Shearing machine for forging and pressing

A shearing machine and forging technology, which is applied in the field of forging, can solve problems such as deformation, collapse, and influence of forging size and angle of metal strip components, and achieve the effects of reducing hollowness, good fit, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

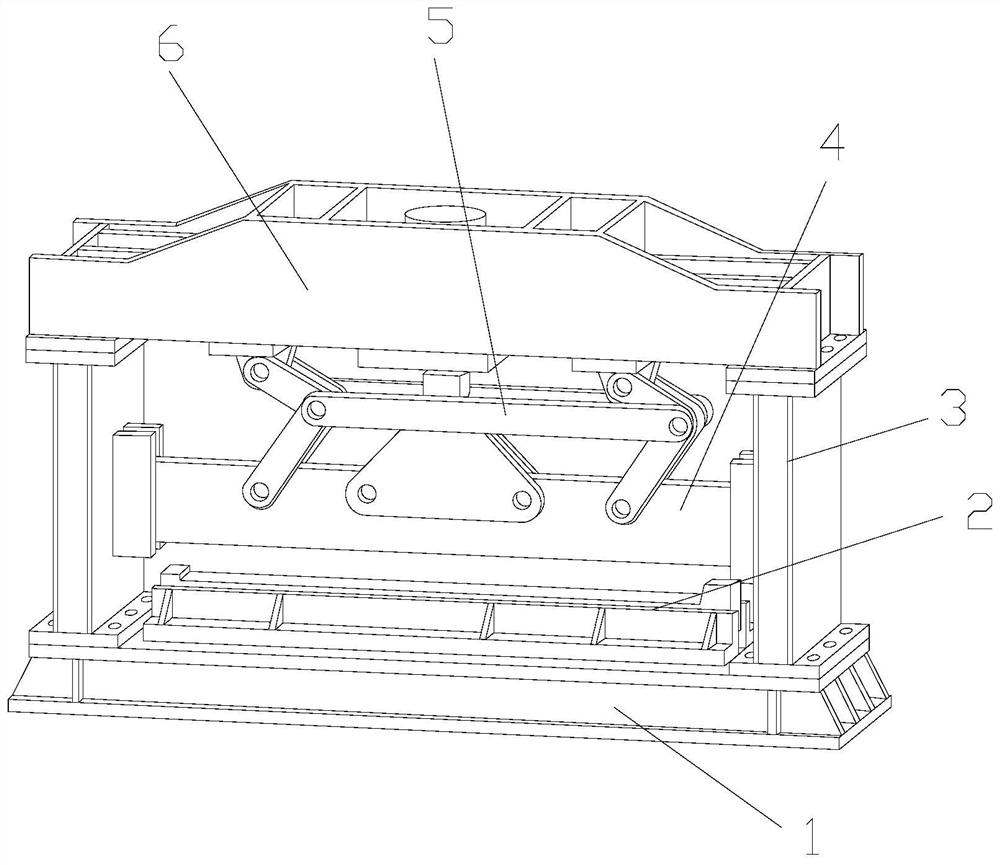

[0029] Example 1: Please refer to Figure 1-Figure 6 , the specific embodiments of the present invention are as follows:

