Environment-friendly functional copper mesh material as well as preparation method and application thereof

A functional and environmentally friendly technology, applied in the field of materials, can solve the problems of affecting wettability, pollution of organic pollutants, affecting separation performance, etc., and achieve the effect of strong recycling ability, good chemical durability and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

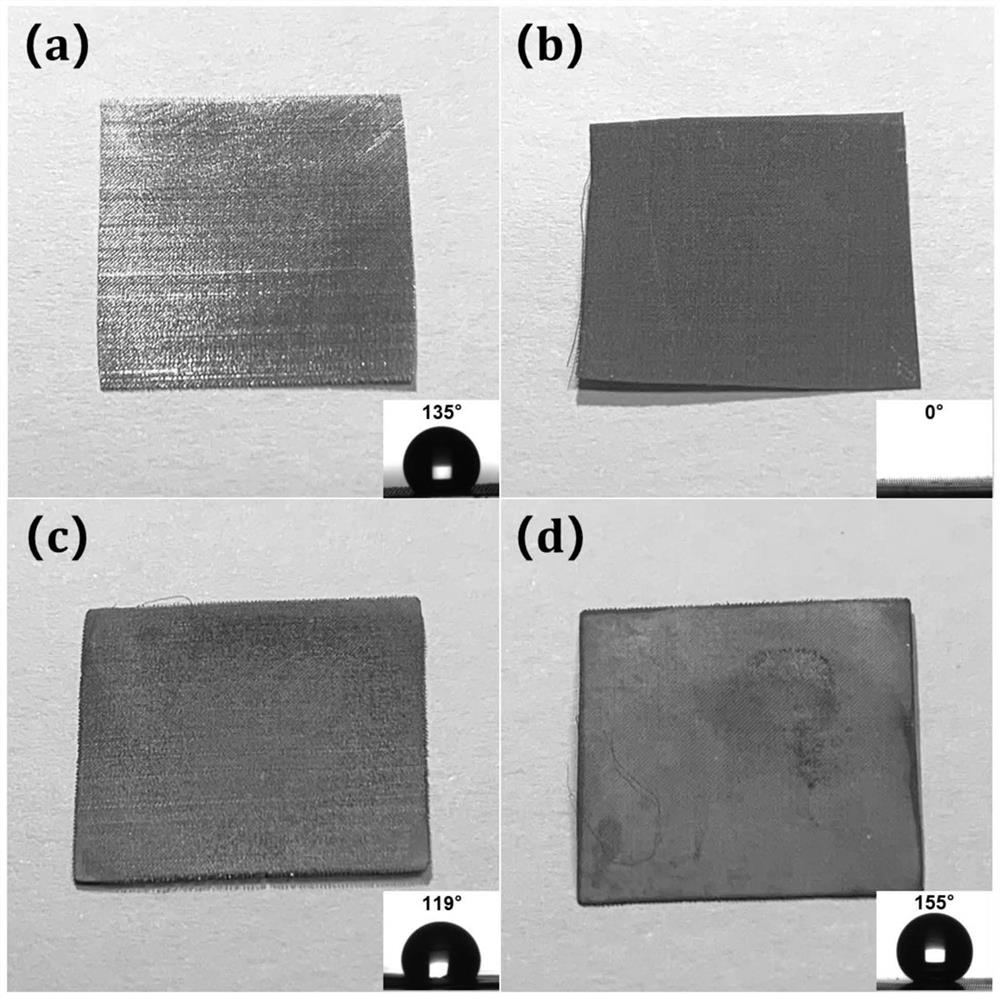

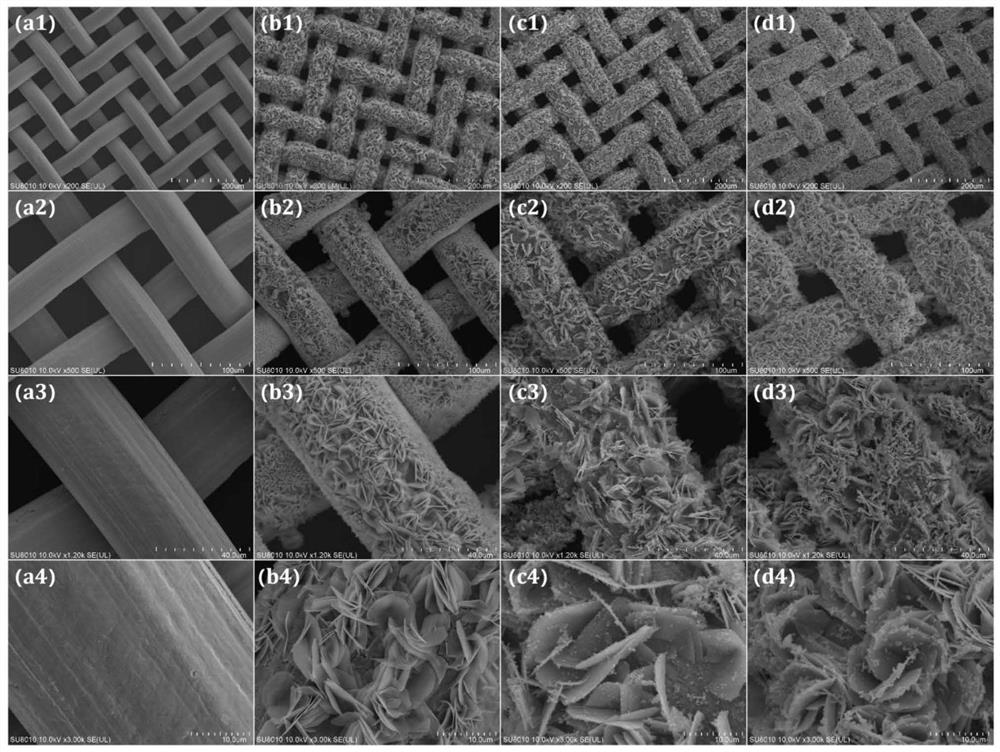

[0036] (1) The preparation method is as follows:

[0037] 1) Wash the original copper mesh (400 mesh, 3cm×3cm, purity 99%) with dilute hydrochloric acid, deionized water, and ethanol by ultrasonic treatment to remove the surface oxide layer and other impurities, and then wash it with deionized water, Vacuum drying at 80°C; then, immerse the obtained copper mesh in 50mL mixed solution containing 1mol·L -1 Sodium dihydrogen phosphate and 1mol L -1 Hydrogen peroxide; after the reaction, take out the copper mesh and wash it three times with deionized water, and dry it in vacuum at 80°C, the surface of the copper mesh is oxidized to form Cu 3 (PO 4 ) 2 Crystal, get Cu 3 (PO 4 ) 2 copper mesh.

[0038] 2) the above Cu 3 (PO 4 ) 2 Copper grid immersed in 25mL 1g·L -1 Soak in polyvinylpyrrolidone methanol solution for 30min, so that the surface of the material is filled with polyvinylpyrrolidone molecules; then add 1.487g zinc nitrate hexahydrate to the system, stir at room...

Embodiment 2

[0047] Example 2 Environment-friendly functionalized material PDMS / ZIF-7@Cu 3 (PO 4 ) 2 Application of Copper Mesh in Adsorbing Oil

