Single-component acrylic adhesive as well as preparation method and application thereof

An acrylic and adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems that affect production efficiency, glue is easy to gel, and coating time is short, so as to improve production efficiency, Easy peeling, extended coating time and storage time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

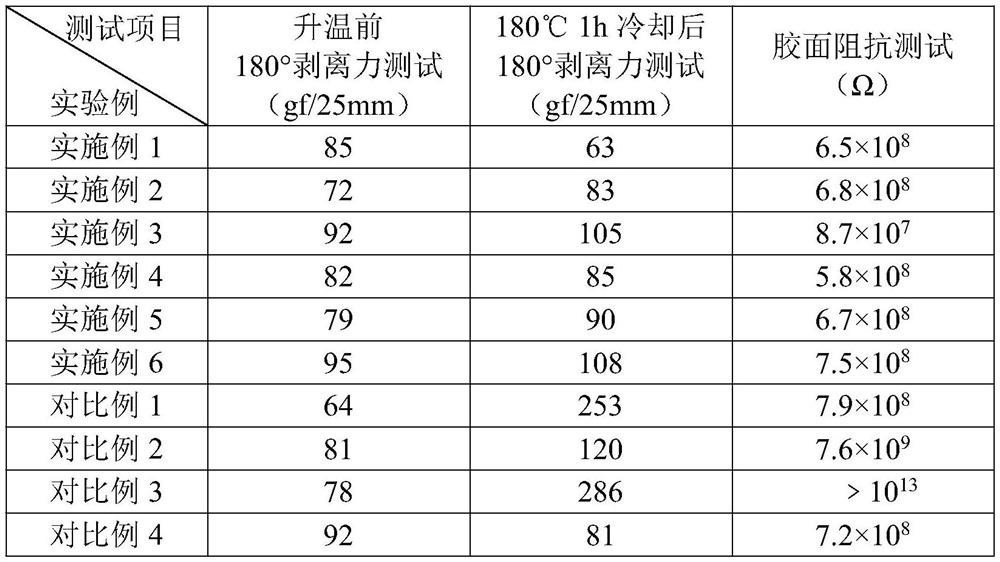

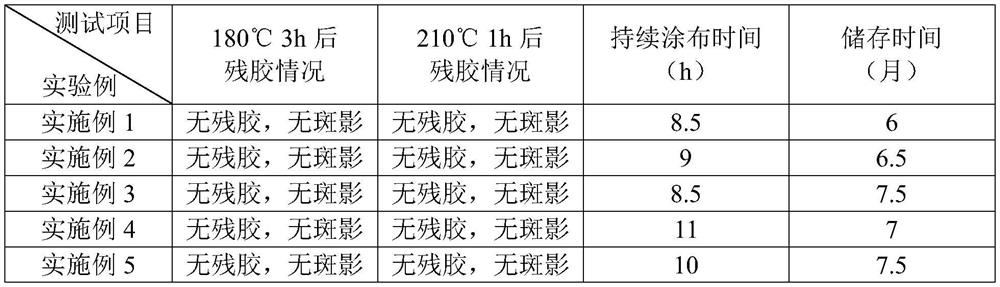

Examples

Embodiment 1

[0024] A one-component acrylic adhesive, calculated in parts by weight, including 70 parts of isobutyl acrylate, 4 parts of methyl acrylate, 1 part of diallyl maleate, and 3 parts of methacryloxytrimethoxysilane , 0.1 parts of azobisisobutyronitrile, 100 parts of toluene, 0.3 parts of Cyastat LS, 0.033 parts of glacial acetic acid and 0.067 parts of aluminum acetylacetonate.

[0025] The preparation method is as follows:

[0026] S1, add 70 parts of isobutyl acrylate, 4 parts of methyl acrylate, 1 part of diallyl maleate and 3 parts of methacryloxytrimethoxysilane to the reaction vessel I in sequence, stir evenly to obtain a mixed Material A;

[0027] S2, add 5% of the weight of the mixture A and 50 parts of toluene in sequence in the reaction vessel II, stir evenly, and heat the mixture to 70°C, then slowly add 0.02 parts of azobisisobutyronitrile dropwise to the mixture , the dropping time is 0.5h, and the reaction is kept at 70°C for 1h to obtain the mixture B;

[0028] ...

Embodiment 2

[0032] A one-component acrylic adhesive, calculated in parts by weight, including 40 parts of n-butyl acrylate, 50 parts of ethyl acrylate, 4 parts of methyl methacrylate, 6 parts of n-butyl methacrylate, 2 parts of pentaerythritol triallyl 3 parts of diallyl terephthalate, 5 parts of acrylic acid, 4 parts of trifluoroethyl methacrylate, 4 parts of hexafluorobutyl ester, 0.3 parts of azobisisobutyronitrile, 0.2 parts of dibenzoyl peroxide Parts, 70 parts of ethyl acetate, 80 parts of butanone, 6091 parts of Cyast, 0.25 parts of glacial acetic acid, 0.25 parts of aluminum acetylacetonate.

[0033] The preparation method is as follows:

[0034] S1, add 40 parts of n-butyl acrylate, 50 parts of ethyl acrylate, 4 parts of methyl methacrylate, 6 parts of n-butyl methacrylate, 2 parts of pentaerythritol triallyl, terephthalic acid 3 parts of diallyl ester, 5 parts of acrylic acid, 4 parts of trifluoroethyl methacrylate and 4 parts of hexafluorobutyl ester, stirred evenly to obtain ...

Embodiment 3

[0040] A one-component acrylic adhesive, calculated in parts by weight, including 30 parts of isobutyl acrylate, 50 parts of isooctyl acrylate, 4 parts of acrylonitrile, 6 parts of styrene, 2 parts of methacrylic acid, and 2 parts of itaconic acid , 2 parts of maleic acid, 2 parts of fumaric acid, 3 parts of N-vinylpyrrolidone, 4 parts of N-vinylcarbazole, 0.2 parts of benzoyl peroxide, 0.2 parts of azobisisoheptanonitrile, 40 parts of toluene, Acetone 80 parts, Cyastat SP 0.8 parts, glacial acetic acid 0.2 parts and aluminum acetylacetonate 0.2 parts.

[0041] The preparation method is as follows:

[0042] S1, add 30 parts of isobutyl acrylate, 50 parts of isooctyl acrylate, 4 parts of acrylonitrile, 6 parts of styrene, 2 parts of methacrylic acid, 2 parts of itaconic acid and 2 parts of maleic acid in the reaction vessel I , 2 parts of fumaric acid, 3 parts of N-vinylpyrrolidone, 4 parts of N-vinylcarbazole, stir evenly to obtain the mixture A;

[0043] S2, add 10% of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com