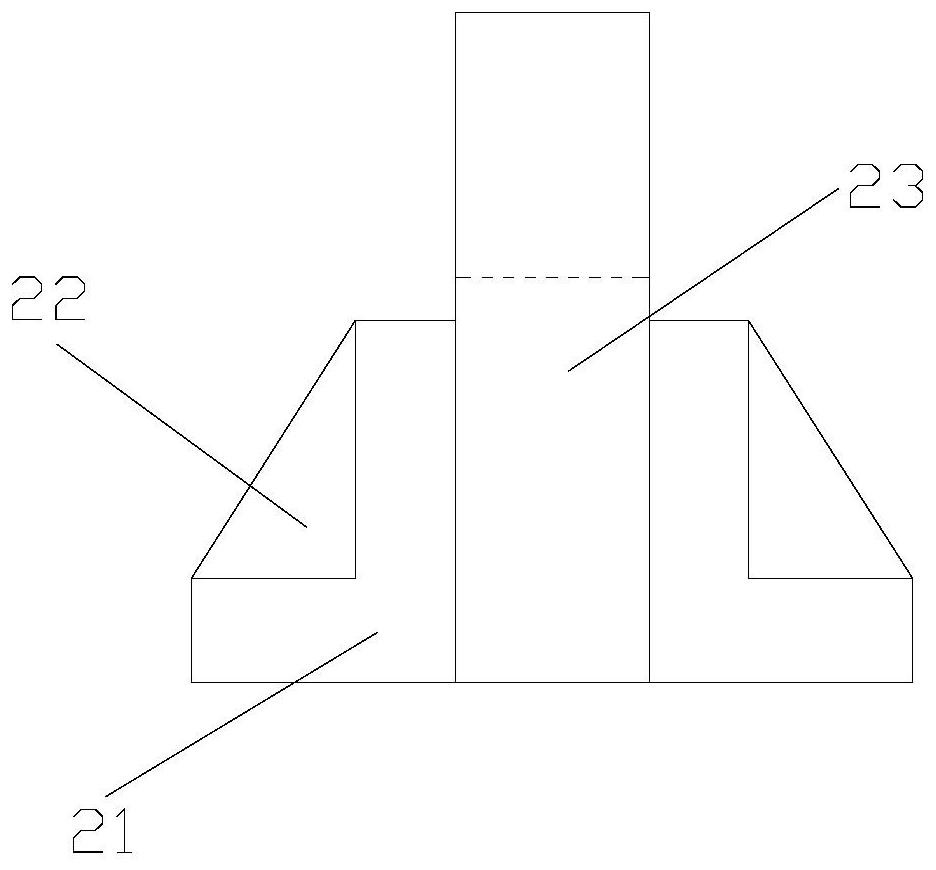

[0030] Its structure includes a base 1, a workbench 2, a support column 3, a shear knife 4, a movable frame 5, and a horizontal frame 6. The workbench 2 is horizontally installed on the upper end of the base 1 and fixed by bolts, and the support column 3 is installed vertically. On the upper end of the base 1 and on both sides of the workbench 2, the horizontal frame 6 is horizontally installed between the support columns 3 and fixed by bolts, the movable frame 5 is hinged to the lower end of the horizontal frame 6, and the shear knife 4 is movable Be connected between the support columns 3 and be hinged to the lower end of the movable frame 5; the workbench 2 includes a support base 21, a support block 22, and a deck 23, and a support block 22 is installed between the support bases 21 and welded, The card holder 23 is embedded between the supporting bloc...

Embodiment 2

[0037] Example 2: Please refer to Figure 4 , Figure 7-Figure 9 , the specific embodiments of the present invention are as follows:

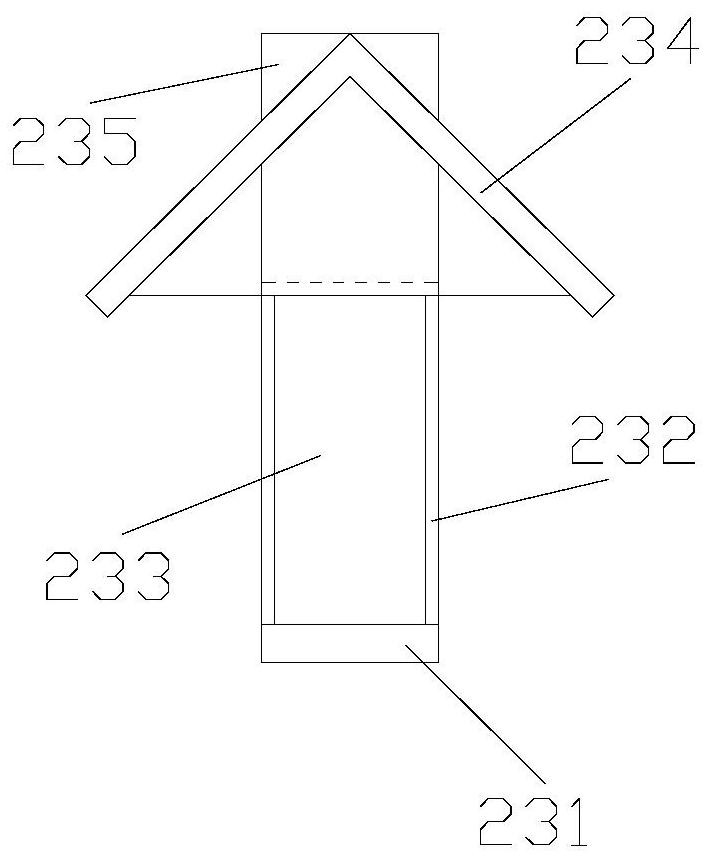

[0038] The fitting structure 234 includes a connection plate 34a, an adjustment structure 34b, an auxiliary frame 34c, and an adaptation structure 34d. The adjustment structure 34b is horizontally installed on the upper end of the connection plate 34a and fixedly connected, and the auxiliary frame 34c is vertically installed on the upper end of the connection plate 34a. And it is arranged outside the adjustment structure 34b. The adaption structure 34d is hingedly connected to the upper end of the adjustment structure 34b and abuts against the upper end of the auxiliary frame 34c.

[0039] refer to Figure 7 , the adapting structure 34d includes a top plate d1, an adapting groove d2, and a linkage structure d3, the top plates d1 are connected by a linkage structure d3 and the angle between them is less than 90 degrees, and the adapting groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com