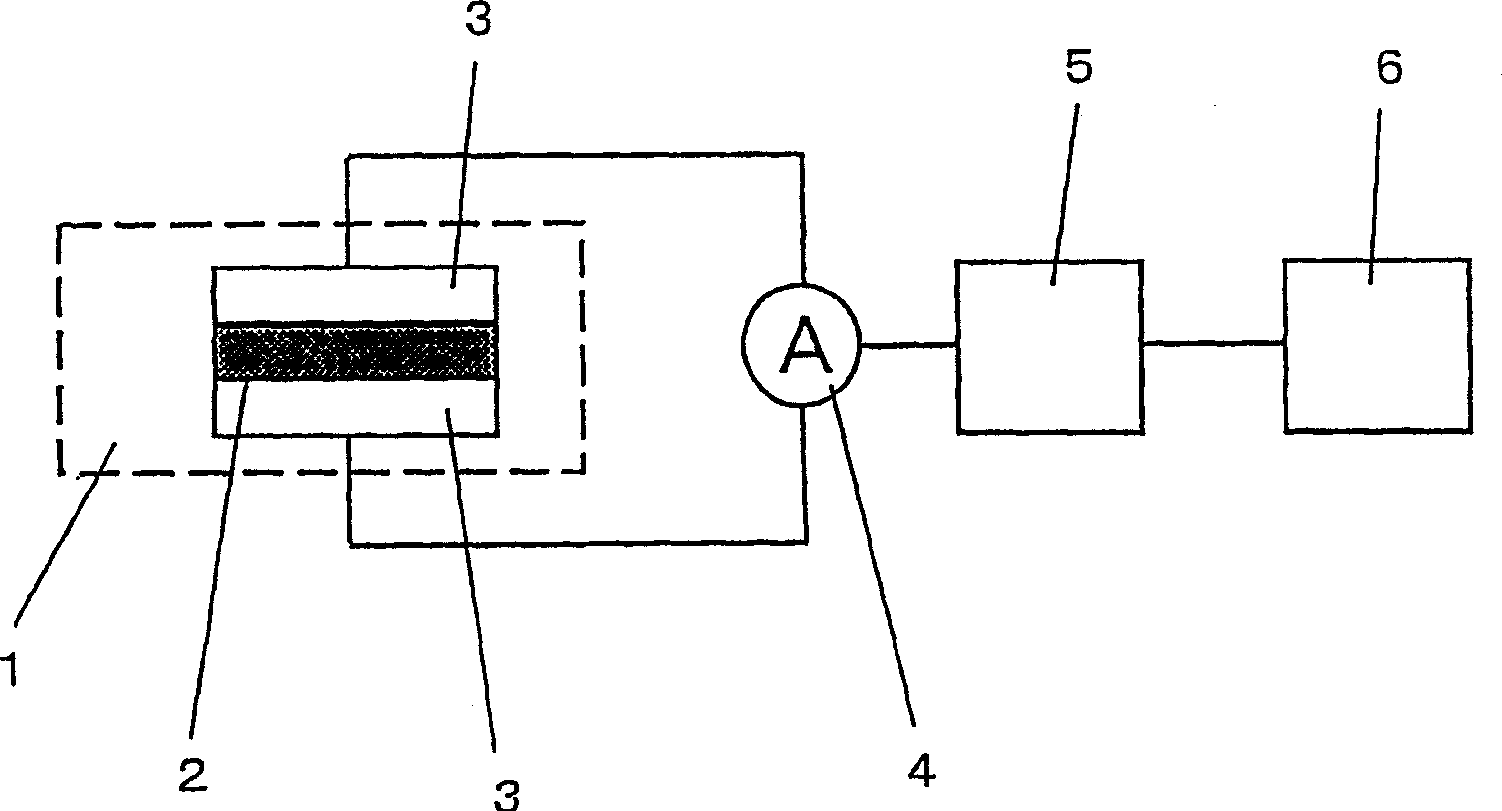

Biocatalyst for production of d-lactic acid (as amended)

ActiveUS20070065930A1Increase productivityHigh selectivityBacteriaFermentationEscherichia coliD-lactate dehydrogenase

A method for producing D-lactic acid in high yield, and to provide a method for producing D-lactic acid with high selectivity, in which optical purity is high and a by-product organic acid is small. In one aspect, a microorganism, wherein activity of pyruvate formate-lyase (pfl) is inactivated or decreased, and further activity of Escherichia coli-derived NADH-dependent D-lactate dehydrogenase (ldhA) is enhanced, is cultured to efficiently produce D-lactic acid. With regard to a method for enhancing ldhA activity, by linking, on a genome, a gene encoding ldhA with a promoter of a gene which controls expression of a protein involved in a glycolytic pathway, a nucleic acid biosynthesis pathway or an amino acid biosynthesis pathway, suitable results are obtained compared to the method for enhancing expression of the gene using an expression vector. A microorganism in which a dld gene is substantially inactivated or decreased is cultured to produce high quality D-lactic acid with reduced concentration of pyruvic acid.

Owner:MITSUI CHEM INC

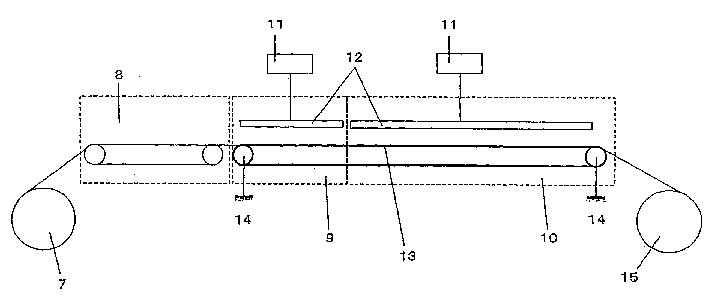

Electret filter and process for producing the same

InactiveCN1658944ADispersed particle filtrationUltrasonic/sonic fibre treatmentVitrificationPolymer science

It is intended to provide an electret filter which has a large surface charge density, sustains stable electret properties over a long time even in a high-temperature atmosphere and yet degrades to reduce its volume when buried for disposal; and a process for producing the same. The molar ratio of an L-lactic acid monomer to a D-lactic acid monomer ranges from 100 to 85 : 0 to 15 or 0 to 15 : 85 to 100. An electret filter having a surface charge density of 1.2x10<-9> C / cm<2> or more can be obtained by crystallizing by heating at a temperature from the glass transition temperature to the melting point and then, while heating to 60 to 140 DEG C, applying a direct current corona electrical field to thereby cool to 40 DEG C or lower under.

