Technology for rapidly improving performance of perovskite solar cell based on organic hole transport layer

A technology for solar cells and hole transport layers, applied in the field of solar cells, can solve the problems of uncontrolled crystallinity and oxidation degree, difficult processing temperature and time, poor process repeatability, etc., and achieve excellent photoelectric conversion performance and uniform texture. , the effect of high photoelectric conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

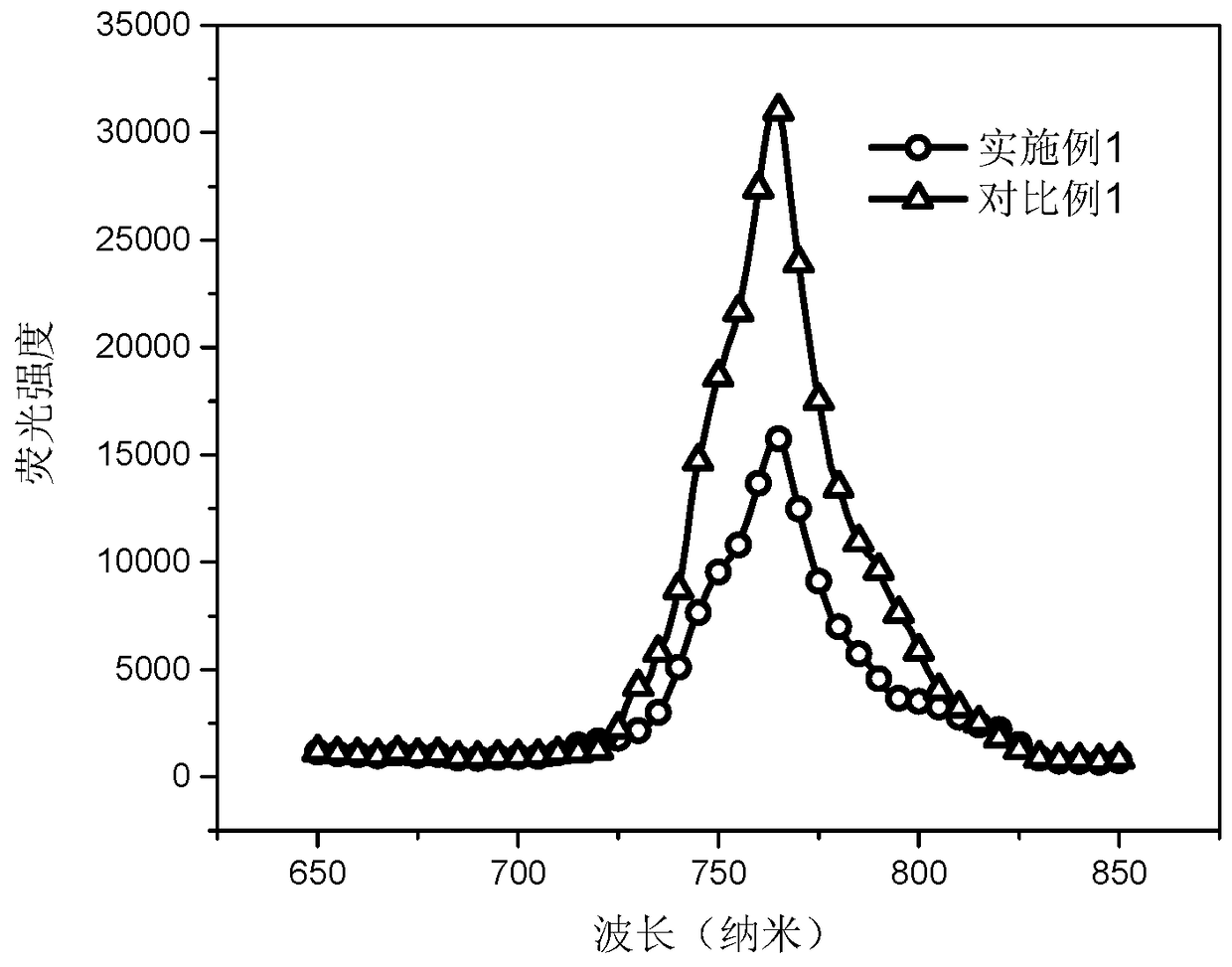

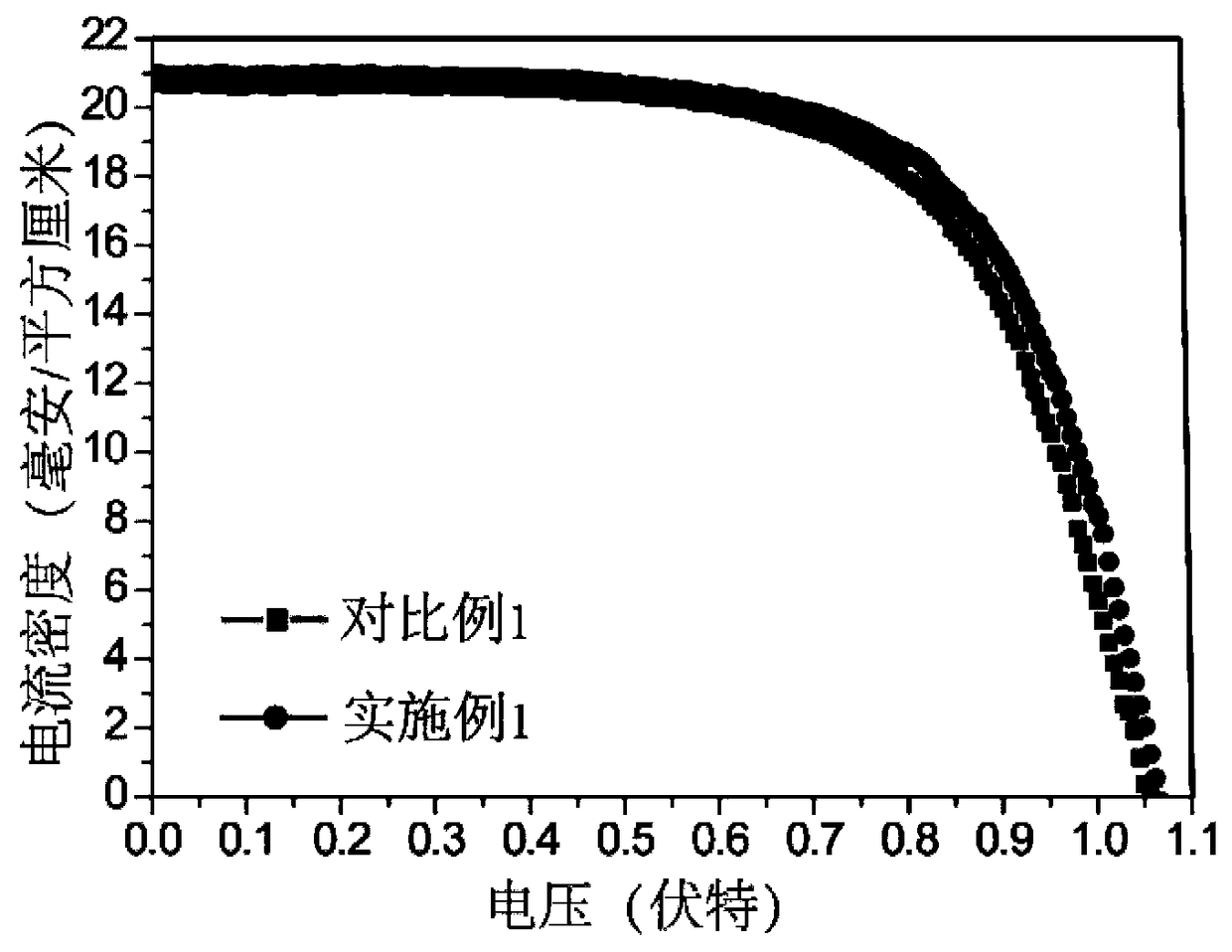

[0028] Through the preparation method of the invention, the performance of the perovskite solar cell based on the organic hole transport layer can be rapidly improved.

[0029] The chemical formula of perovskite light absorbing layer can be expressed as ABX 3 , where A can adopt monovalent cations or mixed cations, including but not limited to CH 3 NH 3 +, NH 2 -CH=NH 2 + 、Cs + , Li + 、C 4 h 9 NH 3 + 、CH 6 N 3 + 、Na + 、K + Wait. B can use Pb 2+ , Sn 2+ 、 Ge 2 + 、Co 2+ , Fe 2+ , Mn 2+ 、Cu 2+ and Ni 2+ At least one of these ions, that is, B can be one of these ions, or a mixed structure of any two or more of these ions. X can adopt Cl - 、Br - , I - 、SCN - , BF 4 - At least one of X, that is, X can be a single ion, or a mixed ion, such as a mixture of any two of the ions. For example, the chemical composition includes but is not limited to methylamine lead iodide, formamidine lead iodide, methylamine formamidine lead iodide mixture, formamidine ces...

