Intelligent humidity control film and preparation method and application thereof

A thin film and intelligent technology, applied in the field of intelligent moisture control thin film and preparation, can solve the problems of high cost, complicated process, high price, etc., and achieve the effects of low cost, simple preparation method and improved moisture permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

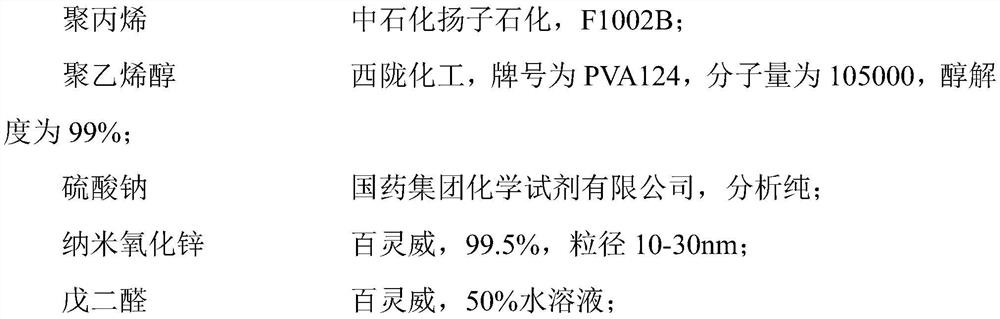

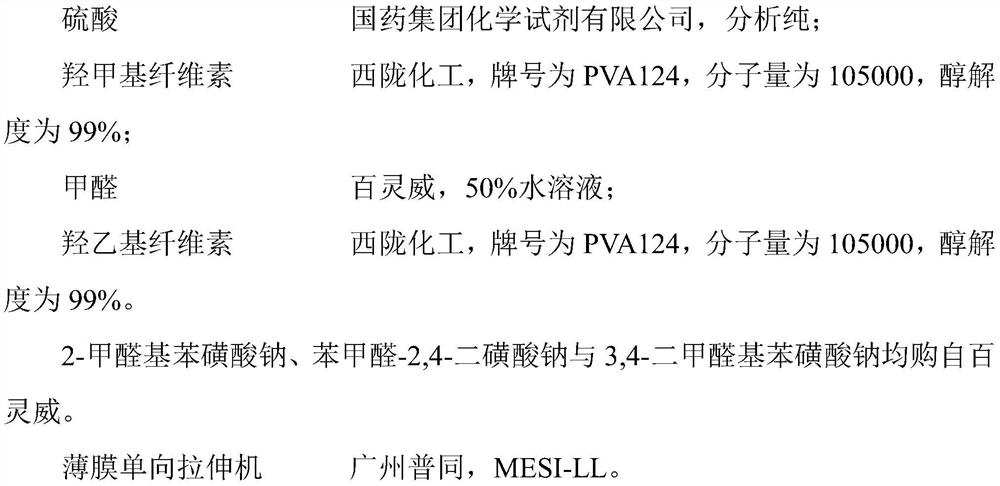

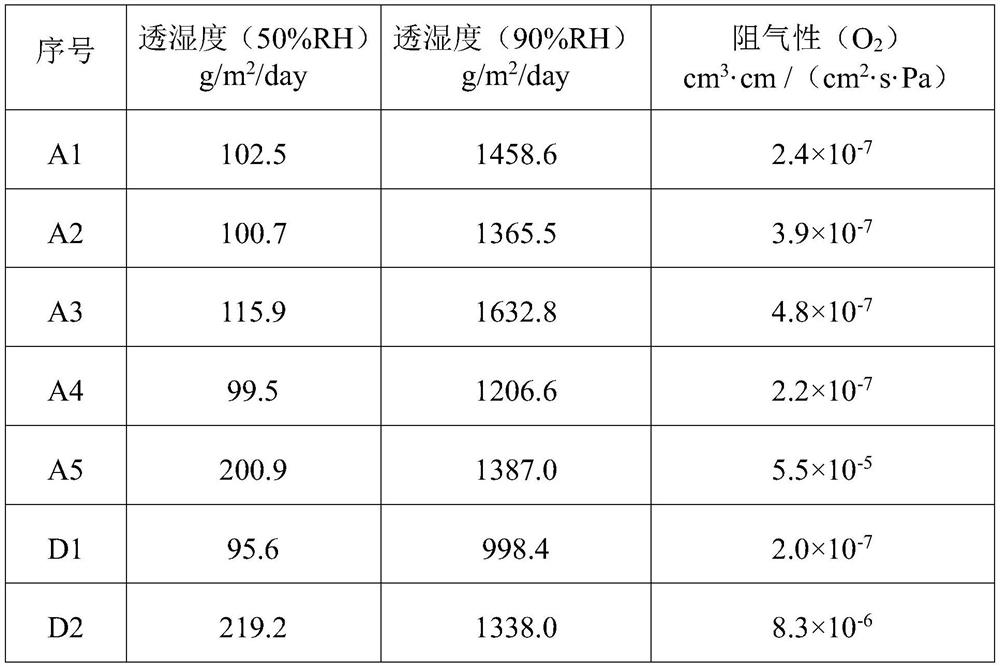

[0049] Get 2kg polypropylene and stretch it into a porous film on a film unidirectional stretching machine. Then take 5g of polyvinyl alcohol and add it into 100mL of distilled water to fully dissolve it, then add 0.1g of nano-zinc oxide, 0.5g of glutaraldehyde and 0.01g of sulfuric acid into the above mixture, and stir until it is evenly mixed. Brush evenly the mixed solution with a pH value of 2.5 on the polypropylene porous film, then place it in an oven, dry it at 70°C for 10 minutes, and then soak the obtained dried film in 5% mass concentration of Sodium 2-formaldehyde benzene sulfonate aqueous solution (pH value is 2.5), take it out after 5 minutes, put it in an oven, and dry it at 70°C for 10 minutes to obtain the intelligent humidity control film A1, the thickness of the support layer is 35 microns, and the pore size is 0.1 The thickness of the functional layer is 2 microns, and the gel content of the functional layer is 85%; the thickness of the hydrophilic modificat...

Embodiment 2

