Etching agent for cobalt-chromium alloy and method using etching agent to acquire metallographic structure

A technology of cobalt-chromium alloy and metallographic structure is applied in the field of obtaining metallographic structure, which can solve the problems of difficulty in obtaining the metallographic structure of cobalt-chromium alloy, and achieve the effects of clear and complete grain boundary outline, obvious microstructure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Measure 15ml of nitric acid with a concentration of 65%, add 2 drops of hydrofluoric acid with a concentration of 40%, and mix well to obtain an acidic etchant.

[0034] Weigh 10g of sodium hydroxide and 15g of potassium ferricyanide, add them into 150ml of water, and stir until completely dissolved to obtain an alkaline etchant.

[0035] The cobalt-chromium alloy powder was scanned by laser cladding technology to make a cobalt-chromium alloy sample. The specific preparation process parameters are: laser power 1000W, scanning speed 2mm / s, spot diameter 2mm.

[0036] Carry out wire cutting on the sample, take a section parallel to the scanning direction of the laser beam, and inlay it with crystal glue.

[0037] Use 400 in turn # 、600 # , 800 # 、1000 # , 1600 # , 2000 # , 2500 # 、3000 # Sandpaper was used to polish the mounted cobalt-chromium alloy samples. During the grinding process, the sandpaper of each grain size is ground along the same direction on the s...

Embodiment 2

[0044] Measure 10ml of nitric acid with a concentration of 67%, add 4 drops of hydrofluoric acid with a concentration of 40%, and mix well to obtain an acidic etchant.

[0045] Weigh 10g of sodium hydroxide and 10g of potassium ferricyanide, add them into 150ml of water, and stir until completely dissolved to obtain an alkaline etchant.

[0046] A cobalt-chromium alloy sample was prepared according to the method in Example 1, and the surface was ground and polished.

[0047]Soak the cobalt-chromium alloy sample in an acid etchant for 20 hours, take out the sample, clean the acid residue on the surface with absolute ethanol and dry it.

[0048] Put the sample into an alkaline etchant heated to 90°C, soak at a constant temperature for 30 minutes, take out the sample, clean it with absolute ethanol and dry it.

[0049] Put the sample under a metallographic microscope, take pictures of the cross-section of the sample to obtain the metallographic structure of the sample.

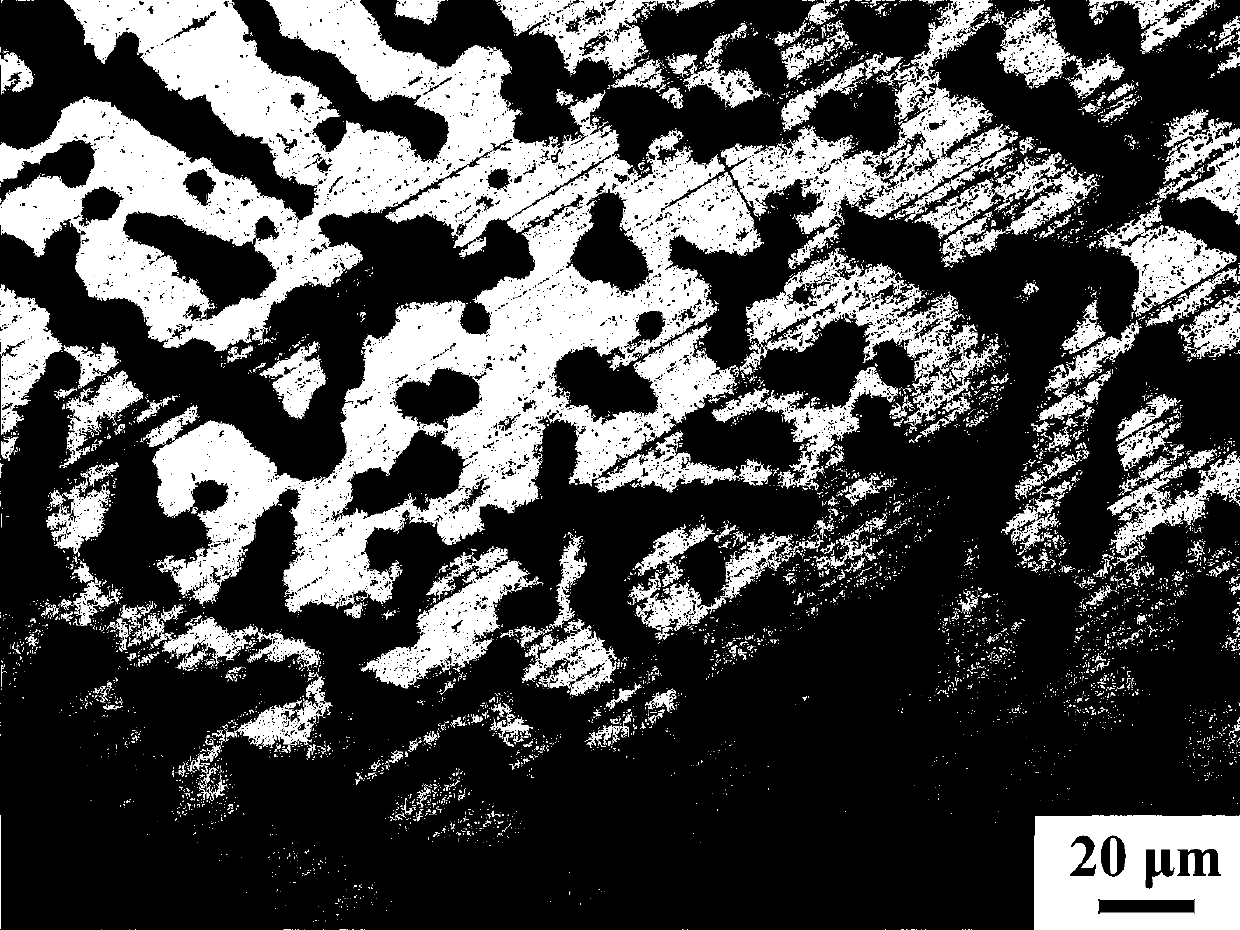

[0050]...

Embodiment 3

[0052] Measure 15ml of nitric acid with a concentration of 68%, add 4 drops of hydrofluoric acid with a concentration of 40%, and mix well to obtain an acid etchant.

[0053] Weigh 10g of sodium hydroxide and 10g of potassium ferricyanide, add them into 100ml of water, stir until completely dissolved, and obtain an alkaline etchant.

[0054] A cobalt-chromium alloy sample was prepared according to the method in Example 1, and the surface was ground and polished.

[0055] Soak the cobalt-chromium alloy sample in an acid etchant for 40 hours, take out the sample, clean the acid residue on the surface with absolute ethanol and dry it.

[0056] Put the sample into an alkaline etchant heated to 90°C, soak at a constant temperature for 30 minutes, take out the sample, clean it with absolute ethanol and dry it.

[0057] Put the sample under a metallographic microscope, take pictures of the cross-section of the sample to obtain the metallographic structure of the sample.

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com