Water-based UV floor paint with scratch-resistant function

A technology of anti-scratch and floor paint, which is applied in the field of floor paint to achieve good anti-scratch effect and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

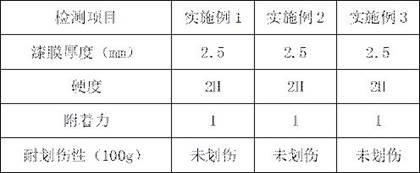

Examples

Embodiment 1

[0034] A water-based UV floor paint with anti-scratch function, consisting of a primer and a top coat;

[0035] Described primer comprises the composition of following percentage by weight:

[0036] Waterborne Polyurethane 55%

[0037] Light calcium carbonate 58%

[0038] Polyethylene glycol 1.8%

[0039] Isocyanate crosslinker 11%

[0041] water balance;

[0042] Described topcoat comprises the composition of following percentage by weight:

[0043] Urethane Acrylic 45%

[0044] Water-based unsaturated polyester acrylate resin 18%

[0045] Photoinitiator 1.2%

[0046] Dispersant 5.5%

[0047] Matting agent 2.5%

[0048] Nano alumina 2.8%

[0050] Coalescent 0.8%

[0051] water balance.

[0052] The photoinitiator is 2-hydroxyl-2-methyl-1-benzene-1-acetone.

[0053] Described matting agent is silicon dioxide matting agent.

[0054] The film-forming aid is light calcium carbonate monobutyl ether or dilight...

Embodiment 2

[0057] A water-based UV floor paint with anti-scratch function, consisting of a primer and a top coat;

[0058] Described primer comprises the composition of following percentage by weight:

[0059] Waterborne Polyurethane 60%

[0060] Light calcium carbonate 5%

[0061] Polyethylene glycol 2.5%

[0062] Isocyanate crosslinker 10%

[0064] water balance;

[0065] Described topcoat comprises the composition of following percentage by weight:

[0066] Urethane Acrylic 42%

[0067] Waterborne unsaturated polyester acrylate resin 22%

[0068] Photoinitiator 1%

[0069] Dispersant 6%

[0070] Matting agent 2%

[0071] Nano alumina 5%

[0073] Coalescent 1%

[0074] water balance.

[0075] The photoinitiator is 2-hydroxyl-2-methyl-1-benzene-1-acetone.

[0076] Described matting agent is silicon dioxide matting agent.

[0077] The film-forming aid is light calcium carbonate monobutyl ether or dilight calcium carbo...

Embodiment 3

[0080] A water-based UV floor paint with anti-scratch function, consisting of a primer and a top coat;

[0081] Described primer comprises the composition of following percentage by weight:

[0082] Waterborne Polyurethane 50%

[0083] Light Calcium Carbonate 10%

[0084] Polyethylene glycol 1.2%

[0085] Isocyanate crosslinker 12%

[0086] Silicone defoamer 0.8%

[0087] water balance;

[0088] Described topcoat comprises the composition of following percentage by weight:

[0089] Urethane Acrylic 50%

[0090] Waterborne unsaturated polyester acrylate resin 15%

[0091] Photoinitiator 1.5%

[0092] Dispersant 3%

[0093] Matting agent 3%

[0094] Nano alumina 2%

[0096] Coalescent 0.5%

[0097] water balance.

[0098] The photoinitiator is 2-hydroxyl-2-methyl-1-benzene-1-acetone.

[0099] Described matting agent is silicon dioxide matting agent.

[0100] The film-forming aid is light calcium carbonate monobutyl ether or dilight calcium ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com