Preparation method of piezoelectric nano-generator with all-weather service capability constructed based on N-doped SiC nano-structure array

A nanogenerator and nanostructure technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., to optimize output performance and enhance piezoelectric response ability, anti-oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

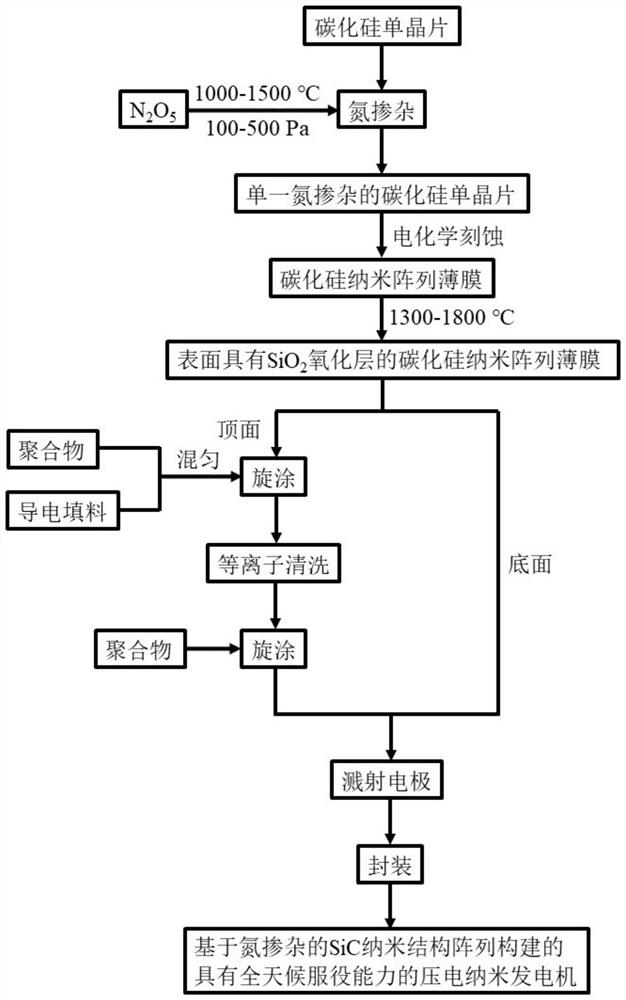

[0039] See figure 1 An embodiment of the present invention is provided method of preparing a piezoelectric generator having a nano-weather service capability of the N-doped SiC-based nanostructure array constructed, comprising the steps of:

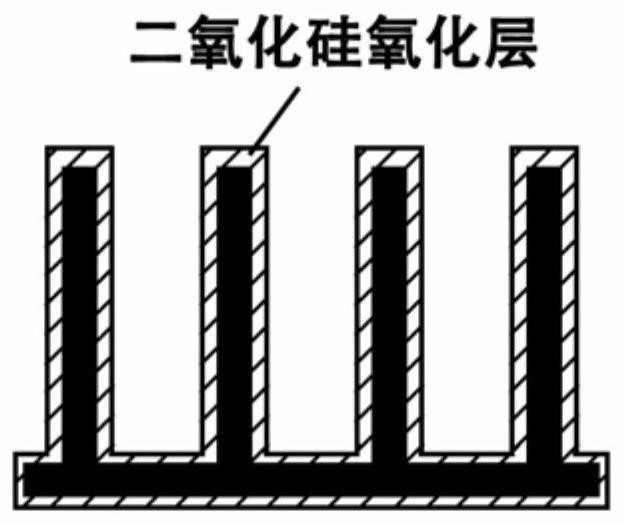

[0040] Preparation of N-doped silicon carbide Step 1): To N 2 O 5 Of nitrogen, at a temperature of 1000-1500 deg.] C, pressure 100-500Pa, protective argon atmosphere for 20 hours doped single crystal silicon carbide of nitrogen to give a nitrogen doping concentration of 0.1 to 10 mol% of silicon carbide. Wherein the silicon carbide single crystal is single or double polishing, a thickness of 100-500 [mu], polymorph as 2H, 4H, or 6H-type silicon carbide single wafer. Performed by a single silicon carbide single crystal doped with nitrogen, one can increase the asymmetry of the silicon carbide crystal structure, improve its piezoelectric coefficient, the ability to enhance its piezoelectric response; on the other hand, the introduction of N ato...

Embodiment 1

[0051] Preparation of N-doped silicon carbide single crystal (1): Example of the present embodiment is selected Form 2H, single-side polished silicon carbide single wafer as the raw material, a thickness of 100μm. By N 2 O 5 As nitrogen source, at 1000 ℃, 100Pa pressure argon atmosphere for the silicon carbide single crystal doped with nitrogen protection for 1 hour, with a nitrogen doping concentration of 0.1mol% of silicon carbide.

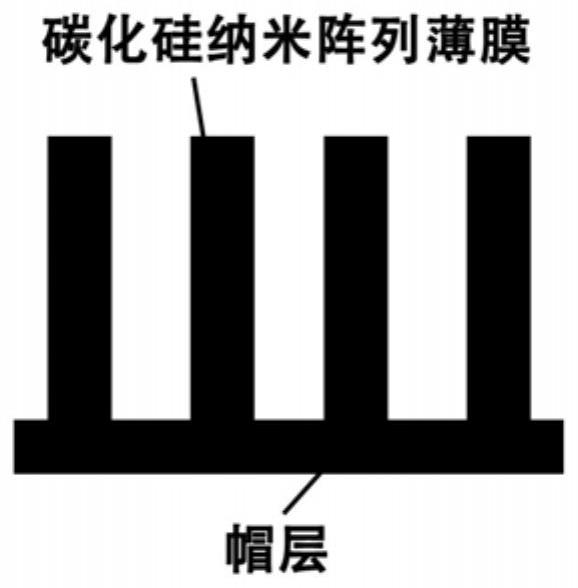

[0052] (2) Preparation of silicon carbide nanostructure array self supporting film: Based on N-doped single crystal silicon carbide, carbon doped silicon carbide surface N single wafer is etched by electrochemical etching. Etching the pulse voltage (5V) and pulse current (100mA) Power; pulse waveform is a sine wave, a pulse duty ratio of 10%; etching solution of hydrofluoric acid, alcohol and hydrogen peroxide, the ratio may be 8: 5: 0 in an amount of 10ml; etching 1min, eventually obtained by changing the surface topography of nanoporous lift-off m...

Embodiment 2

[0057](1) Preparation of N-doped silicon carbide monochrome: This example is selected from 4 h, and the silicon carbide single wafer having double-sided polished is 300 μm. N 2 O 5 For nitrogen sources, the silicon carbide monochrometer was doped for 10 hours at 1300 ° C, 300 Pa, and the argon atmosphere was protected, and silicon carbide of nitrogen doped concentration was 5 mol%.

[0058] (2) Preparation of self-supported silicon carbide nanostructure array film: based on N-doped silicon carbide single wafer, the carbon surface of N-doped silicon carbide monochrometers is etched by electrochemical etching. Eroching is a power supply with DC voltage (25V) and DC current (250mA); pulse waveform is a triangular wave, the pulse duty cycle is 50%; the proportion of hydrofluoric acid, ethanol and hydrogen peroxide in the etch can be 10:10 : 7, the amount is 30ml; etch 50min, finally obtaining a nano-nanostructure array film having a nano-strip with a steel-side strip and a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com