Embodiment 1

[0045] (1) Preparation of the hole transport layer film without heat treatment. The FTO glass was ultrasonically cleaned with lye, deionized water, and acetone for 30 minutes, dried, and treated with ultraviolet light for 15 minutes. TiO was then prepared on the FTO glass substrate 2 Dense layer, the precursor solution solvent is ethanol, which includes the following components: tetraisopropyl titanate (0.3mol / L), acetylacetone (0.45mol / L), hydrochloric acid (0.09mol / L), water (1.8mol / L L). Absorb the precursor solution, drop it on the cleaned FTO substrate, make the solution cover the entire FTO surface, and form a film by spin coating, the spin coating speed is 3000rpm, and the time is 20s. Then sintered at 510 °C for 30 min in a muffle furnace. Then, measure 461 mg of lead iodide (PbI 2 ), 159 mg CH 3 NH 3 I powder, 78 mg dimethyl sulfoxide mixed with 600 mg N,N-dimethylformamide (DMF), stirred at room temperature for 2 hours to form CH 3 NH 3 PB 3 Perovskite precu...

Embodiment 2

[0054] (1) Preparation of the hole transport layer film without heat treatment. With embodiment 1.

[0055] (2) The film prepared in step (1) was placed on a hot plate, the temperature was set to 80° C., and the heat treatment time was 120 seconds to obtain a Spiro-OMeTAD hole transport layer film.

[0056] (3) Preparation of perovskite solar cells. With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com