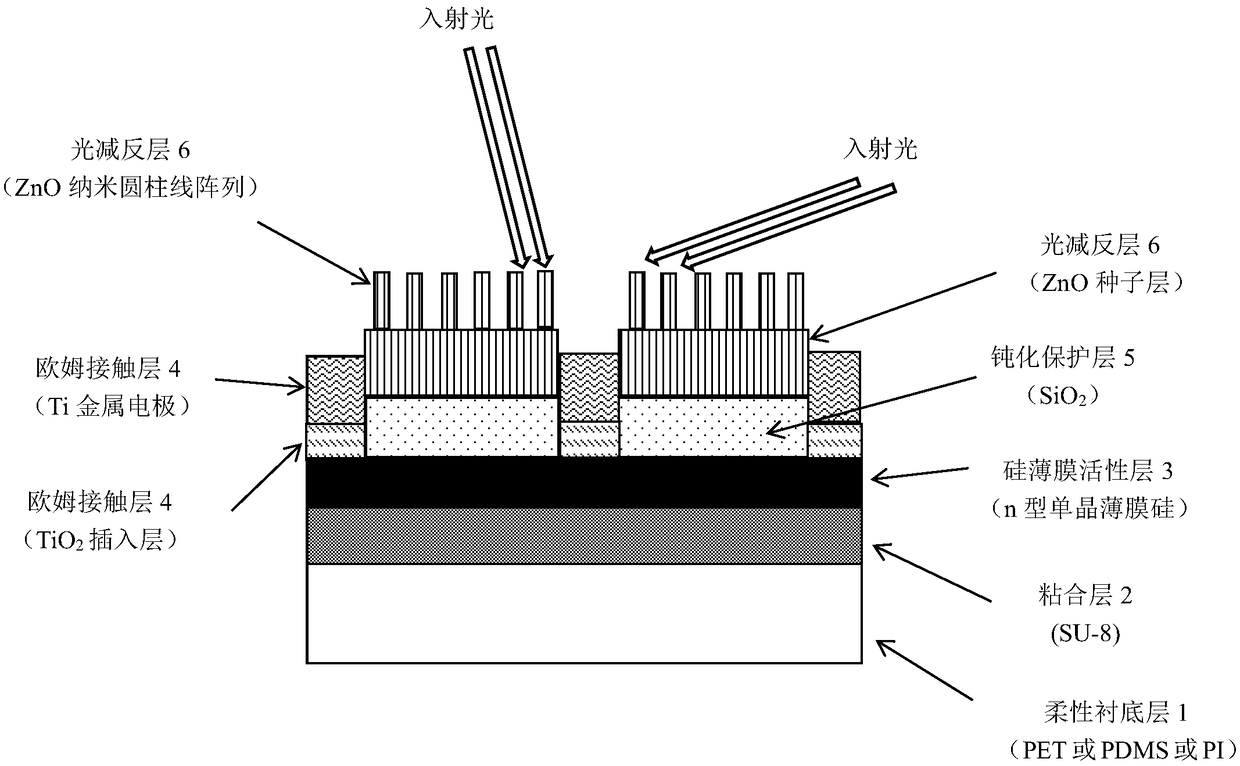

Flexible transient silicon thin film photodetector with MSM structure

A technology of photodetectors and silicon thin films, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of restricting the practical application of devices, failure to respond, slow degradation rate and limiting the transient performance of silicon devices, etc., so as to improve the photoelectric detection capability , avoid damage, and expand the effect of ultraviolet light detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

