Lithium ion battery and method for achieving rapid charge of same

A lithium-ion battery, fast charging technology, applied in secondary battery charging/discharging, battery electrodes, secondary batteries, etc., can solve problems such as poor conductivity and affect performance, and achieve improved conductivity, good crystallization, and long cycle life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

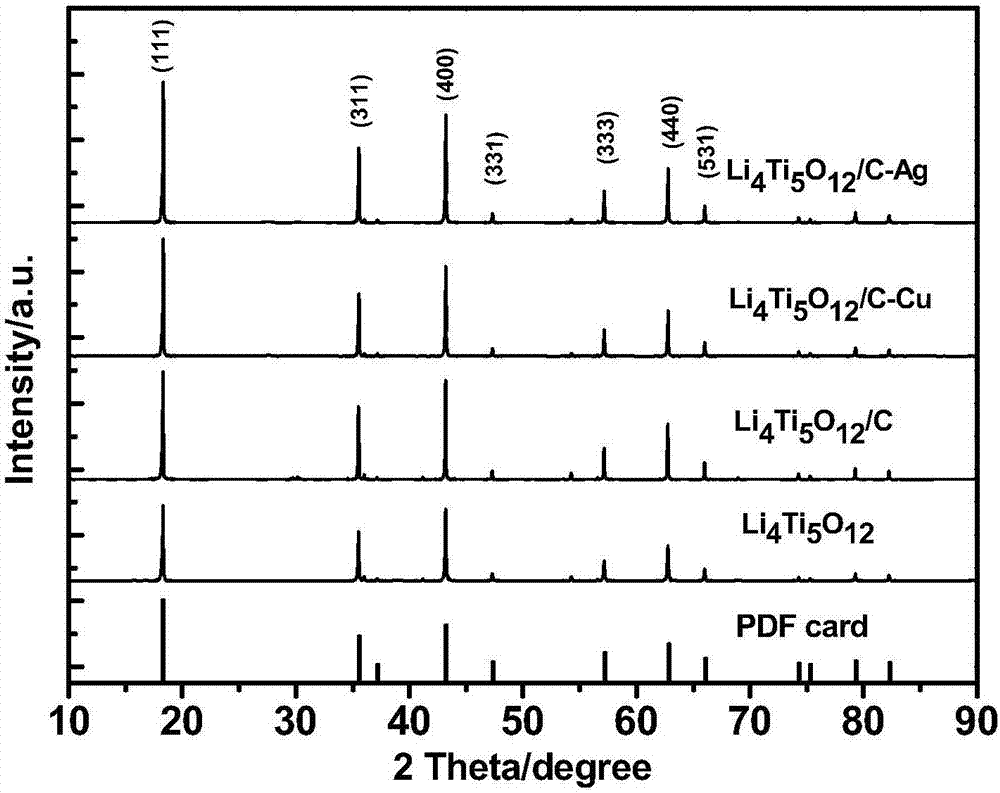

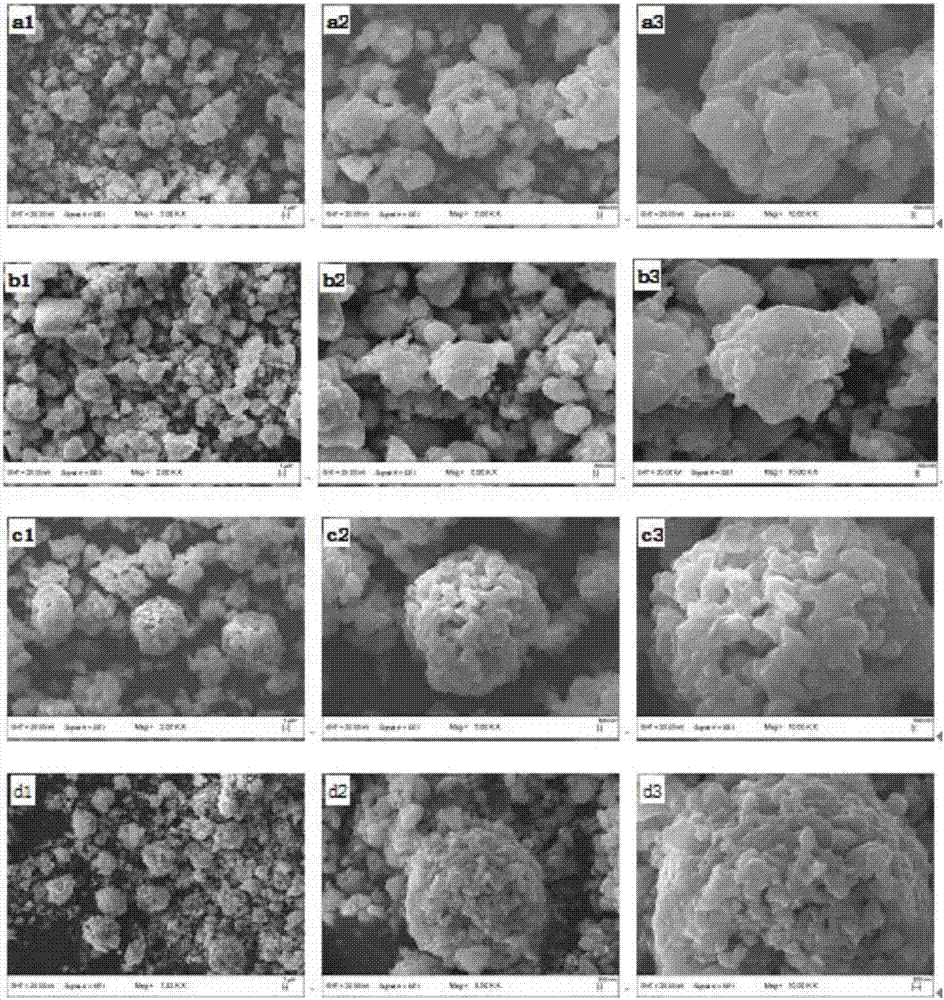

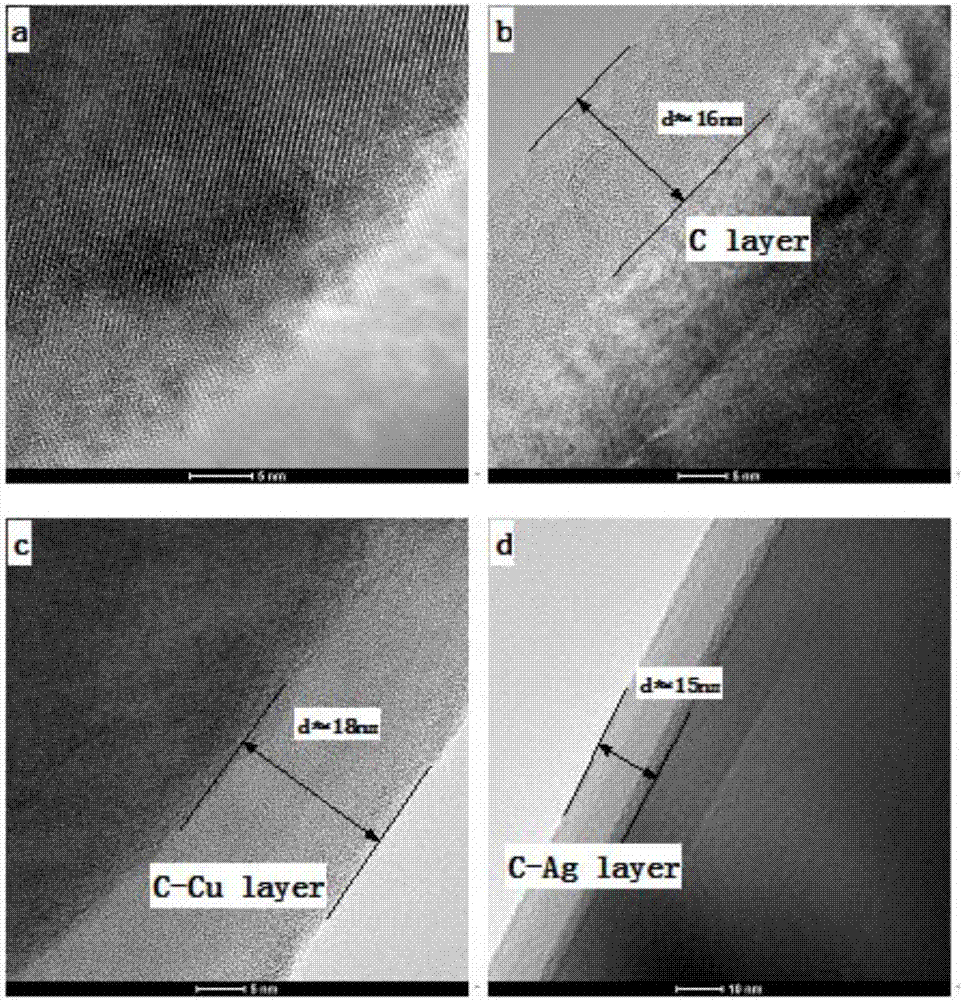

Embodiment 1

[0047] Embodiments of the present invention provide a modified Li 4 Ti 5 o 12 Negative electrode material is prepared by the following method: take a certain amount of lithium acetate (5% excess) (Lithium acetate) and nano titanium dioxide (Titanium oxide) respectively according to the stoichiometric ratio and weigh a little sucrose (the final carbon content is about 5wt%) (Sucrose) and copper sulfate (final copper content about 5wt%) (Coppersulfate) were dissolved in the prepared 30ml dispersion, wherein the dispersion contained 0.05g carboxymethylcellulose (CMC), 3 drops