[0051] Get 2kg of polyethylene and stretch it into a porous film on a film unidirectional stretching machine. Take 7g of hydroxymethyl cellulose and add it into 100mL of distilled water to fully dissolve it, then add 0.2g of nano-zinc oxide, 0.4g of formaldehyde and 0.1g of sulfuric acid into the above mixed solution, and stir until it is evenly mixed. Brush evenly the mixed solution with a pH value of 2 on the polypropylene porous film, then place it in an oven, and dry it at 70°C for 10 minutes, and then soak the obtained dried film in 7.5% mass concentration of benzaldehyde-2,4-sodium disulfonate aqueous solution (pH value is 2.0), take it out after 3 minutes, put it in an oven, and dry it at 70°C for 10 minutes to obtain the intelligent humidity control film A2, the thickness of the support layer is 30 microns, The pore diameter is 0.08 micron, the porosity is 40%; the thickness of the functional layer is 2.3 micron, and the gel content of the functional layer is 74%; the ...

Embodiment 3

[0053] Get 2kg polypropylene and stretch it into a porous film on a film unidirectional stretching machine. Add 9g of hydroxyethyl cellulose into 100mL of distilled water, fully dissolve, then add 0.2g of nano-zinc oxide, 1.0g of glutaraldehyde and 0.1g of sulfuric acid into the obtained solution, and fully stir until mixed evenly. Brush evenly the mixed solution with a pH value of 2 on the polypropylene porous film, then place it in an oven, dry it at 70°C for 10 minutes, and then immerse the obtained dried film in 10% mass concentration of 3,4-diformaldehyde sodium benzene sulfonate aqueous solution (pH value is 1.5), take it out after 3 minutes, put it in an oven, and dry it at 70°C for 10 minutes to obtain the intelligent humidity control film A3, the thickness of the support layer is 35 microns, The pore diameter is 0.1 micron, the porosity is 45%; the thickness of the functional layer is 3.5 micron, and the gel content of the functional layer is 83%; the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com