Anticorrosion treatment method for aluminum alloy

A technology of anti-corrosion treatment and aluminum alloy, applied in the field of metal surface treatment, to achieve the effect of improved salt spray resistance time, good wear resistance and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

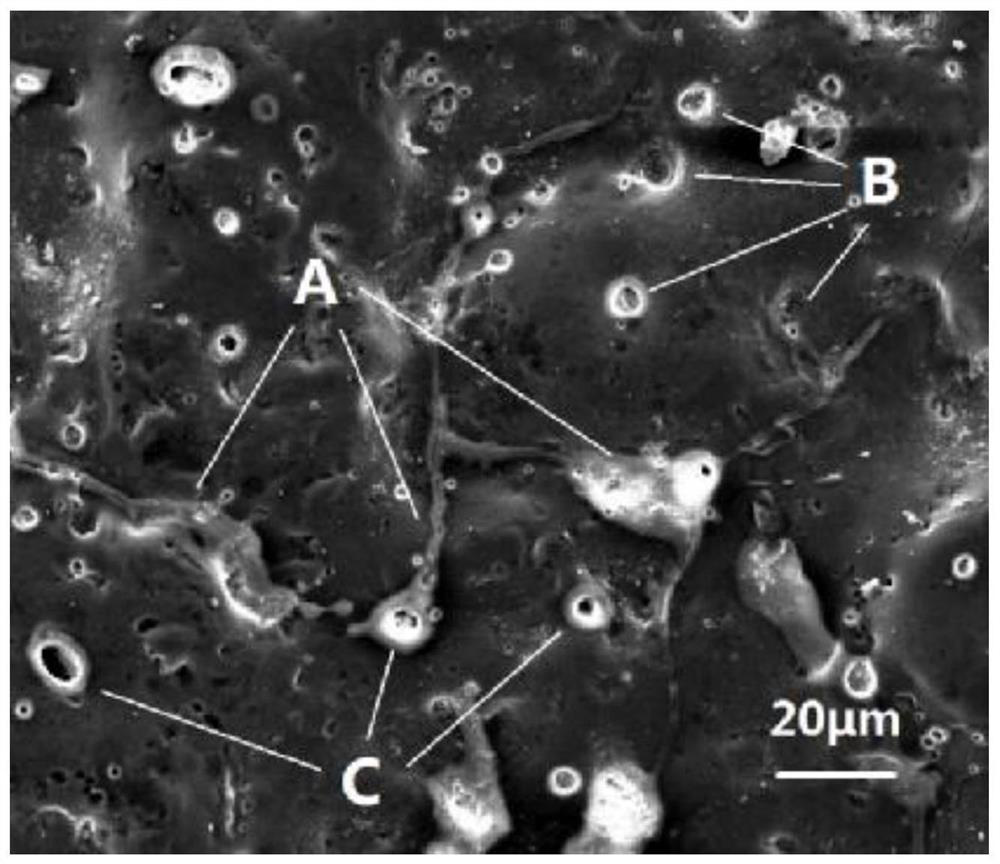

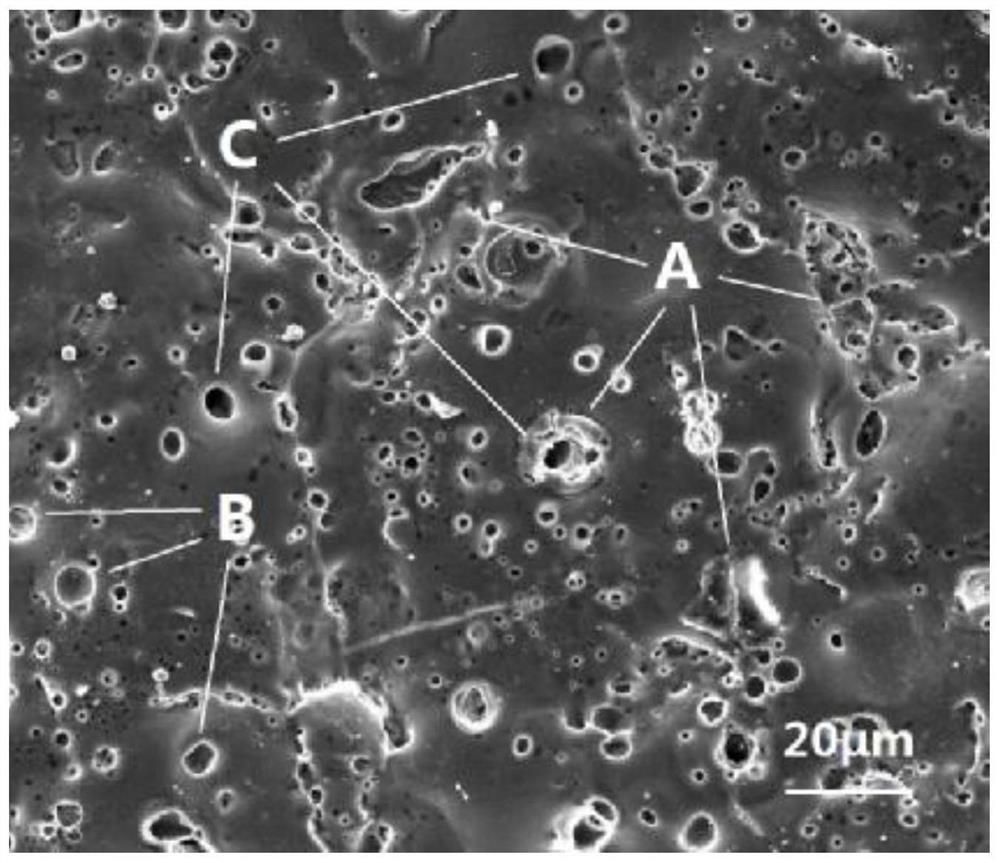

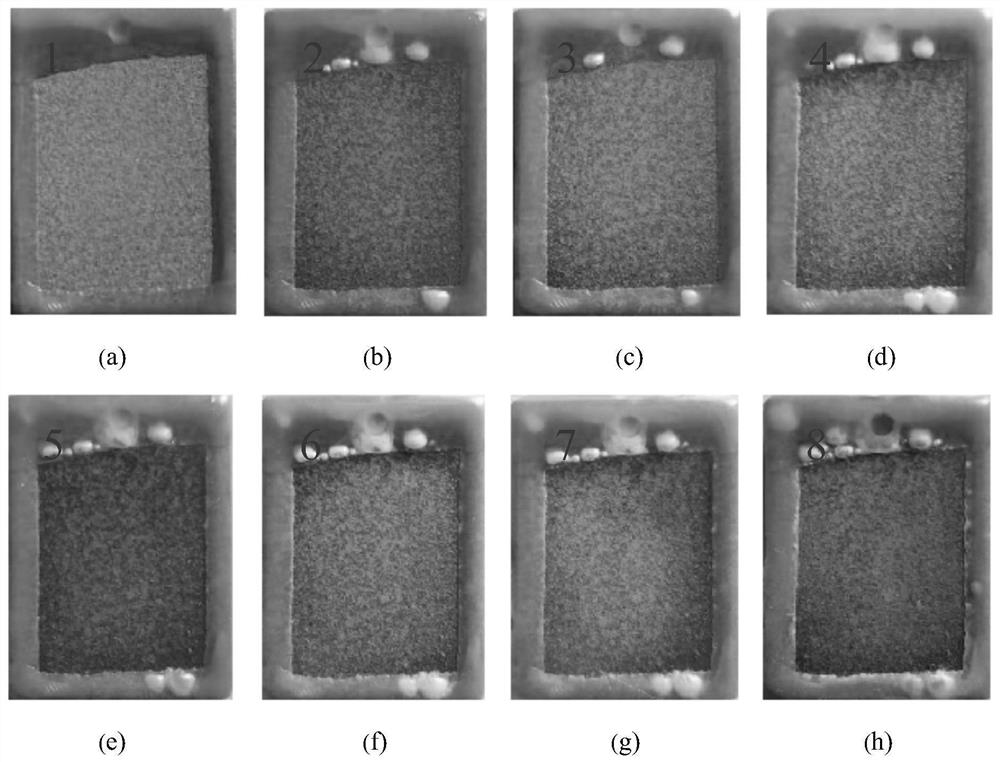

[0028] like figure 1 , 3 As shown, it is a preferred embodiment 1 of an anti-corrosion treatment method for an aluminum alloy of the present invention, and the anti-corrosion treatment method comprises the following steps:

[0029] 1. Preprocessing

[0030] The surface of the aluminum alloy sample was ground, and 100, 400, 800 and 1200 mesh water sandpaper was used to grind the surface of the sample step by step until there was no obvious scratch on the surface; then polished until the surface roughness was less than 0.6 μm.

[0031] Use concentrated sulfuric acid with a mass fraction of more than 98% to passivate the polished aluminum alloy sample for 20s, take out and rinse with a large amount of deionized water; then put the sample into a 2% mass fraction of hydroxide In a sodium solution, ultrasonically cleaned at 40°C for 10 min until the passivation layer was completely peeled off, wherein the ultrasonic power was 300W and the ultrasonic frequency was 40KHz. Finally r...

Embodiment 2

[0042] This embodiment is basically the same as the first embodiment, the difference is:

[0043] 1. The proportions of electrolyte components are different. In this embodiment, 10 parts of sodium silicate, 2 parts of sodium tungstate, 20 parts of sodium fluoride, 1 part of sodium lauryl sulfate, 2 parts of triethanolamine, 2 parts of glycerin.

