A kind of high-quality zinc stannate single crystal thin film and preparation method thereof

A single crystal thin film, zinc stannate technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the basic research that restricts the application, the electrical properties of single crystal thin film materials, etc., and there are few materials. electrical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] According to the present invention, the preparation method of above-mentioned zinc stannate single crystal thin film comprises:

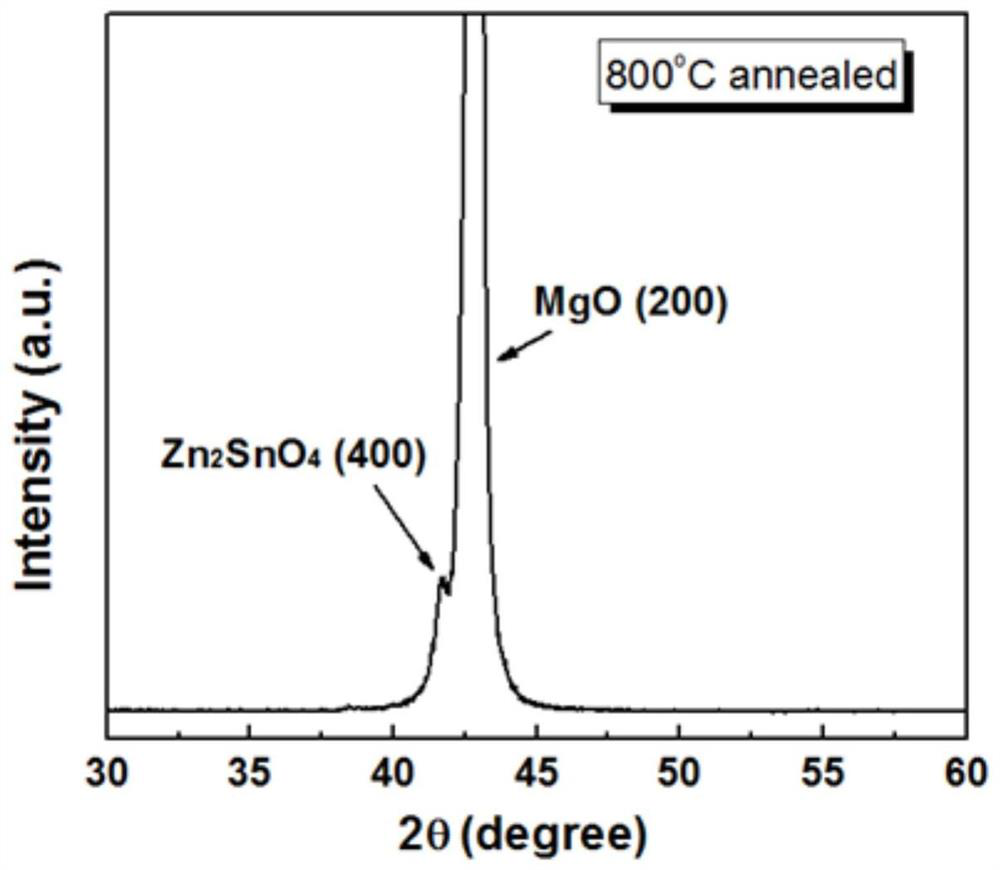

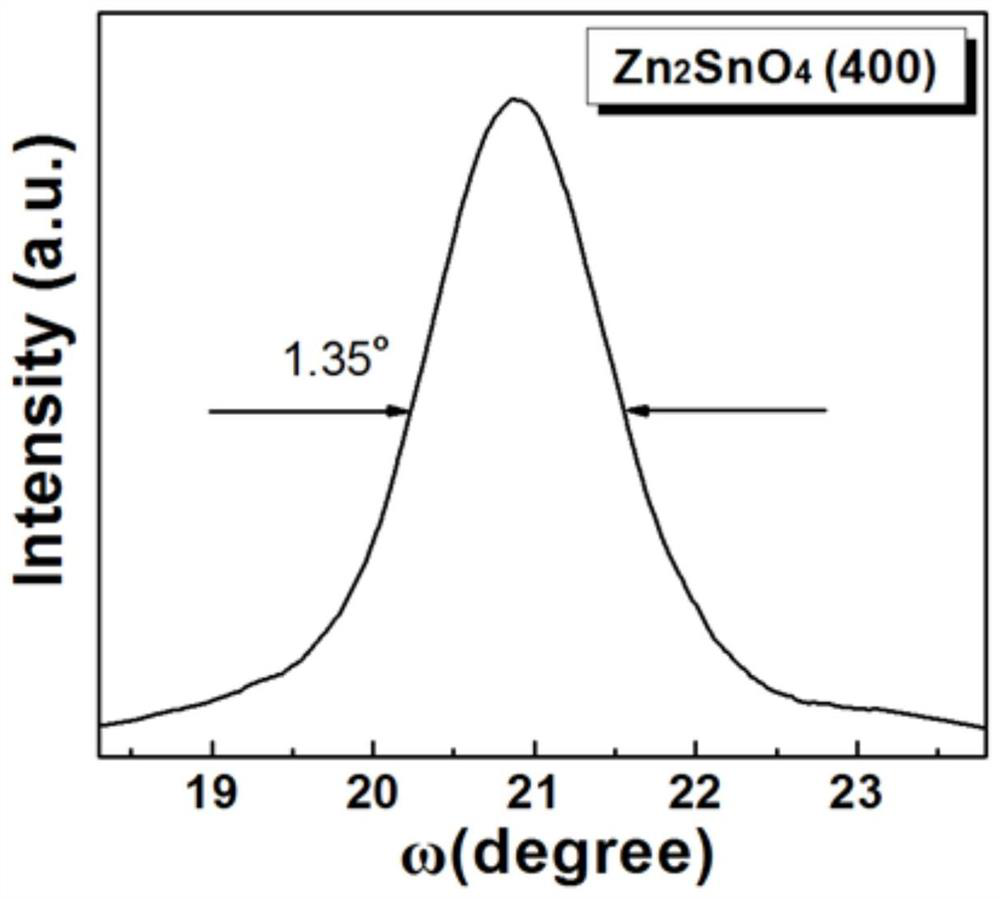

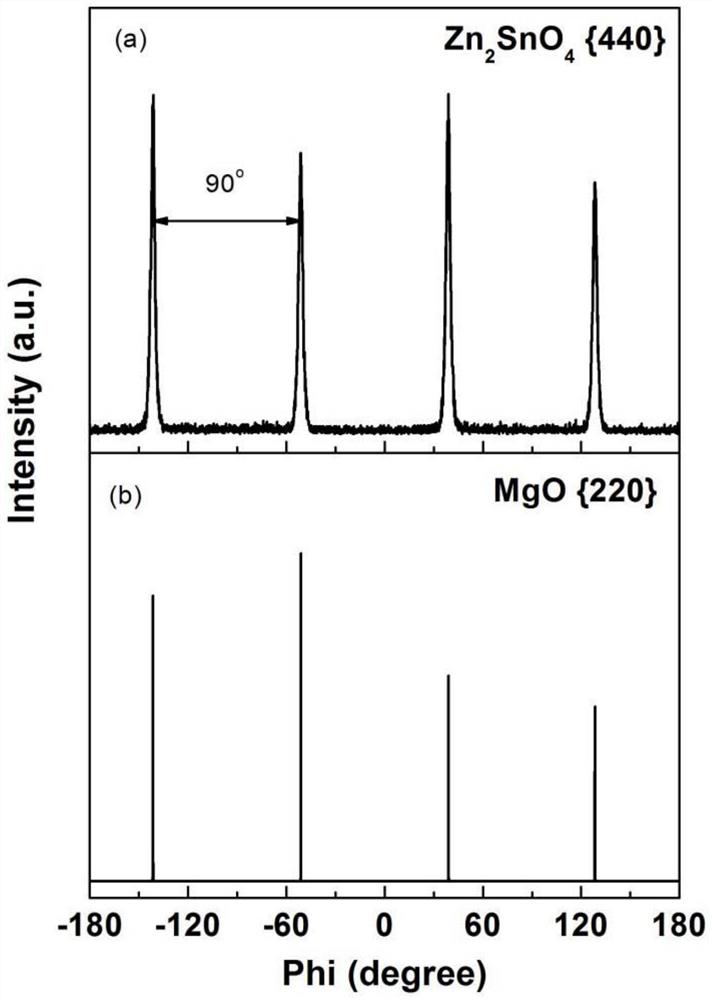

[0019] Zinc stannate target is provided as raw material, and zinc stannate film is grown on the substrate by pulsed laser deposition;

[0020] The zinc stannate thin film is heat-treated to obtain the zinc stannate single crystal thin film.

[0021] According to the present invention, preferably, the zinc stannate target material is Zn 2 SnO 4 The powder is obtained by compression molding and high temperature firing;

[0022] Preferably, the pressing pressure is 40MPa-70MPa, and the high-temperature firing temperature is 1100°C-1300°C.

[0023] Zinc stannate target material, a preferred preparation scheme, includes the following steps:

[0024] 99.99% pure Zn 2 SnO 4 The powder is pressed into a compact under a pressure of 40MPa-70MPa in a hydraulic press, and then sintered at 1100°C-1300°C for 2-4 hours to make a zinc stannate ceramic ...

Embodiment approach

[0054] According to the present invention, the preparation method of zinc stannate single crystal thin film, a kind of preferred embodiment, steps are as follows:

[0055] (1) Place the zinc stannate target material and the cleaned magnesium oxide (100) substrate in the corresponding positions of the target base in the reaction chamber respectively, and pump the PLD reaction chamber into a high vacuum state with a vacuum degree of 8×10 -5 Pa~1×10 -4 Pa, the substrate is heated to a growth temperature of 500°C-750°C;

[0056] (2) Open the valve of the oxygen cylinder, feed oxygen into the reaction chamber, the oxygen flow rate is 10-30sccm, adjust the pressure of the reaction chamber to be 5-30Pa, and keep for 20-30 minutes;

[0057] (3) Turn on the laser and adjust the laser to a stable energy mode, with a single pulse energy of 150-350 mj, a burst length of 20 ns, and a pulse frequency of 1-10 Hz. Run the laser for 10 minutes of pre-deposition to remove possible contaminant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com