Nitric acid tail gas denitration method

A technology of nitric acid tail gas and process, applied in the field of nitric acid tail gas denitrification process, can solve the problems of uneven local mixing, affect the effect of emission reduction, increase production cost, etc., achieve good emission reduction effect, avoid compression or pressurized steam process, operation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

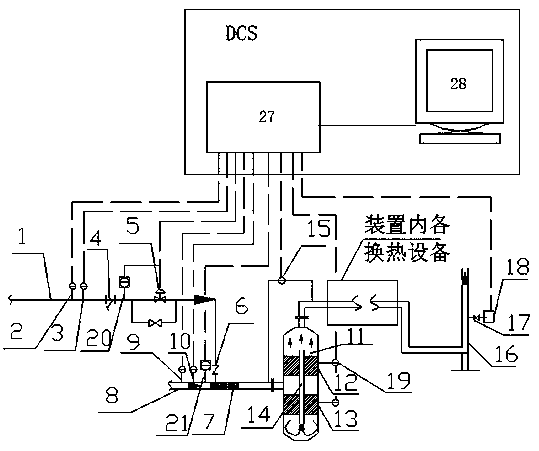

[0029]A nitric acid tail gas denitrification process, for the tail gas of the double pressurized dilute nitric acid process, in the case of selecting a medium temperature selective reduction catalyst (commercially available), the initial activity temperature of the selective reduction catalyst is ≥ 200 °C. The installation position of the emission reduction device is at the exhaust pipe section where the exhaust gas preheating temperature reaches 220°C, that is, between the exhaust gas heater 3 and the exhaust gas heater 4, the exhaust gas pressure is 0.6MPa, the exhaust gas temperature is 230°C, and the exhaust gas flow rate is 65,000 3 / h, the NOx content in the design tail gas is 150ppm, the exhaust gas pressure of the synthetic ammonia ammonia tank is 2.1MPa, and the exhaust gas composition is NH 3 : 38%, H 2 : 42%, CH 4 ~8%, N 2 ~12%, the sum of the total volume percentage is 100%.

[0030] The process specifically includes the following steps:

[0031] The first step...

Embodiment 2

[0037] A nitric acid tail gas denitrification process is aimed at the tail gas of the high-pressure dilute nitric acid process. In the case of selecting a high-temperature selective reduction catalyst, the initial activity temperature of the selective reduction catalyst is ≥ 360°C. The installation position of the emission reduction device is before the tail gas is heated and then enters the expander. Usually, the tail gas pipe section with a temperature ≥ 380°C, the tail gas pressure is 0.6MPa, the tail gas temperature is 380°C, and the tail gas flow rate is 45000Nm 3 / h, the NOx content in the design tail gas is 250ppm, the exhaust gas pressure of the synthetic ammonia ammonia tank is 2.1MPa, and the exhaust gas composition is NH 3 : 40%, H 2 : 38%, CH 4 ~8%, N 2 ~14%, the sum of the total volume percentage is 100%.

[0038] The process specifically includes the following steps:

[0039] Step 1: Use the exhaust gas 1 of the synthetic ammonia tank, pass through the remote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com