A kind of high-performance tungsten alloy rod and its preparation method

A tungsten alloy, high-performance technology, applied in the field of high-performance tungsten alloy rods and its preparation, can solve the problems of high cost, less than 10%, and the unsuitability of the swaging process to prepare large-diameter rods, etc., and achieve a high pass rate , Improving the effect of high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

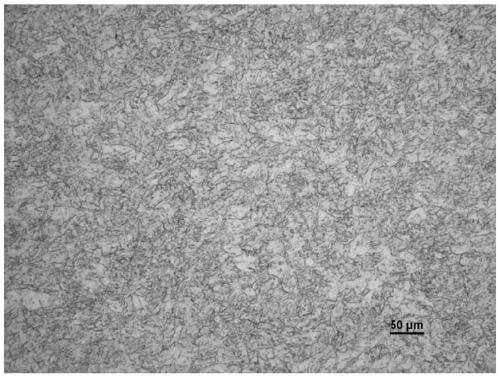

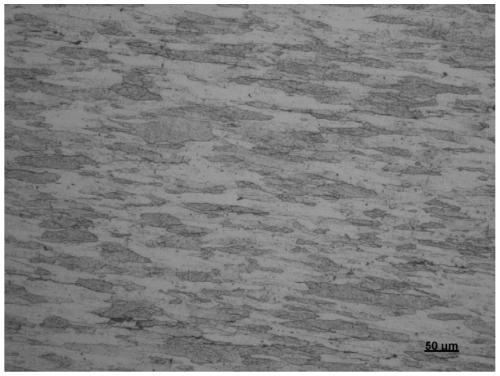

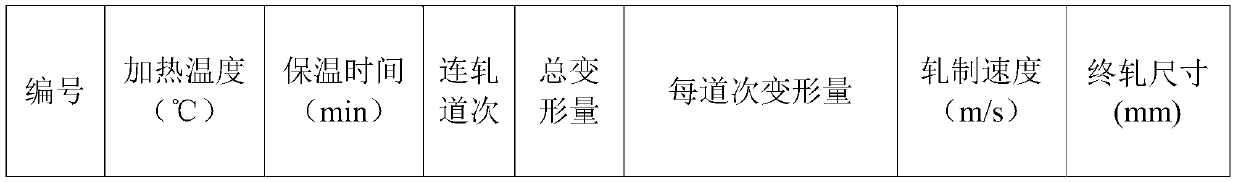

Image

Examples

Embodiment 1

[0043] (1) Preparation of tungsten-rhenium pre-alloyed powder: take respectively 39000g of tungsten powder with a Fibonacci particle size of 3.0 μm and a purity of 99.95% and 14400g of ammonium rhenate powder with a purity of 99.99% after grinding and passing through a 200 mesh sieve, and then Add the ammonium acid powder into a mixer equipped with tungsten powder for mixing, the speed is 20r / min, and the mixing time is 1 hour; after mixing evenly, carry out the first hydrogen reduction treatment, that is, react at 420°C for 40 minutes; then carry out the second The second hydrogen reduction treatment is to react at 850°C for 35 minutes; during the hydrogen reduction treatment, the hydrogen flow rate is 7L / min. After the reduction reaction was completed, 49000g rhenium-tungsten pre-alloyed powder was obtained.

[0044] (2) Preparation of tungsten alloy powder: Weigh 1000g of HfC powder with a particle size of -200 mesh and a purity of 99.6%; mix it with tungsten-rhenium pre-al...

Embodiment 2

[0052] (1) Preparation of tungsten-rhenium pre-alloyed powder: Weigh the doped tungsten powder with a Fibonacci particle size of 4.0 μm and a purity of 99.95% (i.e. Si: 0.035wt%, Al: 0.008wt%, K: 0.007wt%, and the rest 16900g of tungsten) and 4320g of ammonium rhenate powder with a purity of 99.99% after grinding and passing through a 200 mesh sieve, then add the ammonium rhenate powder into a mixer equipped with tungsten powder for mixing, the speed of rotation is 15r / min, and the mixing time After mixing evenly, perform the first hydrogen reduction treatment, that is, react at 400°C for 35 minutes, and then perform the second hydrogen reduction treatment, that is, react at 800°C for 45 minutes; during the hydrogen reduction treatment, the hydrogen flow rate is 6L / min. After the reduction reaction was completed, 19900g of rhenium-tungsten pre-alloyed powder was obtained.

[0053] (2) Preparation of tungsten alloy powder: Weigh 100g of ZrC powder with a particle size of -300...

Embodiment 3

[0061] (1) Preparation of tungsten-rhenium pre-alloyed powder: Weigh respectively 22200g of tungsten powder with a Fibonacci particle size of 3.3 μm and a purity of 99.95% and 10800g of ammonium rhenate powder with a purity of 99.99% after grinding and passing through a 200-mesh sieve, and then the rhenium Add the ammonium acid powder into a mixer equipped with tungsten powder for mixing, the speed is 25r / min, and the mixing time is 2 hours; after mixing evenly, carry out the first hydrogen reduction treatment, that is, react at 450°C for 45 minutes, and then carry out the second The second hydrogen reduction treatment is to react at 750°C for 35 minutes; during the hydrogen reduction treatment, the hydrogen flow rate is 10L / min. After the reduction reaction is completed, 29700g rhenium-tungsten pre-alloyed powder is obtained.

[0062] (2) Preparation of tungsten alloy powder: Weigh 300g of TaC powder with a particle size of -200 mesh and a purity of 99.6%; mix it with tungste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com