Manufacturing method of heat preservation and noise isolation partition plate of star island type structure system

A manufacturing method and technology for separators, which are used in the manufacture of tools, ceramic products, applications, etc., can solve the problems of hardening of fillers, single specifications, and difficulty in meeting customer needs, so as to improve strength, reduce shedding, and improve scratch resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

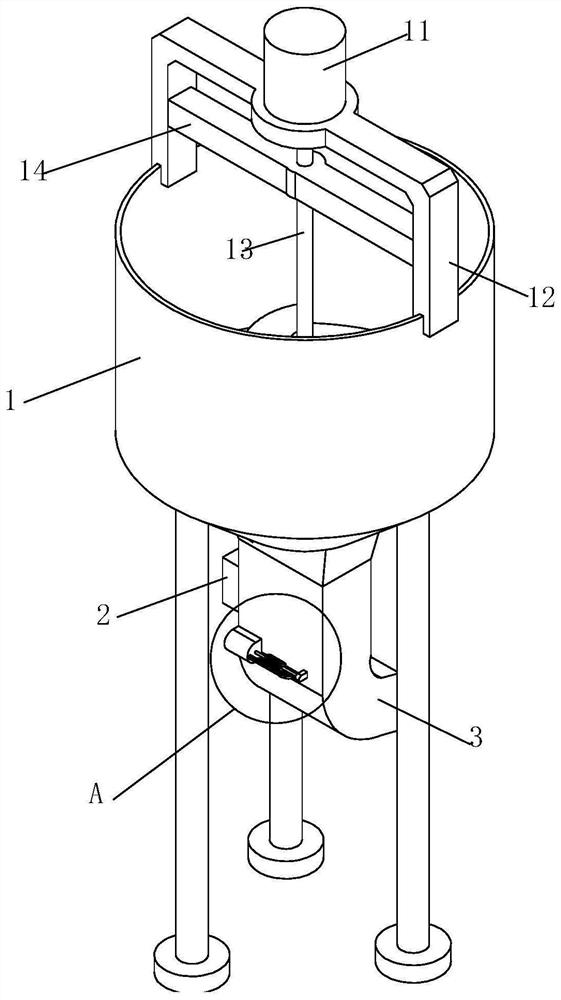

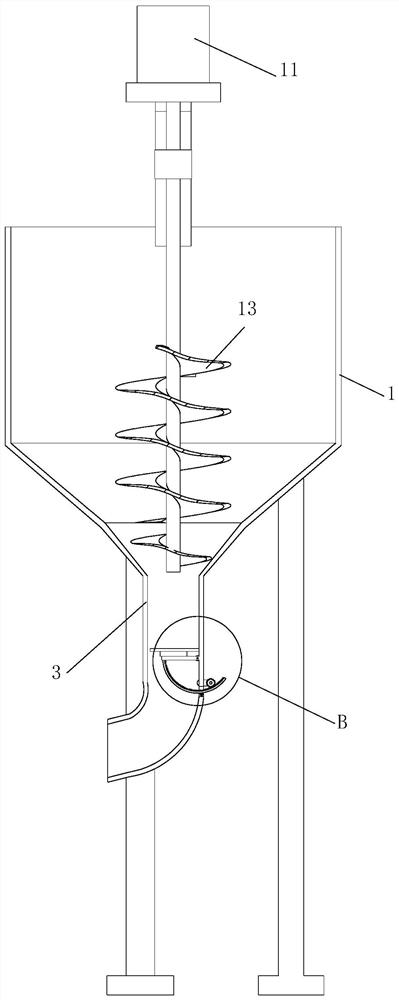

[0034] refer to Figure 1-5 , a method for manufacturing a heat-insulation and noise-insulating partition of a Xingdao structure system, the method for manufacturing comprises the following steps:

[0035] S1: Raw material preparation for the partition, cement, foaming agent, rubber powder, fire retardant and carboxylic acid; put the raw materials into the mixing tank and mix them into a porous slurry, which will be used as the base material for the partition and set aside;

[0036] S2: Filling material preparation, building ceramsite, gravel, perlite and polystyrene particles; put the filling materials into the mixing tank in turn to mix with the base material, and four kinds of filling materials including building ceramsite, gravel, perlite and polystyrene particles , the particles are added with 3-4 grades of different diameters, the base material and the filler are mixed to form the basic structure of the partition, and are used for standby; the particles are selected from...

