Multi-element composite strengthened alloy semisteel sizing/reducing machine roller and preparation method thereof

A strengthening alloy and multi-component compounding technology, applied in the field of casting roll manufacturing, can solve problems such as failure of easy-sticking steel, affecting the surface quality of steel pipes, and high alloy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

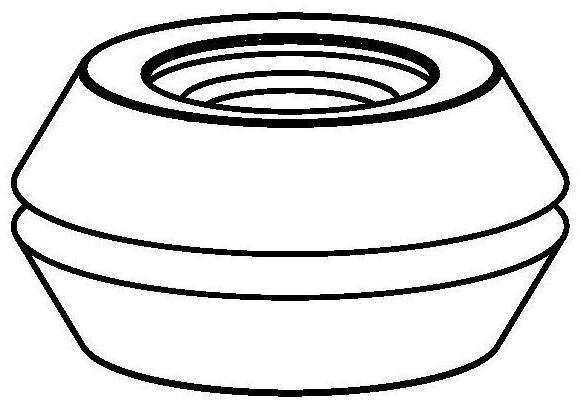

[0048] refer to figure 1 The schematic diagram of the roll structure, half of its section is approximately "M" shape. Example 1 is to manufacture 6 pieces of three-roller hot-rolled seamless steel pipe tension reducer rolls for Φ140 seamless steel pipe continuous rolling mill. Components are shown in Table 1 by weight percentage (%Wt).

[0049] The balance in Table 1 is Fe; composite strengthening particles B 4 The amount of C added is 30kg per ton of molten steel

[0050] C Si mn Cr Ni Mo Al Ti RE Zr Ce Sb Y P S 1.9 0.81 0.48 1.26 0.11 0.13 0.27 0.28 0.14 0.07 0.04 0.02 0.01 0.02 0.01

[0051] The smelting, strengthening composite, inoculation spheroidization, casting, heat treatment and machining processes in this embodiment are all carried out according to the steps of the preparation method.

[0052] According to the design ratio, various elements such as ferrotitanium, rare earth silicon, zirconium sponge, cerium, a...

Embodiment 2

[0056] refer to figure 1The schematic diagram of the roll structure. Example 2 is to manufacture 3 rolls of a three-roller hot-rolled seamless steel pipe sizing mill for a continuous rolling mill of Φ250 seamless steel pipe. The weight is 265kg / piece, and the matrix components are shown in Table 1 by weight percentage (%Wt).

[0057] The balance in Table 2 is Fe; composite strengthening particles B 4 The amount of C added is 20kg per ton of molten steel

[0058] C Si mn Cr Ni Mo Al Ti RE Zr Ce Sb Y P S 1.6 1.02 0.35 1.02 0.09 0.1 0.21 0.18 0.1 0.06 0.02 0.02 0.01 0.02 0.01

[0059] The preparation steps of Example 2 are the same as those of Example 1, and the processes of smelting, strengthening compounding, inoculation and spheroidization, casting, heat treatment, and machining are all carried out according to the steps of the preparation method.

[0060] According to the design ratio, various elements such as ferrotitan...

Embodiment 3

[0064] refer to figure 2 The schematic diagram of the roll structure, half of its section is approximately "M" shape. Example 3 is to manufacture 3 rolls of a three-roller hot-rolled seamless steel pipe sizing mill for a Φ460 seamless steel pipe continuous rolling mill. See Table 1 for matrix components by weight percentage (%Wt).

[0065] The balance in Table 3 is Fe; composite strengthening particles B 4 The amount of C added is 10kg per ton of molten steel

[0066] C Si mn Cr Ni Mo Al Ti RE Zr Ce Sb Y P S 1.5 1.2 0.31 0.82 0.08 0.07 0.10 0.06 0.14 0.04 0.04 0.02 0.01 0.02 0.01

[0067] The preparation steps of Example 3 are the same as those of Examples 1 and 2, wherein the amount of industrially pure iron powder is 0.8 times the total amount of ferrotitanium, rare earth silicon, zirconium sponge, cerium, antimony, and boron carbide powder. 20 minutes before the molten steel comes out of the furnace, three steel cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com