Three-axis compound spinning process for symmetrically protecting carbon fibers and application thereof

A composite spinning and carbon fiber technology, applied in the direction of yarn, textiles and paper making, can solve problems such as splitting, use and processing restrictions, and achieve the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

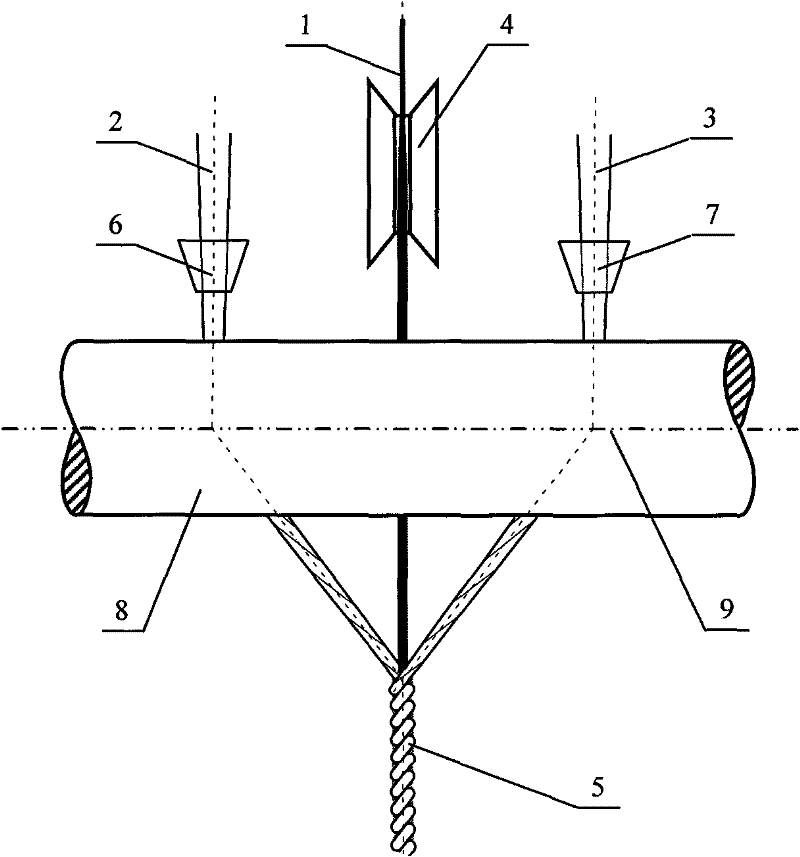

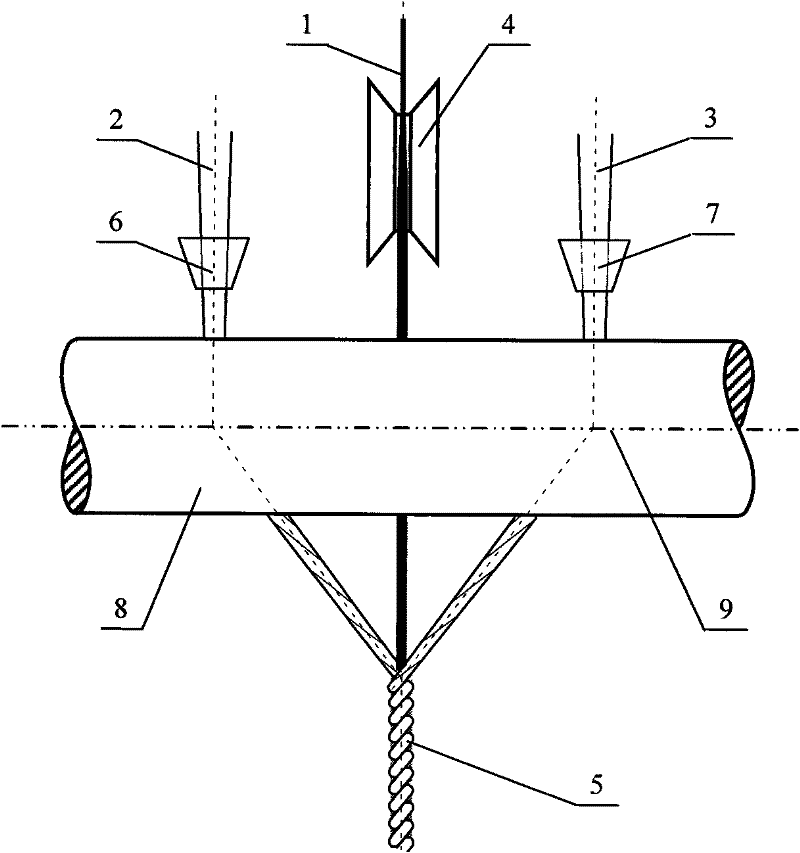

[0030] Embodiment 1: Spinning nylon + carbon filament bundle triaxial composite yarn

[0031] Get two nylon roving bobbins (i.e. two roving bobbins) and one carbon filament bobbin (i.e. a small roll of long filament bobbins equipped with carbon filament bundles), and obtain two bundles of nylon staple fiber strands and a carbon filament bobbin according to the above-mentioned process steps. The composite ratio of filament bundles is: the composite mass ratio of nylon staple fiber strands / nylon staple fiber strands / carbon filament strands is 20 / 20 / 60. The carbon filament tow is flattened with the tension of the positioning tension wheel at 10cN and the enveloping angle of 120°, and is fed into the front roller nip along the central axis; two bundles of nylon staple fibers (axis II and axis III) With the natural tension of drafting and the spacing of 8mm, it is symmetrical to the central axis (axis I) of the carbon filament bundle and fed into the nip of the front roller. For de...

Embodiment 2

[0032] Example 2: Spinning nylon+carbon filament bundle triaxial composite yarn

[0033] Get two nylon roving bobbins (i.e. two roving bobbins) and one carbon filament bobbin (i.e. a small roll of long filament bobbins equipped with carbon filament bundles), and obtain two bundles of nylon staple fiber strands and a carbon filament bobbin according to the above-mentioned process steps. The composite ratio of filament bundles is as follows: the composite mass ratio of nylon staple fiber strands / nylon staple fiber strands / carbon filament strands is 25 / 25 / 50. The carbon filament tow is flattened with the tension of the positioning tension wheel at 8cN and the enveloping angle of 120°, and is fed into the front roller nip along the central axis; two bundles of nylon staple fibers (axis II and axis III) With the natural tension of drafting and 10mm spacing, it is symmetrical to the central axis (axis I) of the carbon filament bundle and fed into the nip of the front roller. For det...

Embodiment 3

[0034] Example 3: spinning polypropylene + basalt filament triaxial composite yarn

[0035] Take two polypropylene roving bobbins and one basalt filament bobbin, and obtain two bundles of polypropylene staple fiber strands and one basalt filament strand according to the above process steps, and the composite ratio is: polypropylene staple fiber strands / polypropylene staple fiber strands / basalt long filament strands The composite mass ratio of the tow is 16 / 16 / 68. The basalt filament bundle is flattened by positioning the tension wheel with a tension of 15cN and a wrapping angle of 150°, and feeds the front roller nip through the central axis; two bundles of polypropylene staple fiber strands (axis II and axis III) With the natural tension of drafting and the spacing of 6mm, it is symmetrical to the central axis (axis I) of the basalt filament bundle and fed into the nip of the front roller. For details, see figure 1 shown. After the three-axis fiber strips come out of the fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com