Preparation method of yttrium oxide stabilized zirconium oxide powder based on supercritical dispersion roasting

A technology for stabilizing zirconia and yttrium oxide, applied in the field of material chemistry, can solve the problems of powder morphology and particle size that cannot meet high-end applications, large powder particle size, low production efficiency, etc. The effect of large particle size and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 97kg of zirconium carbonate and 3kg of yttrium carbonate and add them to the boiling dryer, control the hot air inlet temperature to 135°C, and after drying for 2 hours, the outlet air temperature is stable at 85°C, and the drying is stopped. The dried material is the precursor material for preparing yttria-stabilized zirconia (3.4mol% YSZ).

[0037] Add 40kg of ethanol to the dispersion tank of the nano sand mill in advance, slowly add 30kg of the above precursor material under the stirring state, and add 150g of polyethylene glycol (PEG4000) dispersant at the same time, grind for 3 hours, and analyze the particle size D 10 63.7nm, D 50 It is 109nm, and it is discharged into barrels.

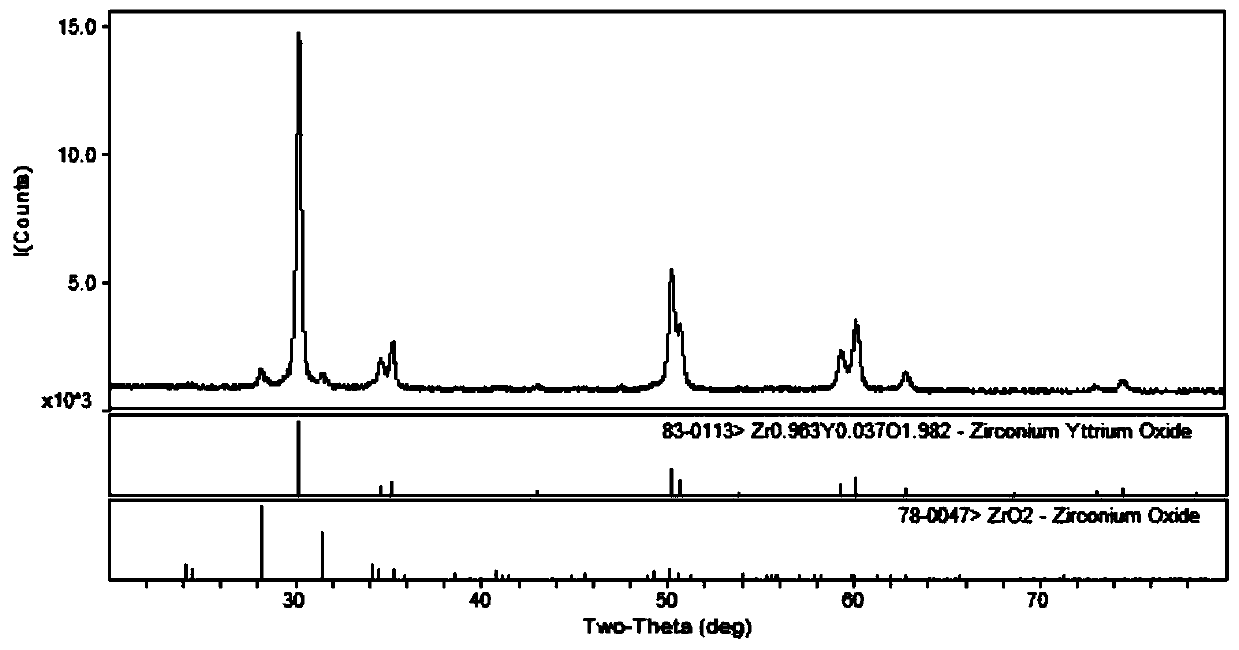

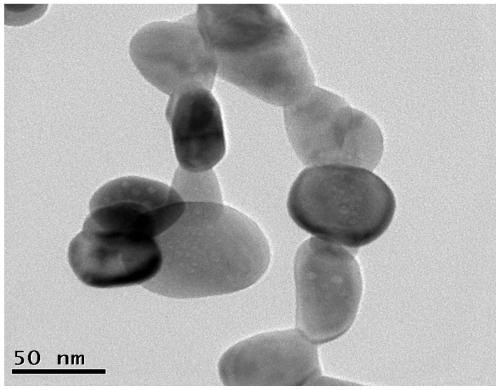

[0038] The autoclave is preheated to 300°C, the pressure is 8MPa, and the above-mentioned grinding slurry is transported into the autoclave by a metering pump (flow rate 40%), and then sprayed into the calciner from the outlet through the ignition gun. The temperature in the calci...

Embodiment 2

[0041] Weigh 92kg of zirconium carbonate and 8kg of yttrium carbonate and add them into the boiling dryer, control the hot air inlet temperature to 150°C, and after drying for 1.5 hours, the outlet air temperature is stable at 90°C, and the drying is stopped. The dried material is the precursor material for preparing yttria-stabilized zirconia (10mol% YSZ).

[0042] Add 20kg of ethanol to the dispersion tank of the nano sand mill in advance, slowly add 10kg of the above precursor material under the stirring state, and add 100g of polyethylene glycol (PEG4000) dispersant at the same time, grind for 2 hours, and analyze the particle size D 10 72.7nm, D 50 It is 130nm, and it is discharged into barrels.

[0043] The autoclave is preheated to 280°C and the pressure is 7MPa. The above-mentioned grinding slurry is transported into the autoclave by a metering pump (flow rate 40%), and then sprayed into the calciner from the outlet through the ignition gun. The temperature in the calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com