Owner:TOYOBO CO LTD

Resin composition and molded article

A resin composition comprising an aromatic polyester having a butylene terephthalate skeleton as the main constituent unit (component A), polylactic acid comprising poly(L-lactic acid) and poly(D-lactic acid) (component B), and a modifier (component C), whereinthe resin composition has (i) a crystal melting peak of stereocomplex-phase polylactic acid at 190° C. or higher in differential scanning calorimeter measurement, (ii) a biomass ratio of not less than 50%, (iii) a notched Izod impact strength of 4 to 15 kJ / m2 and (iv) a flexural modulus of 2.5 to 6 GPa.The resin composition provides a molded article having excellent impact resistance and stiffness. The resin composition has a biomass ratio of not less than 50%. The resin composition has a low moisture absorptivity, hydrolysis resistance and high-speed moldability. The resin composition provides a molded article having excellent heat resistance.

Owner:TEIJIN LTD +1

Heat-shrinkable film, molded product and heat-shrinkable label employing the film, and container employing the molded product or having the label fitted thereon

ActiveUS8420193B2Low environmental burdenMaintain good propertiesWrappers shrinkageShrinkage connectionsPolyolefinAcrylic resin

A heat-shrinkable film having a layer made of a mixed resin containing a polylactic acid resin and a polyolefin resin as the main components, wherein the mass ratio of the polylactic acid resin and the polyolefin resin is 95 / 5 to 50 / 50, the polylactic acid resin is a copolymer of D-lactic acid and L-lactic acid or a mixed resin of the copolymer, the D / L ratio of D-lactic acid and L-lactic acid is 3 / 97 to 15 / 85 or 85 / 15 to 97 / 3, the storage elastic modulus of the polyolefin resin or the soft acrylic resin at 20° C. is ≦100 MPa as measured at an oscillation frequency of 10 Hz and a strain of 0.1%, the film is stretched in at least one direction, and the heat shrinkage ratio of the film in the main shrinking direction is ≧20% as measured after the film is immersed in 80° C. water for 10 seconds.

Owner:MITSUBISHI CHEM CORP

Preparation method of food-grade full-degradable high-temperature-resistant polylactic acid composite material

The invention discloses a preparation method of a food-grade full-degradable high-temperature-resistant polylactic acid composite material, and belongs to the field of biodegradable high polymer materials. The composite material comprises, by weight, 100 parts of poly-l-lactic acid (PLLA), 1-10 parts of poly-d-lactic acid (PDLA) and 0.5-1 part of functional additives. Compared with traditional petroleum-based high polymer materials, the composite material has the advantages of being easy to degrade and renewable; compared with common polylactic acid, the composite material has excellent heat resistance. Thus, the polylactic acid composite material can be applied to high-temperature-resistant food packages.

