Preparation method of micropore copper foil used for negative electrode current collector of lithium ion battery

A lithium-ion battery and current collector technology, which is applied in the field of preparation of microporous copper foil for lithium-ion battery negative electrode current collectors, can solve the problems of large pore size and columnar pores, reduce porosity, accelerate overflow, and improve corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The microporous copper foil for lithium ion battery negative electrode current collector is obtained through the following steps:

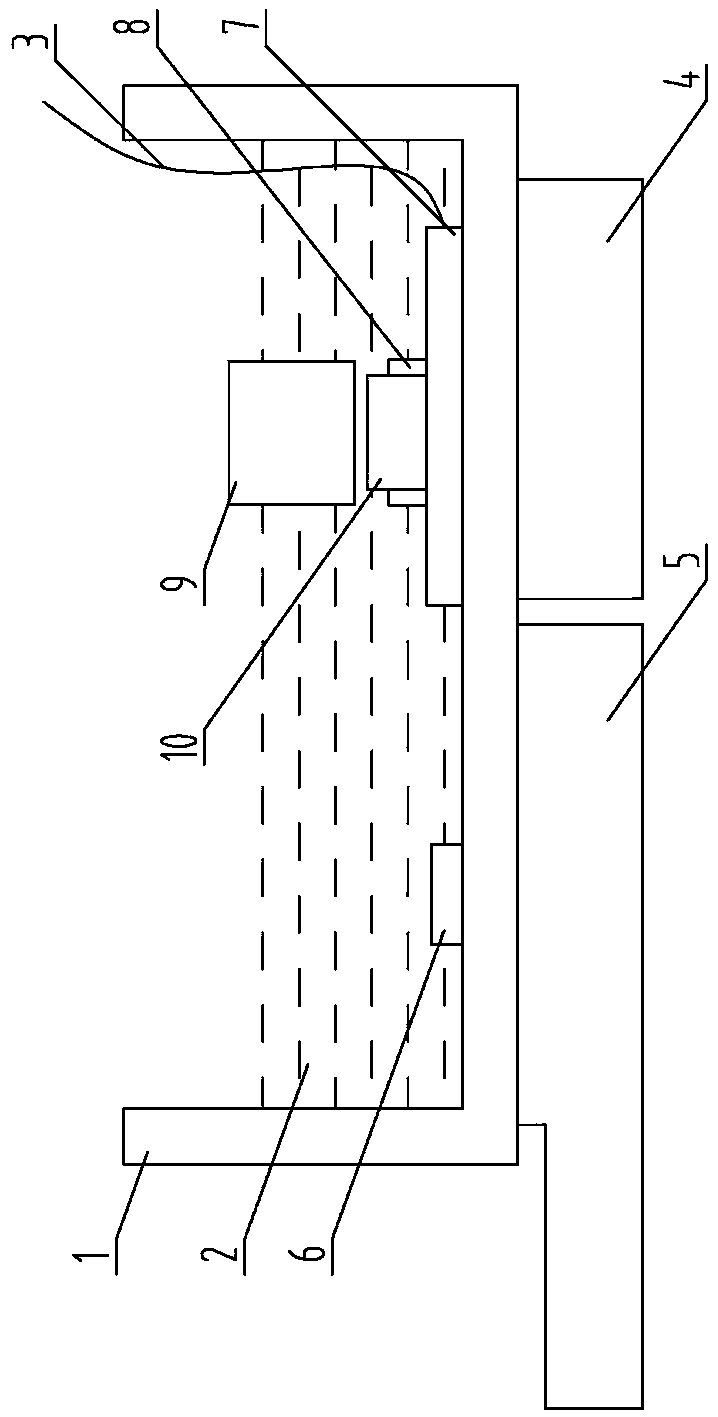

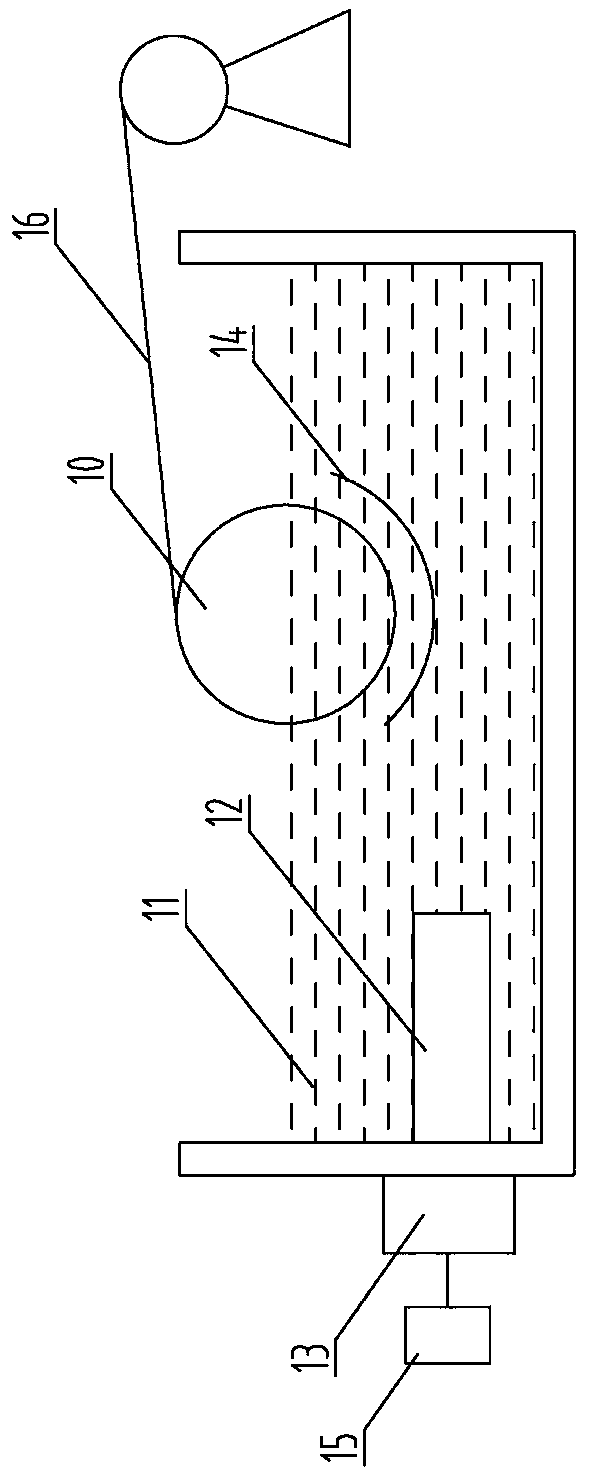

[0025] (1) Treatment of the titanium alloy roller 10: adding carbon powder with a particle size of 6um to the water-based working fluid to obtain the first working fluid 2, the concentration of the carbon powder in the first working fluid 2 being 20g / L. Such as figure 1 As shown, an insulating working fluid tank 1 with a circular cross section is placed on the base 5 of the magnetic stirring device, the first working fluid 2 is placed in the insulating working fluid tank 1, and the stirrer 6 of the magnetic stirring device goes deep into the working fluid tank The first magnet 4 is set outside the bottom wall of the working fluid tank, and the metal briquetting block 7 matched with the first magnet 4 is set in the insulating working fluid tank 1, and the metal briquetting block 7 is connected to the electric spark by a thick copper wire 3 w...

Embodiment 2

[0031]The difference between this example and Example 1 is that in step (1), carbon powder with a particle size of 8um is added to the water-based working fluid to obtain the first working fluid 2; The copper wire 3 is connected to the pulse power supply of the EDM machine tool; the discharge current of the EDM is 1.5A, the pulse width is 35us, and the pulse interval is 6us.

