Method for in-situ construction of superhydrophobic coating on copper alloy surface

A technology of super-hydrophobic coating and copper alloy, applied in the direction of metal material coating process, etc., can solve the problem that the invention has not been reported, and achieve the effect of strong binding force, easy realization and enhanced corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the present embodiment, a method of constructing a superhydrophobic coating on the surface of the copper alloy in situ, comprising the steps of:

[0043] . A copper alloy surface pretreatment:

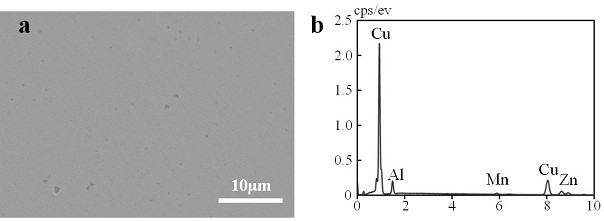

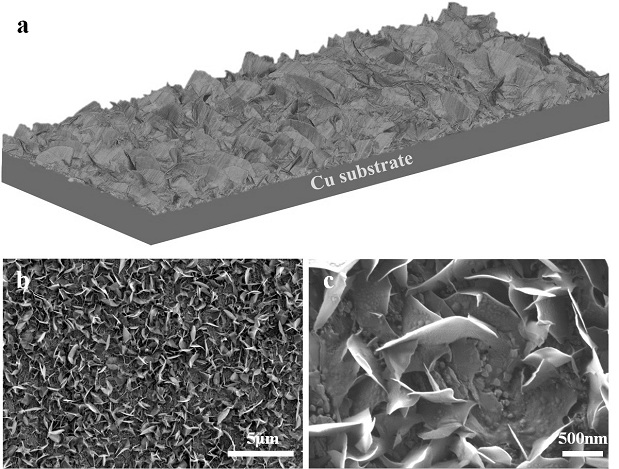

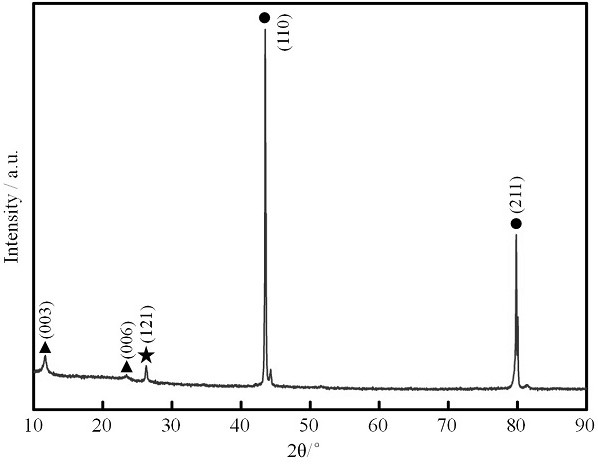

[0044] Aluminum element with a higher copper content aluminum brass alloy as a base material of a copper alloy, a zinc content of 25.09%, aluminum 5.89%, Mn 1.48%, Fe 0.40%, balance copper; cut into copper alloy, width and height of 10mm pieces of any size copper alloy material × 10mm × 5mm, using size No. 240 mesh, 600 mesh, 800 mesh, mesh 2000, 5000 and 7000 mesh SiC paper object, with successively different size SiC papers grinding and diamond suspension was 0.5μm copper alloy material subjected to a surface polishing treatment, and then rinsed with deionized water surface of the copper alloy material, and then the copper alloy material has an ethanol solution, deionized water and subjected to ultrasonic cleaning with a particle size of 5 minutes, then dried with cold air to o...

Embodiment 2

[0053] The present embodiment is substantially the same as first embodiment, is unique in that:

[0054] In the present embodiment, a method of constructing a superhydrophobic coating on the surface of the copper alloy in situ, comprising the steps of:

[0055] . A copper alloy surface pretreatment:

[0056] Aluminum element with a higher copper content aluminum brass alloy as a base material of a copper alloy, a zinc content of 25.09%, aluminum 5.89%, Mn 1.48%, Fe 0.40%, balance copper; cut into copper alloy, width and height of 10mm pieces of any size copper alloy material × 10mm × 5mm, using size No. 240 mesh, 600 mesh, 800 mesh, mesh 2000, 5000 and 7000 mesh SiC paper object, with successively different size SiC papers grinding and diamond suspension was 0.5μm copper alloy material subjected to a surface polishing treatment, and then rinsed with deionized water surface of the copper alloy material, and then the copper alloy material has an ethanol solution, deionized water and...

Embodiment 3

[0069] The present embodiment is substantially the same as the embodiment described above, it is unique in that:

[0070] . A copper alloy surface pretreatment:

[0071] As the base material of brass, a zinc content of 30%, balance copper; cut into the brass, width and height of an arbitrary size 10mm × 10mm × 5mm pieces of brass, with a particle size of 240 mesh number, 600 mesh, 800 mesh, mesh 2000, 5000 and 7000 mesh SiC paper purposes, carried out with different particle size SiC papers sequentially polished, and then the suspension was 0.5μm diamond surface polished brass with a particle size, then deionized water cleaning the surface of the brass, brass, and then successively subjected to ultrasonic cleaning for 5 minutes in ethanol, deionized water, and then dried with cold air to obtain clean dry surface preparation of brass, standby;

[0072] . B brass surface constructed in situ layered double hydroxide / oxide film multistage process:

[0073] Brass surface will be afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com