[0044] 2. The micro-arc oxidation process parameters are different. In this embodiment, the reaction times of the first, second, and third stages are respectively: 15, 10, and 5 min. The positive voltage of the bipolar DC pulse power supply in each stage is 550V, and the negative The voltages are all 200V, the frequencies are all 500Hz, the duty ratios of the positive and negative voltages are both 20%, and the temperature of the electrolyte is about 40°C.

[0045] The apparent morphology of the finished sample prepared in this example is similar to that of Example 1.

Embodiment 3

[0047] This embodiment is basically the same as the first embodiment, the difference is:

[0048] 1. The proportions of electrolyte components are different. In this example, 50 parts of sodium silicate, 2 parts of sodium tungstate, 20 parts of sodium fluoride, 1 part of sodium lauryl sulfate, 8 parts of triethanolamine, 8 parts of glycerin.

[0049] 2. The micro-arc oxidation process parameters are different. In this embodiment, the reaction times of the first, second, and third stages are respectively: 10, 10, and 5 min. The positive voltage of the bipolar DC pulse power supply in each stage is 600V, and the negative The voltages are all 250V, the frequencies are all 500Hz, the duty ratios of the positive and negative voltages are both 20%, and the temperature of the electrolyte is about 40°C.

[0050] The apparent morphology of the finished sample prepared in this example is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com