Polyetherimide-attapulgite-carbon fiber hybrid material and its preparation method, modified uhmwpe and its preparation method

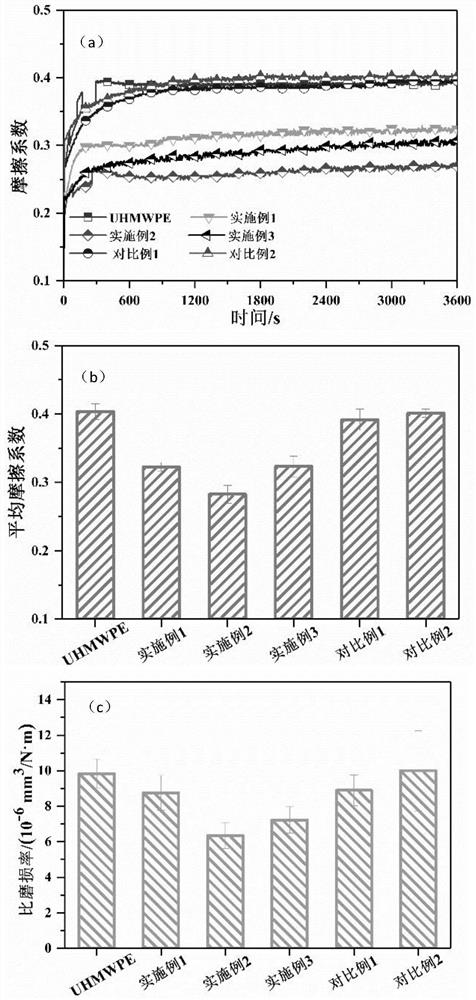

A polyetherimide and attapulgite technology, which is applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of reduced friction reduction performance of composite materials, increased motion resistance of friction pairs, and increased friction coefficient, etc. Achieve the effect of reducing wear, excellent anti-friction and wear resistance, and reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a preparation method of a polyetherimide-attapulgite-carbon fiber hybrid material, comprising the following steps:

[0023] Dissolving the polyetherimide in N,N-dimethylformamide to obtain a polyetherimide solution;

[0024] mixing the polyetherimide solution with attapulgite to obtain a polyetherimide functionalized attapulgite suspension;

[0025] The polyetherimide functionalized attapulgite suspension is mixed with acidified carbon fibers, an amidation reaction is performed, and after solid-liquid separation, a polyetherimide-attapulgite-carbon fiber hybrid material is obtained.

[0026] In the present invention, without special instructions, the raw materials used are all commercially available commodities well known in the art.

[0027] In the present invention, the polyetherimide is dissolved in N,N-dimethylformamide to obtain a polyetherimide solution. In the present invention, the dosage ratio of the polyetherimide and N,N-dimethylforma...