Embodiment 2

[0048] refer to Image 6 , Comparative Example 1, as another embodiment of the present invention, the upper end of the prepackaged barrel 1 is provided with an atomizing tube 16; when the filling material is put into the prepackaged barrel 1, the filling material raises dust, If the dust is not treated, the dust will eventually fall to the ground, affecting the processing and production environment, and causing respiratory hazards to the on-site operators. Therefore, when the filler is put into the pre-barrel, the dust is suppressed through the atomizing tube 16 , the dust is suppressed in the pre-packed barrel 1, and the water used for atomization is light in weight, so it cannot have a negative impact on the processing and production of the partition.

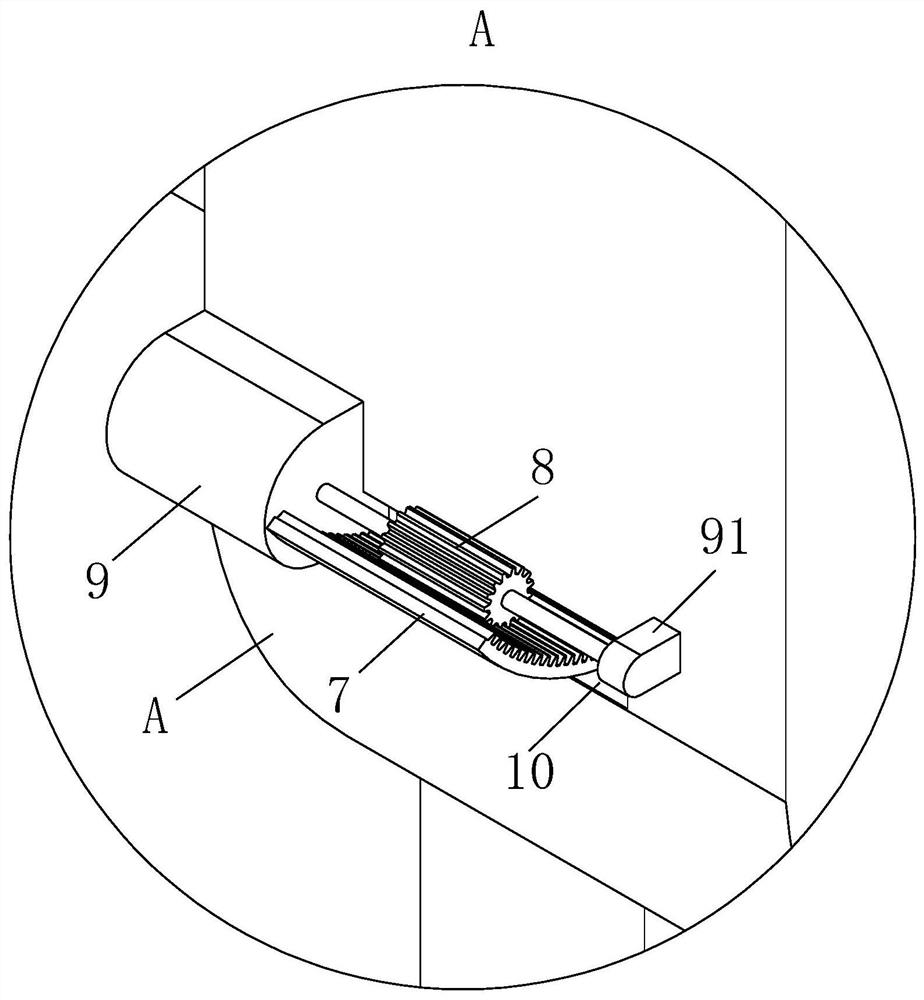

[0049] Working principle: the filling material is put into the pre-loaded barrel 1, the controller 2 controls the rotation of the second motor 11, and the second motor 11 drives the spiral stirring roller 13 to rotate, at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com