Owner:CHANGZHOU UNIV

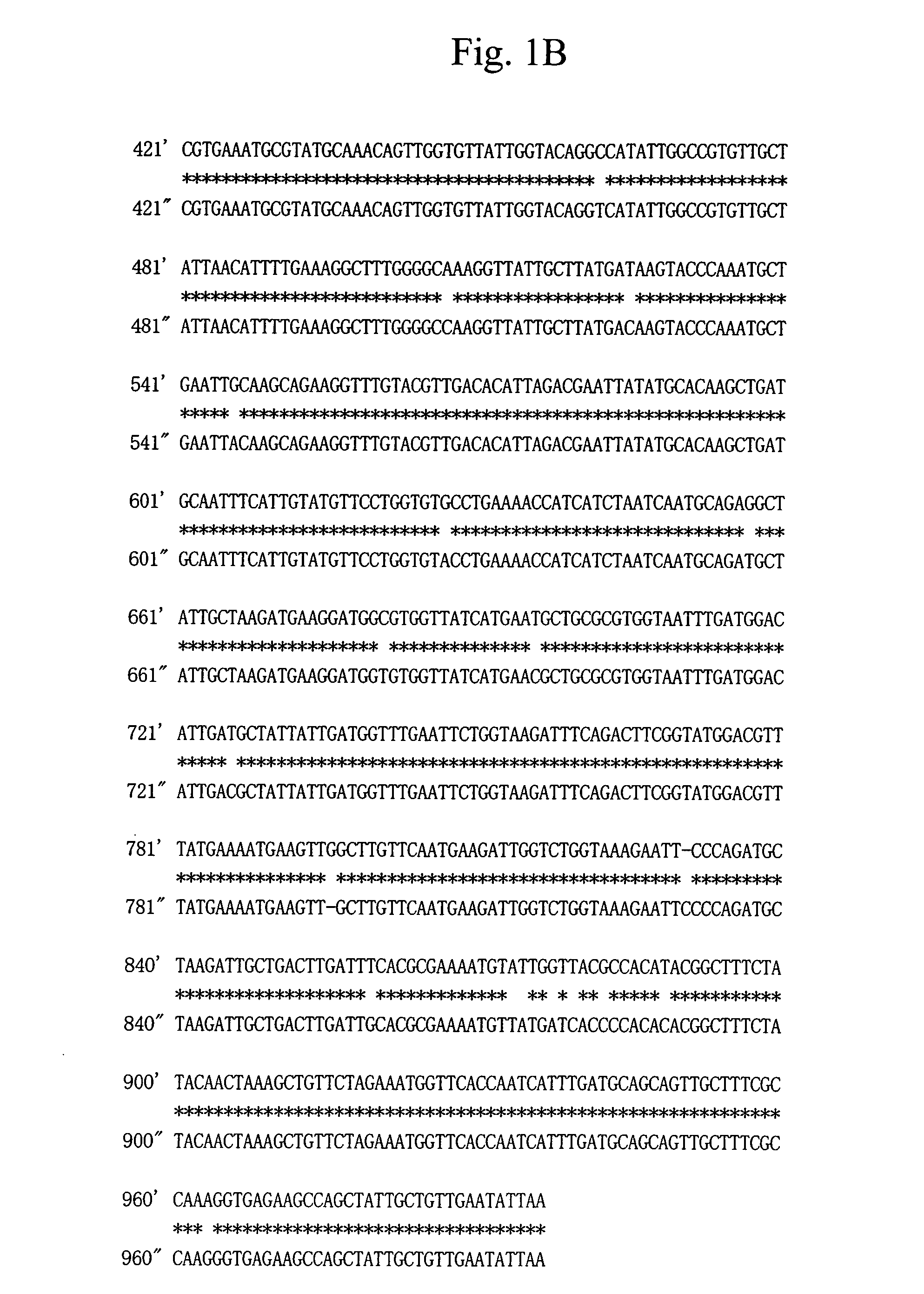

Dna encoding a protein having d-lactate dehydrogenase activity and uses thereof

InactiveUS20070105202A1Large capacityPositively affect production of D-lacticFungiSugar derivativesNucleotideDna encoding

This invention provides a polynucleotide that encodes a protein having lactate dehydrogenase activity and such protein that can be used for producing D-lactic acid. This polynucleotide has the nucleotide sequence as shown in SEQ ID NO: 1 (a), and it hybridizes under stringent conditions with a probe comprising all or part of the nucleotide sequence as shown in SEQ ID NO: 1 or a complementary strand thereof and encodes a protein having D-lactate dehydrogenase activity (b).

Owner:TEIJIN LTD +1

Preparation method of polylactic acid based hydrophobic thin film

InactiveCN108559084ASimple manufacturing methodProcess conditions are easy to controlPolymer sciencePolymer thin films

The invention discloses a preparation method of a polylactic acid based hydrophobic thin film. The preparation method comprises the following steps: preparing a poly-L-lactic acid polymer solution into a poly-L-lactic acid polymer thin film; spin-coating a triblock copolymer PDLA (Poly(D-lactic acid))-PDMS (Polydimethylsiloxane)-PDLA solution on a poly-L-lactic acid polymer thin film matrix; carrying out annealing treatment to obtain the polylactic acid based hydrophobic thin film. The preparation method of the polylactic acid based hydrophobic thin film is simple, efficient and technologicalconditions are easy to control and the uniform hydrophobic thin film can be prepared, so that the preparation method has relatively great actual application value.

Owner:EAST CHINA UNIV OF SCI & TECH

Heat-resistant poly-l-lactic acid preform

ActiveUS20090226655A1High crystallinityImprove heat resistanceCosmetic preparationsLayered productsCompound aBlow molding

A preform is formed by compounding a resin made from poly-L-lactic acid with a functional filler and subjecting a mouth portion to a heat treatment. Also, a hollow shaped product is produced by blow-molding the preform.

Owner:YOSHINO KOGYOSHO CO LTD

Biodegradable layered sheet

ActiveCN1860026ADoes not cause environmental problemsThe need to promote crystallizationSynthetic resin layered productsGlass transitionPolymer chemistry

It is an object to provide a biodegradable laminated sheet which is high in heat resistance, impact resistance and strength when subjected to loads at high temperature, does not develop wrinkles called 'bridges', which can be easily deep-drawn or formed into blister articles, which are typically complicated in shape. The biodegradable sheet is a laminated sheet comprising at least two layers. Each of the layers forming the laminated sheet is a resin composition comprising 75 to 25% by mass of a polylactic acid resin, and 25 to 75% by mass of a polyester resin having a glass transition temperature not exceeding 0 degrees C and a melting point higher than the glass transition temperature of the polylactic acid resin, and not exceeding the melting point of the polylactic acid resin, based on 100 mass percent of the total amount of the polylactic acid resin and the polyester resin. The D-lactic acid content of the polylactic acid resin contained in one layer, and the D-lactic acid content of the polylactic acid resin in the other layer are determined to satisfy a predetermined relationship. The laminated sheet is subjected to crystallization treatment.

