A multi-efficiency corn straw biochar compound fertilizer for repairing soil cadmium pollution and its preparation method

A compound fertilizer and corn stalk technology, which is applied in the preparation/purification of carbon, fertilizer mixture, solid/semi-solid fertilizer, etc., can solve the problems of unstable soil heavy metal passivation effect and low fertility, and achieve good adsorption and passivation performance , good fertility function, good stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of multi-performance corn stalk biochar compound fertilizer for repairing soil cadmium pollution of the present embodiment comprises the following steps: Step 1: firstly collect the corn stalks in batches in the field, and then cut the corn stalks into about 5 cm The short section is dried in a temperature-controlled oven at a temperature of 60°C for 24 hours. The dried corn stalks were placed in a plant micro grinder and pulverized into particles with a diameter of about 2 mm.

[0046] Step 2: Add the air-dried and pulverized corn stalks, heavy superphosphate and diatomaceous earth into the micro-mixer according to the weight ratio of 5:1:1 and 10:1:1 respectively, mix them thoroughly for 5 minutes, and take them out for later use. Among them, the corn stalks used were collected from the farmland in the suburbs of Kaifeng, Henan; the calcium superphosphate used was purchased from Yunnan Yuntianhua International Chemical Co., Ltd. 2 o 5 ) content ≥ 46.0%, avail...

Embodiment 2

[0053] In this embodiment, a single corn stalk is pyrolyzed to prepare a biochar fertilizer, which includes the following steps:

[0054] Step 1: First, collect the corn stalks in batches in the field. After the collection, cut the corn stalks into small pieces of about 5 cm, and dry them in a temperature-controlled oven at 60° C. for 24 hours.

[0055] Step 2: The dried corn stalks are placed in a plant micro grinder and pulverized into granular raw materials with a diameter of about 2mm, and then put into jars and sealed for later use. Among them, the corn stalks used were collected from farmland in the suburbs of Kaifeng, Henan.

[0056] Step 3: Put the single corn stalk raw material in step 2 into a tube furnace for high-temperature pyrolysis.2 Under a protective atmosphere, composite biochar materials were prepared through different pyrolysis temperatures (300°C, 450°C, 600°C), which were marked as B 3 , B 4.5 and B 6 .

[0057] Specifically: Open the stainless steel ...

Embodiment 3

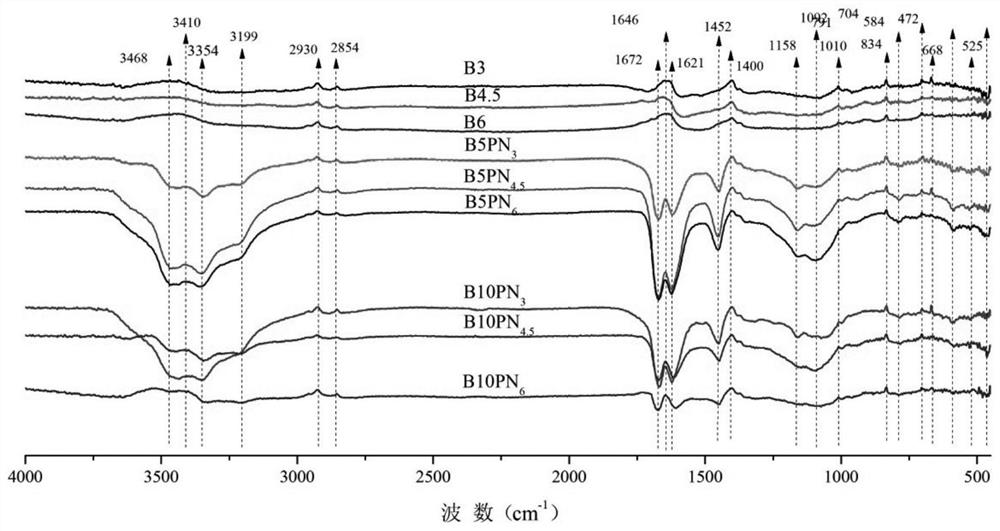

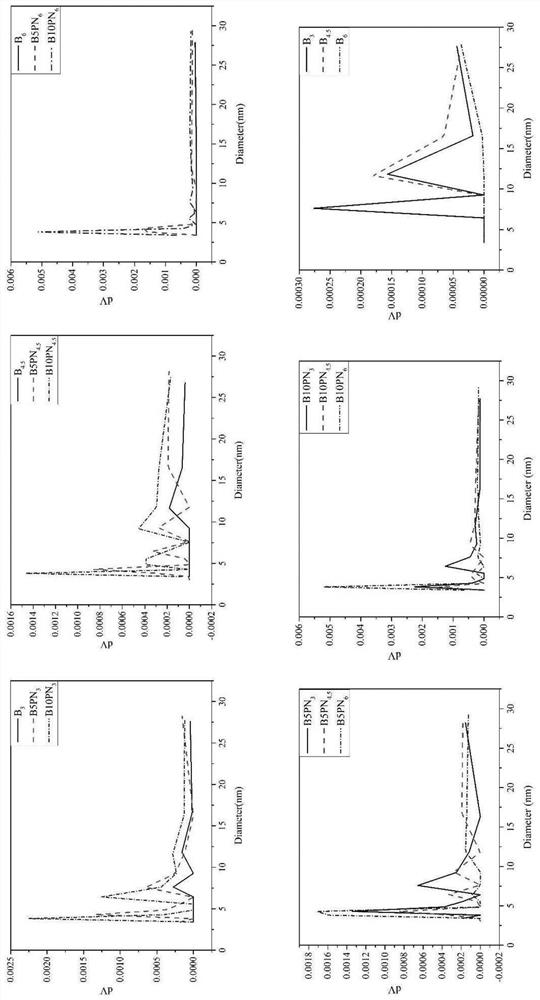

[0061] Measure the specific surface area, average pore size, total pore volume and surface functional group characteristics of the biochar composite fertilizer prepared in Example 1 and the single biochar prepared in Example 2, see Table 1, figure 1 , microstructure scanning energy spectrum, see figure 2 , see the pore size distribution for details image 3 , see the adsorption-desorption isotherm for details Figure 4 , the element contents are shown in Table 2. Among them, Fourier transform infrared spectrometer was used to analyze the surface functional groups, SEM-EDS (field emission scanning electron microscope energy spectrometer) was used to analyze the microstructure and element content, and the specific surface and porosity analyzer was used to analyze the adsorption-desorption of the prepared materials. Isotherms and pore size distributions.

[0062] Table 1 The specific surface area, average pore diameter and total pore volume of single biochar and biochar compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com