Treatment method of silver electrode for ion chromatography ampere detection

An amperometric detection and ion chromatography technology, which is applied to the treatment field of silver electrodes for ion chromatography amperometric detection, can solve the problems of large difference in surface energy spatial distribution, reduced surface roughness of silver electrodes, and reduced surface area of silver electrodes, etc. Stability and effective area, simple and efficient processing procedures, and the effect of improving the electrochemical detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

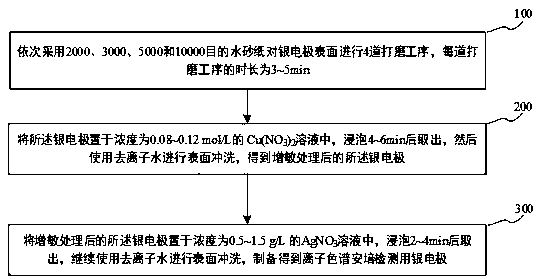

[0084] (1) Use 2000, 3000, 5000 and 10000 mesh water sandpaper in sequence to perform 4 grinding processes on the surface of the silver electrode. The duration of each grinding process is 3 minutes. After each grinding process, the silver electrode is ultrasonicated at a temperature of 50 ° C. After cleaning for 5 minutes, the silver electrode after ultrasonic cleaning was placed in 8% HNO 3 solution, soak it at 28°C for 4 minutes and take it out.

[0085] (2) Put the silver electrode in the concentration of 0.08 mol / L Cu(NO 3 ) 2 solution, after soaking for 4 minutes, take it out, and then rinse the surface with deionized water to obtain the silver electrode after sensitization treatment.

[0086] (3) The silver electrode after the sensitization treatment was placed in AgNO with a concentration of 0.5 g / L 3 After soaking in the solution for 4 minutes, take it out, continue to use deionized water to wash the surface, and prepare a silver electrode for ion chromatography amp...

Embodiment 2

[0089] (1) Use 2000, 3000, 5000 and 10000 mesh water sandpaper to perform 4 grinding processes on the surface of the silver electrode in sequence. The duration of each grinding process is 4 minutes. After each grinding process, put the silver electrode at a temperature of 45 ° C. Ultrasonic cleaning for 6 minutes, and then the silver electrode after ultrasonic cleaning was placed in 9% HNO 3 solution, soak it at 29°C for 5 minutes and take it out.

[0090] (2) Put the silver electrode in the concentration of 0.09 mol / L Cu(NO 3 ) 2 solution, after soaking for 4 minutes, take it out, and then rinse the surface with deionized water to obtain the silver electrode after sensitization treatment.

[0091] (3) The silver electrode after the sensitization treatment was placed in AgNO with a concentration of 0.5 g / L 3 After soaking in the solution for 2 minutes, take it out, continue to use deionized water to wash the surface, and prepare a silver electrode for ion chromatography amp...

Embodiment 3

[0094] (1) Use 2000, 3000, 5000 and 10000 mesh water sandpaper to perform 4 grinding processes on the surface of the silver electrode in sequence. The duration of each grinding process is 4 minutes. After each grinding process, put the silver electrode at a temperature of 45 ° C. Ultrasonic cleaning for 7 minutes, and then the silver electrode after ultrasonic cleaning was placed in 8% HNO 3 solution, soak it at 29°C for 4 minutes and take it out.

[0095] (2) Put the silver electrode in the concentration of 0.10mol / L Cu(NO 3 ) 2 solution, after soaking for 5 minutes, take it out, and then rinse the surface with deionized water to obtain the silver electrode after sensitization treatment.

[0096] (3) The silver electrode after the sensitization treatment was placed in AgNO with a concentration of 1.0 g / L 3 After soaking in the solution for 2 minutes, take it out, continue to use deionized water to wash the surface, and prepare a silver electrode for ion chromatography ampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com