Owner:MITSUBISHI CHEM CORP

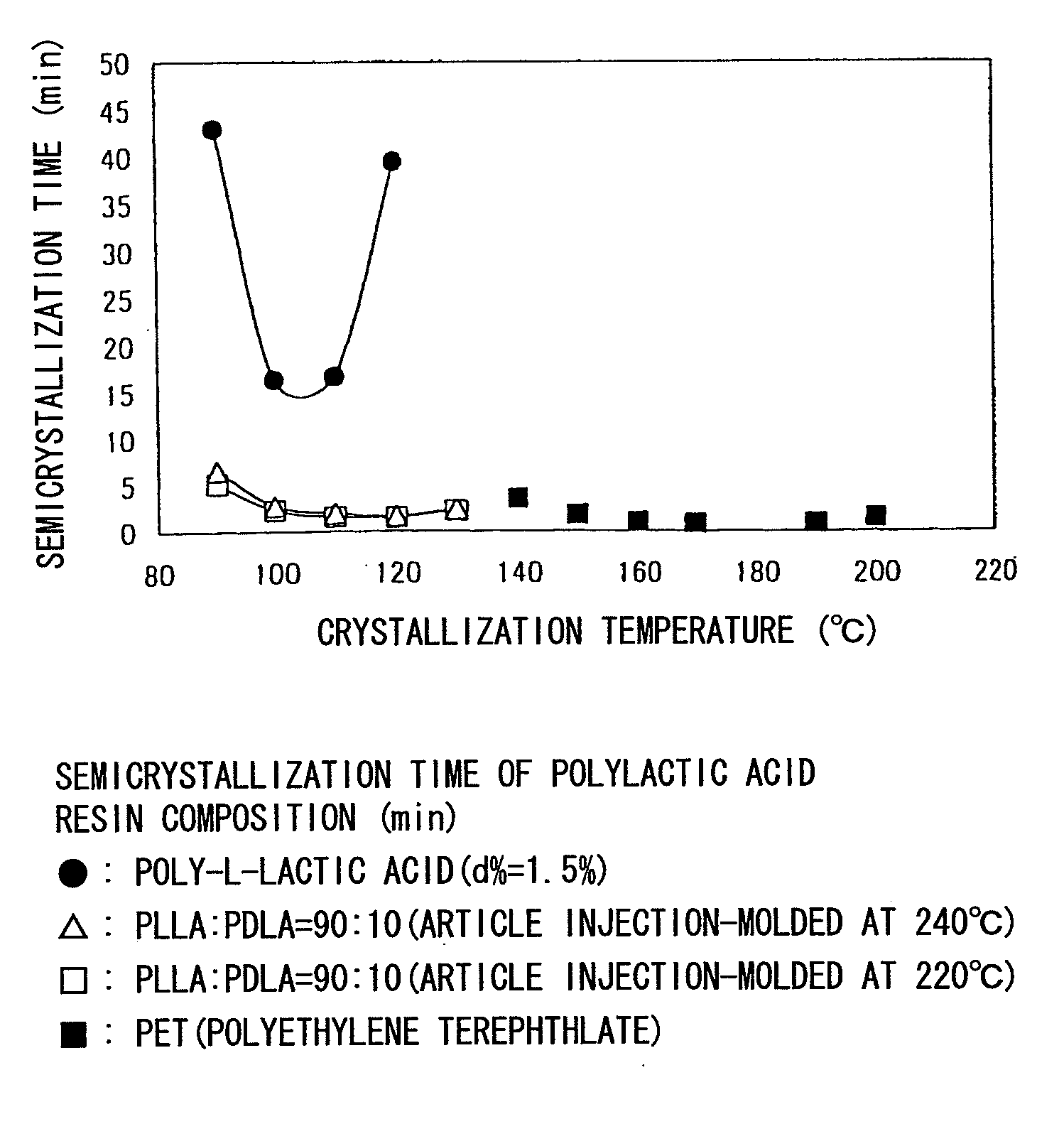

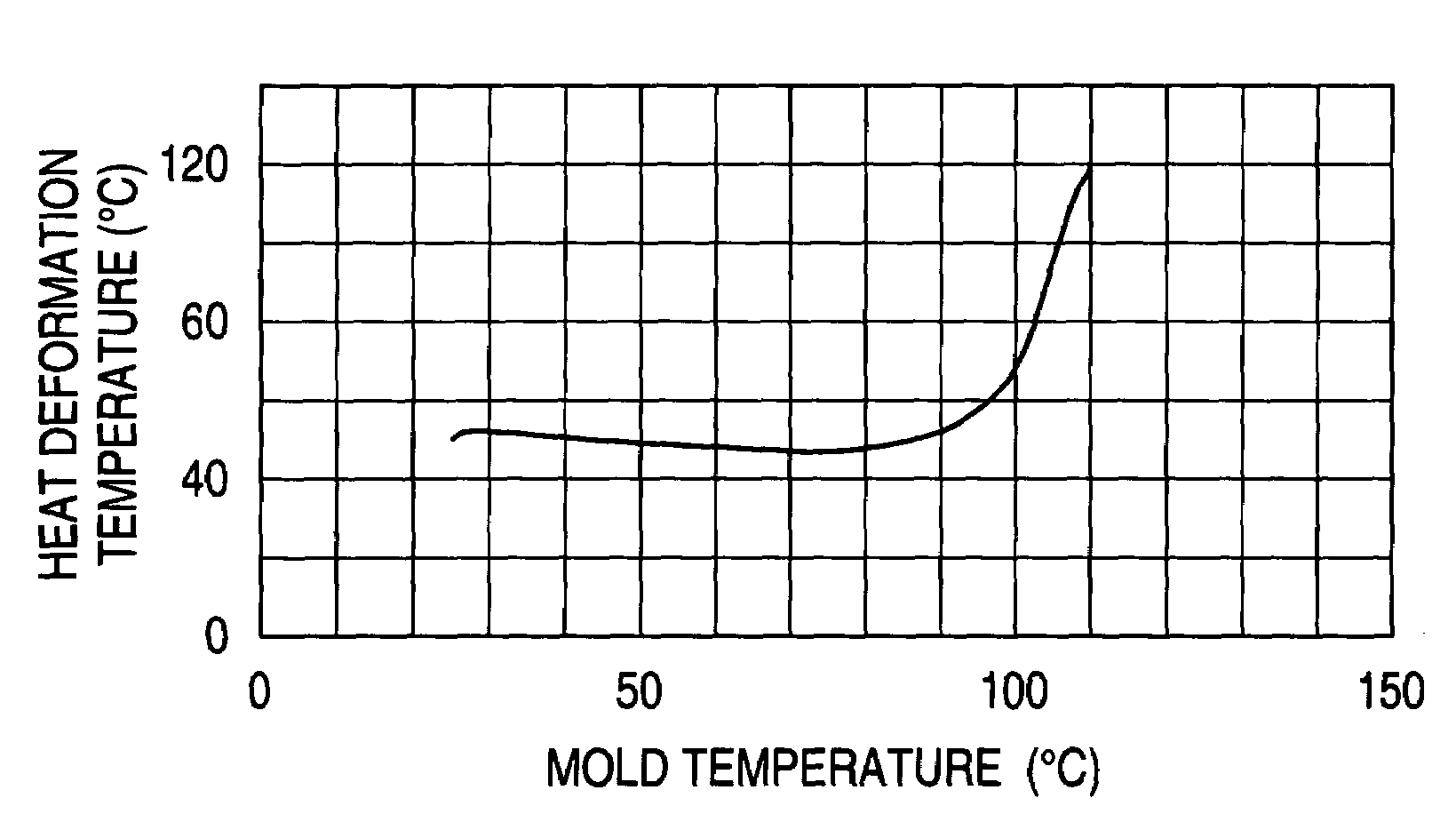

Compound comprising plla and pdla

InactiveUS20140235777A1Easy to transformImprove preferencePlastic/resin/waxes insulatorsInjection mouldingPoly l lactic acid

The present invention relates to a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PLLA) polymer. The present invention also relates to a method for the production of a moulded part comprising the steps of heating a mould, and supplying to the mould a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PDLA) polymer. The present invention relates to a composition comprising a poly-D-lactic acid (PDLA) polymer and a poly-L-lactic acid (PLLA) polymer for use in injection-moulding, thermoforming and / or film blowing. The present invention also relates to a composition that can be obtained by heating a composition comprising a poly-D- lactic acid (PDLA) polymer and a poly-L-lactic acid (PDLA) polymer.