[0032] In step (2), the second working solution 11 is prepared by dissolving 55 parts by mass of copper sulfate, 95 parts by mass of sulfuric acid, 90 parts by mass of polyethylene glycol and 25 parts by mass of sodium bromide in 1000 parts by mass of water.

[0033] In step (3), the temperature is 35°C, the vibration frequency of the ultrasonic vibration device is 22Hz, and the current density in the second working fluid 11 is 0.45 A / cm 2 , the titanium alloy roller 10 is electroplated in the second working solution 11 for 20 seconds.

[0034] The microporous copper foil 16 prepared in this embodiment ...

Embodiment 3

[0036] The difference between this example and Example 1 is that in step (1), carbon powder with a particle size of 10um is added to the water-based working fluid to obtain the first working fluid 2; The copper wire 3 is connected to the pulse power supply of the EDM machine tool; the discharge current of the EDM is 2.1A, the pulse width is 40us, and the pulse interval is 7us.

[0037] In step (2), the second working solution 11 is prepared by dissolving 70 parts by mass of copper sulfate, 100 parts by mass of sulfuric acid, 100 parts by mass of polyethylene glycol and 30 parts by mass of sodium bromide in 1000 parts by mass of water.

[0038] In step (3), the temperature is 40°C, the vibration frequency of the ultrasonic vibration device is 25 Hz, and the current density in the second working fluid 11 is 0.55 A / cm 2 , the titanium alloy roller 10 is electroplated in the second working solution 11 for 25 seconds.

[0039] The microporous copper foil 16 prepared in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com