of styrene-butadiene rubber (SBR ) and 0.1154 g polyethylene glycol 400 (PEG400). Then ball milled in agate jar for 10h. Then spray drying (180°C, 3R / min, 60HZ) to obtain a powder, and the obtained dry powder was calcined at 850°C for 12h under an argon atmosphere (heating rate 5°C / min) to finally obtain Li 4 Ti 5 o 12 / C-Cu material.

Embodiment 2

[0049] Embodiments of the present invention provide a modified Li 4 Ti 5 o 12 The negative electrode material is prepared in the following way: take a certain amount of lithium acetate (excessive 5%) (Lithium acetate), nano titanium dioxide (Titanium oxide) and weigh a little sucrose (5wt%) (Sucrose) and Silver nitrate (final silver content about 5wt%) (Silver nitrate) was dissolved in the prepared 30ml dispersion liquid, wherein, the dispersion liquid contained 0.05g carboxymethylcellulose (CMC), 3 drops of styrene-butadiene rubber (SBR) and 0.1154 g polyethylene glycol 400 (PEG400). Then ball milled in agate jar for 10h. Then spray drying (180°C, 3R / min, 60HZ) to obtain a powder, and the obtained dry powder was calcined at 850°C for 12h under an argon atmosphere (heating rate 5°C / min) to finally obtain Li 4 Ti 5 o 12 / C-Ag material.

Embodiment 3

[0051] The embodiment of the present invention provides a lithium ion battery, which is prepared by the following method: the positive electrode active material LiMn 2 o 4 , Conductive carbon black and binder (PVDF) are mixed in N-methylpyrrolidone according to the mass ratio of 95:2:3 to make a slurry, which is coated on a 15um thick current collector aluminum foil through a coating machine. Vacuum dried for 24 hours, then pressed into a 90um thick pole piece, and finally die-cut into a 98mm×194mm positive pole piece, each positive pole contains 7.6gLiMn 2 o 4 .

[0052] With the Li that embodiment 1 makes 4 Ti 5 o 12 / C-Cu material, conductive carbon black and binder (PVDF) are mixed in N-methylpyrrolidone according to the mass ratio of 93:3:3 to make a slurry, which is coated on a 15um thick current collector aluminum foil by a coating machine , vacuum-dried at 120°C for 24 hours, then pressed into 140um thick pole pieces, cut into 101mm×198mm negative pole pieces, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com