Owner:PURAC BIOCHEM

Polylactic acid resin composition and molded article of the same

InactiveUS7825212B2Improve crystallization speedSatisfactory crystallinityCrystallizationPolylactic acid

This invention provides a polylactic acid resin composition in which stereocomplex crystals of poly-L-lactic acid and poly-D-lactic acid can be selectively crystallized to obtain polylactic acid having a sufficiently high speed of crystallization and a sufficiently high ratio of stereocomplex crystal and a molded article thereof obtained via melt molding and crystallization of the same. Such polylactic acid resin composition comprises polylactic acid capable of generating stereocomplex crystallization and an aromatic urea compound represented by formula (1):wherein R1 represents an alkylene group having 1 to 10 carbon atoms; R2 represents an alkyl group having 1 to 25 carbon atoms; and m is an integer between 1 to 6.

Owner:TEIJIN LTD

Completely-biodegradable high-roundness 3D printing filament and preparation method thereof

ActiveCN105420837AMonocomponent polyesters artificial filamentArtifical filament manufactureWater bathsMicrosphere

The invention relates to a completely-biodegradable high-roundness 3D printing filament and a preparation method thereof. The 3D printing filament is composed of 60-89% of poly-L-lactic acid (PLLA), 5-20% of glass microspheres, 1-5% of poly-D-lactic acid (PDLA) and 5-15% of a PLA-PGA segmented copolymer. The 3D printing filament is prepared through extrusion at 170-190 DEG C in a drawing machine and then water-bath cooling and shaping at 40-60 DEG C. The 3D printing filament is good in roundness, high in strength, quick to crystallize, good in temperature resistance and good in toughness, and is suitable for 3D printing in various types.

Owner:HANGZHOU SEEMORE NEW MATERIAL TECH

Resin composition, molded article, and production methods thereof

There are provided a resin composition including a polylactic acid which (i) includes a poly-L-lactic acid (component B-1) and a poly-D-lactic acid (component B-4), (ii) has a weight ratio of the component B-1 to the component B-4 (component B-1 / component B-4) of 10 / 90 to 90 / 10, and (iii) shows a proportion of melt peaks at 195° C. or higher to all melt peaks in a temperature rising process in measurement by a differential scanning calorimeter (DSC) of at least 20%; a molded article of the resin composition; and methods for producing the resin composition and the molded article.

