Modified polyphenylene sulfide and preparation method thereof

A polyphenylene sulfide, modification technology, applied in the field of modified polyphenylene sulfide and its preparation, can solve the problems of restricting development and application, poor friction reduction and wear resistance, wear and tear, etc., and achieve remarkable friction reduction and wear resistance , good temperature resistance, the effect of improving strength and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of modified polyphenylene sulfide of the present invention is as follows:

[0040] 1. Preparation of ZIF-8 / BN:

[0041] Add 80-120mL of a mixed solution of organic solvent (the organic solvent is isopropanol, methanol or ethanol) and deionized water (the volume ratio of organic solvent and deionized water is 1:1-2:3) into the container , add 2-4g BN powder during stirring, mix well and then ultrasonicate for 3-6h. Then, the above solution was centrifuged in a 6000 rpm centrifuge, and the upper layer solution was taken and lyophilized to obtain BN nanosheets with a two-dimensional layered structure.

[0042] The ultrasonic vibration wave can destroy the weak van der Waals force between the BN layers, thus playing the role of mechanical peeling.

[0043] The exfoliated BN was dispersed in the mixed solution. After exfoliation, the smaller flakes will be suspended in the upper layer of the solution, and the incompletely exfoliated BN will be depos...

Embodiment 1

[0054] The preparation method of the modified polyphenylene sulfide of the present embodiment is as follows:

[0055] 1. Preparation of ZIF-8 / BN:

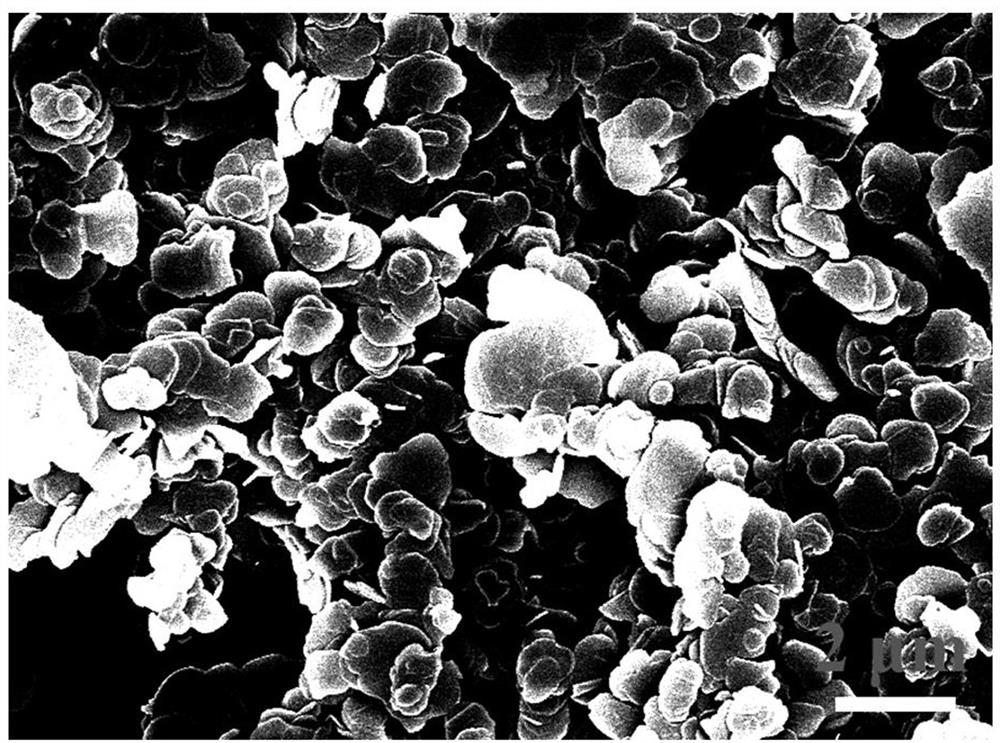

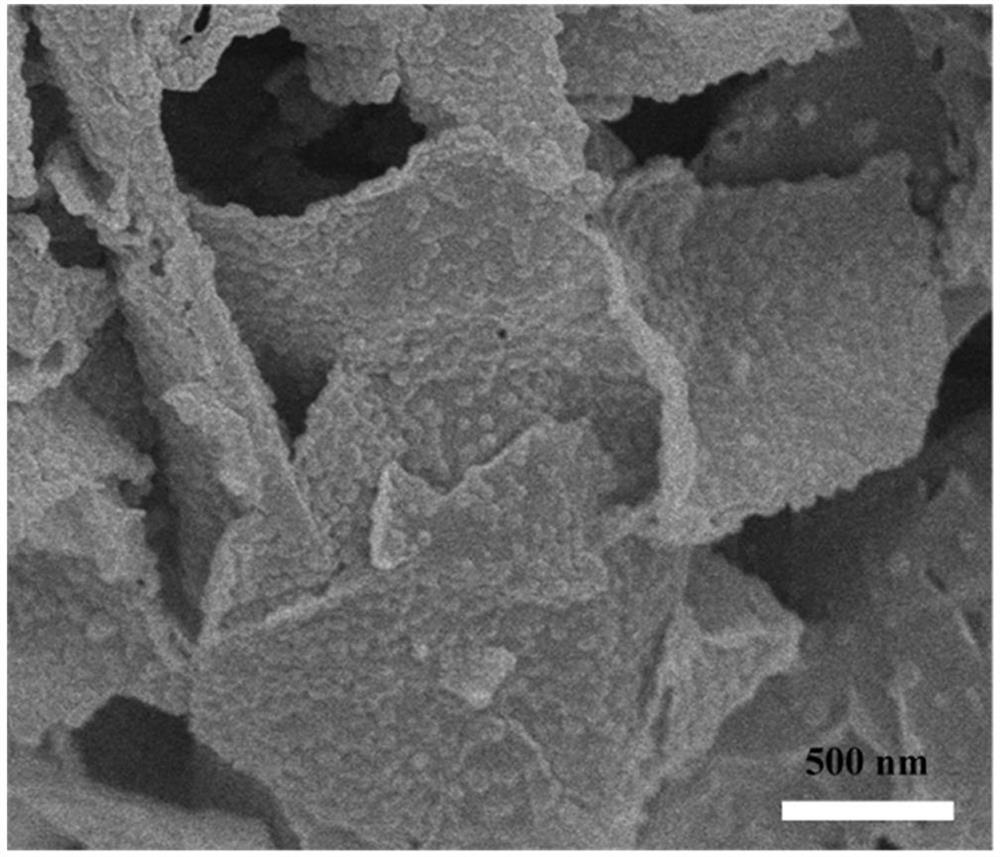

[0056] Add 100 mL of a mixed solution of isopropanol and deionized water (the volume ratio of isopropanol to deionized water is 2:3) into the container, add 3 g of BN powder while stirring, and sonicate for 4 hours after mixing. Then the above solution is centrifuged in a 6000rpm centrifuge, and the upper layer solution is taken for freeze-drying to obtain BN nanosheets with a two-dimensional layered structure, such as figure 1 shown.

[0057] figure 1 The SEM image of the BN nanosheets prepared in Example 1 of the present application.

[0058] Disperse 0.21g of BN nanosheets in 100mL of methanol, take 5g of zinc nitrate hexahydrate and add it to the methanol dispersed with BN nanosheets, then add 3.5g of 2-methylimidazole, let stand at room temperature for 24h, then centrifugally wash and freeze Dry to obtain a ZIF-8 / BN white ...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is:

[0066] The mass ratio of PPS pellets, GF, and ZIF-8 / BN was 57:40:3.

[0067] The remaining steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com