Anti-scratching extra-hard glass and preparation method thereof

A scratch-resistant, hard glass technology, applied in chemical instruments and methods, glass/slag layered products, ion implantation plating, etc., can solve problems such as defects, poor compactness, weakened adhesion, etc., and achieve high transmission rate, low reflectivity, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as figure 1 The illustrated anti-scratch superhard glass includes a glass substrate 1, a buffer nano-layer is arranged on the glass substrate, a nano-transition layer is arranged on the nano-buffer layer, a carbon nitride nano-layer 4 is arranged on the nano-transition layer, and the thickness is selected to be 6-20nm . In this embodiment, the buffer nano layer is an aluminum oxide nano layer 2 with a thickness of 50-75 nm, and the nano transition layer is a silicon dioxide nano layer 3 with a thickness of 40-80 nm.

Embodiment 2

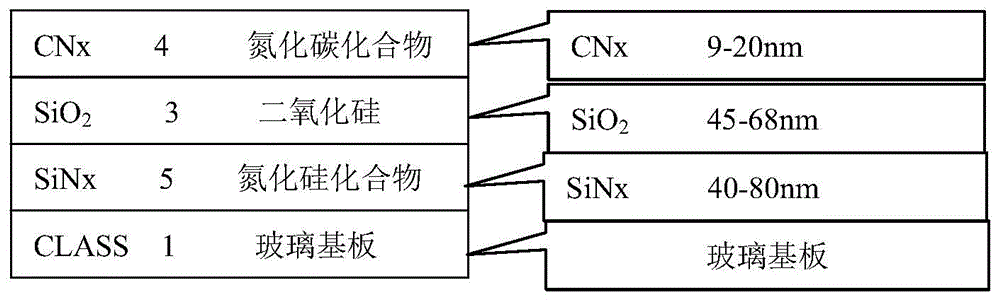

[0036] Such as figure 2 The illustrated anti-scratch superhard glass, the difference between this embodiment and Embodiment 1 is that the buffer nano layer is a silicon nitride nano layer 5, the thickness is selected from 40-80nm, and the nano transition layer is a silicon dioxide nano layer 3. The thickness is selected to be 45-68nm, and the thickness of the carbon nitride nano-layer 4 is selected to be 9-20nm.

Embodiment 3

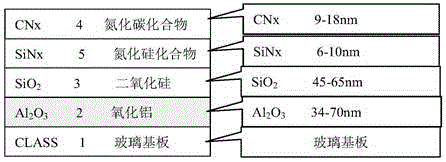

[0038] Such as image 3 The illustrated anti-scratch superhard glass, this embodiment is based on the first embodiment, that is, a nano-buffer layer is added between the nano-transition layer and the carbon nitride nano-4 layer, and the nano-buffer layer is silicon nitride nano- Layer 5. And adjust the thickness of each layer to be: the thickness of aluminum oxide nano-layer 2 is 34-70nm; the thickness of silicon dioxide nano-layer 3 is 45-65nm; the thickness of silicon nitride nano-layer 5 is 6-10nm; The choice is 9-18nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com