Owner:TEIJIN LTD

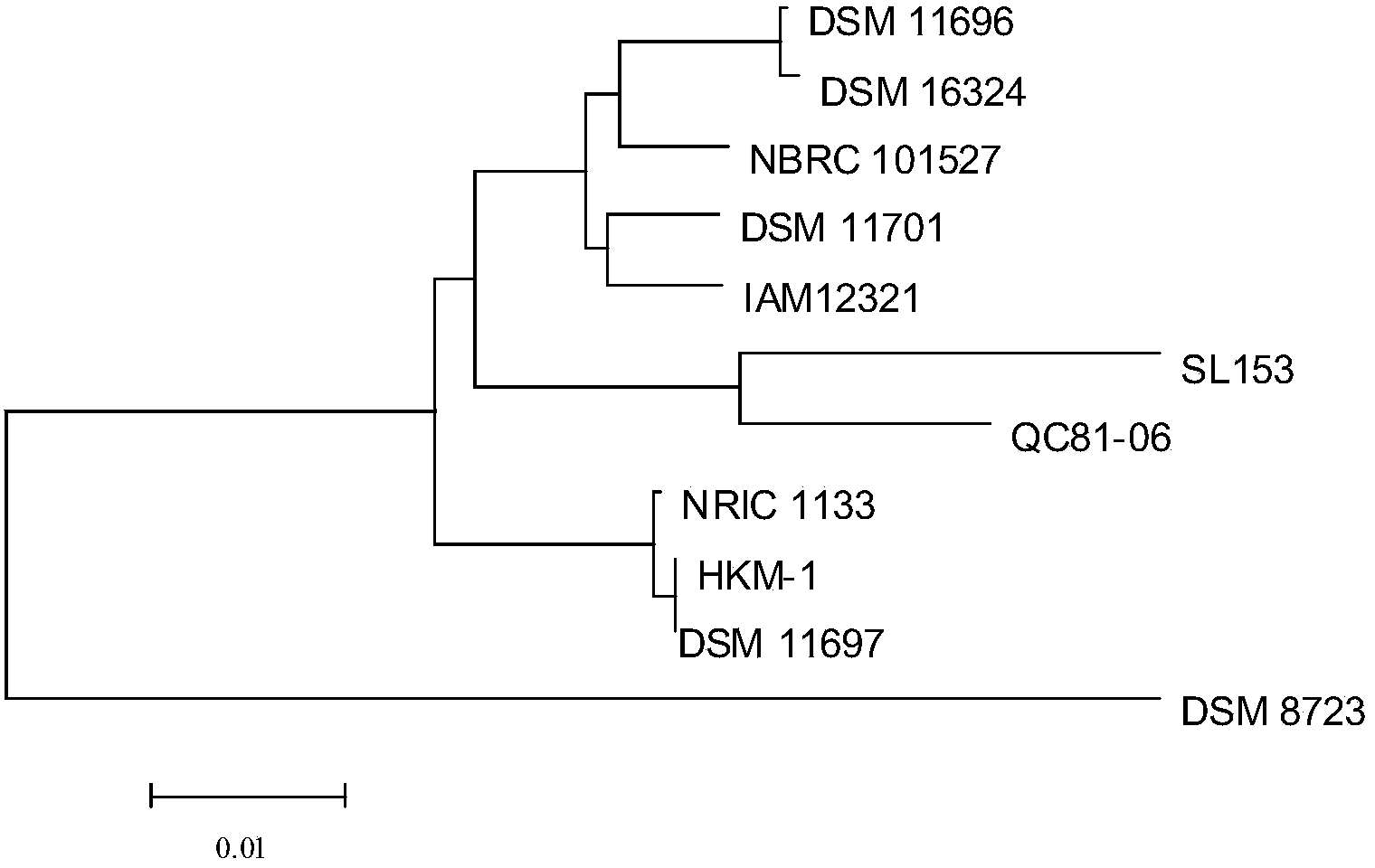

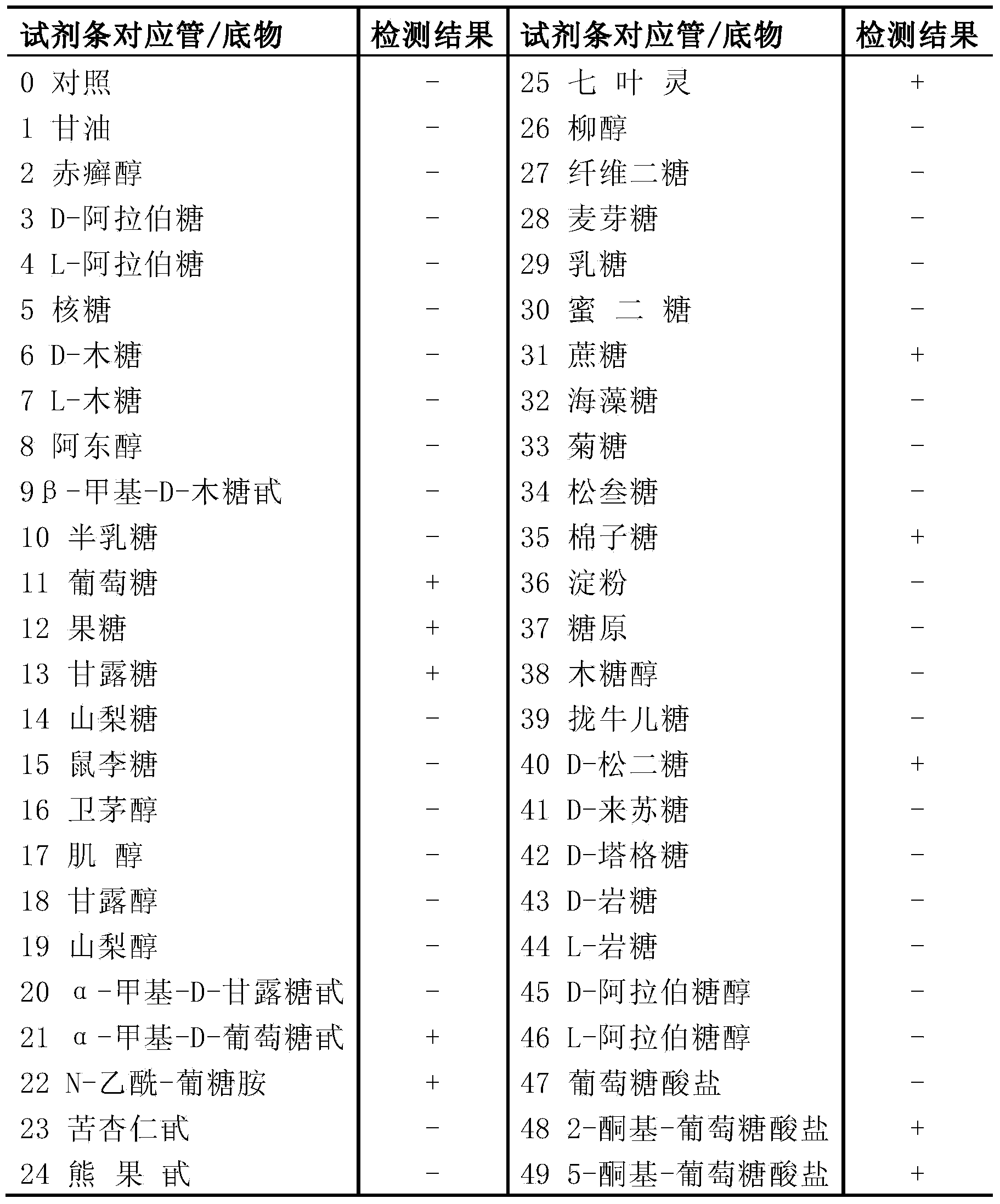

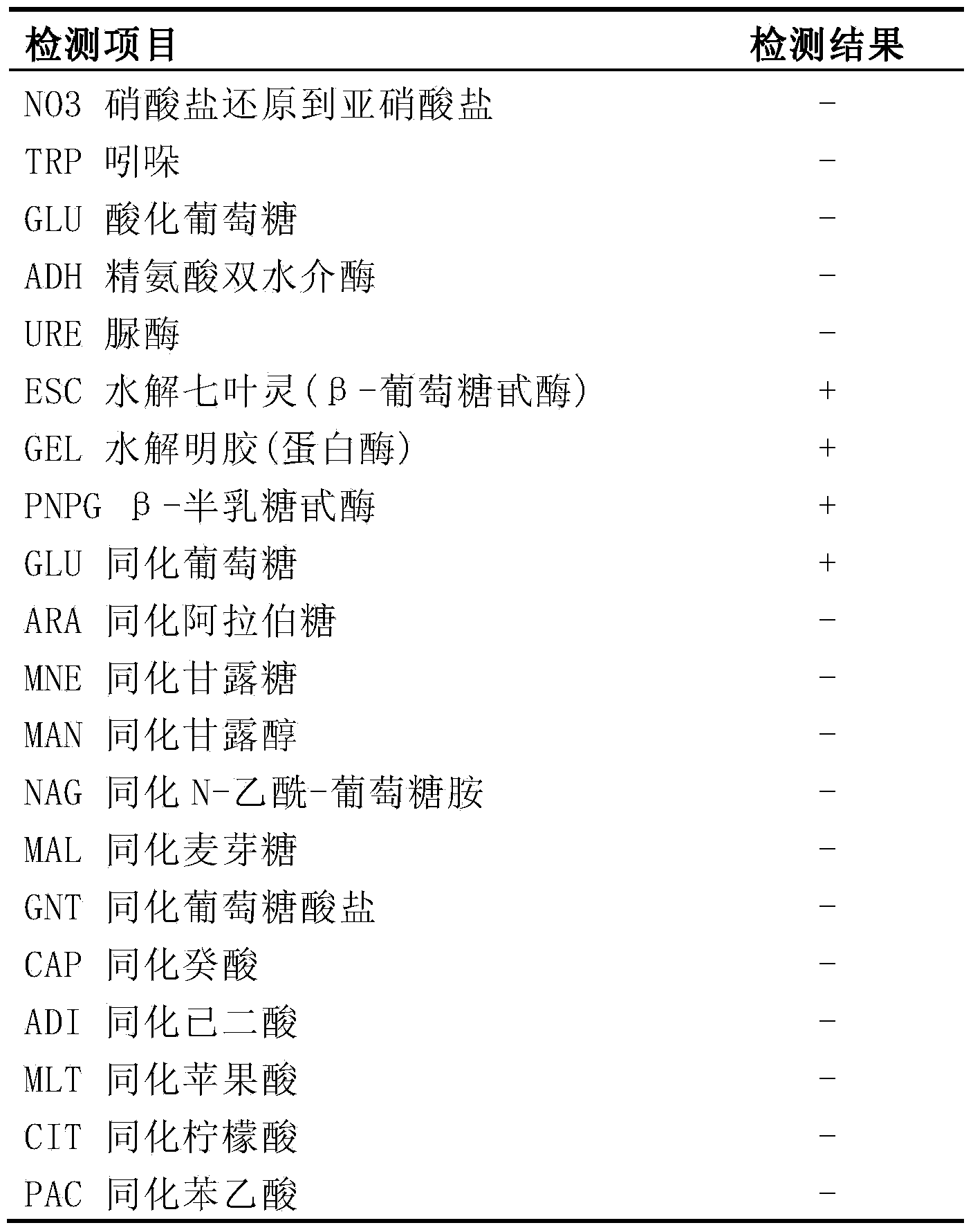

Sporolactobacillus terrae and application thereof

ActiveCN103756939AProduction process raw materials are easy to getLow costBacteriaMicroorganism based processesMicroorganismMicrobiology

The invention discloses sporolactobacillus terrae HKM-1 and a method for producing D-lactic acid therefrom through fermentation. The sporolactobacillus terrae HKM-1 is collected in China Center for Type Culture Collection with the collection number CCTCC NO: M2013389, and also collected in DSMZ (Deutsche Sammlung von Mikroorganismen und Zellkulturen) with the collection number DSM No.27555. HKM-1 can be used for producing D-lactic acid by using a cheap nitrogen source, namely dry powder of corn steep liquor; the highest fermentation yield of D-lactic acid is 197g / L, the corresponding fermentation period is only 47g, and the fermentation production capacity reaches up to 4.19g / L / h which is far higher than the value publically reported already at present; the strain HKM-1 is stable in high yield performance and capable of producing high-optical purity D-lactic acid, and the optical purity of the produced D-lactic acid is 99.9%; raw materials for fermentation are wide in source and low in cost, and the fermentation state is between anaerobic and micro-aerobic; the method provided by the invention can be used for producing the D-lactic acid through fermentation, and is capable of saving cost and improving production efficiency and also has important industrial application value.

Owner:SHANGHAI JIAO TONG UNIV

Kit for detecting barrier function of intestinal tract

ActiveCN105699640ASimple and fast operationImprove accuracyBiological testingBlood plasmaBarrier function

The invention provides a kit for detecting the barrier function of the intestinal tract. The kit comprises a reaction device, one or more colorimetric solutions and one or more dilution solutions; the reaction device comprises a blood plasma separator and a reaction substrate, and the reaction substrate includes a blank hole, a diamine oxidase reaction hole, a D-lactic acid reaction hole and a bacterial endotoxin reaction hole; a blood plasma separating film is arranged in each of the holes of the blood plasma separator; and a blank pad is arranged in the blank hole.