Embodiment 1

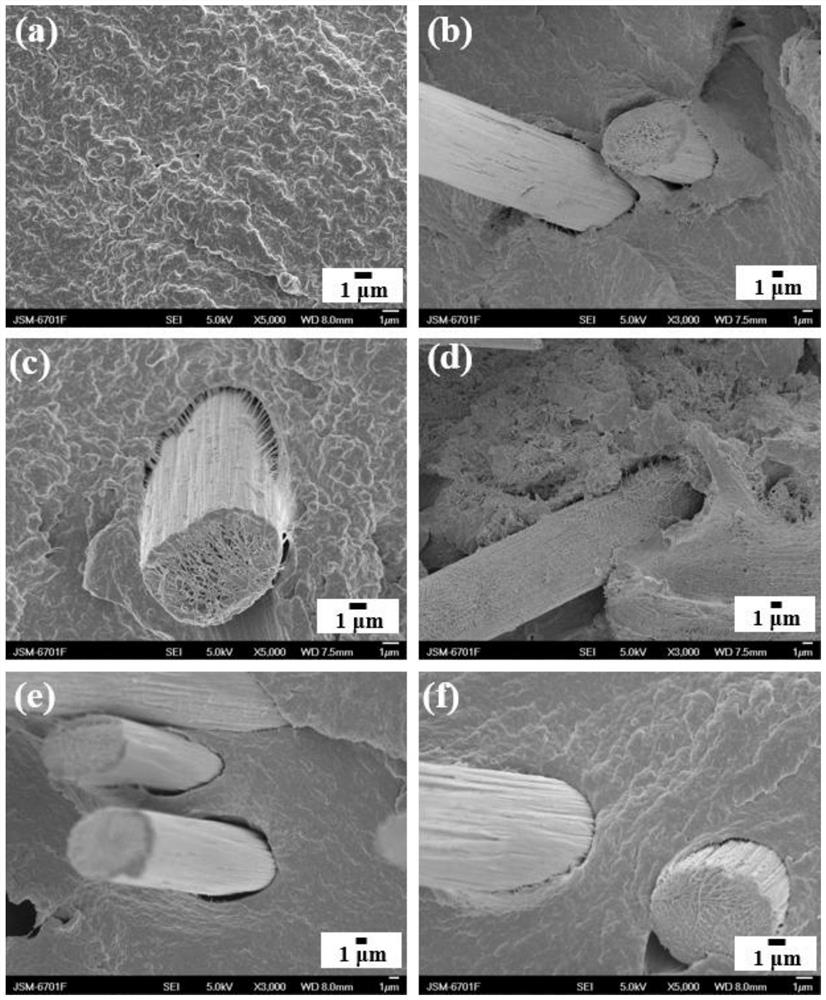

[0052] ① Dissolve 4 g of polyetherimide in 1000 mL of N,N-dimethylformamide (DMF), and stir with ultrasonic until it is completely dissolved. After dissolving, 4 g of purified attapulgite was added, stirred and sonicated for 5 hours to obtain a polyetherimide functionalized attapulgite suspension (referred to as PEI-ATP suspension), and its pH value was adjusted to 6.

[0053] ②Add 20g of acidified carbon fiber to the prepared PEI-ATP suspension, stir at 40°C for 3h to carry out amidation reaction, centrifuge after the reaction, wash the residual polyetherimide with N,N-dimethylformamide, the product is at 50 The polyetherimide-attapulgite-carbon fiber (PEI-ATP-CF) hybrid material was obtained by drying at ℃ for 12 h.

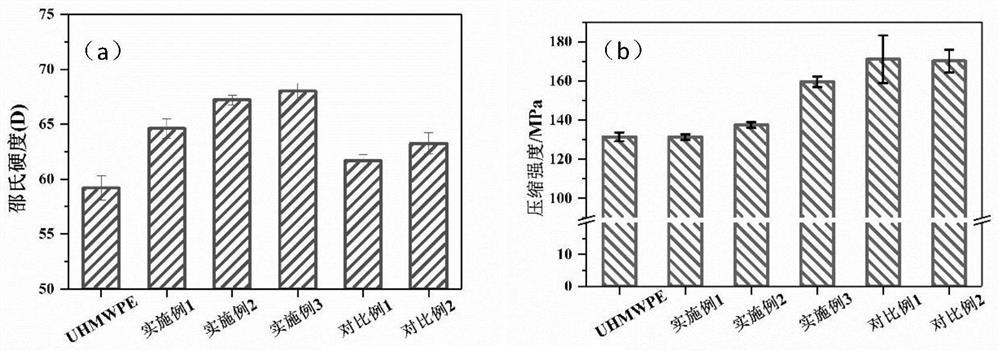

[0054] 3. 30g of dried ultra-high molecular weight polyethylene and 3g of polyetherimide-attapulgite-carbon fiber are mechanically mixed for 10min to obtain a mixed material; the mixed material is loaded into a stainless steel mold, in a 5-ton hot press Sinter...

Embodiment 2

[0056] ① Dissolve 3 g of polyetherimide in 800 mL of N,N-dimethylformamide (DMF), and stir with ultrasonic until it is completely dissolved. After dissolving, 3 g of purified attapulgite was added, stirred and sonicated for 5 hours to obtain the reactant PEI-ATP suspension, and the pH value was adjusted to 5.

[0057] ②Add 15g acidified carbon fiber to the prepared PEI-ATP suspension, stir at 50°C for 3h, centrifuge after the reaction, wash the residual polyetherimide with N,N-dimethylformamide, and dry the product at 60°C for 12h A polyetherimide-attapulgite-carbon fiber (PEI-ATP-CF) hybrid material was obtained.

[0058] 3. 20g of dried ultra-high molecular weight polyethylene and 3g of polyetherimide-attapulgite-carbon fiber are mechanically mixed for 10min to obtain a mixed material; the mixed material is loaded into a stainless steel mold, in a 5-ton hot press Sintering was carried out with a sintering pressure of 10MPa, and the sintering procedure was as follows: at a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com