Composite polymer electrolyte and preparation method and application thereof

A composite polymer and electrolyte technology, applied in the field of electrolytes, can solve the problems of affecting the energy efficiency of batteries, reducing the energy efficiency of lithium-ion batteries, and the low number of lithium-ion migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

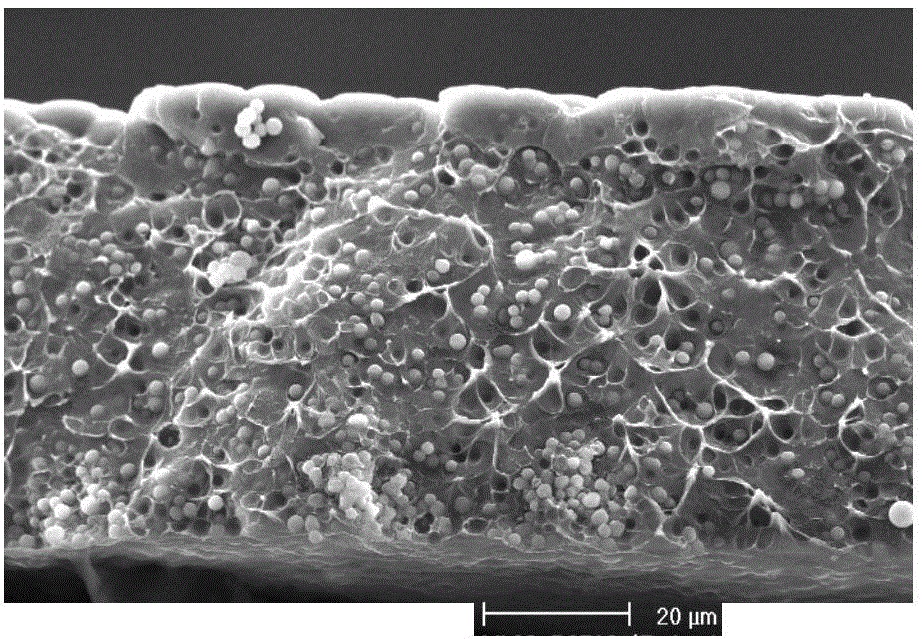

Image

Examples

Embodiment 1

[0049] Add 9mL of tetraethyl orthosilicate to 91mL of absolute ethanol at room temperature, then quickly add a mixture of 49.5mL of water, 18mL of 14mol / L ammonia water, 32.5mL of absolute ethanol and 0.6180g of boric acid, and stir at a speed of 200r / min After reacting for 3 hours, a boron-containing silica particle dispersion was obtained, and the silica particle was about 500 nm in size. The silicon dioxide particle dispersion is centrifuged and dried to obtain silicon dioxide powder. The powder is calcined in a muffle furnace at a high temperature of 500° C. for 6 hours to obtain calcined boron-containing silica microsphere powder.

[0050] figure 1 Infrared spectra of boron-containing silica used in Example 1 before and after calcination and ordinary silica. The characteristic peak of boron-containing silica before calcination is: 1638cm-1 H-OH bending vibration; 936cm -1 Si-OH; 1408cm -1 B-O stretching vibration; 1108 (1120-1020) cm -1 Si-O. 798,473cm -1 Si-O-Si. ...

Embodiment 2

[0060] Aluminum isopropoxide is dissolved in isopropanol to make aluminum alkoxide phase; deionized water, nitric acid and isopropanol are mixed to make water phase. The aluminum alkoxide phase and the water phase are simultaneously added dropwise into a reaction vessel filled with isopropanol, stirred, and the aluminum isopropoxide is hydrolyzed. Sodium tetraborate was then added. The gel is dried to form hydrated alumina, and then calcined at 750°C to obtain boron-containing alumina powder, the powder is about 10nm.

[0061] Add 0.5g of boron-containing alumina powder with a particle size of 10nm to 9.5g of 1-methyl-2-pyrrolidone solution of polyacrylonitrile with a concentration of 10wt.%. After stirring for 1 hour, the polymer solution Apply to stainless steel, evaporate solvent. Immerse the polymer solid film in the electrolyte (1mol / l LiClO 4 EC solution) after 10 min, the polymer electrolyte was obtained. The obtained polymer electrolyte was fixed in the middle of t...

Embodiment 3

[0063] Stir vigorously under an ice-water bath, drop titanium tetrachloride into distilled water, add dropwise an aqueous solution dissolved in ammonium sulfate and concentrated hydrochloric acid into the obtained titanium tetrachloride solution, stir, and control the temperature of the mixing process below 15°C. Lithium tetraborate was then added, and the temperature was raised to 95° C. for 1 hour, and then concentrated ammonia water was added to adjust the pH value to about 6. Cool to room temperature and age for 12 hours to obtain boron-containing titanium dioxide particle dispersion, the titanium dioxide particle size is about 5nm. The titanium dioxide ion dispersion liquid is filtered, washed, dried, and then placed in a muffle furnace for calcination at a high temperature of 500° C. for 6 hours to obtain calcined boron-containing titanium dioxide powder.

[0064] 0.1 g of boron-containing titanium dioxide was added to 4.9 g of 20 wt.% polymethyl methacrylate in acetone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com