Comprehensive utilization method of ore with high contents of aluminum, silicon and iron

A technology of high silicon and high iron, which is applied in the field of clean and efficient comprehensive utilization of high-aluminum, high-silicon and high-iron minerals, can solve problems such as ineffective development, and achieve the effects of efficient utilization, energy, and efficient comprehensive utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Guizhou Qinglong anatase containing TiO 2 4.00%~6.00%, including Sc 2 o 3 60g / t~120g / t. TiO 2 It mainly exists in the form of independent mineral anatase, and no independent mineral of scandium is found in the ore. Scandium element mainly occurs in clay minerals such as kaolinite and sericite, and secondly occurs in limonite and anatase. Metal minerals in raw ore mainly include anatase, limonite, and a small amount of ilmenite, magnetite, galena, pyrite, etc.; gangue minerals mainly include kaolinite, followed by quartz, silk (white ) mica, chlorite, plagioclase, zircon, etc. Technological mineralogy research shows that titanium is mainly produced in the form of fine-grained anatase wrapped in silicate and quartz, with extremely fine particle size, and secondly occurs in limonite in the form of isomorphism, which belongs to Very difficult to select ore.

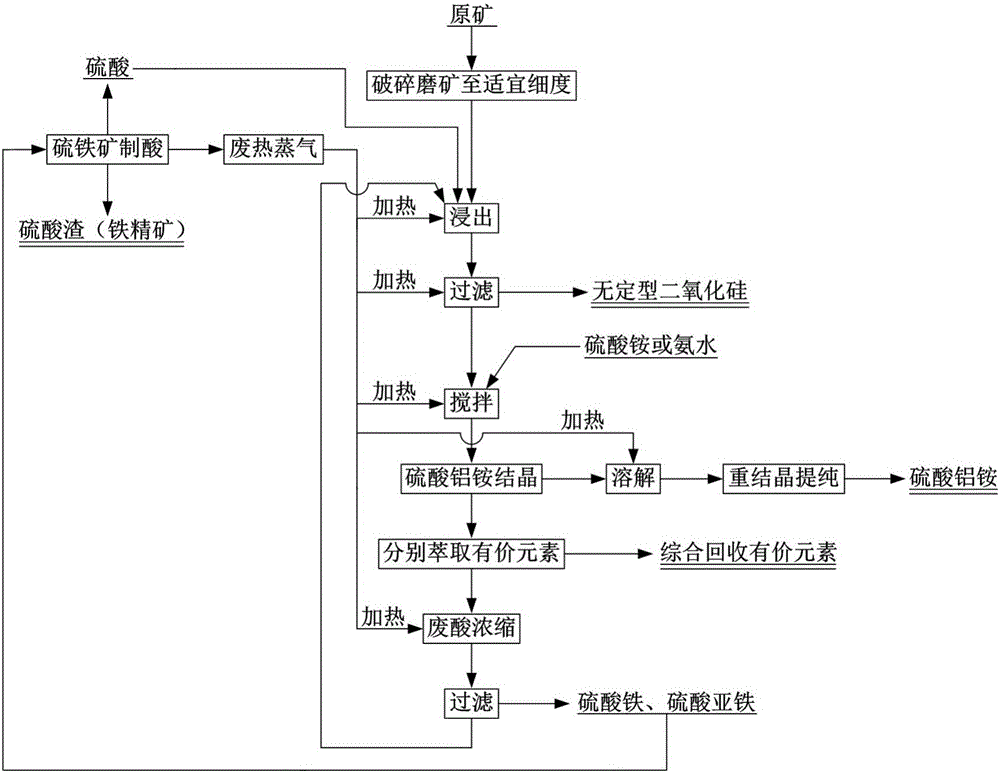

[0023] Such as figure 1 As shown, the ore is broken and ground to a fineness of -200 mesh ≥ 80%, and then tw...

Embodiment 2

[0028] A high-iron bauxite mine in Yunnan, the raw ore contains Al 2 o 3 42.13%, SiO 2 15.73%, TiO 2 3.89%, Fe 2 o 3 15.64%, Sc 2 o 3 110g / t. There are oxides, carbonates, silicates, and a small amount of sulfides in the ore. There are more than 10 kinds of minerals in four categories, of which oxides account for 66.75% and silicates account for 31.64%. Aluminum minerals are mainly diaspore, iron minerals are mainly limonite, goethite, specularite, ilmenite, etc., titanium minerals are ilmenite and anatase, etc., gangue minerals are mainly clay , kaolinite, chlorite, pyrophyllite, illite, muscovite, calcite and organic matter. Aluminum minerals are mostly in the form of plates, flakes, and semi-euhedral-other-shaped granular crystals, often mixed with limonite, kaolinite, anatase and other components to form oolites or mutually wrapped, contiguous, or brown Iron ore and goethite are impregnated with fine particles, with a particle size between 0.03 and 0.1mm. Ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com