Zirconium oxide-based nano ceramic tool and die material added with titanium boride and preparation method thereof

A nano-ceramic and tooling technology, which is applied in the field of ceramic tooling materials and its preparation, can solve the problems of fully exerting the performance advantages of nano-composite ceramics, and achieve the effects of improving oxidation resistance, high strength, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

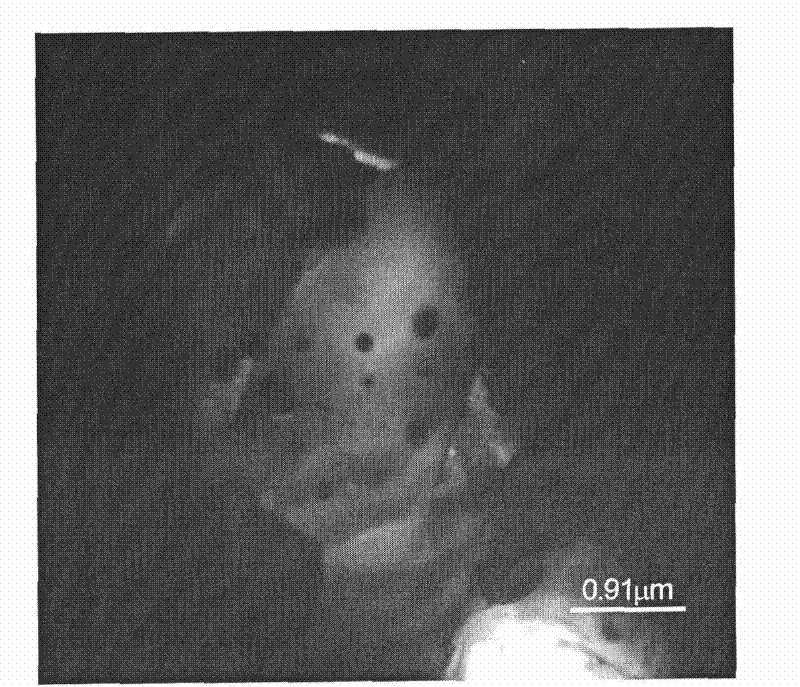

Image

Examples

Embodiment 1

[0036] Nano-ceramic tooling and mold materials, the volume percentage of raw material components is: 81% 5Y-ZrO 2 , 8%TiB 2 , 7% α-Al 2 o 3 , 1.1% Mo, 1.9% Ni, 1% MgO. The preparation method is as follows:

[0037] Weigh 5Y-ZrO in proportion 2 Nano-powder, polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, with 5Y-ZrO 2 The mass of nano-powder is the base number, and the addition amount of the dispersant is 0.6wt%; with an appropriate amount of absolute ethanol as the dispersion medium, it is made into 5Y-ZrO 2 Suspension, fully stirred with a stirrer, ultrasonically dispersed for 25min, and then HCl and NH 4 OH to adjust the pH value of the suspension to 3; the raw material TiB 2 and α-Al 2 o 3 The powders were individually ball-milled for 70 hours, and then dried continuously in an electric vacuum oven at 110°C. After complete drying, they were sieved in an inert gas flow and sealed for later use. Weigh the prepared TiB in proportion 2 ...

Embodiment 2

[0039] Nano-ceramic tooling and mold materials, the volume percentage of raw material components is: 86.7% 5Y-ZrO 2 , 5%TiB 2 , 5% α-Al 2 o 3 , 1% Mo, 1.5% Ni, 0.8% MgO. The preparation method is as follows:

[0040] Weigh 5Y-ZrO in proportion 2 Nano-powder, polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, with 5Y-ZrO 2 The mass of nano-powder is the base number, and the addition amount of the dispersant is 0.3wt%; with an appropriate amount of absolute ethanol as the dispersion medium, it is made into 5Y-ZrO 2 Suspension, fully stirred with a stirrer, ultrasonically dispersed for 20min, and then HCl and NH 4 OH to adjust the pH of the suspension to 4; the TiB 2 and α-Al 2 o 3 The powders were individually ball-milled for 60 hours, and then dried continuously in an electric vacuum oven at 120°C. After complete drying, they were sieved in an inert gas flow and sealed for later use. Weigh the prepared TiB in proportion 2 Powder, add absol...

Embodiment 3

[0042] Nano-ceramic tooling and mold materials, the volume percentage of raw material components is: 72.8% 5Y-ZrO 2 , 12%TiB 2 , 10% α-Al 2 o 3 , 1.5% Mo, 2.5% Ni, 1.2% MgO. The preparation method is as follows:

[0043] Weigh 5Y-ZrO in proportion 2 Nano-powder, polyethylene glycol (PEG4000) with a molecular weight of 4000 as a dispersant, with 5Y-ZrO 2 The mass of nano-powder is the base number, and the addition amount of the dispersant is 0.8wt%; with an appropriate amount of absolute ethanol as the dispersion medium, it is made into 5Y-ZrO 2 Suspension, fully stirred with a stirrer, ultrasonically dispersed for 30min, and then HCl and NH 4 OH to adjust the pH of the suspension to 3; the TiB 2 and α-Al 2 o 3 The powders were individually ball-milled for 80 hours, and then dried continuously in an electric vacuum oven at 110°C. After complete drying, they were sieved in an inert gas flow, and sealed for later use. Weigh the prepared TiB in proportion 2 Powder, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com