Plasma texturing cutter and preparing method thereof

A plasma and texturing technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of poor ability of micro-texture to capture and store chips, uncontrollable size of micro-texture, micro-texture Problems such as low dimensional accuracy can improve the anti-adhesion performance, facilitate the storage of chips, and reduce the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

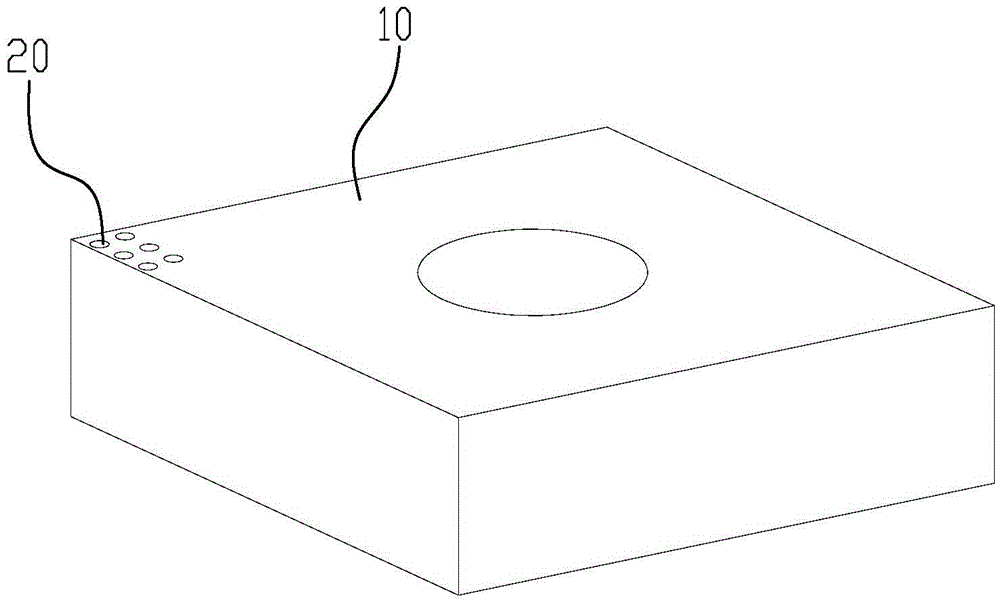

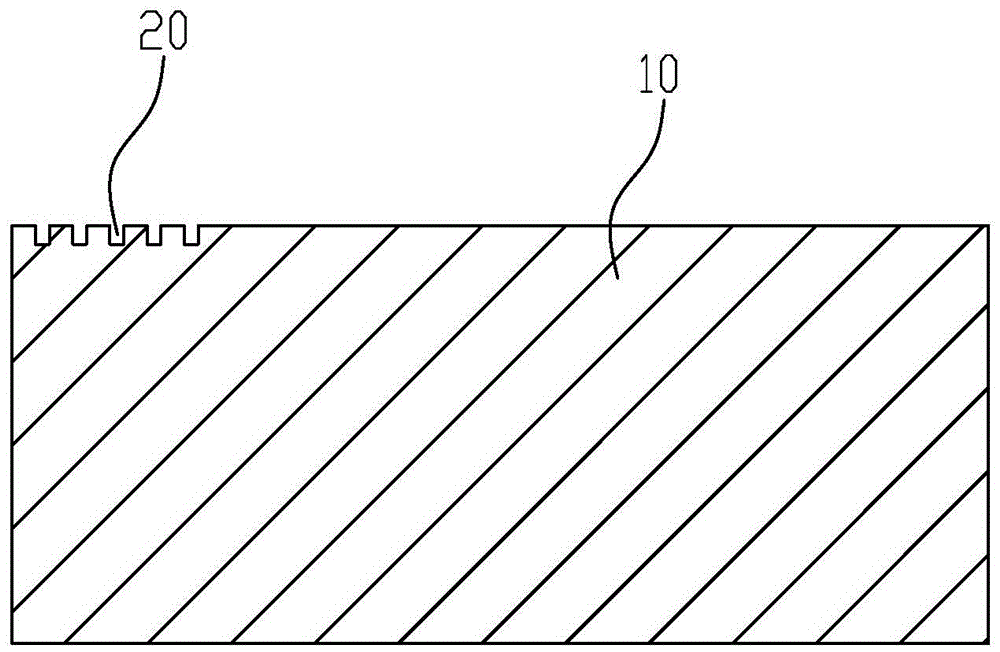

[0033] Please refer to figure 1 and figure 2 , a plasma textured cutting tool 10 of the present invention, the base material of the cutting tool 10 is YG-type cemented carbide (the main component is WC+Co, namely WC / Co cemented carbide). The tool-chip contact area on the rake face of the tool 10 is etched by a plasma etching method to form a nanoscale texture array 20 . The cross-section of the nanoscale textured array is a straight groove. Preferably, the nanoscale textured array 20 has a circular hole diameter=200nm, a circular hole center-to-center distance=300nm, and a circular hole depth=500nm.

[0034] Please refer to Figure 2 to Figure 9 , the preparation method of above-mentioned cutting tool 10, comprises the steps:

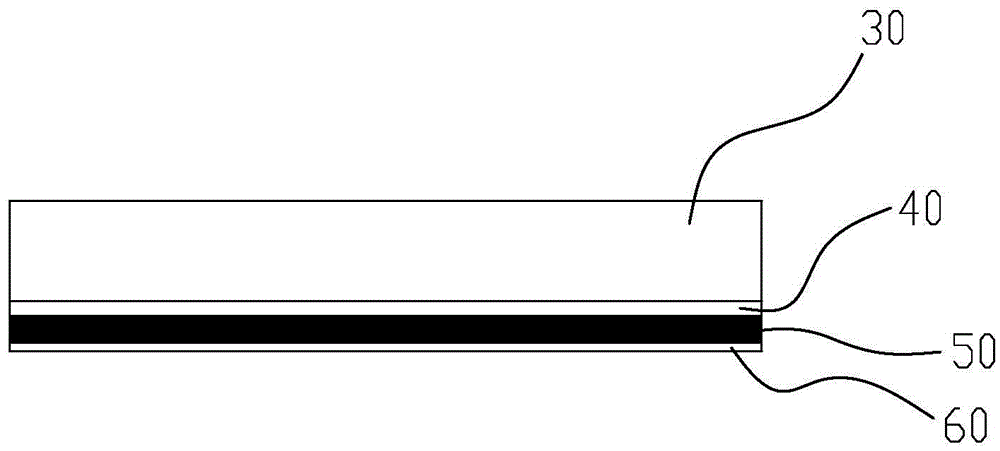

[0035] (1) Prepare the mask plate: as image 3 As shown, the chromium nitride layer 40 is deposited by sputtering on the surface of the glass substrate 30 by sputtering, the chromium film layer 50 is sputtered on the surface of the chromium nitrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com