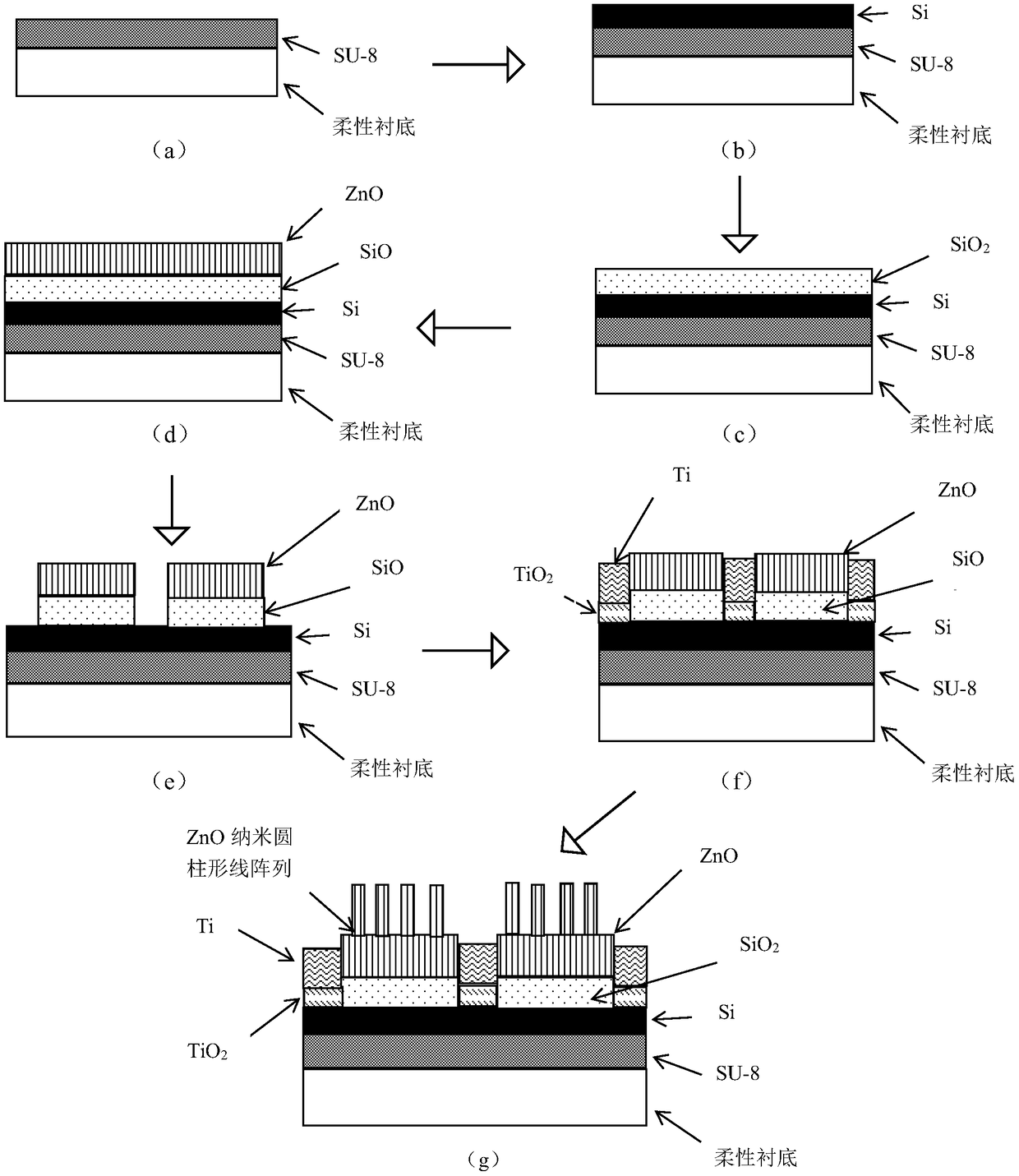

[0038] Example 1, preparing a polyethylene terephthalate PET substrate photodetector grown by magnetron sputtering with a ZnO seed layer thickness of 100 nm.

[0039] Step 1, cleaning the silicon SOI substrate and the polyethylene terephthalate PET flexible substrate on the insulating substrate.

[0040] 1.1) The silicon SOI substrate on the insulating substrate with a thickness of 180nm and the flexible polyethylene terephthalate PET substrate with a thickness of 0.9mm were placed in 10% Decon90 deionized aqueous solution and ultrasonically cleaned for 15min , then placed in deionized water for ultrasonic cleaning for 5 minutes, then placed in acetone for ultrasonic cleaning for 20 minutes, and then placed in absolute ethanol for ultrasonic cleaning for 20 minutes;

[0041] 1.2) Blow dry with nitrogen gun after cleaning, and then in O 2 Hydrophilic treatment for 10 minutes under the environment.

[0042] Step 2, preparing etching holes on the SOI substrate.

[0043] 2.1) P...

Embodiment 2

[0068] Example 2, preparing a polyimide PI substrate photodetector grown by an aqueous solution spin coating method with a ZnO seed layer thickness of 150 nm.

[0069] Step 1, cleaning the silicon SOI substrate and polyimide PI flexible substrate on the insulating substrate.

[0070] The silicon SOI substrate on the insulating substrate with a thickness of 200 nm and the polydimethylsiloxane PDMS flexible substrate with a thickness of 1.2 mm were cleaned, and the cleaning process was the same as step 1 in Embodiment 1.

[0071] Step 2, preparing etching holes on the SOI substrate.

[0072] Carry out photolithography on the SOI substrate after cleaning, it is identical with 2.1) of the step 2 of embodiment 1;

[0073] The conditions of the etching step are the same as 2.2) of Step 2 in Example 1 except that the etching time is 70 s.

[0074] Step 3, transferring the silicon thin film active layer.

[0075] Spin-coat SU-8 photoresist with a thickness of 500nm on the cleaned p...

Embodiment 3

[0094] Example 3, preparing a polydimethylsiloxane PDMS substrate photodetector grown by an organic solvent spin coating method with a ZnO seed layer thickness of 200 nm.

[0095] Step A, cleaning the silicon SOI substrate and the polydimethylsiloxane PDMS flexible substrate on the insulating substrate.

[0096] The silicon SOI substrate on the insulating substrate with a thickness of 220 nm and the polydimethylsiloxane PDMS flexible substrate with a thickness of 1.5 mm were cleaned, and the cleaning process was the same as step 1 in Embodiment 1.

[0097] Step B, preparing etching holes on the SOI substrate.

[0098] Carry out photolithography on the SOI substrate after cleaning, it is identical with 2.1) of the step 2 of embodiment 1;

[0099] The conditions of the etching step are the same as 2.2) of Step 2 in Example 1 except that the etching time is 80 s.

[0100] Step C, transferring the silicon thin film active layer.

[0101] The step of transferring the silicon thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com