Owner:北京中生金域诊断技术股份有限公司

Biodegradable resin composition and biodegradable resin molded article

InactiveUS7517937B2Improve heat resistanceBiodegradation rate be controlledLayered productsInksPolyresinPolymer chemistry

The present invention relates a biodegradable resin composition comprising an L-lactic acid unit-containing resin (1) and a D-lactic acid unit-containing resin (2). Also disclosed is a biodegradable resin molded article obtained from the biodegradable resin composition.

Owner:NISHIKAWA RUBBER

Polylactic acid block copolymer

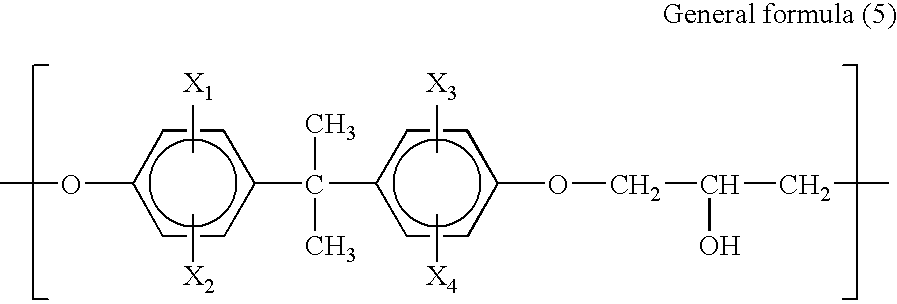

The invention relates to a polylactic acid block copolymer, which solves the problems that current method is hard to prepare the polylactic acid block copolymer with high-melting point polyester. The polylactic acid block copolymer is a two-block copolymer which is shown as A-b-B, wherein A is a single-end hydroxyl aromatic polyester block, and B is a polylactic acid block. The polylactic acid block is one or more of a poly-L-lactic acid block, a poly-D-lactic acid block and a poly-DL lactic acid block. The polylactic acid block copolymer is prepared by the following step of: adopting an organic solvent which can dissolve reactants of single-end hydroxyl aromatic polyester and lactide to be a reaction medium, tin salt as a catalyst, and the single-end hydroxyl aromatic polyester as an initiator to initiate the ring opening polymerization of lactide. With the adoption of the polylactic acid block copolymer, the polymerizing temperature can be controlled to reach a scope in which polylactic acid and lactide cannot be degraded, and the racemization cannot be carried out, so that the generation of transesterification can be effectively inhibited, the regularity of the chain section can be ensured, and the block copolymers of polyester and the polylactic acid can be successfully prepared, including aromatic polyester with the high-melting point.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

