Aqueous epoxy adhering solid lubricant

A solid lubricant, water-based epoxy technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of environmental and human hazards, low friction coefficient, flammability, etc., and achieve good anti-friction and wear resistance, excellent physical and chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

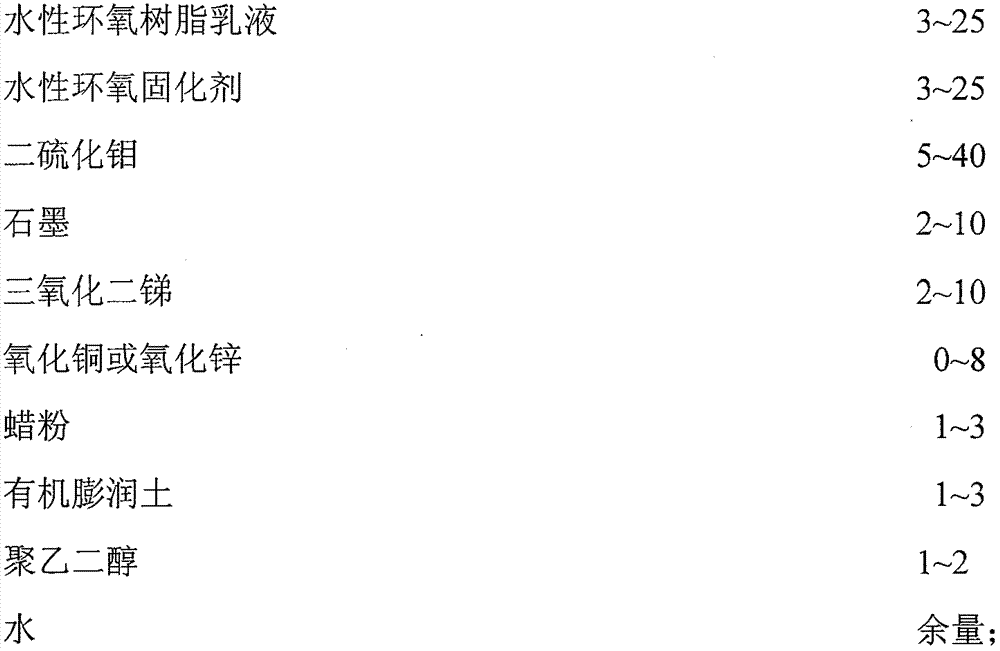

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Weigh 10 grams of molybdenum disulfide, 5 grams of graphite, 3 grams of antimony trioxide, 5 grams of copper oxide, 0.1 gram of wax powder, 0.1 gram of polyethylene glycol, 0.1 gram of organic bentonite, and add 50 grams of water to carry out Ball milling, ball milling for 20 hours, disperse to the required particle size, take out, then add 10 grams of water-based epoxy emulsion, 10 grams of water-based curing agent, and stir for 10 minutes to form a water-based dry film lubricant spray. Under the air pressure of 0.1-0.3MPa, it is sprayed on the surface of the sandblasted stainless steel object with a thickness of 20-25μm. Let stand at room temperature for 1 hour. Slowly raise the temperature to 60°C, cure for two hours, then raise the temperature slowly to 100°C, and cure for two hours to obtain a water-based epoxy bonded solid lubricating coating.

Embodiment 2

[0032] Waterborne Epoxy Emulsion 5 Waterborne Curing Agent 5

[0033] Molybdenum disulfide 10 Antimony trioxide 5

[0034] Cerium Fluoride 3 Wax Powder 1

[0035] Organic bentonite 0.5

[0036] water balance

Embodiment 3

[0038] Waterborne Epoxy Emulsions 8 Waterborne Curing Agents 8

[0039] Molybdenum disulfide 15 Graphite 10

[0040] Zinc Oxide 3 Copper Oxide 5

[0041] Organic bentonite 0.5 Polyethylene glycol 0.5

[0042] water balance

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com