Graphene-based aerogel material with strong and tough structure and preparation method thereof

A graphene-based, aerogel technology, applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of easy collapse, complicated process, poor chemical stability of cellulose airgel, etc., and achieve mechanical Enhanced strength, good electrical conductivity, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment discloses a method for preparing a graphene-based aerogel material with a strong and tough structure, and the specific process is as follows:

[0066] 1) Preparation of graphene oxide solution: using natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, potassium permanganate as raw materials, graphene oxide is prepared by an improved Hummers method, and uniformly dispersed in deionized water. Graphene oxide aqueous solution with a concentration of 5 mg / mL.

[0067] 2) Preparation of nanofiber suspension: the thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain mass and then melted and extruded to obtain PVA-co-PE nanofiber fibrils. The PVA-co-PE nanofiber suspension is placed in an alcohol-water system, and a uniformly dispersed milky white PVA-co-PE nanofiber dispersion with a concentration of 20 mg / mL is prepared by the strong shear action of a stirrer.

...

Embodiment 2

[0071] This embodiment discloses a method for preparing a graphene-based aerogel material with a strong and tough structure, and the specific process is as follows:

[0072] 1) Preparation of graphene oxide solution: using natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, potassium permanganate as raw materials, graphene oxide is prepared by an improved Hummers method, and uniformly dispersed in deionized water. Graphene oxide aqueous solution with a concentration of 5 mg / mL.

[0073] 2) Preparation of nanofiber suspension: the thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain mass and then melted and extruded to obtain PVA-co-PE nanofiber fibrils. The PVA-co-PE nanofiber suspension is placed in an alcohol-water system, and a uniformly dispersed milky white PVA-co-PE nanofiber dispersion with a concentration of 20 mg / mL is prepared by the strong shear action of a stirrer.

...

Embodiment 3

[0077] This embodiment discloses a method for preparing a graphene-based aerogel material with a strong and tough structure, and the specific process is as follows:

[0078] 1) Preparation of graphene oxide solution: using natural graphite powder, concentrated sulfuric acid, potassium persulfate, phosphorus pentoxide, potassium permanganate as raw materials, graphene oxide is prepared by an improved Hummers method, and uniformly dispersed in deionized water. Graphene oxide aqueous solution with a concentration of 5 mg / mL.

[0079] 2) Preparation of nanofiber suspension: the thermoplastic PVA-co-PE masterbatch and cellulose acetate butyrate (CAB) powder are mixed according to a certain mass and then melted and extruded to obtain PVA-co-PE nanofiber fibrils. The PVA-co-PE nanofiber suspension is placed in an alcohol-water system, and a uniformly dispersed milky white PVA-co-PE nanofiber dispersion with a concentration of 20 mg / mL is prepared by the strong shear action of a stirrer.

...

PUM

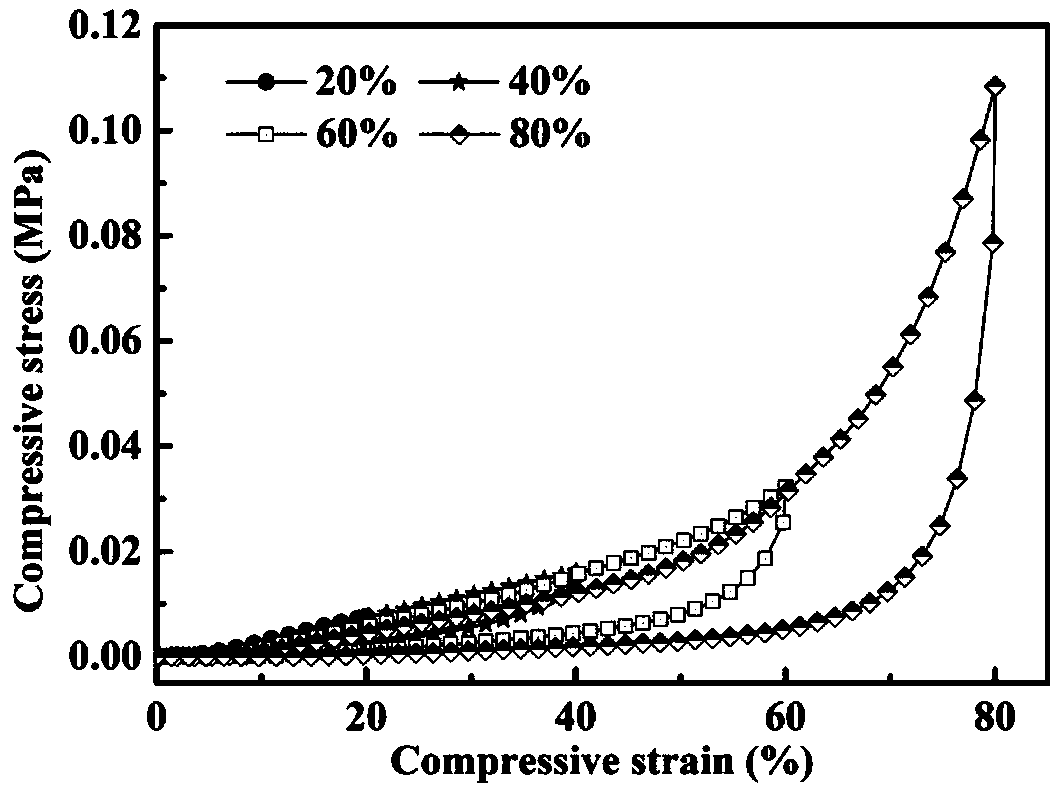

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com