Concrete pavement crack repairing method

A technology for repairing concrete pavement and cracks, which is applied to cohesive pavement paved on site, roads, roads, etc., and can solve problems affecting road comfort and safety, poor fracture toughness and impact resistance, fatigue fracture or impact damage and other issues, to achieve the effect of short open traffic time, good construction performance, resistance to high temperature and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

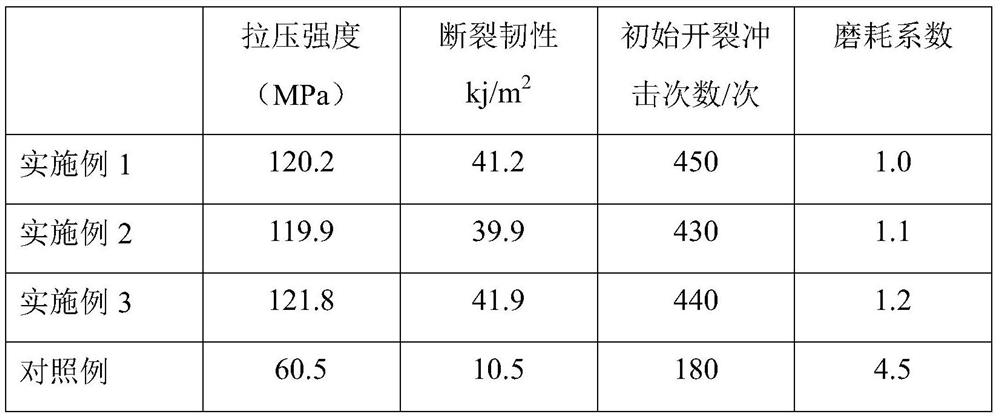

Examples

preparation example Construction

[0040] 9) Casting a layer of wear-resistant layer with a thickness of 0.8-1.2cm on the concrete layer, the preparation method of the wear-resistant layer includes:

[0041] 9.1) Add asphalt and rubber into the heating kettle, heat to 200-220°C, stir for 20-30 minutes, add SBS modifier and pass through a high-speed shearing machine to maintain the heating temperature, shear at a high speed for 30-40 minutes, maintain heating and Stir evenly for 50-70 minutes;

[0042] 9.2) Add bituminous mastic macadam mixture, fine sand and slag powder with a particle size of 6-8mm in sequence in the heating kettle, add binder, lower the temperature to 150-170°C, and stir for 20-30 minutes;

[0043] 10) Carry out curing in a humid environment of 5-20°C.

[0044] The preferred solution of the present invention is that after the repair material is finally set for 1 to 3 hours, it is immediately sprinkled with water and covered with a plastic film for maintenance.

[0045] The preferred solutio...

Embodiment 1

[0053] This embodiment provides a method for repairing concrete pavement cracks, the steps comprising:

[0054] 1) The concrete pavement cracks are detected by ground penetrating radar, and the crack width is calculated;

[0055] 2) Cut off the loose concrete at the edge of the crack and clean the crack;

[0056] 3) According to parts by weight, select 40 parts of aluminum sulfate cement, 20 parts of Portland cement, 8 parts of limestone, 10 parts of slag, 10 parts of fine sand, 6 parts of calcium stone powder, and 5 parts of aluminum tripolyphosphate;

[0057] 4) put the material selected in step 3 into the pulverizer, and grind it into 150 mesh powder;

[0058] 5) Put the powder and abrasive prepared in step 4 into the mixer, add water, and mechanically stir for 25 minutes to make a mixed mortar;

[0059] 6) According to the parts by mass, select 3 parts of desulfurized gypsum, 4 parts of unsaturated polyester resin, 2 parts of sodium phosphate, 8 parts of polyvinyl alcoho...

Embodiment 2

[0067] This embodiment provides a method for repairing concrete pavement cracks, the steps comprising:

[0068] 1) The concrete pavement cracks are detected by ground penetrating radar, and the crack width is calculated;

[0069] 2) Cut off the loose concrete at the edge of the crack and clean the crack;

[0070] 3) According to parts by weight, select 50 parts of aluminum sulfate cement, 30 parts of Portland cement, 12 parts of limestone, 5 parts of slag, 15 parts of fine sand, 10 parts of calcium stone powder, and 10 parts of aluminum tripolyphosphate;

[0071] 4) put the material selected in step 3 into the pulverizer, and grind it into 200 mesh powder;

[0072] 5) Put the powder and abrasive prepared in step 4 into the mixer, add water, and mechanically stir for 35 minutes to make a mixed mortar;

[0073] 6) According to the parts by mass, select 6 parts of desulfurized gypsum, 7 parts of unsaturated polyester resin, 4 parts of sodium phosphate, 10 parts of polyvinyl alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com