Filled modified polytetrafluoroethylene material as well as application and preparation method thereof

A polytetrafluoroethylene modification technology, which is applied in the field of filled modified polytetrafluoroethylene materials and its application and preparation, can solve the problems of slow loss of frictional heat in dynamic seals, poor stability of polytetrafluoroethylene parts, wear parts Serious equipment wear and other problems, to achieve the effect of improving friction and wear resistance and service life, excellent corrosion resistance, and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0098] The preparation method of the present invention has the advantages of simple process, convenient operation, high efficiency and low cost, and the preparation process effectively ensures that each raw material component is fully mixed, and can effectively ensure product quality, uniformity and stability.

[0099] In an optional embodiment, the mixing speed of the high-speed mixer is 2000-3000 rpm, the mixing temperature is 18°C-32°C, the mixing times are 2-4 times, and the mixing time is 15 minutes each time. ~30 seconds;

[0100] Preferably, the molding pressure is 20MPa-65MPa; the molding is a cold molding process.

[0101] Preferably, the sintering temperature is 370°C-385°C, the sintering time is 4-15 hours, after 90-240 minutes of heat preservation, the temperature is lowered to 100-150°C, taken out, cooled to room temperature and machined after 24-48 hours to obtain a sealed pieces of finished products.

[0102] In an optional embodiment, the dry basis moisture c...

Embodiment 1-4

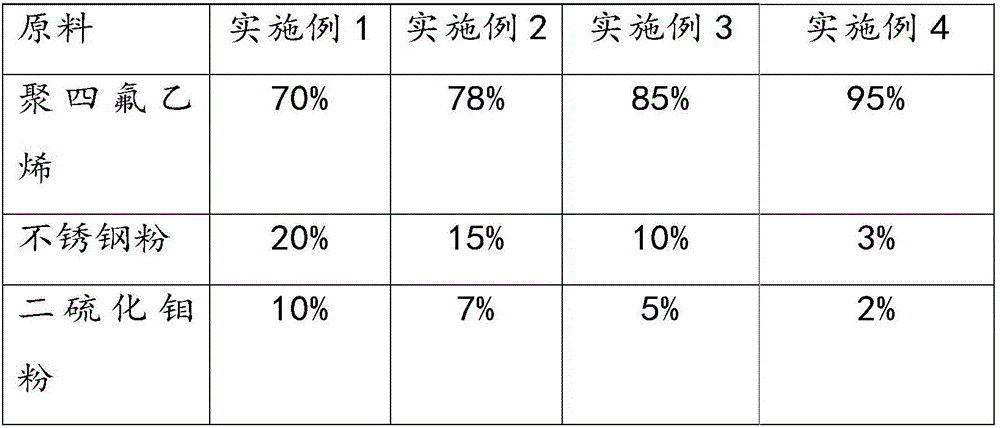

[0109] As shown in Table 1, a filled modified polytetrafluoroethylene material is made of raw materials including the following weight percentages.

[0110] Table 1 Example 1-4 filled modified polytetrafluoroethylene material

[0111]

[0112] Among them, the polytetrafluoroethylene is suspended polytetrafluoroethylene fine particles, the particle size is 20 μm, and the number average molecular weight of the polytetrafluoroethylene is 10 million.

[0113] The stainless steel powder is 06Cr19Ni10, and the particle size of the stainless steel powder is 500 mesh.

[0114] The purity of the molybdenum disulfide powder is 98%, and the particle size of the molybdenum disulfide powder is 6000 mesh.

Embodiment 5-8

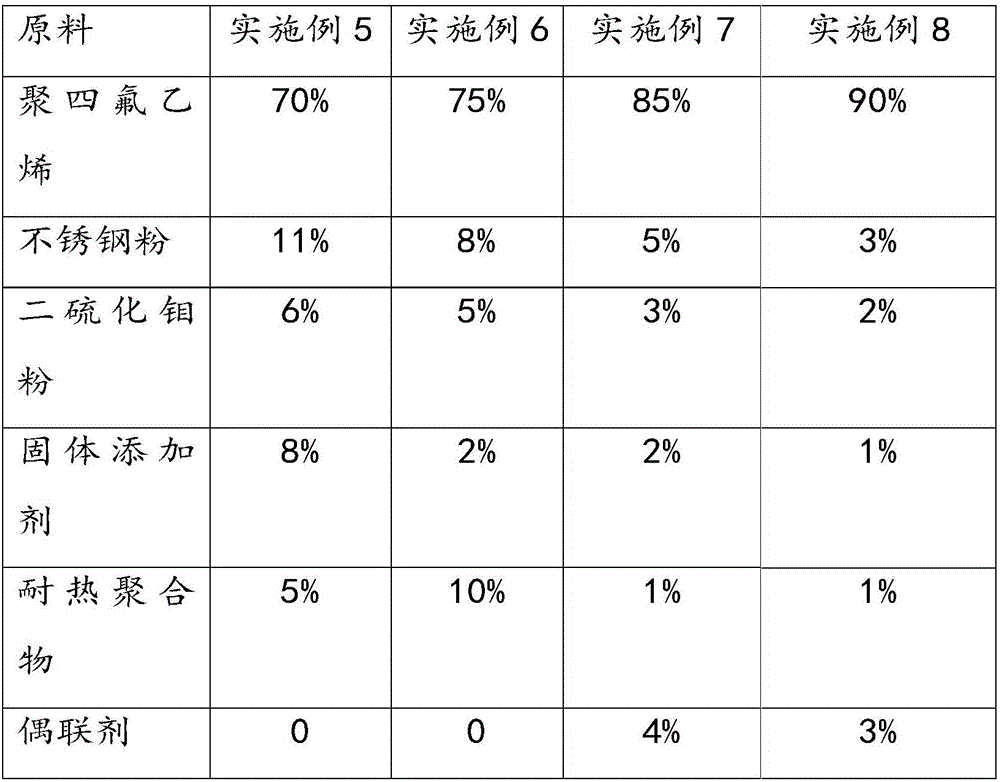

[0116] As shown in Table 2, a filled modified polytetrafluoroethylene material is made of raw materials including the following weight percentages.

[0117] Table 2 Example 5-8 filled modified polytetrafluoroethylene material

[0118]

[0119] Among them, the polytetrafluoroethylene is suspended polytetrafluoroethylene fine particles, the particle size is 60 μm, and the number average molecular weight of polytetrafluoroethylene is 6 million.

[0120] The stainless steel powder is 06Cr17Ni12Mo2, and the particle size of the stainless steel powder is 400 mesh.

[0121] The purity of the molybdenum disulfide powder is 99%, and the particle size of the molybdenum disulfide powder is 8000 mesh.

[0122] The solid additives in Examples 5 and 6 are mica powder, and the solid additives in Examples 7 and 8 are nano ceramic powders.

[0123] The heat-resistant polymer is p-polyphenylene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com