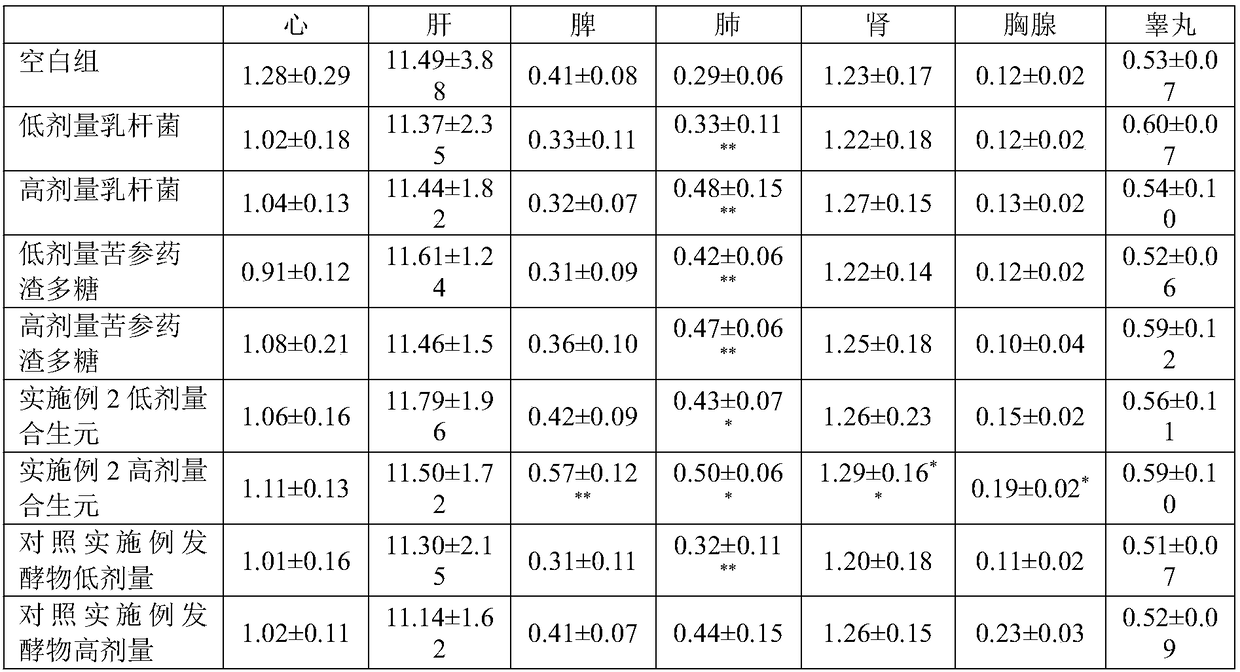

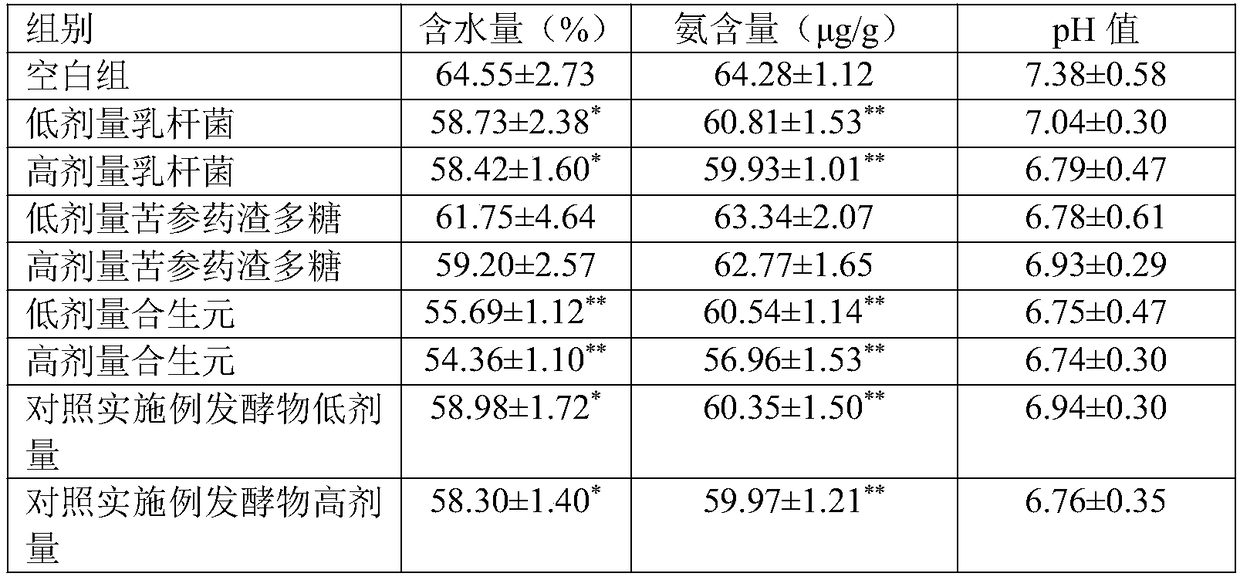

Radix sophorae flavescentis residue polysaccharide synbiotics and preparation method and application thereof

InactiveCN109497558AEfficient use ofExcellent Synbiotics PreparationAnimal feeding stuffFood scienceInflammatory factorsSynbiotics

The invention discloses radix sophorae flavescentis residue polysaccharide synbiotics and a preparation method and application thereof. The radix sophorae flavescentis residue polysaccharide synbiotics is obtained by using radix sophorae flavescentis residue polysaccharide as a unique raw material through fermentation of lactobacillus plantarum. An experiment result shows that the prepared synbiotics is capable of remarkably improving a mouse visceral index and mouse intestinal tract digestive enzyme activity, keeping integrity and permeability of an intestinal tract mucous membrane, maintaining an intestinal tract barrier function, reducing levels of toxin, diamine oxidase, D-lactic acid and an inflammatory factor in a body, and through improving mouse intestinal tract bacterial diversityand flora composition structure, promoting growth of beneficial bacteria, reducing a number of harmful bacteria, regulating animal intestinal microecology, and reinforcing digestive ability and immunocompetence of an animal, and has an important application value.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com