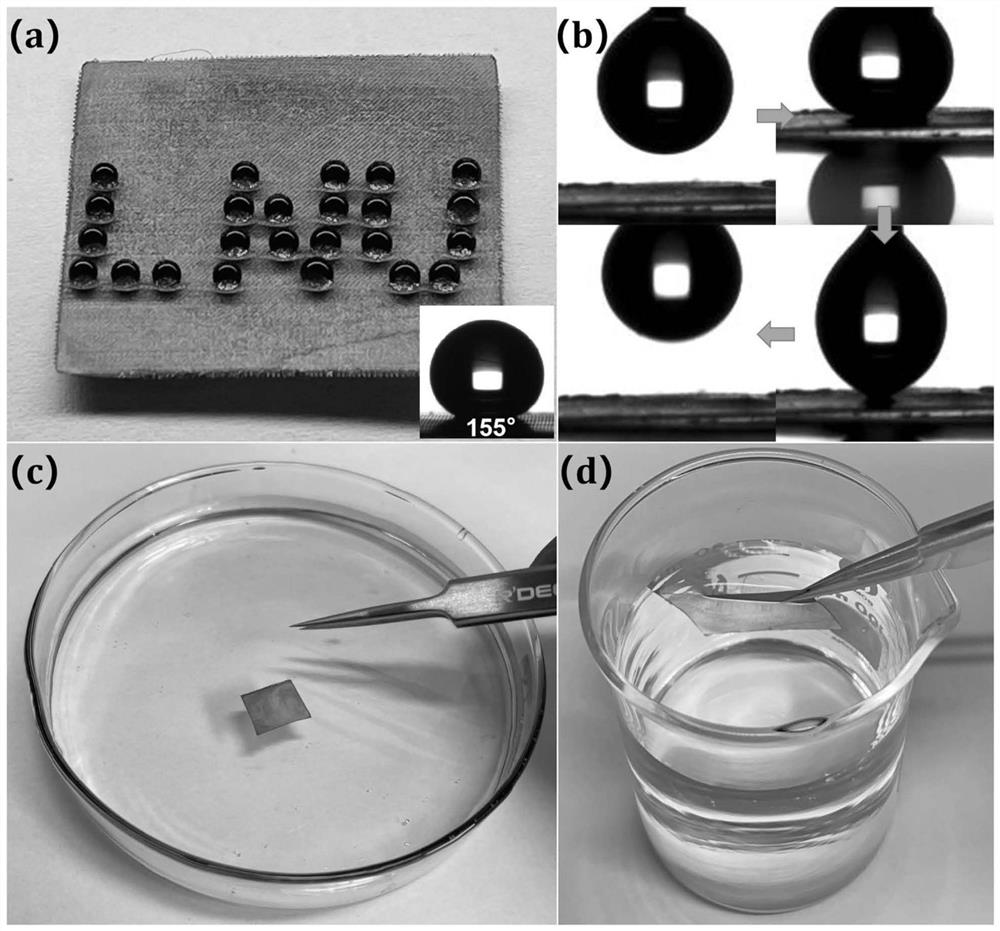

[0048] In order to investigate PDMS / ZIF-7@Cu 3 (PO 4 ) 2 The actual application effect of copper mesh adsorption oil simulates the situation of separating oil from oil-water mixture under natural conditions. Selective adsorption experiments were carried out by mixing n-hexane (light oil, stained with Sudan IV) and chloroform (heavy oil, stained with Sudan III) with water, and the results were as follows: Figure 4 .

[0049] Such as Figure 4 In middle (a1~a3), the relative density of n-hexane is small, floating above the water phase, when PDMS / ZIF-7@Cu 3 (PO 4 ) 2 When the copper mesh is in contact with n-hexane, n-hexane quickly penetrates into the copper mesh, so that n-hexane and water are separated to achieve the purpose of collecting oil. Likewise, for heavy oil / water mixtures such as Figure 4 In the middle (b1~b3), the relati...

Embodiment 3

[0050] Example 3 Environment-friendly functionalized material PDMS / ZIF-7@Cu 3 (PO 4 ) 2 Application of Copper Mesh in Separation of Oil-Water Mixture

[0051] 1. In order to investigate PDMS / ZIF-7@Cu 3 (PO 4 ) 2 Copper mesh continuous oil-water separation capability, the separation process is as follows Figure 5 As shown, the PDMS / ZIF-7@Cu 3 (PO 4 ) 2 The copper mesh is sandwiched between two glass tubes, and a clean beaker is placed below the apparatus to collect the organic phase. Pour the oil-water mixture into the glass tube from above to contact PDMS / ZIF-7@Cu 3 (PO 4 ) 2 The copper mesh, through which the organic phase flows down, is collected by the beaker, while the aqueous phase is trapped in the glass tube, thereby achieving oil-water separation. Such as Figure 5 As shown in (a1~a2), heavy oil (dichloromethane, chloroform, carbon tetrachloride) is dyed with Sudan III, mixed with an equal volume of water dyed with methylene blue to form an oil-water mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil-water separation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com