High-entropy alloy reinforced magnesium-based composite material and preparation method thereof

A high-entropy alloy and composite material technology is applied in the field of high-entropy alloy reinforced magnesium-based composite materials and their preparation, and can solve the problems of poor creep resistance, insufficient strength and hardness, and too fast deformation rate. , to achieve the effect of good industrialization prospects, high hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

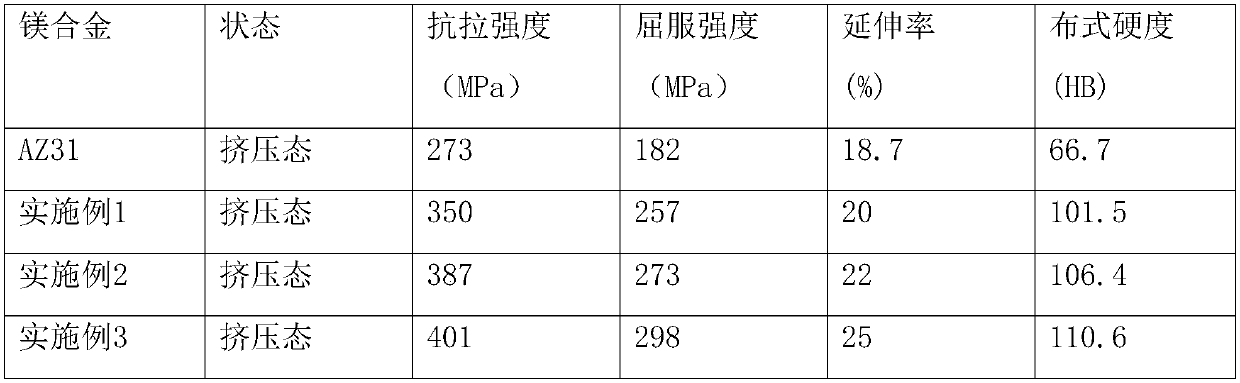

Embodiment example 1

[0038] The preparation method of the magnesium-based composite material reinforced by the above-mentioned high-entropy alloy comprises the following steps:

[0039] (1) Preparation of high-entropy alloy ingot:

[0040] The high-entropy alloy element FeCoCrNiMn to be prepared was weighed according to the equiatomic ratio, placed in a water-cooled copper mold fixed in a vacuum electric arc furnace, smelted in a vacuum environment, and protected by argon. Repeated smelting for 5 times to prevent composition segregation, and obtain a high-entropy alloy ingot with uniform composition;

[0041] The purity of each raw material is not less than 99.5wt.%. When placed in a water-cooled copper crucible, each raw material is placed from bottom to top according to its melting point from low to high;

[0042] (2) Preparation of high entropy alloy powder:

[0043] Firstly, the high-entropy alloy ingot is milled into shavings, and then the metal shavings are put into a ball mill with argon ...

Embodiment example 2

[0054] (1) Preparation of high-entropy alloy ingots:

[0055] Weigh the corresponding mass of the high-entropy alloy element FeCoCrNiCu to be prepared according to the equiatomic ratio, place it in a water-cooled copper mold fixed in a vacuum electric arc furnace, melt it in a vacuum environment, and pass it into argon for protection, repeatedly Smelting more than 5 times to prevent composition segregation and obtain a high-entropy alloy ingot with uniform composition

[0056] The purity of each raw material is not less than 99.5wt.%. When placed in a water-cooled copper crucible, each raw material is placed from bottom to top according to its melting point from low to high;

[0057] (2) Preparation of high-entropy alloy powder:

[0058] Firstly, the high-entropy alloy ingot is milled into shavings, and then the metal shavings are put into a ball mill with argon gas in a vacuum and ball milled to a particle size of 30 μm to prepare high-entropy alloy powder particles; the bal...

Embodiment example 3

[0069] (1) Destined steps for preparing high-entropy alloys:

[0070] Weigh the corresponding mass of the FeCoCrNiAl high-entropy alloy elements to be prepared according to the equiatomic ratio, place them in a water-cooled copper mold fixed in a vacuum electric arc furnace, melt in a vacuum environment, and pass in argon gas for protection and repeated melting Prevent composition segregation for more than 5 times, and obtain high-entropy alloy ingot with uniform composition

[0071] The purity of each raw material is not less than 99.5wt.%. When placed in a water-cooled copper crucible, each raw material is placed from bottom to top according to its melting point from low to high;

[0072] (2) Preparation of high-entropy alloy powder:

[0073] Firstly, the high-entropy alloy ingot is milled into shavings, and then the metal shavings are put into a ball mill with argon gas in a vacuum and ball milled to a particle size of 30 μm to prepare high-entropy alloy powder particles; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com