High-plasticity aluminum-silicon alloy for die casting and preparation method thereof

An aluminum-silicon alloy and high plasticity technology, applied in the field of metal materials, can solve the problems of low plasticity, incomplete degassing and purification, and hole defects of aluminum-silicon alloy materials, and achieve good flow performance, reduce hole defects, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

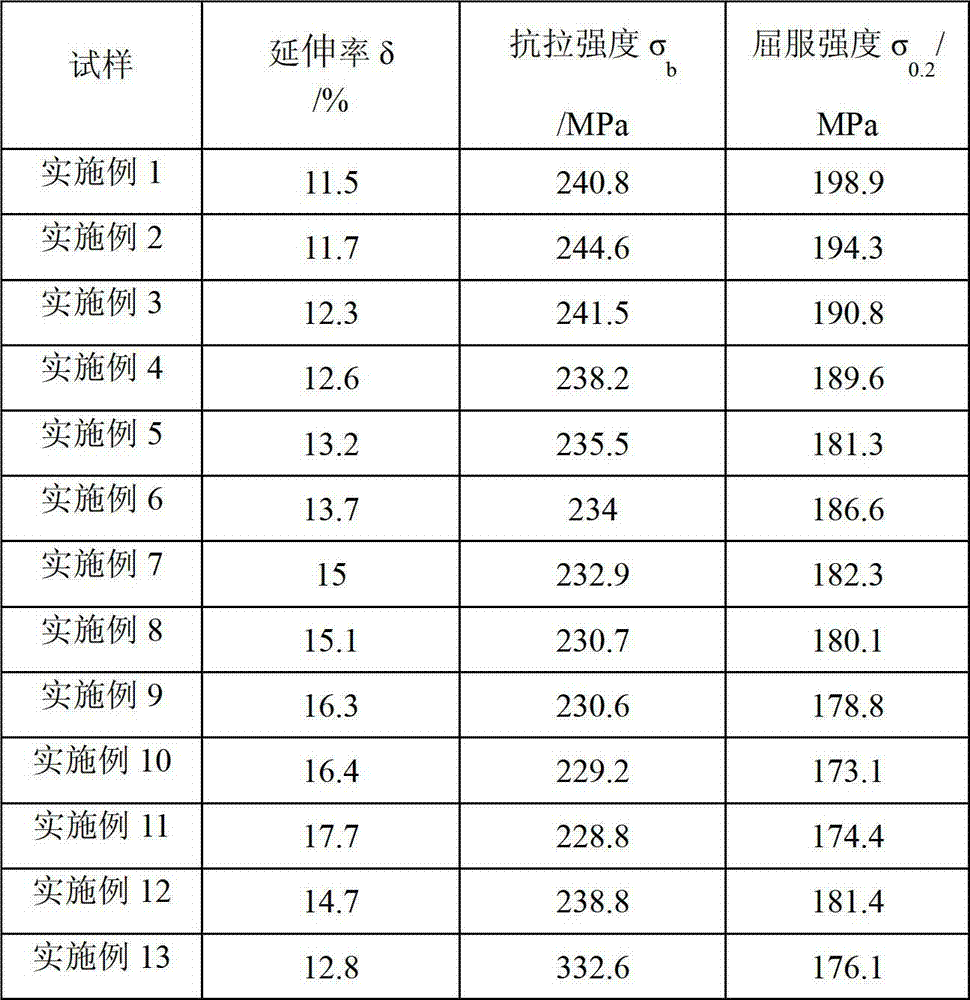

Examples

Embodiment 1

[0030] High plasticity aluminum-silicon alloy, including the following components in weight percentage: 13% silicon, 0.40% manganese, 0.50% magnesium, 0.01% strontium, 0.12% iron, 0.10% copper, 0.07% zinc, and the rest is aluminum. The sum of the percentages is 100%.

[0031] Its preparation method comprises the following steps:

[0032] (1) Melt aluminum-manganese alloy, aluminum and silicon in a melting furnace for 3 hours to 780°C to obtain a smelting solution;

[0033] (2) Spray the sodium-free refining agent powder into the smelting furnace with argon gas as the carrier, refine the smelting liquid at 700°C for 40 minutes at a time, and remove the slag to obtain the refining liquid;

[0034] (3) Add aluminum-strontium alloy and magnesium to the refining solution in turn, and pass through argon gas for secondary refining at 680°C for 10 minutes, and let it stand for 40 minutes to obtain alloy solution;

[0035] (4) The alloy liquid is further purified by installing a glas...

Embodiment 2

[0037] High plasticity aluminum-silicon alloy, including the following components by weight percentage: 9.3% silicon, 0.30% manganese, 0.40% magnesium, 0.04% strontium, 0.12% iron, 0.03% copper, 0.08% zinc, and the rest is aluminum. The sum of the percentages is 100%.

[0038] Its preparation method comprises the following steps:

[0039] (1) Melt aluminum-manganese alloy, aluminum and silicon in a melting furnace for 2 hours to 800°C to obtain a smelting solution;

[0040] (2) Spray the sodium-free refining agent powder into the smelting furnace with argon gas as the carrier, refine the smelting liquid at 710°C for 20 minutes at a time, and remove the slag to obtain the refining liquid;

[0041] (3) Add aluminum-strontium alloy and magnesium to the refining liquid in turn, and pass through argon gas for secondary refining at 710°C for 15 minutes, and let it stand for 20 minutes to obtain alloy liquid;

[0042] (4) The alloy liquid is further purified by installing a glass f...

Embodiment 3

[0044]High plasticity aluminum-silicon alloy, including the following components in weight percentage: 9.0% silicon, 0.33% manganese, 0.38% magnesium, 0.04% strontium, 0.12% iron, 0.01% copper, 0.06% zinc, and the rest is aluminum. The sum of the percentages is 100%.

[0045] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com