Scratch-resistant and high-transparent polycarbonate composite material and preparation method thereof

A polycarbonate and composite material technology is applied in the field of scratch-resistant high-transparency polycarbonate composite materials and their preparation, which can solve the problems of reducing the transparency of polycarbonate and affecting the performance of use, and improve wear resistance and mechanical properties. , good safety, the effect of adding less amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

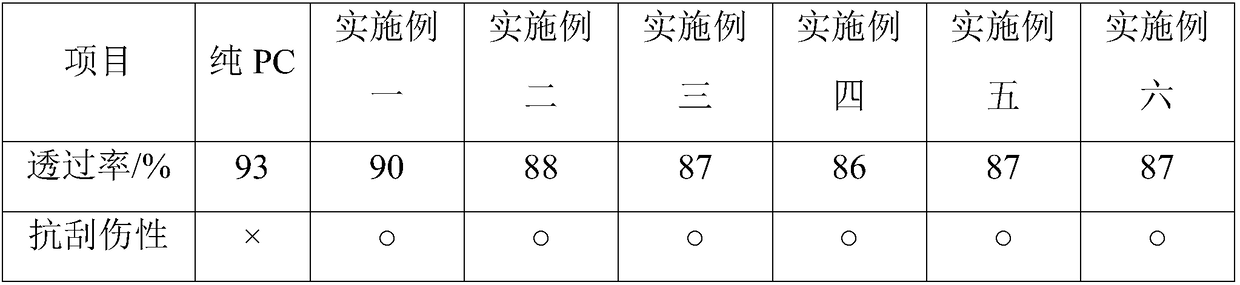

Examples

preparation example Construction

[0034] In addition, the present invention also provides a preparation method for the above scratch-resistant highly transparent polycarbonate composite material, comprising the following steps:

[0035] After weighing all the raw material components in proportion, mix them in a high-speed mixer with a rotation speed of 400-1000r / min for 10-20min to obtain a mixed material;

[0036]Put the mixed material into the twin-screw extruder, the screw length-to-diameter ratio is (35-40):1, the temperature in the first zone is 180-200°C, the temperature in the second zone is 190-210°C, the temperature in the third zone is 200-210°C, and the temperature in the fourth zone is 200-210°C. Zone temperature 200-220°C, zone five temperature 205-210°C, zone six temperature 205-215°C, zone seven temperature 205-215°C, zone eight temperature 205-220°C, zone nine temperature 210-220°C, die head temperature 210-230°C, pressure 10-20MPa, screw speed 250-400r / min; melt and mix for 8-15min under nitro...

Embodiment 1

[0040] This embodiment provides a scratch-resistant high-transparency polycarbonate composite material. The raw material components include: 80 parts of polycarbonate, 10 parts of nano-aluminum hydroxide, and gold treated with a titanate coupling agent. 10 parts of nanowire (diameter 10nm, length 5 μm), 10 parts of glass fiber, 0.5 part of polyethylene wax and 0.2 part of polytetrafluoroethylene powder.

[0041] According to above-mentioned raw material, adopt the preparation method provided by the present invention, prepare anti-scratch highly transparent polycarbonate composite material:

[0042] After weighing all raw material components in proportion, mix them in a high-speed mixer with a rotating speed of 400r / min for 10min to obtain a mixed material;

[0043] Put the mixed material into the twin-screw extruder, the screw length-to-diameter ratio is 35:1, the temperature in the first zone is 180°C, the temperature in the second zone is 200°C, the temperature in the third ...

Embodiment 2

[0046] This embodiment provides a kind of anti-scratch highly transparent polycarbonate composite material, and raw material component is calculated by weight, comprises: 90 parts of polycarbonate, 12 parts of nano-magnesium hydroxide, the silver nanowire of silane coupling agent surface treatment (diameter 50nm, length 20μm) 12 parts, graphene 12 parts, oxidized polyethylene wax 0.6 part and AS coated modified polytetrafluoroethylene powder 0.3 part.

[0047] According to above-mentioned raw material, adopt the preparation method provided by the present invention, prepare anti-scratch highly transparent polycarbonate composite material:

[0048] After weighing all raw material components in proportion, mix them in a high-speed mixer with a rotating speed of 500r / min for 10min to obtain a mixed material;

[0049] Put the mixed material into the twin-screw extruder, the screw length-to-diameter ratio is 36:1, the temperature in the first zone is 185°C, the temperature in the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com